Optimizing Sustainability in Malting Barley: A Practical Approach to Nitrogen Management for Enhanced Environmental, Agronomic, and Economic Benefits

Abstract

:1. Introduction

2. Materials and Methods

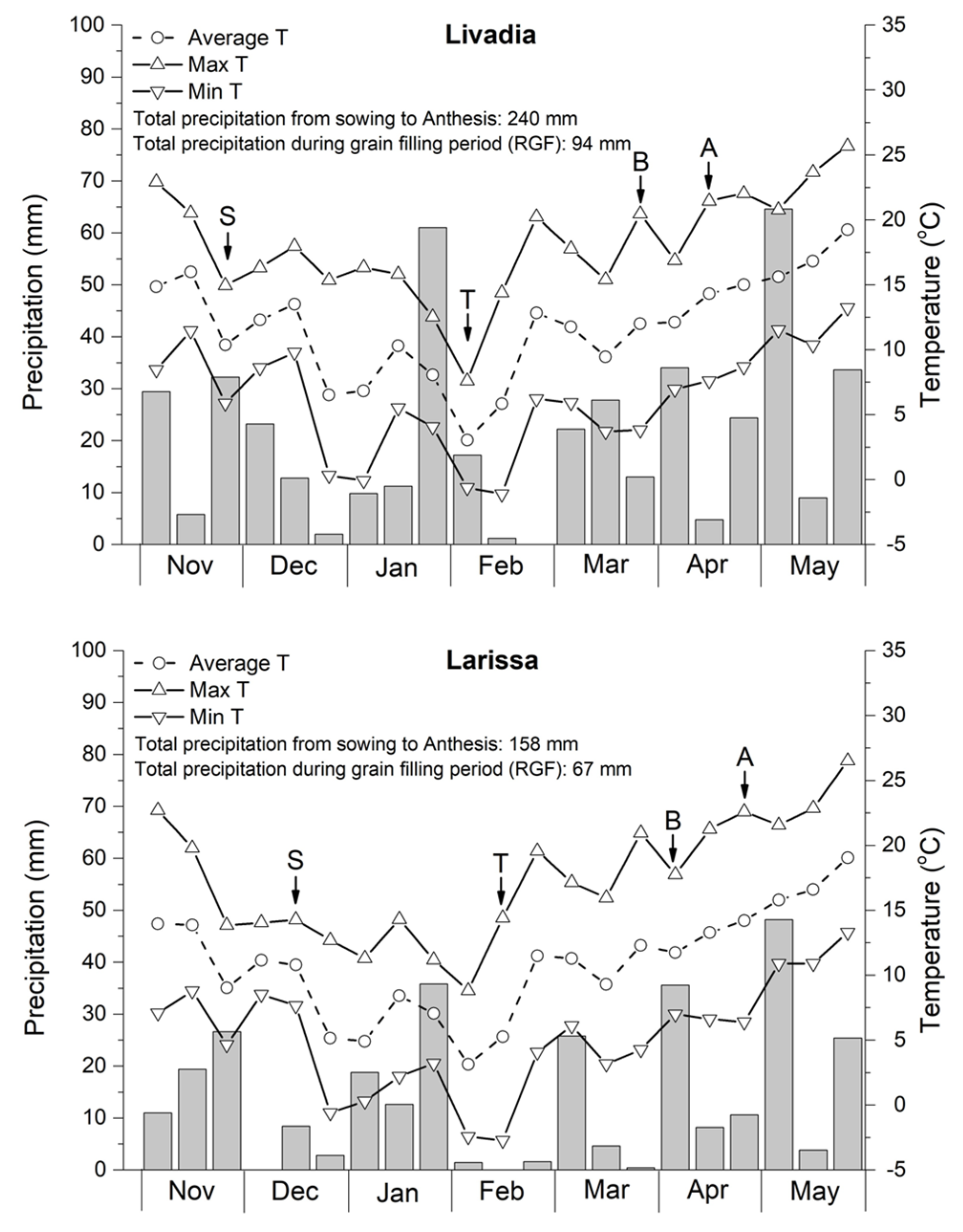

2.1. Site Description and Crop Management

2.2. Treatments and Experimental Design

2.3. Measurements

2.3.1. Ground Cover

2.3.2. Yield and Yield Components

2.3.3. Nitrogen Agronomic Efficiency (NAE)

2.3.4. Grain Size

2.3.5. Grain Protein Content (GPC)

2.4. Carbon Footprint (CF) and Greenhouse Gas Emissions (GHG) Calculation

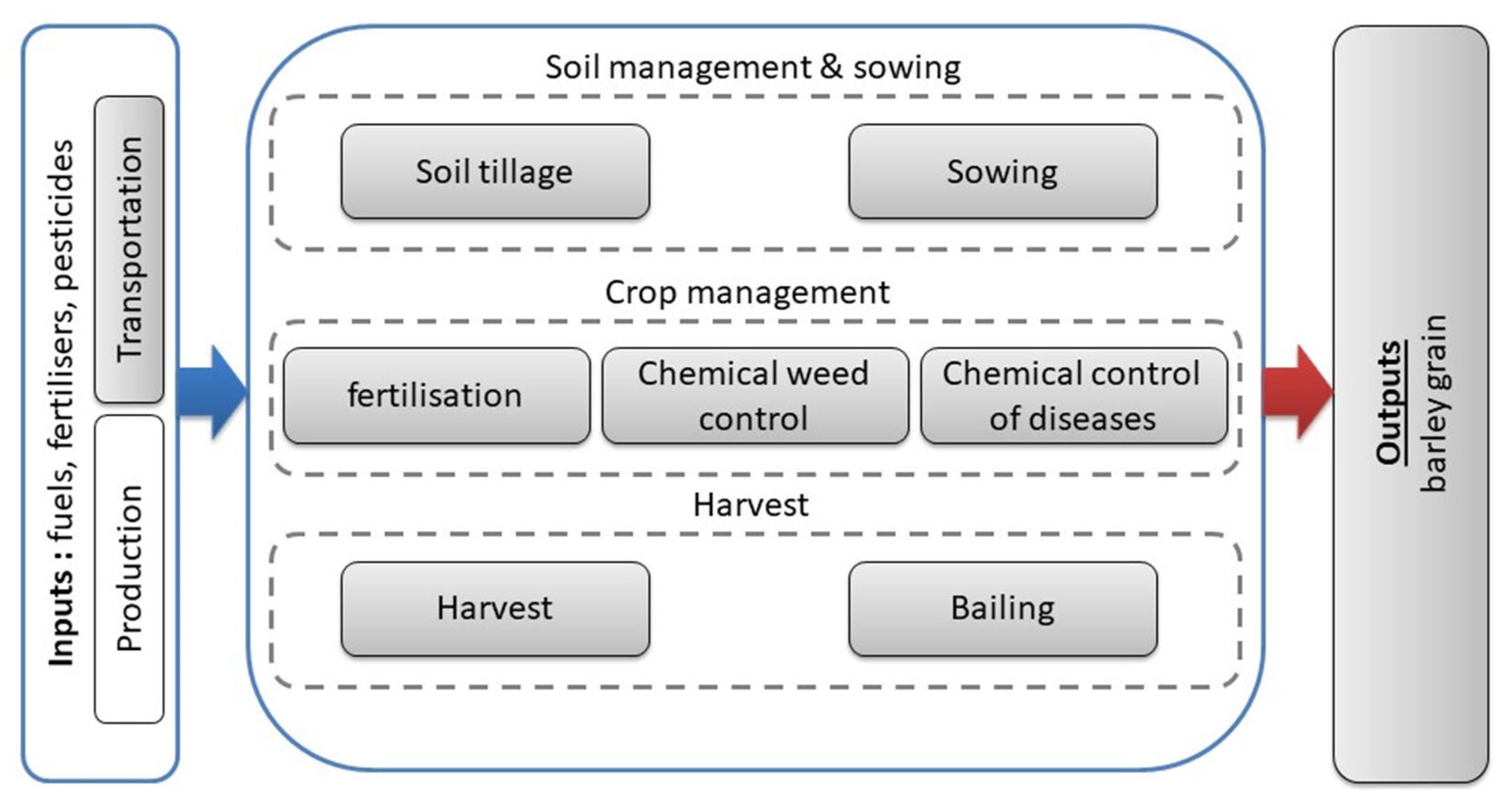

2.4.1. System Bountary

2.4.2. Functional Units

2.5. Economic Analysis

2.6. Statistical Analysis

3. Results

3.1. Green Canopy Cover

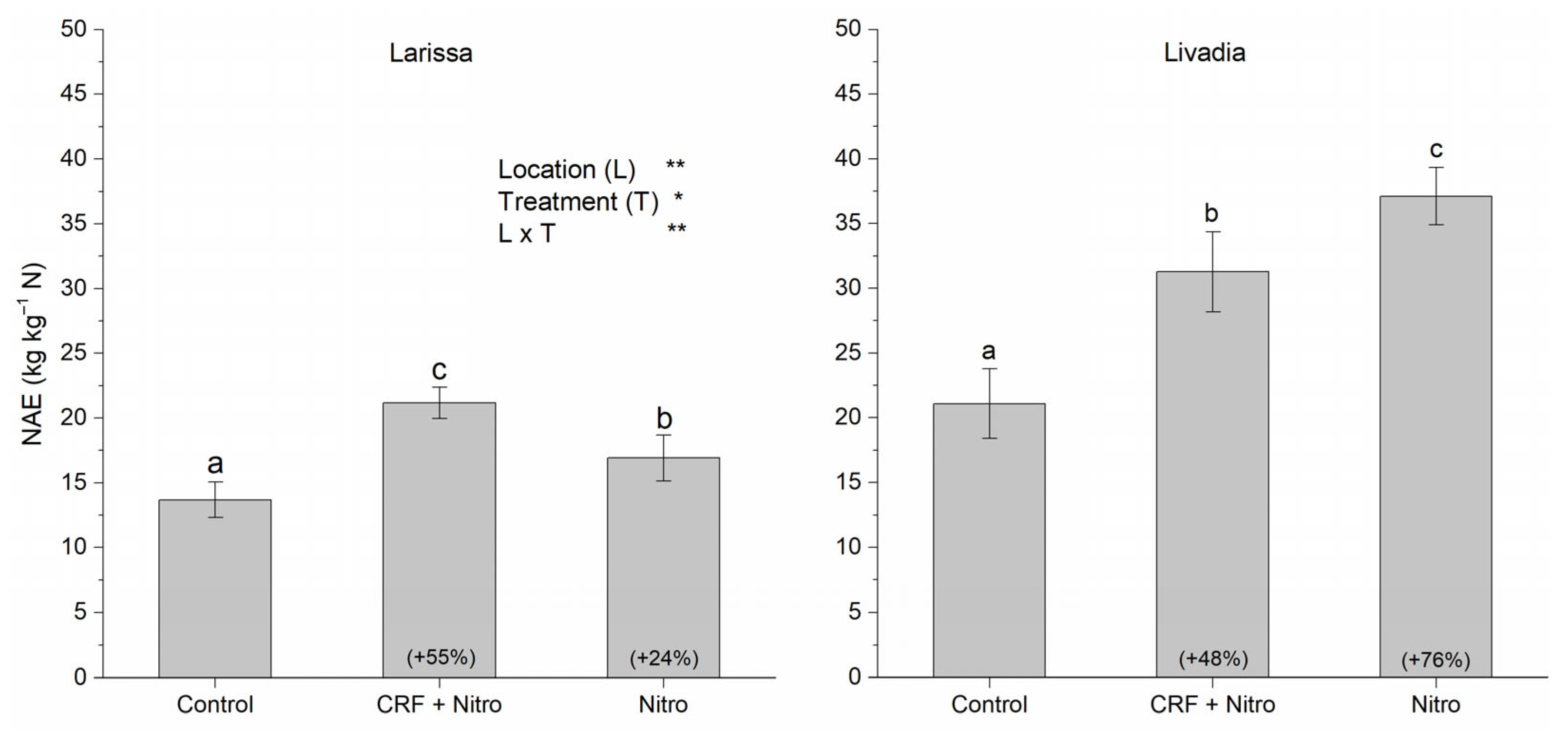

3.2. Yields and Nitrogen Agronomic Efficiency (NAE)

3.3. Quality Characters (Grain Size and Grain Protein Content)

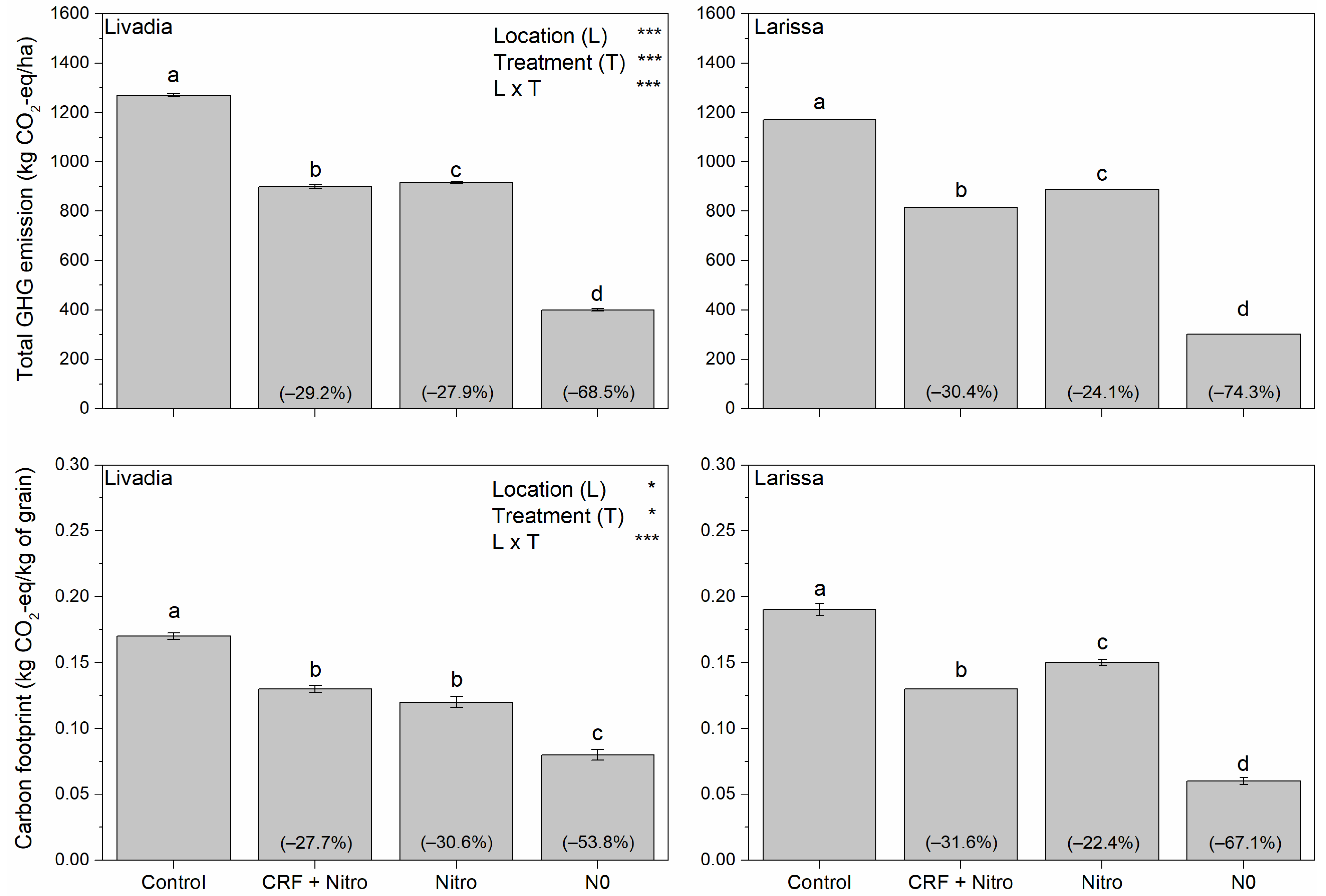

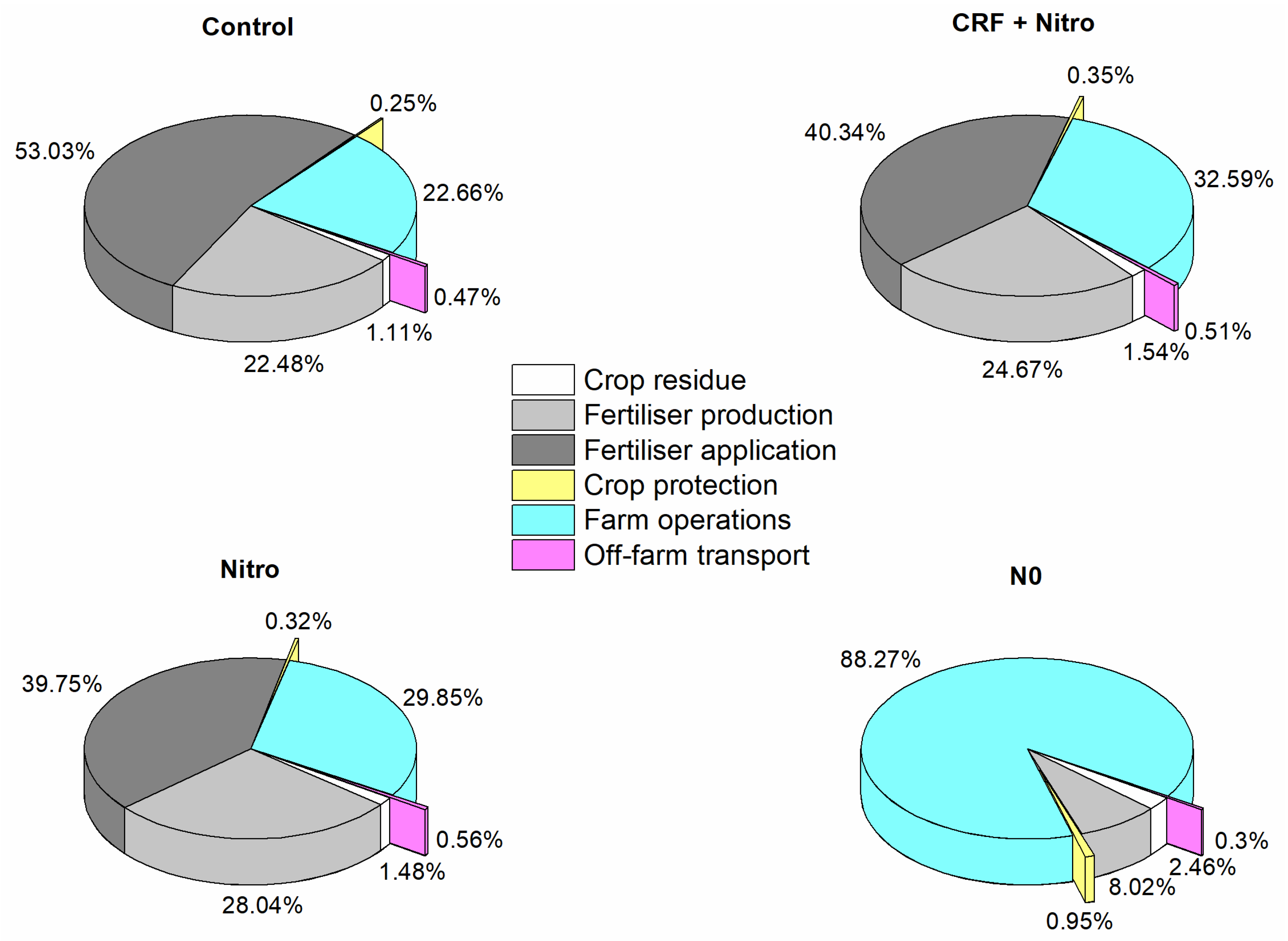

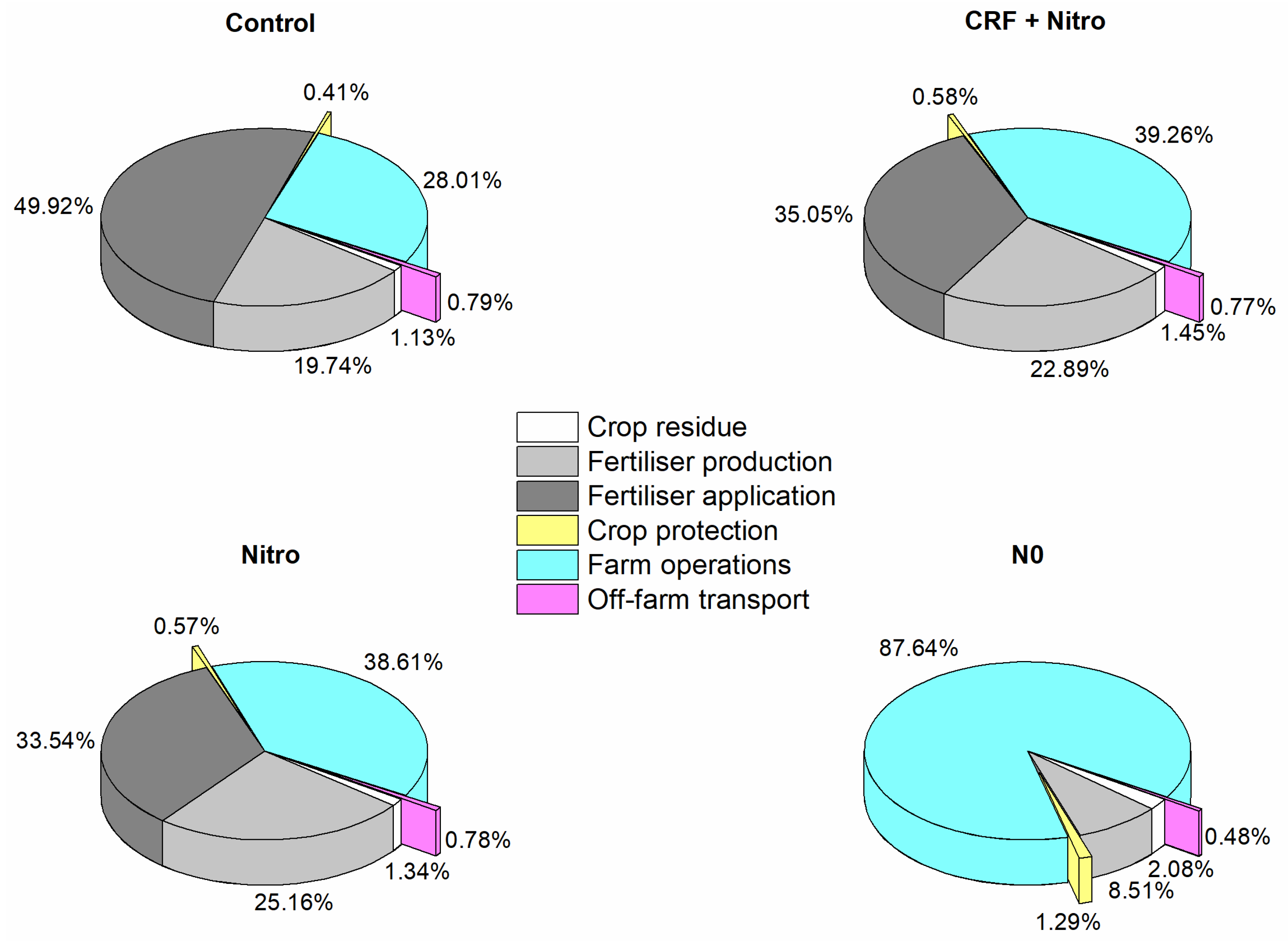

3.4. Life Cycle Emissions

3.5. Economic Analysis

4. Discussion

4.1. Modulating Barley Growth: The Dynamic Interplay of Nitrogen Dosage, Crop Developmental Stage, and Soil Nitrogen Availability

4.2. Exploring the Feasibility of a 34% Nitrogen Rate Reduction in Malt Barley without Compromising Yield

4.3. Decoding the Impact of the Tested Nitrogen Strategies on Grain Protein Content (GPC) and Size

4.4. The Environmental Impacts

4.5. The Economic Benefits

4.6. Limitations of the Study

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; You, L.; Amini, M.; Obersteiner, M.; Herrero, M.; Zehnder, A.J.B.; Yang, H. A High-Resolution Assessment on Global Nitrogen Flows in Cropland. Proc. Natl. Acad. Sci. USA 2010, 107, 8035–8040. [Google Scholar] [CrossRef]

- Drinkwater, L.E.; Snapp, S.S. Nutrients in Agroecosystems: Rethinking the Management Paradigm. In Advances in Agronomy; Elsevier: Amsterdam, The Netherlands, 2007; Volume 92, pp. 163–186. [Google Scholar] [CrossRef]

- Herrera, J.; Rubio, G.; Häner, L.; Delgado, J.; Lucho-Constantino, C.; Islas-Valdez, S.; Pellet, D. Emerging and Established Technologies to Increase Nitrogen Use Efficiency of Cereals. Agronomy 2016, 6, 25. [Google Scholar] [CrossRef]

- Lassaletta, L.; Billen, G.; Grizzetti, B.; Anglade, J.; Garnier, J. 50 Year Trends in Nitrogen Use Efficiency of World Cropping Systems: The Relationship between Yield and Nitrogen Input to Cropland. Environ. Res. Lett. 2014, 9, 105011. [Google Scholar] [CrossRef]

- Yan, X.; Ti, C.; Vitousek, P.; Chen, D.; Leip, A.; Cai, Z.; Zhu, Z. Fertilizer Nitrogen Recovery Efficiencies in Crop Production Systems of China with and without Consideration of the Residual Effect of Nitrogen. Environ. Res. Lett. 2014, 9, 095002. [Google Scholar] [CrossRef]

- Wang, W.; Dalal, R.C. Nitrogen Management Is the Key for Low-Emission Wheat Production in Australia: A Life Cycle Perspective. Eur. J. Agron. 2015, 66, 74–82. [Google Scholar] [CrossRef]

- Alhajj Ali, S.; Tedone, L.; Verdini, L.; De Mastro, G. Effect of Different Crop Management Systems on Rainfed Durum Wheat Greenhouse Gas Emissions and Carbon Footprint under Mediterranean Conditions. J. Clean. Prod. 2017, 140, 608–621. [Google Scholar] [CrossRef]

- Del Hierro, Ó.; Gallejones, P.; Besga, G.; Artetxe, A.; Garbisu, C. A Comparison of IPCC Guidelines and Allocation Methods to Estimate the Environmental Impact of Barley Production in the Basque Country through Life Cycle Assessment (LCA). Agriculture 2021, 11, 1005. [Google Scholar] [CrossRef]

- Gan, Y.; Liang, C.; May, W.; Malhi, S.S.; Niu, J.; Wang, X. Carbon Footprint of Spring Barley in Relation to Preceding Oilseeds and N Fertilization. Int. J. Life Cycle Assess. 2012, 17, 635–645. [Google Scholar] [CrossRef]

- Lovarelli, D.; Garcia, L.R.; Sánchez-Girón, V.; Bacenetti, J. Barley Production in Spain and Italy: Environmental Comparison between Different Cultivation Practices. Sci. Total Environ. 2020, 707, 135982. [Google Scholar] [CrossRef] [PubMed]

- Payandeh, Z.; Jahanbakhshi, A.; Mesri-Gundoshmian, T.; Clark, S. Improving Energy Efficiency of Barley Production Using Joint Data Envelopment Analysis (DEA) and Life Cycle Assessment (LCA): Evaluation of Greenhouse Gas Emissions and Optimization Approach. Sustainability 2021, 13, 6082. [Google Scholar] [CrossRef]

- Tidåker, P.; Bergkvist, G.; Bolinder, M.; Eckersten, H.; Johnsson, H.; Kätterer, T.; Weih, M. Estimating the Environmental Footprint of Barley with Improved Nitrogen Uptake Efficiency—A Swedish Scenario Study. Eur. J. Agron. 2016, 80, 45–54. [Google Scholar] [CrossRef]

- Xu, X.; Ma, F.; Zhou, J.; Du, C. Control-Released Urea Improved Agricultural Production Efficiency and Reduced the Ecological and Environmental Impact in Rice-Wheat Rotation System: A Life-Cycle Perspective. Field Crops Res. 2022, 278, 108445. [Google Scholar] [CrossRef]

- Zhang, L.; Liang, Z.; Hu, Y.; Schmidhalter, U.; Zhang, W.; Ruan, S.; Chen, X. Integrated Assessment of Agronomic, Environmental and Ecosystem Economic Benefits of Blending Use of Controlled-Release and Common Urea in Wheat Production. J. Clean. Prod. 2021, 287, 125572. [Google Scholar] [CrossRef]

- Butterbach-Bahl, K.; Baggs, E.M.; Dannenmann, M.; Kiese, R.; Zechmeister-Boltenstern, S. Nitrous Oxide Emissions from Soils: How Well Do We Understand the Processes and Their Controls? Philos. Trans. R. Soc. B Biol. Sci. 2013, 368, 20130122. [Google Scholar] [CrossRef]

- Charles, A.; Rochette, P.; Whalen, J.K.; Angers, D.A.; Chantigny, M.H.; Bertrand, N. Global Nitrous Oxide Emission Factors from Agricultural Soils after Addition of Organic Amendments: A Meta-Analysis. Agric. Ecosyst. Environ. 2017, 236, 88–98. [Google Scholar] [CrossRef]

- Smith, K.A. Changing Views of Nitrous Oxide Emissions from Agricultural Soil: Key Controlling Processes and Assessment at Different Spatial Scales. Eur. J. Soil Sci. 2017, 68, 137–155. [Google Scholar] [CrossRef]

- Shcherbak, I.; Millar, N.; Robertson, G.P. Global Metaanalysis of the Nonlinear Response of Soil Nitrous Oxide (N2O) Emissions to Fertilizer Nitrogen. Proc. Natl. Acad. Sci. USA 2014, 111, 9199–9204. [Google Scholar] [CrossRef] [PubMed]

- Kassie, M.; Fanataye, K. Nitrogen Uptake and Utilization Efficiency of Malting Barley as Influenced by Variety and Nitrogen Level. J. Crop Sci. Biotechnol. 2019, 22, 65–73. [Google Scholar] [CrossRef]

- Maresma, Á.; Martínez-Casasnovas, J.A.; Santiveri, F.; Lloveras, J. Nitrogen Management in Double-Annual Cropping System (Barley-Maize) under Irrigated Mediterranean Environments. Eur. J. Agron. 2019, 103, 98–107. [Google Scholar] [CrossRef]

- Savin, R.; Cossani, C.M.; Dahan, R.; Ayad, J.Y.; Albrizio, R.; Todorovic, M.; Karrou, M.; Slafer, G.A. Intensifying Cereal Management in Dryland Mediterranean Agriculture: Rainfed Wheat and Barley Responses to Nitrogen Fertilisation. Eur. J. Agron. 2022, 137, 126518. [Google Scholar] [CrossRef]

- Alvarez, R. A Review of Nitrogen Fertilizer and Conservation Tillage Effects on Soil Organic Carbon Storage. Soil Use Manag. 2006, 21, 38–52. [Google Scholar] [CrossRef]

- Cossani, C.M.; Slafer, G.A.; Savin, R. Nitrogen and Water Use Efficiencies of Wheat and Barley under a Mediterranean Environment in Catalonia. Field Crops Res. 2012, 128, 109–118. [Google Scholar] [CrossRef]

- Beillouin, D.; Trépos, R.; Gauffreteau, A.; Jeuffroy, M.-H. Delayed and Reduced Nitrogen Fertilization Strategies Decrease Nitrogen Losses While Still Achieving High Yields and High Grain Quality in Malting Barley. Eur. J. Agron. 2018, 101, 174–182. [Google Scholar] [CrossRef]

- Vahamidis, P.; Stefopoulou, A.; Kotoulas, V.; Bresta, P.; Nikolopoulos, D.; Karabourniotis, G.; Mantonanakis, G.; Vlachos, C.; Dercas, N.; Economou, G. Grain Size Variation in Two-Rowed Malt Barley under Mediterranean Conditions: Phenotypic Plasticity and Relevant Trade-Offs. Field Crops Res. 2022, 279, 108454. [Google Scholar] [CrossRef]

- Vahamidis, P.; Stefopoulou, A.; Kotoulas, V.; Lyra, D.; Dercas, N.; Economou, G. Yield, Grain Size, Protein Content and Water Use Efficiency of Null-LOX Malt Barley in a Semiarid Mediterranean Agroecosystem. Field Crops Res. 2017, 206, 115–127. [Google Scholar] [CrossRef]

- Mikkelsen, R.L. The “4R” Nutrient Stewardship Framework for Horticulture. HortTechnology 2011, 21, 658–662. [Google Scholar] [CrossRef]

- Mansouri, H.; Ait Said, H.; Noukrati, H.; Oukarroum, A.; Ben Youcef, H.; Perreault, F. Advances in Controlled Release Fertilizers: Cost-Effective Coating Techniques and Smart Stimuli-Responsive Hydrogels. Adv. Sustain. Syst. 2023, 7, 2300149. [Google Scholar] [CrossRef]

- Vejan, P.; Khadiran, T.; Abdullah, R.; Ahmad, N. Controlled Release Fertilizer: A Review on Developments, Applications and Potential in Agriculture. J. Control. Release 2021, 339, 321–334. [Google Scholar] [CrossRef] [PubMed]

- Irfan, S.A.; Razali, R.; KuShaari, K.; Mansor, N.; Azeem, B.; Ford Versypt, A.N. A Review of Mathematical Modeling and Simulation of Controlled-Release Fertilizers. J. Control. Release 2018, 271, 45–54. [Google Scholar] [CrossRef]

- Ke, J.; Xing, X.; Li, G.; Ding, Y.; Dou, F.; Wang, S.; Liu, Z.; Tang, S.; Ding, C.; Chen, L. Effects of Different Controlled-Release Nitrogen Fertilisers on Ammonia Volatilisation, Nitrogen Use Efficiency and Yield of Blanket-Seedling Machine-Transplanted Rice. Field Crops Res. 2017, 205, 147–156. [Google Scholar] [CrossRef]

- Akiyama, H.; Yan, X.; Yagi, K. Evaluation of Effectiveness of Enhanced-Efficiency Fertilizers as Mitigation Options for N2O and NO Emissions from Agricultural Soils: Meta-analysis: Mitigation Options for N2O and No Emissions. Glob. Chang. Biol. 2009, 16, 1837–1846. [Google Scholar] [CrossRef]

- Ding, Z.; Li, J.; Hu, R.; Xiao, D.; Huang, F.; Peng, S.; Huang, J.; Li, C.; Hou, J.; Tian, Y.; et al. Root-Zone Fertilization of Controlled-Release Urea Reduces Nitrous Oxide Emissions and Ammonia Volatilization under Two Irrigation Practices in a Ratoon Rice Field. Field Crops Res. 2022, 287, 108673. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Y.; Hao, X.; Song, C.; Zong, Y.; Zhang, D.; Shi, X.; Li, P. Effects of Controlled-Release Fertilizer on N2O Emissions in Wheat under Elevated CO2 Concentration and Temperature. Plant Soil 2023, 488, 343–361. [Google Scholar] [CrossRef]

- Ye, Y.; Liang, X.; Chen, Y.; Liu, J.; Gu, J.; Guo, R.; Li, L. Alternate Wetting and Drying Irrigation and Controlled-Release Nitrogen Fertilizer in Late-Season Rice. Effects on Dry Matter Accumulation, Yield, Water and Nitrogen Use. Field Crops Res. 2013, 144, 212–224. [Google Scholar] [CrossRef]

- Zheng, W.; Sui, C.; Liu, Z.; Geng, J.; Tian, X.; Yang, X.; Li, C.; Zhang, M. Long-Term Effects of Controlled-Release Urea on Crop Yields and Soil Fertility under Wheat–Corn Double Cropping Systems. Agron. J. 2016, 108, 1703–1716. [Google Scholar] [CrossRef]

- Ziadi, N.; Grant, C.; Samson, N.; Nyiraneza, J.; Bélanger, G.; Parent, L. Efficiency of Controlled-Release Urea for a Potato Production System in Quebec, Canada. Agron. J. 2011, 103, 60–66. [Google Scholar] [CrossRef]

- Azeem, B.; KuShaari, K.; Man, Z.B.; Basit, A.; Thanh, T.H. Review on Materials & Methods to Produce Controlled Release Coated Urea Fertilizer. J. Control. Release 2014, 181, 11–21. [Google Scholar] [CrossRef] [PubMed]

- McKenzie, R.H.; Middleton, A.B.; Pfiffner, P.G.; Bremer, E. Evaluation of Polymer-Coated Urea and Urease Inhibitor for Winter Wheat in Southern Alberta. Agron. J. 2010, 102, 1210–1216. [Google Scholar] [CrossRef]

- Middleton, A.B.; Bremer, E.; McKenzie, R.H. Winter Wheat Response to Nitrogen Fertilizer Form and Placement in Southern Alberta. Can. J. Soil Sci. 2004, 84, 125–131. [Google Scholar] [CrossRef]

- Zheng, W.; Zhang, M.; Liu, Z.; Zhou, H.; Lu, H.; Zhang, W.; Yang, Y.; Li, C.; Chen, B. Combining Controlled-Release Urea and Normal Urea to Improve the Nitrogen Use Efficiency and Yield under Wheat-Maize Double Cropping System. Field Crops Res. 2016, 197, 52–62. [Google Scholar] [CrossRef]

- Zhou, Z.; Shen, Y.; Du, C.; Zhou, J.; Qin, Y.; Wu, Y. Economic and Soil Environmental Benefits of Using Controlled-Release Bulk Blending Urea in the North China Plain. Land Degrad. Dev. 2017, 28, 2370–2379. [Google Scholar] [CrossRef]

- Sun, M.; Ma, B.; Lu, P.; Bai, J.; Mi, J.; Liu, J. Blending Controlled-Release Urea and Urea under Ridge-Furrow with Plastic Film Mulching Improves Yield While Mitigating Carbon Footprint in Rainfed Potato. Sci. Rep. 2023, 13, 4018. [Google Scholar] [CrossRef]

- Wu, Q.; Qiao, Y.; Zhou, Q.; Chen, J.; Wang, G. Controlled-Release Blended Fertilizer Combined with Urea Reduces Nitrogen Losses by Runoff and Improves Nitrogen Use Efficiency and Yield of Wet Direct-Seeded Rice in Central China. Sustainability 2023, 15, 12336. [Google Scholar] [CrossRef]

- Guo, J.; Fan, J.; Zhang, F.; Yan, S.; Zheng, J.; Wu, Y.; Li, J.; Wang, Y.; Sun, X.; Liu, X.; et al. Blending Urea and Slow-Release Nitrogen Fertilizer Increases Dryland Maize Yield and Nitrogen Use Efficiency While Mitigating Ammonia Volatilization. Sci. Total Environ. 2021, 790, 148058. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Qi, X.; Shi, R.; Zhao, Y.; Hu, Z.; Chen, Q.; Li, C. Reduced N Fertilizer Application with Optimal Blend of Controlled-Release Urea and Urea Improves Tomato Yield and Quality in Greenhouse Production System. J. Soil Sci. Plant Nutr. 2020, 20, 1741–1750. [Google Scholar] [CrossRef]

- Chambers, B.J.; Dampney, P.M.R. Nitrogen Efficiency and Ammonia Emissions from Urea-Based and Ammonium Nitrate Fertilisers; International Fertiliser Society: Strensall, UK, 2009. [Google Scholar]

- Chaney, K.; Paulson, G.A. Field Experiments Comparing Ammonium Nitrate and Urea Top-Dressing for Winter Cereals and Grassland in the U.K. J. Agric. Sci. 1988, 110, 285–299. [Google Scholar] [CrossRef]

- Cowan, N.; Levy, P.; Maire, J.; Coyle, M.; Leeson, S.R.; Famulari, D.; Carozzi, M.; Nemitz, E.; Skiba, U. An Evaluation of Four Years of Nitrous Oxide Fluxes after Application of Ammonium Nitrate and Urea Fertilisers Measured Using the Eddy Covariance Method. Agric. For. Meteorol. 2020, 280, 107812. [Google Scholar] [CrossRef]

- Sarkis, L.F.; Dutra, M.P.; Dos Santos, C.A.; Rodrigues Alves, B.J.; Urquiaga, S.; Guelfi, D. Nitrogen Fertilizers Technologies as a Smart Strategy to Mitigate Nitrous Oxide Emissions and Preserve Carbon and Nitrogen Soil Stocks in a Coffee Crop System. Atmospheric Environ. X 2023, 20, 100224. [Google Scholar] [CrossRef]

- Tenuta, M.; Beauchamp, E.G. Nitrous Oxide Production from Granular Nitrogen Fertilizers Applied to a Silt Loam Soil. Can. J. Soil Sci. 2003, 83, 521–532. [Google Scholar] [CrossRef]

- Vahamidis, P.; Stefopoulou, A.; Kotoulas, V.; Voloudakis, D.; Dercas, N.; Economou, G. A Further Insight into the Environmental Factors Determining Potential Grain Size in Malt Barley under Mediterranean Conditions. Eur. J. Agron. 2021, 122, 126184. [Google Scholar] [CrossRef]

- Zadoks, J.C.; Chang, T.T.; Konzak, C.F. A Decimal Code for the Growth Stages of Cereals. Weed Res. 1974, 14, 415–421. [Google Scholar] [CrossRef]

- Patrignani, A.; Ochsner, T.E. Canopeo: A Powerful New Tool for Measuring Fractional Green Canopy Cover. Agron. J. 2015, 107, 2312–2320. [Google Scholar] [CrossRef]

- Sunoj, S.; McRoberts, K.C.; Benson, M.; Ketterings, Q.M. Digital Image Analysis Estimates of Biomass, Carbon, and Nitrogen Uptake of Winter Cereal Cover Crops. Comput. Electron. Agric. 2021, 184, 106093. [Google Scholar] [CrossRef]

- Duan, Y.; Xu, M.; Gao, S.; Yang, X.; Huang, S.; Liu, H.; Wang, B. Nitrogen Use Efficiency in a Wheat–Corn Cropping System from 15 Years of Manure and Fertilizer Applications. Field Crops Res. 2014, 157, 47–56. [Google Scholar] [CrossRef]

- Analytica EBC. Sieving Test for Barley Method 3.11. 1998. Available online: https://brewup.eu/ebc-analytica/barley/sieving-test-for-barley/3.11.1 (accessed on 1 July 2023).

- Hillier, J.; Walter, C.; Malin, D.; Garcia-Suarez, T.; Mila-i-Canals, L.; Smith, P. A Farm-Focused Calculator for Emissions from Crop and Livestock Production. Environ. Model. Softw. 2011, 26, 1070–1078. [Google Scholar] [CrossRef]

- Haverkort, A.J.; Sandaña, P.; Kalazich, J. Yield Gaps and Ecological Footprints of Potato Production Systems in Chile. Potato Res. 2014, 57, 13–31. [Google Scholar] [CrossRef]

- Aryal, J.P.; Sapkota, T.B.; Jat, M.L.; Bishnoi, D.K. On-farm economic and environmental impact of zero-tillage wheat: A case of north-west india. Exp. Agric. 2015, 51, 1–16. [Google Scholar] [CrossRef]

- Bajgai, Y.; Yeshey, Y.; De Mastro, G.; Ghimiray, M.; Chhogyel, N.; Tshewang, S.; Alhajj Ali, S. Influence of Nitrogen Application on Wheat Crop Performance, Soil Properties, Greenhouse Gas Emissions and Carbon Footprint in Central Bhutan. Environ. Dev. 2019, 32, 100469. [Google Scholar] [CrossRef]

- Moreno-García, B.; Coronel, E.; Reavis, C.W.; Suvočarev, K.; Runkle, B.R.K. Environmental Sustainability Assessment of Rice Management Practices Using Decision Support Tools. J. Clean. Prod. 2021, 315, 128135. [Google Scholar] [CrossRef]

- Ray, K.; Sen, P.; Goswami, R.; Sarkar, S.; Brahmachari, K.; Ghosh, A.; Nanda, M.K.; Mainuddin, M. Profitability, Energetics and GHGs Emission Estimation from Rice-Based Cropping Systems in the Coastal Saline Zone of West Bengal, India. PLoS ONE 2020, 15, e0233303. [Google Scholar] [CrossRef]

- Kumar, R.; Karmakar, S.; Minz, A.; Singh, J.; Kumar, A.; Kumar, A. Assessment of Greenhouse Gases Emission in Maize-Wheat Cropping System Under Varied N Fertilizer Application Using Cool Farm Tool. Front. Environ. Sci. 2021, 9, 710108. [Google Scholar] [CrossRef]

- Vervuurt, W.; Slingerland, M.A.; Pronk, A.A.; Van Bussel, L.G.J. Modelling Greenhouse Gas Emissions of Cacao Production in the Republic of Côte d’Ivoire. Agrofor. Syst. 2022, 96, 417–434. [Google Scholar] [CrossRef]

- Cool Farm Alliance. Cool Farm Tool-Technical Method Description-Version CFT 2.5. 2023. Available online: https://coolfarmtool.org/ (accessed on 20 September 2023).

- Whittaker, C.; McManus, M.C.; Smith, P. A Comparison of Carbon Accounting Tools for Arable Crops in the United Kingdom. Environ. Model. Softw. 2013, 46, 228–239. [Google Scholar] [CrossRef]

- Xiong, L.; Liang, C.; Ma, B.; Shah, F.; Wu, W. Carbon Footprint and Yield Performance Assessment under Plastic Film Mulching for Winter Wheat Production. J. Clean. Prod. 2020, 270, 122468. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, W.; Cui, Z.; Hu, Y.; Schmidhalter, U.; Chen, X. Environmental, Human Health, and Ecosystem Economic Performance of Long-Term Optimizing Nitrogen Management for Wheat Production. J. Clean. Prod. 2021, 311, 127620. [Google Scholar] [CrossRef]

- Nayak, A.K.; Rahman, M.M.; Naidu, R.; Dhal, B.; Swain, C.K.; Nayak, A.D.; Tripathi, R.; Shahid, M.; Islam, M.R.; Pathak, H. Current and Emerging Methodologies for Estimating Carbon Sequestration in Agricultural Soils: A Review. Sci. Total Environ. 2019, 665, 890–912. [Google Scholar] [CrossRef] [PubMed]

- McIntosh, M.S. Analysis of Combined Experiments. Agron. J. 1983, 75, 153–155. [Google Scholar] [CrossRef]

- Delogu, G.; Cattivelli, L.; Pecchioni, N.; De Falcis, D.; Maggiore, T.; Stanca, A.M. Uptake and Agronomic Efficiency of Nitrogen in Winter Barley and Winter Wheat. Eur. J. Agron. 1998, 9, 11–20. [Google Scholar] [CrossRef]

- Guntiñas, M.E.; Leirós, M.C.; Trasar-Cepeda, C.; Gil-Sotres, F. Effects of Moisture and Temperature on Net Soil Nitrogen Mineralization: A Laboratory Study. Eur. J. Soil Biol. 2012, 48, 73–80. [Google Scholar] [CrossRef]

- Miller, K.S.; Geisseler, D. Temperature Sensitivity of Nitrogen Mineralization in Agricultural Soils. Biol. Fertil. Soils 2018, 54, 853–860. [Google Scholar] [CrossRef]

- Hoffland, E.; Kuyper, T.W.; Comans, R.N.J.; Creamer, R.E. Eco-Functionality of Organic Matter in Soils. Plant Soil 2020, 455, 1–22. [Google Scholar] [CrossRef]

- Loveland, P. Is There a Critical Level of Organic Matter in the Agricultural Soils of Temperate Regions: A Review. Soil Tillage Res. 2003, 70, 1–18. [Google Scholar] [CrossRef]

- Quiroga, A.; Funaro, D.; Noellemeyer, E.; Peinemann, N. Barley Yield Response to Soil Organic Matter and Texture in the Pampas of Argentina. Soil Tillage Res. 2006, 90, 63–68. [Google Scholar] [CrossRef]

- Salvagiotti, F.; Miralles, D.J. Wheat Development as Affected by Nitrogen and Sulfur Nutrition. Aust. J. Agric. Res. 2007, 58, 39. [Google Scholar] [CrossRef]

- Alvarez Prado, S.; Gallardo, J.M.; Kruk, B.C.; Miralles, D.J. Strategies for Yield Determination of Bread Wheat and Two-Row Barley Growing under Different Environments: A Comparative Study. Field Crops Res. 2017, 203, 94–105. [Google Scholar] [CrossRef]

- Cossani, C.M.; Slafer, G.A.; Savin, R. Yield and Biomass in Wheat and Barley under a Range of Conditions in a Mediterranean Site. Field Crops Res. 2009, 112, 205–213. [Google Scholar] [CrossRef]

- Kennedy, S.P.; Bingham, I.J.; Spink, J.H. Determinants of Spring Barley Yield in a High-Yield Potential Environment. J. Agric. Sci. 2017, 155, 60–80. [Google Scholar] [CrossRef]

- Sadras, V.O.; Slafer, G.A. Environmental Modulation of Yield Components in Cereals: Heritabilities Reveal a Hierarchy of Phenotypic Plasticities. Field Crops Res. 2012, 127, 215–224. [Google Scholar] [CrossRef]

- Serrago, R.A.; García, G.A.; Savin, R.; Miralles, D.J.; Slafer, G.A. Determinants of Grain Number Responding to Environmental and Genetic Factors in Two- and Six-Rowed Barley Types. Field Crops Res. 2023, 302, 109073. [Google Scholar] [CrossRef]

- McGlinch, G.J.; Jacquemin, S.J.; Lindsey, L.E. Evaluating Winter Malting Barley Grain Yield with Fractional Green Canopy Cover. Crop Forage Turfgrass Manag. 2021, 7, e20079. [Google Scholar] [CrossRef]

- Agegnehu, G.; Nelson, P.N.; Bird, M.I. The Effects of Biochar, Compost and Their Mixture and Nitrogen Fertilizer on Yield and Nitrogen Use Efficiency of Barley Grown on a Nitisol in the Highlands of Ethiopia. Sci. Total Environ. 2016, 569–570, 869–879. [Google Scholar] [CrossRef] [PubMed]

- Anbessa, Y.; Juskiw, P. Review: Strategies to Increase Nitrogen Use Efficiency of Spring Barley. Can. J. Plant Sci. 2012, 92, 617–625. [Google Scholar] [CrossRef]

- Fageria, N.K.; Baligar, V.C. Enhancing Nitrogen Use Efficiency in Crop Plants. In Advances in Agronomy; Elsevier: Amsterdam, The Netherlands, 2005; Volume 88, pp. 97–185. [Google Scholar] [CrossRef]

- Zheng, B.; Zhang, X.; Wang, Q.; Li, W.; Huang, M.; Zhou, Q.; Cai, J.; Wang, X.; Cao, W.; Dai, T.; et al. Increasing Plant Density Improves Grain Yield, Protein Quality and Nitrogen Agronomic Efficiency of Soft Wheat Cultivars with Reduced Nitrogen Rate. Field Crops Res. 2021, 267, 108145. [Google Scholar] [CrossRef]

- Dreccer, M.F.; Grashoff, C.; Rabbinge, R. Source-Sink Ratio in Barley (Hordeum vulgare L.) during Grain Filling: Effects on Senescence and Grain Protein Concentration. Field Crops Res. 1997, 49, 269–277. [Google Scholar] [CrossRef]

- Angelino, S.A.G.F.; Laarhoven, H.P.M.V.; Westerop, J.J.M.V.; Broekhuijse, B.M.; Mocking, H.C.M. Total nitrogen content in single kernel malting barley samples. J. Inst. Brew. 1997, 103, 41–46. [Google Scholar] [CrossRef]

- Yu, W.; Tan, X.; Zou, W.; Hu, Z.; Fox, G.P.; Gidley, M.J.; Gilbert, R.G. Relationships between Protein Content, Starch Molecular Structure and Grain Size in Barley. Carbohydr. Polym. 2017, 155, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Bertholdsson, N.O. Characterization of Malting Barley Cultivars with More or Less Stable Grain Protein Content under Varying Environmental Conditions. Eur. J. Agron. 1999, 10, 1–8. [Google Scholar] [CrossRef]

- Savin, R.; Nicolas, M. Effects of Short Periods of Drought and High Temperature on Grain Growth and Starch Accumulation of Two Malting Barley Cultivars. Funct. Plant Biol. 1996, 23, 201. [Google Scholar] [CrossRef]

- Savin, R.; Nicolas, M.E. Effects of Timing of Heat Stress and Drought on Growth and Quality of Barley Grains. Aust. J. Agric. Res. 1999, 50, 357. [Google Scholar] [CrossRef]

- Bingham, I.J.; Garzon, D.C. Relative Contribution of Soil N Availability and Grain Sink Demand to the Control of Post-Anthesis N Uptake by Field-Grown Spring Barley. Field Crops Res. 2023, 292, 108829. [Google Scholar] [CrossRef]

- Tanaka, R.; Nakano, H. Barley Yield Response to Nitrogen Application under Different Weather Conditions. Sci. Rep. 2019, 9, 8477. [Google Scholar] [CrossRef] [PubMed]

- Barmeier, G.; Hu, Y.; Schmidhalter, U. Partitioning and Translocation of Dry Matter and Nitrogen During Grain Filling in Spring Barley Varieties and Their Roles in Determining Malting Quality. Front. Plant Sci. 2021, 12, 722871. [Google Scholar] [CrossRef]

- Mansour, E.; Abdul-Hamid, M.I.; Yasin, M.T.; Qabil, N.; Attia, A. Identifying Drought-Tolerant Genotypes of Barley and Their Responses to Various Irrigation Levels in a Mediterranean Environment. Agric. Water Manag. 2017, 194, 58–67. [Google Scholar] [CrossRef]

- Acreche, M.M.; Slafer, G.A. Grain Weight Response to Increases in Number of Grains in Wheat in a Mediterranean Area. Field Crops Res. 2006, 98, 52–59. [Google Scholar] [CrossRef]

- GambÃ-n, B.L.; Borrás, L. Resource Distribution and the Trade-off between Seed Number and Seed Weight: A Comparison across Crop Species. Ann. Appl. Biol. 2010, 156, 91–102. [Google Scholar] [CrossRef]

- Sadras, V.O. Evolutionary Aspects of the Trade-off between Seed Size and Number in Crops. Field Crops Res. 2007, 100, 125–138. [Google Scholar] [CrossRef]

- Liu, C.; Cutforth, H.; Chai, Q.; Gan, Y. Farming Tactics to Reduce the Carbon Footprint of Crop Cultivation in Semiarid Areas. A Review. Agron. Sustain. Dev. 2016, 36, 69. [Google Scholar] [CrossRef]

- Niero, M.; Ingvordsen, C.H.; Peltonen-Sainio, P.; Jalli, M.; Lyngkjær, M.F.; Hauschild, M.Z.; Jørgensen, R.B. Eco-Efficient Production of Spring Barley in a Changed Climate: A Life Cycle Assessment Including Primary Data from Future Climate Scenarios. Agric. Syst. 2015, 136, 46–60. [Google Scholar] [CrossRef]

- Roman-Perez, C.C.; Hernandez-Ramirez, G.; Kryzanowski, L.; Puurveen, D.; Lohstraeter, G. Greenhouse Gas Emissions, Nitrogen Dynamics and Barley Productivity as Impacted by Biosolids Applications. Agric. Ecosyst. Environ. 2021, 320, 107577. [Google Scholar] [CrossRef]

- Żyłowski, T. Evaluation of the technical efficiency and carbon footprint reduction potential of spring barley cultivation. Ann. Pol. Assoc. Agric. Agribus. Econ. 2019, 21, 561–571. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, Z.; He, X.; Wang, X.; Shi, X.; Zou, C.; Chen, X. The Effects of Controlled Release Urea on Maize Productivity and Reactive Nitrogen Losses: A Meta-Analysis. Environ. Pollut. 2019, 246, 559–565. [Google Scholar] [CrossRef] [PubMed]

- Pei, Y.; Chen, X.; Niu, Z.; Su, X.; Wang, Y.; Wang, X. Effects of Nitrogen Fertilizer Substitution by Cow Manure on Yield, Net GHG Emissions, Carbon and Nitrogen Footprints in Sweet Maize Farmland in the Pearl River Delta in China. J. Clean. Prod. 2023, 399, 136676. [Google Scholar] [CrossRef]

- Pockelé, S.; Miserque, O. Introduction to Guidelines for the Production and Handling of Blended Fertilisers; Proceedings/International Fertiliser Society; International Fertiliser Society: New York, NY, USA, 2005. [Google Scholar]

- Ledoux, F.; Winne, E.; Nygaard, E.C. Safe Blends of Ammonium Nitrate (AN) with Urea, or of an AN-Comprising Product with a Urea-Comprising Product. US9284232B2. 2016. Available online: https://patentimages.storage.googleapis.com/df/67/b6/314b10f94bb269/US9284232.pdf (accessed on 10 October 2023).

| Location | Treatment | Basal Fertilisation | N Topdressing * | Total N Rate (kg N ha−1) | ||||

|---|---|---|---|---|---|---|---|---|

| Fertiliser | N Rate (kg ha−1) | Fertiliser | N Rate (kg ha−1) | |||||

| Livadia | Control | 11-15-15 | 20 | Sulfur urea (40-0-0) | 88 | 108 | ||

| CRF + Nitro | 9-22-22 | 11 | CRF | ASN | 60 | 71 | ||

| Nitro | 9-22-22 | 11 | ASN | 60 | 71 | |||

| N0 | 0-46-0 | 0-0-60 | 0 | - | - | 0 | ||

| Larissa | Control | 20-10-0 | 36 | Sulfur urea (40-0-0) | 74 | 110 | ||

| CRF + Nitro | 16-20-0 | 18 | CRF | ASN | 55 | 73 | ||

| Nitro | 16-20-0 | 18 | ASN | 55 | 73 | |||

| N0 | 0-46-0 | 0 | - | - | 0 | |||

| Location | Treatment | GY (t ha−1) | Grains Spike−1 | Spikes m−2 | Biomass (t ha−1) | TKW (g) | Plant Height (cm) |

|---|---|---|---|---|---|---|---|

| Livadia | Control | 7.28 ab | 23.7 a | 669 a | 13.92 a | 45.9 a | 76.4 a |

| CRF + Nitro | 7.22 a | 24.2 a | 615 a | 13.35 a | 48.5 b | 72.7 a | |

| Nitro | 7.63 b | 24.4 a | 650 a | 13.43 a | 48.1 b | 75.2 a | |

| N0 | 4.99 c | 20.2 b | 508 b | 8.92 b | 48.6 b | 58.4 b | |

| Larissa | Control | 6.21 a | 24.9 a | 514 a | 12.20 a | 48.5 a | 72.5 a |

| CRF + Nitro | 6.25 a | 25.0 a | 510 a | 12.07 a | 49.0 ab | 75.0 a | |

| Nitro | 5.94 a | 26.2 a | 455 a | 12.02 a | 49.9 b | 77.7 a | |

| N0 | 4.71 b | 26.2 a | 369 b | 8.12 b | 48.7 a | 59.2 b | |

| ANOVA | |||||||

| Location (L) | *** | *** | *** | * | ns | ns | |

| Treatment (T) | * | ns | * | ** | ns | ** | |

| L × T | *** | *** | *** | ns | * | ns | |

| Location | Treatment | GPC (%) | Retention (>2.5 mm) | >2.8 mm | 2.5–2.8 mm | 2.2–2.5 mm | <2.2 mm |

|---|---|---|---|---|---|---|---|

| Livadia | Control | 9.37 a | 82.48 a | 55.35 | 27.13 | 12.14 a | 2.42 a |

| CRF + Nitro | 8.21 b | 88.99 b | 61.61 | 27.38 | 8.44 b | 0.96 b | |

| Nitro | 8.30 b | 88.02 b | 62.33 | 25.69 | 8.11 bc | 1.42 b | |

| N0 | 7.62 b | 89.26 b | 59.39 | 29.87 | 6.80 c | 1.10 b | |

| Larissa | Control | 11.20 a | 89.03 a | 70.84 | 18.19 | 7.03 a | 1.59 a |

| CRF + Nitro | 10.30 b | 90.19 ab | 69.14 | 21.06 | 7.08 a | 1.49 a | |

| Nitro | 9.90 b | 92.37 b | 77.87 | 14.51 | 5.33 b | 1.42 a | |

| N0 | 10.20 b | 89.44 a | 73.29 | 16.16 | 6.80 a | 1.90 a | |

| ANOVA | |||||||

| Location (L) | * | ns | ns | * | ns | ns | |

| Treatment (T) | * | ns | ns | ns | ns | ns | |

| L × T | ns | * | ns | ns | ** | * | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vahamidis, P.; Stefopoulou, A.; Kotoulas, V. Optimizing Sustainability in Malting Barley: A Practical Approach to Nitrogen Management for Enhanced Environmental, Agronomic, and Economic Benefits. Agriculture 2023, 13, 2272. https://doi.org/10.3390/agriculture13122272

Vahamidis P, Stefopoulou A, Kotoulas V. Optimizing Sustainability in Malting Barley: A Practical Approach to Nitrogen Management for Enhanced Environmental, Agronomic, and Economic Benefits. Agriculture. 2023; 13(12):2272. https://doi.org/10.3390/agriculture13122272

Chicago/Turabian StyleVahamidis, Petros, Angeliki Stefopoulou, and Vassilis Kotoulas. 2023. "Optimizing Sustainability in Malting Barley: A Practical Approach to Nitrogen Management for Enhanced Environmental, Agronomic, and Economic Benefits" Agriculture 13, no. 12: 2272. https://doi.org/10.3390/agriculture13122272

APA StyleVahamidis, P., Stefopoulou, A., & Kotoulas, V. (2023). Optimizing Sustainability in Malting Barley: A Practical Approach to Nitrogen Management for Enhanced Environmental, Agronomic, and Economic Benefits. Agriculture, 13(12), 2272. https://doi.org/10.3390/agriculture13122272