Cost Comparison between Digital Management and Traditional Management of Cotton Fields—Evidence from Cotton Fields in Xinjiang, China

Abstract

:1. Introduction

2. Methods and Data

2.1. Methods

2.1.1. Cost–Benefit Analysis

2.1.2. Sensitivity Analysis

2.2. Data Source

3. Results

3.1. Cost–Benefit Analysis Results

3.2. Sensitivity Analysis Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bakhsh, A.; Anayol, E.; Özcan, S.F.; Hussain, T.; Aasim, M.; Khawar, K.M.; Özcan, S. An insight into cotton genetic engineering (Gossypium hirsutum L.): Current endeavors and prospects. Acta Physiol. Plant. 2015, 37, 117. [Google Scholar] [CrossRef]

- Qian, J.F.; Li, H.S. Subsidy policy adjustment, comparative benefit change and farmers’ cotton production decisions: Based on the provincial dynamic panel data of the major producing areas. J. Hunan Agric. Univ. Soc. Sci. 2020, 21, 1–7. [Google Scholar]

- Wang, W.; Zhang, C.M.; Song, J.H.; Xu, D.D. The impact of target price policy on cotton cultivation: Analysis of county-level panel data from China. Agriculture 2021, 11, 988. [Google Scholar] [CrossRef]

- Li, J.M.; Wang, K. Factors influencing Xinjiang cotton’s participation in different organization. Modes Soc. Sci. 2017, 6, 101–104. [Google Scholar]

- National Bureau of Statistics. Available online: http://www.stats.gov.cn/tjsj/tjgb/ndtjgb/ (accessed on 18 April 2022).

- Rouzi, A.; Halik, Ü.; Thevs, N.; Welp, M.; Aishan, T. Water efficient alternative crops for sustainable agriculture along the Tarim Basin: A comparison of the economic potentials of apocynum pictum, Chinese red date and cotton in Xinjiang, China. Sustainability 2018, 10, 35. [Google Scholar] [CrossRef] [Green Version]

- Qian, J.F.; Song, Y.L.; Yuan, R.L.; Feng, L. China’s cotton industry safety issues and development strategies under open conditions. Chin. J. Agric. Resour. Reg. Plan. 2020, 41, 140–145. [Google Scholar]

- Hou, Y.L.; Ma, Q.; He, L.J. Study on the changing trend of cotton production factors’s cost-profit and returns to scale in Xinjiang—Based on the questionnaire survey data of 465 farm households. Chin. J. Agric. Resour. Reg. Plan. 2021, 42, 243–252. [Google Scholar]

- Feng, L.; Dai, J.; Tian, L.; Zhang, H.; Li, W.; Dong, H. Review of the technology for high-yielding and efficient cotton cultivation in the northwest inland cotton-growing region of China. Field Crops Res. 2017, 208, 18–26. [Google Scholar] [CrossRef]

- Mahan, J.; Payton, P. An agrocentric analysis of regional rain patterns as they relate to a rained cotton cropping system on the Southern High Plains of Texas. Agriculture 2017, 7, 93. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.R.; Jia, X.Y.; Niu, J.H. The present situation and prospects of cotton industry development in China. Sci. Agric. Sin. 2018, 51, 26–36. [Google Scholar]

- Wu, C.Y.; Feng, J.; Chen, C.Q.; Wang, J.H.; Liu, C.; Liu, Y.; Kang, J.M. Analysis of the status quo and mechanization development of cotton producing industry in China. J. Chin. Agric. Mech. 2021, 42, 215–221. [Google Scholar]

- Hou, T.Y.; Hao, T.L.; Wang, H.J.; Zhang, Z.; Lv, X. Advances in cotton growth and development modelling and its applications in China. Sci. Agric. Sin. 2021, 54, 1112–1126. [Google Scholar]

- Madasamy, B.; Balasubramaniam, P.; Dutta, R. Microclimate-based pest and disease management through a forewarning system for sustainable cotton production. Agriculture 2020, 10, 641. [Google Scholar] [CrossRef]

- Nie, J.J.; Dai, J.L.; Du, M.W.; Zhang, Y.J.; Tian, X.L.; Li, Z.H.; Dong, H.Z. New development of modern cotton farming theory and technology in China—Concentrated maturation cultivation of cotton. Sci. Agric. Sin. 2021, 54, 4286–4298. [Google Scholar]

- Zhu, H.H.; Geng, L. Analysis of technical efficiency and factors of cotton production in Xinjiang corps. Sci. Technol. Manag. Res. 2015, 35, 90–94. [Google Scholar]

- Tang, S.; Zhu, Q.; Zhou, X.; Liu, S.; Wu, M. A conception of digital agriculture. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium, Toronto, ON, Canada, 24–28 June 2002; pp. 3026–3028. [Google Scholar]

- Bullock, D.S.; Boerngen, M.; Tao, H.; Maxwell, B.D.; Martin, N.F. The Data-Intensive farm management project: Changing agronomic research through on-farm precision experimentation. Agron. J. 2019, 111, 2736–2746. [Google Scholar] [CrossRef] [Green Version]

- Haseeb, K.; Din, I.U.; Almogren, A.; Islam, N. An energy efficient and secure IoT-based WSN framework: An application to smart agriculture. Sensors 2020, 20, 2081. [Google Scholar] [CrossRef]

- Li, J.Y.; Hu, X.D.; Lan, Y.B.; Deng, X.L. Research advance on worldwide agricultural UAVs in 2001–2020 based on bibliometrics. Trans. Chin. Soc. Agric. Eng. 2021, 37, 328–339. [Google Scholar]

- Wang, Y.S.; Li, Y.L.; Wu, H.R.; Guo, W.; Chen, C.; Meng, S.C. Design and application of digital system for agricultural park based on panorama GIS. Trans. Chin. Soc. Agric. Eng. 2018, 34, 143–149. [Google Scholar]

- Kaila, H.; Masters, W.A.; Shively, G.E. Can the Internet improve agricultural production? Evidence from Viet Nam. Agric. Econ. 2019, 50, 675–691. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.X.; Han, Y.C.; Feng, L.; Yang, B.F.; Lei, Y.P.; Wang, Z.B.; Li, Y.B. Application of smart agriculture in cotton production management. Cotton Sci. 2020, 32, 269–278. [Google Scholar]

- Jamil, I.; Wen, J.; Mughal, B.; Wheed, J.; Waseem, M. Agricultural innovation: A comparative analysis of economic benefits gained by farmers under climate resilient and conventional agricultural practices. Land Use Policy 2021, 108, 105581. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, X.G.; Wen, H.J. Application of the development of precision agriculture and the China’s Beidou Satellite navigation System in agricultural production in The Xinjiang Production and Construction Corps. J. Shihezi Univ. Nat. Sci. 2018, 36, 397–404. [Google Scholar]

- Shelkovnikov, S.A.; Petukhova, M.S.; Alekseev, A.A. Theoretical bases of managing agricultural production based on digital technologies. RUDN J. Econ. 2020, 28, 137–145. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, J.H. Digitalization of agricultural production and management and economic benefits of farmers. J. Soc. Sci. 2021, 8, 80–90. [Google Scholar]

- Basso, B.; Antle, J. Digital agriculture to design sustainable agricultural systems. Nat. Sustain. 2020, 3, 254–256. [Google Scholar] [CrossRef]

- Wang, P.; Sun, L.Y.; Wang, L. Has the rise of labor cost forced cotton to upgrade its total factor productivity in China?—Based on the mediating effect of factor input structure. J. Agrotech. Econ. 2020, 12, 122–132. [Google Scholar]

- Macháč, J.; Trantinová, M.; Zaňková, L. Externalities in agriculture: How to include their monetary value in decision-making? Int. J. Environ. Sci. Technol. 2021, 18, 3–20. [Google Scholar] [CrossRef]

- Galioto, F.; Marconi, V.; Raggi, M.; Viaggi, D. An assessment of disproportionate costs in WFD: The experience of Emilia-Romagna. Water 2013, 5, 1967–1995. [Google Scholar] [CrossRef] [Green Version]

- Lv, Y.Q.; Zhang, Z.Y.; Lv, X.L. Analysis of economic benefit of orchard mechanization: Taking Yejia pear orchard in Jiangsu as an example. J. China Agric. Univ. 2021, 26, 222–231. [Google Scholar]

- Macháč, J.; Brabec, J. Assessment of disproportionate costs according to the WFD: Comparison of applications of two approaches in the catchment of the Stanovice Reservoir (Czech Republic). Water Resour. Manag. 2018, 32, 1453–1466. [Google Scholar] [CrossRef]

- Verlicchi, P.; Sacoto, E.C.A.; Zanni, G. Zootechnical farm wastewaters in Ecuador: A treatment proposal and cost-benefit analysis. Water 2019, 11, 779. [Google Scholar] [CrossRef] [Green Version]

- Erdal, G.; Esengün, K.; Erdal, H.; Gündüz, O. Energy use and economical analysis of sugar beet production in Tokat province of Turkey. Energy 2007, 32, 35–41. [Google Scholar] [CrossRef]

- Coppola, G.; Costantini, M.; Orsi, L.; Facchinetti, D.; Santoro, F.; Pessina, D.; Bacenetti, J. A comparative cost-benefit analysis of conventional and organic hazelnuts production systems in center Italy. Agriculture 2020, 10, 409. [Google Scholar] [CrossRef]

- Fu, W.F.; Guo, J.; Ou, M.H.; Meng, L.; Yin, S. Cost-benefit, policy recognition and households’ compensation satisfaction of rural settlements consolidation. China Popul. Resour. Environ. 2017, 27, 138–145. [Google Scholar]

- Zhang, Z.Y.; Cao, G.Q.; Yi, Z.Y. Economic evaluation of several brands combine of rice and wheat. J. Chin. Agric. Mech. 2010, 5, 6–9, 27. [Google Scholar]

- Wang, J.M.; Zhang, L.; Zhao, S.S. Study on cotton plant protection mechanization technology. Hebei Agric. Mach. 1995, 3, 25. [Google Scholar]

- Liu, J.; Yao, W. Intelligent agriculture system based on LoRa and Qt technology. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 4755–4760. [Google Scholar]

- Heble, S.; Kumar, A.; Prasad, K.V.V.D.; Samirana, S.; Rajalakshmi, P.; Desai, U.B. A low power IoT network for smart agriculture. In Proceedings of the 2018 IEEE 4th World Forum on Internet of Things (WF-IoT), Singapore, 5–8 February 2018; pp. 609–614. [Google Scholar]

- Xu, W.C.; Lan, Y.B.; Li, Y.H.; Luo, Y.F.; He, Z.Y. Classification method of cultivated land based on UAV visible light remote sensing. Int. J. Agric. Biol. Eng. 2019, 12, 103–109. [Google Scholar] [CrossRef] [Green Version]

- He, X.K. Rapid development of Unmanned Aerial Vehicles (UAV) for plant protection and application technology in China. Outlooks Pest Manag. 2018, 29, 162–167. [Google Scholar] [CrossRef]

- Nawandar, N.K.; Satpute, V.R. IoT based low cost and intelligent module for smart irrigation system. Comput. Electron. Agric. 2019, 162, 979–990. [Google Scholar] [CrossRef]

- Cao, B.X.; Li, J.; Feng, X.; He, F. Development status, path, and countermeasures of smart agriculture in China. Res. Agric. Mod. 2021, 42, 785–794. [Google Scholar]

- Adhao, A.S.; Pawar, V.R. Automatic cotton leaf disease diagnosis and controlling using raspberry Pi and IoT. In Proceedings of the Intelligent Communication and Computational Technologies, Singapore, 24 October 2017; pp. 157–167. [Google Scholar]

- Boursianis, A.D.; Papadopoulou, M.S.; Diamantoulakis, P.; Liopa-Tsakalidi, A.; Goudos, S.K. Internet of Things (IoT) and agricultural Unmanned Aerial Vehicles (UAVs) in smart farming: A comprehensive review. Internet Things 2020, 18, 100187. [Google Scholar] [CrossRef]

- Ruan, J.H.; Liu, T.J.; Feng, X.C.; Qiao, Z.W.; Huo, X.X.; Zhu, Y.C.; Hu, X.P. Digital agriculture operation and management: Key issues, methodology and demonstration project. Manag. World 2020, 36, 222–233. [Google Scholar]

- Hu, H.Y.; Ren, X.L.; Jiang, W.L.; Ma, X.Y.; Ma, Y.J.; Wang, D.; Ma, Y. Pesticide spray distribution of plant protection UAV in cotton field. J. Huazhong Agric. Univ. 2018, 37, 59–64. [Google Scholar]

- Wu, J.L.; Feng, H.Z.; Ma, X.Y.; Wang, L.; Zhang, Y.L.; Wu, G. Screening of fly control agents for cotton aphid in cotton fields in Xinjiang and preliminary report of pesticide reduction and efficiency improvement. Xinjiang Agric. Sci. 2020, 57, 167–172. [Google Scholar]

- Bhattacharjee, D.; Prakash, O.; Islam, H. Smart fertilizer dispensary system for automated drip irrigation. In Proceedings of the 2018 3rd IEEE International Conference on Recent Trends in Electronics, Information & Commnication Technology (RTEICT), Bangalore, India, 18–19 May 2018; pp. 1458–1462. [Google Scholar]

- Liu, Y.H.; Yu, W.D.; Shen, M.X.; Kong, D.Z. Research and development of automatic control system for precision irrigation fertilization. Water Sav. Irrig. 2014, 12, 80–83. [Google Scholar]

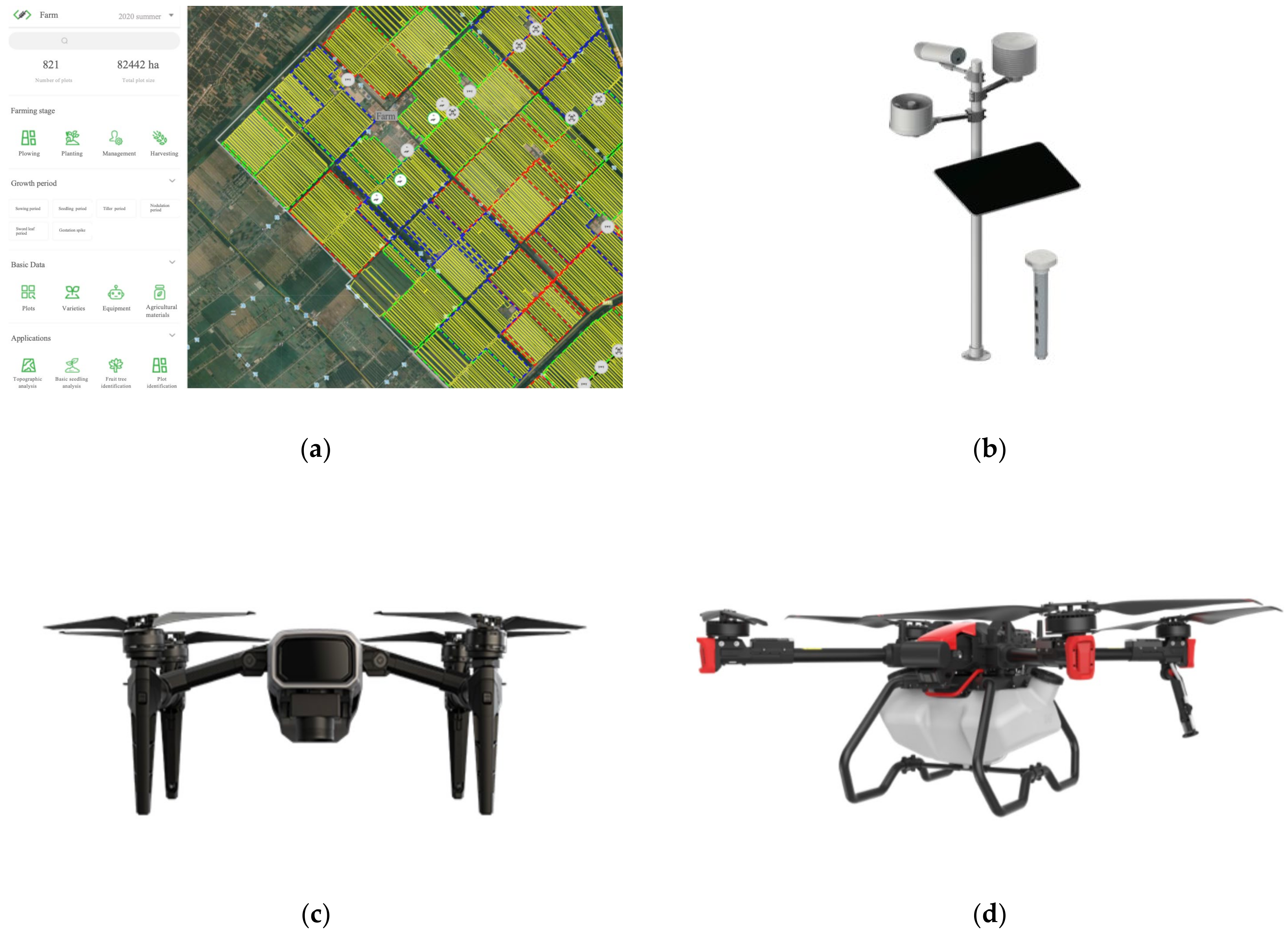

| Agricultural Equipment | Function | Advantage | |

|---|---|---|---|

| Smart agriculture system | Sensory flight (smart identification), decision making (planting plan, traceability: view operation records/problems), execution (generate tasks to send to drones, self-pilot devices, irrigation systems, etc.) | This is conducive to improving the quality and management efficiency of cotton field management and precise operation to effectively reduce costs [40]. | |

| Agricultural IoT equipment | Agricultural smart camera | Monitoring crop growth, remote crop management | This improves data accuracy and accessibility and reduces human capital investment [41]. |

| Agricultural weather stations | Accurate measurement of meteorological elements such as air pressure, temperature, humidity, light, rainfall, wind speed and wind direction | ||

| Soil monitor | Monitoring soil temperature, water content, conductivity | ||

| Remote sensing drone | Intelligent identification of plot boundaries, generation of multispectral images to monitor pests and weeds | This improves the efficiency of cotton field operations and saves a lot of labor [42]. | |

| Agricultural drone | Spraying pesticides, defoliants, chemical weed control, etc. | This improves the utilization rate and operational efficiency of pesticides and saves a lot of labor [43]. | |

| Automatic water and fertilizer irrigation system | Irrigation water and fertilizer | This improves the utilization of resources such as water and electricity, reduces the waste of fertilizers and saves a lot of labor [44]. | |

| Management Link | Operation Method | Equipment Purchase Cost/(CNY/unit) | Equipment Cost/(CNY/Year) | Maintenance Cost/(CNY/Year) | Purchase Agricultural Machinery Service cost/(CNY/m2) | Crop Damage from Mechanical Operations/(CNY/ha) | Operation Efficiency/ha/(Unit. Day) | Labor Wage/(CNY/ha) | Smart Agriculture System Cost/(CNY/ha) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Field scouting | Traditional method | Manual work | - | - | - | - | - | - | long-time agricultural workers 1500.00skilled agricultural workers 750.00 | - |

| Super Cotton Field | Remote sensing drone | 17,000.00 | 5666.67 | 340.00 | - | - | 320.00 | 15.00 | 49.50 + 90,000/S | |

| IoT equipment | 900.00 CNY/ha | 300.00 CNY/ (ha.year) | 18.00 CNY/ (ha.year) | - | - | - | - | |||

| Plant protection | Traditional method | Tractor | - | - | - | 60.00 | 312.00 | - | - | - |

| Super Cotton Field | Agricultural drone | - | - | - | 90.00 | - | 32.00 | - | - | |

| Purchasing machinery | 60,000.00 | 20,000.00 | 1200.00 | - | - | 45.00 | - | |||

| Topping | Traditional method | Manual work | - | - | - | - | - | - | 750.00 | - |

| Super Cotton Field | Agricultural drone | - | - | - | 90.00 | - | 32.00 | - | - | |

| Purchasing machinery | 60,000.00 | 20,000.00 | 1200.00 | - | - | 45.00 | - | |||

| Irrigation | Traditional method | Traditional water and fertilizer irrigation system | - | - | - | - | - | - | 1500.00 | - |

| Super Cotton Field | Automatic water and fertilizer irrigation system | 130,000.00 | 43,333.33 | 2600.00 | - | - | 100.00 | 45.00 | 49.50 + 90,000/S | |

| Electric valve | 3150.00 CNY/ha | 1050.00 CNY/ (ha.year) | 157.50 CNY /(ha.year) | - | - | - | - | - | ||

| Management Link | Operation Method | Drip Irrigation Belt/(CNY/ha) | Water Cost/(CNY/ha) | Electricity Cost/(CNY/ha) | Fertilizer Cost/(CNY/ha) | Pesticide Cost/(CNY/ha) | Operation Time/(Time) | Optimal Operation Day/(Day) | ||

| Field scouting | Traditional method | Manual work | - | - | - | - | - | - | - | |

| Super Cotton Field | Remote sensing drone | - | - | - | - | - | 42.00 | 2.00 | ||

| Agricultural IoT equipment | - | - | - | - | - | - | - | |||

| Plant protection | Traditional method | Tractor | - | - | - | - | 120.00 | 10.00 | - | |

| Super Cotton Field | Agricultural drone | - | - | - | - | 75.00 | 9.00 | - | ||

| Purchasing machinery | - | - | - | - | 75.00 | 9.00 | 2.00 | |||

| Topping | Traditional method | Manual work | - | - | - | - | - | - | - | |

| Super Cotton Field | Agricultural drone | - | - | - | - | 300.00 | 1.00 | - | ||

| Purchasing machinery | - | - | - | - | 300.00 | 1.00 | 3.00 | |||

| Irrigation | Traditional method | Traditional water and fertilizer irrigation system | 1200.00 | 3750.00 | 1200.00 | 5250.00 | - | - | - | |

| Super Cotton Field | Automatic water and fertilizer irrigation system | 1440.00 | 2610.00 | 375.00 | 4995.00 | - | 10.00 | 1.00 | ||

| Electric valve | - | - | - | - | - | - | - | |||

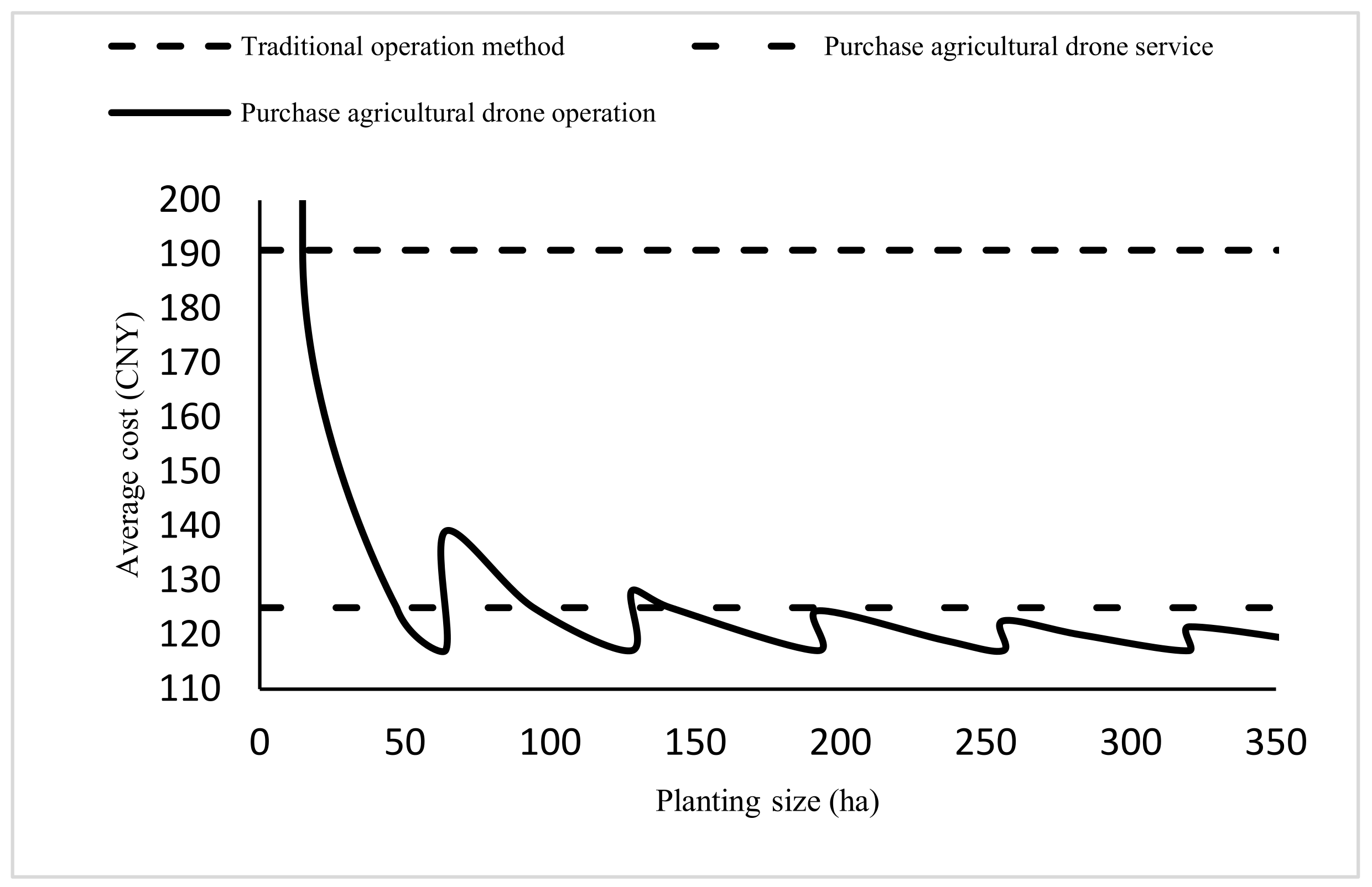

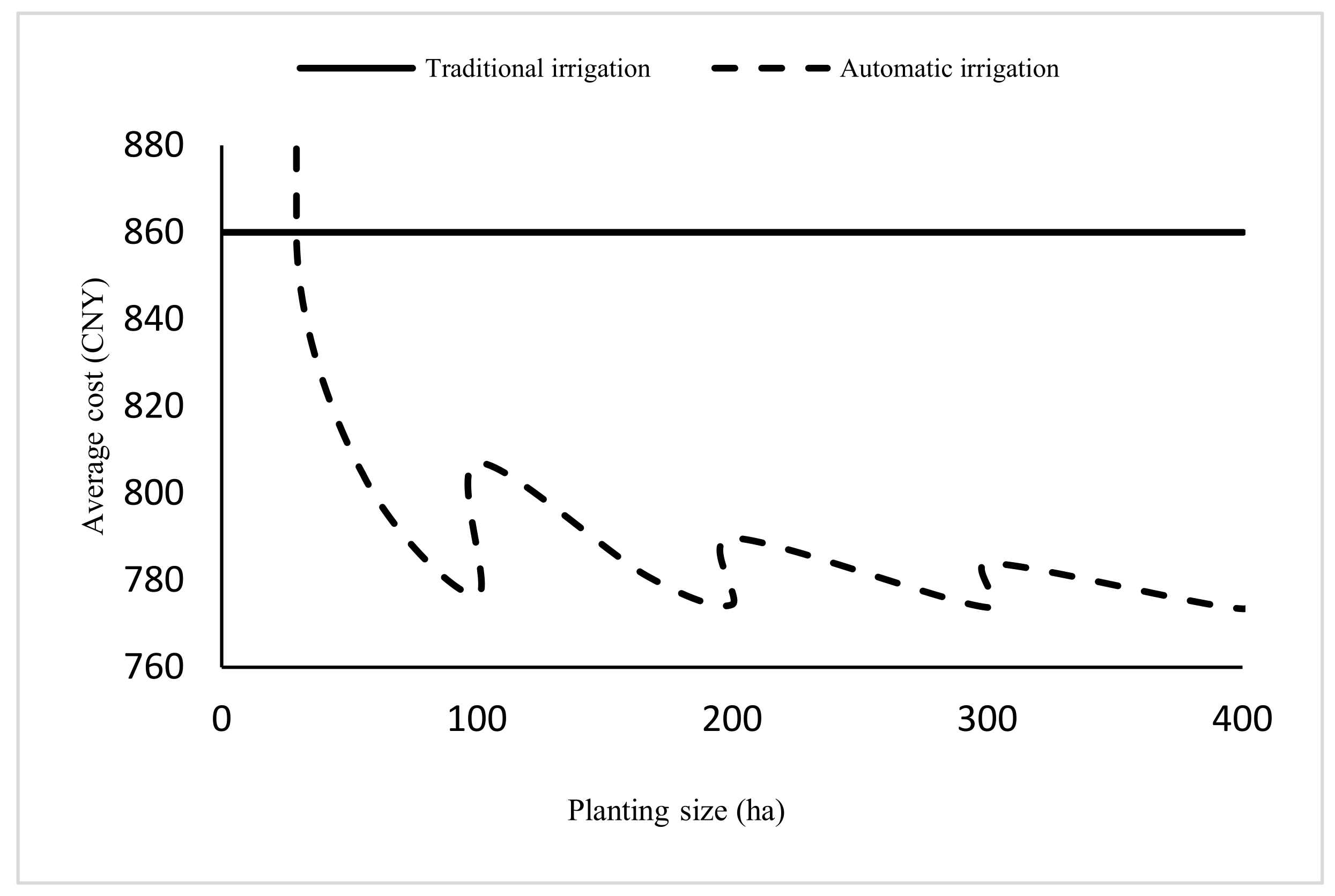

| Management Link | Operation Method | Fixed Cost/(CNY/Year) | Variable Cost/(CNY/ha) | Lowest Average Cost/(CNY/ha) | Critical Size/(ha) | Average Cost Saving/(CNY/ha) |

|---|---|---|---|---|---|---|

| Field scouting | Manual work | - | 2250.00 | 2250.00 | - | - |

| Remote sensing drone and agricultural IoT equipment | 6006.67 | 997.50 + 90,000/S | 1065.75 | 9.59 | 1184.25 | |

| Plant protection | Purchase tractor service | - | 2112.00 | 2112.00 | - | - |

| Purchase agricultural drone service | - | 1485.00 | 1485.00 | 0.00 | 627.00 | |

| Topping | Manual work | - | 750.00 | 750.00 | - | - |

| Purchase agricultural drone service | - | 390.00 | 390.00 | 0.00 | 360.00 | |

| Irrigation | Traditional water and fertilizer irrigation system | - | 12,900.00 | 12,900.00 | - | - |

| Automatic water and fertilizer irrigation system | 45,933.33 | 11,127.00 + 90,000/S | 11,646.30 | 29.29 | 1253.70 |

| Management Link | Operation Method | Fixed Cost/(CNY/Year) | Variable Cost/(CNY/ha) | Lowest Average Cost/(CNY/ha) | Critical Size/(ha) | Average Cost Saving/(CNY/ha) |

|---|---|---|---|---|---|---|

| Plant protection | Purchase tractor service | - | 2112.00 | 2112.00 | - | - |

| Purchase agricultural drone | 21,200.00 | 1080.00 | 1411.20 | 20.54 | 700.80 | |

| Topping | Manual work | - | 750.00 | 750.00 | - | - |

| Purchase agricultural drone | 21,200.00 | 345.00 | 565.80 | 52.35 | 184.20 | |

| Plant protection and topping combinations | Traditional method | - | 2862.00 | 2862.00 | - | - |

| Purchase agricultural drone | 21,200.00 | 1425.00 | 1756.20 | 14.75 | 1105.80 |

| Management Link | Operation Method | Fixed Cost/(CNY/Year) | Variable Cost/(CNY/ha) | Lowest Average Cost/(CNY/ha) | Critical Size/(ha) | Average Cost Saving/(CNY/ha) |

|---|---|---|---|---|---|---|

| Plant protection | Purchase agricultural drone service | - | 1485.00 | 1485.00 | - | - |

| Purchase agricultural drone | 21,200.00 | 1080.00 | 1411.20 | 52.35 | 73.80 | |

| Topping | Purchase agricultural drone service | - | 390.00 | 390.00 | - | - |

| Purchase agricultural drone | 21,200.00 | 345.00 | 565.80 | 0.00 | −175.80 | |

| Plant protection and topping combinations | Purchase agricultural drone service | - | 1875.00 | 1875.00 | - | - |

| Purchase agricultural drone | 21,200.00 | 1425.00 | 1756.20 | 47.11 | 118.80 |

| Operation Method | Fixed Equipment Cost | Variable Equipment Cost | Labor Wage | Wages for Farm Machinery Operators | Smart Agriculture System | Water Cost | Electricity Cost | Fertilizer and Pesticide Cost |

|---|---|---|---|---|---|---|---|---|

| Digital field scouting | 10.01 | 5.35 | −26.43 | 11.19 | 10.87 | 0.00 | 0.00 | 0.00 |

| Purchase agricultural drone for plant protection | 20.00 | 0.00 | 0.00 | 2.15 | 0.00 | 0.00 | 0.00 | −2.66 |

| Purchase agricultural drone for topping | 20.00 | 0.00 | −27.03 | 2.27 | 0.00 | 0.00 | 0.00 | 17.39 |

| Purchase agricultural drone for plant protection and topping | 20.00 | 0.00 | −9.45 | 6.68 | 0.00 | 0.00 | 0.00 | −3.04 |

| Automatic water and fertilizer irrigation system | 17.69 | 15.77 | −10.59 | 0.00 | 2.89 | −11.39 | −8.51 | −2.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, L.; Gong, J.; Fan, W.; Zhang, Z.; Zhang, M. Cost Comparison between Digital Management and Traditional Management of Cotton Fields—Evidence from Cotton Fields in Xinjiang, China. Agriculture 2022, 12, 1105. https://doi.org/10.3390/agriculture12081105

Shao L, Gong J, Fan W, Zhang Z, Zhang M. Cost Comparison between Digital Management and Traditional Management of Cotton Fields—Evidence from Cotton Fields in Xinjiang, China. Agriculture. 2022; 12(8):1105. https://doi.org/10.3390/agriculture12081105

Chicago/Turabian StyleShao, Lantong, Jiaqin Gong, Wenqing Fan, Zongyi Zhang, and Meng Zhang. 2022. "Cost Comparison between Digital Management and Traditional Management of Cotton Fields—Evidence from Cotton Fields in Xinjiang, China" Agriculture 12, no. 8: 1105. https://doi.org/10.3390/agriculture12081105

APA StyleShao, L., Gong, J., Fan, W., Zhang, Z., & Zhang, M. (2022). Cost Comparison between Digital Management and Traditional Management of Cotton Fields—Evidence from Cotton Fields in Xinjiang, China. Agriculture, 12(8), 1105. https://doi.org/10.3390/agriculture12081105