Compression Molding Characteristics of Seed Cotton and Damage from Cottonseed Crushing

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

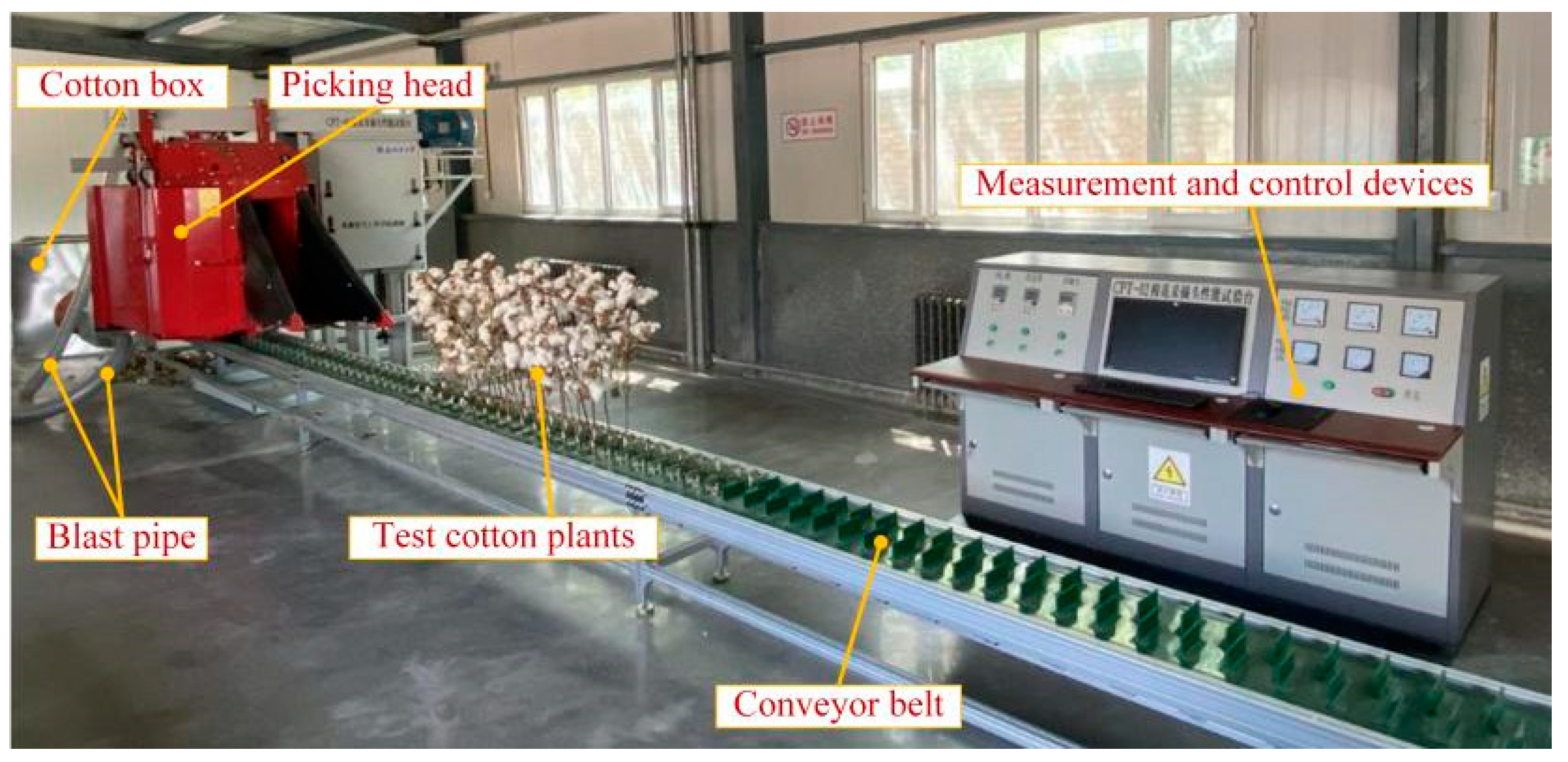

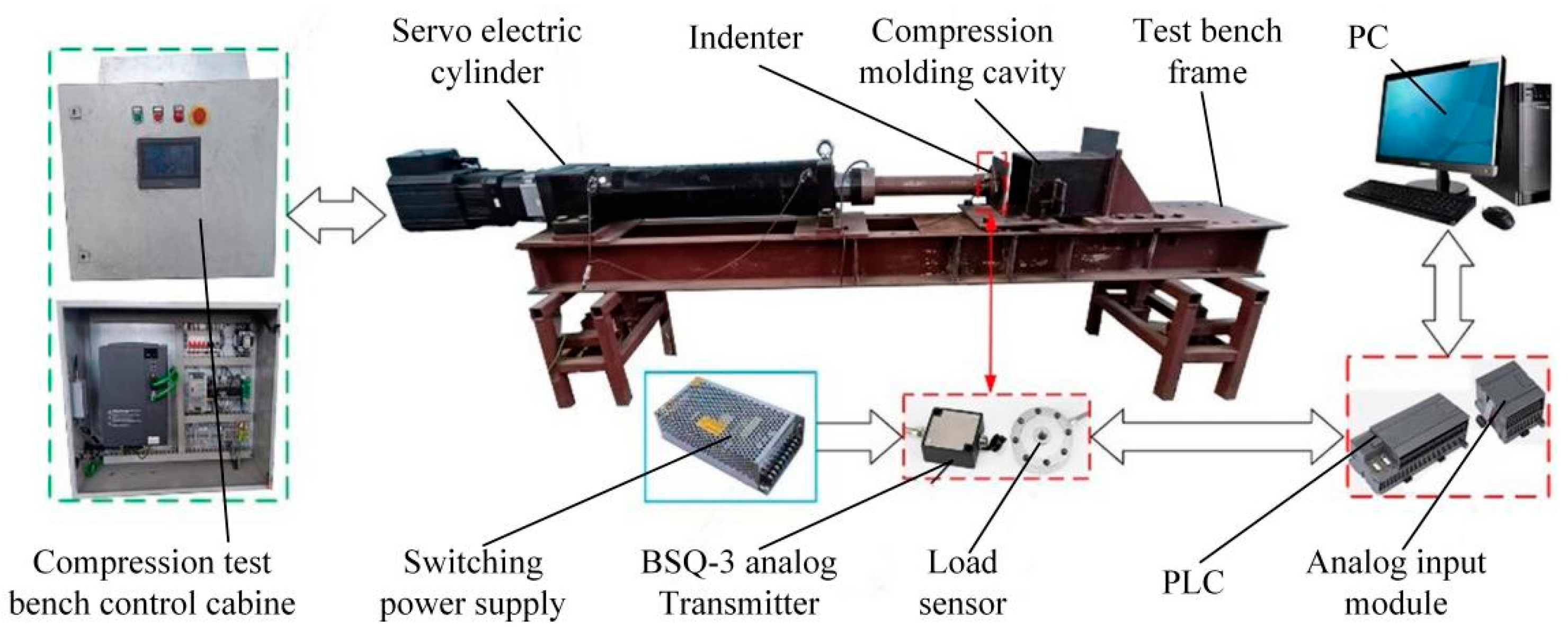

2.2. Experimental Instruments

2.3. Experimental Method

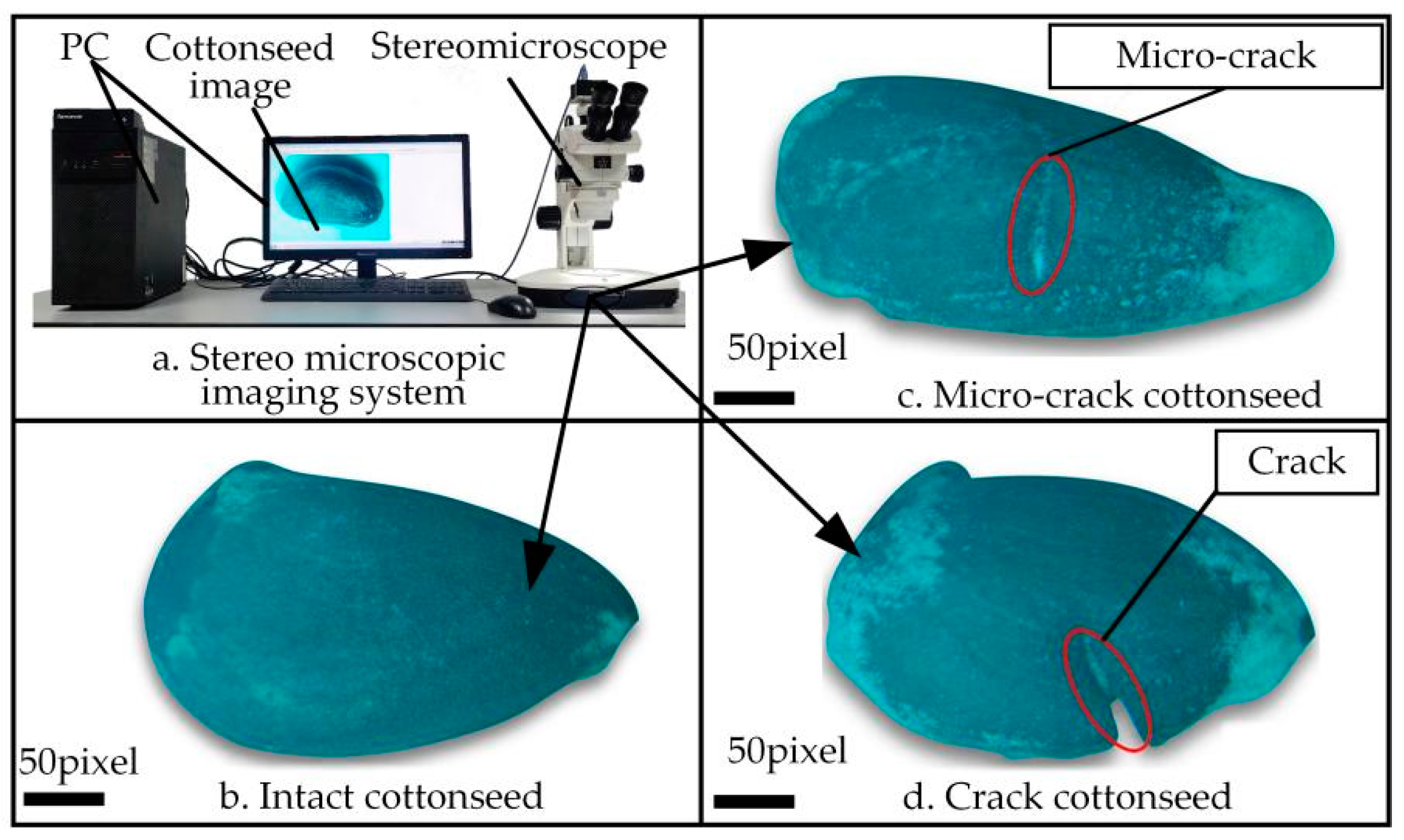

2.4. Test Evaluation Criteria

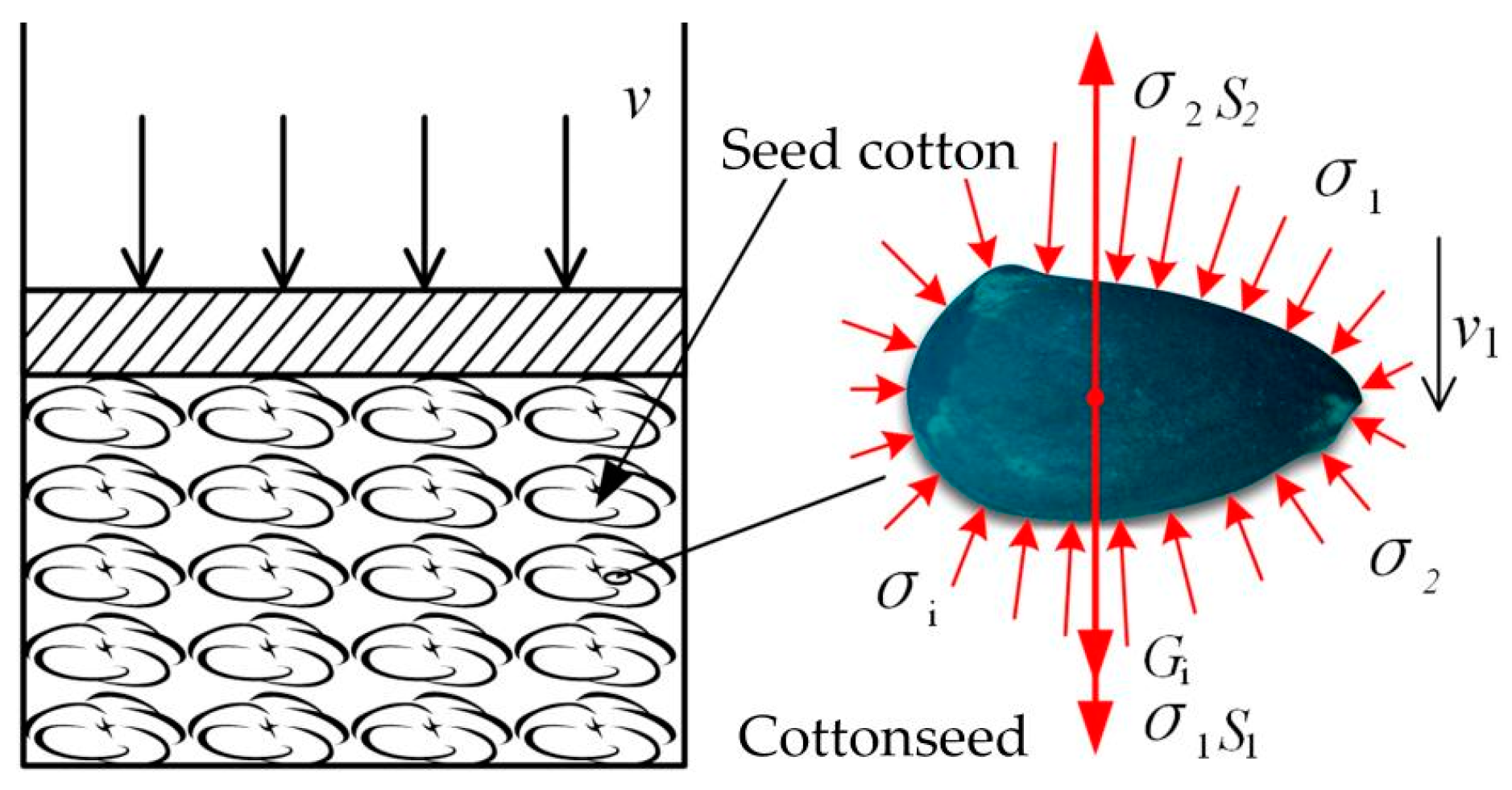

3. Analysis of Cottonseed Force during Compression

4. Seed Cotton Compression Molding Test

4.1. Single-Factor Test

4.1.1. Test Design

4.1.2. Analysis of Test Results

- (1)

- Moisture content

- (2)

- Initial Density

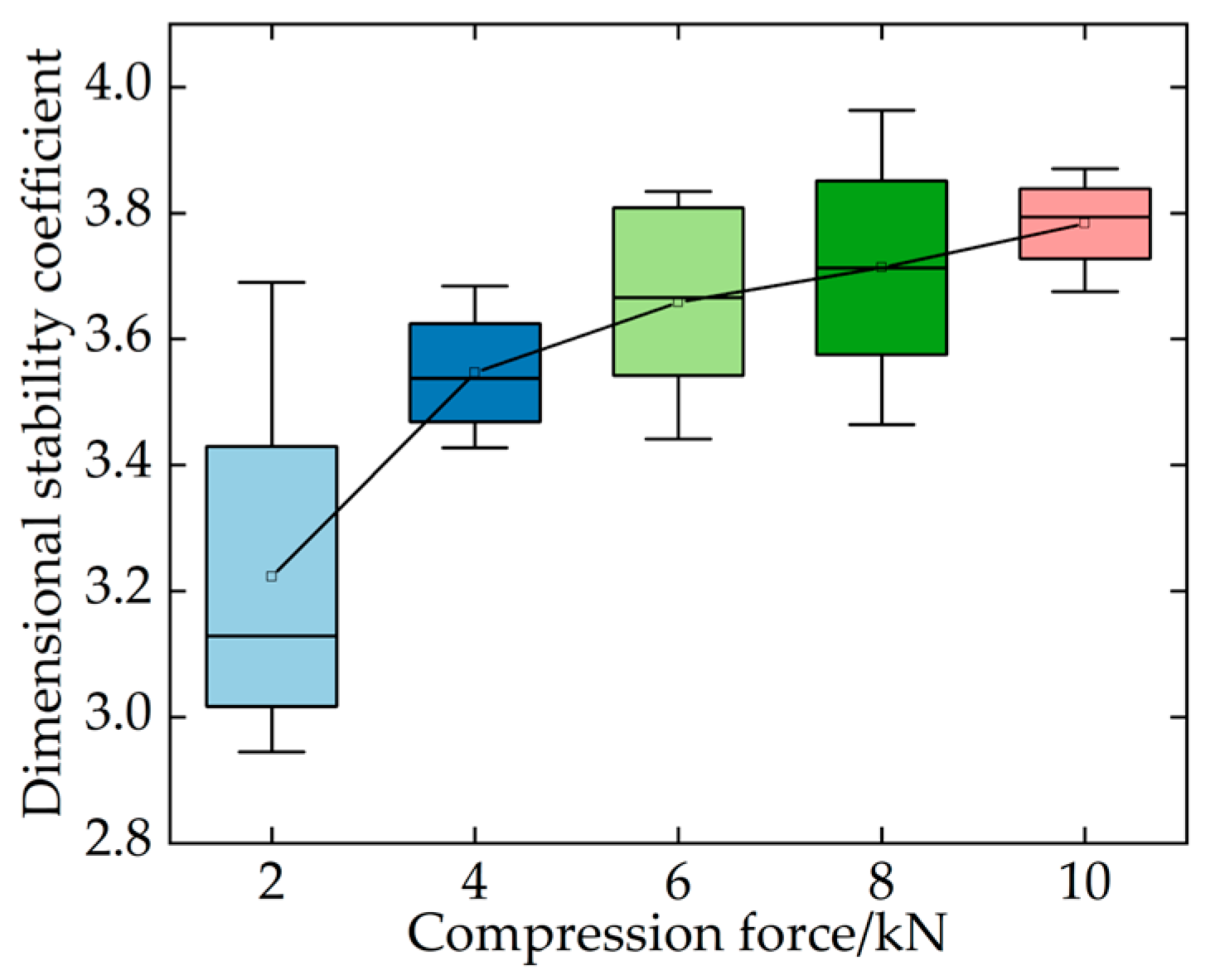

- (3)

- Compression Force

- (4)

- Holding Time

4.2. Multifactor Combination Test

4.2.1. Test Design

4.2.2. Analysis of Test Results

4.2.3. Impact of Factors on Corresponding Indicators

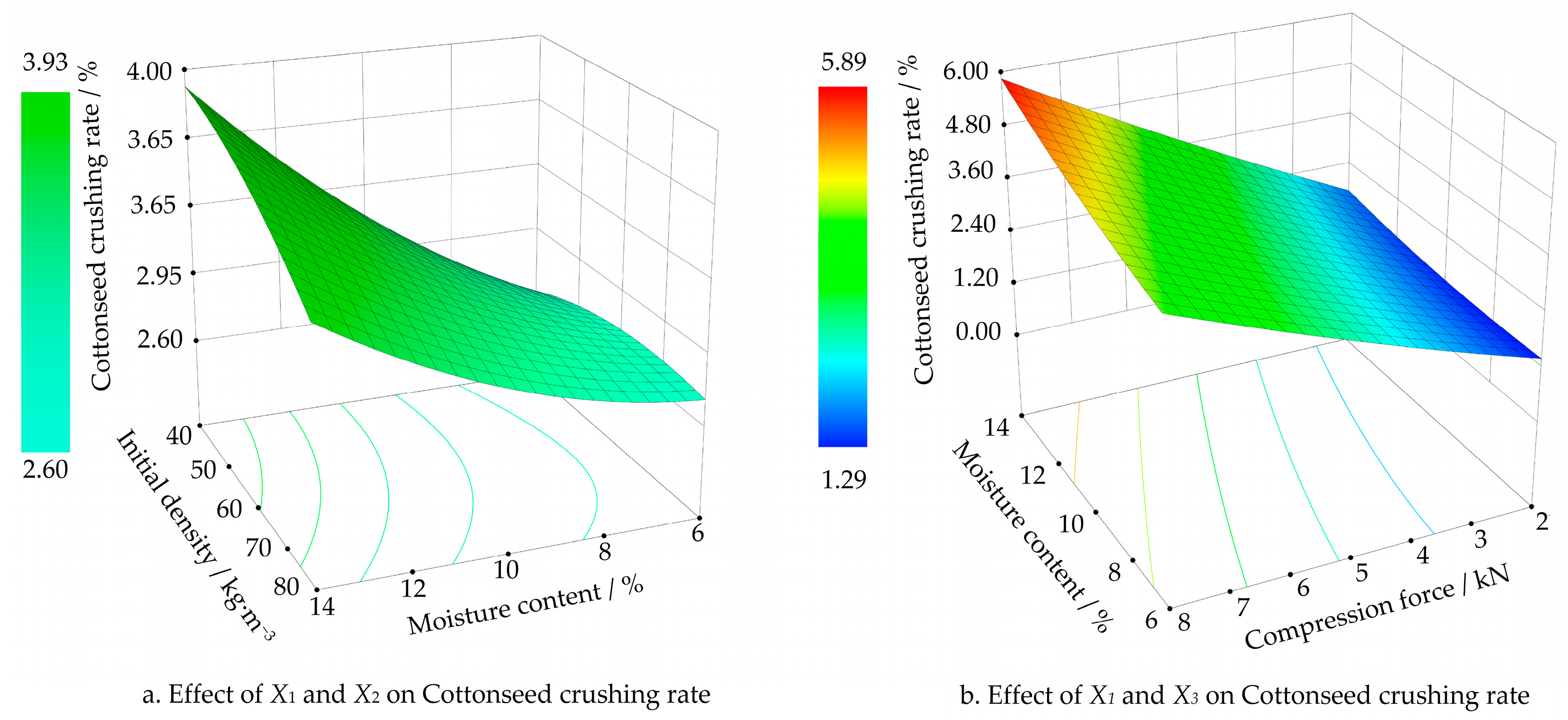

- (1)

- Influence of the interaction of several factors on the cottonseed crushing rate

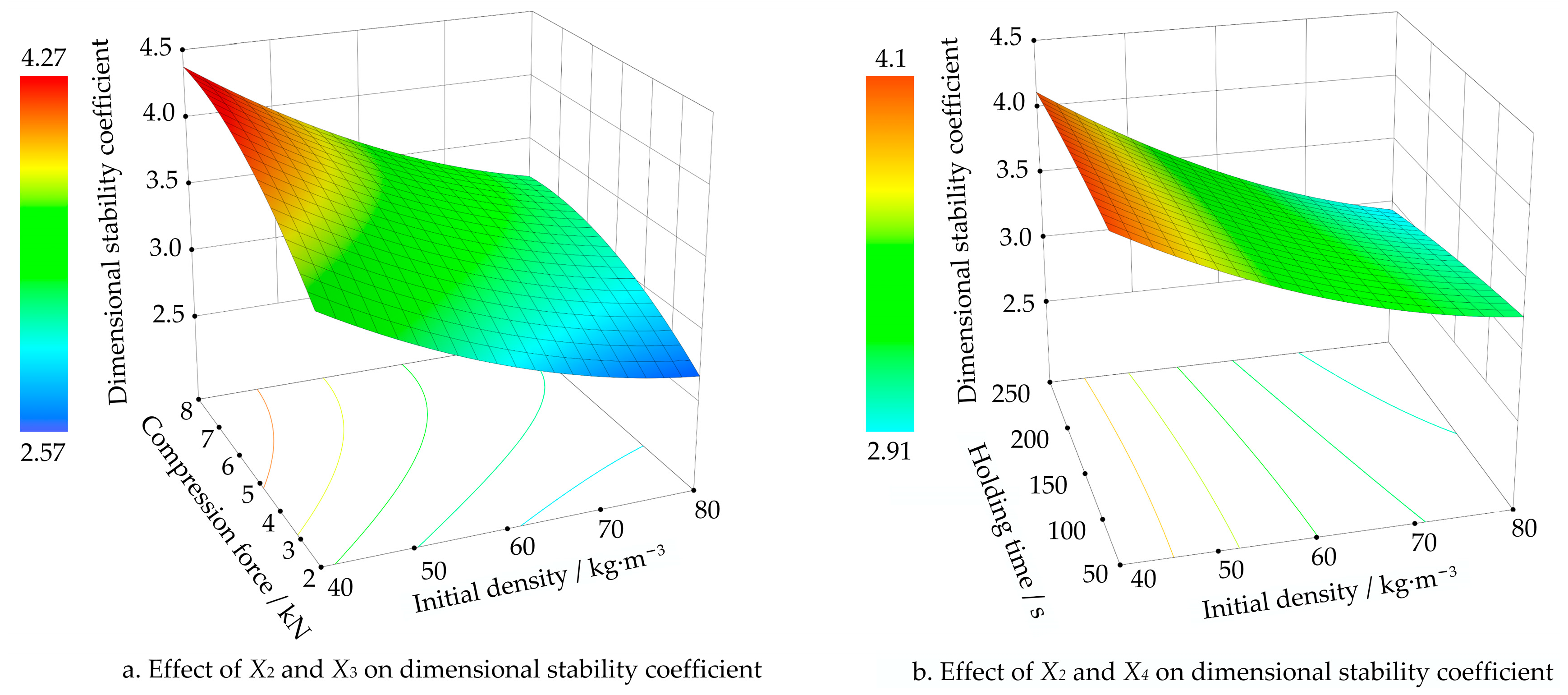

- (2)

- Influence of interactive factors on the dimensional stability coefficient

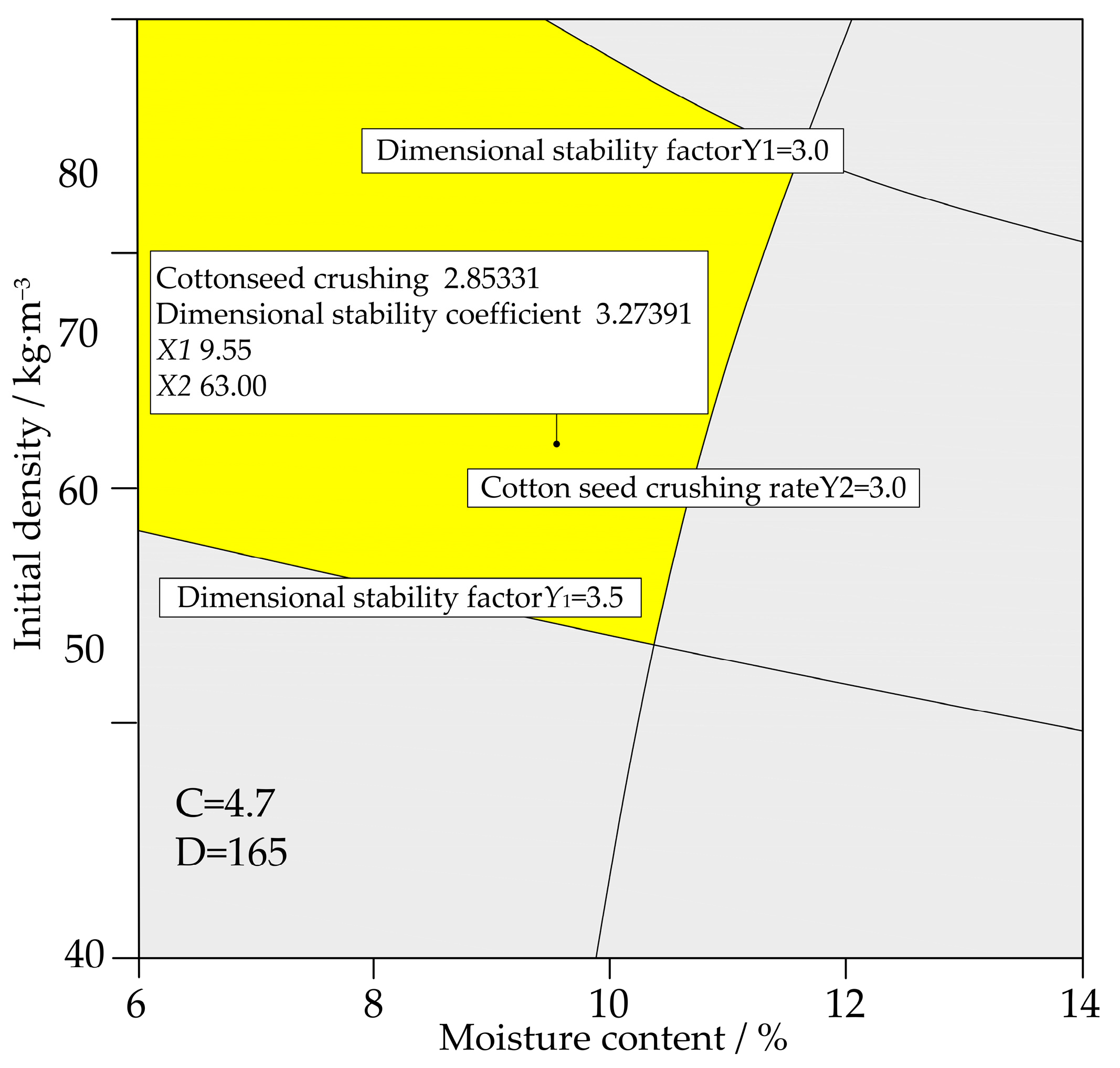

4.2.4. Solution and Verification of Improved Parameters

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, M. China’s Cotton Industry Development Research Report. Chin. Commer. Publ. House 2022, 1, 31–48. [Google Scholar]

- Lu, X.; Jia, X.; Niu, J. The present situation and prospects of cotton industry development in China. Sci. Agric. Sin. 2018, 51, 26–36. Available online: http://kns.cnki.net/kcms/detail/11.1328.S.20180118.1110.006.html (accessed on 5 April 2023).

- Zou, Z. A brief discussion on the development of machine picking cotton in Xinjiang corps. China Fiber Insp. 2020, 5, 33. [Google Scholar] [CrossRef]

- Yu, S. The development of cotton production in the recent hundred years of China. J. Agric. 2018, 8, 85–91. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=XKKJ201801016&DbName=CJFQ2018 (accessed on 15 April 2023).

- Kong, F.; Shi, L.; Zhang, Y.; Chen, C.; Sun, Y.; Xie, Q.; Huang, M. Simulation and Analysis on Compression Effect of Screw Conveyor in the Hopper on Seed Cotton. Agric. Mech. Res. 2017, 39, 77–81. [Google Scholar] [CrossRef]

- Anonymous. Case’s new CE630 cotton picker is coming. Farm Mach. 2018, 10, 129–130. [Google Scholar] [CrossRef]

- Yimin, K. The development and key technologies of cotton picker. China South. Agric. Mach. 2019, 50, 29. [Google Scholar] [CrossRef]

- Chen, X.; Wen, H.; Zhang, W.; Pan, F.; Zhao, Y. Advences and progress of agricultural machinery and sensing technology fusion. Smart Agric. 2020, 2, 1–16. [Google Scholar] [CrossRef]

- Nur Azuan Bin, H. Impact of Seed Cotton Compression on Cottonseed Quality. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2016. Available online: https://hdl.handle.net/1969.1/156809 (accessed on 5 August 2023).

- Mark, T.H. Impact of Cotton Harvesting and Storage Methods on Seed and Fiber Quality. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2012. Available online: https://oaktrust.library.tamu.edu/bitstream/handle/1969.1/ETD-TAMU-2011-12-10230/HAMANN-THESIS.pdf?sequence=2 (accessed on 5 August 2023).

- van der Sluijs, M.H.; Long, R.L.; Bange, M.P. Comparing cotton fiber quality from conventional and round module harvesting methods. Text. Res. J. 2015, 85, 987–997. [Google Scholar] [CrossRef]

- Anthony, W.S. The harvesting and ginning of cotton. In Cotton: Science and Technology; Woodhead Publishing Limited: Cambridge, UK, 2007; pp. 176–202. [Google Scholar] [CrossRef]

- Columbus, E.P.; Mangialardi, G.J. Cottonseed moisture and seed damage at gins. Trans. ASAE 1996, 39, 1617–1621. [Google Scholar] [CrossRef]

- Wang, Z. Comparison of cotton compression characteristic formulas between the United States and the Soviet Union. China Cotton Process. 1994, 3, 26–27. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CJFD&filename=MHJG199403016 (accessed on 26 July 2022).

- Jing, H. Characterization for Mico-Structure and Compressional Behaviour of General Fibrous Assemblies. Ph.D. Thesis, Donghua University, Shanghai, China, 2018. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CDFDLAST2019&filename=1019803372.nh (accessed on 2 July 2022).

- Li, Y.; Zhang, H.; Zhang, Y.; Chen, X.; Liu, W. Research on compressive force transmission properties and densities-mechanical properties model of cotton fiber assembly. J. Text. Res. 2016, 37, 19–25. [Google Scholar] [CrossRef]

- Xu, M.; Chen, X.; Wang, J.; Li, Y. Finite element analysis modeling research on the compression process of cotton fiber assembly. Text. Res. J. 2020, 90, 1414–1427. [Google Scholar] [CrossRef]

- Tian, L. Research on Residual Film Compression and Forming Device and Mechanism. Master’s Thesis, Shihezi University, Shihezi, China, 2019. Available online: https://d.wanfangdata.com.cn/thesis/D01843438 (accessed on 9 March 2022).

- Chen, T.; Jia, H.; Li, M.; Zhao, J.; Deng, J.; Fu, J.; Yuan, H. Mechanism of restraining maize stalk block springback under pressure maintenance/strain maintenance. Trans. Chin. Soc. Agric. Eng. 2021, 37, 51–58. [Google Scholar] [CrossRef]

- Zhang, F.; Meng, H.; Zhang, L.; Chen, X.; Fu, D.; Qi, M. The Experimental Study on the Influence of Different Factors on the Compression of Molding of Tobacco Stalk Grains. J. Agric. Mech. Res. 2020, 42, 139–144. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Tabil, L.G.; Song, Y.; Iroba, K.L.; Meda, V. Impact of process conditions on the density and durability of wheat, oat, canola, and barley straw briquettes. Bioenergy Res. 2015, 8, 388–401. Available online: https://link.springer.com/article/10.1007/s12155-014-9527-4 (accessed on 20 April 2023). [CrossRef]

- GB/T 25416-2010; Cottonseed Dehulling Equipment. China Standard Press: Beijing, China, 2010.

- Kong, F.; Wu, T.; Chen, C.; Sun, Y.; Xie, Q.; Shi, L. Mechanical properties and construction of constitutive model for compression and stress relaxation of seed cotton. Trans. Chin. Soc. Agric. Eng. 2021, 37, 53–60. [Google Scholar] [CrossRef]

- Duan, Y. Study on Shell System of Sightseeing Mini-Submarine. Master’s Thesis, Harbin Engineering University, Harbin, China, 2011. [Google Scholar]

- Gao, Y.; Jiao, Q.; Tang, G.; Wang, R.; Chen, A. Analysis of response to the external compressive force on tomatoes. Trans. Chin. Soc. Agric. Eng. 2008, 24, 40–44. Available online: http://www.cqvip.com/qk/90712x/200801/26566480.html (accessed on 5 June 2022).

- Temmerman, M.; Rabier, F.; Jensen, P.D.; Hartmann, H.; Böhm, T. Comparative study of durability test methods for pellets and briquettes. Biomass Bioenergy 2006, 30, 964–972. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.; Wang, L.; Fu, X.; Chen, Y.; Wang, J.; Gu, Y. Influence of different boll shell physical parameters on mechanical properties of machine-harvested cottons. J. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 2020, 36, 30–37. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, H.; Wang, L.; Wei, X.; Gu, Y.; Zhang, L.; Cai, Y. Study on compression characteristics and compressibility of machine-harvested seed cotton. Acta Agric. Univ. Jiangxiensis 2022, 44, 212–221. [Google Scholar] [CrossRef]

- Wang, M. The Experiment Study on Cleaning and Processing Technology of Unginned Cotton by Cotton Picker. Master’s Thesis, Gansu Agricultural University, Lanzhou, China, 2010. [Google Scholar] [CrossRef]

- Wang, S. Experimental Research on Machine-Harvested Seed Cotton’ Pre-Processing and Cleaning Flow in Xinjiang Production and Construction Crops. Master’s Thesis, Northwest A&F University, Xianyang, China, 2008. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CMFD&filename=2009031461.nh (accessed on 26 October 2023).

- ASABE Standards S358.2; Moisture Measurement-Forages. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2008.

- Sheng, K.; Qian, X.; Wu, J. Experimental studies on compressing chopped cotton stalks to high densities. J. Zhengjiang Univ. (Agric. Life Sci.) 2003, 29, 24–27. Available online: http://www.cqvip.com/qk/94288a/200302/7594047.html (accessed on 25 October 2023).

- Yin, H. The Experimental Study on the Effect of Moisture Content on the Compression Process of Herbage Materials. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2005. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10129-2005091484.htm (accessed on 20 May 2023).

- Du, X. Experimental Study on Compressive and Stress Relaxation Characteristics of Solid Sweet Sorghum Straw. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2019. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, Y.; Yang, M.; Wang, A.; Wang, J.; Liu, D.; Gao, J.; Li, H. Stress relaxation behavior and modeling of alfalfa during rotary compression. Trans. Chin. Soc. Agric. Eng. 2018, 34, 50–56. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, J.; Guo, Y. Effect of moisture content on compression mechanical properties and frictional characteristics of millet grain. Trans. Chin. Soc. Agric. Eng. 2015, 31, 253–260. [Google Scholar] [CrossRef]

- Bi, Y. The Experimental Study on the Compression Pressure Law of the Fresh Herbage Materials. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2005. Available online: https://d.wanfangdata.com.cn/thesis/Y726878 (accessed on 8 September 2023).

- Afzal, I.; Kamran, M.; Basra, S.M.A.; Khan, S.H.U.; Mahmood, A.; Farooq, M.; Tan, D.K. Harvesting and post-harvest management approaches for preserving cottonseed quality. Ind. Crops Prod. 2020, 155, 112842. [Google Scholar] [CrossRef]

- Ma, S. Experimental analysis of factors affecting productivity of seed cotton flanneler. Farm Mach. 2012, 14, 66–67. [Google Scholar] [CrossRef]

- Deng, X. The Mechanism Research on Cottonseed’s Internal Quality Testing Based on Image Processing Technology. Master’s Thesis, Shihezi University, Shihezi, China, 2014. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10759-1015510991.htm (accessed on 26 October 2023).

| Factor | Variance Sources | Sum of Squares | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|---|

| Moisture content | Between groups | 0.616 | 4 | 0.154 | 9.589 | <0.001 ** |

| Within groups | 0.321 | 20 | 0.016 | |||

| Total | 0.937 | 24 | ||||

| Initial density | Between groups | 4.402 | 4 | 1.101 | 29.490 | <0.001 ** |

| Within groups | 0.746 | 20 | 0.037 | |||

| Total | 5.149 | 24 | ||||

| Compression force | Between groups | 1.963 | 4 | 0.491 | 19.136 | <0.001 ** |

| Within groups | 0.513 | 20 | 0.026 | |||

| Total | 2.476 | 24 | ||||

| Holding time | Between groups | 0.494 | 4 | 0.123 | 11.578 | <0.001 ** |

| Within groups | 0.213 | 20 | 0.011 | |||

| Total | 0.707 | 24 |

| Level | Moisture Content (X1/%) | Initial Density (X2/kg·m−3) | Compression Force (X3/kN) | Holding Time (X4/s) |

|---|---|---|---|---|

| −1 | 6 | 40 | 2 | 50 |

| 0 | 10 | 60 | 5 | 150 |

| 1 | 14 | 80 | 8 | 250 |

| Run | X1 | X2 | X3 | X4 | Cottonseed Crushing Rate (Y1/%) | Dimensional Stability Coefficient (Y2) |

|---|---|---|---|---|---|---|

| 1 | 6 | 40 | 5 | 150 | 2.45 | 4.18 |

| 2 | 14 | 40 | 5 | 150 | 3.84 | 3.93 |

| 3 | 6 | 80 | 5 | 150 | 2.85 | 3.09 |

| 4 | 14 | 80 | 5 | 150 | 3.58 | 2.91 |

| 5 | 10 | 60 | 2 | 50 | 1.37 | 2.86 |

| 6 | 10 | 60 | 8 | 50 | 4.94 | 3.58 |

| 7 | 10 | 60 | 2 | 250 | 1.44 | 2.82 |

| 8 | 10 | 60 | 8 | 250 | 4.91 | 3.51 |

| 9 | 6 | 60 | 5 | 50 | 2.56 | 3.62 |

| 10 | 14 | 60 | 5 | 50 | 3.35 | 3.26 |

| 11 | 6 | 60 | 5 | 250 | 2.62 | 3.32 |

| 12 | 14 | 60 | 5 | 250 | 3.79 | 3.16 |

| 13 | 10 | 40 | 2 | 150 | 1.41 | 3.46 |

| 14 | 10 | 80 | 2 | 150 | 1.29 | 2.57 |

| 15 | 10 | 40 | 8 | 150 | 4.98 | 4.27 |

| 16 | 10 | 80 | 8 | 150 | 4.44 | 3.12 |

| 17 | 6 | 60 | 2 | 150 | 1.54 | 3.05 |

| 18 | 14 | 60 | 2 | 150 | 1.83 | 2.76 |

| 19 | 6 | 60 | 8 | 150 | 4.39 | 3.68 |

| 20 | 14 | 60 | 8 | 150 | 5.89 | 3.41 |

| 21 | 10 | 40 | 5 | 50 | 3.17 | 3.93 |

| 22 | 10 | 80 | 5 | 50 | 2.73 | 3.14 |

| 23 | 10 | 40 | 5 | 250 | 3.27 | 4.09 |

| 24 | 10 | 80 | 5 | 250 | 2.99 | 3.01 |

| 25 | 10 | 60 | 5 | 150 | 3.07 | 3.37 |

| 26 | 10 | 60 | 5 | 150 | 3.14 | 3.44 |

| 27 | 10 | 60 | 5 | 150 | 3.25 | 3.39 |

| 28 | 10 | 60 | 5 | 150 | 3.09 | 3.34 |

| 29 | 10 | 60 | 5 | 150 | 3.01 | 3.43 |

| Variance Source | Degrees of Freedom | Cottonseed Crushing Rate (Y1/%) | Dimensional Stability Coefficient (Y2) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SS | MS | F Value | p Value | SS | MS | F Value | p Value | ||

| Model | 14 | 39.52 | 2.82 | 121.67 | <0.0001 ** | 5.08 | 0.36 | 104.92 | <0.0001 ** |

| X1 | 1 | 2.87 | 2.87 | 123.75 | <0.0001 ** | 0.19 | 0.19 | 54.99 | <0.0001 ** |

| X2 | 1 | 0.13 | 0.13 | 5.52 | 0.0340 * | 3.02 | 3.02 | 873.95 | <0.0001 ** |

| X3 | 1 | 35.60 | 35.60 | 1534.48 | <0.0001 ** | 1.37 | 1.37 | 395.55 | <0.0001 ** |

| X4 | 1 | 0.068 | 0.068 | 2.91 | 0.1102 | 0.019 | 0.019 | 5.56 | 0.0335 * |

| X1X2 | 1 | 0.11 | 0.11 | 4.69 | 0.0480 * | 0.0012 | 0.0012 | 0.35 | 0.5611 |

| X1X3 | 1 | 0.37 | 0.37 | 15.78 | 0.0014 * | 0.0001 | 0.0001 | 0.029 | 0.8674 |

| X1X4 | 1 | 0.036 | 0.036 | 1.56 | 0.2327 | 0.010 | 0.010 | 2.89 | 0.1110 |

| X2X3 | 1 | 0.044 | 0.044 | 1.90 | 0.1896 | 0.017 | 0.017 | 4.89 | 0.0441 * |

| X2X4 | 1 | 0.0064 | 0.0064 | 0.28 | 0.6077 | 0.021 | 0.021 | 6.08 | 0.0272 * |

| X3X4 | 1 | 0.0025 | 0.0025 | 0.11 | 0.7476 | 0.0002 | 0.0002 | 0.065 | 0.8023 |

| X12 | 1 | 0.11 | 0.11 | 4.65 | 0.0489 * | 0.0014 | 0.0014 | 0.39 | 0.5400 |

| X22 | 1 | 0.044 | 0.044 | 1.89 | 0.1907 | 0.15 | 0.15 | 43.23 | <0.0001 ** |

| X32 | 1 | 0.060 | 0.060 | 2.60 | 0.1289 | 0.20 | 0.20 | 57.16 | <0.0001 ** |

| X42 | 1 | 0.027 | 0.027 | 1.17 | 0.2973 | 0.0035 | 0.0035 | 1.01 | 0.3309 |

| Residuals | 14 | 0.32 | 0.023 | 0.048 | 0.0035 | ||||

| Lack of fit | 10 | 0.29 | 0.029 | 3.60 | 0.1142 | 0.041 | 0.0041 | 2.40 | 0.2073 |

| Pure error | 4 | 0.032 | 0.0081 | 0.0069 | 0.0017 | ||||

| Cor total | 28 | 39.85 | 5.12 | 0.36 | |||||

| No. | Cottonseed Crushing Rate (Y1/%) | Error/% | Dimensional Stability Coefficient (Y2) | Error/% |

|---|---|---|---|---|

| Measured Values | Measured Values | |||

| 1 | 2.92 | 2.35 | 3.32 | 1.41 |

| 2 | 2.90 | 1.65 | 3.25 | 2.32 |

| 3 | 2.80 | 1.86 | 3.28 | 0.18 |

| 4 | 2.87 | 0.60 | 3.40 | 3.85 |

| 5 | 2.95 | 3.40 | 3.21 | 1.95 |

| Average value | 2.888 | 1.972 | 3.282 | 1.942 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, X.; Wei, X.; Wang, M.; Zhang, H.; Wang, L.; Wang, J.; Zheng, Y. Compression Molding Characteristics of Seed Cotton and Damage from Cottonseed Crushing. Agriculture 2024, 14, 92. https://doi.org/10.3390/agriculture14010092

Fu X, Wei X, Wang M, Zhang H, Wang L, Wang J, Zheng Y. Compression Molding Characteristics of Seed Cotton and Damage from Cottonseed Crushing. Agriculture. 2024; 14(1):92. https://doi.org/10.3390/agriculture14010092

Chicago/Turabian StyleFu, Xuewen, Ximei Wei, Meng Wang, Hongwen Zhang, Lei Wang, Jun Wang, and Yuanzhao Zheng. 2024. "Compression Molding Characteristics of Seed Cotton and Damage from Cottonseed Crushing" Agriculture 14, no. 1: 92. https://doi.org/10.3390/agriculture14010092

APA StyleFu, X., Wei, X., Wang, M., Zhang, H., Wang, L., Wang, J., & Zheng, Y. (2024). Compression Molding Characteristics of Seed Cotton and Damage from Cottonseed Crushing. Agriculture, 14(1), 92. https://doi.org/10.3390/agriculture14010092