Research on UAV Remote Sensing Method of Mold Detection Suitable for Pericarp of Citri Reticulatae ‘Chachi’ Warehouses

Abstract

1. Introduction

2. Materials and Methods

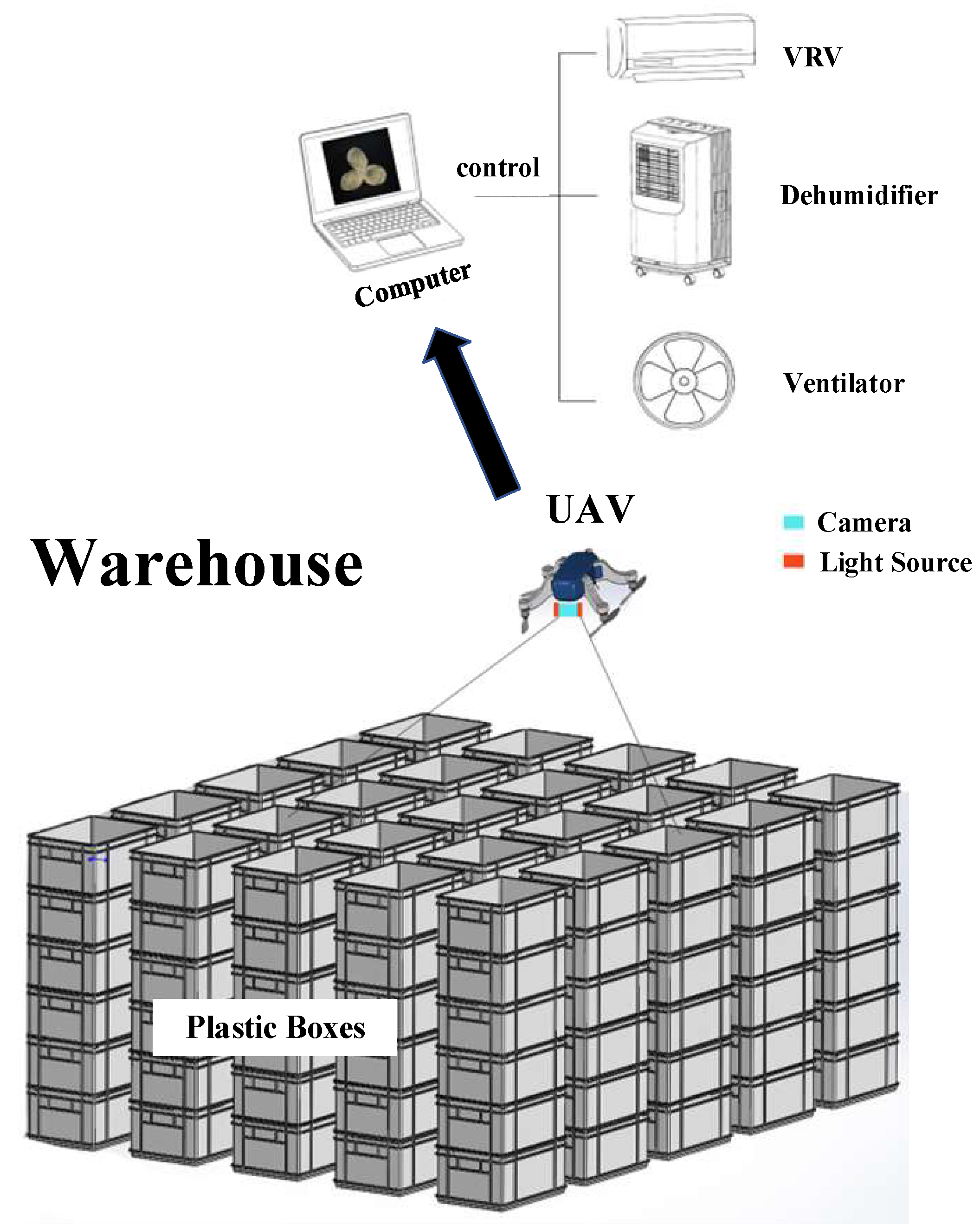

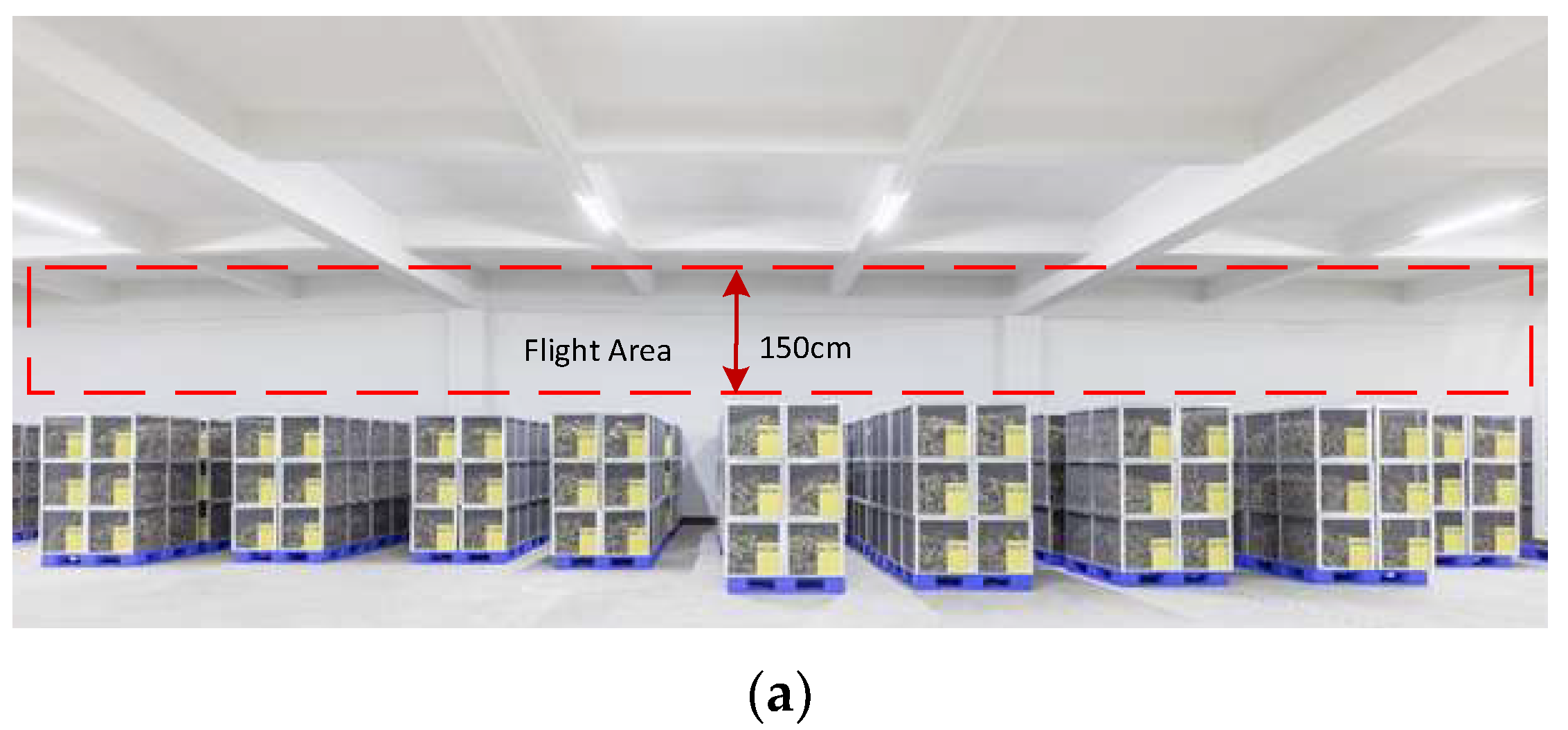

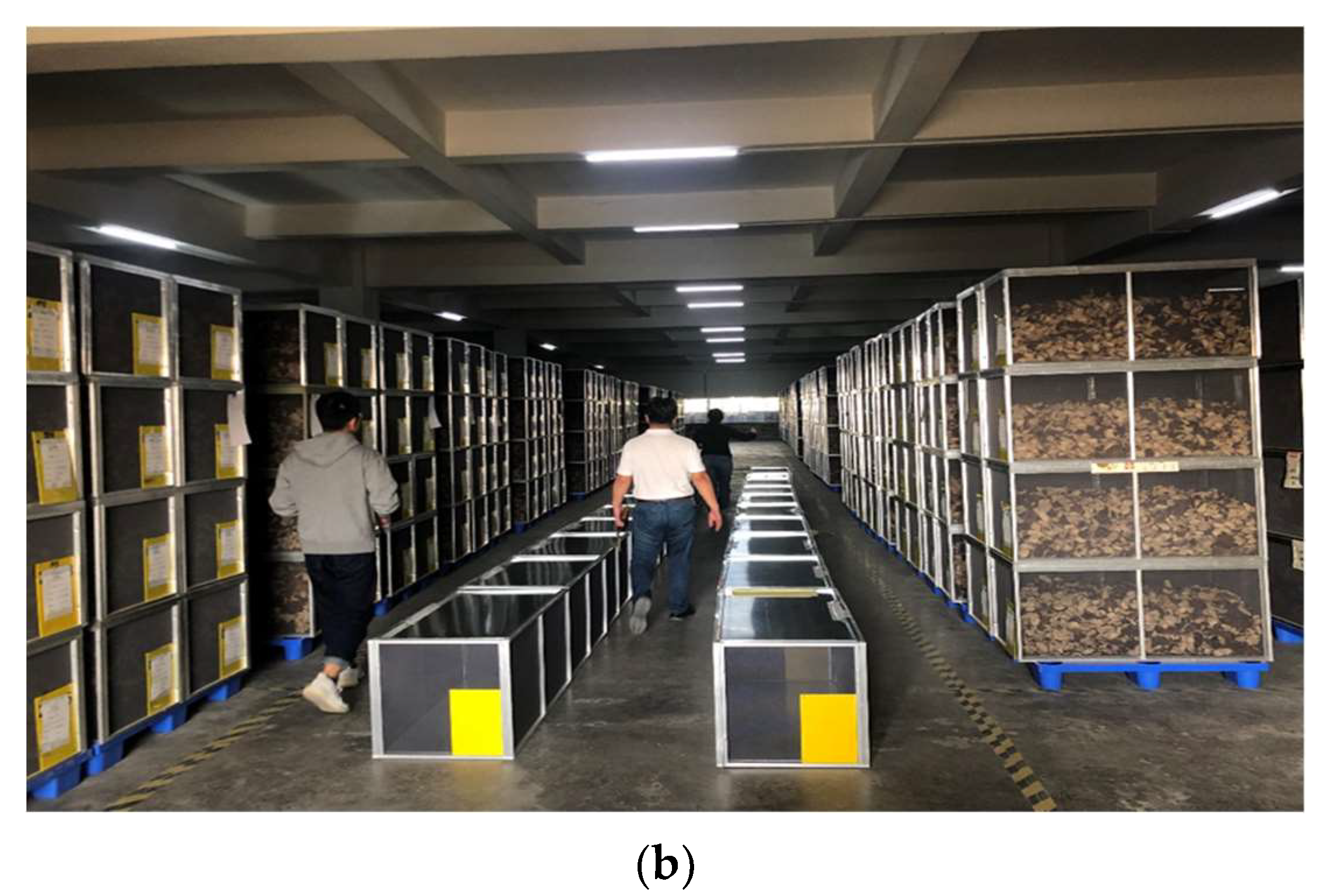

2.1. Storage Environment and UAV Inspection Methods of PCRC

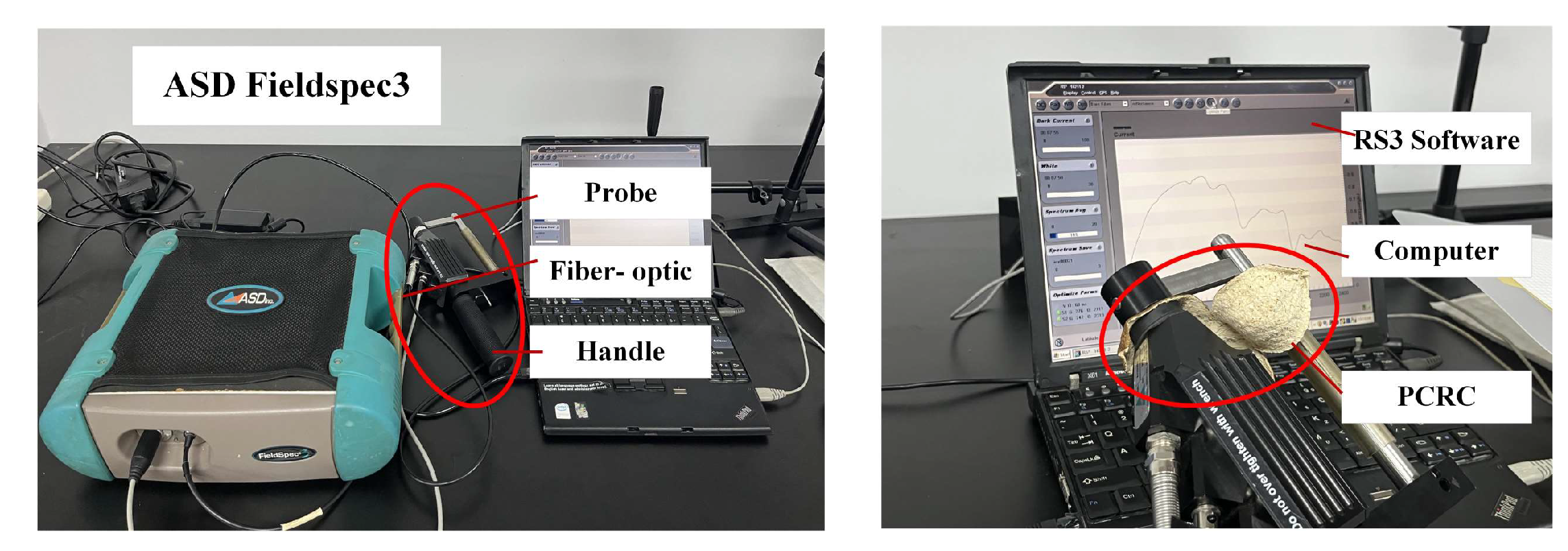

2.2. Experimental Design of Spectral Characteristic Analysis of PCRC

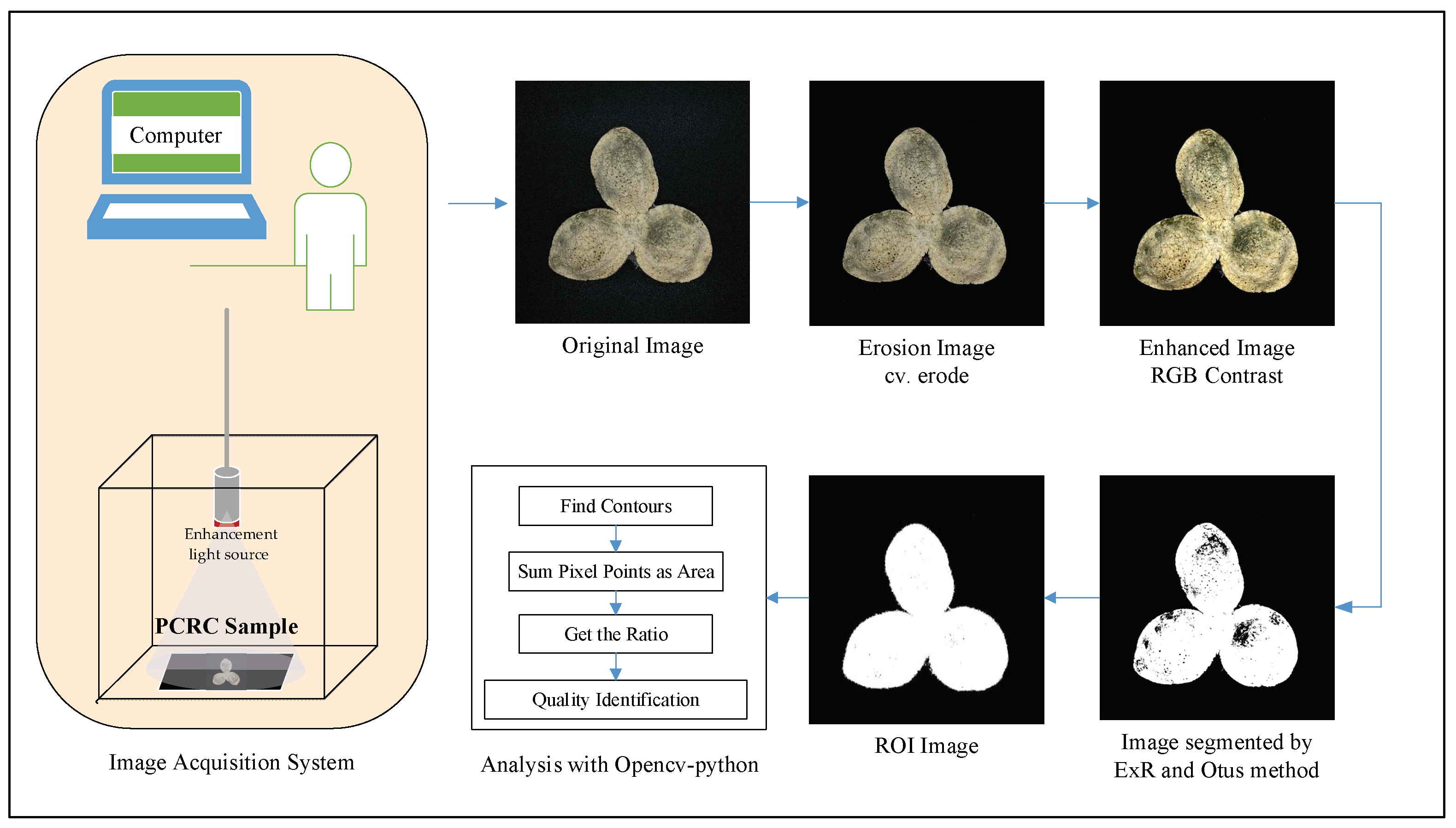

2.3. Analysis Method of Image Acquisition and Identification of Mildew in PCRC Samples

3. Results and Discussion

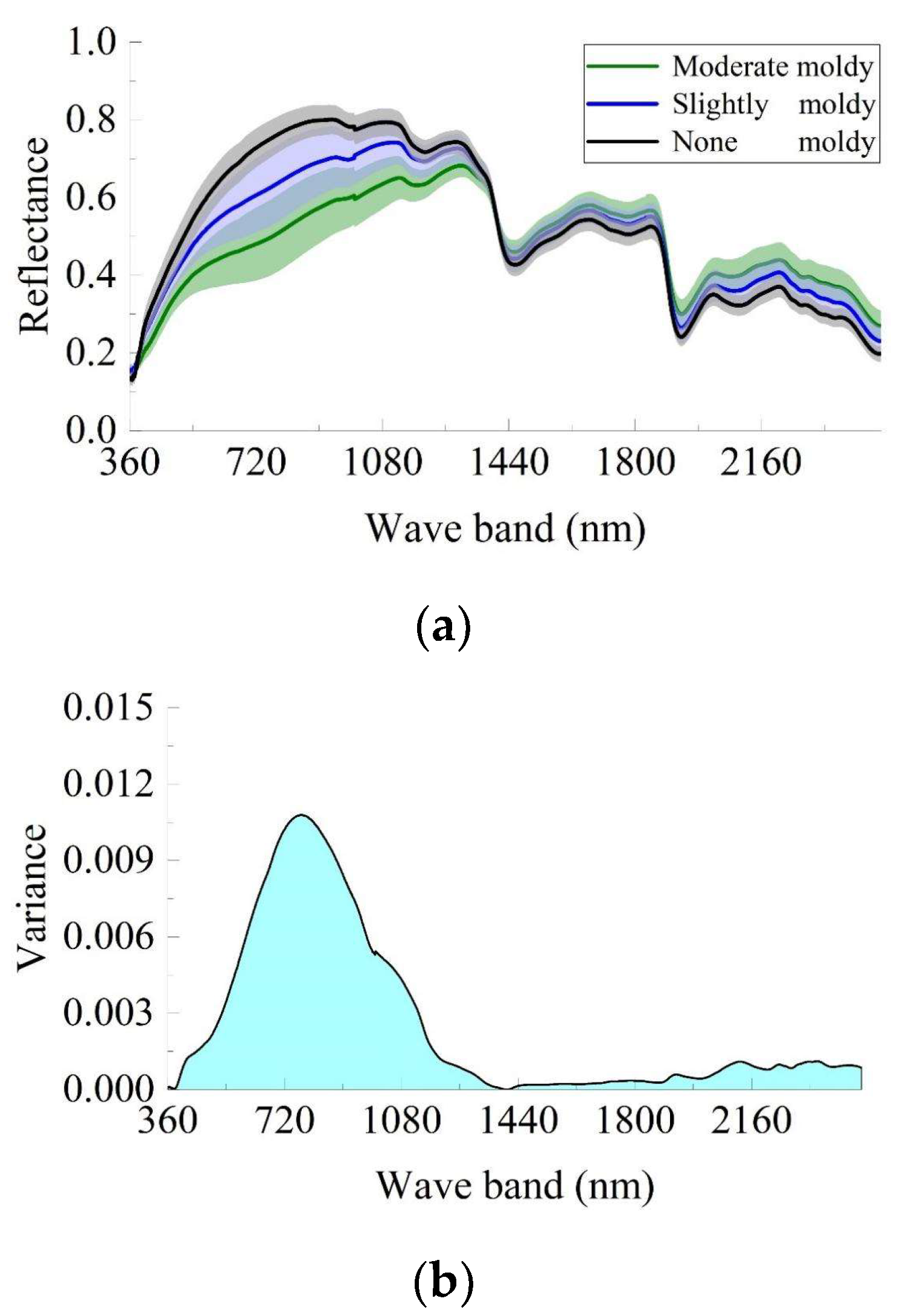

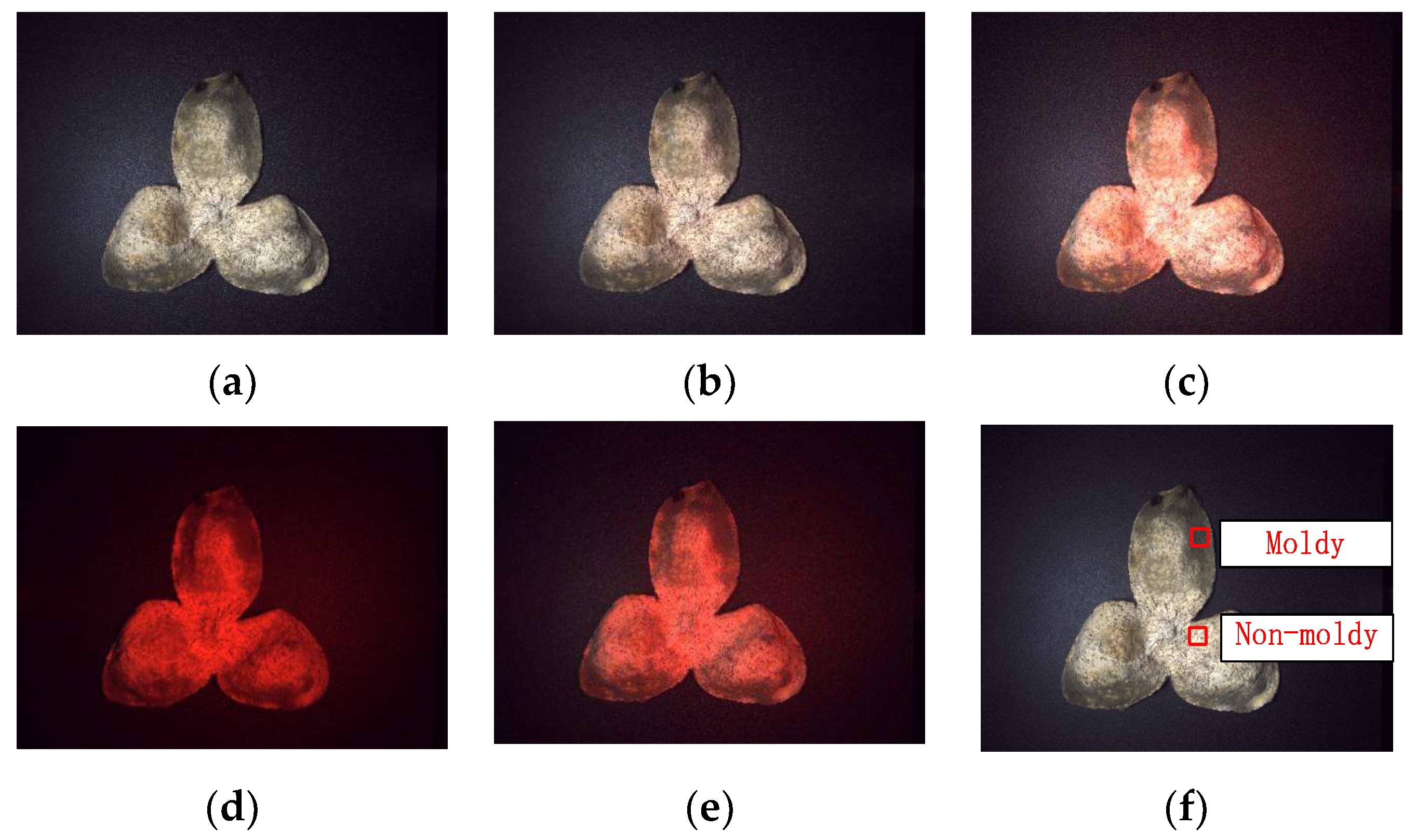

3.1. Characteristic Waveband Analysis and Enhanced Light Source Design for Mildew Spectra of PCRC

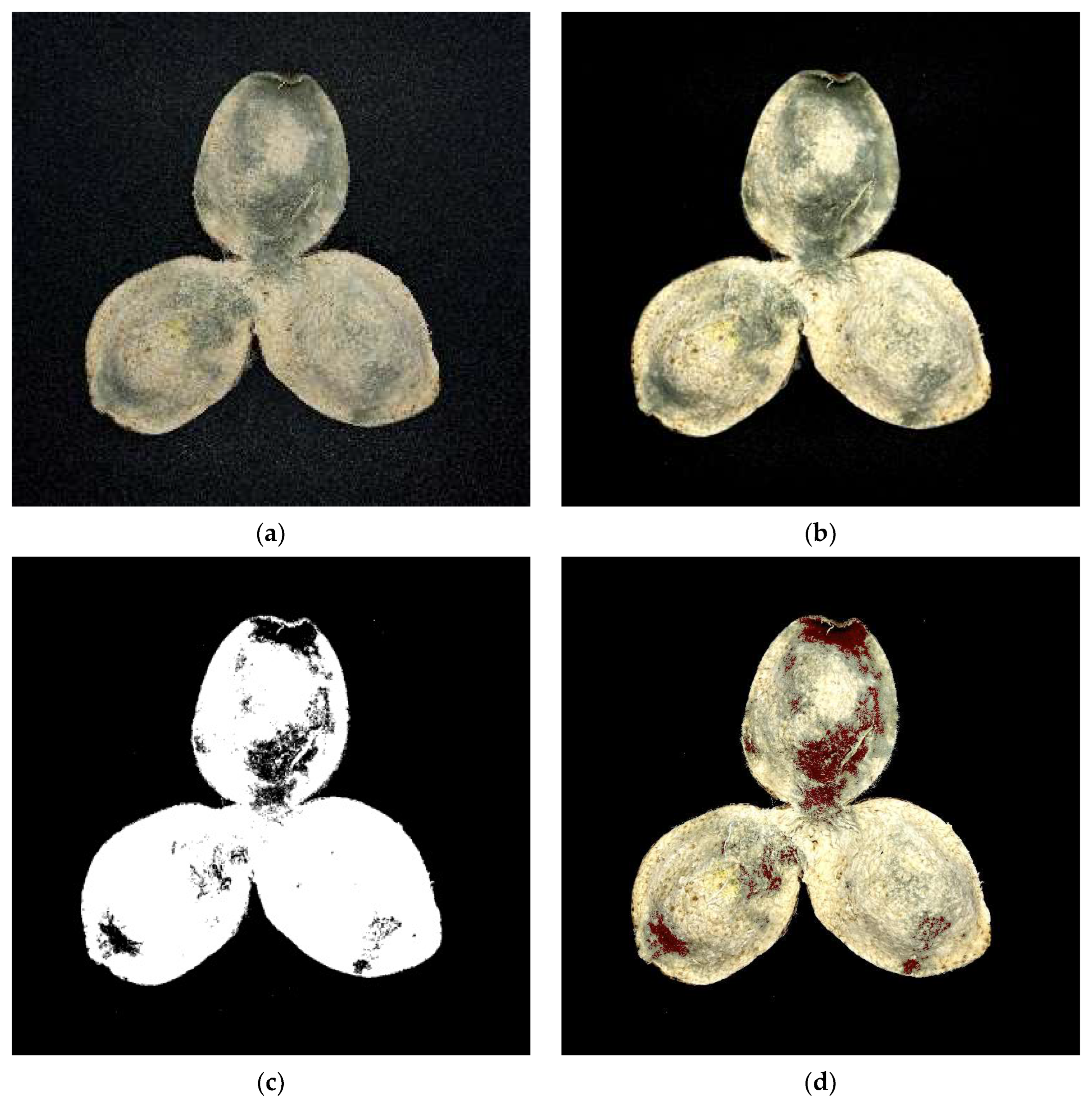

3.2. Analysis of Moldy Identification Test on PCRC Samples

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Pharmacopoeia Commission. Pharmacopoeia of the People’s Republic of China, One Sections; China Medical Science and Technology Press: Beijing, China, 2020; pp. 199–200. [Google Scholar]

- Devi, K.P.; Rajavel, T.; Nabavi, S.F.; Setzer, W.N.; Ahmadi, A.; Mansouri, K.; Nabavi, S.M. Hesperidin: A promising anticancer agent from nature. Ind. Crop. Prod. 2015, 76, 582–589. [Google Scholar] [CrossRef]

- Pari, L.; Karthikeyan, A.; Karthika, P.; Rathinam, A. Protective effects of hesperidin on oxidative stress, dyslipidaemia and histological changes in iron-induced hepatic and renal toxicity in rats. Toxicol. Rep. 2015, 2, 46–55. [Google Scholar] [CrossRef]

- Huang, Y.; Ho, S. Polymethoxy flavones are responsible for the anti-inflammatory activity of citrus fruit peel. Food Chem. 2010, 119, 868–873. [Google Scholar] [CrossRef]

- Morley, K.L.; Ferguson, P.J.; Koropatnick, J. Tangeretin and nobiletin induce G1 cell cycle arrest but not apoptosis in human breast and colon cancer cells. Cancer Lett. 2007, 251, 168–178. [Google Scholar] [CrossRef]

- Song, B.L. Pharmacological effects of Chen Pi. J. Pract. Chin. Intern. Med. 2014, 8, 132–133. [Google Scholar]

- Luo, Y.; Zeng, W.; Huang, K.-E.; Li, D.-X.; Chen, W.; Yu, X.-Q.; Ke, X.-H. Discrimination of Citrus reticulata Blanco and Citrus reticulata ‘Chachi’ as well as the Citrus reticulata ‘Chachi’ within different storage years using ultra high performance liquid chromatography quadrupole/time-of-flight mass spectrometry based metabolomics approach. J. Pharmaceut. Biomed. 2019, 171, 218–231. [Google Scholar]

- Fu, M.; Xu, Y.; Chen, Y.; Wu, J.; Yu, Y.; Zou, B.; An, K.; Xiao, G. Evaluation of bioactive flavonoids and antioxidant activity in Pericarpium Citri Reticulatae (Citrus reticulata ‘Chachi’) during storage. Food Chem. 2017, 230, 649–656. [Google Scholar] [CrossRef]

- Yi, L.; Xie, P.; Liang, Y. Validity test of parlance “Pericarpium Citri Reticulatae, the older the bette” by GC/MS and HPLC. Chin. Pharm. J. Beijing 2005, 40, 1610. [Google Scholar]

- Zhang, L.; Zhou, J.; Zhu, Y.; Zhang, S.H. Comparative analysis on the chemical components of pericarpium Citri Reticulatae, citrus peels and fermented citrus peels with HPLC-DAD-ESI-MSn and GC-MS. Food Ferment. Ind. 2013, 39, 192–199. [Google Scholar]

- Yan, G.Q.; Qu, J.L.; Ou, G.L.; Mo, J.S.; Zhong, C.M.; Chen, D.Y.; Liu, Q.H.; Zhang, D.F. Current situation and countermeasures of drying and storage technology and equipment of Citrus reticulata ‘Chachi’. J. South. Agric. 2021, 52, 2543–2553. [Google Scholar]

- Yan, H.J.; Zhuo, Y.; Li, M.N.; Wang, Y.L.; Guo, H.; Wang, J.J.; Li, C.S.; Ding, F. Alfalfa yield prediction using machine learning and UAV multispectral remote sensing. Trans. Chin. Soc. Agric. Eng. 2022, 38, 64–71. [Google Scholar]

- Tao, H.L.; Xu, L.J.; Feng, H.K.; Yang, G.; Yang, X.; Miao, M.; Dai, Y. Estimation of plant height and biomass of winter wheat based on UAV digital image. Trans. Chin. Soc. Agric. Eng. 2019, 35, 107–116. [Google Scholar]

- Liu, Z.; Wan, W.; Huang, J.Y.; Han, Y.W.; Wang, J.Y. Estimation of peanut seedling emergence rate of based on UAV visible light image. Trans. Chin. Soc. Agric. Eng. 2018, 34, 60–71. [Google Scholar]

- Zhang, Y.; Liu, T.; He, J.; Yang, X.; Wang, L.; Guo, Y. Estimation of peanut seedling emergence rate of based on UAV visible light image. In Proceedings of the International Conference on Agri-Photonics and Smart Agricultural Sensing Technologies (ICASAST 2022), Zhengzhou, China, 4–6 August 2022; pp. 259–265. [Google Scholar]

- Su, W.; Jiang, K.; Yan, A.; Liu, Z.; Zhang, M.Z.; Wei, W. Monitoring of planted lines for breeding corn using UAV remote sensing image. Trans. Chin. Soc. Agric. Eng. 2018, 34, 92–98. [Google Scholar]

- Dai, J.G.; Zhang, G.S.; Guo, P.; Zeng, Y.J.; Cui, M.N.; Xue, J.L. Classification method of main crops in northern Xinjiang based on UAV visible waveband images. Trans. Chin. Soc. Agric. Eng. 2018, 34, 122–129. [Google Scholar]

- Frachtenberg, E. Practical drone delivery. Computer 2019, 52, 53–57. [Google Scholar] [CrossRef]

- Wang, P.C.; Duan, F.; Song, H.T.; Wang, S.; Ma, Y.C. An overview of the U.S. air-launched UAV program. In Proceedings of the 2020 Annual Academic Conference, Science and Technology Committee of China Academy of Spaceflight Electronics Technology, Chengdu, China, 26–28 November 2020. [Google Scholar]

- Xiao, B. Research on Warehouse Cargo Defect Detection System Based on UAV Vision; Southwest University of Science and Technology: Mianyang, China, 2021. [Google Scholar]

- Wang, J. Research and Implementation of a Quadrotor UAV Warehouse Inventory System Based on Machine Vision. Master’s Thesis, Southwest University of Science and Technology, Mianyang, China, 2021. [Google Scholar]

- Zhu, M.Y.; Yang, H.B.; Li, Z.W. Early detection and identification of rice sheath blight disease based on hyperspectral image and chlorophyll content. Spectrosc. Spect. Anal. 2019, 39, 1898–1904. [Google Scholar]

- Huang, S.P.; Qi, L.; Ma, X.; Xue, K.N.; Wang, W.J. Grading method of rice panicle blast severity based on hyperspectral image. Trans. Chin. Soc. Agric. Eng. 2015, 31, 212–219. [Google Scholar]

- Chen, Y.J.; Zhang, J.X.; Li, W.; Ren, Y.X.; Tan, Y.Z. A machine vision-based method for grading the maximum cross-sectional diameter of apples. J. Agric. Eng. 2012, 28, 284–288. [Google Scholar]

- Bu, X.Y. Research on Crop Disease Identification Method Based on Leaf Images. Master’s Thesis, Hefei University of Technology, Hefei, China, 2019. [Google Scholar]

- Blasco, J.; Aleixos, N.; Moltó, E. Computer vision detection of peel defects in citrus by means of a region oriented segmentation algorithm. J. Food Eng. 2007, 81, 535–543. [Google Scholar] [CrossRef]

- Diao, Z.H.; Wang, H.; Song, Y.M.; Wang, Y.P. A color and shape feature-based image segmentation method for cotton pest mites. Agric. Mech. Res. 2013, 30, 177–180. [Google Scholar]

- Zhang, N.N.; Liu, W.; Wang, W.; Lu, W.L.; Yuan, N. Research on the detection method of corn grain mold degree based on image processing. Chin. J. Cereals Oils 2015, 30, 112–116. [Google Scholar]

- Long, Z.; Jiang, Q.; Wang, J.; Zhu, H.; Li, B.; Wen, F. Research on method of tea flushes vision recognition and picking point localization. Transducer Microsyst. Technol. 2022, 2, 41–45. [Google Scholar]

- Arribas, J.I.; Sánchez-Ferrero, G.V.; Ruiz-Ruiz, G.; Gómez-Gil, J. Leaf classification in sunflower crops by computer vision and neural networks. Comput. Electron Agric. 2011, 78, 9–18. [Google Scholar] [CrossRef]

- Zhao, J.H.; Luo, X.W.; Zhou, Z.Y. A method of sugarcane disease image segmentation based on color and shape features. J. Agric. Mach. 2008, 39, 100–103. [Google Scholar]

- Pérez, A.; López, F.; Benlloch, J.; Christensen, S. Colour and shape analysis techniques for weed detection in cereal fields. Comput. Electron. Agric. 2000, 25, 197–212. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

| No. | White Light Electric Power/mW | Red Light Electric Power/mW | Correlation |

|---|---|---|---|

| a | 360 | 0 | 0.00319 |

| b | 360 | 195 | 0.00288 |

| c | 360 | 360 | 0.00244 |

| d | 0 | 360 | 0.00036 |

| e | 195 | 360 | 0.00129 |

| PCRC Quality | Non-Moldy Area n | All Areas m | Ratio r (%) |

|---|---|---|---|

| Non-moldy | 1,619,428 | 1,627,746 | 99.49% |

| Non-moldy | 1,297,719 | 1,313,758 | 98.78% |

| Non-moldy | 1,381,373 | 1,409,750 | 97.99% |

| Moldy | 1,600,767 | 1,693,612 | 94.52% |

| No. | Ratio (%) | Identification Results | Actual Results |

|---|---|---|---|

| 1 | 94.74% | Moldy | Moldy |

| 2 | 95.11% | Non-moldy | Non-moldy |

| 3 | 95.04% | Non-moldy | Moldy |

| 4 | 85.03% | Moldy | Moldy |

| 5 | 90.76% | Moldy | Moldy |

| 6 | 96.61% | Non-moldy | Non-moldy |

| 7 | 90.12% | Moldy | Moldy |

| 8 | 89.87% | Moldy | Moldy |

| 9 | 96.92% | Non-moldy | Non-moldy |

| 10 | 90.66% | Moldy | Moldy |

| 11 | 68.02% | Moldy | Moldy |

| 12 | 93.55% | Moldy | Moldy |

| 13 | 91.10% | Moldy | Moldy |

| 14 | 90.68% | Moldy | Moldy |

| 15 | 84.09% | Moldy | Moldy |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, G.; Qu, J.; Li, W.; Chen, D.; Zhong, C.; Luo, H.; Ou, G.; Mo, J. Research on UAV Remote Sensing Method of Mold Detection Suitable for Pericarp of Citri Reticulatae ‘Chachi’ Warehouses. Agriculture 2023, 13, 528. https://doi.org/10.3390/agriculture13030528

Yan G, Qu J, Li W, Chen D, Zhong C, Luo H, Ou G, Mo J. Research on UAV Remote Sensing Method of Mold Detection Suitable for Pericarp of Citri Reticulatae ‘Chachi’ Warehouses. Agriculture. 2023; 13(3):528. https://doi.org/10.3390/agriculture13030528

Chicago/Turabian StyleYan, Guoqi, Jialei Qu, Wei Li, Dongyi Chen, Chumin Zhong, Hao Luo, Guoliang Ou, and Jiasi Mo. 2023. "Research on UAV Remote Sensing Method of Mold Detection Suitable for Pericarp of Citri Reticulatae ‘Chachi’ Warehouses" Agriculture 13, no. 3: 528. https://doi.org/10.3390/agriculture13030528

APA StyleYan, G., Qu, J., Li, W., Chen, D., Zhong, C., Luo, H., Ou, G., & Mo, J. (2023). Research on UAV Remote Sensing Method of Mold Detection Suitable for Pericarp of Citri Reticulatae ‘Chachi’ Warehouses. Agriculture, 13(3), 528. https://doi.org/10.3390/agriculture13030528