1. Introduction

Agriculture is developing towards the goal of improving the utilization rate of resources. Fine agriculture is the core direction of improving the utilization rate of resources, and automatic navigation of agricultural machinery is the prerequisite of fine agriculture. As society develops, people’s living standards steadily improve, and the demand for agricultural products also increases; however, due to the attraction of urbanization to the labor force and population aging factors, the agricultural labor force is increasingly limited. Agricultural machinery automation can reduce the demand for labor, reduce labor intensity, reduce production costs, and improve production efficiency, which is an important technical means to alleviate the agricultural labor shortage. In the operation of unmanned agricultural machinery, obstacle avoidance and path planning are important aspects related to the safety of agricultural machinery itself, reducing economic losses and energy consumption. With the proposal of the concept of unmanned farms, unmanned agricultural machinery is the focus of future development, and reducing manual intervention is the only way for unmanned farms to operate. However, even before the operation of unmanned agricultural machinery, some static obstacles will be dealt with manually, such as telephone poles, electromechanical wells, stacked materials, etc., and there may still be some moving obstacles, such as personnel, other agricultural machinery, transport vehicles, etc. Therefore, it is necessary to propose a path planning method considering the kinematic model of agricultural machinery, so that agricultural machinery can automatically avoid obstacles after detecting obstacles and continue working.

Traditional path planning algorithms generally simplify the subject into a particle without considering the constraint conditions of the subject. Therefore, although the shortest path to avoid obstacles can be generated, the subject is unable to complete the path, which results in tracking control jumping and reduced control performance and stability. The RoadMap algorithm uses a simple connected graph to represent configuration space. It will first build a continuous graph of the space in the construction phase, which usually takes a lot of time, but the final graph can be used for multiple queries and modified a little. In the query phase, the search algorithm will search the path from the starting point to the target point. The algorithm includes Visibility Graph [

1] and Voronoi Diagram [

2]. The graph search algorithm relies on the known environment map and the obstacle information in the map to construct the path from the starting point to the end point, including depth first and breadth first. Such algorithms are generally heuristic algorithms, including Dijkasta algorithm [

3], A* algorithm [

4], D* algorithm [

5,

6], etc. Li et al. [

7] proposed a path planning method combining the improved A* algorithm and improved DWA algorithm to avoid temporary obstacles. Zhang et al. [

8] introduced the radar threat estimation function and a 3D bidirectional sector multilayer variable step search strategy into the conventional A-star algorithm. RRT series algorithms [

9] rapidly expand tree-like paths to search most areas in space and find feasible paths, which is an algorithm for random sampling of state space. By carrying out collision detection on sampling points, it avoids large computation caused by the accurate modeling of space and effectively solves the path planning problems of high-dimensional space and complex constraints. However, due to randomness, the path found by this kind of algorithm is often not the optimal solution. Wang et al. [

10] proposed an improved RRT* algorithm, including dynamic step size, steering angle constraints, and optimal tree reconnection. The artificial potential field method [

11] is a common algorithm for local path planning. The algorithm assumes that the subject is moving under a virtual force field, the target point exerts gravity on the subject to guide the object to move towards it, and the obstacle exerts repulsive force on the subject to avoid collision with it. However, this algorithm can easily fall into the local optimal solution. The VFH series algorithm [

12] is an improvement on the artificial potential field method. By calculating the traveling cost in each direction, the direction is selected. Theoretically, the area with low cost is convenient for traveling, but it may offset the target direction.

With the vigorous development of subjects with more constraints on kinematic models, such as driverless cars, the path planning problem needs to introduce kinematic models to make it possible for subsequent subjects to be controlled according to the planned path. The Hybrid A* algorithm is an improved algorithm of the A* algorithm, considering the actual motion constraints of objects and defining more complex cost functions. However, as it is still a graph search algorithm, Hybrid A* algorithm is only applicable to static environments. The parametric trajectory method [

13,

14,

15] directly uses dynamic or kinematic models to generate trajectories conforming to model constraints. The algorithm proposed by Yuan et al. [

13] contains uneven inputs, which could not be directly used for control. Therefore, Yang et al. [

15] proposed smoothing the inputs by rotating the coordinate system and adding intermediate points. On this basis, Yuan et al. [

16] proposed to use the dynamics model for modeling, use the ten-degree polynomial to fit the path of the car-like robot, replace the objective function of the shortest path with the objective function of the path closest to the straight line, and conclude that the optimal path solution can be obtained by directly using the analytical solution method. On this basis, a calculation method is further given to find the second-best solution that can avoid obstacles when considering obstacles. However, due to the replacement of the objective function and the addition of the hypothesis of the approximate method, the path obtained by the algorithm is often not optimal, resulting in too long a path. Kuo et al. [

17] proposed a dual-optimization trajectory planning algorithm, which consists of optimal path planning and optimal motion profile planning for robot manipulators, where path planning is based on parametric curves. Ghosh et al. [

18] proposed the kinematic constraint Bi-RRT (KB-RRT) algorithm to limit the number of nodes generated and generate smooth trajectories combined with kinematic constraints. Essaidi et al. [

19] proposed a minimum-time trajectory planning algorithm considering constraints, including obstacle avoidance, boundary conditions, maximum articulation angle between the two platforms, dynamic capacities of the actuators, and dynamic stability of the system. Faroni et al. [

20] proposed a predictive approach to trajectory scaling subject to joint velocity, acceleration, and torque limitations.

In addition, there are also path planning algorithms using optimization algorithms, including PSO [

21]. Such algorithms can only be used as global path planning due to the problem of search efficiency but cannot be used for real-time path planning directly. Kun et al. [

22] proposed a path planning algorithm based on an improved obstacle avoidance strategy and double ant colony optimization algorithm. How to model the path planning problem into an optimization problem that can be solved quickly is the key to this kind of method. Xue et al. [

23] combined the particle swarm optimization algorithm with the sine cosine algorithm to improve the performance of PSO, which maintains a balance in exploration and exploitation. Xu et al. [

24] proposed a new approach for the smooth path planning of a mobile robot based on a new quartic Bezier transition curve and an improved particle swarm optimization algorithm. In fact, optimization algorithms are used in many fields. Chen et al. [

25] used an optimization algorithm in multi-agents to achieve better performance. Ker et al. [

26] introduced an optimization algorithm to improve the efficiency of the farm supply and demand relationship. Wang et al. [

27] used optimization algorithms in machine selection to push the method widely used in real companies.

However, there are not many studies about the obstacle avoidance path planning of agricultural machinery. Liu et al. [

28] proposed a path consisting of three circular arcs, which can achieve obstacle avoidance for single small obstacles. This kind of path is fixed and cannot solve problems in different situations. Zhao et al. [

29] proposed a collision-free path planning method using the minimum snap algorithm to enable a tractor to safely navigate from one point to another. This method directly uses a polynomial to describe the path, resulting in too many optimization parameters and low optimization efficiency.

On the basis of the above studies, this paper proposes a real-time path planning algorithm based on particle swarm optimization [

21] for an agricultural machinery parametric kinematic model. On the basis of Yuan [

16], the overly complex dynamic model is replaced by a kinematic model, and the search space is defined adaptively through quantitative experiments. The particle swarm optimization algorithm is used to optimize the path that avoids obstacles and meet the operation requirements of agricultural machinery. In addition, two objective functions are designed according to different tasks. The following sections are organized as follows:

Section 2 introduces the algorithm in detail according to the research process.

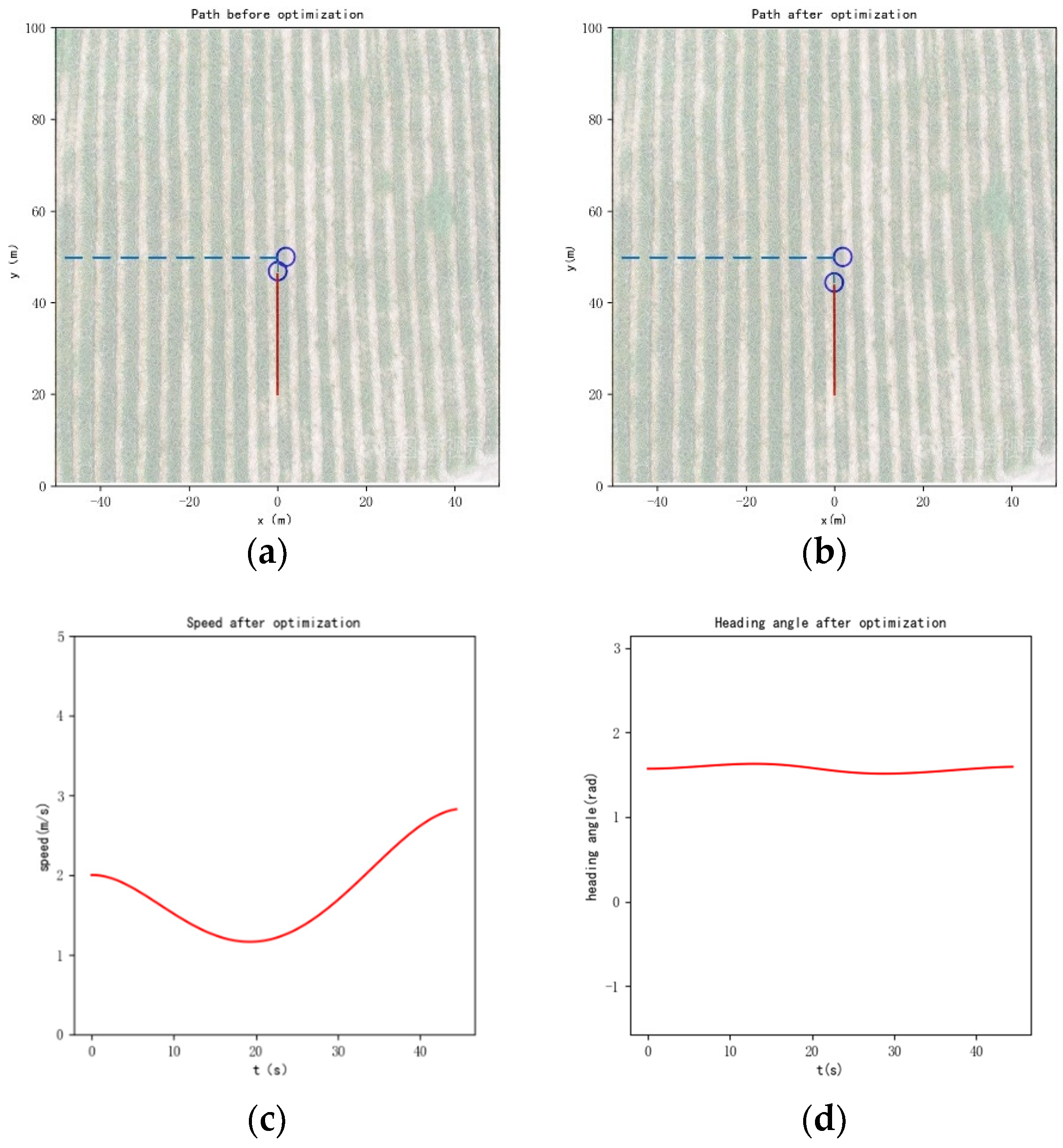

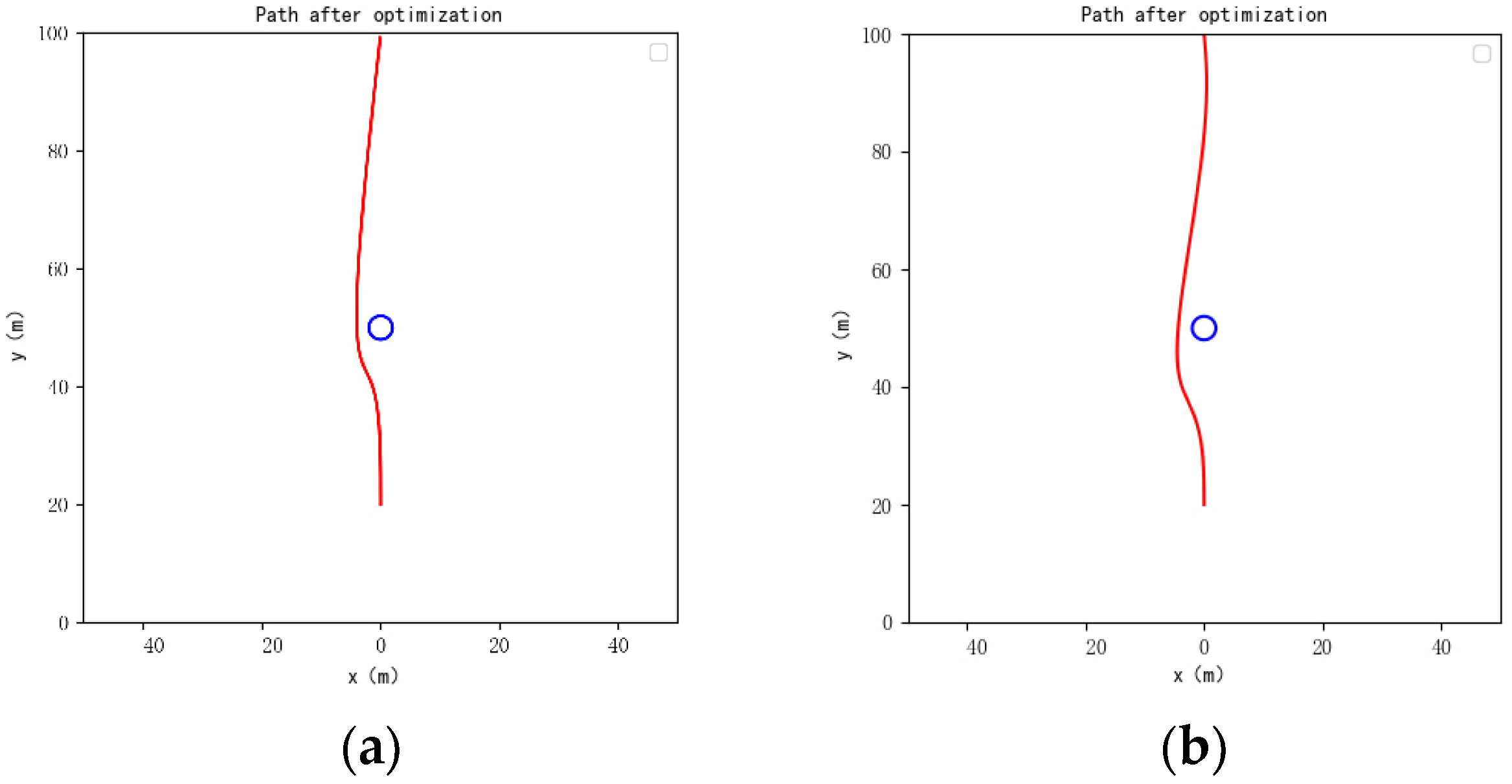

Section 3 outlines the experiment of the static obstacle and dynamic obstacle.

Section 4 gives a conclusion of this paper.

2. Materials and Methods

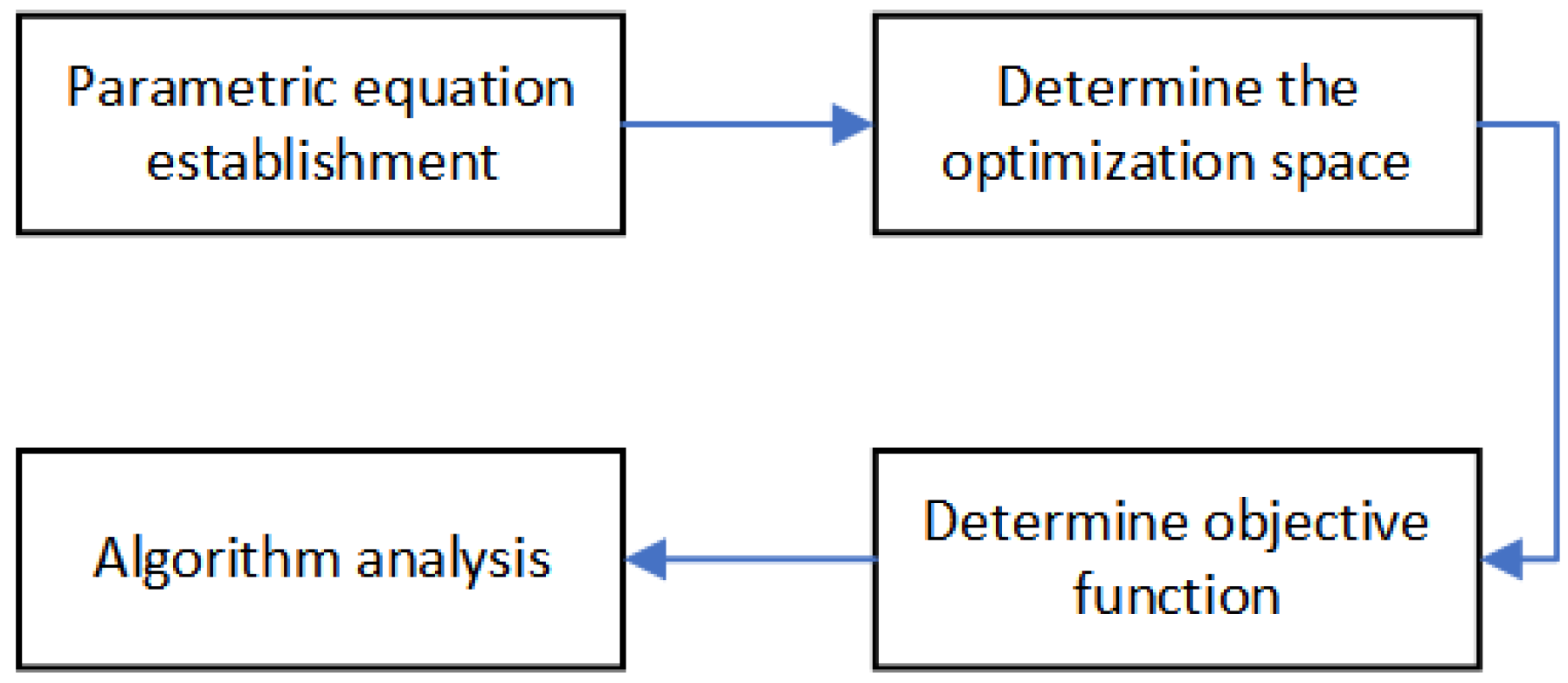

This section introduces the research process method, as shown in

Figure 1. Firstly, parametric equations are established through the kinematic model; then, the optimization space of parameters and the objective function are determined, and, finally, the efficiency of the algorithm is analyzed.

2.1. Parameter Equation Path Considering Kinematic Model

The kinematics model of typical wheeled agricultural machinery can be described according to Equation (1):

where

represents the Cartesian coordinate of the middle point of the rear axle of agricultural machinery,

represents the linear velocity of agricultural machinery,

represents the heading angle of agricultural machinery,

represents the steering angle of agricultural machinery,

represents the acceleration of agricultural machinery, and

is the wheel base.

For the given initial time and arrival time, agricultural machinery has initial constraints

at

and end constraints

at

, where

In practical applications, the initial time

is generally 0 and the other state constraints are the current state of the machinery. And, in the end constraint, since the radius of obstacles on the farm is generally much smaller than the desired path, the ideal path to avoid obstacles should be similar to the length of the desired path, so the end time

can be calculated from the given initial and end positions and the average speed with Equation (3), which is defined in Equation (2):

where

is an adjustable parameter that can be set to be larger for smooth operation and smaller for efficient operation of the machinery. In this way, the machinery is able to avoid obstacles by slightly accelerating. In addition, in order to ensure the stable state of the machine at the end,

and

are set as 0.

Thus, the parameter equation path

should satisfy Equation (4) according to the initial and end limits:

According to Equation (4),

needs 6 parameters at least. In the same way,

must satisfy a similar constraint. Adding one degree of freedom, the following polynomial trajectory is proposed:

which defines:

Combining Equations (4) and (5):

which can be described in matrix form:

where

is defined in Equation (6).

Similarly,

must satisfy:

where

is defined in Equation (6).

For a practical mission, it is always true that

. Hence, the matrix

L is nonsingular. Thus,

and

can be calculated via Equation (10):

The planned trajectory

can be rewritten as:

where

In short, given the initial constraints at and end constraints at , fixed and give a path, satisfying the constraints mentioned above, which is described in Equation (11). The following algorithm optimizes and to obtain a path.

2.2. Definition of Search Space

Before using an optimization algorithm, defining an appropriate search space can help the algorithm find a relatively optimal solution faster. Therefore, it is necessary to first determine the search space of and to improve the solving efficiency of the optimization algorithm. To determine the search space, the search center and search radius for each variable need to be determined.

Determine the search center first. Generally, the objective function of a path planning algorithm is the path length:

However, since the objective function contains the square root, the optimal analytic solution cannot be derived directly. Therefore, the objective function is considered, as Equation (12) shows, which indicates that the path is expected to be a straight line from the starting point to the end point as far as possible.

where

Expanding Equation (13):

where

The optimal solution of Equation (13) is obtained:

The optimal trajectory can be described as follows:

An optimal analytical solution of the objective function can be obtained directly from Equation (16) efficiently. Therefore, and are chosen as the center of the search space of and .

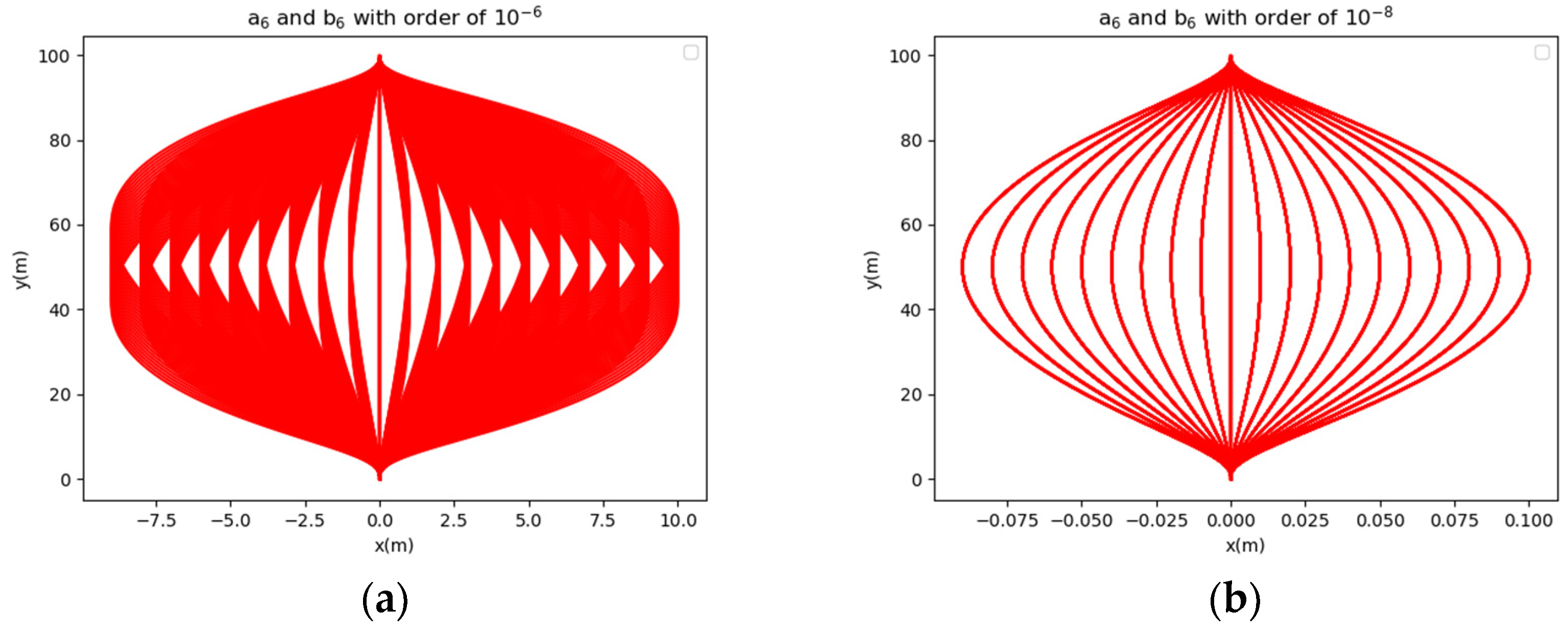

Then, the search radius is determined via quantitative experiments.

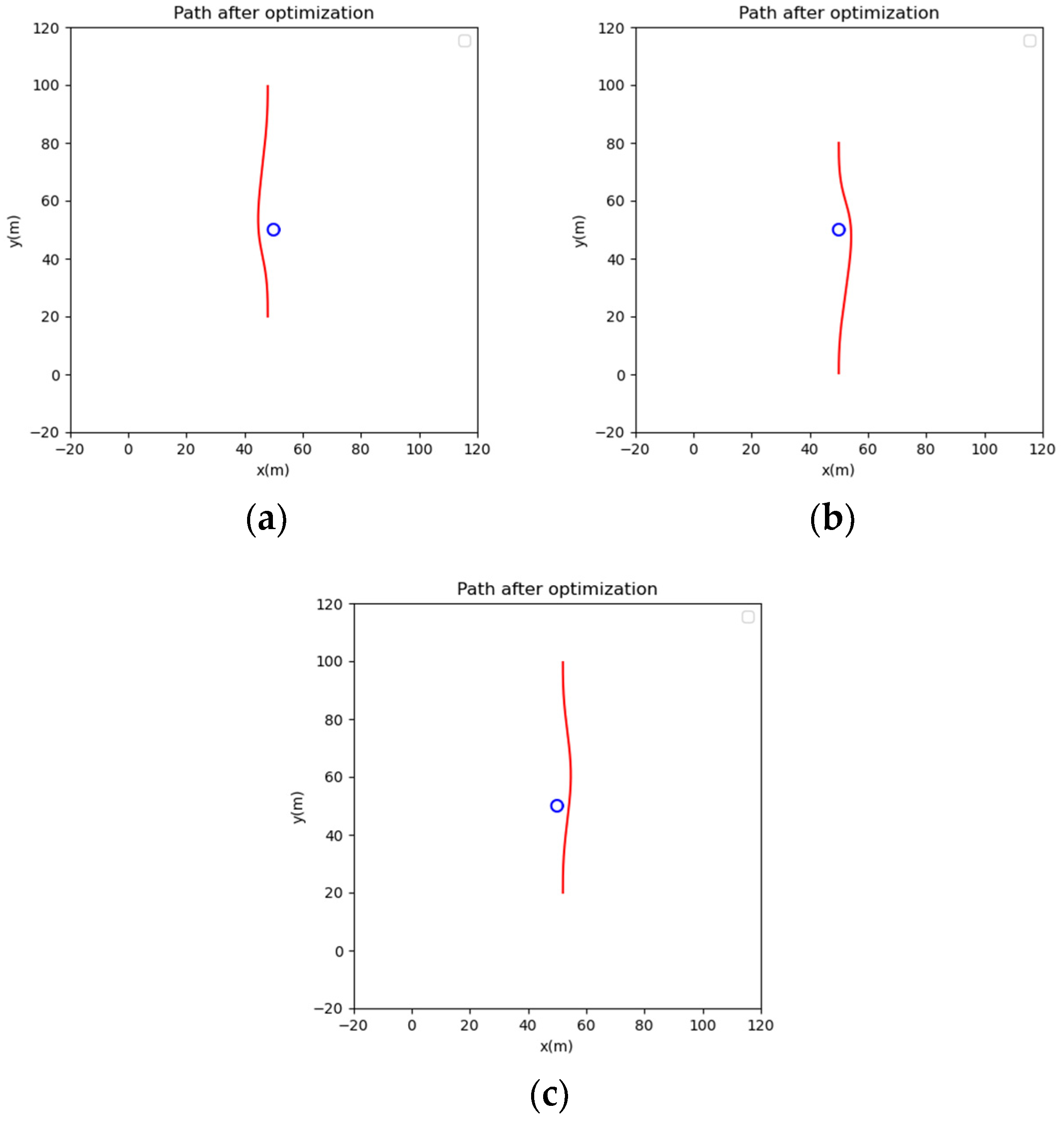

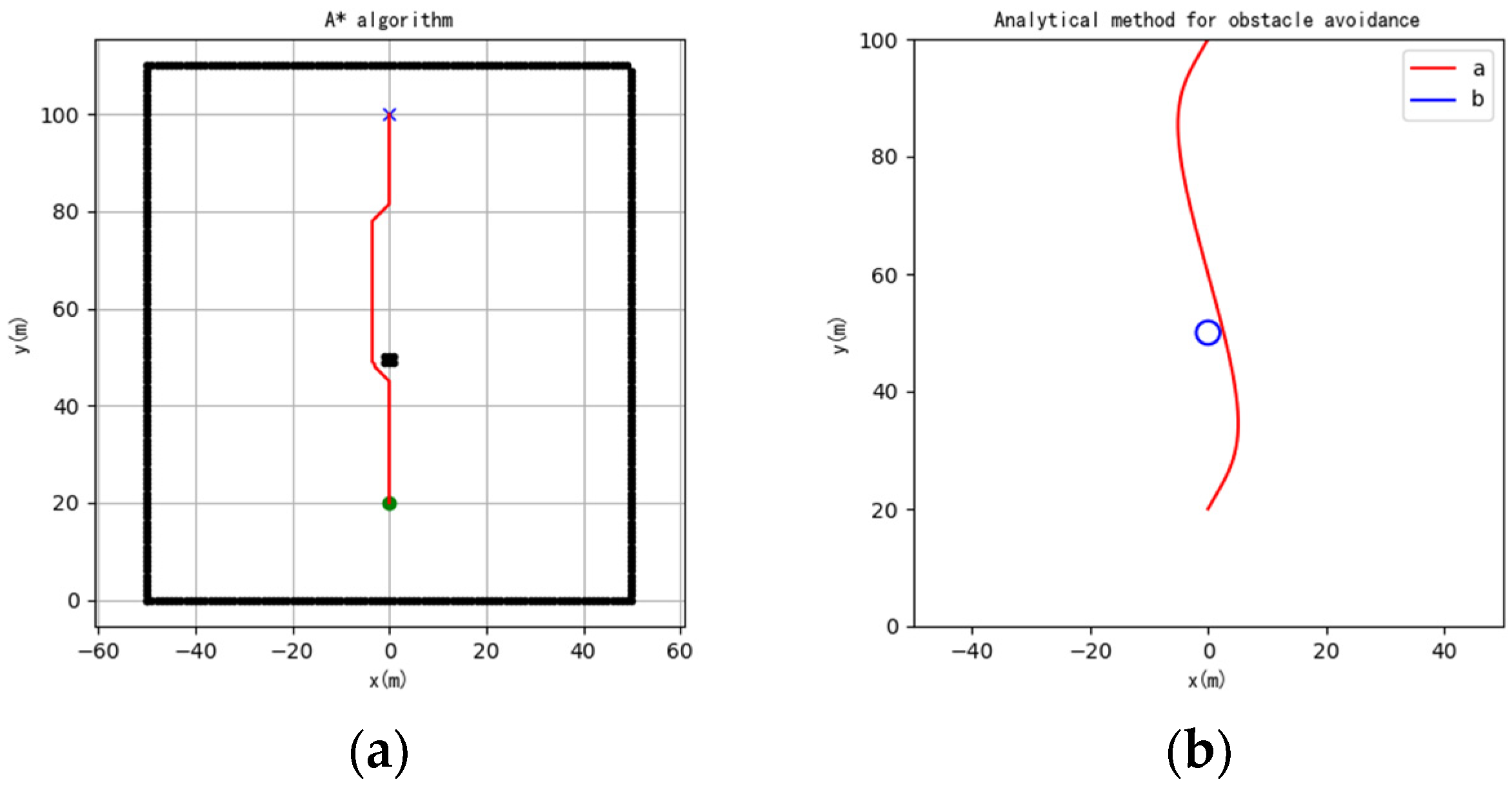

Figure 2 shows the paths for different orders of

and

.

Figure 2a shows 100 paths when the values of

and

are set as an order of

, which are within a range of 10 m.

Figure 2b shows 100 paths when the values of

and

are set as an order of

, which are within a range of 0.1 m. Quantitative experiments show that the order of

and

directly affects the scope of search paths, and the scope order of paths is linearly related to the order of

and

. In addition, the value of

and

is also related to the total time; thus, different total times require a different search radius.

2.3. Particle Swarm Optimization

The particle swarm optimization algorithm [

21] is a heuristic optimization algorithm that uses multiple particles to simulate the cooperation process of bird predation to find the solution that maximizes the value of the objective function. The focus of the particle swarm optimization algorithm is to determine the objective function and search space, which is described in

Section 2.2. This section defines the objective function.

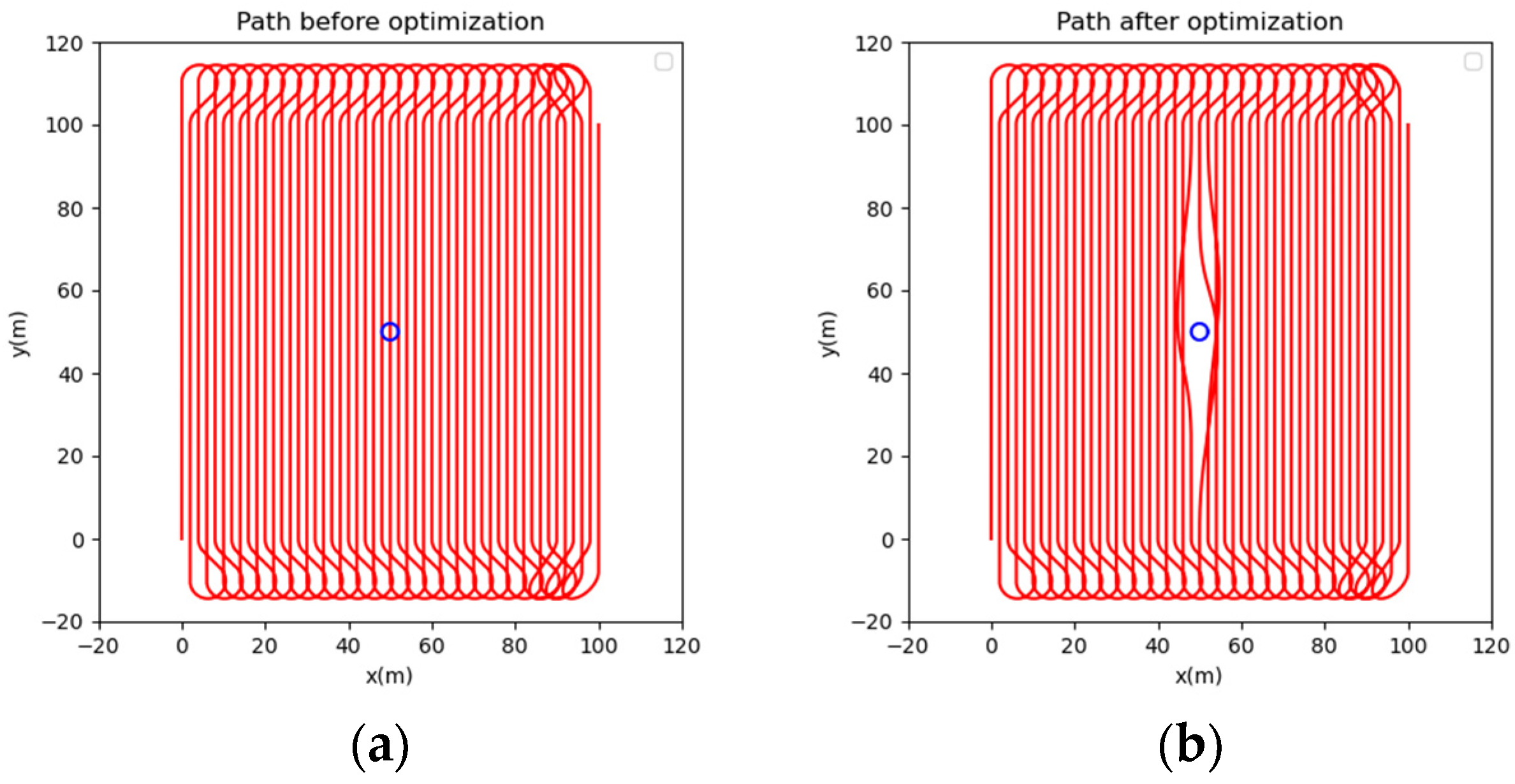

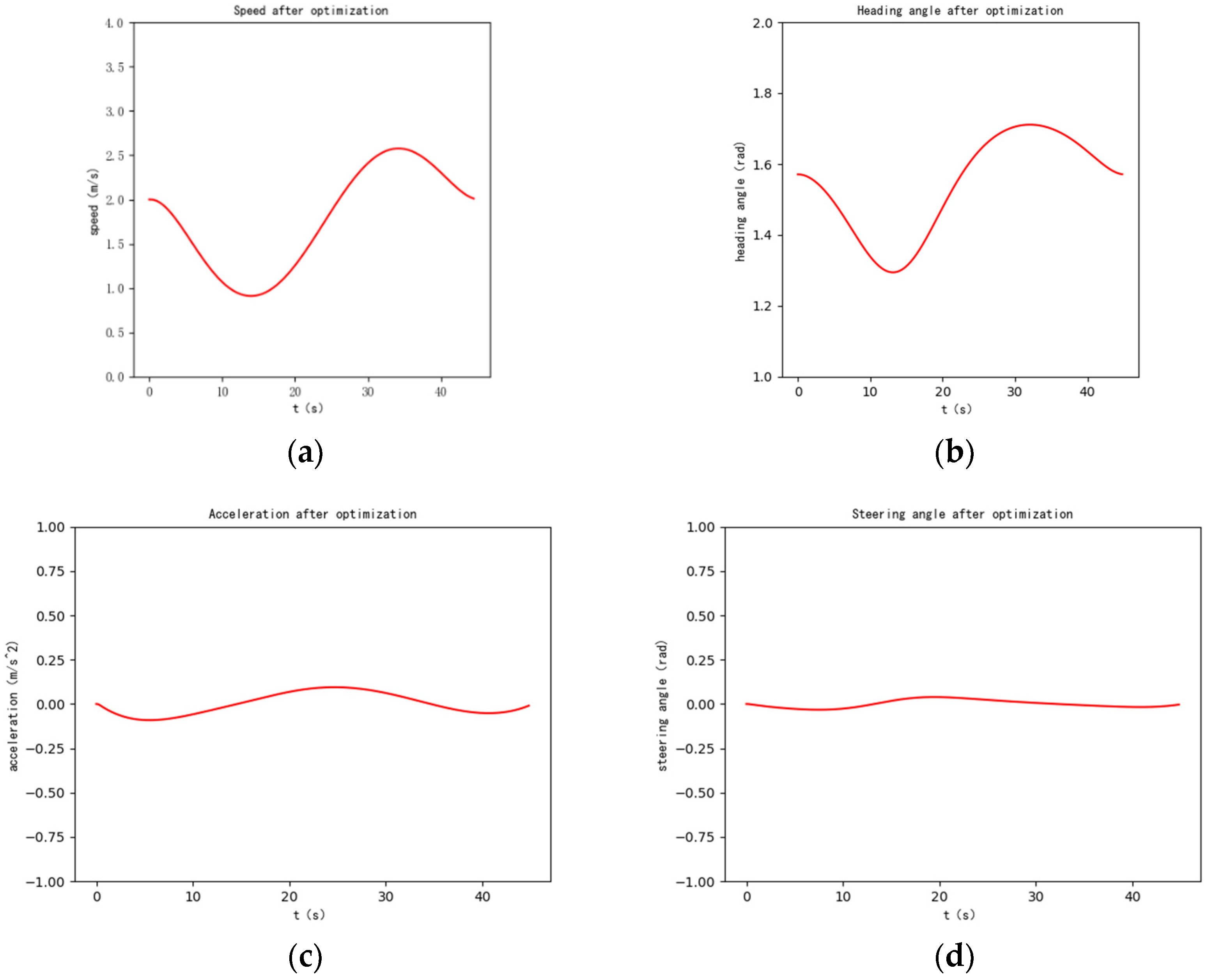

For a general path planning algorithm, the objective function is defined by Equation (12), and the objective of the optimization algorithm is to find the shortest path. However, due to the particularity of the work of unmanned agricultural machinery, the unmanned agricultural machinery is expected to avoid obstacles and, as far as possible, to keep itself running along the expected path to complete the task better. Therefore, two kinds of objective functions are defined, one defined by Equation (12) and the other defined by Equation (17), to find a path that minimizes the area enclosed by the path and the expected path.

where

are the parameters of the expected path

.

In addition, the path should satisfy the constraint of not colliding with obstacles. When the path of obstacles is known, the path needs to satisfy Equation (18).

where

and

are the parametric equation of obstacles with respect to time, for

,

is the radius of the unmanned agricultural machinery, and

is the radius of the obstacles, for

. To meet the condition described above, define the objective function for avoiding obstacles, as in Equation (19).

where

can be any number much larger than the length of the path, as the goal of path planning is to avoid obstacles first.

In addition, when determining the path, the acceleration and steering angle at each moment can be calculated according to the parametric equation of the path. According to the characteristics of the actual operation of agricultural machinery, acceleration constraints and steering angle constraints need to be added, which are expressed by Equation (20) and Equation (21), respectively.

where

and

represent the lower limit and the upper limit of acceleration for agricultural machinery;

and

represent the lower limit and the upper limit of the steering angle for agricultural machinery.

Based on the above constraints and objective functions, the objective function of the particle swarm optimization algorithm is represented by Equation (22) when the path length is selected as the target and by Equation (23) when the target is to find a path close to the expected path.

It is worth noting that when the optimization result of the objective function value is greater than the preset large number, it means that the current optimization algorithm has not found a path to avoid obstacles, while when the optimization result of the objective function value is less than the preset large number, it means that the current optimization algorithm has found a path to avoid obstacles and is relatively better. For the optimization algorithm, avoiding obstacles is the priority, so it has a large penalty. Only when the path does not conflict with the obstacle, other objective functions of the optimized path are considered. In addition, since the parametric equation of obstacle with time is used in , this optimization method can theoretically avoid any dynamic obstacle with a known trajectory, but for an obstacle with too large a radius, it needs to search in a larger search space with a higher end time, so that the algorithm can plan the path that the agricultural machine can achieve. Considering the actual farm scene, it is considered that the radius of the obstacle is far less than the path length, so it is feasible in practical application. What is more, the end speed and end heading angle can also be used as search variables, which can help the optimization algorithm find the second-best solution when the obstacle is close to the end point and still reach the end point with a small deviation in the speed and heading angle, and then the control algorithm can be used to complete the desired path tracking.

2.4. Algorithm Efficiency Analysis

In the running process of the algorithm, the initial solution is solved first. Since the analytical solution is directly solved, the running time is short, about 0.002 s. The main time cost of the algorithm is the process of solving the objective function in the following particle swarm optimization algorithm. As described in

Section 2.3, the objective function needs discrete calculation, so the calculation of the objective function is related to the total time and discrete time. In addition, obstacle collision detection is also related to the number of obstacles. The number of iterations and populations in the particle swarm optimization algorithm determines the calculation times of the objective function. In short, the running time of the algorithm is positively correlated with the total time, the number of iterations, and the number of populations, and it is negatively correlated with the discrete time. The number of obstacles has little influence on the running time of the algorithm compared with other factors.

2.5. Influence of Discrete Time on Obstacle Collision Detection

In obstacle collision detection, agricultural machinery coordinates and obstacle coordinates cannot be detected at every moment, so it is necessary to conduct obstacle detection after the discretization of the agricultural machinery path and obstacle path. Therefore, the discrete time has an impact on obstacle detection. In the past, the radius of the obstacle or the collision radius of the moving subject was generally expanded. In this section, the expanded value was quantitatively defined.

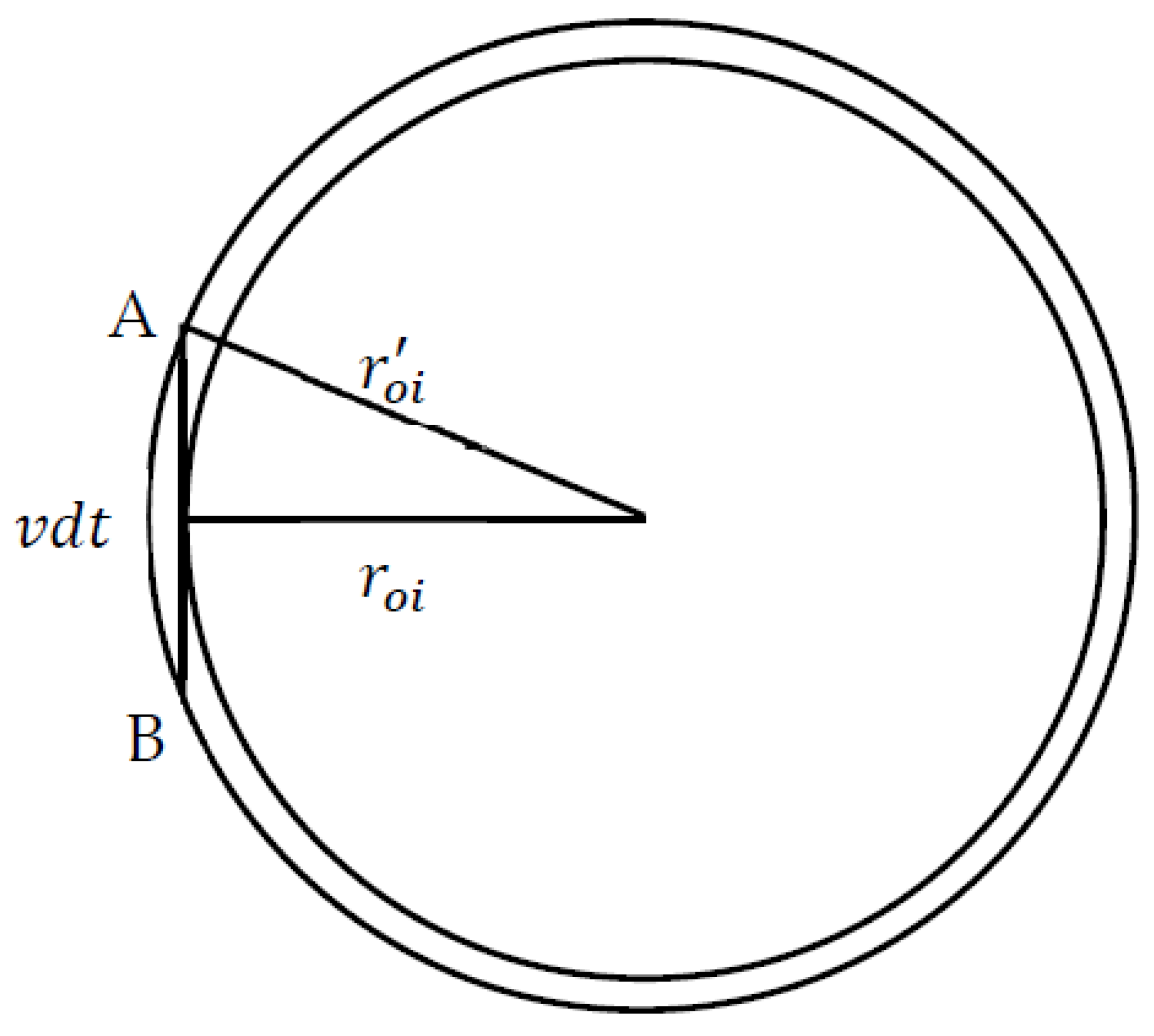

As shown in

Figure 3, the worst case of collision detection after discretization is that discretized points A and B are close to obstacles, and then the compensation value

can be calculated via Equation (24).

where

is the mean speed, and

is the discrete time. In addition,

cannot be greater than the minimum diameter of all obstacles; otherwise, collision detection may fail.

4. Conclusions

In this paper, the kinematic model of agricultural machinery is used to construct a parametric curve under the initial constraints and end constraints. The curve contains two degrees of freedom, and . On this basis, firstly, the center of the search space is obtained directly via the analytical method. Through quantitative experiments, the search radius is determined. Then, the particle swarm optimization algorithm is used to optimize the path that satisfies the constraints of obstacles, acceleration, and steering angle and has relatively optimal objective function value. The objective function can select the length of the path, the area enclosed by the path, and the expected path. And the algorithm’s operating efficiency and the effect of discrete time on obstacle collision detection are analyzed. Finally, the effectiveness and real-time performance of the algorithm for static and dynamic obstacles are verified through experiments.

The uniqueness of the proposed algorithm is that it is aimed at the working purpose of the actual operation of agricultural machinery, while other obstacle avoidance path planning algorithms limit the optimization objective to the path length or operation efficiency. In addition, the proposed algorithm can satisfy the kinematic model constraints, and the planned path is feasible, directly controlled by algorithms. Although the proposed algorithm can obtain better obstacle avoidance path planning results in simulation, the parameterized path method still has limitations. Some parameters such as termination time need to be set manually. Therefore, more effective automatic setting methods of such parameters can be explored in the future.