Performance Analysis and Operation Parameter Optimization of Shaker-Type Harvesting for Camellia Fruits

Abstract

1. Introduction

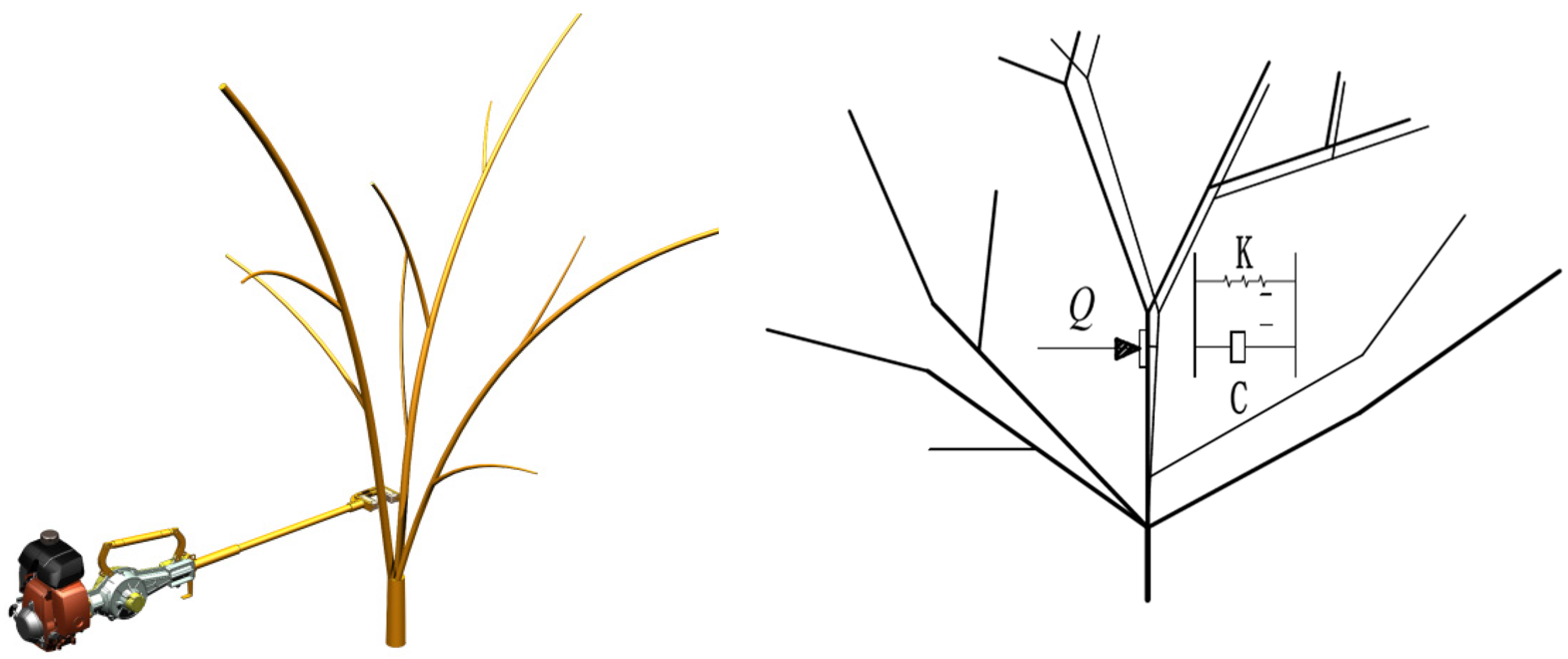

2. Working Principle of Shaker-Type Harvesting Machine for Camellia Fruit

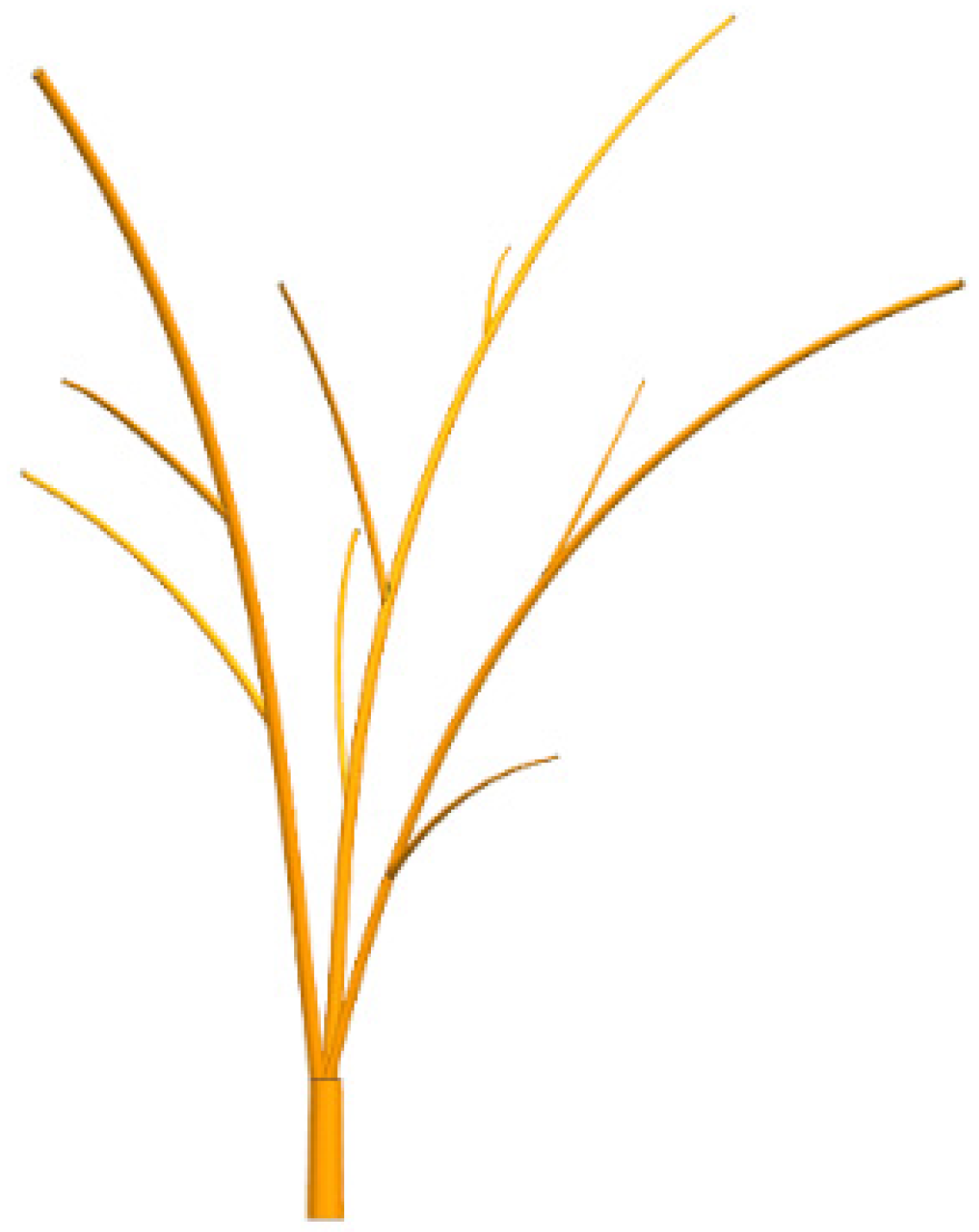

3. Physical Characteristics of a CO Tree

4. Kinetic Characterization of the CO Tree

4.1. Finite Element Model of the CO Tree

4.2. Modal Analysis of the CO Tree

4.3. Frequency Response Characteristics of the CO Tree

5. Shaker-Type Harvesting Experiment on the CO Tree

5.1. Test Materials and Methods

5.2. Evaluation Criteria for CO Fruit Harvesting Rate and Flower Bud Damage Rate

5.3. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, M.; Zhang, Y.; Wu, C. Analysis of the development status quo of woody oilseeds in China and research on supply and demand issues. China Oil Fats 2021, 46, 1–6. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.; Zhou, Y.; Long, B. Extraction of Camellia oleifera Planting Areas in Southern Hilly Area by Combining Multi-features of Time-series Sentinel Data. Trans. Chin. Soc. Agric. Mach. 2024, 55, 241–251. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Zhou, H. A review of Camellia oleifera fruit harvesting machinery and sorting technology. J. For. Eng. 2024, 9, 12–24. [Google Scholar] [CrossRef]

- Fan, X.; Du, J.; Zhou, X.; Liu, Z.; Yan, M. Analysis of regional comparative advantages and influencing factors of Camellia oleifera production in China. China Oil Fats 2023, 48, 9–19, 39. [Google Scholar] [CrossRef]

- Yuan, T.; Zhang, Y.; Yin, J.; Wang, H.; Zhang, Z.; Tan, Y. Study on Seedling Taking and Throwing Device Based on Combined Struture of Crank Rocker and Guide Rail for Vegetable Transplanter. Trans. Chin. Soc. Agric. Mach. 2022, 53, 113–121. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, H.; Rao, H.; Kang, L.; Yang, J.; Liu, M. Design and test of portable oil tea fruit layered picking device. J. Agric. Mech. Res. 2024, 46, 191–195, 201. [Google Scholar] [CrossRef]

- Wu, C.; Jia, W.; Yang, J.; Zhang, T.; Dai, A.; Zhou, H. Economic Fruit Forest Classification Based on Improved U-Net Model in UAV Multispectral Imagery. Remote Sens. 2023, 15, 2500. [Google Scholar] [CrossRef]

- Zhen, Q.; He, M.; Wang, J.; Chen, Q.; Zhou, H.; Jiang, X. Research progress of oil tea fruit picking equipment in China. World For. Res. 2023, 36, 101–106. [Google Scholar] [CrossRef]

- Wu, D.; Yuan, J.; Li, C.; Jiang, S.; Ding, D.; Chao, C.M. Design and Experiment of Twist-comb End Effector for Picking Camellia Fruit. Trans. Chin. Soc. Agric. Mach. 2021, 52, 21–33. [Google Scholar] [CrossRef]

- Wu, D.; Ding, D.; Cui, B.; Jiang, S.; Zhao, E.; Liu, Y.; Cao, C. Design and experiment of vibration plate type camellia fruit picking machine. Agric. Eng. Technol. 2023, 43, 126. [Google Scholar] [CrossRef]

- Li, Z.; Tang, L.; Wu, M.; Zhang, S.; Zhang, H. Design and test of the fruit collecting device of camellia oleifera with angular scissor mechanism. Trans. Chin. Soc. Agric. Eng. 2024, 40, 62–71. [Google Scholar] [CrossRef]

- Li, Z.; Lai, Q.; Deng, Y.; Liu, M.; Hu, S.; Zhang, L.; Hu, J.; Cao, X.; Lin, Y. Design and testing of key components of comb- type Camellia oleifera anther collector. Acta Agric. Univ. Jiangxiensis 2024, 46, 1037–1051. [Google Scholar] [CrossRef]

- Tu, H.M.; Rao, H.F.; Li, T.; Tong, J.; Wang, B.; Liu, M. Research on light and simple oil tea lateral branch clamping vibration picking device. J. Chin. Agric. Mech. 2024, 45, 33–38. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, G.; Yi, X.; Yan, F. Design and simulation of impact components of oil tea fruit picker. J. Northwest A F Univ. (Nat. Sci. Ed.) 2024, 52, 143–154. [Google Scholar] [CrossRef]

- Gao, Y.; Du, H. Design of Vibration Excitation Mechanism of Picking Machinery based on Branch’s Vibration Picking Mechanism. Noise Vib. Control 2019, 39, 46–51. [Google Scholar] [CrossRef]

- Gao, Z.; Zhao, K.; Li, L.; Pang, G.; Wang, X. Design and experiment of suspended vibratory actuator for picking Camellia olerfera fruits. Trans. Chin. Soc. Agric. Eng. 2019, 35, 9–17. [Google Scholar] [CrossRef]

- Bentaher, H.; Haddar, M.; Fakhfakh, T.; Mâalej, A. Finite elements modeling of olive tree mechanical harvesting using different shakers. Trees. Struct. Funct. 2013, 27, 1537–1545. [Google Scholar] [CrossRef]

- Wang, D.; Chen, D.; Wang, S.; Chen, Z.; Zhang, F. Analysis on vibratory harvesting mechanism for trained fruit tree based on finite element method. Trans. Chin. Soc. Agric. Eng. 2017, 33, 56–62. [Google Scholar] [CrossRef]

- Tinoco, H.A.; Ocampo, D.A.; Peña, F.M.; Sanz-Uribe, J.R. Finite element modal analysis of the fruit-peduncle of Coffea arabica L. var. Colombia estimating its geometrical and mechanical properties. Comput. Electron. Agric. 2014, 108, 17–27. [Google Scholar] [CrossRef]

- Liu, Z.; Jin, C.; Yuan, W.; Feng, Y.; Yuan, J. Design Optimization and Experiment of Spring-tooth Drum Type Picking Device for Vegetable Soybean Harvester. Trans. Chin. Soc. Agric. Mach. 2022, 53, 171–180. [Google Scholar]

- Ru, Y.; Fan, G.; Xu, G.; Xu, L.; Zhou, H.; Chen, J. Current status and development trend of walnut vibratory harvesting research. J. For. Eng. 2024, 9, 21–31. [Google Scholar] [CrossRef]

- Qu, Y.; Fang, Z.; Liu, Y.; Dai, Z.; Wu, M. Development of a vibrating and roller pushing type Allium chinense harvester. Trans. Chin. Soc. Agric. Eng. 2022, 38, 51–59. [Google Scholar] [CrossRef]

- Zhang, X.; Dai, F.; Shi, R.; Zhao, W.; Ma, H.; Zhao, X. Design and test of vibratory separating root and tuber Chinese herbal medicine harvester. Agric. Res. Arid Areas 2024, 42, 264–275. [Google Scholar] [CrossRef]

- Shan, Y.; Liao, Q.; Wan, X.; Yuan, J.; Chen, L.; Liao, Y. Design and Experiment of Self-propelled Six-row Harvester for Oilseed Rape Shoot. Trans. Chin. Soc. Agric. Mach. 2024, 55, 93–104. [Google Scholar] [CrossRef]

| Measuring Part | dmax | dmin | avg | Major Diameter Distribution | Main Diameters in % |

|---|---|---|---|---|---|

| first branch | 58.7 | 17.4 | 34.5 | 20–35 | 70% |

| secondary branch | 36.7 | 10.1 | 19.9 | 15–25 | 80% |

| Order | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Frequency/Hz | 3.05 | 3.15 | 3.16 | 3.99 | 4.13 | 4.93 | 4.98 | 12.46 |

| Order | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Frequency/Hz | 12.64 | 13.79 | 14.32 | 14.71 | 15.56 | 17.52 | 18.49 | 24.64 |

| Order | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| Frequency/Hz | 25.61 | 26.97 | 27.19 | 32.90 | 33.70 | 35.52 | 36.22 | 38.5 |

| Encodings | Considerations | ||

|---|---|---|---|

| Loading Height/cm | Excitation Frequency/Hz | Excitation Time/s | |

| −1 | 30–40 | 10 | 20 |

| 0 | 40–50 | 12.5 | 25 |

| 1 | 50–60 | 15 | 30 |

| Serial Number | Considerations | Evaluation Indicators | |||

|---|---|---|---|---|---|

| Load High A/cm | Excitation Frequency B/Hz | Excitation Duration C/s | Harvesting Rate/% | Pod Damage Rate/% | |

| 1 | 30–40 | 15 | 25 | 95.1 | 14.26 |

| 2 | 40–50 | 10 | 30 | 79.29 | 10.41 |

| 3 | 50–60 | 12.5 | 30 | 91.58 | 17.14 |

| 4 | 30–40 | 12.5 | 20 | 90.1 | 5.26 |

| 5 | 50–60 | 12.5 | 20 | 86.11 | 12.41 |

| 6 | 50–60 | 10 | 25 | 78.36 | 8 |

| 7 | 40–50 | 12.5 | 25 | 88.59 | 10.81 |

| 8 | 50–60 | 12.5 | 30 | 96.97 | 6 |

| 9 | 30–40 | 12.5 | 30 | 86.95 | 26.32 |

| 10 | 40–50 | 12.5 | 25 | 84.09 | 9.52 |

| 11 | 40–50 | 15 | 20 | 92.1 | 14.29 |

| 12 | 50–60 | 12.5 | 30 | 94.32 | 20 |

| 13 | 40–50 | 10 | 20 | 74.98 | 5.56 |

| 14 | 30–40 | 10 | 20 | 79.07 | 28.38 |

| 15 | 40–50 | 15 | 30 | 92.68 | 16.25 |

| 16 | 50–60 | 15 | 25 | 96.36 | 56.41 |

| 17 | 30–40 | 10 | 25 | 83.65 | 26.92 |

| Source | Degrees of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|

| Model | 9 | 79.24 | 14.27 | 0.0010 * |

| A-loading height | 1 | 0.5279 | 0.0951 | 0.7668 |

| B-Excitation frequency | 1 | 500.17 | 90.08 | <0.0001 ** |

| C-Excitation duration | 1 | 23.25 | 4.19 | 0.0800 ** |

| AB | 1 | 6.71 | 1.21 | 0.3081 |

| AC | 1 | 39.22 | 7.06 | 0.0326 * |

| BC | 1 | 8.05 | 1.45 | 0.2677 |

| A2 | 1 | 33.87 | 6.10 | 0.0428 * |

| B2 | 1 | 10.30 | 1.86 | 0.2153 |

| C2 | 1 | 0.8186 | 0.1474 | 0.7124 |

| Residual | 7 | 5.55 | ||

| Lack of fit | 4 | 3.55 | 0.4325 | 0.7822 |

| Pure error | 3 | 8.22 | ||

| Cor total | 16 | |||

| Determination R2 | 0.9483 | |||

| Source | Degrees of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|

| Model | 9 | 242.51 | 5.01 | 0.0226 * |

| A-loading height | 1 | 24.41 | 0.5039 | 0.5008 |

| B-Excitation frequency | 1 | 281.99 | 5.82 | 0.0466 * |

| C-Excitation duration | 1 | 87.33 | 1.80 | 0.2213 |

| AB | 1 | 1182.50 | 24.41 | 0.0017 ** |

| AC | 1 | 96.30 | 1.99 | 0.2014 |

| BC | 1 | 0.3838 | 0.0079 | 0.9316 |

| A2 | 1 | 359.37 | 7.42 | 0.0296 * |

| B2 | 1 | 203.41 | 4.20 | 0.0796 |

| C2 | 1 | 73.88 | 1.52 | 0.2567 |

| Residual | 7 | 48.45 | ||

| Lack of fit | 4 | 57.22 | 1.56 | 0.3730 |

| Pure error | 3 | 36.75 | ||

| Cor total | 16 | |||

| Determination R2 | 0.8655 | |||

| Source | Degrees of Freedom | Harvesting Rate | Bud Damage Rate | ||||

|---|---|---|---|---|---|---|---|

| Mean Square | F-Value | p-Value | Mean Square | F-Value | p-Value | ||

| Model | 9 | 79.24 | 14.27 | 0.0010 * | 242.51 | 5.01 | 0.0226 * |

| A-loading height | 1 | 0.5279 | 0.0951 | 0.7668 | 24.41 | 0.5039 | 0.5008 |

| B-Excitation frequency | 1 | 500.17 | 90.08 | <0.0001 ** | 281.99 | 5.82 | 0.0466 * |

| C-Excitation duration | 1 | 23.25 | 4.19 | 0.0800 ** | 87.33 | 1.80 | 0.2213 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Q.; Han, J.; Zeng, S.; Wang, Y.; Wei, W.; Wang, D.; Ye, H.; Lu, J.; Zeng, H. Performance Analysis and Operation Parameter Optimization of Shaker-Type Harvesting for Camellia Fruits. Agriculture 2024, 14, 1989. https://doi.org/10.3390/agriculture14111989

Gao Q, Han J, Zeng S, Wang Y, Wei W, Wang D, Ye H, Lu J, Zeng H. Performance Analysis and Operation Parameter Optimization of Shaker-Type Harvesting for Camellia Fruits. Agriculture. 2024; 14(11):1989. https://doi.org/10.3390/agriculture14111989

Chicago/Turabian StyleGao, Qiaoming, Jianfeng Han, Shan Zeng, Yu Wang, Wei Wei, Dongxue Wang, Hang Ye, Jing Lu, and Haoxiang Zeng. 2024. "Performance Analysis and Operation Parameter Optimization of Shaker-Type Harvesting for Camellia Fruits" Agriculture 14, no. 11: 1989. https://doi.org/10.3390/agriculture14111989

APA StyleGao, Q., Han, J., Zeng, S., Wang, Y., Wei, W., Wang, D., Ye, H., Lu, J., & Zeng, H. (2024). Performance Analysis and Operation Parameter Optimization of Shaker-Type Harvesting for Camellia Fruits. Agriculture, 14(11), 1989. https://doi.org/10.3390/agriculture14111989