Design and Testing of a Pleurotus pulmonarius Stick Cutting Machine

Abstract

1. Introduction

2. Materials and Methods

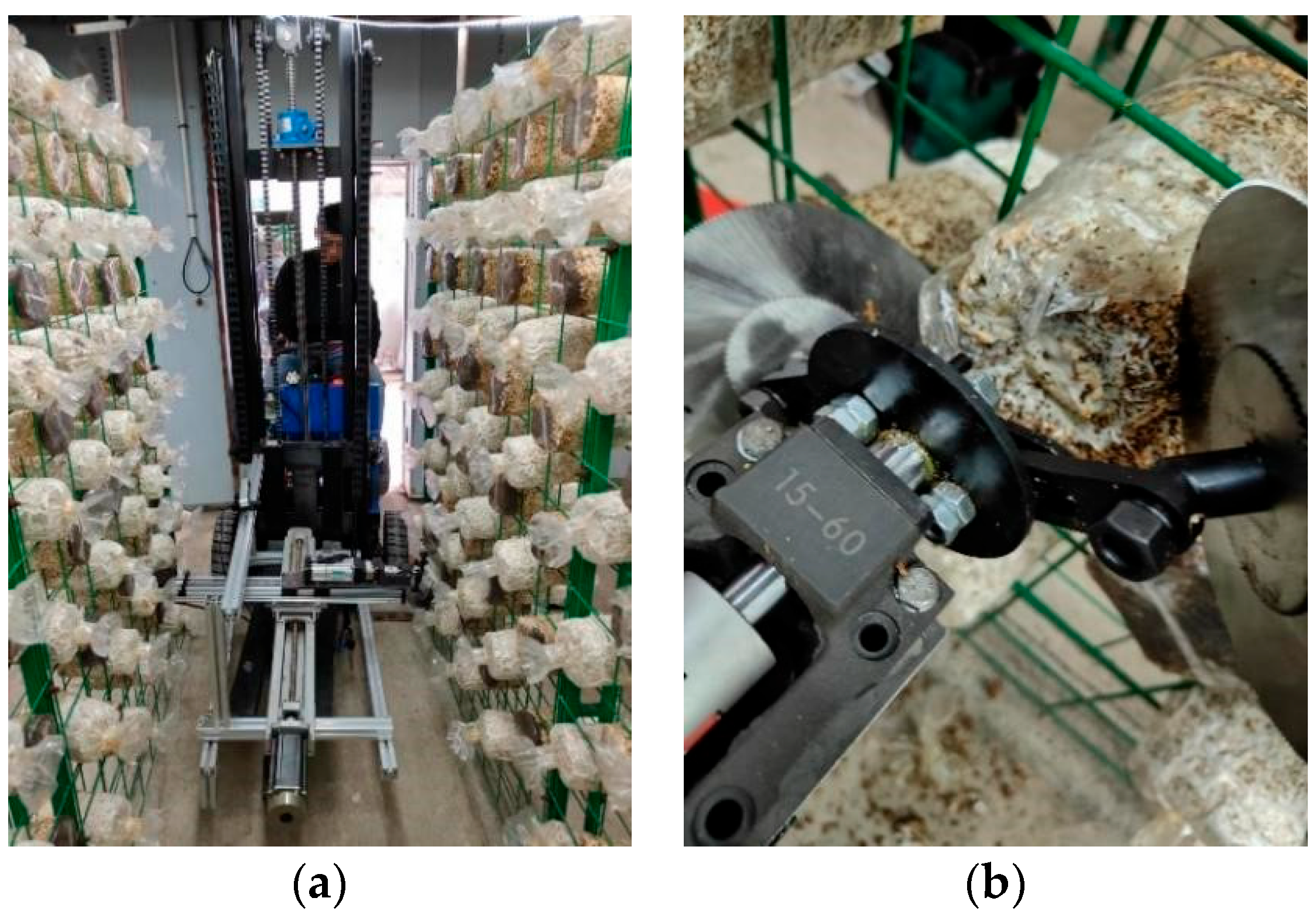

2.1. Design of a Pleurotus pulmonarius Stick Cutting Machine

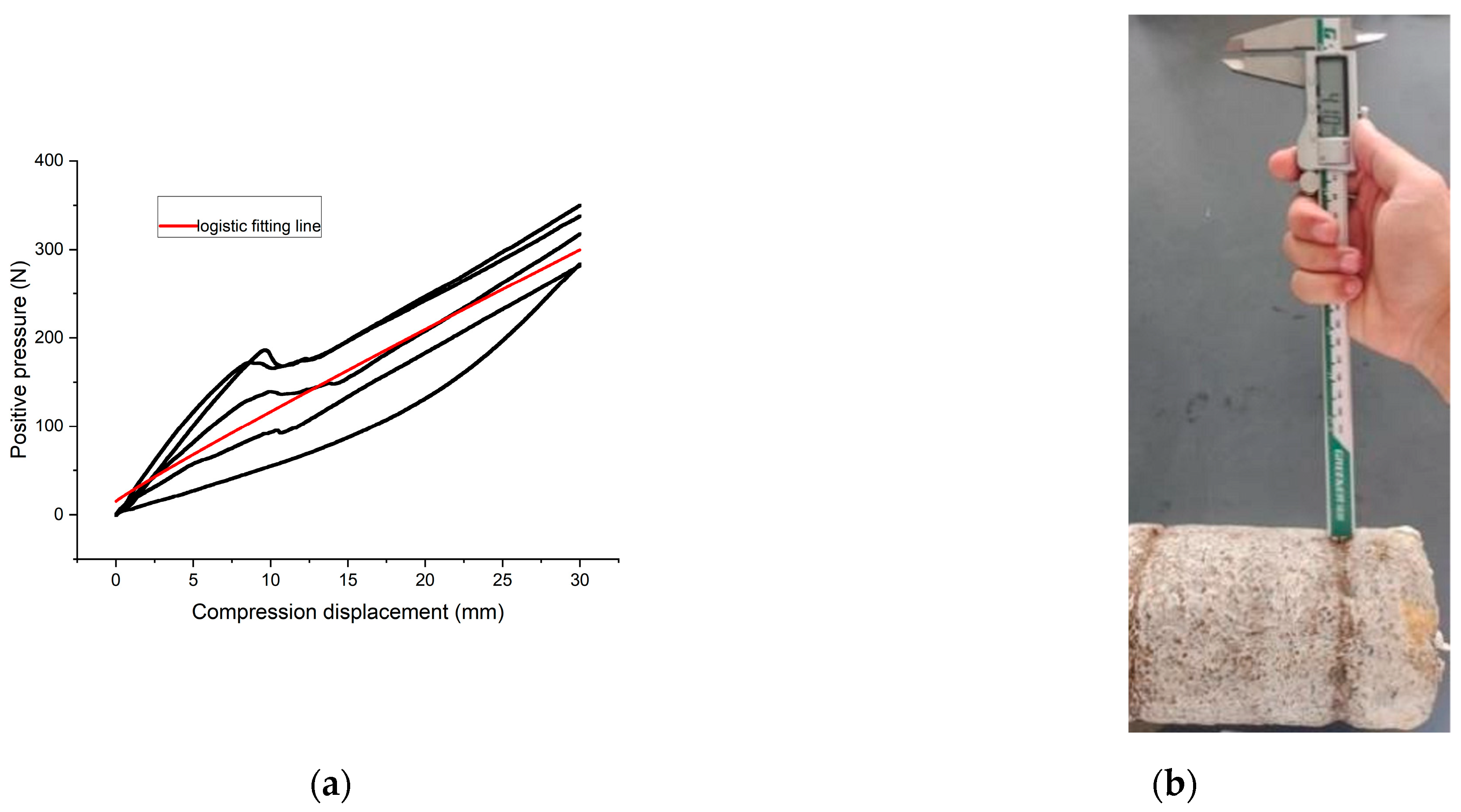

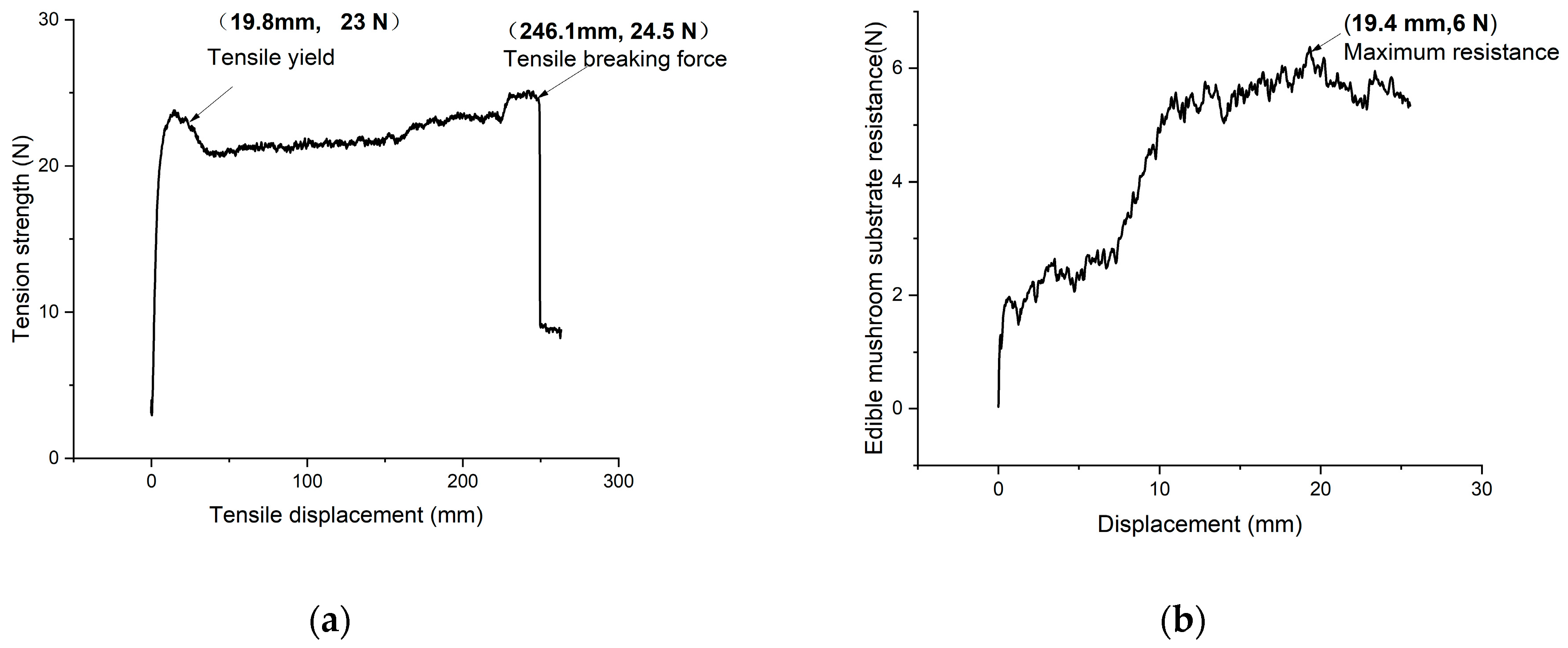

2.1.1. Cultivation Environment and Material Parameters of P. pulmonarius Sticks

2.1.2. Overall Structure and Working Principle of Stick Cutting Machine

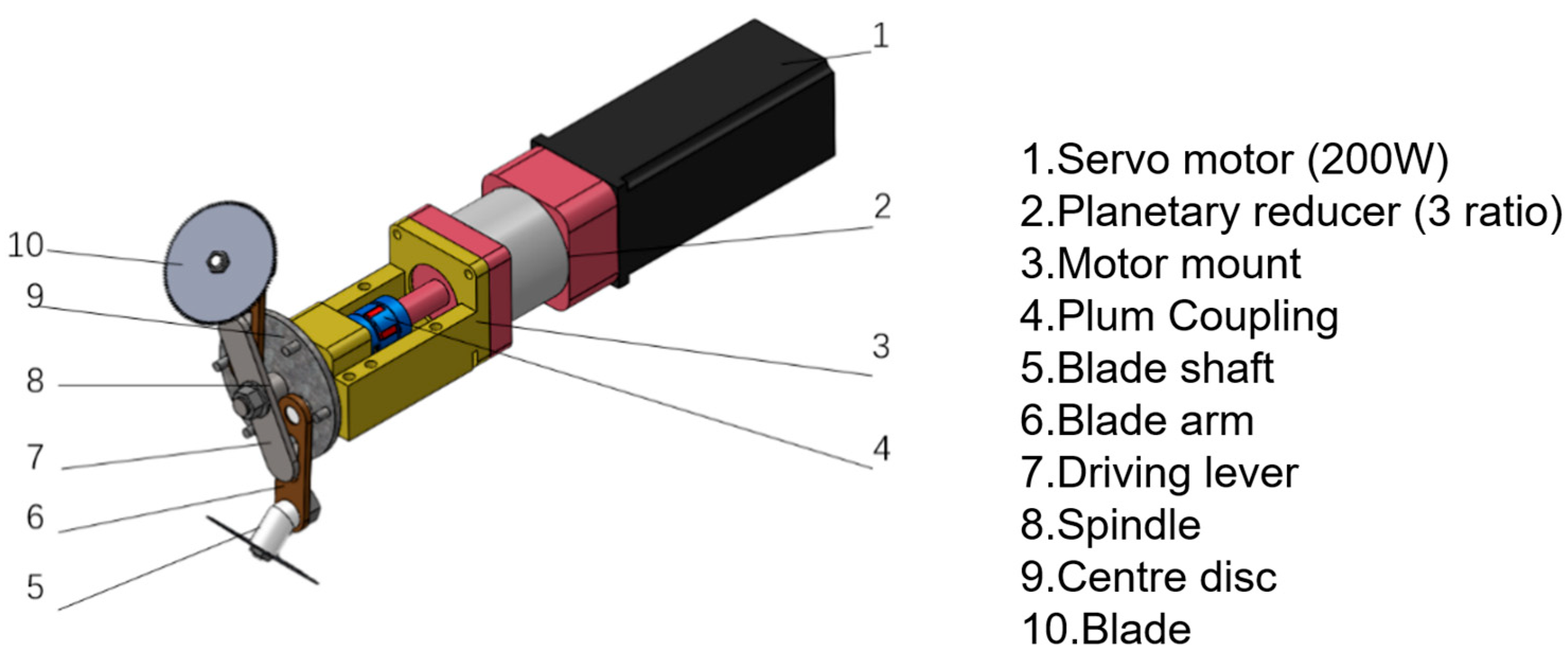

2.1.3. Structure and Working Principle of End-Effector Clamping and Cutting Mechanism

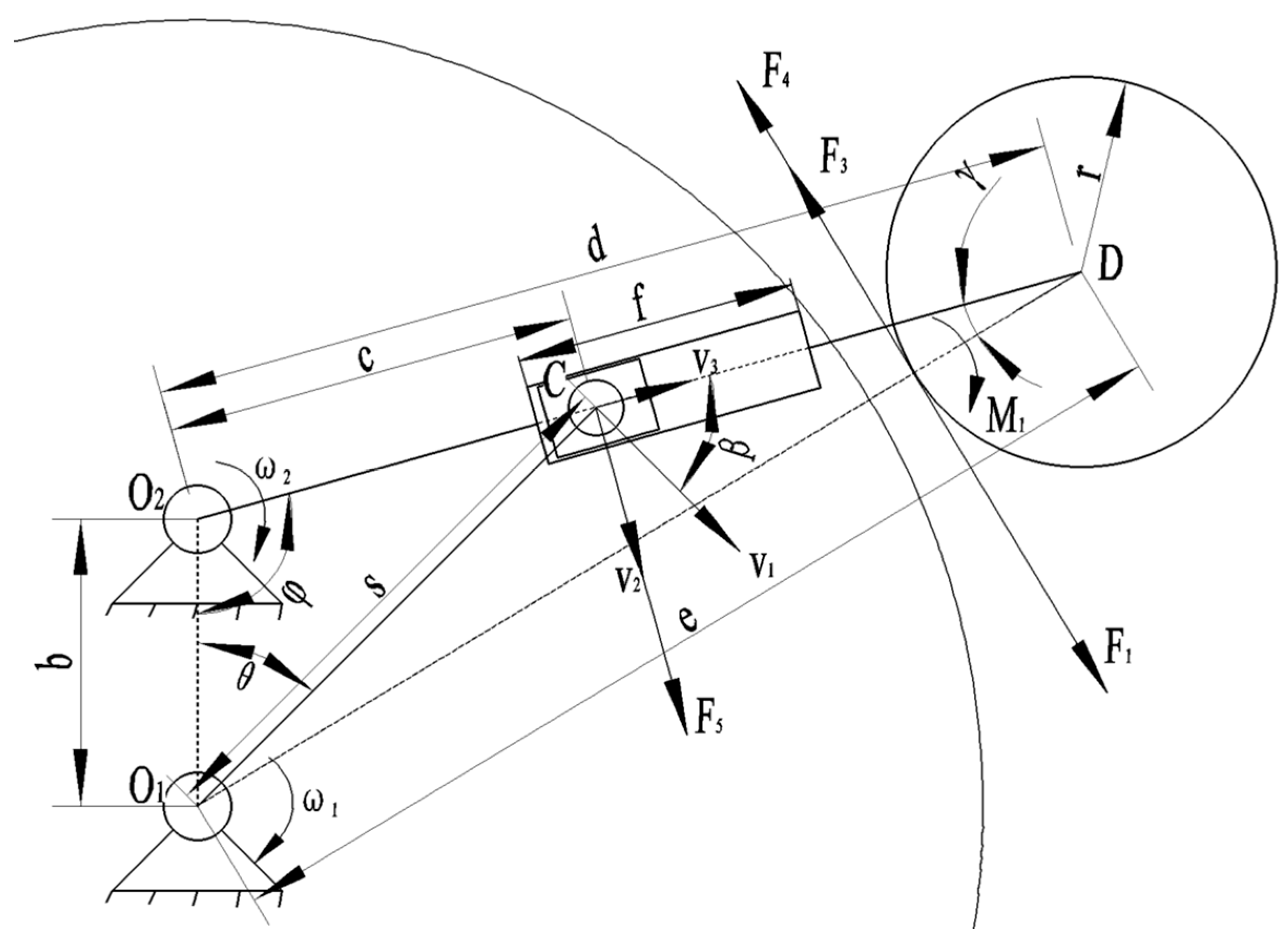

2.2. Mechanical Analyses during Cutting Operations

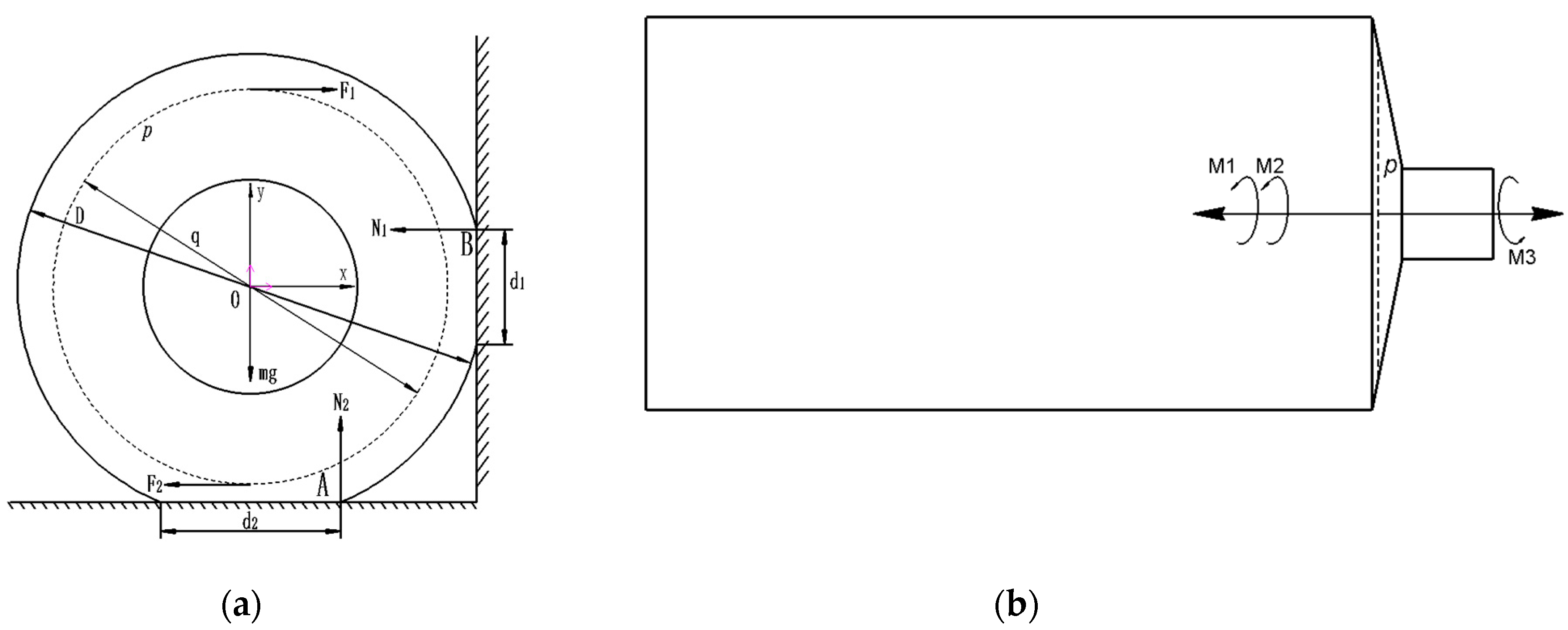

2.2.1. Force Analysis of P. pulmonarius Sticks

2.2.2. Clamping Cutting Mechanism Force Analysis and Key Components Selection

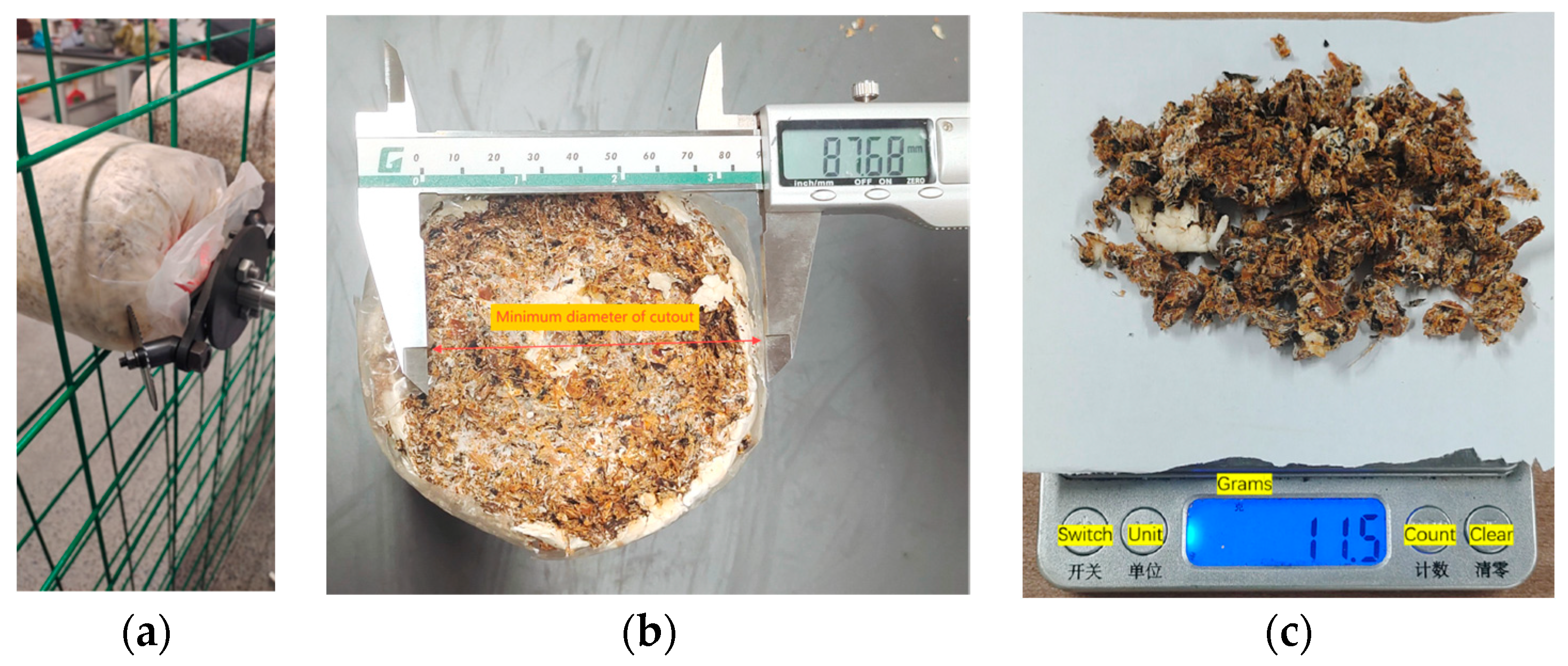

2.3. Cutout Performance Test

2.3.1. Test Equipment

2.3.2. Test Indicators and Methods

3. Results and Analysis

3.1. Test Results

3.2. Establishment of Regression Equation and Significance Analysis

3.3. Factor Response Surface Analysis and Optimization

3.3.1. Influence of Factors on the Success Rate of Cutting

3.3.2. Influence of Factors on the Roundness of the Cut

3.3.3. Influence of Factors on the Degree of Loss of Cutout Substrate

4. Verification Test

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, C.; Qu, M.; Cao, H.; Deng, W.; Shang, X.; Song, B.; Tan, Q. List of common names of edible fungi in China. J. Edible Fungi 2013, 20, 50–72. [Google Scholar] [CrossRef]

- Zhao, B.; Guo, Y. Progress in the extraction and purification of polysaccharides from edible mushrooms and their bioactivities. China Biotechnol. 2022, 42, 146–159. [Google Scholar] [CrossRef]

- Zhang, R.; Su, D.; Zhang, X. Nutrition and health function of mushroom and its product development. Food Res. Dev. 2004, 125–128. [Google Scholar]

- Yu, T.; Lian, X. Research progress on the mechanism of antitumor action of medicinal fungal polysaccharides. Contemp. Med. Symp. 2020, 18, 27–29. [Google Scholar]

- Liu, F.; Yuan, Z.; Yuan, B.; Ke, L.; Chen, G.; Xie, B. Biological characteristics and industrial cultivation technology of Xiuzhen mushroom. Edible Med. Mushrooms 2023, 31, 72–76. [Google Scholar]

- Liu, L.; Zhou, Y.; Chen, H.; Weng, B.; Lin, D.; Liu, P.; Jiang, Z. Research progress of Pleurous pulmonarius. Microbiol. China 2020, 47, 3650–3657. [Google Scholar] [CrossRef]

- Huang, Y. Analysis on the export situation of edible fungi in China in the post-epidemic era. Edible Med. Mushrooms 2021, 29, 369–371. [Google Scholar]

- Chian Edible Mushroom Association. Edible Fungi Society of China Analysis of the results of the national edible fungi statistical survey in 2022. Edible Fungi China 2024, 43, 118–126. [Google Scholar] [CrossRef]

- Li, Y.; Shang, X.; Song, C.; Li, Z.; Li, Q.; Tan, Q.; Zhou, F. Comparison of long stick model and breathable bag model in factory cultivation of mushroom. Edible Med. Mushrooms 2016, 24, 406–408. [Google Scholar]

- Cai, J.; Zhu, B. Key points of efficient fruiting management in the whole process of large-scale cultivation of Pleurous pulmonarius. Edible Med. Mushrooms 2022, 30, 154–157. [Google Scholar]

- Wang, X. Research and design of automatic cutting equipment for fungus packets. Farm Mach. Using Maint. 2021, 5, 11–13. [Google Scholar] [CrossRef]

- Ma, S. Study on Design and Key Technology of Mushroom Mushroom Bar Bag Bar Separator. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2023. [Google Scholar]

- Ma, S.; Song, W.; Wang, M.; Ding, T.; Wang, J.; Zhou, D. Research status and prospect of Chinese mushroom stick bagging equipment. J. Chin. Agric. Mech. 2022, 43, 50–55. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, W.; Zhuang, H.; Pei, Z. Fibre bale automatic debanding and bag splitter bag cutting device design. Cotton Text. Technol. 2023, 51, 59–64. [Google Scholar]

- Wang, J. Application of light and simple facilities for high yield cultivation of Pleurous pulmonarius. Agric. Technol. 2018, 38, 74. [Google Scholar]

- GB/T 5262-2008; Measuring Methods for Agricultural Machinery Testing Conditions-General Rules. National Standardization Administration: Beijing, China, 2008.

- Xu, L.; Liu, X.; Zhang, K.; Xingfa, J.; Yuan, Q.; Chen, J.; Duan, Z.; Ma, S.; Yu, C. Design and testing of navel orange picking robot end-effector. Trans. Chin. Soc. Agric. Mach. 2018, 34, 53–61. [Google Scholar]

- Liu, Y. Damage Mechanism of Vegetable Pot Transplanting Pot and Optimization and Experiment of Planter Potting Movement. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2020. [Google Scholar]

- Chen, J.; Zhao, J.; Chen, Y.; Bu, L.; Hu, G.; Zhang, E. Design and experimental optimization of vibrating medlar harvester. Trans. Chin. Soc. Agric. Mach. 2019, 50, 152–161+95. [Google Scholar]

- Yang, Z.; Stachler, R.; Heyne, J.S. Orthogonal Reference Surrogate Fuels for Operability Testing. Energies 2020, 13, 1948. [Google Scholar] [CrossRef]

- Tang, F.; Tong, S.; Zhang, H.; Li, W.; Chen, Z.; Zhen, Y. Analysis and test of reciprocating cutting and pruning parameters of apple branches. Trans. Chin. Soc. Agric. Eng. 2020, 36, 9–16. [Google Scholar]

- Liu, P.; He, J.; Li, Y.; Li, H.; Wang, Q.; Lu, C.; Zhang, Z.; Li, S. Design and test of opposite-speed roller type corn stover crushing and returning device. Trans. Chin. Soc. Agric. Eng. 2020, 36, 69–79. [Google Scholar]

- Cao, L.; Ma, C.; Jiao, H.; Ma, W.; Wang, L.; Li, C. Construction and testing of an empirical model for calculating the tumbled range of dry prickly ash particles on the separation belt. Comput. Electron. Agric. 2024, 218, 108711. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, L.; Yan, J.; Shi, Z.; Kang, M.; Yao, J. Simulation Analysis and Parameter Optimization of Residual Film Pickup Process Based on Finite Element Method. Agriculture 2024, 14, 524. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, T.; Liu, S.; Yan, X.; Zhao, H.; Wu, X.; Zhang, S. Design and Experimental Study of a Bionic Blade for Harvesting the Wild Chrysanthemum Stem. Agriculture 2023, 13, 190. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, J.; Zhang, Q.; Liu, C.; Fang, X. Design and Experimental Study of Bionic Reverse Picking Header for Fresh Corn. Agriculture 2022, 13, 93. [Google Scholar] [CrossRef]

- Jia, C.; Wang, A.; Zong, L.; Yu, L. Structural optimization and performance improvement of rock drill seals based on orthogonal test. J. Eng. Appl. Sci. 2024, 71, 14. [Google Scholar] [CrossRef]

- Hannah, T.; Martin, V.; Ellis, S.; Kraft, R.H. High Speed Impact Testing of UHMWPE Composite Using Orthogonal Arrays. Exp. Mech. 2024, 64, 823–838. [Google Scholar] [CrossRef]

- Weng, W.; Chen, W.; Chen, L.; He, M.; Wang, J.; Zheng, S. Optimization of Working Parameters for Rotary-Cutting Soil Collection Device: Experiment and Simulation. Agriculture 2023, 14, 38. [Google Scholar] [CrossRef]

- Zhang, D.; Zuo, G.; Tong, J.; Zhang, Z. Optimization and experimentation of the working parameters of a bionic liquid-filled fertile soil device. Trans. Chin. Soc. Agric. Eng. 2020, 36, 31–39. [Google Scholar]

- Wang, Y.; Xia, X.; He, X.; Zhao, X.; Chen, J. Dynamics optimization and test of planting device with eccentric-elliptical gear planetary wheel system. Trans. Chin. Soc. Agric. Mach. 2017, 48, 38–46. [Google Scholar]

| Parameters | Value |

|---|---|

| Diameter of P. pulmonarius stick /mm | 115 |

| Ring diameter /mm | 50 |

| Overall height /mm | 240 |

| Height of bag opening from the bottom /mm | 190 |

| Cylinder height /mm Quality of Hidatsumi P. pulmonarius stick /kg | 180 1.25 |

| Levels | Factor | ||

|---|---|---|---|

| Cutting Speed v | Number of Cutout Turns p | Depth of Cut h | |

| −1 | 350 | 3 | 3 |

| 0 | 400 | 5 | 4 |

| 1 | 450 | 7 | 5 |

| No. | Factors | Response Values | ||||

|---|---|---|---|---|---|---|

| Cutting Speed A | Number of Cutout Turns B | Depth of Cut C | Cutting Success Rate (%) | Roundness of Cut | Degree of Loss of Cutout Substrate (%) | |

| 1 | −1 | −1 | 0 | 66.8 | 0.340 | 1.0 |

| 2 | 1 | −1 | 0 | 67.6 | 0.330 | 1.3 |

| 3 | −1 | 1 | 0 | 81.0 | 0.198 | 1.3 |

| 4 | 1 | 1 | 0 | 98.0 | 0.120 | 1.4 |

| 5 | −1 | 0 | −1 | 80.8 | 0.200 | 0.6 |

| 6 | 1 | 0 | −1 | 91.0 | 0.080 | 1.0 |

| 7 | −1 | 0 | 1 | 86.1 | 0.100 | 1.4 |

| 8 | 1 | 0 | 1 | 91.5 | 0.150 | 1.6 |

| 9 | 0 | −1 | −1 | 70.0 | 0.318 | 0.6 |

| 10 | 0 | 1 | −1 | 95.0 | 0.073 | 1.1 |

| 11 | 0 | −1 | 1 | 76.0 | 0.240 | 1.3 |

| 12 | 0 | 1 | 1 | 96.0 | 0.016 | 1.7 |

| 13 | 0 | 0 | 0 | 91.0 | 0.100 | 1.2 |

| 14 | 0 | 0 | 0 | 90.6 | 0.100 | 1.1 |

| 15 | 0 | 0 | 0 | 90.9 | 0.095 | 1.2 |

| 16 | 0 | 0 | 0 | 90.8 | 0.097 | 1.1 |

| 17 | 0 | 0 | 0 | 91.2 | 0.090 | 1.2 |

| Source | Success Rate of Incision | Roundness of Incision | The Degree of Loss of Cutout Substrate | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Freedom | F Value | p Value | Sum of Squares | Freedom | F Value | p Value | Sum of Squares | Freedom | F Value | p Value | |

| Model | 1611.26 | 9 | 179.03 | ** | 0.1346 | 9 | 267.75 | ** | 1.30 | 9 | 20.35 | ** |

| A | 139.44 | 1 | 139.44 | ** | 0.031 | 1 | 55.87 | ** | 0.1250 | 1 | 17.68 | ** |

| B | 1003.52 | 1 | 1003.52 | ** | 0.0573 | 1 | 1025.80 | ** | 0.2112 | 1 | 29.87 | ** |

| C | 20.48 | 1 | 20.48 | ** | 0.0001 | 1 | 0.9870 | 0.9113 | 1 | 128.86 | ** | |

| AB | 65.61 | 1 | 65.61 | ** | 0.0012 | 1 | 20.70 | ** | 0.0100 | 1 | 1.41 | |

| AC | 5.76 | 1 | 5.76 | ** | 0.0072 | 1 | 129.36 | ** | 0.0100 | 1 | 1.41 | |

| BC | 6.25 | 1 | 6.25 | ** | 0.0068 | 1 | 121.87 | ** | 0.0025 | 1 | 0.3535 | |

| A2 | 94.00 | 1 | 94.00 | ** | 0.0077 | 1 | 137.30 | ** | 0.0044 | 1 | 0.6289 | |

| B2 | 257.81 | 1 | 257.81 | ** | 0.0490 | 1 | 878.13 | ** | 0.0139 | 1 | 1.97 | |

| C2 | 5.81 | 1 | 5.81 | ** | 0.0002 | 1 | 3.26 | 0.0076 | 1 | 1.08 | ||

| Lack of fit | 0.80 | 3 | 0.27 | 0.0691 | 0.0003 | 3 | 6.20 | 0.0552 | 0.0375 | 3 | 4.17 | 0.1008 |

| Pure Error | 0.20 | 4 | 0.05 | 0.0001 | 4 | 0.0120 | 4 | |||||

| Sum | 1612.26 | 16 | 0.1350 | 16 | 1.34 | 16 | ||||||

| Bag Breaking Components | Cutting Part | Advantage | Limitations |

|---|---|---|---|

| Ring cutter [11] | Cylindrical side | Uniformity of cut, consistent depth | Large size, need to design specialized righting device |

| Cross-cutting, vertical cutting and flipping ring-cutting mechanism [12] | Cylindrical ends and sides | Full cutout, High efficiency and low loss | Higher tool sharpness requirements, faster tool wear, complex process |

| Longitudinal and circumferential cutting mechanisms [13] | Cylindrical side | Automatically adjusts the depth of cut by floating up and down according to the booster | Large size, lower efficiency |

| Bottom serrated knife mechanism and side linear drive knife mechanism [14] | Cylindrical ends and sides | Full range of cuts and high efficiency | Complicated and costly cutting process |

| Clamping and cutting mechanism (mine) | Cylindrical front face | Smaller dimensions for flexible notching and high notching efficiency | Higher positioning accuracy requirements |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, C.; Jing, P.; Wang, L.; Niu, Q.; Jiao, H.; Ma, C.; Li, C. Design and Testing of a Pleurotus pulmonarius Stick Cutting Machine. Agriculture 2024, 14, 1795. https://doi.org/10.3390/agriculture14101795

Cai C, Jing P, Wang L, Niu Q, Jiao H, Ma C, Li C. Design and Testing of a Pleurotus pulmonarius Stick Cutting Machine. Agriculture. 2024; 14(10):1795. https://doi.org/10.3390/agriculture14101795

Chicago/Turabian StyleCai, Chunlin, Pengyu Jing, Lihong Wang, Qi Niu, Haobo Jiao, Chen Ma, and Chengsong Li. 2024. "Design and Testing of a Pleurotus pulmonarius Stick Cutting Machine" Agriculture 14, no. 10: 1795. https://doi.org/10.3390/agriculture14101795

APA StyleCai, C., Jing, P., Wang, L., Niu, Q., Jiao, H., Ma, C., & Li, C. (2024). Design and Testing of a Pleurotus pulmonarius Stick Cutting Machine. Agriculture, 14(10), 1795. https://doi.org/10.3390/agriculture14101795