Effects of Homogenization on Organoleptic Quality and Stability of Pasteurized Milk Samples

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Preparation of Pasteurized Milk Samples

2.3. Sensory Evaluation Group Establishment

2.4. Sensory Assessor Training

2.5. Descriptive Sensory Language for Pasteurized Milk

2.6. Sensory Assessment Experiments

2.7. Determination of Volatile Components in Pasteurized Milk Samples by Using an Electric Nose

2.8. Colorimetric Analysis of Pasteurized Milk Samples

2.9. Stability Analysis of Pasteurized Milk Samples

2.10. Particle Size Analysis of Pasteurized Milk Samples

2.11. Statistical Analysis

3. Results and Discussion

3.1. Organoleptic Quality

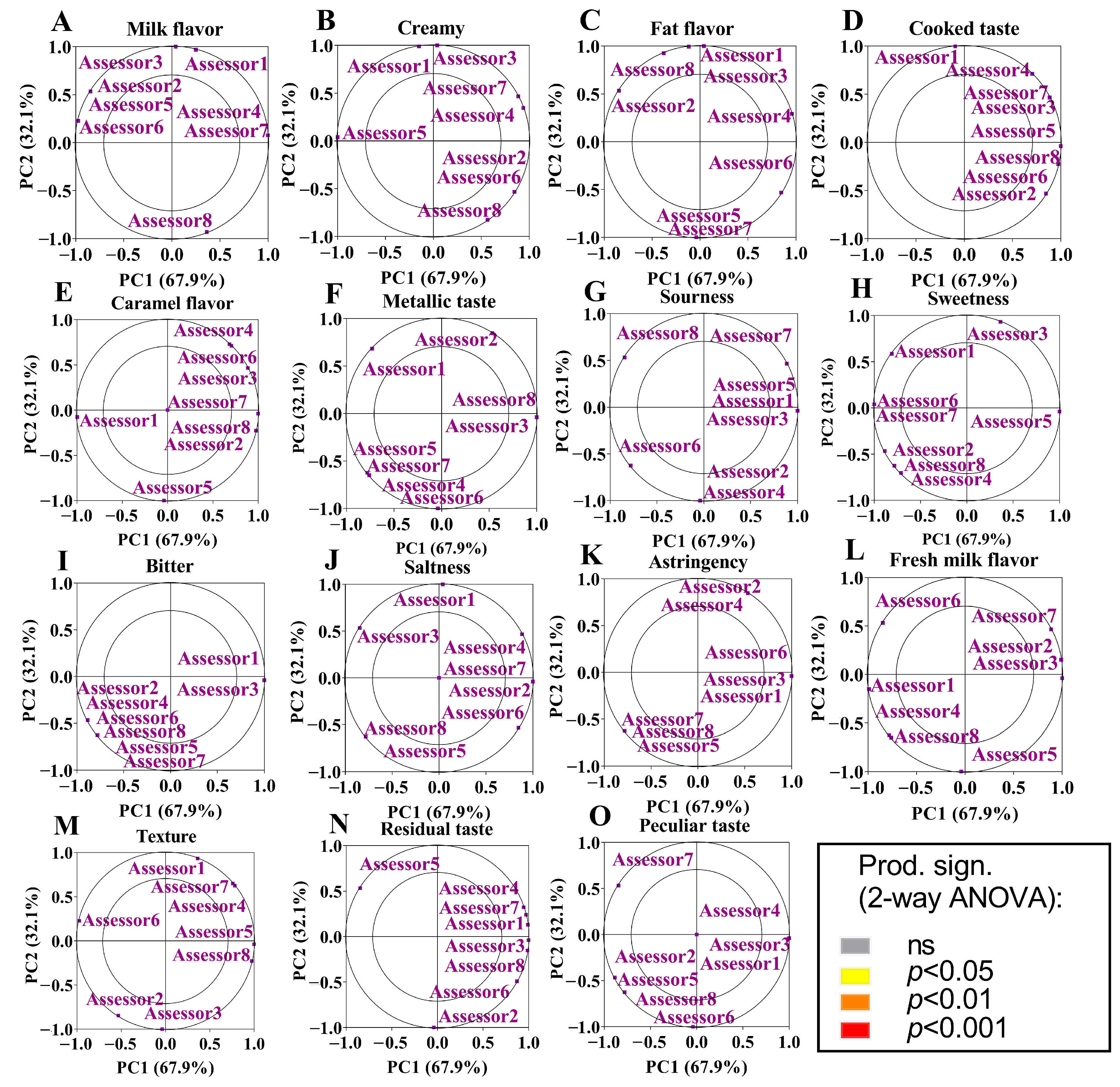

3.1.1. Consistency and Capacity Assessment of Evaluation Group

3.1.2. Sensory Evaluation Experiment

3.1.3. Electronic Nose Data Results

3.2. Physical Properties

3.2.1. Color

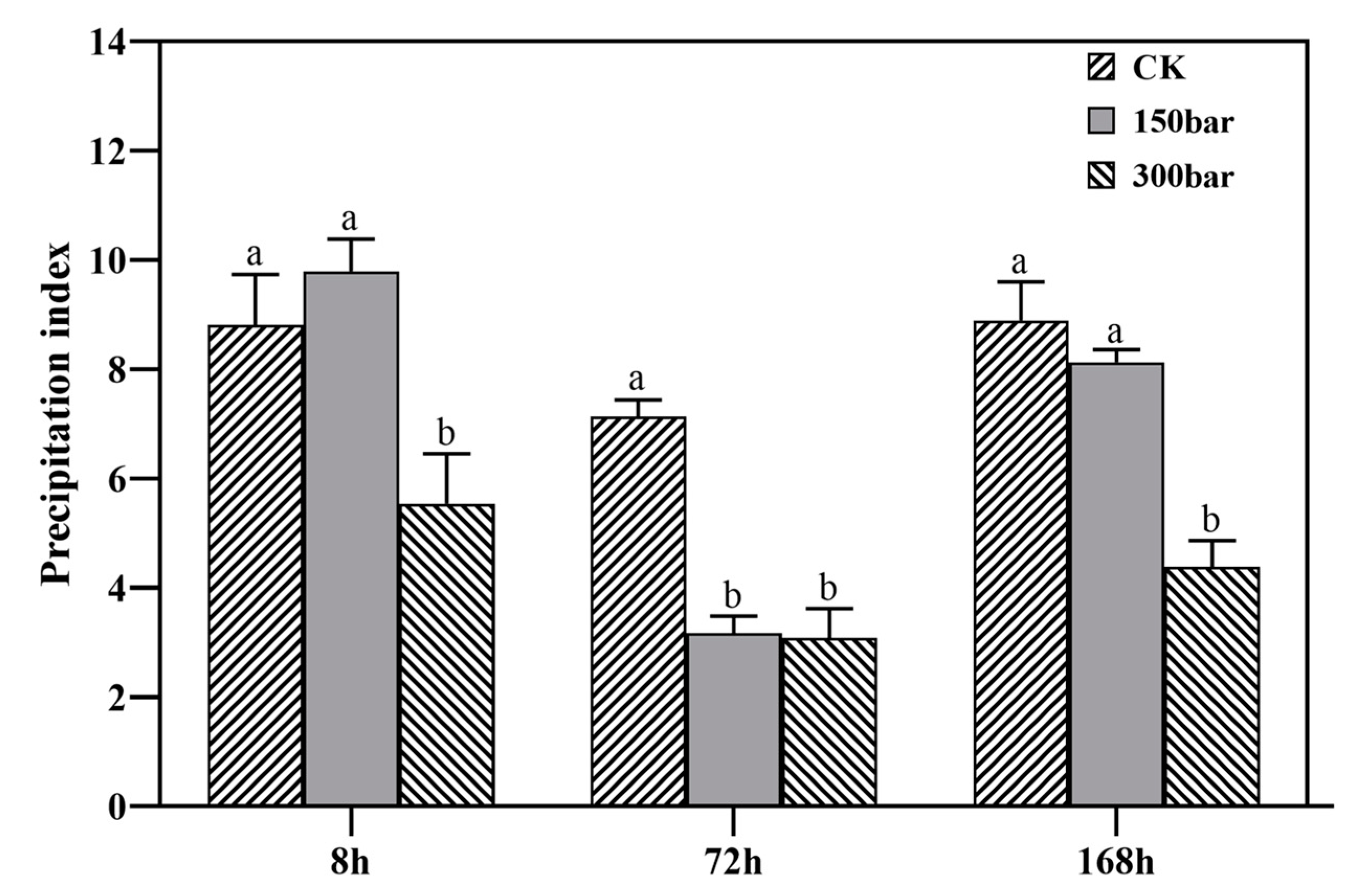

3.2.2. Stability

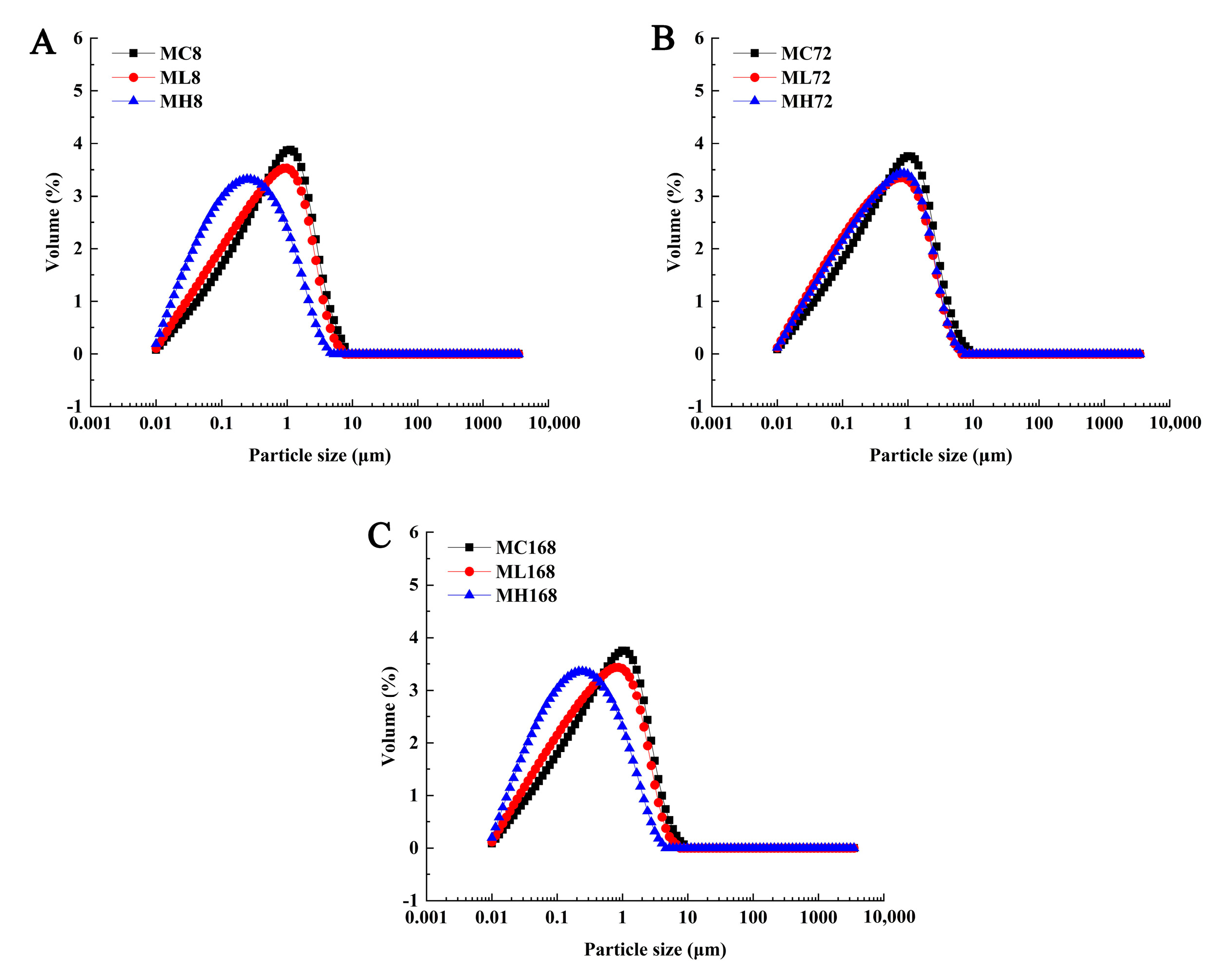

3.2.3. Particle Size

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Birlouez-Aragon, I.; Sabat, P.; Gouti, N. A new method for discriminating milk heat treatment. Int. Dairy J. 2002, 12, 59–67. [Google Scholar] [CrossRef]

- Karlsson, M.A.; Langton, M.; Innings, F.; Malmgren, B.; Höjer, A.; Wikström, M.; Lundh, Å. Changes in stability and shelf-life of ultra-high temperature treated milk during long term storage at different temperatures. Heliyon 2019, 5, e02431. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.H.; Zhang, L.W.; Wang, W.J.; Han, X. Differences in particle characteristics and oxidized flavor as affected by heat-related processes of milk powder. J. Dairy Sci. 2013, 96, 4784–4793. [Google Scholar] [CrossRef]

- D’Incecco, P.; Rosi, V.; Cabassi, G.; Hogenboom, J.A.; Pellegrino, L. Microfiltration and ultra-high-pressure homogenization for extending the shelf-storage stability of UHT milk. Food Res. Int. 2018, 107, 477–485. [Google Scholar] [CrossRef] [PubMed]

- Sfakianakis, P.; Tzia, C. Conventional and innovative processing of milk for yogurt manufacture; development of texture and flavor: A review. Foods 2014, 3, 176–193. [Google Scholar] [CrossRef]

- Xiong, Y.L.; Aguilera, J.M.; Kinsella, J.E. Emulsified milkfat effects on rheology of acid-induced milk gels. J. Food Sci. 1991, 56, 920–925. [Google Scholar] [CrossRef]

- Sodini, I.; Remeuf, F.; Haddad, S.; Corrieu, G. The relative effect of milk base, starter, and process on yogurt texture: A review. Crit. Rev. Food Sci. Nutr. 2004, 44, 113–137. [Google Scholar] [CrossRef]

- Wilbey, R.A. Homogenization of milk: Principles and mechanism of homogenization, effects and assessment of efficiency: Valve homogenizers. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–5. [Google Scholar]

- Ren, Q.; Li, Q.; Liu, H.; Ma, Y. Thermal and storage properties of milk fat globules treated with different homogenisation pressures. Int. Dairy J. 2020, 110, 104725. [Google Scholar] [CrossRef]

- Lu, C.; Wang, G.; Li, Y.; Zhang, L. Effects of homogenisation pressures on physicochemical changes in different layers of ultra-high temperature whole milk during storage. Int. J. Dairy Technol. 2013, 66, 325–332. [Google Scholar] [CrossRef]

- Abdel-Aziz, M.E.D.; Darwish, M.S.; Mohamed, A.H.; El-Khateeb, A.Y.; Hamed, S.E. Potential activity of aqueous fig leaves extract, olive leaves extract and their mixture as natural preservatives to extend the shelf life of pasteurized buffalo mil. Foods 2020, 9, 615. [Google Scholar] [CrossRef]

- Limbo, S.; Pellegrino, L.; D’Incecco, P.; Gobbi, S.; Rosi, V.; Fracassetti, D. Storage of pasteurized milk in clear PET bottles combined with light exposure on a retail display case: A possible strategy to define the shelf life and support a recyclable packaging. Food Chem. 2020, 329, 127116. [Google Scholar] [CrossRef] [PubMed]

- Woldemariam, H.W.; Am, A. Microbial and physicochemical qualities of pasteurized milk. J. Food Process. Technol. 2017, 8, 651. [Google Scholar] [CrossRef]

- Ansari, J.A.; Ismail, M.; Farid, M. Extension of shelf life of pasteurized trim milk using ultraviolet treatment. J. Food Saf. 2020, 40, e12768. [Google Scholar] [CrossRef]

- Stone, H.; Sidel, J.; Oliver, S.; Woolsey, A.; Singleton, R.C. Sensory evaluation by quantitative descriptive analysis. In Descriptive Sensory Analysis in Practice; Food & Nutrition Press, Inc.: Malden, MA, USA, 2004; pp. 23–34. [Google Scholar]

- Klimanova, Y.; Polzonetti, V.; Pucciarelli, S.; Perinelli, D.R.; Bonacucina, G.; Cespi, M.; Gabrielli, M.G.; Santini, G.; Fioretti, L.; Cognigni, L.; et al. Effect of steam frothing on milk microfoam: Chemical composition, texture, stability and organoleptic properties. Int. Dairy J. 2022, 135, 105476. [Google Scholar] [CrossRef]

- Stone, H.; Bleibaum, R.N.; Thomas, H.A. Chapter 6—Descriptive Analysis. In Sensory Evaluation Practices, 4th ed.; Academic Press: San Diego, CA, USA, 2012; pp. 233–289. [Google Scholar]

- Liu, X.W. A comparative study on the method of evaluating the sensory quality of strawberry. Food R D 2018, 8, 20–23+47. [Google Scholar] [CrossRef]

- Puri, R.; Khamrui, K.; Khetra, Y.; Malhotra, R.; Devraja, H.C. Quantitative descriptive analysis and principal component analysis for sensory characterization of Indian milk product cham-cham. J. Food Sci. Technol. 2016, 53, 1238–1246. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, R.; Zhao, W.; Hua, X.; Zhang, W.; Zhang, Z. Influence of pulsed electric field treatments on the volatile compounds of milk in comparison with pasteurized processing. J. Food Sci. 2011, 76, C127–C132. [Google Scholar] [CrossRef]

- Tan, J.; Xu, J. Applications of electronic nose (e-nose) and electronic tongue (e-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 2020, 4, 104–115. [Google Scholar] [CrossRef]

- Lu, N.; Wang, J.; Chen, Z.; Zhang, X.; Chen, C.; Wang, S. The effect of adding phospholipids before homogenization on the properties of milk fat globules. LWT 2021, 146, 111659. [Google Scholar] [CrossRef]

- Kuntsche, J.; Klaus, K.; Steiniger, F. Size determinations of colloidal fat emulsions: A comparative study. J. Biomed. Nanotechnol. 2009, 5, 384–395. [Google Scholar] [CrossRef]

- Kermit, M.; Lengard, V. Assessing the performance of a sensory panel–panellist monitoring and tracking. J. Chemom. 2005, 19, 154–161. [Google Scholar] [CrossRef]

- Liu, L.L.; Dong, H.; Shi, Y.G. Study on the evaluation method of the quality of dried bean curd. Sci. Technol. Food Ind. 2011, 32, 420–423. [Google Scholar] [CrossRef]

- Lanza, B.; Amoruso, F. Panel performance, discrimination power of descriptors, and sensory characterization of table olive samples. J. Sens. Stud. 2020, 35, e12542. [Google Scholar] [CrossRef]

- Leksrisompong, P.; Gerard, P.; Lopetcharat, K.; Drake, M. Bitter taste inhibiting agents for whey protein hydrolysate and whey protein hydrolysate beverages. J. Food Sci. 2012, 77, S282–S287. [Google Scholar] [CrossRef] [PubMed]

- Fuchsmann, P.; Stern, M.T.; Brügger, Y.A.; Breme, K. Olfactometry profiles and quantitation of volatile sulfur compounds of swiss tilsit cheeses. J. Agric. Food Chem. 2015, 63, 7511–7521. [Google Scholar] [CrossRef]

- Ai, N.S.; Liu, H.L.; Wang, J.; Zhang, X.M.; Zhang, H.J.; Chen, H.T.; Huang, M.Q.; Liu, Y.G.; Zheng, F.P.; Sun, B.G. Triple-channel comparative analysis of volatile flavour composition in raw whole and skim milk via electronic nose, GC-MS and GC-O. Anal. Methods 2015, 7, 4278–4284. [Google Scholar] [CrossRef]

- Li, Y.; Joyner, H.S.; Carter, B.G.; Drake, M.A. Effects of fat content, pasteurization method, homogenization pressure, and storage time on the mechanical and sensory properties of bovine milk. J. Dairy Sci. 2018, 101, 2941–2955. [Google Scholar] [CrossRef]

- Cheng, N.; Barbano, D.M.; Drake, M. Effects of milk fat, casein, and serum protein concentrations on sensory properties of milk-based beverages. J. Dairy Sci. 2019, 102, 8670–8690. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Stevenson, R.J.; Ang, X.; Peng, Y.; Quek, S.Y. Lipase-catalyzed modification of milk fat: A promising way to alter flavor notes of goat milk products. LWT 2021, 145, 111286. [Google Scholar] [CrossRef]

- Wiking, L.; Løkke, M.M.; Kidmose, U.; Sundekilde, U.K.; Dalsgaard, T.K.; Larsen, T.; Feilberg, A. Comparison between novel and standard methods for analysis of free fatty acids in milk-Including relation to rancid flavour. Int. Dairy J. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Cadwallader, K.R.; Singh, T.K. Flavours and Off-Flavours in Milk and Dairy Products. In Advanced Dairy Chemistry: Volume 3: Lactose, Water, Salts and Minor Constituents; Springer: New York, NY, USA, 2009; pp. 631–690. [Google Scholar]

- Santos, M.V.; Ma, Y.; Caplan, Z.; Barbano, D.M. Sensory threshold of off-flavors caused by proteolysis and lipolysis in milk. J. Dairy Sci. 2003, 86, 1601–1607. [Google Scholar] [CrossRef] [PubMed]

- Gardner, J.W.; Bartlett, P.N. A brief history of electronic noses. Sensor. Actuat. B-Chem. 1994, 18, 210–211. [Google Scholar] [CrossRef]

- Haugen, J.E.; Kvaal, K. Electronic nose and artificial neural network. Meat Sci. 1998, 49, S273–S286. [Google Scholar] [CrossRef]

- Echeverría, G.; Correa, E.; Ruiz-Altisent, M.; Graell, J.; Puy, J.; López, L. Characterization of Fuji apples from different harvest dates and storage conditions from measurements of volatiles by gas chromatography and electronic nose. J. Agric. Food Chem. 2004, 52, 3069–3076. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Tian, X.; Yu, H.; Yu, Y. Optimization of sensor array and detection of stored duration of wheat by electronic nose. J. Food Eng. 2007, 82, 403–408. [Google Scholar] [CrossRef]

- Buchin, S.; Delague, V.; Duboz, G.; Berdague, J.L.; Beuvier, E.; Pochet, S.; Grappin, R. Influence of pasteurization and fat composition of milk on the volatile compounds and flavor characteristics of a semi-hard cheese. J. Dairy Sci. 1998, 81, 3097–3108. [Google Scholar] [CrossRef]

- Chen, L.; Daniel, R.M.; Coolbear, T. Detection and impact of protease and lipase activities in milk and milk powders. Int. Dairy J. 2003, 13, 255–275. [Google Scholar] [CrossRef]

- Zhao, X.; Cheng, M.; Wang, C.; Jiang, H.; Zhang, X. Effects of dairy bioactive peptides and lotus seeds/lily bulb powder on flavor and quality characteristics of goat milk yogurt. Food Biosci. 2022, 47, 101510. [Google Scholar] [CrossRef]

- Solah, V.A.; Staines, V.; Honda, S.; Limley, H.A. Measurement of milk color and composition: Effect of dietary intervention on Western Australian Holstein-Friesian cow’s milk quality. J. Food Sci. 2007, 72, S560–S566. [Google Scholar] [CrossRef]

- McDermott, A.; Visentin, G.; McParland, S.; Berry, D.P.; Fenelon, M.A.; De Marchi, M. Effectiveness of mid-infrared spectroscopy to predict the color of bovine milk and the relationship between milk color and traditional milk quality traits. J. Dairy Sci. 2016, 99, 3267–3273. [Google Scholar] [CrossRef]

- Cheng, N.; Barbano, D.M.; Drake, M.A. Effect of pasteurization and fat, protein, casein to serum protein ratio, and milk temperature on milk beverage color and viscosity. J. Dairy Sci. 2019, 102, 2022–2043. [Google Scholar] [CrossRef]

- Lucey, J.A. Cultured dairy products: An overview of their gelation and texture properties. Int. J. Dairy Technol. 2004, 57, 77–84. [Google Scholar] [CrossRef]

- Tamime, A.Y.; Robinson, R.K. Tamime and Robinson’s Yoghurt, 3rd ed.; Woodhead Publishing: Cambridge, UK, 2007; pp. 83–108. [Google Scholar]

- Park, C.W.; Drake, M. The effect of homogenization pressure on the flavor and flavor stability of whole milk powder. J. Dairy Sci. 2017, 100, 5195–5205. [Google Scholar] [CrossRef] [PubMed]

- Tribst, A.A.L.; Falcade, L.T.P.; Carvalho, N.S.; Junior, B.R.d.C.L.; de Oliveira, M.M. Using stirring and homogenization to improve the fermentation profile and physicochemical characteristics of set yogurt from fresh, refrigerated and frozen/thawed sheep milk. LWT 2020, 130, 109557. [Google Scholar] [CrossRef]

- Juttulapa, M.; Piriyaprasarth, S.; Takeuchi, H.; Sriamornsak, P. Effect of high-pressure homogenization on stability of emulsions containing zein and pectin. Asian J. Pharm. Sci. 2017, 12, 21–27. [Google Scholar] [CrossRef]

- Kashaninejad, M.; Razavi, S.M.A. Influence of thermosonication treatment on the average size of fat globules, emulsion stability, rheological properties and color of camel milk cream. LWT 2020, 132, 109852. [Google Scholar] [CrossRef]

- Hayes, M.G.; Kelly, A.L. High pressure homogenisation of raw whole bovine milk (a) effects on fat globule size and other properties. J. Dairy Res. 2003, 70, 297–305. [Google Scholar] [CrossRef]

| Homogenization Time | 8 h | 72 h | 168 h | |

|---|---|---|---|---|

| Homogenization Pressure | ||||

| 0 bar | MC8 | MC72 | MC168 | |

| 150 bar | ML8 | ML72 | ML168 | |

| 300 bar | MH8 | MH72 | MH168 | |

| Sensory Attributes | Evaluation Method |

|---|---|

| Milk flavor | After tasting, the intensity of residual milk flavor. |

| Creamy | Oil scent. |

| Fat flavor | After tasting, the intensity of fat feeling in the mouth. |

| Cooked taste | Have a slight taste of feed, carton, iron pot boiled water taste |

| Caramel flavor | The flavor produced by heating or cooking. |

| Metallic taste | Taste of rust-like metal, tasting whether the sample has a metallic smell. |

| Sourness | The intensity of sourness was felt in the mouth. |

| Sweetness | After tasting, the intensity of residual sweetness. |

| Bitter | Bitter taste after preservation at room temperature. |

| Saltness | The intensity of salt was felt in the mouth. Slight salt should exist in the optimum sample. |

| Astringency | After processing and storage produced astringent taste, tongue slightly bitter feeling. |

| Fresh milk flavor | taste intensity from oral to MSG. |

| Texture | Whether the sample is a uniform liquid, and whether there is a clot or precipitation. |

| Residual taste | After tasting, the greasy feeling remains on the tongue and upper teeth. |

| Peculiar taste | Unpleasant taste, the greater the odor, the higher the score, normal milk will not taste. |

| Sensor Number in Array Sensor | General | Description | Reference (mL/m3) |

|---|---|---|---|

| S1 | W1C | Sensitive to aromatic constituents | C7H8, 10 |

| S2 | W5S | High sensitivity to nitrogen oxides | NO2, 1 |

| S3 | W3C | sensitive to aromatic components | C6H6, 10 |

| S4 | W6S | Selectivity to hydrogen | H2, 100 |

| S5 | W5C | Sensitive to aromatic compounds | C3H8, 1 |

| S6 | W1S | Sensitiveto methane and hydrocarbons | CH4, 100 |

| S7 | W1W | Sensitive to sulfides | H2S, 1 |

| S8 | W2S | Sensitive to ethanol | CO, 100 |

| S9 | W2W | Sensitive to sulfides and chlorides | H2S, 1 |

| S10 | W3S | Sensitive to methane | CH4, 100 |

| Homogeneous Parameters | L* | a* | b* | ∆E |

|---|---|---|---|---|

| 8 h | ||||

| CK | 58.22 ± 0.02 b | 0.94 ± 0.00 a | 16.89 ± 0.01 ab | 0.14 ± 0.02 ab |

| 150 bar | 47.74 ± 0.13 d | 0.67 ± 0.02 c | 17.05 ± 0.13 a | 0.32 ± 0.16 a |

| 300 bar | 49.52 ± 0.01 c | 0.80 ± 0.01 b | 16.82 ± 0.01 b | 0.07 ± 0.01 b |

| 72 h | ||||

| CK | 59.05 ± 0.54 a | 0.90 ± 0.03 a | 16.13 ± 0.04 c | 0.31 ± 0.17 a |

| 150 bar | 50.08 ± 0.07 b | 0.89 ± 0.01 a | 16.97 ± 0.01 a | 0.14 ± 0.07 a |

| 300 bar | 49.96 ± 0.06 b | 0.86 ± 0.01 a | 16.82 ± 0.02 b | 0.21 ± 0.05 a |

| 168 h | ||||

| CK | 59.23 ± 0.19 a | 0.76 ± 0.04 a | 16.11 ± 0.10 b | 0.36 ± 0.20 b |

| 150 bar | 52.42 ± 0.08 c | 0.69 ± 0.02 b | 15.88 ± 0.04 c | 0.53 ± 0.09 b |

| 300 bar | 50.39 ± 0.06 d | 0.79 ± 0.01 a | 16.50 ± 0.03 a | 0.10 ± 0.03 b |

| Homogenization Parameters | Surveillance Project | |||||

|---|---|---|---|---|---|---|

| D [3,2] | D [4,3] | Dv(10) | Dv(50) | Dv(90) | ||

| 8 h | 0 bar | 0.184 | 1.051 | 0.070 | 0.622 | 2.600 |

| 150 bar | 0.148 | 0.856 | 0.054 | 0.475 | 2.200 | |

| 300bar | 0.097 | 0.471 | 0.035 | 0.226 | 1.25 | |

| 72 h | 0 bar | 0.171 | 1.003 | 0.064 | 0.575 | 2.507 |

| 150 bar | 0.133 | 0.762 | 0.048 | 0.402 | 2.000 | |

| 300bar | 0.095 | 0.449 | 0.035 | 0.216 | 1.190 | |

| 168 h | 0 bar | 0.170 | 0.994 | 0.063 | 0.571 | 2.483 |

| 150 bar | 0.138 | 0.792 | 0.050 | 0.426 | 2.057 | |

| 300 bar | 0.095 | 0.449 | 0.035 | 0.216 | 1.193 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, Y.; Yuan, Y.; Xi, Y.; Zhao, T.; Ai, N. Effects of Homogenization on Organoleptic Quality and Stability of Pasteurized Milk Samples. Agriculture 2023, 13, 205. https://doi.org/10.3390/agriculture13010205

Shao Y, Yuan Y, Xi Y, Zhao T, Ai N. Effects of Homogenization on Organoleptic Quality and Stability of Pasteurized Milk Samples. Agriculture. 2023; 13(1):205. https://doi.org/10.3390/agriculture13010205

Chicago/Turabian StyleShao, Yiwei, Yiting Yuan, Yanmei Xi, Tong Zhao, and Nasi Ai. 2023. "Effects of Homogenization on Organoleptic Quality and Stability of Pasteurized Milk Samples" Agriculture 13, no. 1: 205. https://doi.org/10.3390/agriculture13010205

APA StyleShao, Y., Yuan, Y., Xi, Y., Zhao, T., & Ai, N. (2023). Effects of Homogenization on Organoleptic Quality and Stability of Pasteurized Milk Samples. Agriculture, 13(1), 205. https://doi.org/10.3390/agriculture13010205