Analysis and Experimental Investigation of Steering Kinematics of Driven Steering Crawler Harvester Chassis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Basic Structure of Driven Steering Crawler Harvester Chassis

2.2. Analysis of Speed of Drive and Steering Transmission System

2.3. Analysis of Steering Characteristics of Driven Steering Crawler Harvester

2.4. Kinematics Analysis of Tracked Vehicle Steering

3. Results and Discussion

3.1. Test Conditions and Process

3.2. Test Data

3.3. Test Analysis

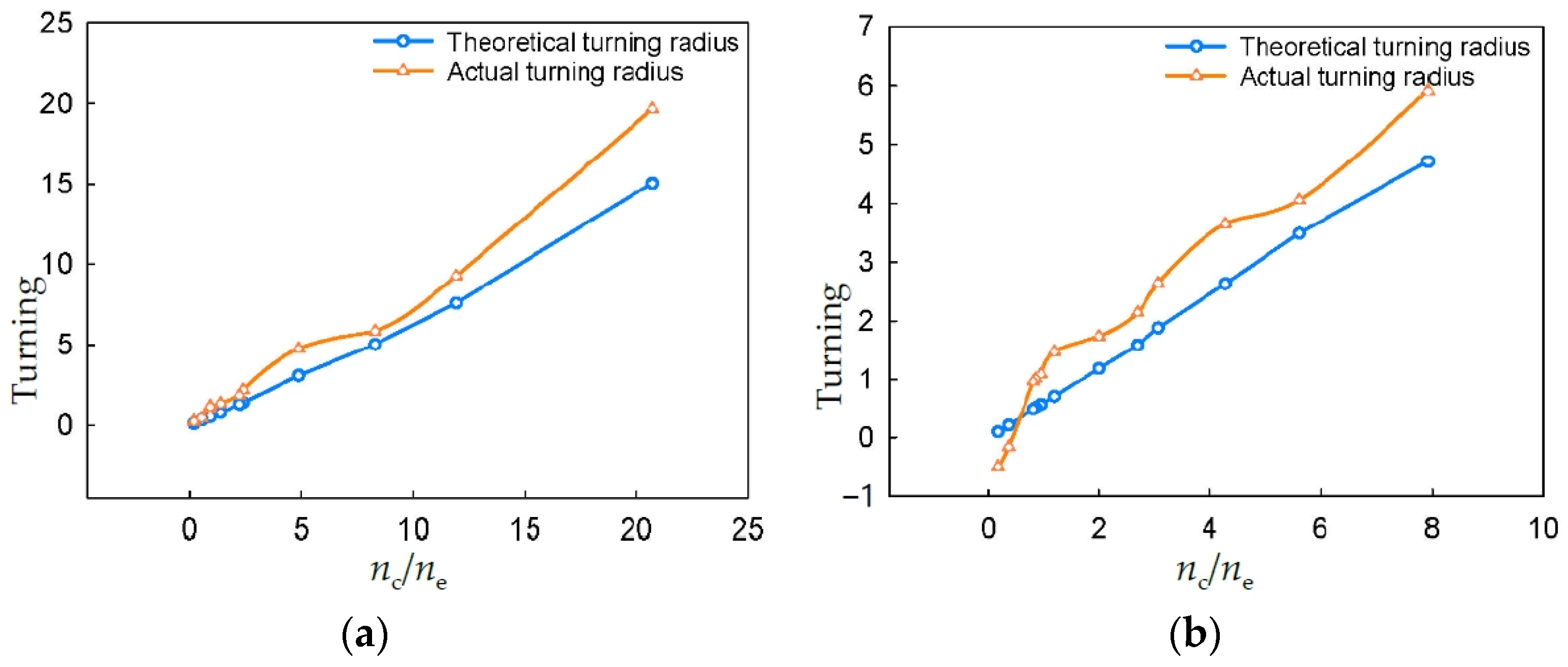

3.3.1. Relationship between Input Speed and Steering Parameters

3.3.2. Correction Calculation of Steering Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, Y.; Zhou, J.; Sun, J.; Jia, H.; Liang, Z.; Awuah, E. An adaptive control system for path tracking of crawler combine harvester based on paddy ground conditions identification. Comput. Electron. Agric. 2023, 210, 107948. [Google Scholar] [CrossRef]

- Hossain, M.; Hoque, M.; Wohab, M.; Miah, M.M.; Hassan, M. Technical and economic performance of combined harvester in farmers field. Bangladesh J. Agric. Res. 2015, 40, 291–304. [Google Scholar] [CrossRef]

- Lv, Y.; Wu, X.; Fu, Y.; Li, Z. Research on the Influence of Four-wheel Chassis ’Working Stroke Rate. J. Agric. Mech. Res. 2015, 37, 23–26+30. [Google Scholar] [CrossRef]

- Chen, T.; Xu, L.; Ahn, H.S.; Lu, E.; Liu, Y.; Xu, R. Evaluation of headland turning types of adjacent parallel paths for combine harvesters. Biosyst. Eng. 2023, 233, 93–113. [Google Scholar] [CrossRef]

- Guan, Z.; Zhang, M.; Jin, M.; Li, H.; Jiang, T.; Mu, S. Research progress of mechanical damage to soil bywalking mechanism of tracked agricultural equipment. J. Intell. Agric. Mech. 2022, 3, 62–70. [Google Scholar]

- Zhang, L.; Liu, G.; Qi, Y.; Yang, T.; Jin, C. Research progress on key technologies of agriculturalmachinery unmanned driving system. J. Intell. Agric. Mech. 2022, 3, 27–36. [Google Scholar]

- Munir, F.; Azam, S.; Yow, K.-C.; Lee, B.-G.; Jeon, M. Multimodal fusion for sensorimotor control in steering angle prediction. Eng. Appl. Artif. Intell. 2023, 126, 107087. [Google Scholar] [CrossRef]

- Yang, H.; Zhou, J.; Wang, X.; Wu, Y. Parameter Matching and Tillage Depth Control Method for Electric Crawler Tractor Platforms. J. Eng. Sci. Technol. Rev. 2021, 14, 83–90. [Google Scholar] [CrossRef]

- Inoue, E.; Mitsuoka, M.; Rabbani, M. Investigation of nonlinear vibration characteristics of agricultural rubber crawler vehicles. AMA-Agric. Mech. Asia Afr. Lat. Am. 2011, 42, 89. [Google Scholar]

- Shi, R.; Dai, F.; Zhao, W.; Liu, X.; Wang, T.; Zhao, Y. Optimal design and testing of a crawler-type flax combine harvester. Agriculture 2023, 13, 229. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, G.; Chu, G.; Niu, H.; Zhang, Y.; Yang, F. Design matching and dynamic performance test for an HST-based drive system of a hillside crawler tractor. Agriculture 2021, 11, 466. [Google Scholar] [CrossRef]

- Tang, Z.; Ren, H.; Li, X.; Liu, X.; Zhang, B. Structure Design and Bearing Capacity Analysis for Crawler Chassis of Rice Combine Harvester. Complexity 2020, 2020, 7610767. [Google Scholar] [CrossRef]

- Adams, B.; Darr, M.; Shah, A. Optimized Chassis Stability Relative to Dynamic Terrain Profiles in a Self-Propelled Sprayer Multibody Dynamics Model. J. ASABE 2023, 66, 127–139. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, L.; Jing, B.; Chai, X.; Li, Y. Development of a four-point adjustable lifting crawler chassis and experiments in a combine harvester. Comput. Electron. Agric. 2020, 173, 105416. [Google Scholar] [CrossRef]

- Shinzato, Y.; Komesu, H.; Akati, T.; Ueno, M. Estimating the performance of small sugarcane harvesters in Okinawa. Eng. Agric. Environ. Food 2019, 12, 499–504. [Google Scholar] [CrossRef]

- Xu, L.; Zhou, Z.; Wang, B. Study on Matching Strategies of Hydro-Mechanical Continuously Variable Transmission System of Tractor. Int. J. Digit. Content Technol. Its Appl. 2013, 7, 843–849. [Google Scholar]

- Shao, X.; Yang, Z.; Mowafy, S.; Zheng, B.; Song, Z.; Luo, Z.; Guo, W. Load characteristics analysis of tractor drivetrain under field plowing operation considering tire-soil interaction. Soil Tillage Res. 2023, 227, 105620. [Google Scholar] [CrossRef]

- Liu, P.; Wang, Z.; Li, H.; Zhang, S.; Wei, W. Design and overcoming obstacles ability research of tracked driving chassis with planetary structure. Trans. Chin. Soc. Agric. Mach. 2014, 45, 17–23. [Google Scholar]

- Sun, S.; Wang, J.; Ke, J. New HST optimal design and test in harvester. J. Mach. Des. 2014, 31, 34–38. [Google Scholar] [CrossRef]

- Previati, G.; Gobbi, M.; Mastinu, G. Farm tractor models for research and development purposes. Veh. Syst. Dyn. 2007, 45, 37–60. [Google Scholar] [CrossRef]

- Letherwood, M.D.; Gunter, D.D. Ground vehicle modeling and simulation of military vehicles using high performance computing. Parallel Comput. 2001, 27, 109–140. [Google Scholar] [CrossRef]

- Du, P.; Ma, Z.; Chen, H.; Xu, D.; Wang, Y.; Jiang, Y.; Lian, X. Speed-adaptive motion control algorithm for differential steering vehicle. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2020, 235, 672–685. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Hu, J.; Li, X.; Zhou, J.; Guo, J. Modeling of steady-state performance of skid-steering for high-speed tracked vehicles. J. Terramech. 2017, 73, 25–35. [Google Scholar] [CrossRef]

- Soodmand, I.; Heidari Shirazi, K.; Moradi, S. Analysis of ride comfort of a continuous tracked bogie system with variable configuration. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2020, 234, 3429–3439. [Google Scholar] [CrossRef]

- Xin, Z.; Jiang, Q.; Zhu, Z.; Shao, M. Design and optimization of a new terrain-adaptive hitch mechanism for hilly tractors. Int. J. Agric. Biol. Eng. 2023, 16, 134–144. [Google Scholar] [CrossRef]

- Matsuda, S.; Mukai, H. Effects of the Combination of Sloped Farm Field, Crawler Compaction and Open Channels on Moisture and Hardness and Temperature of the Surface Soil Layer after Disappearance of the Snow Cover. Trans. Jpn. Soc. Irrig. 2010, 77, 411–416. [Google Scholar]

- Fu, J.; Li, J.; Tang, X.; Wang, R.; Chen, Z. Optimization of Structure Parameters of the Grouser Shoes for Adhesion Reduction under Black Soil. Agriculture 2021, 11, 795. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, J.; Ding, L.; Gao, H.; Guo, T.; Deng, Z. Online estimation of terrain parameters and resistance force based on equivalent sinkage for planetary rovers in longitudinal skid. Mech. Syst. Signal Process. 2019, 119, 39–54. [Google Scholar] [CrossRef]

- Yokoyama, A.; Nakashima, H.; Shimizu, H.; Miyasaka, J.; Ohdoi, K. Effect of open spaces between grousers on the gross traction of a track shoe for lightweight vehicles analyzed using 2D DEM. J. Terramech. 2020, 90, 31–40. [Google Scholar] [CrossRef]

- Nakashima, H.; Yoshida, T.; Wang, X.L.; Shimizu, H.; Miyasaka, J.; Ohdoi, K. On a Gross Traction Generated at Grouser for Tracked Agricultural Vehicles. IFAC Proc. Vol. 2013, 46, 311–316. [Google Scholar] [CrossRef]

| Parameter | Numerical Value |

|---|---|

| Machine size (length × width × height)/(mm) | 5640 × 2600 × 2800 |

| Weight/(kg) | 4030 |

| Track grounding length/center distance/(mm) | 2300 |

| Track gauge/(mm) | 1200 |

| Mean ground voltage (kPa) | 19.1 |

| Track pitch × number × width | 90 mm × 58 segment × 550 mm |

| Number of driving gear teeth | 8 |

| Spacing between antenna and central axis/(mm) | 740 |

| Spacing between antenna and track axis/(mm) | 420 |

| No. | Steering Type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 157.065 | 7.584 | 2.087 | 1.892 | 20.71 | 15.036 | 19.643 | 0.57 | 0.523 | 0.193 | 0.97 | a |

| 2 | 161.92 | 13.574 | 2.223 | 1.875 | 11.929 | 7.559 | 9.262 | 1.016 | 0.904 | 0.362 | 0.962 | a |

| 3 | 122.065 | 14.76 | 1.738 | 1.359 | 8.27 | 5.016 | 5.836 | 1.112 | 1.079 | 0.364 | 0.962 | a |

| 4 | 80.632 | 16.557 | 1.234 | 0.809 | 4.87 | 3.091 | 4.741 | 1.176 | 1.102 | 0.241 | 0.972 | a |

| 5 | 101.377 | 42.352 | 1.83 | 0.743 | 2.394 | 1.429 | 2.201 | 3.178 | 3.079 | 0.25 | 0.976 | a |

| 6 | 111.033 | 49.126 | 2.045 | 0.772 | 2.26 | 1.328 | 1.875 | 3.723 | 3.602 | 0.306 | 0.973 | a |

| 7 | 92.258 | 68.187 | 2.046 | 0.296 | 1.353 | 0.803 | 1.368 | 5.116 | 4.69 | 0.282 | 0.987 | a |

| 8 | 61.939 | 68.293 | 1.662 | −0.09 | 0.907 | 0.538 | 1.2 | 5.124 | 4.886 | 0.158 | 0.995 | a |

| 9 | 66.749 | 74.471 | 1.802 | −0.109 | 0.896 | 0.532 | 1.17 | 5.588 | 5.359 | 0.162 | 0.994 | a |

| 10 | 61.872 | 69.309 | 1.674 | −0.104 | 0.893 | 0.529 | 0.99 | 5.36 | 5.19 | 0.215 | 0.992 | a |

| 11 | 40.452 | 51.422 | 1.171 | −0.146 | 0.787 | 0.468 | 0.818 | 3.85 | 3.983 | 0.232 | 0.973 | b |

| 12 | 45.893 | 85.762 | 1.676 | −0.516 | 0.535 | 0.318 | 0.554 | 6.408 | 6.2 | 0.379 | 0.721 | b |

| 13 | 17.754 | 92.978 | 1.418 | −0.968 | 0.191 | 0.113 | 0.244 | 6.98 | 6.757 | 0.36 | 0.604 | b |

| 14 | 7.283 | 63.55 | 0.908 | −0.721 | 0.115 | 0.068 | 0.343 | 4.758 | 4.402 | 0.272 | 0.743 | b |

| 15 | 2.839 | 108.739 | 1.424 | −1.352 | 0.026 | 0.015 | −0.248 | 8.119 | 8.955 | 0.151 | 0.629 | b |

| No. | Steering Type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 163.68 | 20.645 | 2.343 | 1.812 | 7.928 | 4.704 | 5.904 | 1.549 | 1.486 | 0.343 | 0.963 | a |

| 2 | 150.544 | 26.819 | 2.254 | 1.566 | 5.613 | 3.487 | 4.052 | 2.012 | 1.982 | 0.349 | 0.964 | a |

| 3 | 143.934 | 33.654 | 2.258 | 1.395 | 4.279 | 2.634 | 3.651 | 2.525 | 2.499 | 0.251 | 0.971 | a |

| 4 | 118.982 | 38.798 | 2.008 | 1.012 | 3.067 | 1.883 | 2.644 | 2.911 | 2.878 | 0.26 | 0.973 | a |

| 5 | 115.349 | 42.982 | 2.015 | 0.912 | 2.684 | 1.59 | 2.139 | 3.225 | 3.117 | 0.326 | 0.97 | a |

| 6 | 107.416 | 53.816 | 2.053 | 0.672 | 1.996 | 1.192 | 1.74 | 4.038 | 3.911 | 0.291 | 0.976 | a |

| 7 | 77.24 | 65.102 | 1.815 | 0.148 | 1.186 | 0.704 | 1.48 | 4.884 | 4.685 | 0.145 | 0.994 | a |

| 8 | 69.457 | 73.186 | 1.82 | −0.058 | 0.949 | 0.564 | 1.097 | 5.491 | 5.265 | 0.219 | 0.996 | a |

| 9 | 63.411 | 74.089 | 1.755 | −0.146 | 0.856 | 0.508 | 1.011 | 5.559 | 5.398 | 0.211 | 0.99 | b |

| 10 | 60.572 | 74.668 | 1.727 | −0.189 | 0.811 | 0.481 | 0.961 | 5.603 | 4.701 | 0.324 | 0.982 | b |

| 11 | 34.408 | 54.348 | 1.134 | −0.261 | 0.633 | 0.377 | 0.563 | 4.078 | 3.692 | 0.397 | 0.917 | b |

| 12 | 28.561 | 80.591 | 1.396 | −0.672 | 0.354 | 0.21 | −0.159 | 6.047 | 6.155 | 0.691 | 0.357 | b |

| 13 | 11.897 | 49.918 | 0.791 | −0.49 | 0.238 | 0.147 | −0.245 | 3.745 | 3.293 | 0.44 | 0.62 | b |

| 14 | 14.27 | 86.73 | 1.294 | −0.931 | 0.165 | 0.097 | −0.486 | 6.508 | 6.684 | 0.906 | 0.87 | b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Jin, C.; Yang, T.; Wang, T.; Ni, Y. Analysis and Experimental Investigation of Steering Kinematics of Driven Steering Crawler Harvester Chassis. Agriculture 2024, 14, 65. https://doi.org/10.3390/agriculture14010065

Wang Y, Jin C, Yang T, Wang T, Ni Y. Analysis and Experimental Investigation of Steering Kinematics of Driven Steering Crawler Harvester Chassis. Agriculture. 2024; 14(1):65. https://doi.org/10.3390/agriculture14010065

Chicago/Turabian StyleWang, Yanxin, Chengqian Jin, Tengxiang Yang, Tingen Wang, and Youliang Ni. 2024. "Analysis and Experimental Investigation of Steering Kinematics of Driven Steering Crawler Harvester Chassis" Agriculture 14, no. 1: 65. https://doi.org/10.3390/agriculture14010065

APA StyleWang, Y., Jin, C., Yang, T., Wang, T., & Ni, Y. (2024). Analysis and Experimental Investigation of Steering Kinematics of Driven Steering Crawler Harvester Chassis. Agriculture, 14(1), 65. https://doi.org/10.3390/agriculture14010065