Simulated Ecosystem and Farm-Level Economic Impacts of Conservation Tillage in a Northeastern Iowa County

Abstract

1. Introduction

1.1. Disparities in Existing Studies on the Cost-Effectiveness of Conservation Tillage

1.2. Previous Work That Informs the Present Study

1.3. Purpose of This Study

2. Materials and Methods

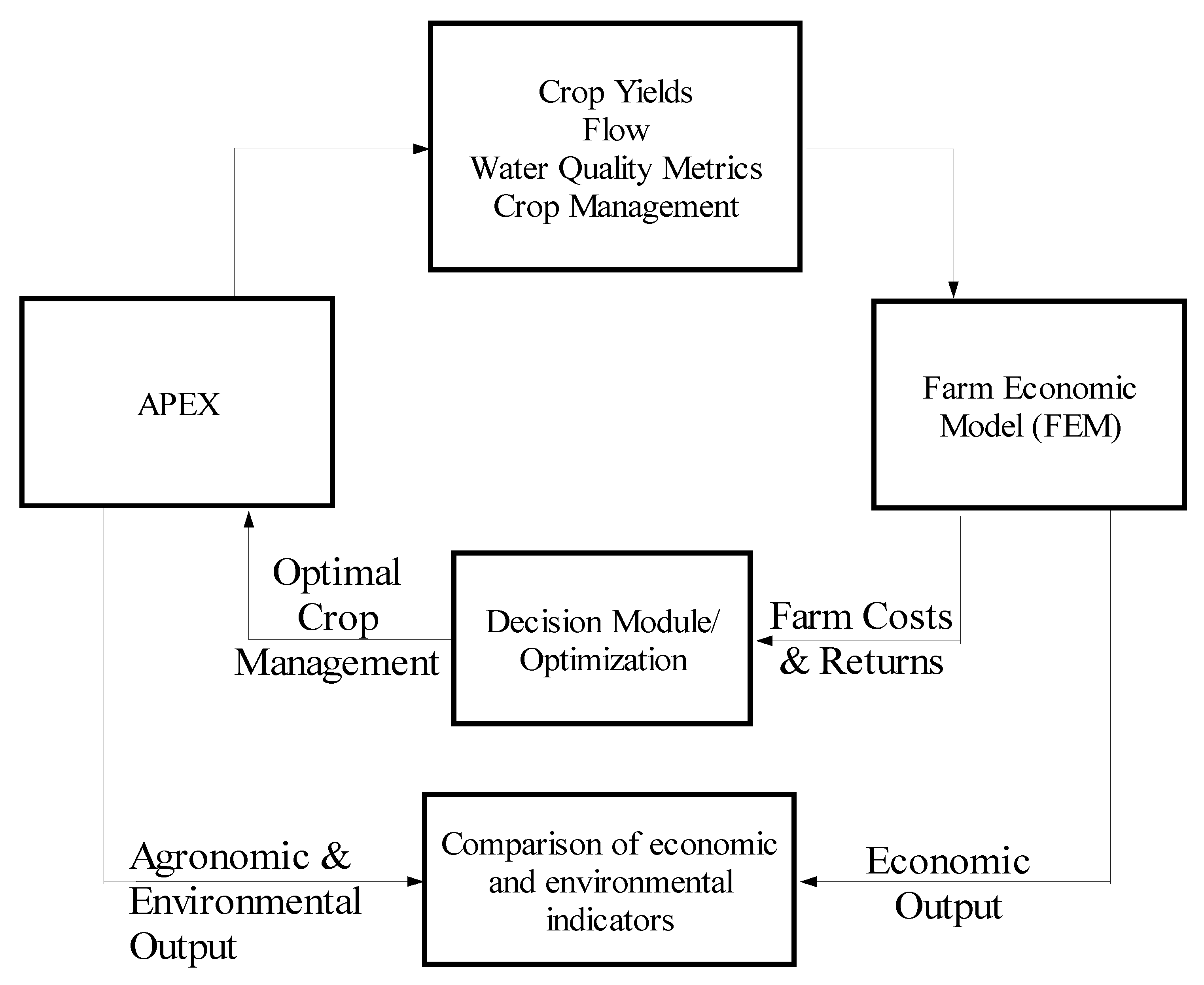

2.1. Modeling System

- is the number of hours machinery was used in field operation in year ,

- is the number of hours machinery was used in all field operations in year ,

- and are ASAE repair and maintenance factors,

- is the purchase price of machinery , and

- is the cumulative hours of use of machinery through the end of year .

2.2. Data Sources

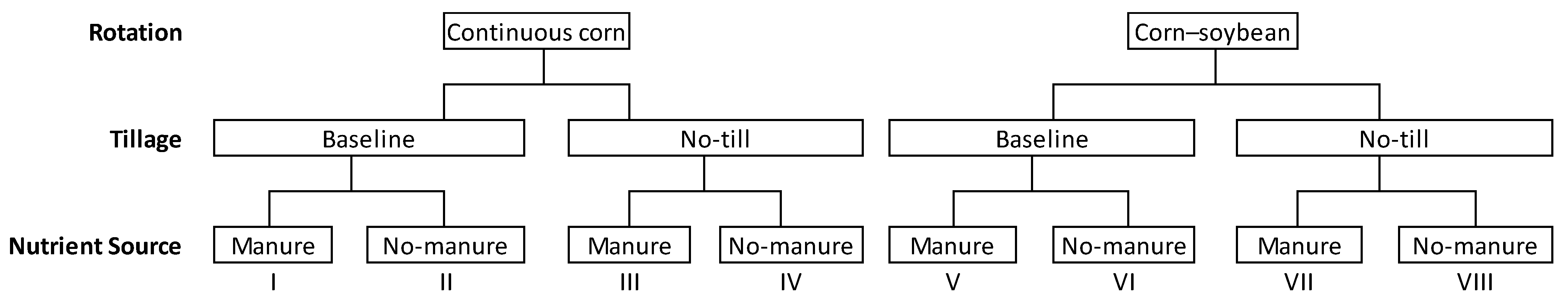

2.3. Representative Farms for Economic Simulations

2.4. APEX Validation

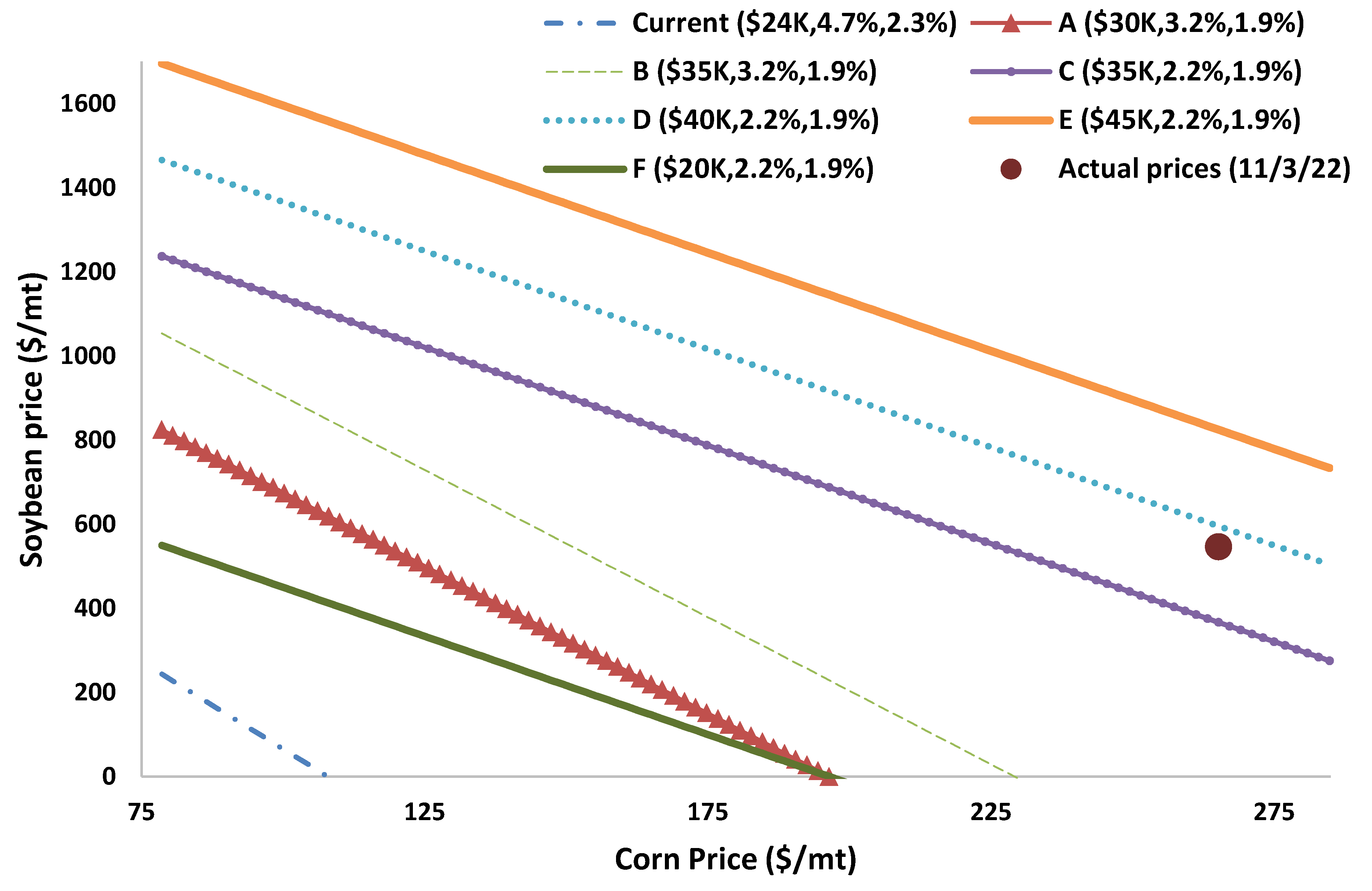

2.5. FEM Validation

2.6. Simulation Procedure

3. Results

- Runoff and sediment losses;

- Nutrient losses in surface runoff;

- Carbon sequestration rates;

- Corn and soybean yields;

- Farm-level economic impacts.

3.1. Impacts on Runoff and Sediment Losses

3.2. Impacts on Nutrient Losses

3.3. Impacts on Carbon Sequestration

3.4. Impacts on Corn and Soybean Yields

3.5. Farm-Level Economic Impacts

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carpenter, S.; Caraco, N.; Correll, D.; Howarth, R.; Sharply, A.; Smith, V. Nonpoint source pollution of surface waters with phosphorus and nitrogen. Ecol. Appl. 1998, 8, 559–568. [Google Scholar] [CrossRef]

- Xu, Y.; Elbakidze, L.; Yen, H.; Arnold, J.G.; Gassman, P.W.; Hubbart, J.; Strager, M.P. Integrated assessment of nitrogen runoff to the Gulf of Mexico. Resour. Energy Econ. 2022, 67, 101279. [Google Scholar] [CrossRef]

- Elizabeth, M.; Aillery, M.; Ribaudo, M.; Key, N.; Sneeringer, S.; Hansen, L.; Malcolm, S.; Riddle, A. Reducing Nutrient Losses from Cropland in the Mississippi/Atchafalaya River Basin: Cost Efficiency and Regional Distribution, ERR-258, U.S. Department of Agriculture, Economic Research Service, September 2018. Available online: https://www.ers.usda.gov/publications/pub-details/?pubid=90175 (accessed on 9 March 2023).

- Delgado, J.A.; Groffman, P.M.; Nearing, M.A.; Goddard, T.; Reicosky, D.; Lal, R.; Kitchen, N.R.; Rice, C.W.; Towery, D.; Salon, P. Conservation practices to mitigate and adapt to climate change. J. Soil Water Conserv. 2011, 66, 118A–129A. [Google Scholar] [CrossRef]

- Macrae, M.; Jarvie, H.; Brouwer, R.; Gunn, G.; Reid, K.; Joosse, P.; King, K.; Kleinman, P.; Smith, D.; Williams, M.; et al. One size does not fit all: Toward regional conservation practice guidance to reduce phosphorus loss risk in the Lake Erie watershed. J. Environ. Qual. 2021, 50, 529–546. [Google Scholar] [CrossRef]

- Roland, V.; Garcia, A.; Saad, D.; Ator, S.; Robertson, D.; Schwarz, G. Quantifying regional effects of best management practices on nutrient losses from agricultural lands. J. Soil Water Conserv. 2021, 77, 15–29. [Google Scholar] [CrossRef]

- Wallace, C.W.; Flanagan, D.C.; Engel, B.A. Quantifying the effects of conservation practice implementation on predicted runoff and chemical losses under climate change. Agric. Water Manag. 2017, 186, 51–65. [Google Scholar] [CrossRef]

- Garbrecht, J.D.; Nearing, M.A.; Shields, F.D., Jr.; Tomer, M.D.; Sadler, E.J.; Bonta, J.V.; Baffaut, C. Impact of weather and climate scenarios on conservation assessment outcomes. J. Soil Water Conserv. 2014, 69, 374–392. [Google Scholar] [CrossRef]

- Keith, G.; Norvell, S.; Jones, R.; Maquire, C.; Osei, E.; Saleh, A.; Gassman, P.; Rodecap, J. Livestock and The Environment: A National Pilot Project: CEEOT-LP Modeling for the Upper Maquoketa River Watershed, Iowa: Final Report; Report No. PR0003; Texas Institute for Applied Environmental Research, Tarleton State University: Stephenville, TX, USA, 2000. [Google Scholar]

- Gassman, P.W.; Osei, E.; Saleh, A.; Rodecap, J.; Norvell, S.; Williams, J. Alternative practices for sediment and nutrient loss con-trol on livestock farms in northeast Iowa. Agric. Ecosyst. Environ. 2006, 117, 135–144. [Google Scholar] [CrossRef]

- Palm, C.; Blanco-Canqui, H.; DeClerck, F.; Gatere, L.; Grace, P. Conservation agriculture and eco-system services: An overview. Agric. Ecosyst. Environ. 2014, 187, 87–105. [Google Scholar] [CrossRef]

- Daryanto, S.; Wang, L.; Jacinthe, P.A. Impacts of no-tillage management on nitrate loss from corn, soybean and wheat cultivation: A meta-analysis. Sci. Rep. 2017, 7, 12117. [Google Scholar] [CrossRef]

- Delate, K.; Cwach, D.; Chase, C. Organic No-Tillage System Effects on Soybean, Corn and Irrigated Tomato Production and Economic Performance in Iowa, USA. Renew. Agric. Food Syst. 2012, 27, 49–59. [Google Scholar] [CrossRef]

- Hristovska, T.; Watkins, K.B.; Anders, M.M. An economic risk analysis of no-till management for the rice-soybean rotation system used in Arkansas. J. Soil Water Conserv. 2013, 68, 132–137. [Google Scholar] [CrossRef]

- Norwood, C.A.; Currie, R.S. An Agronomic and Economic Comparison of the Wheat-Corn-Fallow and Wheat-Sorghum-Fallow Rotations. J. Prod. Agric. 1998, 11, 67–73. [Google Scholar] [CrossRef]

- Pendell, D.L.; Williams, J.R.; Rice, C.W.; Nelson, R.G.; Boyles, S.B. Economic feasibility of no-tillage and manure for soil carbon sequestration in corn production in northeastern Kansas. J. Environ. Qual. 2006, 35, 1364–1373. [Google Scholar] [CrossRef] [PubMed]

- Ribera, L.A.; Hons, F.M.; Richardson, J.W. An economic comparison between conventional and no-tillage farming systems in Burleson County, Texas. Agron. J. 2004, 96, 415–424. [Google Scholar] [CrossRef]

- Buman, R.A.; Alesii, B.A.; Hatfield, J.L.; Karlen, D.L. Profit, yield, and soil quality effects of tillage systems in corn–Soybean rotations. J. Soil Water Conserv. 2004, 59, 260–270. [Google Scholar]

- Dhuyvetter, K.C.; Thompson, C.R.; Norwood, C.A.; Halvorson, A.D. Economics of Dryland Cropping Systems in the Great Plains: A Review. J. Prod. Agric. 1996, 9, 216–222. [Google Scholar] [CrossRef]

- Toliver, D.K.; Larson, J.A.; Roberts, R.K.; English, B.C.; De La Torre Ugarte, D.G.; West, T.O. Effects of no-till on yields as influenced by crop and environmental factors. Agron. J. 2012, 104, 530–541. [Google Scholar] [CrossRef]

- Al-Kaisi, M.; Kwaw-Mensah, D. Effect of tillage and nitrogen rate on corn yield and nitrogen and phosphorus uptake in a corn-soybean rotation. Agron. J. 2007, 99, 1548–1558. [Google Scholar] [CrossRef]

- Al-Kaisi, M.; Licht, M.A. Effect of strip tillage on corn nitrogen uptake and residual soil nitrate accumulation compared with no-tillage and chisel plow. Agron. J. 2004, 96, 1164–1171. [Google Scholar] [CrossRef]

- Williams, J.R.; Arnold, J.G.; Kiniry, J.R.; Gassman, P.W.; Green, C.H. History of model development at Temple, Texas. Hydrol. Sci. J. 2008, 53, 948–960. [Google Scholar] [CrossRef]

- Williams, J.R.; Arnold, J.G.; Srinivasan, R. The APEX Model; BRC Report; No. 00-06; Blackland Research Center, Texas Agricultural Experiment Station, Texas Agricultural Extension Service, Texas A&M University System: Temple, TX, USA, 2000. [Google Scholar]

- Gassman, P.W.; Williams, J.R.; Wang, X.; Saleh, A.; Osei, E.; Hauck, L.M.; Izaurralde, R.; Flowers, J.D. Invited Review Article: The Agricultural Policy/Environmental eXtender (APEX) Model: An Emerging Tool for Landscape and Watershed Environmental Analyses. Trans. ASABE 2010, 53, 711–740. [Google Scholar] [CrossRef]

- Edward, O.; Gassman, P.; Saleh, A. Livestock and the Environment: A National Pilot Project: Economic and Environmental Modeling Using CEEOT.; Report No. PR0002; Texas Institute for Applied Environmental Research, Tarleton State University: Stephenville, TX, USA, 2000. [Google Scholar]

- Arnold, J.G.; Srinivasan, R.; Muttiah, R.S.; Williams, J.R. Large Area Hydrologic Modeling and Assessment Part I: Model Development. JAWRA J. Am. Water Resour. Assoc. 1998, 34, 73–89. [Google Scholar] [CrossRef]

- Arnold, J.G.; Moriasi, D.N.; Gassman, P.W.; Abbaspour, K.C.; White, M.J.; Srinivasan, R.; Santhi, C.; Harmel, R.D.; van Griensven, A.; Van Liew, M.W.; et al. SWAT: Model use, calibration, and validation. Trans. ASABE 2012, 55, 1491–1508. [Google Scholar] [CrossRef]

- Wang, X.; Williams, J.R.; Gassman, P.W.; Baffaut, C.; Izaurralde, R.; Jeong, J.; Kiniry, J.R. The EPIC and APEX models: Use, calibration and validation. Trans. ASABE 2012, 55, 1447–1462. [Google Scholar] [CrossRef]

- Tadesse, H.K.; Moriasi, D.N.; Gowda, P.H.; Marek, G.; Steiner, J.L.; Brauer, D.; Talebi-zadeh, M.; Nelson, A.; Starks, P. Evaluating evapotranspiration estimation methods in APEX model for dryland cropping systems in a semi-arid region. Agric. Water Manag. 2018, 206, 217–228. [Google Scholar] [CrossRef]

- Timlin; Dennis; Chun, J.A.; Meisinger, J.; Kang, K.; Fleisher, D.; Staver, K.; Doherty, C.; Russ, A. Evaluation of the agricultural policy environmental extender (APEX) for the Chesapeake Bay watershed. Agric. Water Manag. 2019, 221, 477–485. [Google Scholar] [CrossRef]

- Gautam, S.; Mbonimpa, E.G.; Kumar, S.; Bonta, J.V.; Lal, R. Agricultural Policy Environmental eXtender model simulation of climate change impacts on runoff from a small no-till watershed. J. Soil Water Conserv. 2015, 70, 101–109. [Google Scholar] [CrossRef]

- Ford, W.; King, K.; Williams, M.; Williams, J.; Fausey, N. Sensitivity Analysis of the Agricultural Policy/Environmental eXtender (APEX) for Phosphorus Loads in Tile-Drained Landscapes. J. Environ. Qual. 2015, 44, 1099–1110. [Google Scholar] [CrossRef]

- Osei, E.; Jafri, S.H.; Saleh, A.; Gassman, P.W.; Gallego, O. Simulated Climate Change Impacts on Corn and Soybean Yields in Buchanan County, Iowa. Agriculture 2023, 13, 268. [Google Scholar] [CrossRef]

- Osei, E.; Jafri, S.H.; Gassman, P.W.; Saleh, A.; Gallego, O. Climate Change Impacts on Surface Runoff and Nutrient and Sediment Losses in Buchanan County, Iowa. Agriculture 2023, 13, 470. [Google Scholar] [CrossRef]

- Kim, D.-H.; Jang, T.; Hwang, S. Evaluating impacts of climate change on hydrology and total nitrogen loads using coupled APEX-paddy and SWAT models. Paddy Water Environ. 2020, 18, 515–529. [Google Scholar] [CrossRef]

- Bailey, R.T.; Tasdighi, A.; Park, S.; Tavakoli-Kivi, S.; Abitew, T.; Jeong, J.; Green, C.H.; Worqlul, A.W. APEX-MODFLOW: A New integrated model to simulate hydrological processes in watershed systems. Environ. Model. Softw. 2021, 143, 105093. [Google Scholar] [CrossRef]

- Worqlul, A.W.; Jeong, J.; Green, C.H.M.; Abitew, T.A. The impact of rainfall distribution methods on streamflow throughout multiple elevations in the Rocky Mountains using the APEX model—Price River watershed, Utah. J. Environ. Qual. 2021, 50, 1395–1407. [Google Scholar] [CrossRef] [PubMed]

- Cheng, G.; Harmel, R.; Ma, L.; Derner, J.; Augustine, D.; Bartling, P.; Fang, Q.; Williams, J.; Zilverberg, C.; Boone, R.; et al. Evaluation of APEX modifications to simulate forage production for grazing management decision-support in the Western US Great Plains. Agric. Syst. 2021, 191, 103139. [Google Scholar] [CrossRef]

- Carroll, S.R.; Le, K.N.; Moreno-García, B.; Runkle, B.R.K. Simulating Soybean–Rice Rotation and Irrigation Strategies in Arkansas, USA Using APEX. Sustainability 2020, 12, 6822. [Google Scholar] [CrossRef]

- Mason, R.E.; Merrill, S.; Görres, J.; Faulkner, J.; Niles, M. Agronomic and environmental performance of dairy farms in a warmer, wetter climate. J. Soil Water Conserv. 2021, 76, 76–88. [Google Scholar] [CrossRef]

- Raj, A.D.; Kumar, S.; Sooryamol, K. Sooryamol. Modelling climate change impact on soil loss and erosion vulnerability in a watershed of Shiwalik Himalayas. Catena 2022, 214, 106279. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Hwang, S.; Choi, S.-K.; Cho, J.; Song, I.; Song, J.-h.; Jeong, H.; Jang, T.; Yoo, S.-H. Evaluating the Impact of Climate Change on Paddy Water Balance Using APEX-Paddy Model. Water 2020, 12, 852. [Google Scholar] [CrossRef]

- Mohammad, K.; Hwang, S.; Choi, S.-K.; Cho, J.; Song, I.; Jeong, H.; Song, J.-H.; Jang, T.; Yoo, S.-H. Prediction of the effects of management practices on discharge and mineral nitrogen yield from paddy fields under future climate using APEX-paddy model. Agric. Water Manag. 2020, 241, 106345. [Google Scholar] [CrossRef]

- Osei, E.; Moriasi, D.N.; Steiner, J.L.; Starks, P.J.; Saleh, A. Farm-Level Economic Impact of No-Till Farming in the Fort Cobb Reservoir Watershed. J. Soil Water Conserv. 2012, 67, 75–86. [Google Scholar] [CrossRef]

- Miller, D. Equipment Roundup: John Deere Discontinues 3710 Moldboard Plow. Progressive Farmer, DTN. 6/20/2022. Available online: https://www.dtnpf.com/agriculture/web/ag/equipment/article/2022/06/20/deere-retires-3710-moldboard-plow#:~:text=%22On%20July%208%2C%202022%2C,the%20995%20Reversible%20Moldboard%20Plow (accessed on 18 February 2023).

- Williams, J.R. The erosion-productivity impact calculator (EPIC) model: A case history. Philos. Trans. R. Soc. B Biol. Sci. 1990, 329, 421–428. [Google Scholar]

- USEPA. EnviroAtlas Data Download. National Table Downloads. Available online: https://www.epa.gov/enviroatlas/forms/enviroatlas-data-download (accessed on 11 November 2022).

- Osei, E.; Gassman, P.; Saleh, A. Livestock and the Environment: A National Pilot Project: CEEOT–LP Modeling for the Upper Maquoketa River Watershed, Iowa: Technical Report; Report No. RR0001; Texas Institute for Applied Environmental Research, Tarleton State University: Stephenville, TX, USA, 2000. [Google Scholar]

- Osei, E.; Bekele, A.; Du, B.; Rose, R.; Hauck, L.; Saleh, A.; Houser, J.; Keplinger, K.; Beran, L. CEEOT-MMS: A Macro Modeling System for Environmental Assessment; Technical Report TR0303; Texas Institute for Applied Environmental Research, Tarleton State Univ.: Stephenville, TX, USA, 2003. [Google Scholar]

- Brooke, A.; Kendrick, D.; Meeraus, A. GAMS: A User’s Guide; World Bank: Washington, DC, USA, 1992. [Google Scholar]

- ASAE. Agricultural Machinery Management. ASAE Engineering Practice: EP496.1, ASAE Standards; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1995. [Google Scholar]

- ASABE. Agricultural Machinery Management. ASABE Engineering Practice: EP496.3, ASABE Standards; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2006; Available online: https://elibrary.asabe.org/abstract.asp?aid=47748 (accessed on 29 January 2023).

- ASAE. Agricultural Machinery Management Data. ASAE Data: ASAE D497.1, ASAE Standards; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1995. [Google Scholar]

- ASABE. Agricultural Machinery Management Data. ASAE Data: ASAE D497.5, ASABE Standards; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2021; Available online: https://www.tractoresymaquinas.com/wp-content/uploads/2021/07/ASABE_D497.5.pdf (accessed on 29 January 2023).

- Plastina, A. Estimated Costs of Crop Production in Iowa. Iowa State University, Ames, Iowa. Ag Decision Maker. File A1-20. FM 1712 Revised January 2022. Available online: https://www.extension.iastate.edu/agdm/crops/pdf/a1-20-2022.pdf (accessed on 12 March 2023).

- USDA-NASS. USDA National Agricultural Statistics Service Cropland Data Layer; USDA-NASS: Washington, DC, USA, 2022. Available online: https://nassgeodata.gmu.edu/CropScape/ (accessed on 21 November 2022).

- USDA-NRCS. Soil Survey Staff, Natural Resources Conservation Service, United States Department of Agriculture. Soil Survey Geographic (SSURGO) Database. 2022. Available online: https://websoilsurvey.nrcs.usda.gov (accessed on 21 November 2022).

- PRISM Climate Group. PRISM Climate Group, Oregon State University. 2022. Available online: https://prism.oregonstate.edu (accessed on 21 November 2022).

- Lattz, D.; Schnitkey, G. Machinery Cost Estimates for 2021. FarmDoc Dly. 2021, 11, 143, Department of Agricultural and Consumer Economics, University of Illinois at Urbana-Champaign, 12 October 2021. [Google Scholar]

- Alejandro, P.; Ann; Johanns, M. Iowa Farm Custom Rate Survey. Iowa State University, Ames, Iowa. Ag Decision Maker. File A3-10. FM 1698 Revised March 2022. Available online: https://www.extension.iastate.edu/agdm/crops/html/a3-10.html (accessed on 12 March 2023).

- Edwards, K.A.; Foulger, M. A review of the efficacy of contemporary agricultural stewardship measures for ameliorating water pollution problems of key concern to the UK water industry. Agric. Syst. 2009, 99, 67–75. [Google Scholar]

- Jarvie, H.P.; Johnson, L.T.; Sharpley, A.N.; Smith, D.R.; Baker, D.B.; Bruulsema, T.W.; Confesor, R. Increased Soluble Phosphorus Loads to Lake Erie: Unintended Consequences of Conservation Practices? J. Environ. Qual. 2017, 46, 123–132. [Google Scholar] [CrossRef]

- Sharpley, A.N.; Daniel, T.; Gibson, G.; Bundy, L.; Cabrera, M.; Sims, T.; Stevens, R.; Lemunyon, J.; Kleinman, P.; Parry, R. Best Management Practices to Minimize Agricultural Phosphorus Impacts on Water Quality; ARS–163; United States Department of Agriculture, Agricultural Research Service: Washington, DC, USA, 2006. Available online: https://naldc.nal.usda.gov/catalog/26763 (accessed on 4 April 2023).

- Pittelkow, C.M.; Linquist, B.A.; Lundy, M.E.; Liang, X.; van Groenigen, K.J.; Lee, J.; van Gestel, N.; Six, J.; Venterea, R.T.; van Kessel, C. When does no-till yield more? A global meta-analysis. Field Crops Res. 2015, 183, 156–168. [Google Scholar] [CrossRef]

- Griffith, D.R.; Kladivko, E.J.; Mannering, J.V.; West, T.D.; Parsons, S.D. Long-Term Tillage and Rotation Effects on Corn Growth and Yield on High and Low Organic Matter. Poorly Drained Soils. Agron. J. 1988, 80, 599–605. [Google Scholar] [CrossRef]

| Date | Operation * |

|---|---|

| 16 April | Apply manure (44.9 MT/ha) |

| 29 April | Apply herbicide |

| 3 May | Plant |

| 3 May | Incorporate starter fertilizer (kg/ha) (10.1 + 11.3 + 27.9) |

| 12 June | Cultivate |

| 18 October | Harvest corn |

| 23 October | Bulk spread (kg/ha) (17.9 + 20.2 + 41.9) |

| 12 November | Apply Ammonia (194.2 kg/ha) |

| Date | Operation |

|---|---|

| Corn following soybean | |

| 16 April | Apply manure (44.9 MT/ha) |

| 29 April | Apply herbicide |

| 29 April | Apply fertilizer N (128.2 kg/ha) |

| 1 May | Plant corn |

| 1 May | Incorporate starter fertilizer (kg/ha) (10.1 + 11.3 + 27.9) |

| 12 June | Cultivate |

| 15 October | Harvest corn |

| 25 October | Bulk spread (kg/ha) (17.9 + 20.2 + 41.9) |

| Soybean following corn | |

| 16 April | Apply manure (44.9 MT/ha) |

| 29 April | Apply herbicide |

| 10 May | Field cultivate |

| 12 May | Plant soybean |

| 2 October | Harvest soybean |

| 27 October | Bulk spread (kg/ha) (15.4 + 17.3 + 41.9) |

| Machine | Price ($) | Hours | Width (m) | Speed (ms−1) | Field Eff. | Horse-Power | RF1 | RF2 |

|---|---|---|---|---|---|---|---|---|

| 95 HP Tractor | 120,866 | 12,800 | NA | NA | 80 | 95 | 0.003 | 2.0 |

| 240 HP Tractor | 284,690 | 12,800 | NA | NA | 80 | 240 | 0.003 | 2.0 |

| Bulk fert spreader: 7.6 m | 7700 | 2500 | 7.6 | 2.9 | 75 | NA | 0.63 | 1.3 |

| Ammonia applicator—11.4 m | 99,663 | 4000 | 11.4 | 3.4 | 90 | NA | 0.63 | 1.3 |

| Sprayer | 61,776 | 1500 | 27.4 | 2.6 | 65 | 73 | 0.43 | 1.8 |

| Chisel plow: 7 m | 55,661 | 3000 | 7.0 | 2.6 | 85 | NA | 0.28 | 1.4 |

| Row cultivator | 66,771 | 2500 | 12.2 | 2.7 | 80 | NA | 0.17 | 2.2 |

| Field cultivator—9 m | 71,109 | 2200 | 9.0 | 2.7 | 85 | NA | 0.27 | 1.4 |

| Planter, 8 row narrow | 52,261 | 2800 | 6.1 | 2.9 | 85 | NA | 0.32 | 2.1 |

| No-till planter | 64,181 | 1500 | 6.1 | 2.9 | 70 | NA | 0.007 | 2.0 |

| Manure spreader | 26,232 | 3000 | 4.6 | 3.0 | 85 | NA | 0.63 | 1.3 |

| Corn Head, 8 row narrow | 83,000 | 8000 | 6.7 | 2.0 | 85 | NA | 0.12 | 2.3 |

| 270 HP Combine | 339,250 | 6000 | NA | NA | 85 | 270 | 0.02 | 2.1 |

| Current Custom Rate | FEM Model Estimate | ||

|---|---|---|---|

| Total | Variable | ||

| Bulk fertilizer spreading | 15.20 | 15.07 | 10.06 |

| Chisel plow | 44.48 | 44.21 | 26.51 |

| Row cultivation | 31.01 | 30.15 | 16.41 |

| Field cultivation | 39.29 | 38.82 | 20.31 |

| Row planting | 51.89 | 51.89 | 34.10 |

| No-till planting | 57.45 | 56.61 | 26.41 |

| Ammonia application | 33.11 | 29.01 | 17.47 |

| Manure application | NA | 66.12 | 34.72 |

| Combine corn | 90.81 | 90.91 | 45.76 |

| Herbicide spraying | 16.68 | 17.15 | 7.31 |

| Baseline | No-Till | Percentage Change | ||||

|---|---|---|---|---|---|---|

| Rotation and Management | Surface Runoff (mm) | Sediment Losses (mt/ha) | Surface Runoff (mm) | Sediment Losses (mt/ha) | Surface Runoff (%) | Sediment Losses (%) |

| Corn without manure | 134.59 | 2.90 | 135.75 | 1.03 | 0.9 | −64.4 |

| Corn with manure | 133.79 | 1.63 | 135.81 | 0.48 | 1.5 | −70.7 |

| Corn–soybean without manure | 133.27 | 1.97 | 130.47 | 0.76 | −2.1 | −61.3 |

| Corn–soybean with manure | 132.93 | 1.01 | 130.52 | 0.18 | −1.8 | −81.7 |

| Area weighted average | 133.46 | 1.99 | 131.53 | 0.72 | −1.5 | −63.6 |

| Rotation and Management | Soluble N | Sediment-Bound N | Total N | Soluble P | Sediment-Bound P | Total P |

|---|---|---|---|---|---|---|

| Baseline | ||||||

| Corn without manure | 6.58 | 16.17 | 22.75 | 0.72 | 2.27 | 3.00 |

| Corn with manure | 10.09 | 55.68 | 65.77 | 1.91 | 2.82 | 4.73 |

| Corn–soybean without manure | 4.41 | 11.71 | 16.12 | 0.78 | 1.63 | 2.40 |

| Corn–soybean with manure | 6.78 | 48.79 | 55.57 | 2.08 | 2.64 | 4.72 |

| Area weighted average | 5.26 | 18.72 | 23.98 | 0.97 | 1.91 | 2.88 |

| No-till | ||||||

| Corn without manure | 4.99 | 7.03 | 12.02 | 1.24 | 1.08 | 2.31 |

| Corn with manure | 7.20 | 38.36 | 45.56 | 3.50 | 1.39 | 4.89 |

| Corn–soybean without manure | 4.61 | 5.71 | 10.32 | 1.22 | 0.88 | 2.10 |

| Corn–soybean with manure | 6.16 | 36.18 | 42.34 | 3.65 | 1.07 | 4.72 |

| Area weighted average | 4.95 | 10.96 | 15.92 | 1.61 | 0.95 | 2.57 |

| Percentage changes from baseline | ||||||

| Corn without manure | −24.3 | −56.5 | −47.2 | 70.8 | −52.7 | −22.8 |

| Corn with manure | −28.7 | −31.1 | −30.7 | 83.2 | −50.6 | 3.5 |

| Corn–soybean without manure | 4.5 | −51.2 | −36.0 | 56.8 | −45.9 | −12.7 |

| Corn–soybean with manure | −9.1 | −25.9 | −23.8 | 75.3 | −59.5 | −0.1 |

| Area weighted average | −5.9 | −41.4 | −33.6 | 65.4 | −49.9 | −10.9 |

| Rotation and Management | Depth of Soil Layer | |||

|---|---|---|---|---|

| 0.25 m | 0.5 m | 1 m | 2 m | |

| Baseline (mt/ha [%]) | ||||

| Corn without manure | 120.9 [3.27] | 215.7 [2.86] | 302.0 [1.89] | 352.7 [1.11] |

| Corn with manure | 135.9 [3.68] | 231.3 [3.07] | 317.9 [1.99] | 368.8 [1.16] |

| Corn–soybean without manure | 120.4 [3.26] | 215.1 [2.85] | 301.0 [1.89] | 351.8 [1.11] |

| Corn–soybean with manure | 137.2 [3.71] | 232.1 [3.08] | 318.1 [1.99] | 369.0 [1.16] |

| Area weighted average | 123.2 [3.33] | 218.0 [2.89] | 303.9 [1.90] | 354.8 [1.12] |

| No-till (mt/ha [%]) | ||||

| Corn without manure | 123.9 [3.31] | 219.0 [2.89] | 305.4 [1.91] | 356.2 [1.12] |

| Corn with manure | 144.2 [3.86] | 239.4 [3.16] | 325.9 [2.04] | 376.7 [1.19] |

| Corn–soybean without manure | 122.3 [3.27] | 217.0 [2.86] | 302.8 [1.89] | 353.6 [1.11] |

| Corn–soybean with manure | 144.5 [3.86] | 239.3 [3.15] | 325.1 [2.03] | 375.9 [1.18] |

| Area weighted average | 126.2 [3.37] | 220.9 [2.91] | 306.9 [1.92] | 357.7 [1.12] |

| Percentage changes from baseline | ||||

| Corn without manure | 2.5 | 1.5 | 1.1 | 1.0 |

| Corn with manure | 6.1 | 3.5 | 2.5 | 2.1 |

| Corn–soybean without manure | 1.6 | 0.9 | 0.6 | 0.5 |

| Corn–soybean with manure | 5.3 | 3.1 | 2.2 | 1.9 |

| Area weighted average | 2.4 | 1.4 | 1.0 | 0.8 |

| Change in soil carbon sequestration rate (mt/ha/yr) | ||||

| Corn without manure | 0.12 | 0.13 | 0.14 | 0.14 |

| Corn with manure | 0.33 | 0.32 | 0.32 | 0.32 |

| Corn–soybean without manure | 0.08 | 0.07 | 0.07 | 0.07 |

| Corn–soybean with manure | 0.29 | 0.28 | 0.28 | 0.28 |

| Area weighted average | 0.12 | 0.12 | 0.12 | 0.12 |

| Rotation and Management | Corn Following Corn | Corn Following Soybean | Soybean |

|---|---|---|---|

| Baseline | |||

| Corn without manure | 8.40 | ||

| Corn with manure | 8.45 | ||

| Corn–soybean without manure | 8.45 | 3.17 | |

| Corn–soybean with manure | 8.46 | 3.17 | |

| Area weighted average | 8.41 | 8.45 | 3.17 |

| No-till | |||

| Corn without manure | 7.99 | ||

| Corn with manure | 8.05 | ||

| Corn–soybean without manure | 8.06 | 3.09 | |

| Corn–soybean with manure | 8.07 | 3.10 | |

| Area weighted average | 8.00 | 8.06 | 3.10 |

| Percentage changes from baseline | |||

| Corn without manure | −4.9 | ||

| Corn with manure | −4.7 | ||

| Corn–soybean without manure | −4.6 | −2.3 | |

| Corn–soybean with manure | −4.7 | −2.3 | |

| Area weighted average | −4.9 | −4.6 | −2.3 |

| Total Revenue ($/Farm) | Total Cost ($/Farm) | Net Income ($/Farm) | Net Income per Hectare ($/ha) | |

|---|---|---|---|---|

| Baseline | ||||

| Corn without manure | $2,111,081 | $1,912,136 | $198,945 | $245.80 |

| Corn with manure | $2,123,011 | $1,923,390 | $199,621 | $246.63 |

| Corn–soybean without manure | $1,858,562 | $1,560,999 | $297,562 | $367.64 |

| Corn–soybean with manure | $1,860,690 | $1,586,248 | $274,442 | $339.07 |

| Area-weighted average | $1,909,718 | $1,634,902 | $274,816 | $339.53 |

| No-till | ||||

| Corn without manure | $2,008,292 | $1,881,208 | $127,084 | $157.01 |

| Corn with manure | $2,022,481 | $1,898,650 | $123,832 | $152.99 |

| Corn–soybean without manure | $1,791,821 | $1,540,188 | $251,633 | $310.89 |

| Corn–soybean with manure | $1,792,532 | $1,531,972 | $260,560 | $321.92 |

| Area-weighted average | $1,835,652 | $1,607,854 | $227,797 | $281.44 |

| Impact of no-till | ||||

| Corn without manure | −$102,789 | −$30,928 | −$71,861 | −$88.78 |

| Corn with manure | −$100,530 | −$24,740 | −$75,789 | −$93.64 |

| Corn–soybean without manure | −$66,741 | −$20,812 | −$45,929 | −$56.75 |

| Corn–soybean with manure | −$68,157 | −$54,276 | −$13,882 | −$17.15 |

| Area-weighted average | −$74,066 | −$27,048 | −$47,019 | −$58.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osei, E.; Jafri, S.H.; Gassman, P.W.; Saleh, A. Simulated Ecosystem and Farm-Level Economic Impacts of Conservation Tillage in a Northeastern Iowa County. Agriculture 2023, 13, 891. https://doi.org/10.3390/agriculture13040891

Osei E, Jafri SH, Gassman PW, Saleh A. Simulated Ecosystem and Farm-Level Economic Impacts of Conservation Tillage in a Northeastern Iowa County. Agriculture. 2023; 13(4):891. https://doi.org/10.3390/agriculture13040891

Chicago/Turabian StyleOsei, Edward, Syed H. Jafri, Philip W. Gassman, and Ali Saleh. 2023. "Simulated Ecosystem and Farm-Level Economic Impacts of Conservation Tillage in a Northeastern Iowa County" Agriculture 13, no. 4: 891. https://doi.org/10.3390/agriculture13040891

APA StyleOsei, E., Jafri, S. H., Gassman, P. W., & Saleh, A. (2023). Simulated Ecosystem and Farm-Level Economic Impacts of Conservation Tillage in a Northeastern Iowa County. Agriculture, 13(4), 891. https://doi.org/10.3390/agriculture13040891