Geometric and Thermo-Gravimetric Evaluation of Bananas during Convective Drying: An Experimental Investigation

Abstract

1. Introduction

2. Methodology

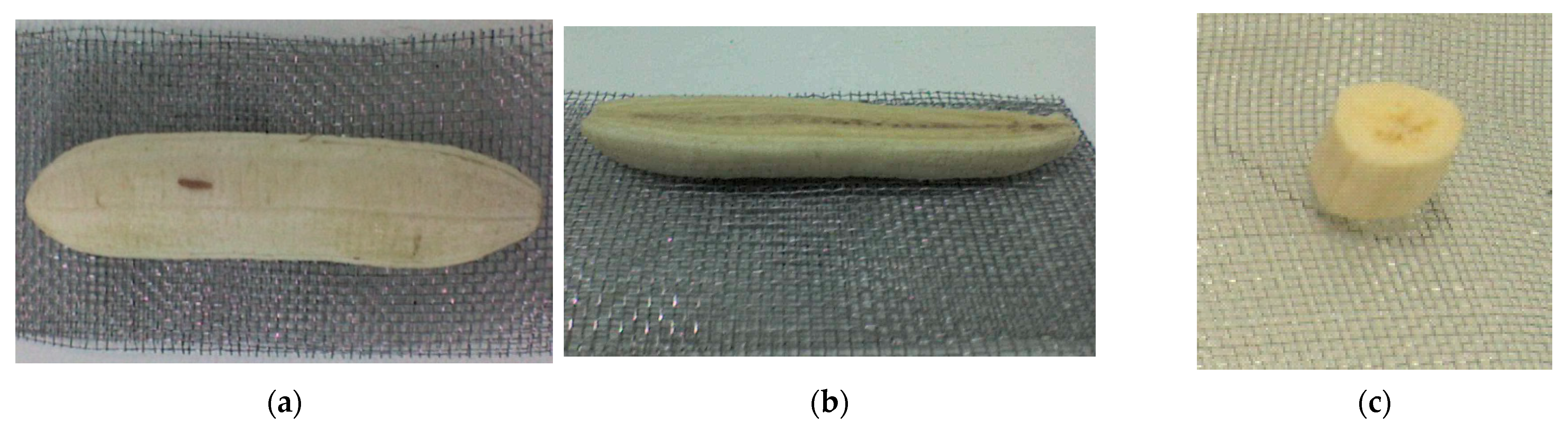

2.1. Material and Experimental Procedures

2.2. Auxiliary Parameters

- (a)

- Mass of water

- (b)

- Moisture content on a wet basis

- (c)

- Moisture content on a dry basis

- (d)

- Dimensionless moisture content

- (e)

- Dimensionless temperature

- (f)

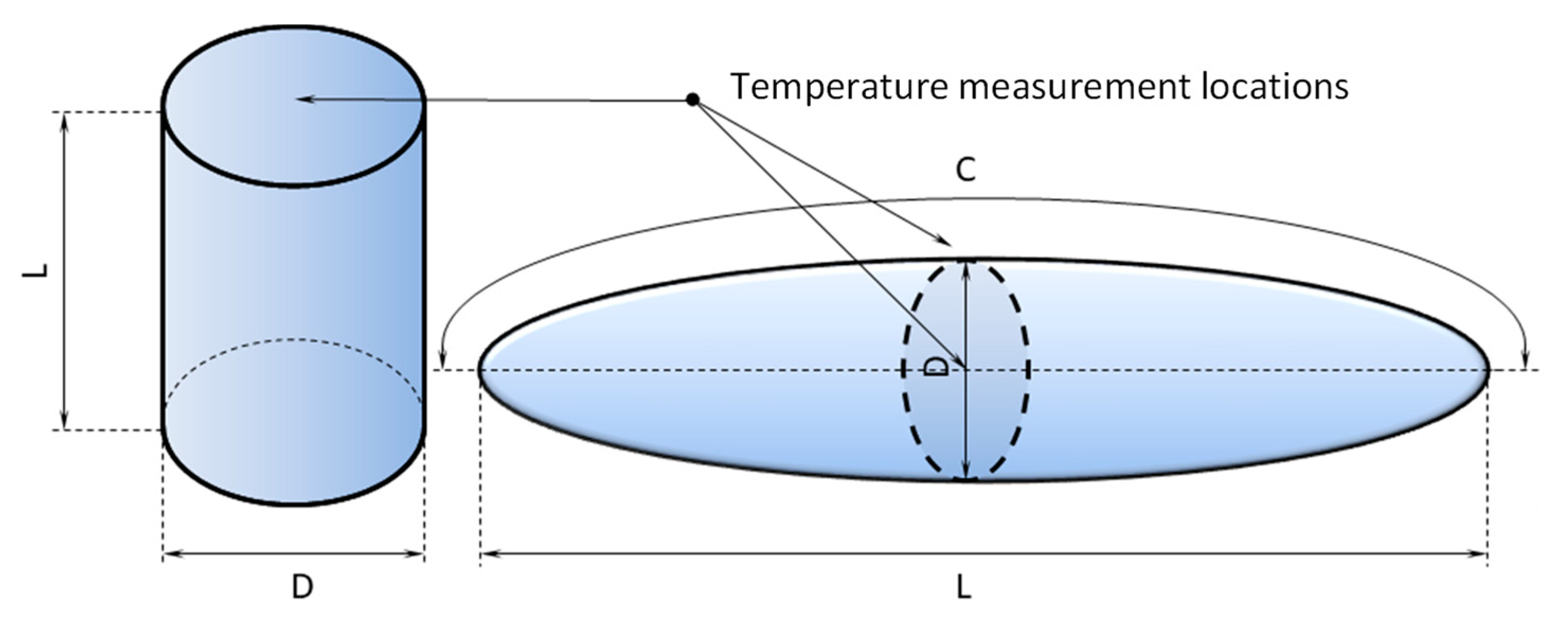

- Volume and surface area of the banana

- -

- For the whole banana (considered as a prolate spheroid, Figure 3)

- -

- For the banana cut lengthwise in half:

- -

- Banana cut transversally (considered as a finite cylinder).

2.3. Experimental Drying Conditions

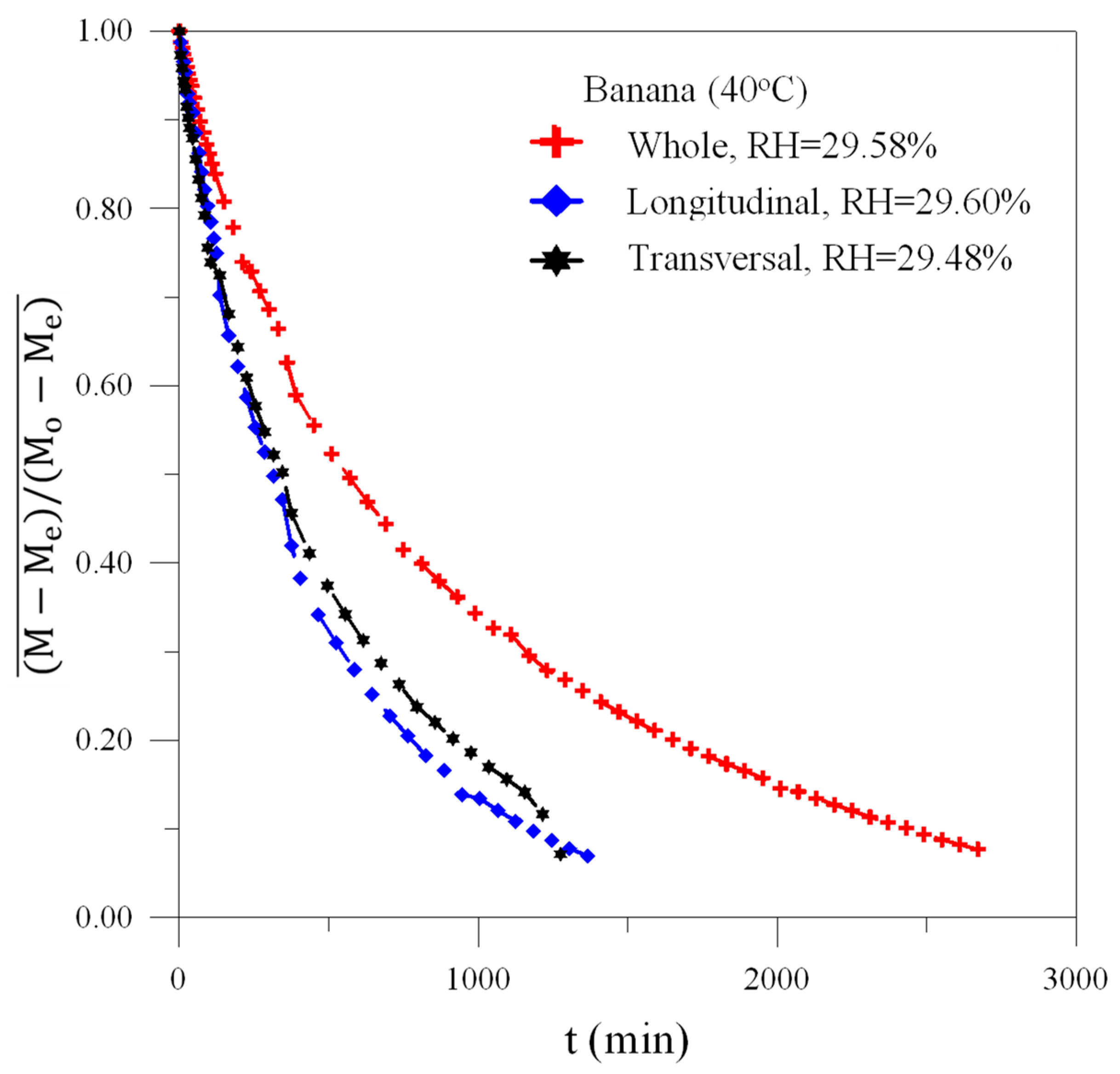

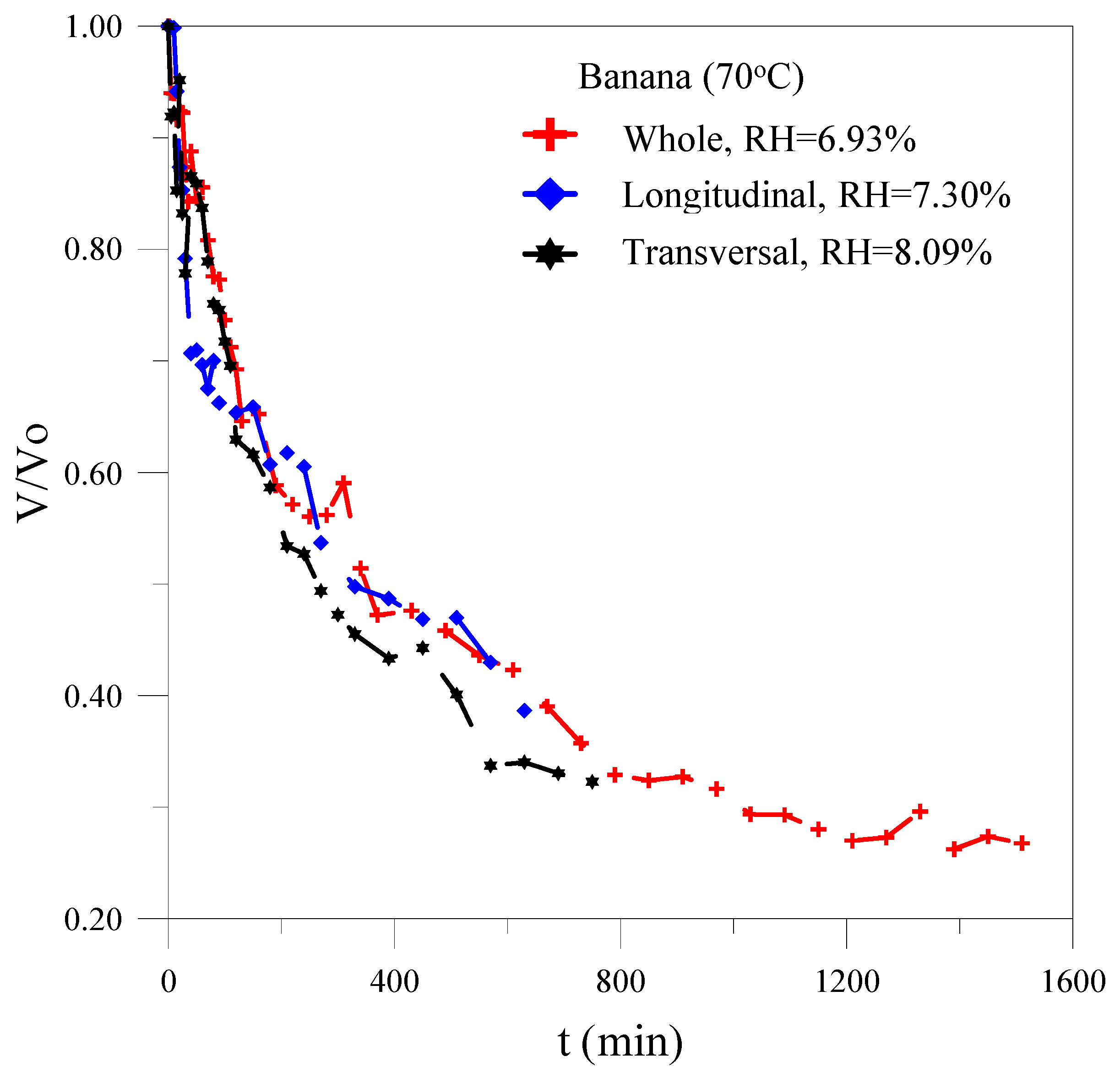

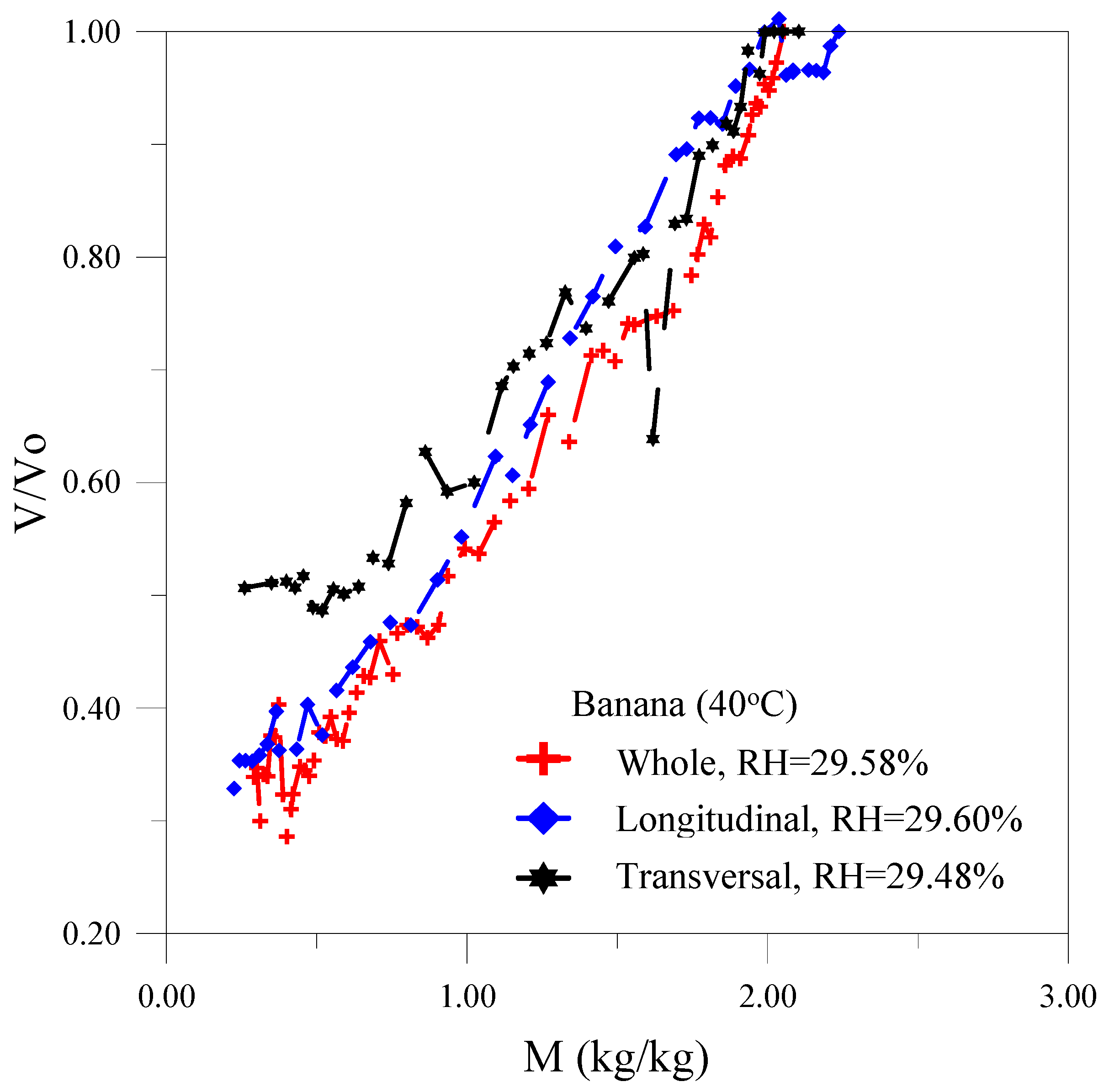

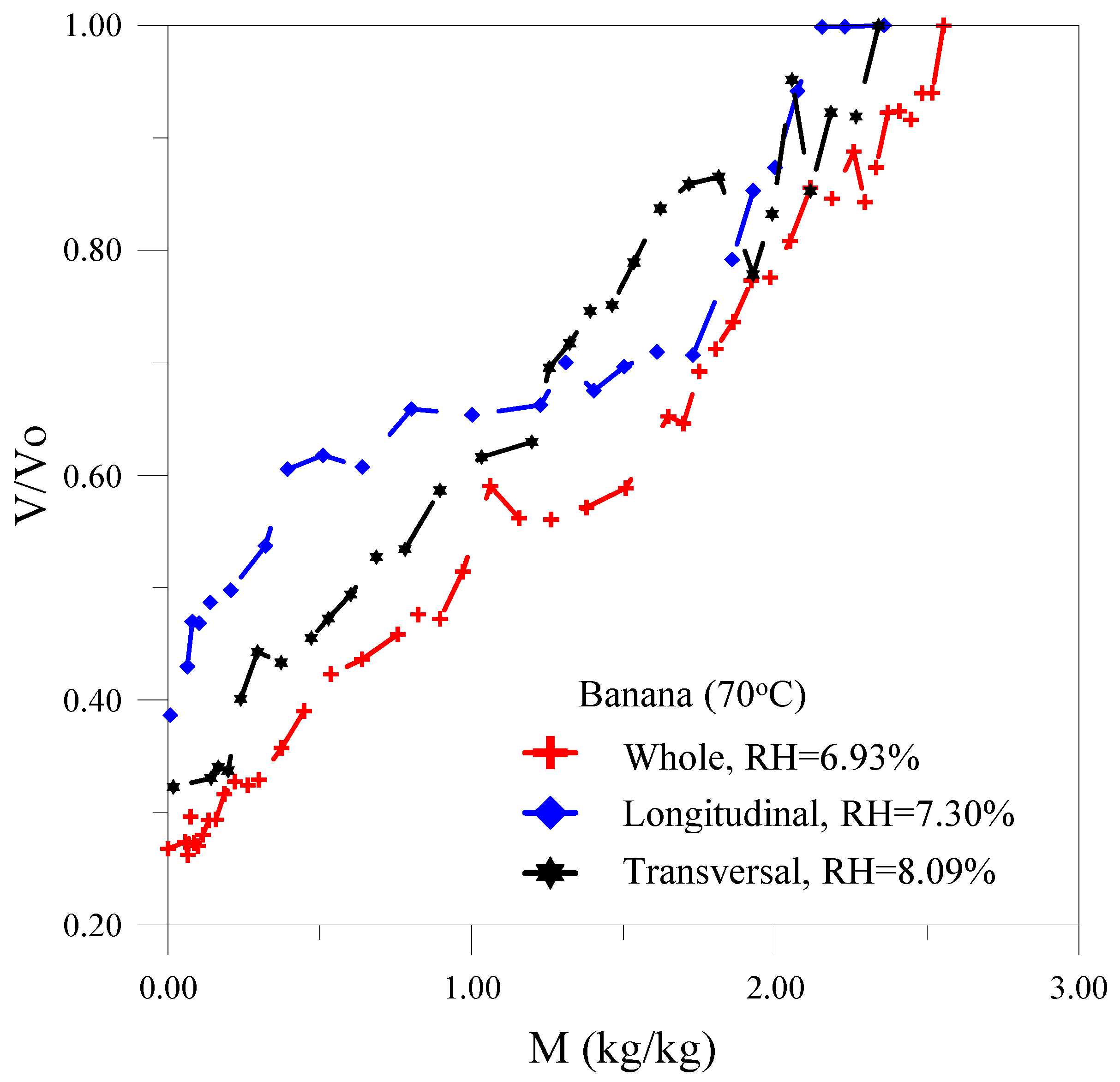

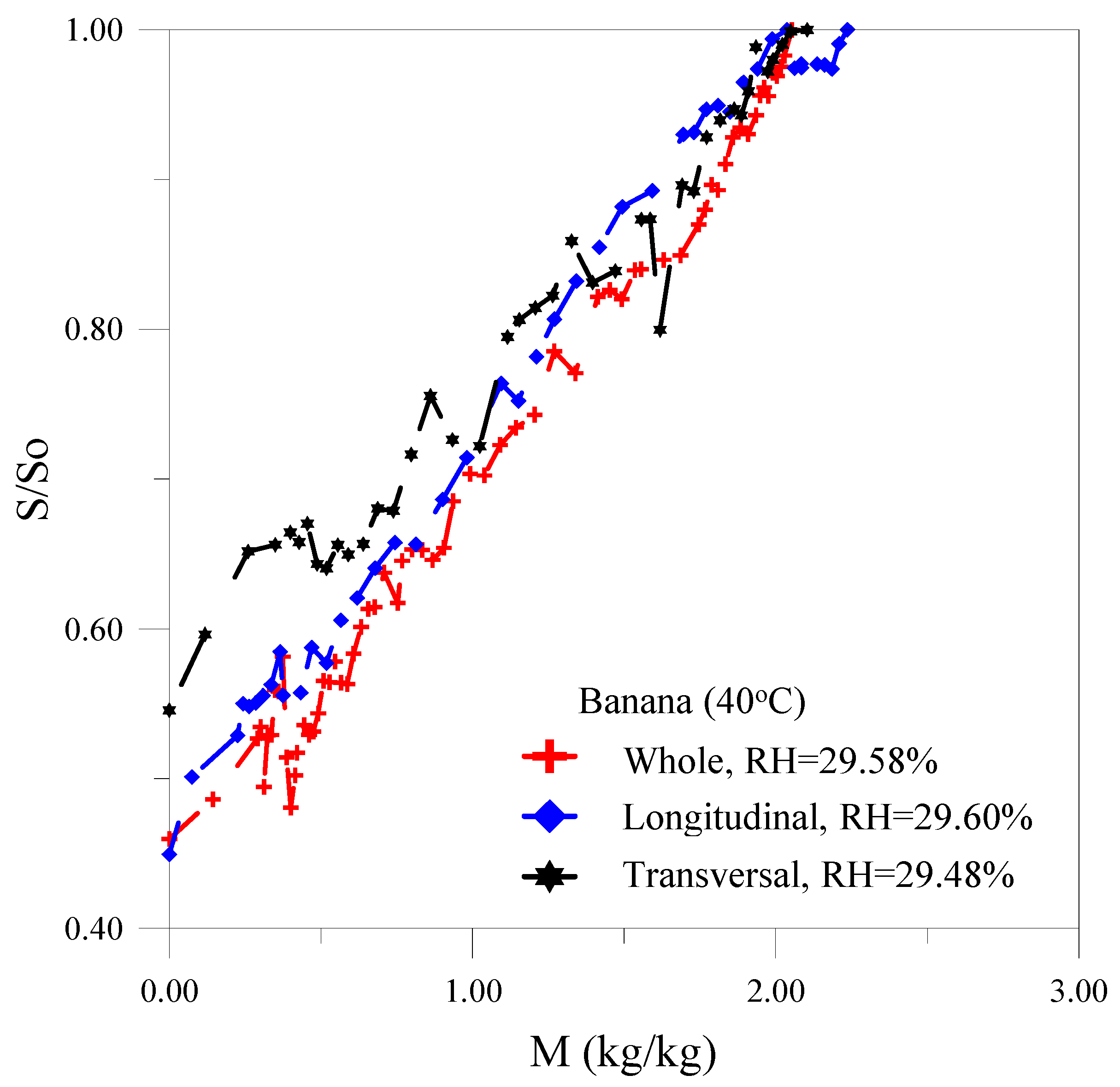

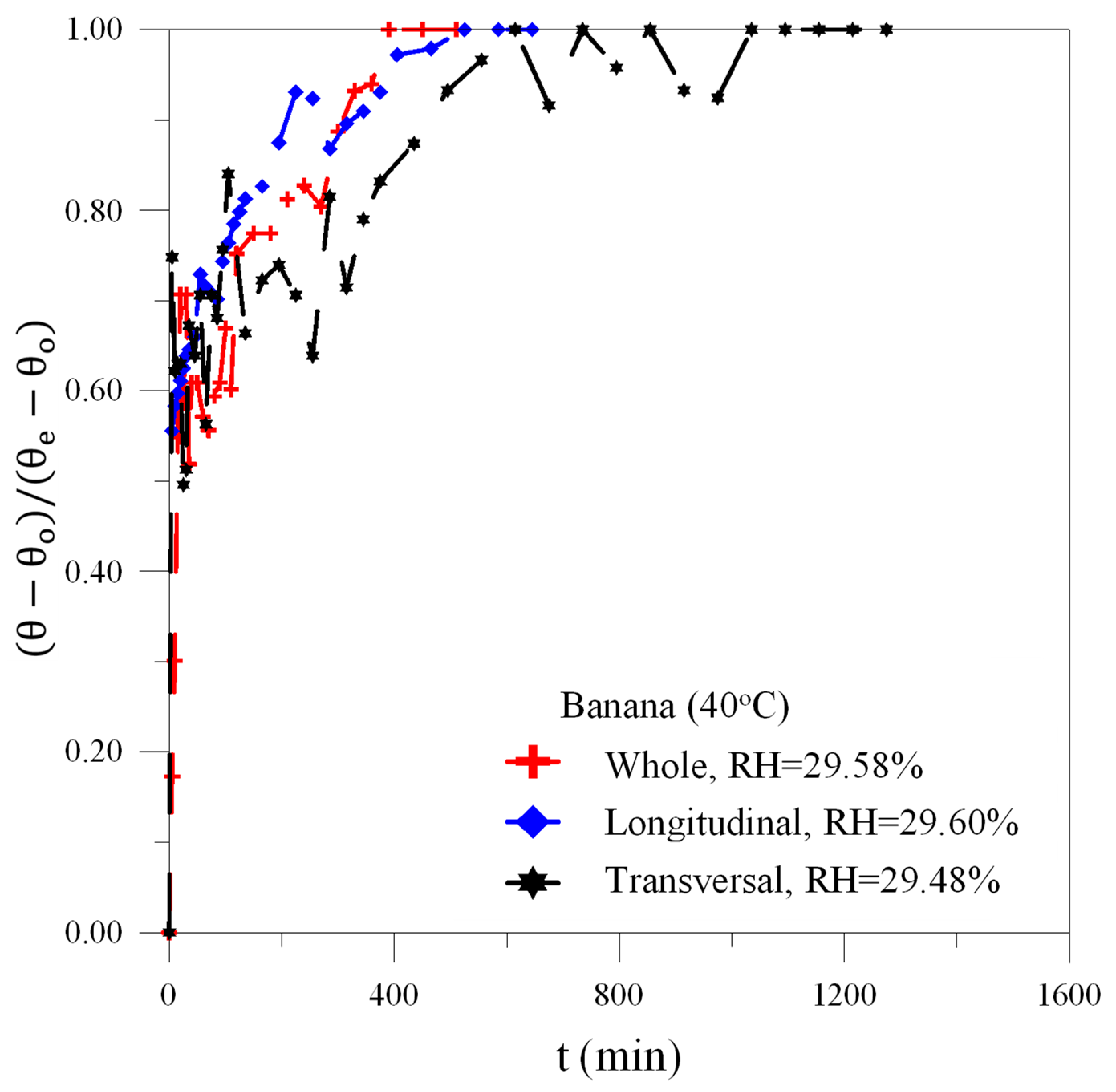

3. Results and Discussion

4. Conclusions

- (a)

- Banana drying occurs in a decreasing rate period, regardless of the drying air temperature and for a relative humidity of the drying air lower than 100%;

- (b)

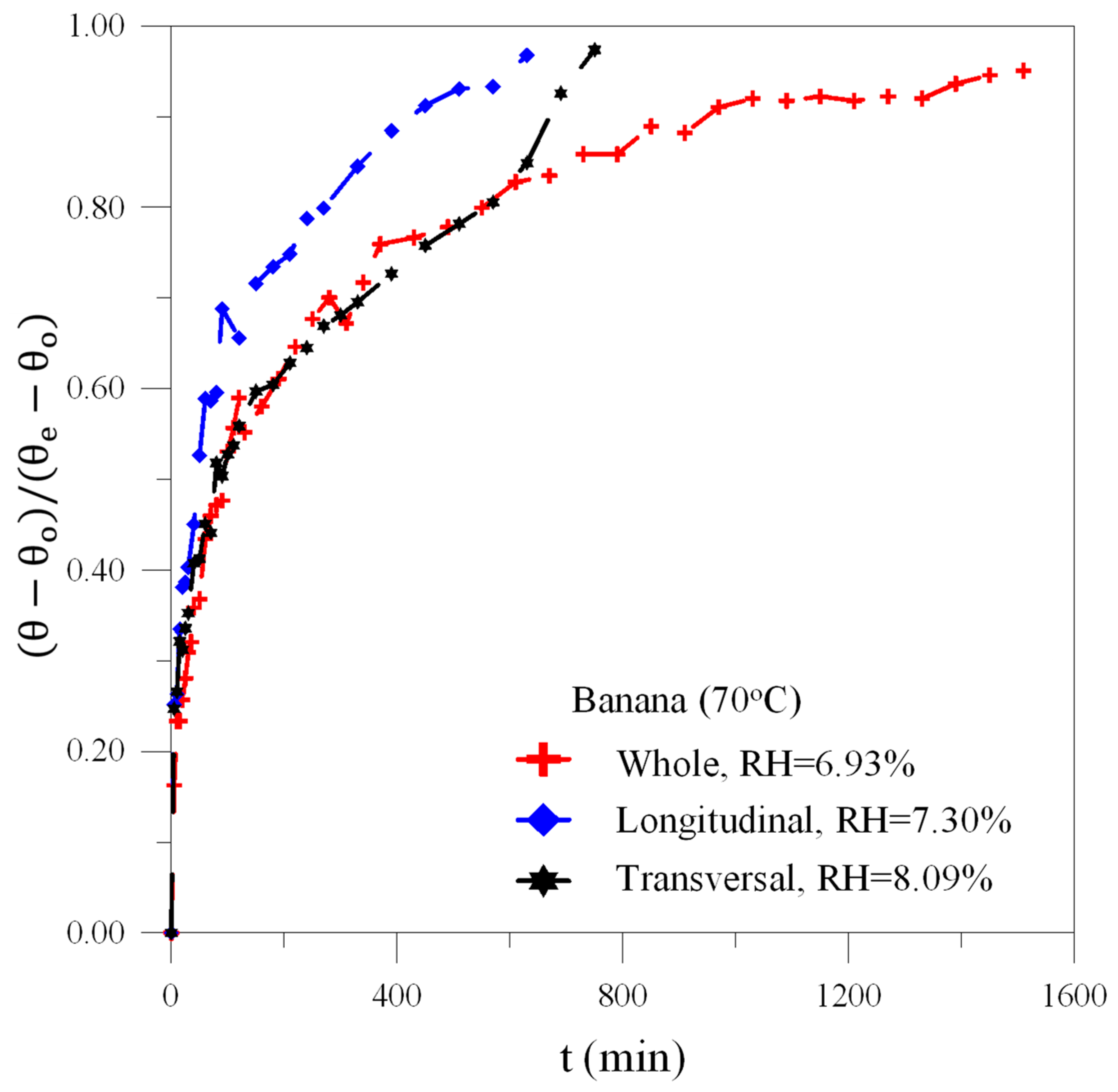

- Drying air temperature and geometric shape have a strong effect on banana drying, heating and shrinkage kinetics;

- (c)

- The higher the temperature, the faster drying occurs;

- (d)

- In general, the higher the area/volume relationships, the faster drying occurs, which fixed the other experimental conditions and for a relative humidity of the drying air lower than 100%;

- (e)

- The volumetric shrinkage of the banana shows a linearly decreasing trend with the loss of water from the product.

- (f)

- Product quality is strongly affected by thermal effects, and a browning process has been observed in all drying conditions and fruit shapes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wakjira, M.; Adugna, D.; Yadessa, G. Determining slice thickness of banana (Musa spp.) for enclosed solar drying using solar cabinet dryer under ethiopian condition. Am. J. Food Technol. 2011, 6, 568–580. [Google Scholar] [CrossRef]

- Omolola, A.O.; Jideani, A.I.O.; Kapila, P.F. Drying kinetics of banana (Musa spp.). Interciencia 2015, 40, 374–380. [Google Scholar]

- Ahmad, B.A.; Zakariyya, U.A.; Abubakar, M.; Sani, M.M.; Ahmad, M.A. Pharmacological activities of banana. In Banana Nutrition—Function and Processing Kinetics, 1st ed.; Jideani, A.I.O., Anyasi, T.A., Eds.; IntechOpen: London, UK, 2019; Volume 1, Available online: https://www.intechopen.com/books/banana-nutrition-function-and-processing-kinetics/pharmacological-activities-of-banana (accessed on 20 April 2020). [CrossRef]

- Yang, H.; Sombatngamwilai, T.; Yu, W.-Y.; Kuo, M.-I. Drying applications during value-added sustainable processing for selected mass-produced food coproducts. Processes 2020, 8, 307. [Google Scholar] [CrossRef]

- Soetan, K.O.; Olaiya, C.O.; Oyewole, O.E. The importance of mineral elements for humans, domestic animals and plants—A review. Afr. J. Food Sci. 2010, 4, 200–222. [Google Scholar] [CrossRef]

- Lima, A.G.B.; Queiroz, M.R.; Nebra, S.A. Simultaneous moisture transport and shrinkage during drying of solids with ellipsoidal configuration. Chem. Eng. J. 2002, 86, 85–93. [Google Scholar] [CrossRef]

- Lima, A.G.B.; Farias Neto, S.R.; Silva, W.P. Heat and mass transfer in porous materials with complex geometry: Fundamentals and applications. In Heat and Mass Transfer in Porous Media, 1st ed.; Delgado, J.M.P.Q., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 13, pp. 161–185. [Google Scholar]

- Ganesapillai, M.; Regupathi, I.; Murugesan, T. Modeling of thin layer drying of banana (Nendran Spp.) under microwave, convective and combined microwave-convective processes. Chem. Prod. Process Model. 2011, 6, 10. [Google Scholar] [CrossRef]

- Obiageli, O.A.; Ohia, G.U.; Pauline, I.A.; Helen, O.N. Glycoside, moisture and dry matter compositions of fruits of three musa species at three stages of development. IOSR J. Pharm. Biol. Sci. 2016, 11, 60–67. [Google Scholar] [CrossRef]

- Netshiheni, R.K.; Omolola, A.O.; Anyasi, T.A.; Jideani, A.I.O. Banana bioactives: Absorption, utilisation and health benefits. In Banana Nutrition—Function and Processing Kinetics, 1st ed.; Jideani, A.I.O., Anyasi, T.A., Eds.; IntechOpen: London, UK, 2019; Volume 1, p. 83369. Available online: https://www.intechopen.com/books/banana-nutrition-function-and-processing-kinetics/pharmacological-activities-of-banana (accessed on 22 April 2020). [CrossRef]

- Tanada, P.S. Obtaining an Extract of (Musa cavendish) Free from Polyphenol Oxidase by Ultra-Filtration and Concentrated by Reverse Osmosis. Master’s Dissertation, State University of Campinas, Campinas, Brazil, 1996. Available online: http://repositorio.unicamp.br/jspui/handle/REPOSIP/254572 (accessed on 20 October 2021).

- Wang, N.; Brennan, J.G. Change in structure, density and porosity of potato during dehydration. J. Food Eng. 1995, 24, 61–76. [Google Scholar] [CrossRef]

- Ramos, I.N.; Brandão, T.R.S.; Silva, C.L.M. Structural changes during air drying of fruits and vegetables. Food Sci. Technol. Int. 2003, 9, 201–206. [Google Scholar] [CrossRef]

- Nguyen, M.H.; Price, W.E. Air-drying of banana: Influence of experimental parameters, slab thickness, banana maturity and harvesting season. J. Food Eng. 2007, 79, 200–207. [Google Scholar] [CrossRef]

- Pan, Z.; Shih, C.; Mchugh, T.H.; Hirschberg, E. Study of banana dehydration using sequential infrared radiation heating and freeze-drying. LTW—Food Sci. Technol. 2008, 41, 194–195. [Google Scholar] [CrossRef]

- Swasdisevi, R.; Devahastin, S.; Sa-Adchom, P.; Soponronnarit, S. Mathematical modeling of combined far-infrared and vacuum drying banana slice. J. Food Eng. 2009, 92, 100–106. [Google Scholar] [CrossRef]

- Junlakan, W.; Yamsaengsung, R.; Tirawanichakul, S. Effects of vacuum drying on structural changes of banana slices. J. Chem. Eng. 2011, 106, 298–305. [Google Scholar] [CrossRef][Green Version]

- Kumar, P.S.; Nambi, E.; Shiva, K.N.; Vaganan, M.M.; Ravi, I.; Jeyabaskaran, K.J.; Uma, S. Thin layer drying kinetics of Banana var. Monthan (ABB): Influence of convective drying on nutritional quality, microstructure, thermal properties, color, and sensory characteristics. J. Food Process Eng. 2019, 42, 12. [Google Scholar] [CrossRef]

- Páramo, D.; García-Alamilla, P.; Salgado-Cervantes, M.A.; Robles-Olvera, V.J.; Rodríguez-Jimenes, G.C.; García-Alvarado, M.A. Mass transfer of water and volatile fatty acids in cocoa beans during drying. J. Food Eng. 2010, 99, 276–283. [Google Scholar] [CrossRef]

- Silva, E.G.; Lima, E.S.; Lima, W.M.P.B.; Lima, A.G.B.; Nascimento, J.J.S.; Simões, F.J. Convective and microwave drying of prolate spheroidal solids: Modeling and simulation. Defect Diffus. Forum 2019, 391, 233–238. [Google Scholar] [CrossRef]

- Hernández-Díaz, W.N.; Ruiz-López, I.; Salgado-Cervantes, M.; Rodriguez-Jimenes, G.; García-Alvarado, M. Modeling heat and mass transfer during drying of green coffee beans using prolate spheroidal geometry. J. Food Eng. 2008, 86, 1–9. [Google Scholar] [CrossRef]

- Maskan, M. Microwave/air and microwave finish drying of banana. J. Food Eng. 2000, 44, 71–78. [Google Scholar] [CrossRef]

- Phoungchandang, S.; Woods, J.L. Moisture diffusion and desorption isotherms for banana. J. Food Sci. 2000, 65, 651–657. [Google Scholar] [CrossRef]

- Dandamrongrak, R.; Young, G.; Mason, R. Evaluation of pre-treatments for the dehydration of banana and selection of suitable drying models. J. Food Eng. 2002, 55, 139–146. [Google Scholar] [CrossRef]

- Queiroz, M.R.; Nebra, S.A. Theoretical and experimental analysis of the drying kinetics of bananas. J. Food Eng. 2001, 47, 127–132. [Google Scholar] [CrossRef]

- Demirel, D.; Turhan, M. Air-drying behavior of Dwarf cavendish and Gros michel banana slices. J. Food Eng. 2003, 59, 1–11. [Google Scholar] [CrossRef]

- Karim, A.M.D.; Hawlader, M.N.A. Drying characteristics of banana: Theoretical modeling and experimental validation. J. Food Eng. 2005, 70, 35–45. [Google Scholar] [CrossRef]

| Air | Banana (Whole) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | RH (%) | v (m/s) | C (mm) | L (mm) | D (mm) | Mo (d.b.) | Mf (d.b.) | Me (d.b.) | θo (°C) | θf (°C) | t (min) |

| 40 | 29.58 | 0.04 | 110 | 112.76 | 29.65 | 2.0534 | 0.2911 | 0.1441 | 26.7 | 40.0 | 2670 |

| 70 | 6.93 | 0.07 | 115 | 105.36 | 27.83 | 2.5541 | 0.0574 | 0.0015 | 27.6 | 67.7 | 1450 |

| Air | Banana (Whole) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | RH (%) | v (m/s) | C (mm) | L (mm) | D (mm) | Mo (d.b.) | Mf (d.b.) | Me (d.b.) | θo (°C) | θf (°C) | t (min) |

| 40 | 29.60 | 0.04 | 133 | 119.04 | 25.34 | 2.2366 | 0.2256 | 0.0749 | 25.6 | 40.0 | 1365 |

| 70 | 7.30 | 0.07 | 112 | 95.55 | 21.62 | 2.3587 | 0.0079 | 0.0080 | 26.7 | 68.6 | 630 |

| Air | Banana (Whole) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | RH (%) | v (m/s) | C (mm) | L (mm) | D (mm) | Mo (d.b.) | Mf (d.b.) | Me (d.b.) | θo (°C) | θf (°C) | t (min) |

| 40 | 29.48 | 0.04 | ---- | 15.18 | 30.22 | 2.1037 | 0.2603 | 0.1181 | 28.1 | 40.0 | 1275 |

| 70 | 8.09 | 0.07 | ---- | 18.64 | 26.99 | 2.3405 | 0.0179 | 0.0010 | 28.3 | 68.9 | 750 |

| Geometric Shape | T (°C) | t (min) | |||||

|---|---|---|---|---|---|---|---|

| Whole | 40 | 2670 | 0.6361 | 0.8374 | 0.5269 | 0.3388 | 0.1634 |

| 70 | 1450 | 0.5738 | 0.8313 | 0.4705 | 0.2737 | 0.1741 | |

| Longitudinal slice | 40 | 1365 | 0.6156 | 0.8667 | 0.5288 | 0.3285 | 0.1895 |

| 70 | 630 | 0.6563 | 0.8973 | 0.5835 | 0.3865 | 0.2226 | |

| Transversal slice | 40 | 1275 | 0.8345 | 0.7272 | 0.6516 | 0.5065 | 0.2641 |

| 70 | 750 | 0.6784 | 0.7012 | 0.4692 | 0.3227 | 0.2555 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farias, R.P.; Gomez, R.S.; Lima, E.S.; Silva, W.P.; Santos, I.B.; Figueredo, M.J.; Almeida, G.S.; Rolim, F.D.; Oliveira, V.A.B.; Oliveira Neto, G.L.; et al. Geometric and Thermo-Gravimetric Evaluation of Bananas during Convective Drying: An Experimental Investigation. Agriculture 2022, 12, 1181. https://doi.org/10.3390/agriculture12081181

Farias RP, Gomez RS, Lima ES, Silva WP, Santos IB, Figueredo MJ, Almeida GS, Rolim FD, Oliveira VAB, Oliveira Neto GL, et al. Geometric and Thermo-Gravimetric Evaluation of Bananas during Convective Drying: An Experimental Investigation. Agriculture. 2022; 12(8):1181. https://doi.org/10.3390/agriculture12081181

Chicago/Turabian StyleFarias, Raimundo P., Ricardo S. Gomez, Elisiane S. Lima, Wilton P. Silva, Ivonete B. Santos, Maria J. Figueredo, Genival S. Almeida, Fagno D. Rolim, Vital A. B. Oliveira, Guilherme L. Oliveira Neto, and et al. 2022. "Geometric and Thermo-Gravimetric Evaluation of Bananas during Convective Drying: An Experimental Investigation" Agriculture 12, no. 8: 1181. https://doi.org/10.3390/agriculture12081181

APA StyleFarias, R. P., Gomez, R. S., Lima, E. S., Silva, W. P., Santos, I. B., Figueredo, M. J., Almeida, G. S., Rolim, F. D., Oliveira, V. A. B., Oliveira Neto, G. L., & Lima, A. G. B. (2022). Geometric and Thermo-Gravimetric Evaluation of Bananas during Convective Drying: An Experimental Investigation. Agriculture, 12(8), 1181. https://doi.org/10.3390/agriculture12081181