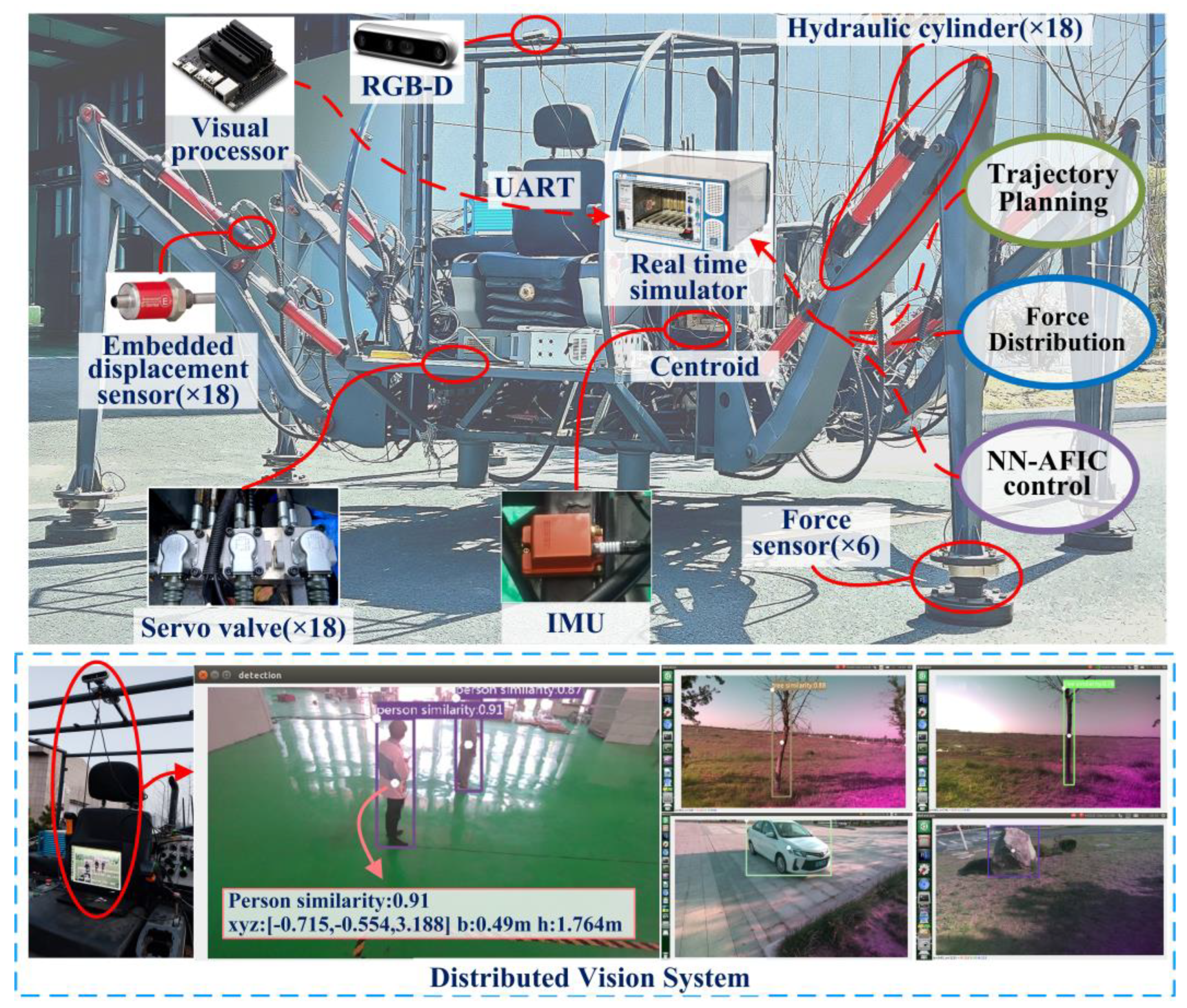

Motion-Control Strategy for a Heavy-Duty Transport Hexapod Robot on Rugged Agricultural Terrains

Abstract

:1. Introduction

- (1)

- A terrain-adaptive motion strategy was proposed, one which improves the stability of the robot’s motion process by estimating the angle of the support surface on the current terrain, setting up corresponding reaction mechanisms, and analyzing the energy consumption of different positions on the same support surface to select the most energy-efficient motion posture.

- (2)

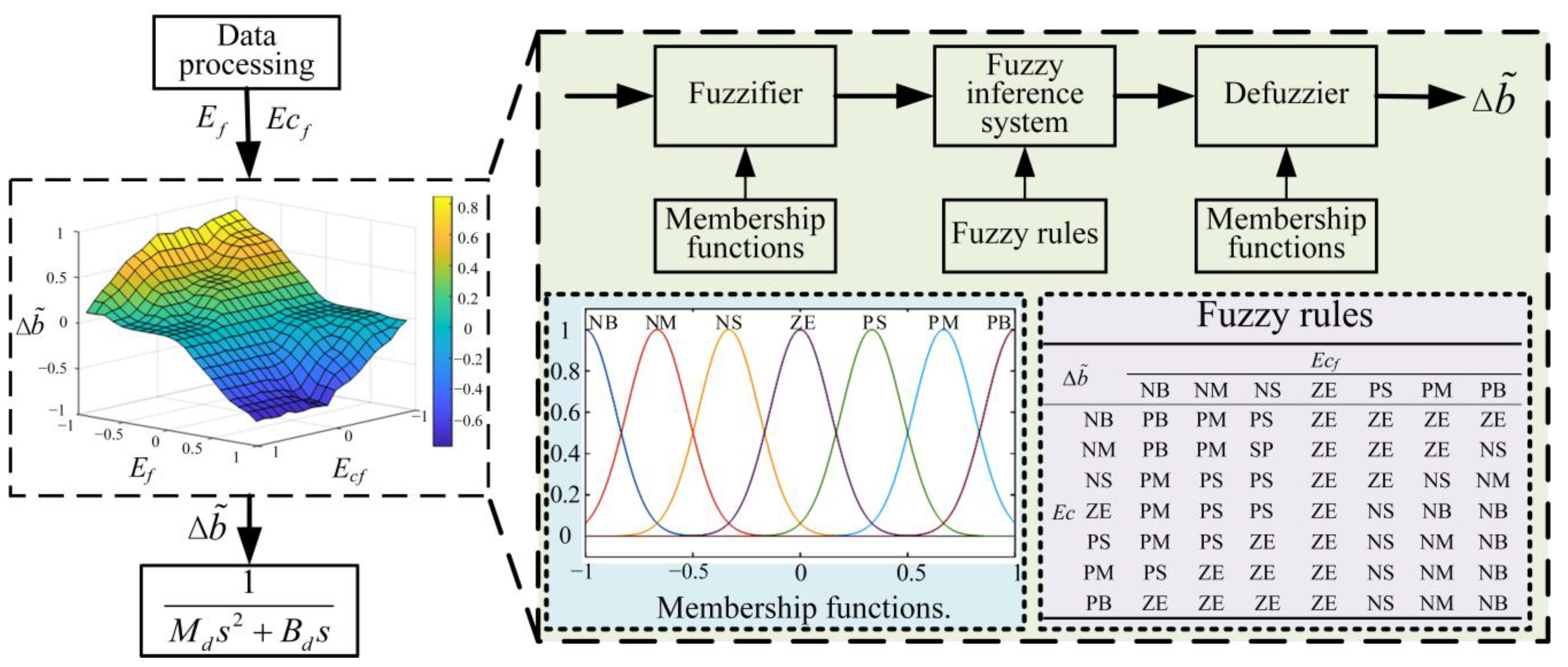

- The contact force dynamics were used to describe the influence of parameters such as environmental stiffness on the impedance model, and an adaptive fuzzy impedance control strategy based on force–position control was proposed to mitigate the impact of the external environment on impedance control.

- (3)

- The efficacy of the proposed control strategy in complex environments was verified through comparative experiments.

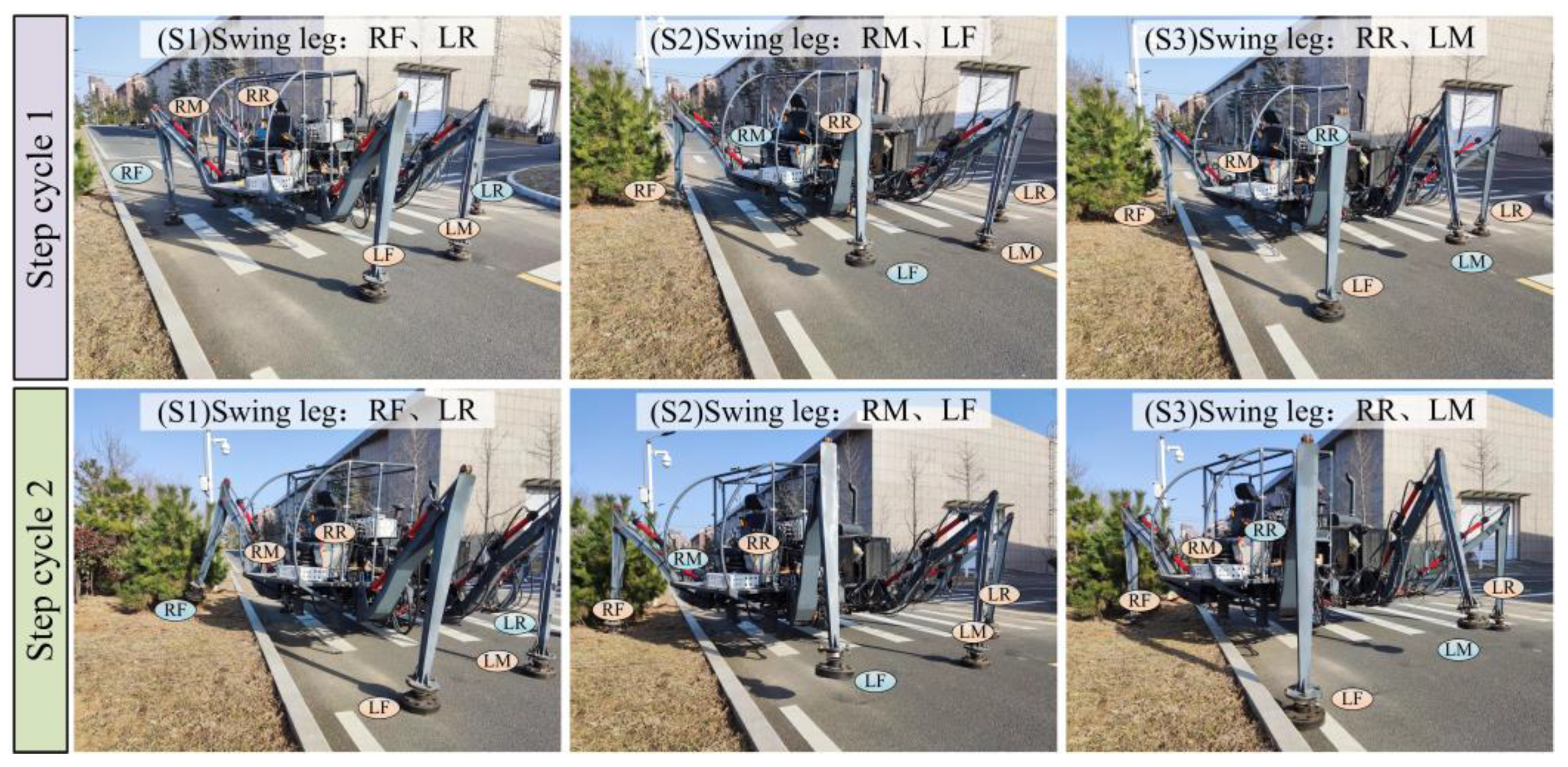

2. Terrain-Adaptive Methods

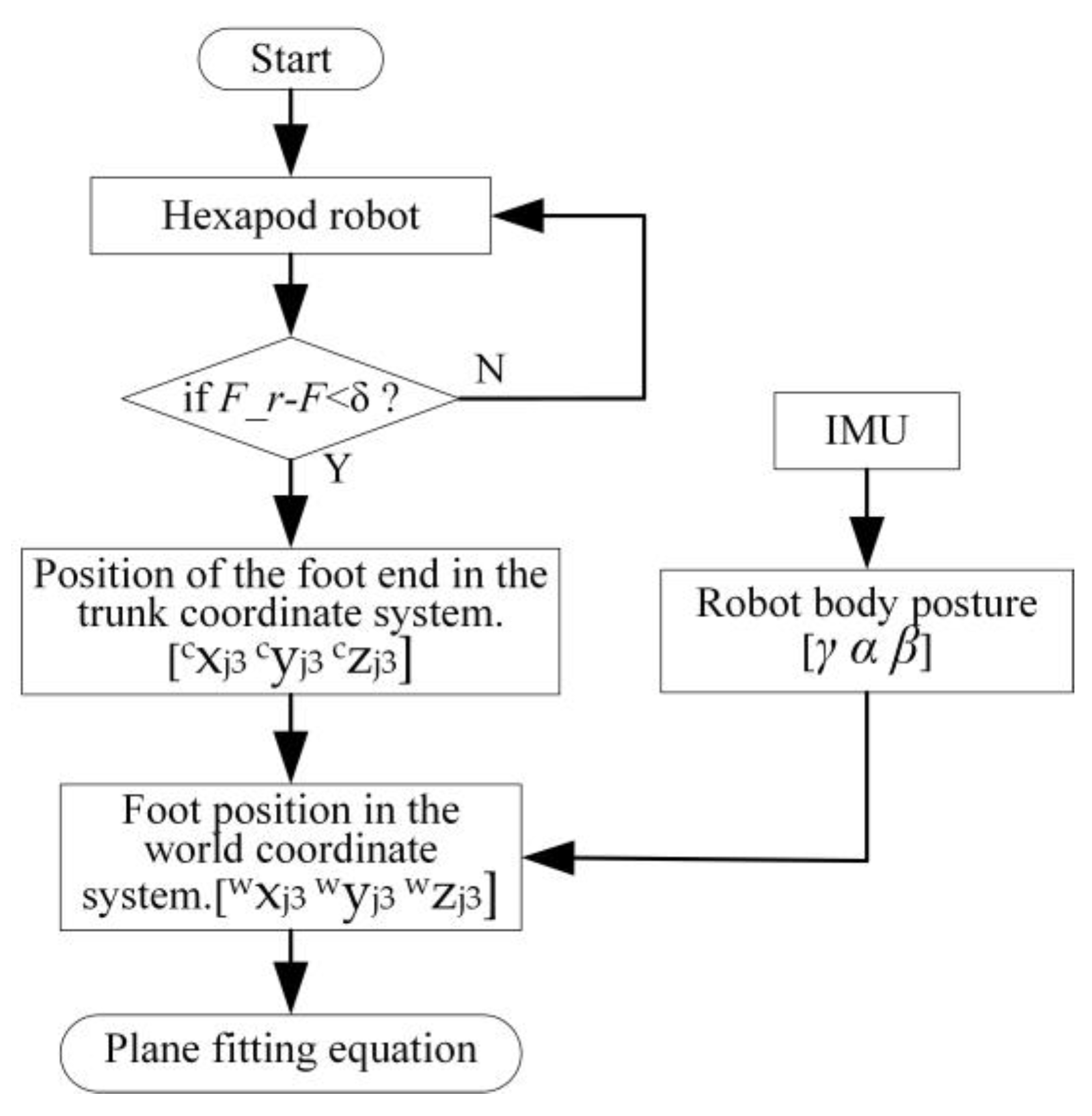

2.1. Terrain Estimation

2.2. Attitude Adaptive Adjustment

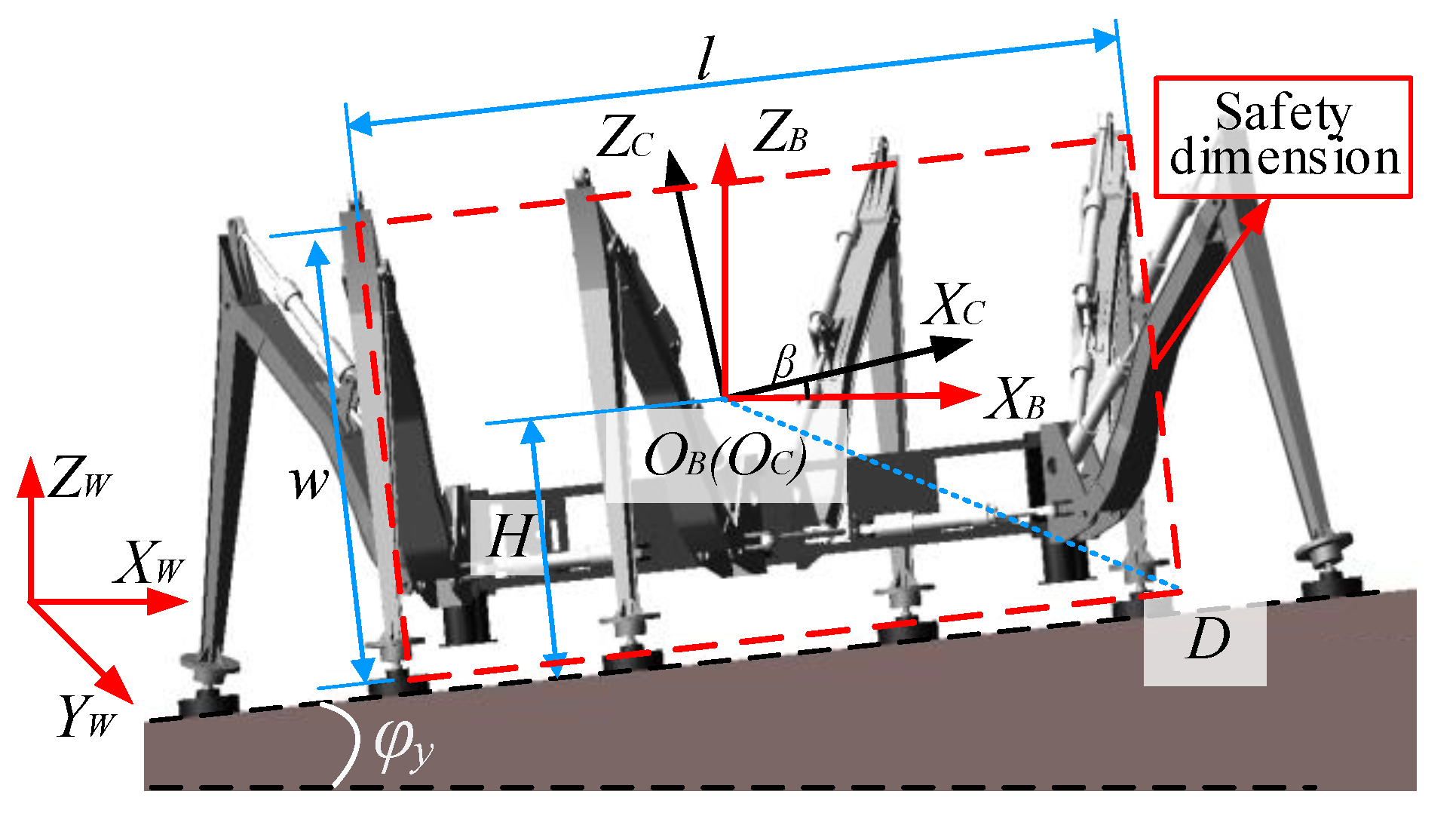

2.2.1. Torso Safety Dimension Constraints

2.2.2. Stability Constraints on Inclined Terrain

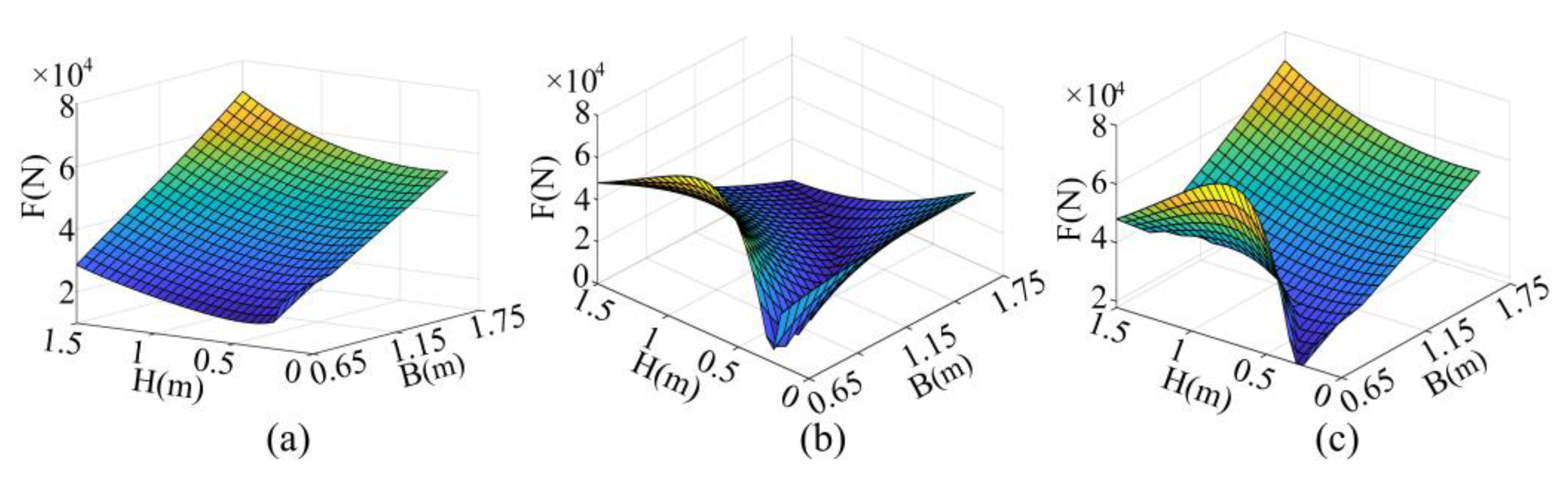

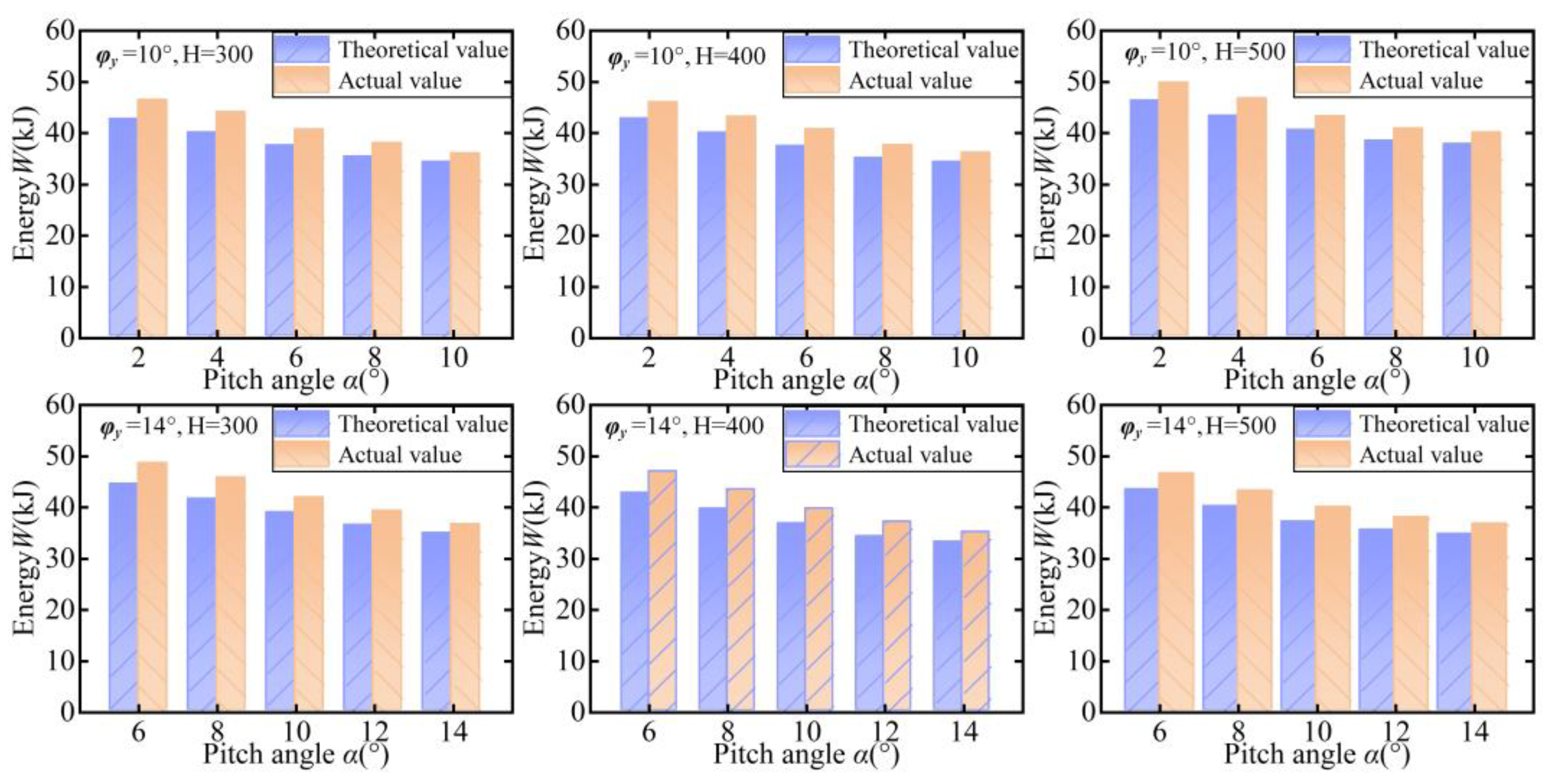

2.2.3. Adaptive Attitude in Terms of Energy Consumption

3. Force–Position Adaptive Impedance Control of Legs

3.1. Attitude Adaptive Adjustment

3.2. Adaptive Impedance Control

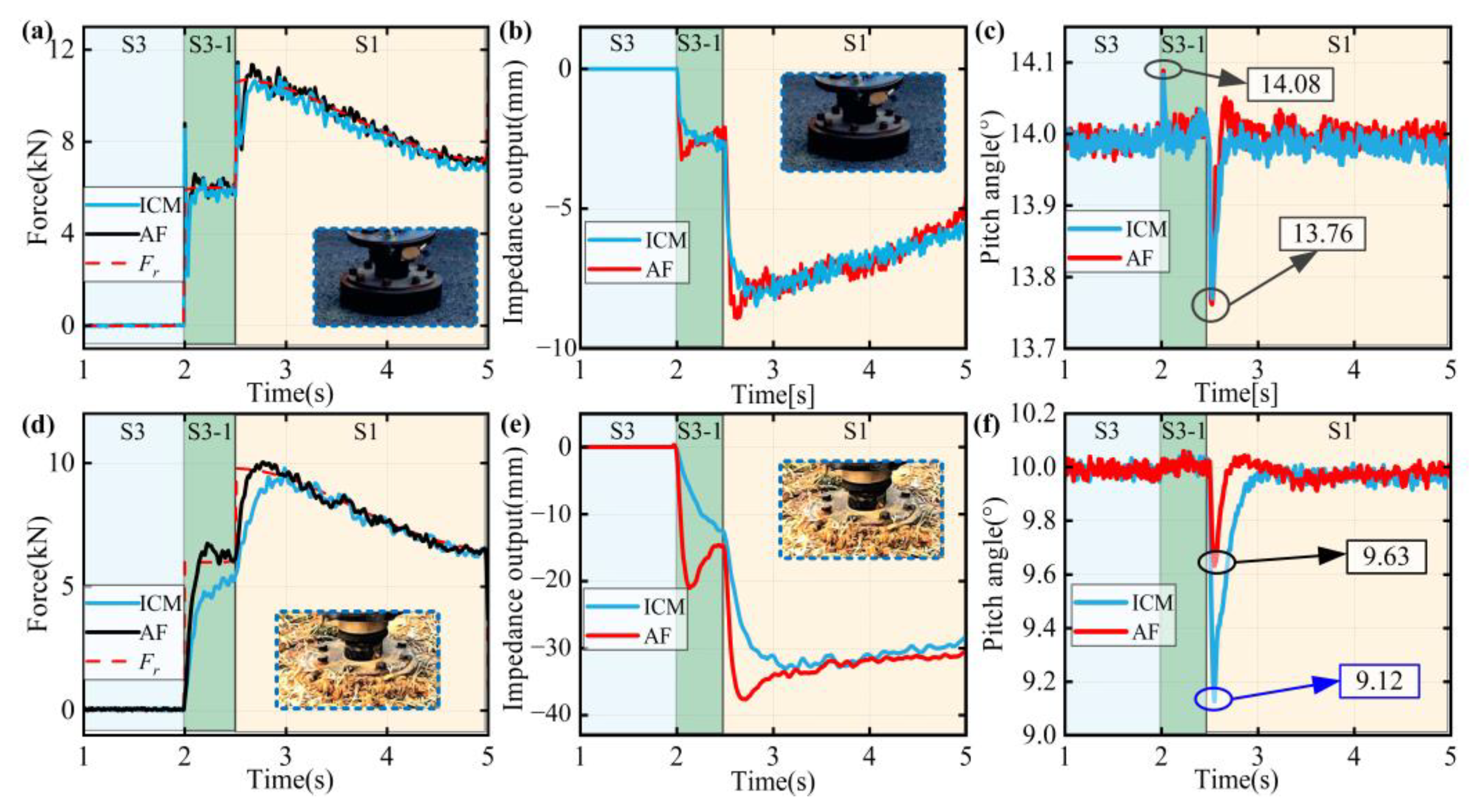

3.3. Force Tracking Experiment

4. Experimental Studies and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yuan, J.; Ji, W.; Feng, Q. Robots and Autonomous Machines for Sustainable Agriculture Production. Agriculture 2023, 13, 1340. [Google Scholar] [CrossRef]

- Tiozzo Fasiolo, D.; Scalera, L.; Maset, E.; Gasparetto, A. Towards Autonomous Mapping in Agriculture: A Review of Supportive Technologies for Ground Robotics. Robot. Auton. Syst. 2023, 169, 104514. [Google Scholar] [CrossRef]

- Gai, J.; Xiang, L.; Tang, L. Using a Depth Camera for Crop Row Detection and Mapping for Under-Canopy Navigation of Agricultural Robotic Vehicle. Comput. Electron. Agric. 2021, 188, 106301. [Google Scholar] [CrossRef]

- Vrochidou, E.; Tsakalidou, V.N.; Kalathas, I.; Gkrimpizis, T.; Pachidis, T.; Kaburlasos, V.G. An Overview of End Effectors in Agricultural Robotic Harvesting Systems. Agriculture 2022, 12, 1240. [Google Scholar] [CrossRef]

- Ferreira, J.; Moreira, A.P.; Silva, M.; Santos, F. A Survey on Localization, Mapping, and Trajectory Planning for Quadruped Robots in Vineyards. In Proceedings of the 2022 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Santa Maria da Feira, Portugal, 29–30 April 2022. [Google Scholar]

- Song, X.; Zhang, X.; Meng, X.; Chen, C.; Huang, D. Gait Optimization of Step Climbing for a Hexapod Robot. J. Field Robot. 2021, 39, 55–68. [Google Scholar] [CrossRef]

- Lee, W.-J.; Orin, D.E. The Kinematics of Motion Planning for Multilegged Vehicles over Uneven Terrain. IEEE J. Robot. Autom. 1988, 4, 204–212. [Google Scholar] [CrossRef]

- Xu, K.; Lu, Y.; Shi, L.; Li, J.; Wang, S.; Lei, T. Whole-Body Stability Control with High Contact Redundancy for Wheel-Legged Hexapod Robot Driving over Rough Terrain. Mech. Mach. Theory 2023, 181, 105199. [Google Scholar] [CrossRef]

- Choi, S.; Ji, G.; Park, J.; Kim, H.; Mun, J.; Lee, J.H.; Hwangbo, J. Learning Quadrupedal Locomotion on Deformable Terrain. Sci. Robot. 2023, 8, eade2256. [Google Scholar] [CrossRef] [PubMed]

- Kalakrishnan, M.; Buchli, J.; Pastor, P.; Mistry, M.; Schaal, S. Learning, Planning, and Control for Quadruped Locomotion over Challenging Terrain. Int. J. Robot. Res. 2010, 30, 236–258. [Google Scholar] [CrossRef]

- Grzelczyk, D.; Stanczyk, B.; Awrejcewicz, J. Kinematics, Dynamics and Power Consumption Analysis of the Hexapod Robot During Walking with Tripod Gait. Int. J. Struct. Stab. Dyn. 2017, 17, 1740010. [Google Scholar] [CrossRef]

- Ott, C.; Mukherjee, R.; Nakamura, Y. Unified Impedance and Admittance Control. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010. [Google Scholar]

- Zhu, Q.; Huang, D.; Yu, B.; Ba, K.; Kong, X.; Wang, S. An Improved Method Combined SMC and MLESO for Impedance Control of Legged Robots’ Electro-Hydraulic Servo System. ISA Trans. 2022, 130, 598–609. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, J.; Li, X.; Zong, H.; Yu, B.; Ba, K.; Kong, X. An Adaptive Composite Control for a Hydraulic Actuator Impedance System of Legged Robots. Mechatronics 2023, 91, 102951. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Z.; Li, J.; Wang, J.; Li, J.; Zhao, J. Flexible Motion Framework of the Six Wheel-Legged Robot: Experimental Results. IEEE/ASME Trans. Mechatron. 2022, 27, 2246–2257. [Google Scholar] [CrossRef]

- Kronander, K.; Billard, A. Stability Considerations for Variable Impedance Control. IEEE Trans. Robot. 2016, 32, 1298–1305. [Google Scholar] [CrossRef]

- Roveda, L.; Iannacci, N.; Vicentini, F.; Pedrocchi, N.; Braghin, F.; Tosatti, L.M. Optimal Impedance Force-Tracking Control Design With Impact Formulation for Interaction Tasks. IEEE Robot. Autom. Lett. 2016, 1, 130–136. [Google Scholar] [CrossRef]

- Deng, Z.; Jin, H.; Hu, Y.; He, Y.; Zhang, P.; Tian, W.; Zhang, J. Fuzzy Force Control and State Detection in Vertebral Lamina Milling. Mechatronics 2016, 35, 1–10. [Google Scholar] [CrossRef]

- Yang, J.; Sun, T.; Yang, H. Spatial Hybrid Adaptive Impedance Learning Control for Robots in Repetitive Interactive Tasks. ISA Trans. 2023, 138, 151–159. [Google Scholar] [CrossRef]

- Wang, W.; Li, Q.; Lu, C.; Gu, J.; Li, A.; Li, Y.; Huo, Q.; Chu, H.; Zhu, M. Impedance Estimation for Robot Contact with Uncalibrated Environments. Mech. Syst. Signal Process. 2021, 159, 107819. [Google Scholar] [CrossRef]

- Huang, B.; Ye, Z.; Li, Z.; Yuan, W.; Yang, C. Admittance Control of a Robotic Exoskeleton for Physical Human Robot Interaction. In Proceedings of the 2017 2nd International Conference on Advanced Robotics and Mechatronics (ICARMT), Ai’an, China, 27–31 August 2017. [Google Scholar]

- Yang, C.; Zeng, C.; Fang, C.; He, W.; Li, Z. A DMPs-Based Framework for Robot Learning and Generalization of Humanlike Variable Impedance Skills. IEEE/ASME Trans. Mechatron. 2018, 23, 1193–1203. [Google Scholar] [CrossRef]

- Zeng, C.; Yang, C.; Cheng, H.; Li, Y.; Dai, S.-L. Simultaneously Encoding Movement and sEMG-Based Stiffness for Robotic Skill Learning. IEEE Trans. Ind. Inform. 2021, 17, 1244–1252. [Google Scholar] [CrossRef]

- Zhang, T.; Liang, X.; Zou, Y. Robot Peg-in-Hole Assembly Based on Contact Force Estimation Compensated by Convolutional Neural Network. Control. Eng. Pract. 2022, 120, 105012. [Google Scholar] [CrossRef]

- Modares, H.; Ranatunga, I.; Lewis, F.L.; Popa, D.O. Optimized Assistive Human–Robot Interaction Using Reinforcement Learning. IEEE Trans. Cybern. 2016, 46, 655–667. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, X.; Song, B.; Li, Z. Whole-Body Fuzzy Based Impedance Control of a Humanoid Wheeled Robot. IEEE Robot. Autom. Lett. 2022, 7, 4909–4916. [Google Scholar] [CrossRef]

- Homchanthanakul, J.; Manoonpong, P. Continuous Online Adaptation of Bioinspired Adaptive Neuroendocrine Control for Autonomous Walking Robots. IEEE Trans. Neural Netw. Learn. Syst. 2022, 33, 1833–1845. [Google Scholar] [CrossRef]

- Li, Z.; Ge, Q.; Ye, W.; Yuan, P. Dynamic Balance Optimization and Control of Quadruped Robot Systems With Flexible Joints. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 1338–1351. [Google Scholar] [CrossRef]

- Ferraz, R.S.C.; Mello, T.P.; Borges Filho, M.N.; Borges, R.F.O.; Magalhães Filho, S.C.; Scheid, C.M.; Meleiro, L.A.C.; Calçada, L.A. An Experimental and Theoretical Approach on Real-Time Control and Monitoring of the Apparent Viscosity by Fuzzy-Based Control. J. Pet. Sci. Eng. 2022, 217, 110896. [Google Scholar] [CrossRef]

- Lu, A.; Ma, L.; Cui, H.; Liu, J.; Ma, Q. Instance Segmentation of Lotus Pods and Stalks in Unstructured Planting Environment Based on Improved YOLOv5. Agriculture 2023, 13, 1568. [Google Scholar] [CrossRef]

| Hip joint | 0 | |||

| Thigh | 0 | 0 | ||

| Shin | 0 | 0 |

| fr = A | fr = Bt2 | fr = ct2 | |

|---|---|---|---|

| IC | ∞ | ∞ | |

| KdZ = 0 | 0 | ∞ | |

| AD | 0 | 0 |

| Pitch Angle | H = 200 mm | H = 300 mm | H = 400 mm | H = 500 mm | |

|---|---|---|---|---|---|

| φy = 10° | 0° | - | - | 49.7 | 54.2 |

| 2° | - | 46.4 | 45.9 | 49.8 | |

| 4° | 43.1 | 44.0 | 43.1 | 46.7 | |

| 6° | 40.3 | 40.6 | 40.6 | 43.2 | |

| 8° | 38.7 | 37.9 | 37.5 | 40.8 | |

| 10° | 36.3 | 35.9 | 36.1 | 40.0 | |

| φy = 14° | 2° | - | - | - | 55.2 |

| 4° | - | - | 50.1 | 50.8 | |

| 6° | - | 48.6 | 46.9 | 46.6 | |

| 8° | 45.7 | 45.7 | 43.4 | 43.2 | |

| 10° | 42.7 | 41.8 | 39.6 | 39.9 | |

| 12° | 39.5 | 39.2 | 37.0 | 38.0 | |

| 14° | 37.9 | 36.5 | 35.0 | 36.6 |

| Maximum Error of Pitch Angle | Steady-State Time | ||

|---|---|---|---|

| Hard terrain | ICM | 0.25° | 0.11 s |

| AF | 0.24° | 0.15 s | |

| Soft terrain | ICM | 0.88° | 0.43 s |

| AF | 0.37° | 0.16 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Liu, X.; Liu, C.; Wang, Z. Motion-Control Strategy for a Heavy-Duty Transport Hexapod Robot on Rugged Agricultural Terrains. Agriculture 2023, 13, 2131. https://doi.org/10.3390/agriculture13112131

Yang K, Liu X, Liu C, Wang Z. Motion-Control Strategy for a Heavy-Duty Transport Hexapod Robot on Rugged Agricultural Terrains. Agriculture. 2023; 13(11):2131. https://doi.org/10.3390/agriculture13112131

Chicago/Turabian StyleYang, Kuo, Xinhui Liu, Changyi Liu, and Ziwei Wang. 2023. "Motion-Control Strategy for a Heavy-Duty Transport Hexapod Robot on Rugged Agricultural Terrains" Agriculture 13, no. 11: 2131. https://doi.org/10.3390/agriculture13112131

APA StyleYang, K., Liu, X., Liu, C., & Wang, Z. (2023). Motion-Control Strategy for a Heavy-Duty Transport Hexapod Robot on Rugged Agricultural Terrains. Agriculture, 13(11), 2131. https://doi.org/10.3390/agriculture13112131