Abstract

Owing to its wealth of nutritional values and low cultivation requirements, millet can become a key crop in global food systems. Thus, the Food and Agriculture Organization (FAO) declared that 2023 is the International Year of Millet. The introduction of this cereal and its products into universal food circulation calls for a multidimensional approach, which would also consider threats posed by pests during the storage of cereal kernels. The aim of this study was to evaluate the development of the confused flour beetle (Tribolium confusum Duv.) on common millet (Panicum miliaceum L.) and products obtained from this cereal, and to analyze the factors which influence its development (chemical composition of kernels, degree of their fragmentation). The study was conducted under laboratory conditions in an environmental test chamber (temperature 30 °C, humidity 70%, light—complete darkness). Millet grains of the Jagna cultivar and its products were weighed at 20 g, placed in vinidur dishes, and 10 beetles were then placed on the prepared material. The experiment demonstrated that the millet grain and food products obtained from this grain (millet flour, flakes, groats) could be a suitable habitat for the development of the confused flour beetle. The key regulator for the development of this pest insect is the degree of fragmentation of the infested material. The millet grain and millet products (except millet flour) are characterized by less numerous developments of beetle progeny than wheat products, which could be another advantage of millet in an integrated international system of grain storage. Chemical analysis also showed a significant correlation between the abundance of offspring generation and the content of crude fat (especially linoleic acid—C 18:2). Knowledge of the resistance or susceptibility of millet to storage pests may be useful in implementing integrated principles of protection of stored products against pests.

1. Introduction

Food security in a time of global polycrisis is one of the most serious problems of the contemporary world and has grown considerably worse in the third decade of the 21st century [1,2]. It is estimated that in 2023 the number of people across the world suffering from famine will oscillate around 690–783 million [2]. Ongoing climate change (global warming, extreme weather events) and economic events (the COVID-19 pandemic, war in Ukraine) have significantly affected the global supply chain [3,4]. In view of the above, the Food and Agriculture Organization of the United Nations (FAO) is in search of alternative methods of combating famine, undernutrition, and diet-related diseases [2]. Within the measures dedicated to this goal, an important role is assigned to functional food, which—apart from basic nutritional values—has health-promoting properties [5,6]. Ancient plants, whose cropped acreage has shrunk as a result of agricultural reforms in favour of high-yielding cereals, such as rice and wheat, possess desirable genetic traits [7,8,9].

Cultivation and processing of common millet Panicum miliaceum L. aligns with the concept of a sustainable and food-safe future [10]. Its species-specific traits respond to current challenges: climatic (low carbon footprint) and ecological (lower demand for water, herbicides and insecticides than is needed by traditional cereal crops). This cereal can play a key role in international food production, solving the most urgent problems in global food production: economic (low financial inputs in the production process) and humanitarian issues (feeding people in agriculturally poor areas) [8,11,12,13]. Owing to its high nutritional values, millet is often called the nutri-cereal or nutritious cereal [14,15], and because of its large pro-health potential alongside its small cultivation acreage, millet is also referred to as an untapped crop [14].

Millet grain is an easily digestible, gluten-free cereal, characterized by a low glycemic index. Moreover, it also has high caloric value, while possessing a high profile of nutrients (including niacin, magnesium, potassium, copper, iron, zinc, calcium, B and K vitamins, and folic acid), which makes this cereal an ideal tool for combating famine [10,11,13,15,16,17].

In addition, millet is characterized by high tolerance to climate change, a short plant-growing season, and economical water management. To acknowledge its attributes, the Food and Agriculture Organization of the United Nations (FAO) has declared 2023 to be the International Year of Millet [2]. This initiative is intendent to stimulate public awareness concerning the values of millet and its possible cultivation, which could directly translate into the improvement of food and nutrition security throughout the world [18].

In the fight against hunger, not only the quantity but also the quality of produced cereals matters, both during cultivation and after, and during the storage of harvested grain. Because of the small area of cultivation of millet up to now, there is little information on pests foraging on this cereal [19]. Nor has the development of storage pest insects foraging on P. miliaceum been thoroughly investigated, which adds to the need to recognize the potential risks to millet grain at the grain storage stage.

The millet storage pests most often mentioned include Tribolium castaneum Herbst, T. confusum Duv., Sitophilus oryzae L., Corcyra cephalonica St., Cryptolestes ferrugineus St., Oryzaephilus surinamensis L., Sitophilus zeamais Motsch., and Ephestia cautella Walker [20]. One of the most noxious pests of stored cereal products is Tribolium confusum Duv. (Coleoptera: Tenebrionidae). This beetle feed mainly on damaged kernels and cereal products, therefore, it is also called the confused flour beetle. However, it can also be found when storing pea seeds, beans, nuts, dried fruits, and spices [20]. The losses caused by this beetle’s foraging behaviour extend beyond loss of the grain mass. This insect also contaminates the infested grain with its molts, excreta, and dead specimens. Moreover, during foraging, the confused flour beetle exudes toxic substances such as benzoquinones, which are then absorbed by the grain, rendering it unsuitable for consumption.

The aims of the study were:

- (I)

- to find out if millet is another cereal that can be a suitable food for T. confusum;

- (II)

- to check whether the development of T. confusum on products from millet grain depends more on the type of product (degree of fragmentation) or on the chemical composition of these products.

2. Materials and Methods

2.1. Materials

Entomological observations were carried out on kernels of common millet of the cultivar Jagna and of winter wheat of the cultivar Bamberka, and on products obtained from these cereals: groats, flakes, and flour. The tested millet originated from the conventional cultivation of this cereal conducted by the Smolice Plant Breeding Enterprise at its branch in Przebłędów (Przebłędów, Poland), and wheat kernels were obtained from the Bałcyny Experimental and Production Station Plc., affiliated with the University of Warmia and Mazury in Olsztyn (Bałcyny, Poland). The mechanical grinding of the kernels of both cereals to groats, flakes, and flour was done in an A11 Basic analytical mill, IKA (IKA-Werke GmbH & Co. KG, Staufen, Germany), Germany (University of Warmia and Mazury in Olsztyn). The entomological material (T. confusum) came from maternal breeding carried out on oat flakes with the addition of dried baker’s yeast [21] at the Department of Entomology, Phytopathology and Molecular Diagnostics, University of Warmia and Mazury in Olsztyn.

2.2. Bioassays

The experiment was carried out under laboratory conditions, in a SANYO MLR 351-H (Sanyo Electric Co. Ltd., Moriguchi, Japan) environmental test chamber with controlled humidity (70%), light (complete darkness), and temperature (30 °C) [22,23,24]. In order to reach the equilibrium value, the plant material was conditioned for 7 days before the experiment. Then, 20 g batches were weighed on a WPS 220/C/2 (RADWAG, Radom, Poland) laboratory balance and placed on vinidur plates with a diameter of 10 cm and height of 3 cm, fitted with a ventilation hole (10 mm) and secured with a chiffon mesh. 10 beetles (aged 14 days, in a 1:1 sex ratio) were placed on the plant material prepared as described above. The sex of the beetles was determined based on the shape of the external genital appendages [24]. The experiment was carried out with 10 replications for each treatment (Mf—millet flour; Wf—wheat flour; Mfl—millet flakes; Wfl—wheat flakes; Mg—millet groats; Wg—wheat groats; M—millet whole grain; W—wheat whole grain). After 23 days, all adult beetles were removed. The duration of the experiment was determined according to our own previous observations and studies on the development of the confused flour beetle. From day 30 of the experiment, every 7 days, adult beetles from the emerging progeny were counted and removed until all adult specimens were obtained. On the basis of this experiment, the abundance of the confused flour beetle’s progeny on the tested products was determined. After the experiment was completed, the remaining material was weighed, which enabled the determination of the loss of mass of each product tested and the mass of dust produced. A LABORSET ISO5223 (LABORSET, Łódź, Poland) series X01/10 sieve was used to determine the dust mass.

2.3. Physicochemical Properties of Grain

Values for the chemical parameters of millet and wheat were determined at the Department of Animal Nutrition and Feed Science, University of Warmia and Mazury in Olsztyn. The content of dry matter of the products analyzed was determined using a thermogravimetric technique. This consisted of drying a fragmented sample (5 g) at a temperature of 105 °C (5–8 h) until a constant mass was obtained. Crude ash was determined using a method consisting of burning an air-dry sample (5 g) in a muffle oven at a temperature of 500–550 °C for 5–6 h (determination of the mass of the sample before and after incineration). The content of total protein was assayed on the basis of the content of total nitrogen (N) determined using Kjeldahl’s method, and then converting the result into total protein (N × 6.25) (Polish Standard: PN–EN ISO 5983-1:2006). The content of crude fat was determined using the extraction method on a Soxhelt apparatus in line with the Polish Standard PN-ISO-6492:200 (Polish Standard: PN–ISO 6492:2005). The Henneberg–Stohmann method with intermediate filtration was used to determine the content of crude fibre in the cereals analyzed and their products (Polish Standard: PN–EN ISO 6865:2002). The content of starch was determined using the polarimetric method according to the Polish Standard PN-R-64785:1994. Finally, the content of WSCs (water-soluble carbohydrates) was determined according to the Polish Standard PN-R-64784:1994.

2.4. Statistical Analysis

The research data concerning the chemical composition of the analyzed cereal products and the development of the confused flour beetle (abundance of the offspring generation, mass of produced dust, and loss of the mass of grain) on the tested products made from millet and wheat (flour, flakes, groats, and whole kernels) were submitted to an analysis of distribution using the Shapiro–Wilk test. The results of this test showed that these data did not follow normal distribution. Hence, they underwent logarithmic transformation (ln x + 1), and the assessment of the significance of differences between the variables from the combinations with the cereal cultivars was based on a one-factorial analysis of variance ANOVA. Groups of means of the analyzed parameters related to the development of T. confusum, not statistically different, were denoted with the same letter index, a, b, c, d and e and were analyzed using the HSD Tukey test. Differences between the analyzed millet products and wheat kernels regarding their chemical composition were demonstrated via nonmetric multidimensional scaling (NMDS) using the Bray–Curdis measure of similarity. The graphic evaluation of dependence between the chemical composition of the tested products, the degree of their fragmentation, and the number of the offspring generation for T. confusum was achieved using ordinance techniques [25]. RDA (Redundancy Analysis) was applied, and the length of the gradient was SD = 0.3. The same method (SD = 0.99) was also employed to determine the dependence between the content of fatty acids in the analyzed millet and wheat products and the number of progenies of T. confusum. All statistical calculations and their visual interpretation were supported by the following software: Statistica 13.1, Canoco 4.51, and Past 2.01.

3. Results

The ANOVA one-factorial analysis of variance revealed the significance of difference between the means describing the T. confusum development parameters (progeny, loss of mass, and mass of dust) growing on products obtained from the processing of millet and wheat (Table 1).

Table 1.

Results of one-factorial analysis of variance, ANOVA, for the tested T. confusum development parameters (progeny, loss of mass, and mass of dust) in total on the tested millet and wheat products.

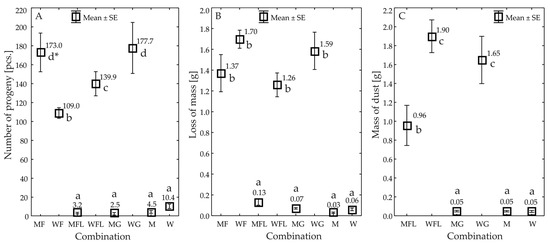

Analysis of the development of T. confusum on products from the two-cereal species indicated that the beetle developed similarly (the same homogenous group, the HSD Tukey test) only on the combinations of whole millet grain and whole wheat grain. The mean number of progenies of this pest was 4.5 and 10.4 individuals, respectively (Figure 1A).

Figure 1.

Comparison of development parameters (number of progeny—(A), loss of mass—(B) and mass of dust—(C) of T. confusum developing on millet and wheat products. (Mf—millet flour; Wf—wheat flour; Mfl—millet flakes; Wfl—wheat flakes; Mg—millet groats; Wg—wheat groats; M—millet whole grain; W—wheat whole grain) (* means followed by the same letter do not differ).

Products made from the tested cereals had a significant effect on the number of progenies of T. confusum (Table 1). A higher number of progenies was found on the combination composed of millet flour (173.0 individuals on average) than on those composed of wheat flour (109.0 individuals). The higher granulation of products (groats, flakes) resulted in more numerous progeny individuals of T. confusum on wheat products. Wheat groats were determined to be infested by the highest number of T. confusum progeny individuals in the entire experiment (177.7 individuals on average, while only 2.5 individuals of this pest completed their development on millet groats (Figure 1A). On average, 3.2 individuals completed their development on millet flakes, compared to an average of 139.9 individuals on wheat flakes (Figure 1A).

The T. confusum beetles developed on the tested millet and wheat products invariably ate more food than those on the combinations with wheat (Figure 1B). Significant differences in this parameter were noted in the combination with flakes (millet: 0.13 g and wheat: 1.26 g on average) and with groats (millet: 0.07 g and wheat: 1.59 g on average). No significant differences were observed in the loss of mass of the products from both cereals in the combination with flour and on whole kernels (Figure 1B).

The factor of the species of cereal did not significantly affect the mass of dust produced during the foraging by the confused flour beetle on whole kernels. When developing on whole grains of millet or wheat, this pest insect generated a similar amount of dust—0.05 g on average (Figure 1C). A significantly higher mass of dust was found on flakes and groats made from wheat (flakes: 1.90 g and groats: 1.65 g on average) than from millet (flakes: 0.96 g and groat: 0.05 g on average) (Figure 1C).

An analysis of the chemical composition of the tested millet and wheat grain products was made, determining the % of dry matter, crude ash, total protein, crude fat and fibre, starch, and WSCs. The analyzed products were characterized by significant differences in the content of these ingredients (Table 2).

Table 2.

Results of statistical analyses (ANOVA) for selected chemical properties of the tested products.

Millet flakes proved to be the product, relative to the others, with the lowest percentages of crude ash (0.49%), total protein (9.58%), crude fat, and fibre (0.15%, 0.63%). This product was also found to have the highest dry matter (88.68%) and starch content (70.17%) (Table 3).

Table 3.

Mean values of the tested chemical parameters describing the selected products from millet and from cv. Bamberka wheat.

Millet grain, in turn, was distinguished by the highest content of crude ash (1.96%), total protein (14.18%), and crude fibre (6.69%). Wheat kernels were found to contain the highest percentages of WSCs (3.75%) and total protein (14.37%) (Table 3).

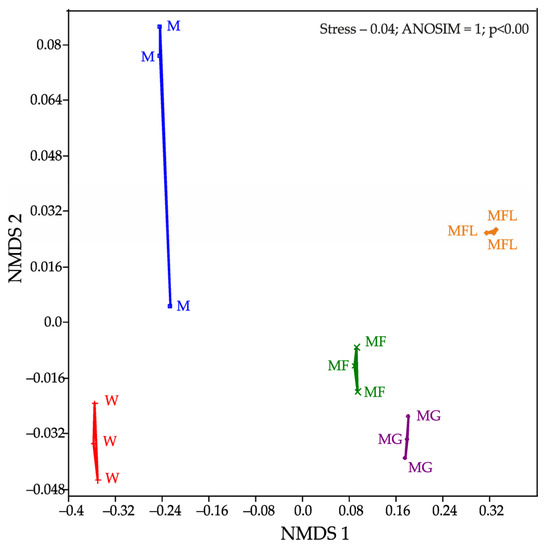

In order to verify similarities between the tested millet products and wheat grain products concerning their chemical composition, a nonmetric multidimensional scaling (NMDS) analysis was carried out (Figure 2).

Figure 2.

NMDS diagram describing similarities of the tested grain products with respect to chosen chemical characteristics. (Mf—millet flour; Mfl—millet flakes; Mg—millet groats; M—millet whole grain; W—wheat whole grain).

The ordinance diagram displays the tested products and distances between them indicate whether they differed significantly in relation to the analyzed chemical properties. These differences were also confirmed by ANOSIM analysis, which is a nonparametric test that determines similarity between groups of characteristics (Stress = 0.04, R = 1, p < 0.00) (significant difference between sampling units). The grain of the millet and wheat as well as millet flakes are placed in this diagram at quite large distances from one another, suggesting that these products are different in chemical composition. On the other hand, millet flour and millet flakes, located in the right-hand lower corner of the ordinance diagram, are similar to each other in this respect (Figure 3).

Figure 3.

Redundancy analysis diagram (RDA) presenting correlations between selected factors influencing the development of T. confusum (number of progeny and degree of grain fragmentation) and the chemical characteristics of tested grain products. (Mf—millet flour; Mfl—millet flakes; Mg—millet groats; M—millet whole grain; W—wheat whole grain).

For more precise determination of the correlations between the chemical composition of the products and the development of T. confusum, ordinance techniques, using the RDA (redundance analysis) (SD = 0.3), were used (Figure 3).

The determined chemical composition of the tested products from millet and wheat grains was submitted to an evaluation of dependences on the factors that describe the intensity of the development of T. confusum (number of progeny) and the degree of fragmentation of the products. The first ordinance axis, referring to 96% of the variance, correlated with a high content of starch and dry matter in the tested products. The second ordinance axis was strongly correlated with the high number of progeny of T. confusum, found on the combination consisting of millet flour. Another strong correlation identified here was that between the number of progeny of the pest insect and the content of crude fat. Combinations with millet grain and wheat grain are located close to each other, in the left-hand lower quadrant of the ordinance diagram. Vectors describing high content of crude fibre and WSCs in these products strongly correlated with these combinations (Figure 3).

The strong correlation between a higher content of crude fats with the number of progeny individuals of T. confusum served as the basis for a more precise analysis of these substances in terms of their chemical composition and the content of these substances. The results, shown in Table 4, demonstrate that the group of crude fats contained 14 acids of different lengths of carbon chains.

Table 4.

Mean content of fatty acids in tested grain products (in % of sum of fatty acids).

The tested products contained the highest amounts of linoleic (C 18:2), oleic (C 18:1), and palmitic acids (C 16:0). Linoleic acid occurred in the highest quantity in millet grain and flour (71.6% and 70.94%, respectively) (Table 4). Millet flakes, on the other hand, contained more oleic (44.32%) and palmitic (26.34%) acids than the other tested products. In order to determine relationships between the content of fatty acids in the tested products and the development of T. confusum, another redundancy analysis (RDA) was run, the results of which are shown in Figure 4. The fatty acid which appears in a large number of the tested products and may have a positive influence on the development of T. confusum is linoleic acid (C 18:2). Some evidence supporting this finding can be found in the RDA ordinance diagram. The vector describing the above relationship is situated in the right-hand lower quadrant of the ordinance diagram, and strongly correlates with its first axis (Figure 4).

Figure 4.

RDA diagram illustrating dependences between the composition of fatty acids in the tested products from millet versus the progeny of T. confusum. (Mf—millet flour; Mfl—millet flakes; Mg—millet groats; M—millet whole grain; W—wheat whole grain).

On the opposite side of the diagram (left-hand upper quadrant), there is the combination of millet flakes, where the content of linoleic acid was the lowest among the tested products. The analyzed RDA diagram attests to the previous observations, which suggest that the degree of fragmentation of cereal products is the most significant factor influencing the abundance of progeny of T. confusum (Figure 4).

4. Discussion

The problem of famine throughout the world does not only arise from the shortage of food. Nearly a third of the food produced (1.3 billion tons) is wasted or spoiled [2,26,27,28]. In total, 80% of plant food across the world is produced from cereals and papilionaceous plants, whose post-harvest handling is associated with losses in the order of 9–18% [2,29]. The loss of stored plant material only during the storage stage can oscillate within 6–10%, and such losses in countries with a low plant cultivation culture can be very high, sometimes reaching 50% of harvested yields [29,30,31].

The high yielding and multidimensional nutritional advantages of millet can be obliterated by losses that occur while storing millet kernels [32]. Panicum miliaceum is a cereal plant, which is why the list of pests typical for cereal crops, which threaten it both during the field cultivation and the storage of millet kernels, is theoretically very long [33,34]. Because of its low popularity, the development of pests directly foraging on millet has not been completely investigated [35].

The confused flour beetle is a cosmopolitan species, considered to be among the most widespread pests of stored cereal products, including those produced from millet [36]. The aim of this study was to determine the potential of P. miliaceum grains and products made from millet as habitats for the development of this pest. The vulnerability of cereals to foraging by storage pests is evaluated by analyzing the size of a progeny population of the pest developing on given plant material, which is direct evidence of its attractiveness to pests [37,38]. In our experiment, the abundance of progeny, mass of produced dust, and loss of grain mass showed statistically significant differences among the tested products (millet and wheat). The dynamics of the development of T. confusum on other cereal species mainly depends on the type of infested food and the degree of its grinding [33,39,40], and its development can be slowed down by ensuring controlled abiotic conditions at the storage stage (low temperature and humidity) [24]. The confused flour beetle is classified as a secondary pest, not penetrating intact kernels of cereals [23,41]. Hence, the confused flour beetle dwells mainly on moist (loss of the hardness of the seed cover), damaged (mechanically or due to foraging by primary pests), or processed grain [32,36]. This was confirmed in our study, which demonstrated the beetle’s limited development rate on whole kernels of millet and wheat, remaining on a comparably lower level. The effect of the seed cover hardness on the foraging by the confused flour beetle, as a factor that could shape the attractiveness of this food, was the subject of previous studies [41]. In our experiment, it was shown that the millet’s seed cover, being harder than that of wheat [20], could have slightly affected the preferences of the confused flour beetle.

The direct effect of the development of the confused flour beetle is the loss of mass of the product on which this pest forages [39]. Compared to wheat and wheat products, in all experimental combinations millet was characterized by a lower loss of grain mass. Lower losses directly translate into the quality of the food that enters the food market, and consequently improve food security. Moreover, as regards millet products, the mass of dust produced due to the foraging by T. confusum was lower, which has an influence on the quality of stored products. The high concentration of dust in warehouses may lead to inadequate aeration of stored material, and therefore be conducive to the development of mould [37].

Apart from the grain form, processed food products from millet, such as flour, flakes, and groats, are available on the market. The main factor that affects the analyzed pest is the degree of fragmentation of the infested plant material [24,39,40]. The confused flour beetle develops best on a fraction less than 2.2 mm, which is why it is often referred to as “a flour beetle”. The survivability on the fraction oscillates around 95–100% [39]. Preferences of this pest have been confirmed by our study. The finest fraction of millet (millet flour) enabled the most intensive development of this beetle.

The chemical composition of kernels of both cereal species (and their products) can differ from one another to a large degree, but such differences can be a factor that is both attracting and deterring storage pests [38,42,43,44]. The tested products (millet, wheat) were also characterized by differentiated chemical composition. Chemical analyses of cereal products settled by storage pests made in earlier studies have revealed a correlation between the development of such pests and the content of protein in the products [30,38,43]. Astuti et al. [45] demonstrated a significant impact of the protein content of floury products on the survival rate and duration of the development of Tribolium castaneum. In our study, the highest content of protein was determined in whole kernels of wheat and millet, but also in millet flour, that is, the combinations with the greatest and smallest fraction. Warchlewski [37] maintains that the main factor shaping the feeding preferences of the confused flour beetle is the starch content. Higher concentrations of starch in all millet products compared to wheat products were noted, which nevertheless did not have a direct impact on the abundance of progeny of the beetle. The high number of confused flour beetle individuals in millet flour may depend on the highest content of crude fibre among all tested combinations, and this included linoleic acid. The positive correlation between the intensive development of storage pests and the content of fat in infested kernels has already been the subject of research [30,38,46]. Our earlier observations on Sitophilus granarius L. showed a positive correlation between the intensity of the development of this beetle species with the content of crude fat in kernels [38,44]. According to observations reported by Warchlewski [37], starch is the key ingredient affecting the development of this beetle, although the current study has revealed that this is a more complex process. When the stored plant material is rich in starch, a subsequent factor influencing feeding preferences of T. confusum could be another ingredient, e.g., fats. Millet flour, because of the degree of its fragmentation and chemical composition, is an ideal habitat for the confused flour beetle, which is why millet flour can be infested by this beetle species during its storage [47]. The chemical composition of cereal products can affect the feeding preferences of pest insects, although the dominant factor for T. confusum is the degree of fragmentation of stored grains or grain products.

Chemical factors of millet grain and its products may be related to its natural resistance to feeding by storage pests. Knowledge of these relationships can be used by millet breeders and distributors. This may also result in lower consumption of chemicals at the storage stage. This will result in greater nutritional value and food security, as well as environmental protection. Therefore, research on the natural resistance of millet should be conducted in a broader context, including its chemical composition, which will be the subject of our further research.

5. Conclusions

Our study showed that stored millet grain is not a good habitat for the development of T. confusum and the degree of fragmentation of millet products is the most important factor affecting the number of progeny individuals. Moreover, it has been shown that during storage, millet flour can be exposed to risk of losses due to foraging by this pest beetle. Among the chemical factors influencing the abundance of progeny of T. confusum, an elevated concentration of crude fats may play a role. Among the fatty acids in the tested products, the compound whose increased concentration has a positive effect on the number of the confused flour beetle’s progeny was linoleic acid (C 18:2).

Author Contributions

Validation, conceptualisation, methodology software, formal analysis, writing—review and editing M.N.; writing—original draft preparation, conceptualisation, methodology E.L.; validation, conceptualisation, methodology, formal analysis B.K.; validation, conceptualisation, methodology, formal analysis B.G.; validation, conceptualisation, methodology, formal analysis A.L.-D.; validation, methodology, formal analysis C.P. All authors have read and agreed to the published version of the manuscript.

Funding

The results presented in this paper were obtained as a part of comprehensive study financed by the University of Warmia and Mazury in Olsztyn, Faculty of Agriculture and Forestry, Department of Entomology Phytopathology and Molecular Diagnostics, no 30.610.010-110. Project financially supported by the Minister of Education and Science under the program entitled “Regional Initiative of Excellence” for the years 2019–2023, Project No. 010/RID/2018/19, amount of funding 12.000.000 PLN.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The development data for T. confusum presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kozłowska-Burdziak, M. Warunki Bezpieczeństwa Żywnościowego Polski (Ze Szczególnym Uwzględnieniem Województwa Podlaskiego). Optim. Econ. Stud. 2019, 3, 33–48. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations World Food Situation. Available online: https://www.fao.org/home/en (accessed on 21 August 2023).

- Rabbi, M.F.; Ben Hassen, T.; El Bilali, H.; Raheem, D.; Raposo, A. Food Security Challenges in Europe in the Context of the Prolonged Russian–Ukrainian Conflict. Sustainability 2023, 15, 4745. [Google Scholar] [CrossRef]

- Rezvi, H.U.A.; Tahjib-Ul-Arif, M.; Azim, M.A.; Tumpa, T.A.; Tipu, M.M.H.; Najnine, F.; Dawood, M.F.A.; Skalicky, M.; Brestič, M. Rice and Food Security: Climate Change Implications and the Future Prospects for Nutritional Security. Food Energy Secur. 2022, 12, e430. [Google Scholar] [CrossRef]

- Dixit, V.; Joseph Kamal, S.W.; Bajrang Chole, P.; Dayal, D.; Chaubey, K.K.; Pal, A.K.; Xavier, J.; Manjunath, B.T.; Bachheti, R.K. Functional Foods: Exploring the Health Benefits of Bioactive Compounds from Plant and Animal Sources. J. Food Qual. 2023, 2023, 5546753. [Google Scholar] [CrossRef]

- Balli, D.; Bellumori, M.; Masoni, A.; Moretta, M.; Palchetti, E.; Bertaccini, B.; Mulinacci, N.; Innocenti, M. Proso Millet (Panicum miliaceum L.) as Alternative Source of Starch and Phenolic Compounds: A Study on Twenty-Five Worldwide Accessions. Molecules 2023, 28, 6339. [Google Scholar] [CrossRef] [PubMed]

- Cooper, R. Re-Discovering Ancient Wheat Varieties as Functional Foods. J. Tradit. Complement. Med. 2015, 5, 138–143. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, T.; Vyas, S. From Ancient Grains to Modern Solutions: A History of Millets and Their Significance in Agriculture and Food Security. Int. J. Home Sci. 2023, 9, 72–78. [Google Scholar]

- Motuzaitė Matuzevičiūtė, G.; Laužikas, R. A Brief History of Broomcorn Millet Cultivation in Lithuania. Agronomy 2023, 13, 2171. [Google Scholar] [CrossRef]

- Dayakar Rao, B.; Malleshi, N.G.; Annor, G.A.; Patil, J.V. Nutritional and Health Benefits of Millets; ICAR—Indian Institute of Millets Research: Hyderabad, India, 2017; ISBN 8189335685. [Google Scholar]

- Das, S.; Khound, R.; Santra, M.; Santra, D.K. Beyond Bird Feed: Proso Millet for Human Health and Environment. Agriculture 2019, 9, 64. [Google Scholar] [CrossRef]

- Oleszczuk, M. Spider Fauna (Araneae) of the Sieraków Landscape Park (Central Poland)—Preliminary Data. Fragm. Faun. 2017, 60, 53–60. [Google Scholar] [CrossRef]

- Habiyaremye, C.; Matanguihan, J.B.; D’Alpoim Guedes, J.; Ganjyal, G.M.; Whiteman, M.R.; Kidwell, K.K.; Murphy, K.M. Proso Millet (Panicum miliaceum L.) and Its Potential for Cultivation in the Pacific Northwest, U.S.: A Review. Front. Plant Sci. 2017, 7, 1961. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Tripathi, M.K.; Joshi, D.; Kumar, V. Millets and Millet Technology; Springer: Singapore, 2021; ISBN 9789811606762. [Google Scholar]

- Poshadri, A.; Deshpande, H.; Kshirsagar, R. The International Year of Millets-2023, Millets as Nutri-Cereals of 21st Centenary for Health and Wellness Value Addition to Millets View Project Spices, Tastemakers and Seasonings View Project Poshadri Achinna. Agric. Assoc. Text. Chem. Crit. Rev. J. 2023, 7–12. [Google Scholar]

- Hassan, Z.M.; Sebola, N.A.; Mabelebele, M. The Nutritional Use of Millet Grain for Food and Feed: A Review. Agric. Food Secur. 2021, 10, 16. [Google Scholar] [CrossRef]

- Reddy, V.G.; Upadhyaya, H.D.; Gowda, C.L.L. Morphological Characterization of World’s Proso Millet Germplasm Collection. J. SAT Agric. Res. 2007, 3, 1–4. [Google Scholar]

- Panigrahy, A.; Padhi, M. The International Year of Millets 2023: A Multi-Dimensional Opportunity for India. World J. Biol. Pharm. Health Sci. 2023, 15, 122–127. [Google Scholar] [CrossRef]

- Lamparski, R.; Rolbiecki, R.; Piesik, D. Wpływ Nawaniania i Nawożenia Azotowego Prosa Odmiany Gierczyckie Na Występowanie Fitofagicznej Entomofauny. Infrastruktura i Ekologia Terenów Wiejskich 2013, 1/II, 123–131. [Google Scholar]

- Kubasiak, W.; Strażyński, P.; Mrówczyński, M. Metodyka Integrowanej Ochrony Prosa Dla Doradców; Plant Protection Institute–National Research Institute: Poznań, Poland, 2018; ISBN 9788364655258. [Google Scholar]

- Khalequzzaman, M.; Khatun, M.; Talukdar, D. Growth of Tribolium confusum Duv. on wheat flour with various yeast levels. Int. Pest Control 1994, 36, 128–130. [Google Scholar]

- Park, T.; Burton, M. The Fecundity and Development of the Flour Beetles, Tribolium confusum and Tribolium Castaneum, at Three Constant Temperatures. Ecology 1948, 29, 368–374. [Google Scholar] [CrossRef]

- Gołębiowska, Z.; Nawrot, J.; Prądzyńska, A. Studia Nad Szkodliwością Kilku Gatunków Chrząszczy Żerujących Na Ziarnie Zbóż. Pr. Nauk. Inst. Ochr. Rosl. 1976, XVIII, 49–87. [Google Scholar]

- Howe, R.W. The Effects of Temperature and Humidity on the Rate of Development and the Mortality of Tribolium confusum Duval (Coleoptera, Tenebrionidae). Ann. Appl. Biol. 1960, 48, 363–376. [Google Scholar] [CrossRef]

- Ter Braak, C.J.R.; Smilauer, P. CANOCO Reference Manual and User’s Guide to Canoco for Windows: Software for Canonical Community Ordination (Version 4); Microcomputer Power: Ithaca, NY, USA, 1998. [Google Scholar]

- Nicastro, R.; Carillo, P. Food Loss and Waste Prevention Strategies from Farm to Fork. Sustainability 2021, 13, 5443. [Google Scholar] [CrossRef]

- Sawicka, B. Post-Harvest Losses of Agricultural Produce. In ero Hunger. Encyclopedia of the UN Sustainable Development Goals; Leal Filho, W., Azul, A., Brandli, L., Özuyar, P., Wall, T., Eds.; Springer Nature: Chem, Switzerland, 2019. [Google Scholar]

- Abdullahi, N.; Dandago, M.A. Postharvest Losses in Food Grains—A Review. Turk. J. Food Agric. Sci. 2021, 3, 25–36. [Google Scholar] [CrossRef]

- Stathas, I.G.; Sakellaridis, A.C.; Papadelli, M.; Kapolos, J.; Papadimitriou, K.; Stathas, G.J. The Effects of Insect Infestation on Stored Agricultural Products and the Quality of Food. Foods 2023, 12, 2046. [Google Scholar] [CrossRef] [PubMed]

- Mebarkia, A.; Rahbé, Y.; Guechi, A.; Bouras, A.; Makhlouf, M.; Sciences, F.; Insa, I.; Biology, F.; Pasteur, B.L.; Mebarkia, C.A. Susceptibility of Twelve Soft Wheat Varieties (Triticum aestivum) to Sitophilus granarius (L.) (Coleoptera: Curculionidae). Agric. Biol. J. N. Am. 2010, 1, 571–578. [Google Scholar]

- Ikegwu, T.; Ezegbe, C.; Okolo, C.; Ofoedu, C. Postharvest Preservation Technology of Cereals and Legumes. In Postharvest Technology—Recent Advances, New Perspectives and Applications; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Chava, N.R.; Nebapure, S.; Thakur, S. Pests and Diseases of Millets 3. In Pest Management Strategies in Pulses and Cereal Crops; KD Publishers: Delhi, India, 2023; pp. 25–38. ISBN 9788119149063. [Google Scholar]

- Trematerra, P.; Sciarreta, A.; Tamasi, E. Behavioural Responses of Oryzaephilus Surinamensis, Tribolium Castaneum and Tribolium confusum to Naturally and Artificially Damaged Durum Wheat Kernels. Entomol. Exp. Et Appl. 2000, 94, 195–200. [Google Scholar] [CrossRef]

- Mahendra, K.R.; Anokhe, A.; Thakur, S. A Brief Overview of Nutri-Millet’s Insect Pests and Their Management. Indian Farming 2023, 73, 17–20. [Google Scholar]

- Sharma, H.C.; Ashok, A.S.; Ravinder, R.C.; Jayaraj, K.; Varaprasad, V.J.; Varaprasad Reddy, K.M.; Belum, V.S.; Rai, K.N. Management of Sorghum and Pearl Millet Pests in Bulk Storage: Global Theme on Crop Improvement; International Crops Research Institute for the Semi-Arid Tropics: Patancheru, India, 2007. [Google Scholar]

- Banga, K.S.; Kumar, S.; Kotwaliwale, N.; Mohapatra, D. Major Insects of Stored Food Grains. Int. J. Chem. Stud. 2019, 8, 2380–2384. [Google Scholar] [CrossRef]

- Warchlewski, J.R.; Gralik, J.; Nawrot, J. Możliwości Zmniejszania Powodowanych Przez Szkodniki Owadzie Strat Magazynowanego Ziarna Zbóż. Zesz. Probl. Postępów Nauk Rol. 2000, 47, 85–96. [Google Scholar]

- Kordan, B.; Nietupski, M.; Ludwiczak, E.; Gabryś, B.; Cabaj, R. Selected Cultivar-Specific Parameters of Wheat Grain as Factors Influencing Intensity of Development of Grain Weevil Sitophilus granarius (L.). Agriculture 2023, 13, 1492. [Google Scholar] [CrossRef]

- Laszczak-Dawid, A.; Ciepielewska, D.; Kosewska, A. Rozwój Populacji Trojszyka Ulca Tribolium confusum (Duv.) Na Ziarnie Wybranych Odmian Pszenicy O Zróżnicowanej Wielkości. Pamięt. Puławski 2010, 152, 153–161. [Google Scholar]

- Laszczak-Dawid, A.; Ciepielewska, D.; Kosewska, A. Zdolności Adaptacyjne Tribolium confusum Zasiedlającego Odmiany Pszenicy o Zróżnicowanej Jakości Technologicznej Ziarna. Prog. Plant Prot./Postępy W Ochr. Roślin 2010, 50, 1–4. [Google Scholar]

- Kordan, B.; Gabryś, B.; Załuski, D.; Zdunowski, K. Podatność Wybranych Gatunków Zbóż Na Żerowanie Trojszyka Ulca (Tribolium confusum DUV.). Prog. Plant Prot./Postępy W Ochr. Roślin 2011, 51, 1559–1562. [Google Scholar]

- Ajayi, E.O.; Oladipupo, S.O.; Ajisafe, O. Influence of Processing and Substrate Variety on Survival and Development of Tribolium confusum (Coleoptera: Tenebrionidae). Arch. Phytopathol. Plant Prot. 2019, 52, 356–370. [Google Scholar] [CrossRef]

- Wong, N.; Chow-Yang, L. Relationship Between Population Growth of the Red Flour Beetle Tribolium Castaneum and Protein and Carbohydrate Content in Flour and Starch. J. Econ. Entomol. 2011, 104, 2087–2094. [Google Scholar] [CrossRef]

- Nietupski, M.; Ludwiczak, E.; Cabaj, R.; Purwin, C.; Kordan, B. Fatty Acids Present in Wheat Kernels Influence the Development of the Grain Weevil (Sitophilus granarius L.). Insects 2021, 12, 806. [Google Scholar] [CrossRef]

- Astuti, L.P.; Rizali, A.; Firnanda, R.; Widjayanti, T. Physical and Chemical Properties of Flour Products Affect the Development of Tribolium Castaneum. J. Stored Prod. Res. 2020, 86, 101555. [Google Scholar] [CrossRef]

- Niewiada, A.; Nawrot, J.; Szafranek, J.; Szafranek, B.; Synak, E.; Jeleń, H.; Wa̧sowicz, E. Some Factors Affecting Egg-Laying of the Granary Weevil (Sitophilus granarius L.). J. Stored Prod. Res. 2005, 41, 544–555. [Google Scholar] [CrossRef]

- Gueye, M.T.; Delobel, A. Relative Susceptibility of Stored Pearl Millet Products and Fonio to Insect Infestation. J. Stored Prod. Res. 1999, 35, 277–283. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).