Experimental Study on the Effect of Water Jet Cutting Parameters on Maize Stalks

Abstract

1. Introduction

2. Water Jet Cutting Principle

3. Materials and Methods

3.1. Sample Preparation

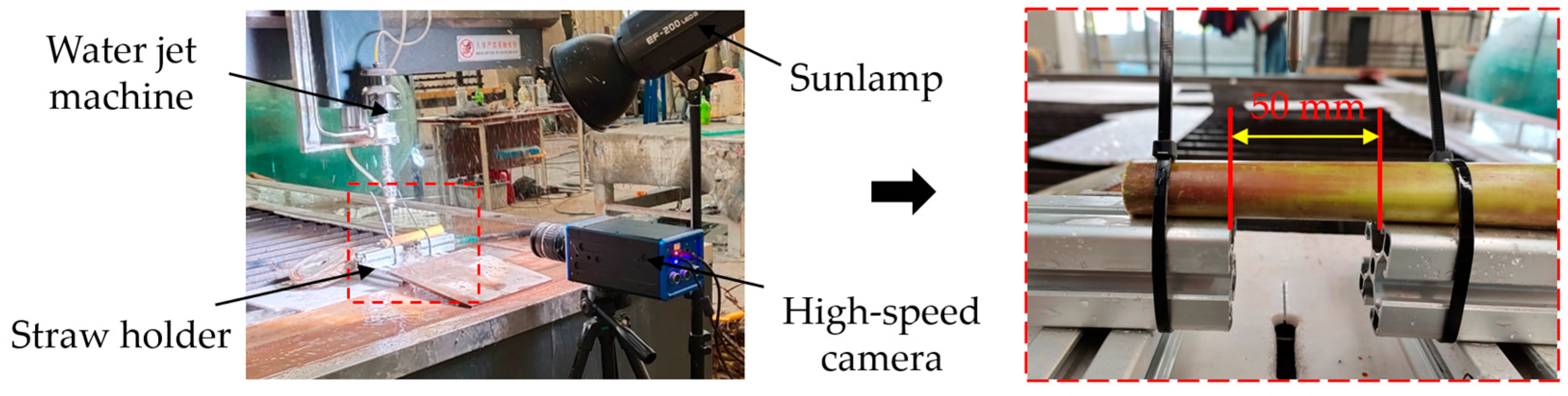

3.2. Experimental Equipment

3.3. Experiments

3.3.1. Cutting Stems

3.3.2. Cutting Stem Nodes

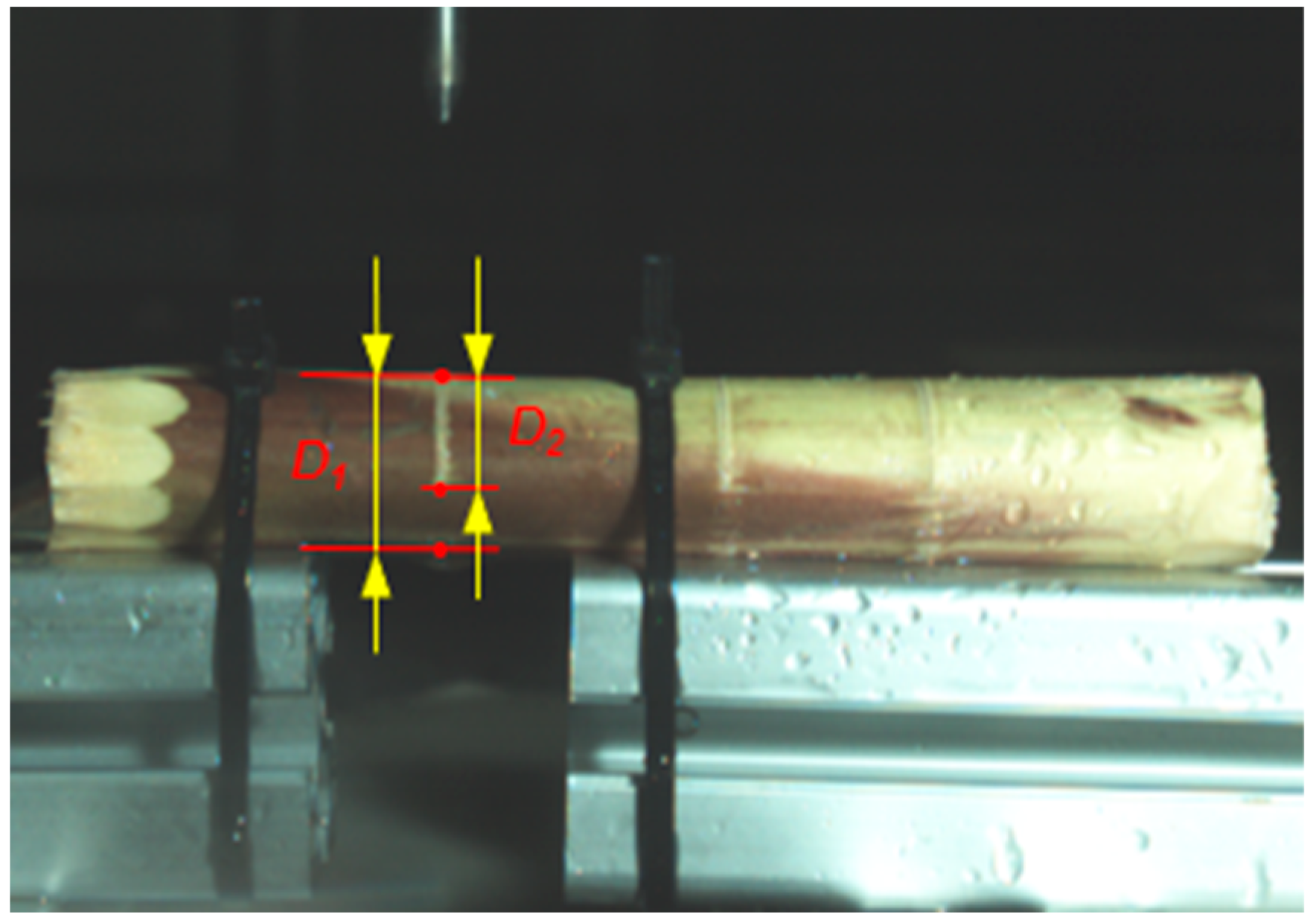

3.4. Cutoff Ratio

4. Results and Discussion

4.1. Influence of Cutting Parameters on the Cutoff Ratio of Stems

4.1.1. Results of Different Cutting Parameters

4.1.2. Multilinear Stepwise Regression Analysis

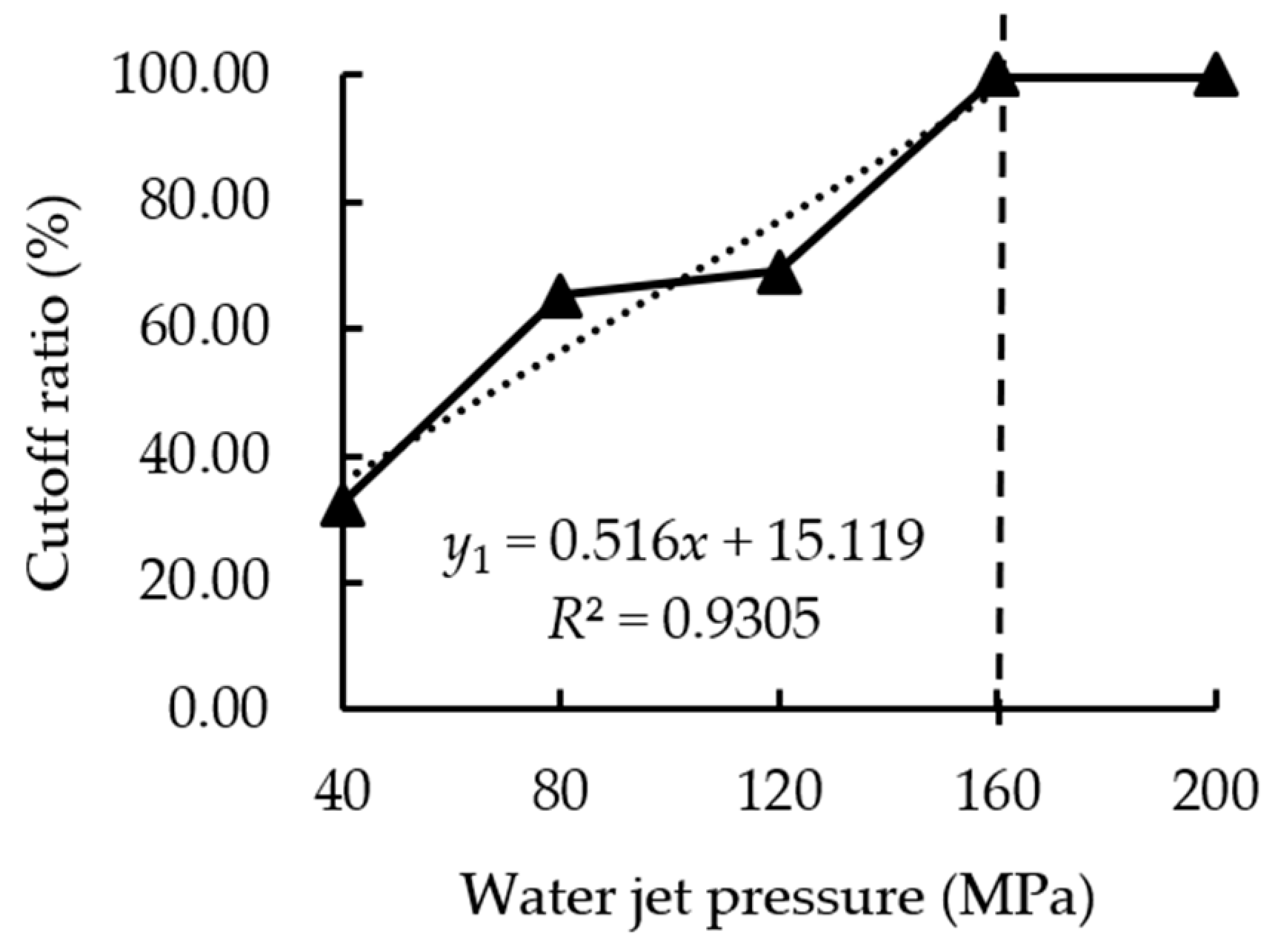

4.2. Influence of Single Factors on the Cutoff Ratio of Stem Nodes

4.2.1. Influence of the Water Jet Pressure

4.2.2. Influence of the Target Distance

4.2.3. Influence of the Traverse Speed

4.3. Analysis of the Phenomena after Cutting

4.3.1. Bottom Burrs

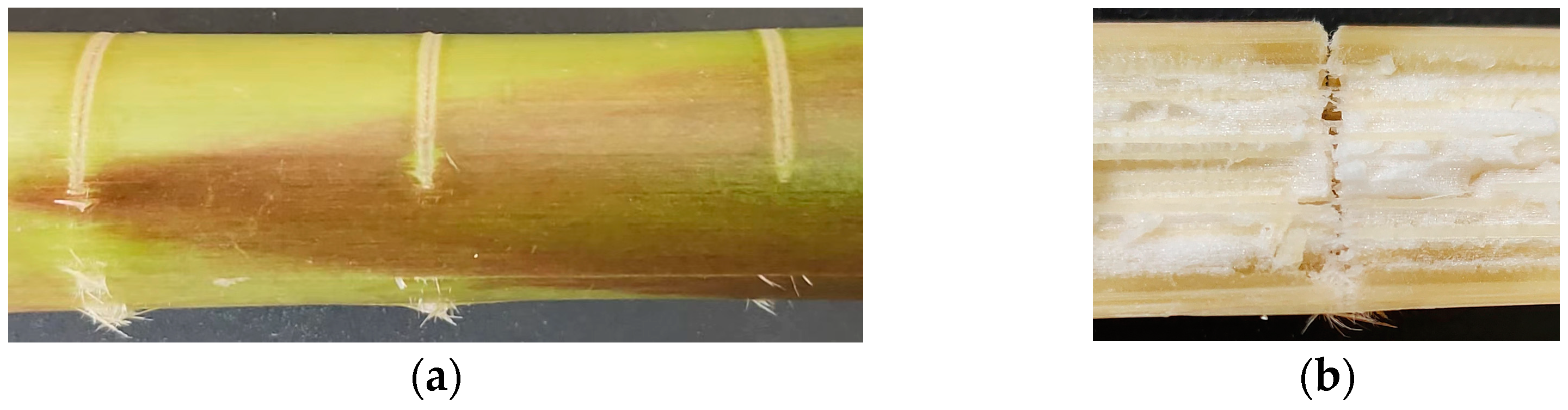

4.3.2. Surface Stripes

4.3.3. Cutting Residue

5. Conclusions

- (1)

- The cutoff ratio of stems and stem nodes cut by water jets increases with the increase in the water jet pressure and the decrease in the target distance and the traverse speed. Compared with the target distance, the water jet pressure and the traverse speed have more significant effects on the cutoff ratio of maize stalks.

- (2)

- We carried out 27 groups of all-factor cutting tests on the stems, and a significance analysis of the results and the establishment of a regression equation were completed. Under the optimal condition that the traverse speed is the maximum and the stem is cut off, the corresponding parameter combination is: a water jet pressure of 120 MPa, target distance of 10 mm, and traverse speed of 1371 mm/min. Next, single-factor cutting tests were carried out on the stem nodes. When the target distance is 30 mm, the traverse speed is 4000 mm/min, and the water jet pressure is greater than or equal to 160 MPa, the cutoff ratio of the stem nodes is 100%. To cut off stems and stem nodes simultaneously, a parameter range of a water jet pressure ≥ 160 MPa, target distance ≤ 10 mm, and traverse speed ≤ 1371 mm/min should be ensured.

- (3)

- Bottom burrs, surface stripes, and cutting residue may appear after cutting because of the divergent and lagging characteristics of the water jet. The bottom burrs are caused by the insufficient impact force of the water jet, which cannot completely break the bottom of the maize stalk. The surface stripes only affect the surface quality but not the cutting results. However, even though the upper and lower parts of the maize stalks are cut off, cutting residue may appear at the end of the maize stalks. Improving the impact force or cutting again with a disc opener is essential to deal with this phenomenon.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Du, X.; Jian, J.; Du, D.; Stewart, R.D. Conservation management decreases surface runoff and soil erosion. Int. Soil Water Conserv. Res. 2022, 10, 188–196. [Google Scholar] [CrossRef]

- Wang, Q.; Cao, X.; Wang, C.; Li, H.; He, J.; Lu, C. Research progress of no/minimum tillage corn seeding technology and machine in northeast black land of China. Trans. CSAM 2021, 52, 1–15. [Google Scholar]

- He, J.; Li, H.; Chen, H.; Lu, C.; Wang, Q. Research progress of conservation tillage technology and machine. Trans. CSAM 2018, 49, 1–19. [Google Scholar]

- Hu, H.; Li, H.; Wang, Q.; He, J.; Lu, C.; Wang, Y.; Liu, P. Anti-blocking performance of ultrahigh-pressure waterjet assisted furrow opener for no-till seeder. Int. J. Agric. Biol. Eng. 2020, 13, 64–70. [Google Scholar] [CrossRef]

- Natarajan, Y.; Murugesan, P.K.; Mohan, M.; Khan, S.A.L.A. Abrasive water jet machining process: A state of art of review. J. Manuf. Process. 2020, 49, 271–322. [Google Scholar] [CrossRef]

- Elamin, W.M.; Endan, J.B.; Yosuf, Y.A.; Shamsudin, R.; Ahmedov, A. High pressure processing technology and equipment evolution: A review. J. Eng. Sci. Technol. Rev. 2015, 8, 75–83. [Google Scholar] [CrossRef]

- Cui, D.; Li, H.; He, J.; Wang, Q.; Lu, C.; Hu, H.; Cheng, X.; Wang, C. Applications of water jet cutting technology in agricultural engineering: A review. Appl. Sci. 2022, 12, 8988. [Google Scholar] [CrossRef]

- Ishida, Y.; Okamoto, T.; Imou, K.; Kaizu, Y. A study on physical weeding using a water jet. J. Jpn. Soc. Agric. Machin. 2005, 67, 93–99. [Google Scholar]

- Fogelberg, F.; Blom, A. Water-jet cutting for weed control. In Proceedings of the 5th EWRS Workshop on Physical and Cultural Weed Control, Pisa, Italy, 11–13 March 2002. [Google Scholar]

- Zheng, W.; Jiang, Y.; Ma, X.; Qi, L. Development of a liquid-jet nozzle for fertilizer injection in paddy fields using CFD. Comput. Electron. Agric. 2019, 167, 105061. [Google Scholar] [CrossRef]

- Valco, T.D.; Coble, C.G.; Ruff, J.H. Water jet cutting of sugarcane. Trans. ASAE 1989, 32, 373–378. [Google Scholar] [CrossRef]

- Thanomputra, S.; Kiatiwat, T. Simulation study of cutting sugarcane using fine sand abrasive waterjet. Agric. Nat. Resour. 2016, 50, 146–153. [Google Scholar] [CrossRef]

- Hu, H.; Li, H.; Wang, Q.; He, J.; Lu, C.; Wang, Y.; Wang, C. Performance of waterjet on cutting maize stalks: A preliminary investigation. Int. J. Agric. Biol. Eng. 2019, 12, 64–70. [Google Scholar] [CrossRef]

- Desbiolles, J.; Taki, O.; Butler, G. A laboratory evaluation of waterjet cutting of crop residue using the Aqua-Till® liquid coulter. Soil Tillage Res. 2020, 198, 104537. [Google Scholar] [CrossRef]

- Perotti, F.; Annoni, M.; Calcante, A.; Monno, M.; Mussi, V.; Oberti, R. Experimental study of abrasive waterjet cutting for managing residues in no-tillage techniques. Agriculture 2021, 11, 392. [Google Scholar] [CrossRef]

- Sun, X. Research on Key Technologies of a High Pressure Waterjet Cutting System. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2013. [Google Scholar]

- Lu, S.; Yu, T.; Yu, T.; Liu, S. Experiment and mechanism analysis of inhibiting browning of semi-processed lettuce cutting with water jet. Trans. CSAM 2007, 38, 202–204. [Google Scholar]

- Kowsari, K.; Nouraei, H.; James, D.F.; Spelt, J.K.; Papini, M. Abrasive slurry jet micro-machining of holes in brittle and ductile materials. J. Mater. Process. Technol. 2014, 214, 1909–1920. [Google Scholar] [CrossRef]

- Xue, S. High Pressure Waterjet Technology and Engineering; Hefei University of Technology Press: Hefei, China, 2006. [Google Scholar]

- Miu, X.J. Study on Cutting Mechanisms and Quality Improvement Methods of Abrasive Water Jet. Ph.D. Thesis, Jiangnan University, Wuxi, China, 2020. [Google Scholar]

- Xing, F. Experimental Study on the Physical and Mechanical Characteristic of Corn Stover. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2017. [Google Scholar]

- Hu, H.N. Study on Anti-Blocking Device for No-Till Seeder with Non-Connect Stalk Cutting by Ultra-High-Pressure Waterjet. Ph.D. Thesis, China Agricultural University, Beijing, China, 2020. [Google Scholar]

- Xie, W.; Fang, J.; Wang, Z.; Huang, L. Optimization of technological parameters of water jet cutting of red oak and bamboo based on three-dimensional surface topography measurement. BioResources 2020, 15, 3270. [Google Scholar] [CrossRef]

- Olejua, R.C.; Hofacker, W.C.; Hensel, O. Use of image analysis in process control of high pressure water-jet peeling and cutting of fruits. In Proceedings of the ASABE Annual International Meeting, Reno, Nevada, 21–24 June 2009. [Google Scholar]

- Wu, Y.Q. Fundamental Research of 3D Model in Accurate Abrasive Water Jet Cutting. Ph.D. Thesis, Chongqing University, Chongqing, China, 2015. [Google Scholar]

- Chen, J.; Yuan, Y.; Gao, H.; Zhou, T.; Wu, Z. Predictive modeling approach for the jet lag in multi-pass cutting of thick materials using abrasive waterjet. J. Manuf. Process 2022, 83, 143–156. [Google Scholar] [CrossRef]

| Levels | Water Jet Pressure (MPa) | Target Distance (mm) | Traverse Speed (mm/min) |

|---|---|---|---|

| 1 | 40 | 10 | 1000 |

| 2 | 80 | 20 | 4000 |

| 3 | 120 | 30 | 7000 |

| Groups | Water Jet Pressure (MPa) | Target Distance (mm) | Traverse Speed (mm/min) |

|---|---|---|---|

| 1 | 40, 80, 120, 160, 200 | 30 | 4000 |

| 2 | 120 | 10, 20, 30, 40, 50 | 4000 |

| 3 | 120 | 30 | 1000, 2500, 4000, 5500, 7000 |

| Source | F Values | p Values |

|---|---|---|

| Model | 38.340 | 0.000 |

| A (Water jet pressure) | 235.927 | 0.000 |

| B (Target distance) | 8.709 | 0.010 |

| C (Traverse speed) | 74.771 | 0.000 |

| A × B (Water jet pressure × Target distance) | 7.120 | 0.010 |

| A × C (Water jet pressure × Traverse speed) | 4.607 | 0.032 |

| B × C (Target distance × Traverse speed) | 1.100 | 0.419 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, D.; Li, H.; He, J.; Wang, Q.; Lu, C.; Gao, Z.; Tong, Z.; Zhong, G. Experimental Study on the Effect of Water Jet Cutting Parameters on Maize Stalks. Agriculture 2023, 13, 880. https://doi.org/10.3390/agriculture13040880

Cui D, Li H, He J, Wang Q, Lu C, Gao Z, Tong Z, Zhong G. Experimental Study on the Effect of Water Jet Cutting Parameters on Maize Stalks. Agriculture. 2023; 13(4):880. https://doi.org/10.3390/agriculture13040880

Chicago/Turabian StyleCui, Dandan, Hongwen Li, Jin He, Qingjie Wang, Caiyun Lu, Zhen Gao, Zhenwei Tong, and Guangyuan Zhong. 2023. "Experimental Study on the Effect of Water Jet Cutting Parameters on Maize Stalks" Agriculture 13, no. 4: 880. https://doi.org/10.3390/agriculture13040880

APA StyleCui, D., Li, H., He, J., Wang, Q., Lu, C., Gao, Z., Tong, Z., & Zhong, G. (2023). Experimental Study on the Effect of Water Jet Cutting Parameters on Maize Stalks. Agriculture, 13(4), 880. https://doi.org/10.3390/agriculture13040880