Abstract

In view of the difficulty in diagnosing and discriminating fault conditions during the operation of combine harvesters, difficulty in real-time processing of health status, and low timeliness of fault processing, a comprehensive operation and maintenance platform for combine harvesters was developed in this study which realized the functions of data monitoring and the full operation and maintenance of a combine harvester. At the same time, through the comprehensive operation and maintenance platform, the harvester information was obtained in real-time, the diagnosis results were obtained, and the maintenance service was effectively carried out through the platform. The IPSO-SVM fault diagnosis algorithm was proposed, and the performance of the fault diagnosis of the combine harvester was verified by the simulation test. The experimental verification showed that the system met the requirements of remote monitoring of combine harvesters, and the prediction accuracy of this method was 97.96%. Compared with SVM (87.51%), GA-SVM (89.44%), and PSO-SVM (92.56%), this system had better generalization ability and effectively improved the management level of the comprehensive operation and maintenance of the combine harvester. A theoretical basis and technical reference will be provided for the follow-up research for the comprehensive operation and maintenance platform of the combine harvester in this paper.

1. Introduction

Due to the harsh operating environment of the combine harvester in the field, and the long-term centralized and continuous operation in cross-regional operations, it is easy for harvester malfunctions to occur [1,2] which will affect harvesting quality and efficiency. The traditional fault diagnosis of combine harvesters relies on the experience of the harvester and agricultural machinery operator to predict and diagnose the fault [3,4]. However, it is difficult to accurately judge the types of failure. Therefore, fault diagnosis technology has been developed as support to keep the harvesting machinery running normally. Research on fault diagnosis [5,6,7] can effectively carry out operation and maintenance service of combine harvesters.

Fault diagnosis technology is widely used in rolling bearings [8], agricultural machinery operation [9], and other machinery [10,11]. In recent years, relevant research on fault diagnosis has also been increasing [12,13,14]. In view of the fault diagnosis of combine harvesters [15,16,17], experts and scholars adopted SDAE [18,19], random forest [20,21,22], and SVM [23,24] to carry out the analysis and fault diagnosis of the combine harvester by obtaining the monitoring data of combine harvesters. Due to the complex structure of the equipment and the large number of parts to be diagnosed [25,26,27], the fusion of multi-sensor signal features can increase the diversity and integrity of fault information [28,29]. Zhou et al. [30] adopted the multi-parameter intelligent fault diagnosis method based on a modified random forest algorithm (RFNB algorithm) which improved the fault diagnosis accuracy and effectively reduced the impact of blockage fault on the operation of the forage harvester. Qiu et al. [31] designed a remote monitoring system of combine harvester based on multi-source information fusion which can not only realize effective monitoring of combine harvester but also realize the functions of fault diagnosis and remote scheduling guidance. Zhang et al. [32] established a bearing fault diagnosis method based on a stacked denoising autoencoder network (SDAE) and support vector machine (SVM) which can effectively improve the bearing fault identification accuracy of presses. Zhang et al. [33] proposed a particle swarm optimization algorithm based on improved inertia weight and acceleration factor to optimize SVM parameters. XIA et al. [19] proposed a fault diagnosis framework for machine intelligence based on DT and deep transfer learning under the condition of limited measured data. XU et al. [34] developed a novel depth structure based on a novel sparse denoising autoencoder (NSDAE). Based on the improved particle swarm optimization (IPSO-LSSVM), an intelligent diagnosis method for bearing faults was proposed which can effectively improve the recognition accuracy and convergence rate. There are many fault diagnoses for various types of equipment, but there is little feedback and application of the output after fault diagnosis [35], such as system platform [36,37], intelligent maintenance [38], maintenance response after fault diagnosis, and how to carry out maintenance work [39].

A joint harvester fault diagnosis system was designed in this study and a comprehensive operation and maintenance platform was developed. The purpose was to monitor and diagnose the fault problems during the operation of the joint harvesting machine through information technology and quickly realize the maintenance through the platform, which also laid a foundation for the follow-up research of the comprehensive operation of the joint harvester, so maintenance plans and repair services can be pushed to users in real-time.

2. Comprehensive Operation and Maintenance Structure Design for Combine Harvester Fault Diagnosis

2.1. Fault Diagnosis Structure of Combine Harvester Operation

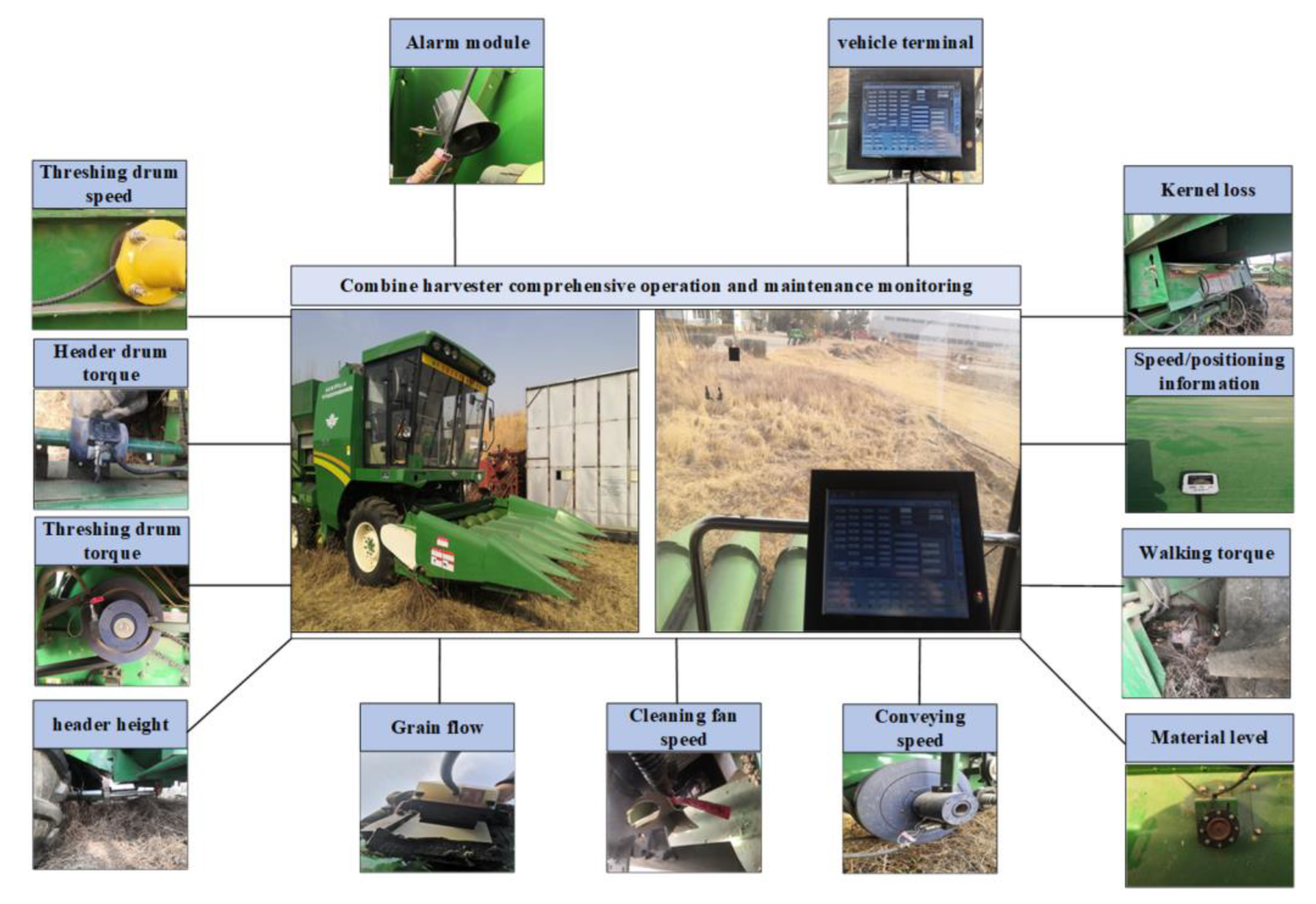

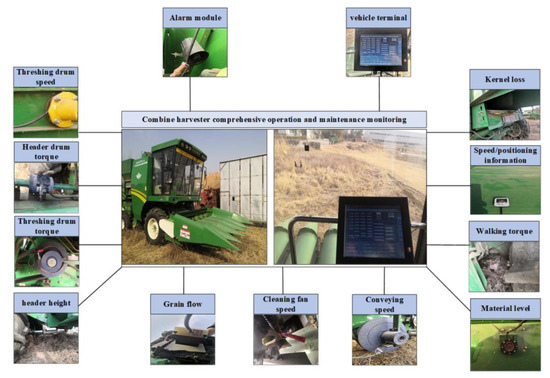

The combined harvester operation fault monitoring system based on comprehensive operation and maintenance mainly included the Senke SK-15GB industrial computer in Shanghai, China, and Advantech (ADVANTECH) USB-4761 data acquisition module in Kunshan, China, Soway Technology’s SPH-318 speed sensor in Shenzhen, China, TYHC/Tianyu Hengchuang CYT-302 dynamic torque sensor in Beijing, China and Hangya YS-BJ02 industrial sound and light alarm device in Hangzhou, China, etc. Among them, the SPH-318 speed sensor had an accuracy of less than 1%, linearity of less than 0.1%, a detection distance of 0.5–3 mm, and a response frequency of 10 kHz. The dynamic torque sensor had an accuracy of ±0.3% in the ambient temperature range of −20~60 °C, the torque range was 0~1000 Nm, and the response frequency was 3 ms. The structure of the fault diagnosis and monitoring module of the combine harvester is shown in Figure 1.

Figure 1.

Structure of fault diagnosis and monitoring system of combine harvester.

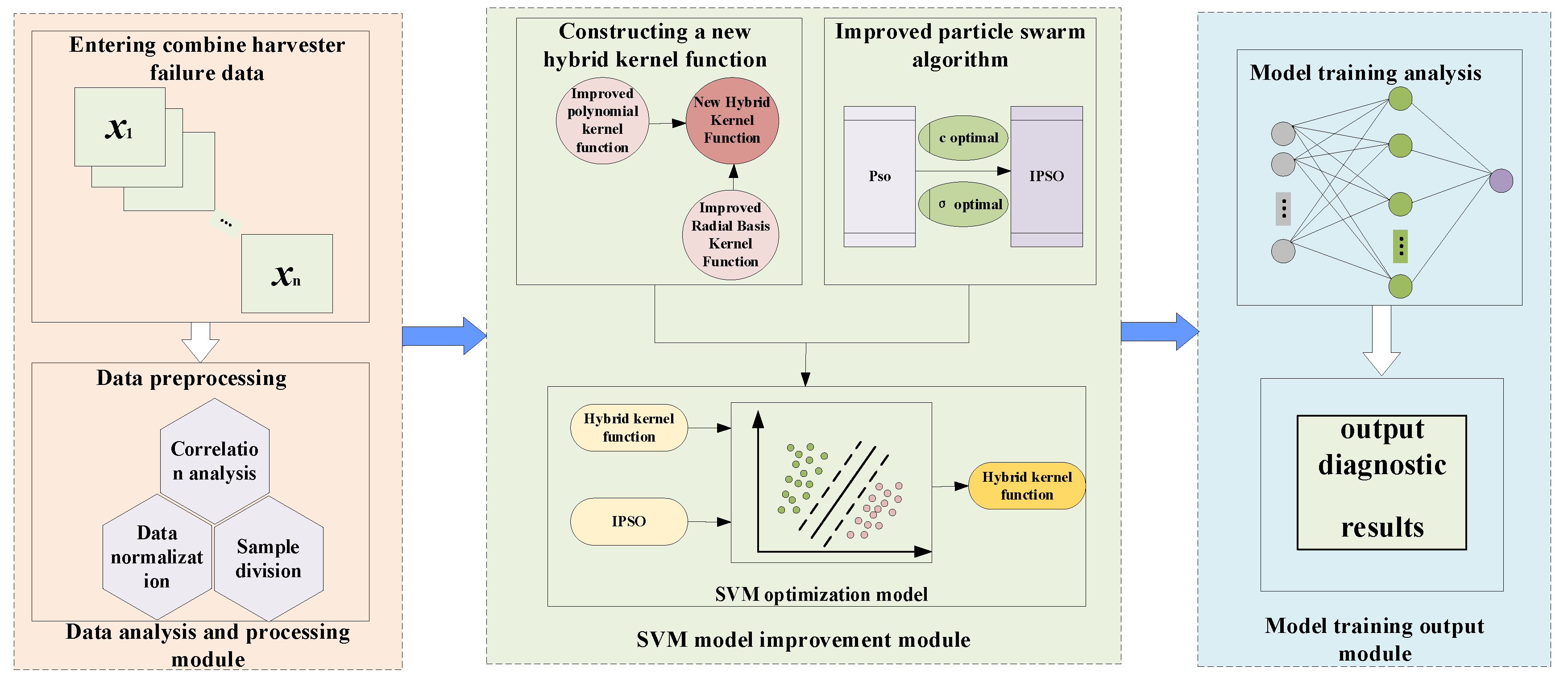

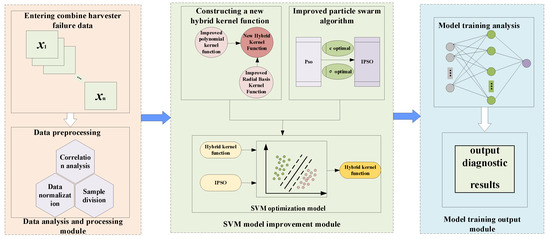

The fault diagnosis system of the combine harvester was mainly composed of a data acquisition module and a fault diagnosis module. Among them, the acquisition module mainly used sensors to collect information, such as the speed and torque changes during the operation of the combine harvester, and stored and processed the collected information; the fault diagnosis module mainly compared the collected signal with the normal signal through the extraction of signal characteristics, realized the automatic fault diagnosis, and output the diagnosis result. The fault diagnosis structure is shown in Figure 2.

Figure 2.

Structure diagram of fault diagnosis of combine harvester.

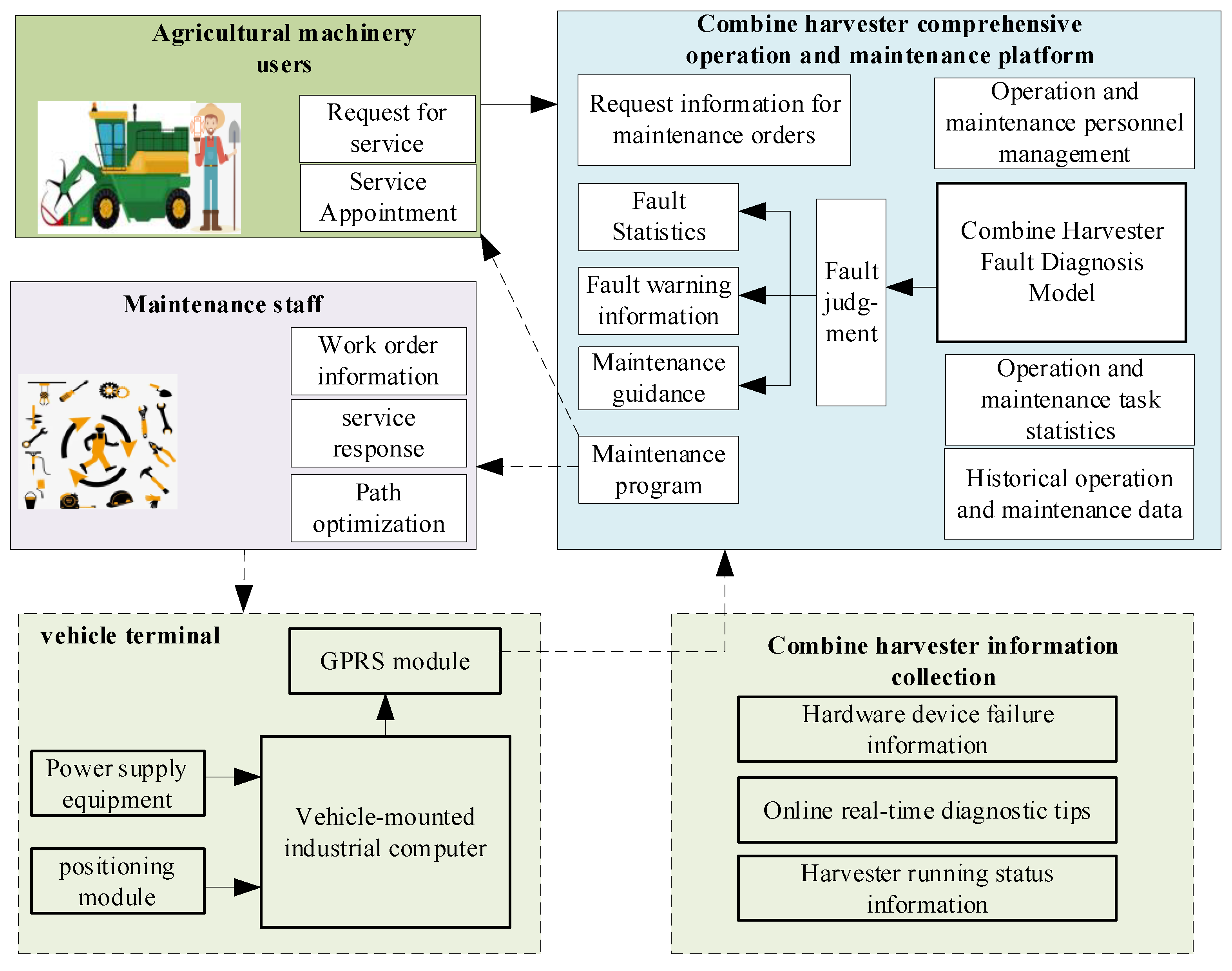

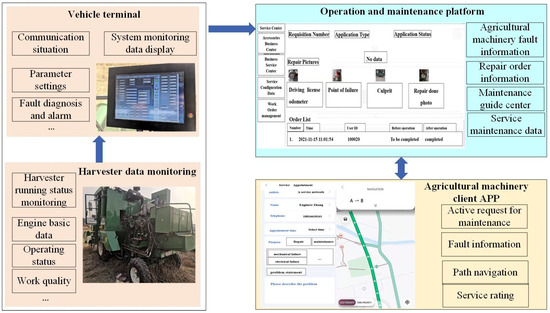

2.2. Comprehensive Operation and Maintenance Structure

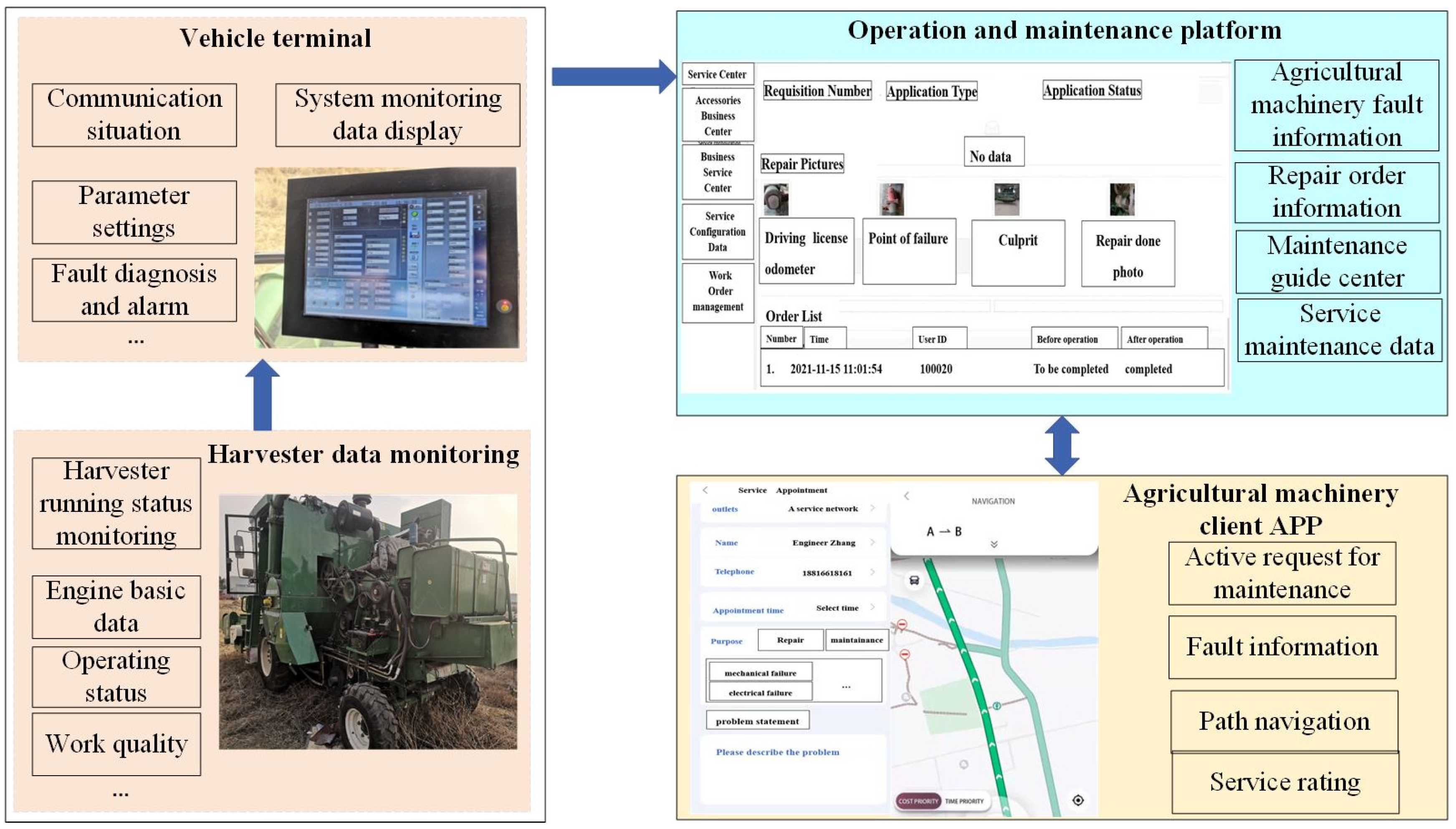

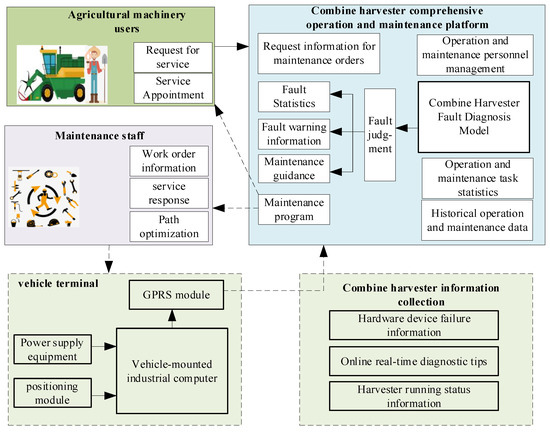

Fault information is the basis of fault diagnosis, and comprehensive operation and maintenance are the purposes of fault diagnosis. This includes the agricultural machinery user client, maintenance personnel server, vehicle terminal, information collection and operation, and maintenance platform.

On the service demand side, agricultural machinery users mainly use the APP to send maintenance requests, reserve maintenance plans, and check maintenance instructions on the operation and maintenance platform. Maintenance personnel are technicians of agricultural machinery operation and maintenance service providers, providing door-to-door service for harvester maintenance and receiving and sending maintenance instructions.

As the driving computer of agricultural machinery, the onboard terminal can view the operating parameters, the positioning information, and the quality information of the harvester in real-time. The information collected on the combine harvester is used to monitor and send the information of key components of the harvester by the installation of sensors.

The comprehensive operation and maintenance platform provides application services to service providers, operation and maintenance personnel, and agricultural machinery users of manufacturing enterprises in the form of web applications and can be accessed through browsers. Then, the operation and maintenance information can be received and sent to agricultural users and technicians by the management in real-time. The fault diagnosis model is the core of the harvester fault diagnosis. The collected monitoring data and operating status data of each module of the harvester are determined through the fault diagnosis model to determine the fault type. The fault information statistics are used to realize the interaction with the system operation and maintenance management users, realize the functions of fault information statistics, management, display, alarm, etc., and provide services such as fault statistics and query. The overall operation and maintenance architecture of the combine harvester is shown in Figure 3.

Figure 3.

Overall operation and maintenance framework of combine harvester.

3. Principle and Realization Process of Fault Diagnosis Algorithm

3.1. SVM Classifier

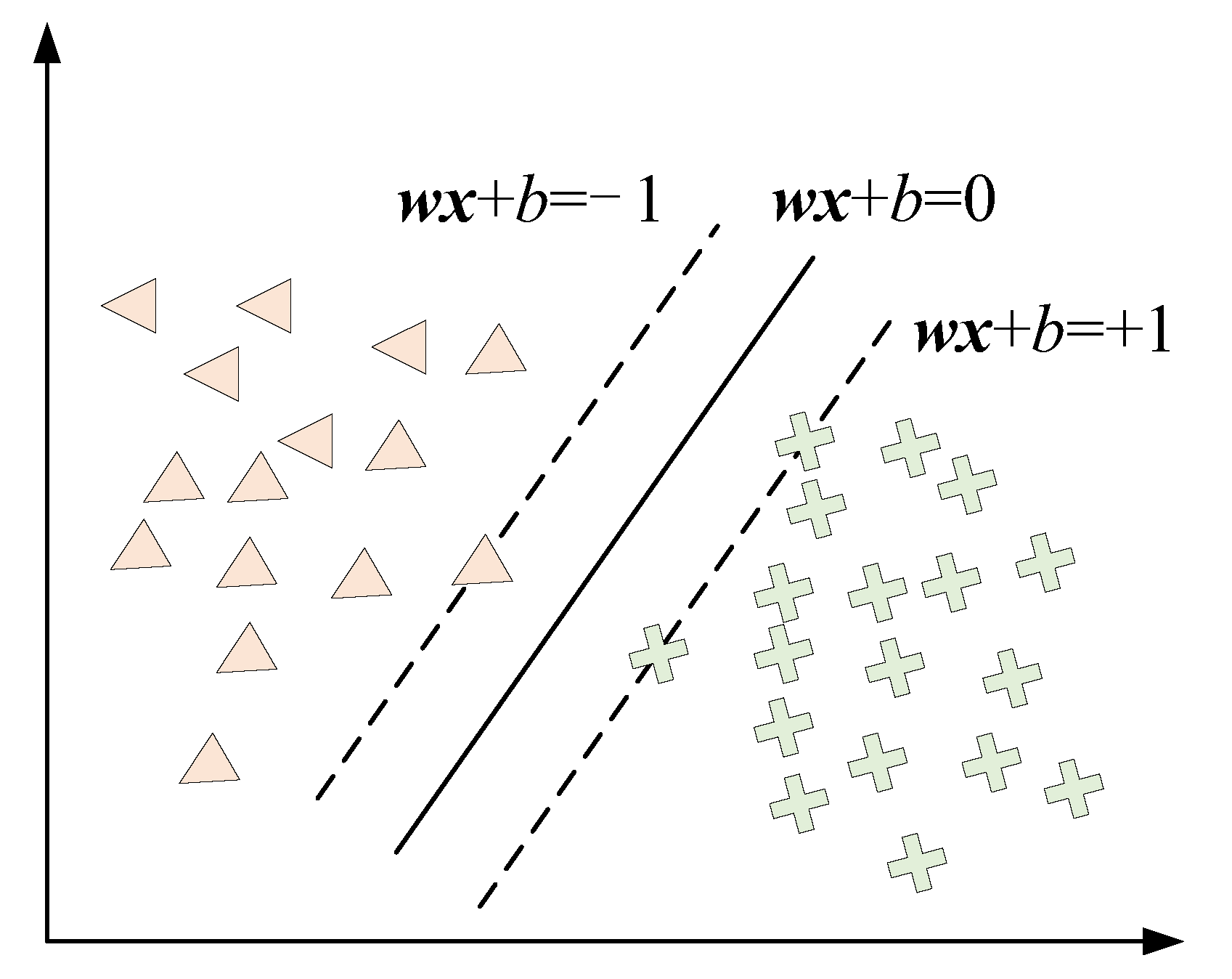

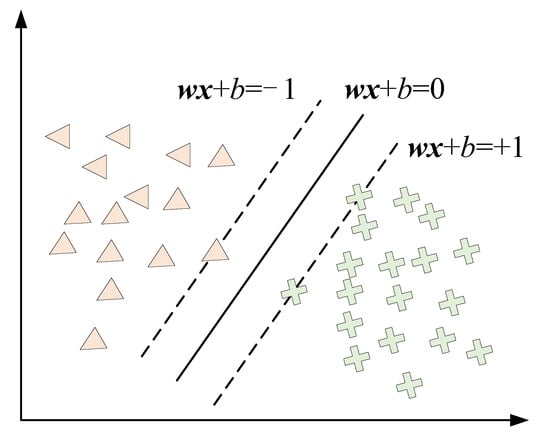

SVM is a machine learning algorithm based on the principle of structural risk minimization, which was first used in pattern recognition. SVM has strong generalization performance in solving fault diagnosis problems with few samples, while the problem of fault diagnosis in the operation process of combine harvesters is the lack of fault samples. Therefore, SVM was chosen as the fault classification algorithm under the actual situation of a few fault samples of combine harvesters.

The basic idea of designing a nonlinear SVM model is to map the input vector x ∈ Rn to the high-dimensional feature space F through the pre-selected nonlinear mapping function and create the optimal classification hyperplane in this high-dimensional feature space F. As shown in Figure 4, it is supposed that the given dataset is {xi, yi}, i = 1, 2, …, N, yi ∈ {−1, +1}, xi ∈ Rd, with triangles and crosses on the plane, respectively, represents the two samples to be classified.

Figure 4.

SVM model.

The decision function of the optimal classification hyperplane is as follows:

In the formula: sgn(·) is the symbolic function, w is the weight vector, x is the input vector, and b is a constant. After the data is mapped to the high-dimensional feature space through the nonlinear mapping function φ(x), the classification decision function is

Constraints are

xi refers to the i th training data, yi = ±1.

According to the VC dimension theory, to minimize the structural risk under the above constraints, the mathematical process can be expressed as the following quadratic programming problem:

Introducing the slack variable ξi ≥ 0. If the sample is accurately classified, then ξi = 0, otherwise ξi > 0. Equation (3) becomes

The classification hyperplane should maximize the minimum distance between the two types of samples and the hyperplane so the optimized objective function is as follows:

In Equation (6), the penalty factor C represents the degree of penalty for misclassified samples. Lagrange multipliers and quadratic programming optimization methods are used in the minimization process, and the transformed dual problem is

where αi is the Lagrange multiplier. Then the optimal decision function can be expressed as

In the formula: I is the number of support vectors. For nonlinear problems, it is necessary to map the data to a higher-dimensional feature space through nonlinear mapping. Assuming that the kernel function K (xi, x) is a nonlinear mapping function, the decision function for

Since radial basis kernel function (RBF) only needs to determine one parameter, which is beneficial to parameter optimization, RBF is selected as the kernel function in this paper:

where σ is the kernel function parameter.

It is shown that the penalty parameter c and the kernel function parameter σ are the main factors affecting the performance of SVM. In order to obtain a better generalization ability of SVM, the particle swarm algorithm based on global optimization is used to find the optimal penalty function parameters and kernel function parameters.

3.2. Improved PSO Optimization Algorithm

The particle swarm optimization algorithm is a global search algorithm evolved from bird flock foraging. The “velocity-position” search method is adopted by POS, which treats particles as points with only speed and position, ignoring the influence of their mass and volume. Due to its simple concept and fast convergence, it has been successfully applied in many fields [40,41]. The basic idea is that each particle flies at a certain speed in the D-dimensional search space, and the particle’s own speed and optimal position are dynamically adjusted by the fitness value function, individual particle flight experience, and other particle flight experience, so as to obtain the optimal solution of the optimization problem.

3.2.1. Improvement of Inertia Weight Search Method

The standard PSO algorithm linearly reduces the inertia weight w during the operation. At this time, the search step size will become smaller and the iteration will gradually converge to the extreme point. However, by only linearly reducing w, it will be difficult for the algorithm to jump out once the algorithm enters the neighborhood of the local extreme value, which will make the global optimization more difficult. To solve the problem, in the iterative process, the global search ability and local search ability in the optimization process can be balanced by the nonlinear reduction in parameter W. The inertia weight w is improved as follows:

where: wmax is the initial inertia weight, wmin is the final inertia weight, s is the current number of iterations, and smax is the maximum number of iterations.

3.2.2. Judgment of Premature Convergence

When there was no change in the historical optimal value Pbj of the particle itself during X iterations or the global maximum Gbj within the particle swarm during Y iterations, it was considered that the population has fallen into premature convergence, which indicates that the swarm had fallen into or was about to fall into local optimal value. The larger the value of X and Y, the looser the conditions for judging premature stagnation. The premature stagnation calculators K1 and K2 were added to the PSO algorithm to calculate the stagnation times. If the value of Pb or Gb was the same as the previous one, the value of K1 or K2 was incremented by 1; otherwise, it was cleared to zero when the value of K1 and K2 reached the limit. X, Y, Pb and Gb were reset to make the particles jump out of the local optimum.

Improvements to Pb:

Improvements to Gb:

The velocity and position equations of the swarm particles in the improved algorithm are obtained as follows:

In the formula, i is the i th particle; j = 1, 2, …, d, d represents the dimension of the particle; w is the inertia weight; t is the number of iterations; c1, c2 are learning factors.

It can be seen from the theoretical analysis that invalid iterations can be reduced and the convergence speed and optimization accuracy can be greatly improved by the algorithm.

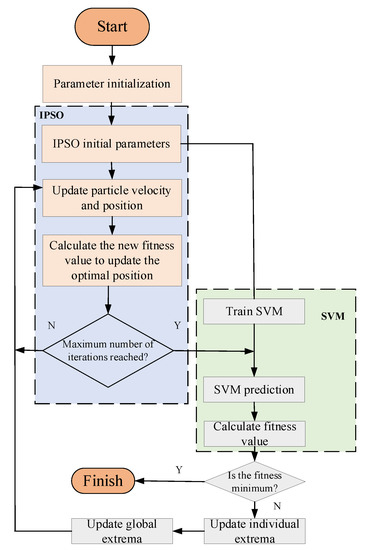

3.3. IPSO-SVM Algorithm Implementation

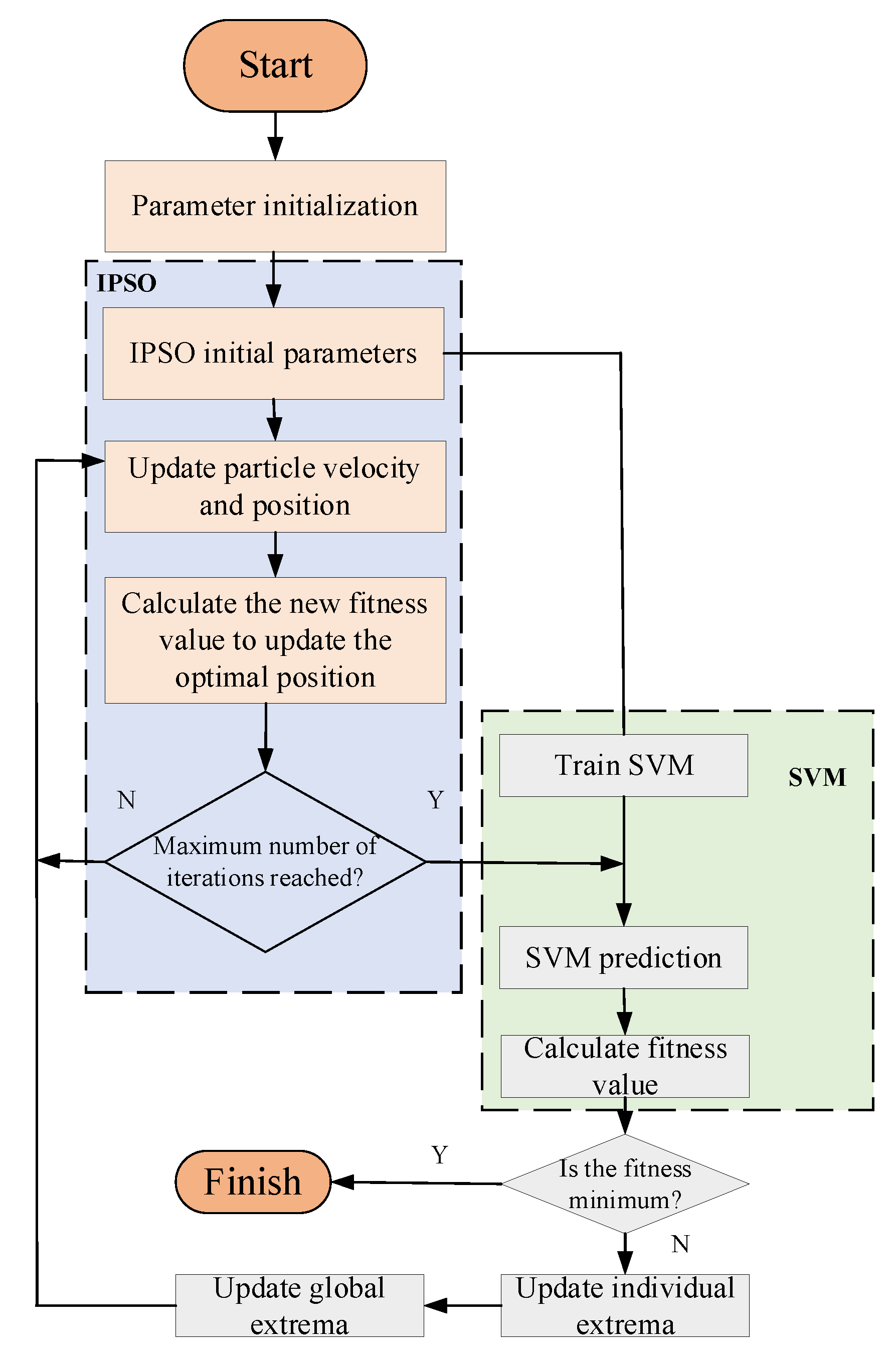

The PSO optimization SVM algorithm has been widely used in the fault diagnosis of combine harvesters, but after a lot of experiments, it was found that the particles in the PSO-SVM optimization algorithm were prone to the phenomenon of “prematurity”, that is, in the process of fault classification and diagnosis, the particles will gather in a specific position. The implementation process of IPSO-SVM is shown in Figure 5.

Figure 5.

IPSO-SVM fault diagnosis flow chart.

Through the IPSO Algorithm 1, the optimal values of the penalty parameter c and the kernel function parameter σ that minimize the SVM error are obtained, which are used for SVM training and classification prediction.

| Algorithm 1 Steps |

| Step 1: The penalty parameter c and the kernel parameter σ of the SVM are used as the variables to be optimized, and real coding is performed. Step 2: In the d-dimensional parameter space, m particles are randomly initialized, and their positions and velocities are determined, that is, the SVM parameters are determined, and certain input samples are selected to establish the SVM model. Step 3: It is judged whether the termination condition is met. If so, the optimal individual is output and assigned to the penalty parameter c and kernel parameter σ of the SVM. Step 4: If it was not suitable, the SVM was trained to calculate and evaluate the particle fitness value. After the suspension condition is met, the optimal parameters are output and classified. Step 5: If the optimal parameters are not output, the speed and position of the particles will be iteratively searched and updated, the SWM will be retrained, and r the fitness of the particles will be re-evaluated. After the suspension conditions are met, the optimal parameters will be output and classified; otherwise, the velocity and position of particles will be iteratively searched and updated all the time. |

3.4. Comprehensive Operation and Maintenance Architecture

The comprehensive operation and maintenance consist of the perception layer, the network layer, and the application layer, as shown in Figure 6.

Figure 6.

Overall operation and maintenance system diagram.

Perception layer: the sensor was installed on the monitoring object of the combine harvester to monitor the operation status, operation quality, operation status, and other data of the combine harvester.

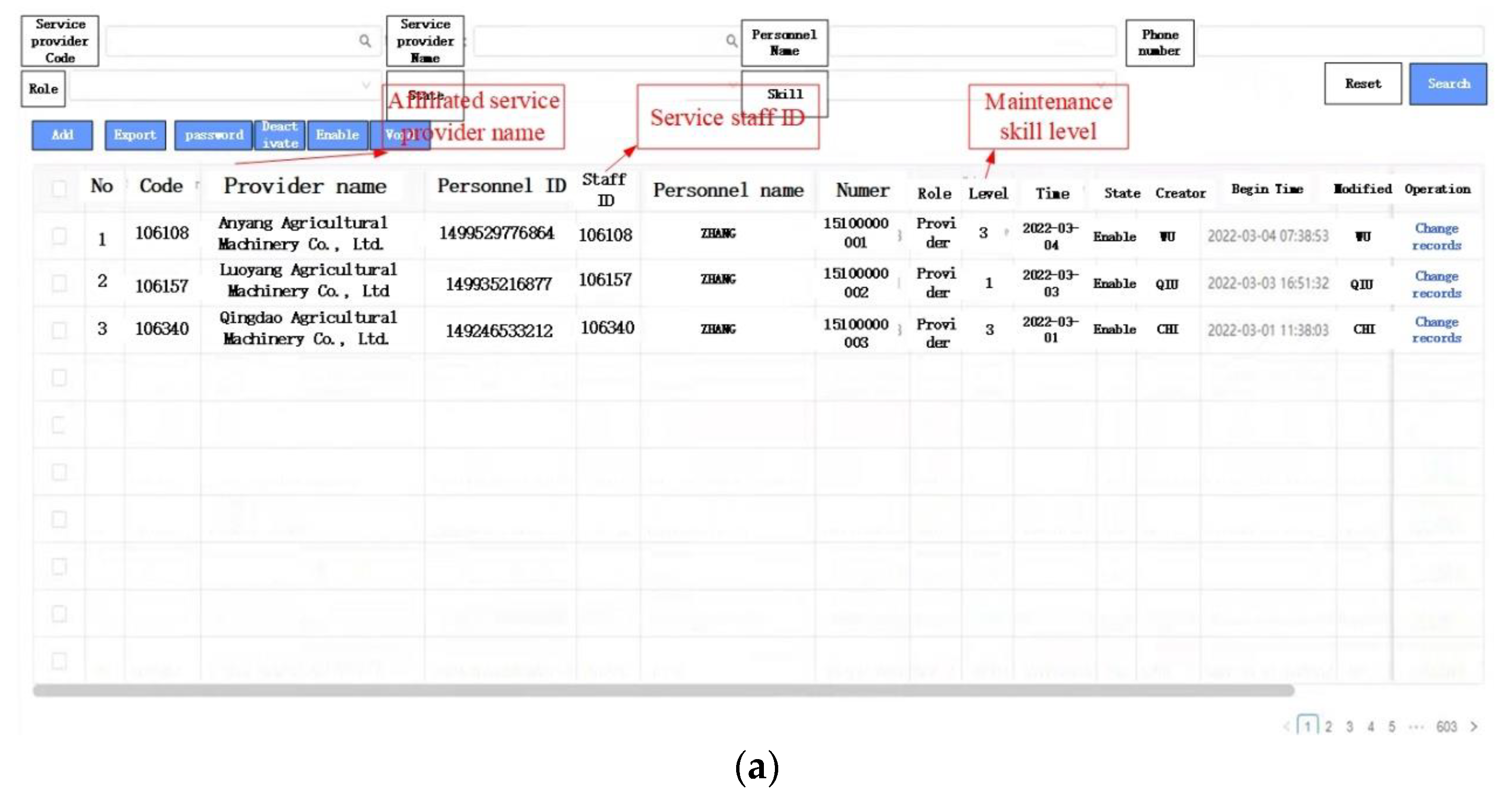

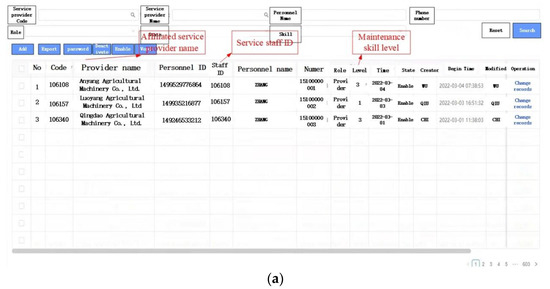

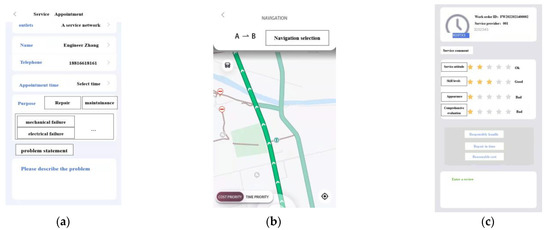

Network layer: The operation and maintenance platform of agricultural machinery was deployed in the service provider center of agricultural machinery enterprises, including the oracle database system, JRE operating environment, and security control equipment. As shown in Figure 7, the platform was provided in the form of a B/S application system and was realized by a multi-layer hierarchical structure which mainly included: service order management, service maintenance network management, maintenance personnel work management, agricultural machinery user reporting management, operation and maintenance data upload, maintenance guidance automatic push management, and data import and export modules.

Figure 7.

Operation and maintenance platform information management system. (a) Maintenance personnel information management; (b) Order History Repair Record Details.

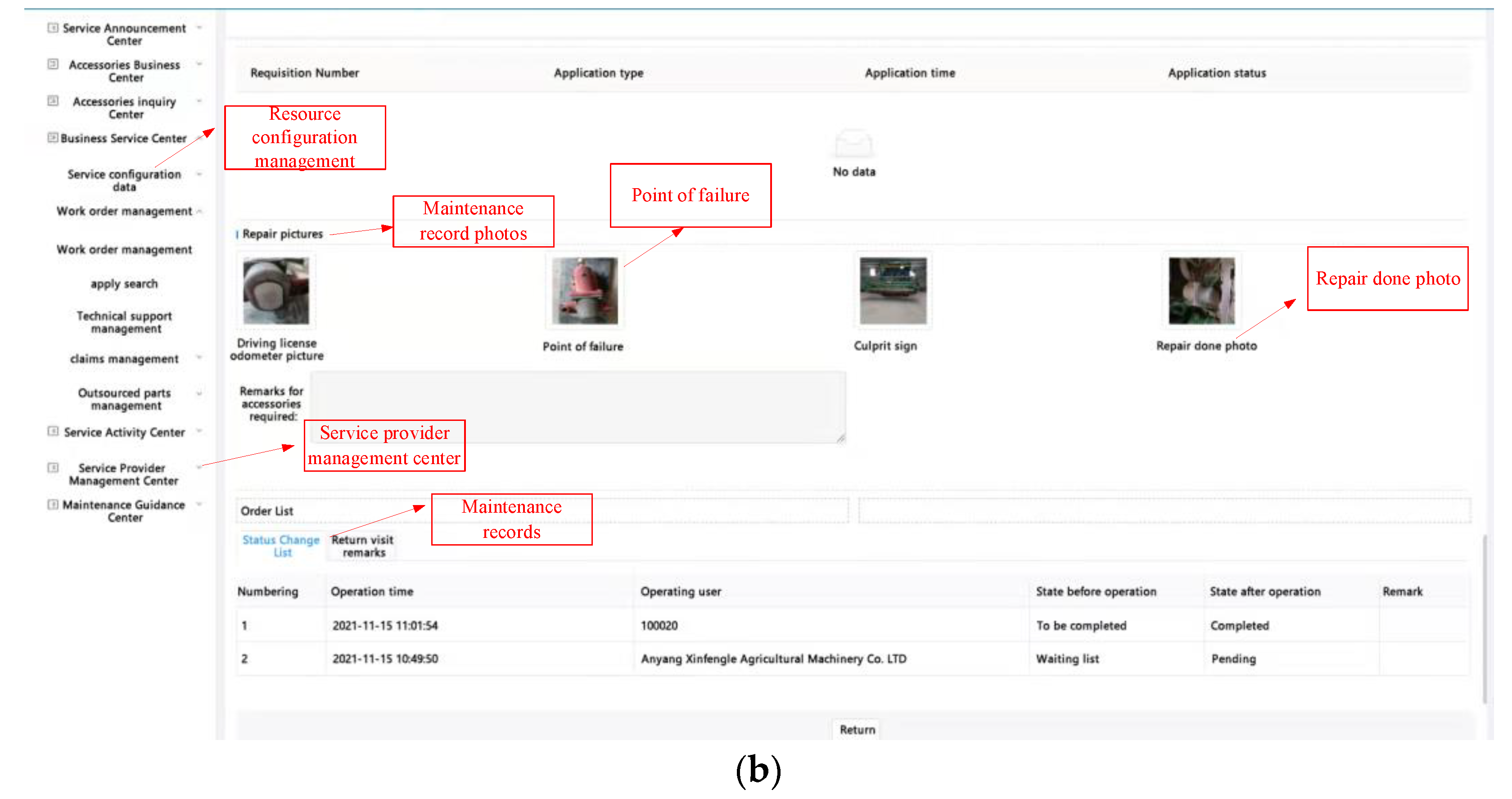

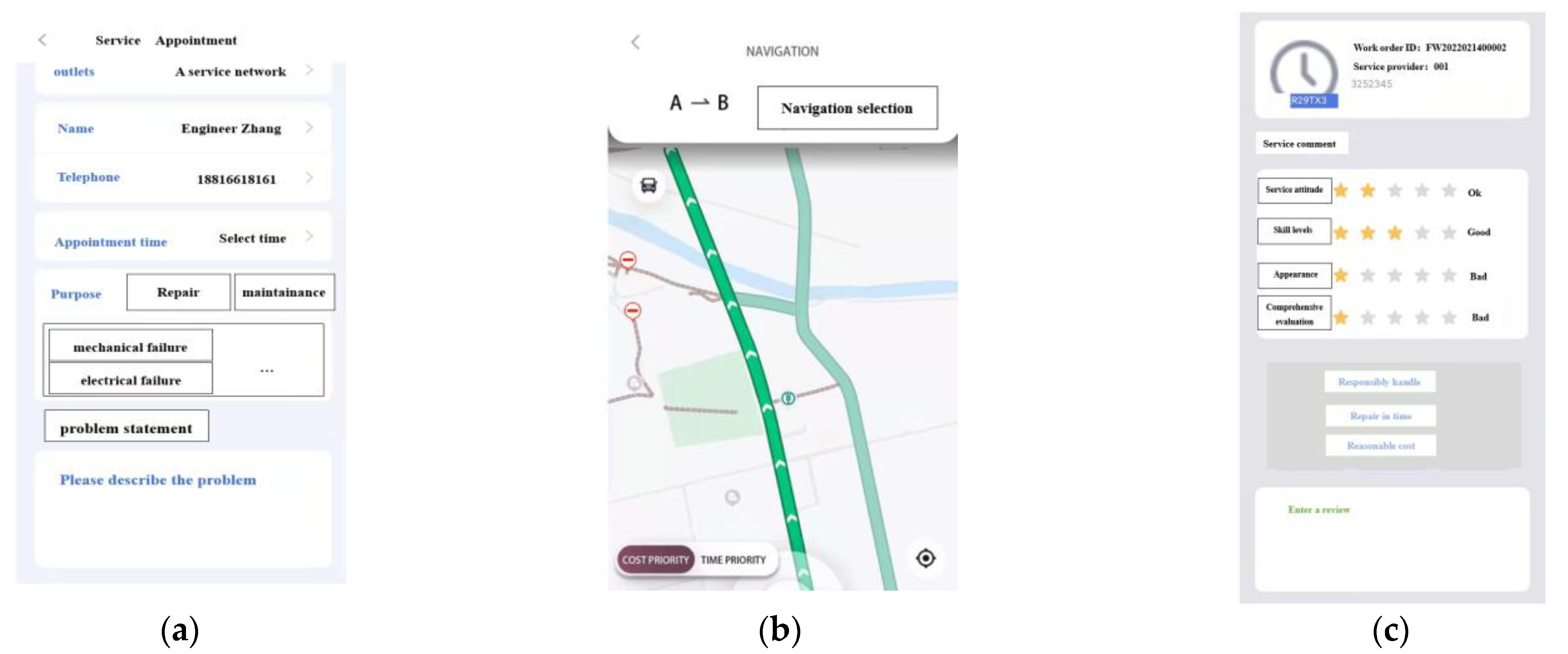

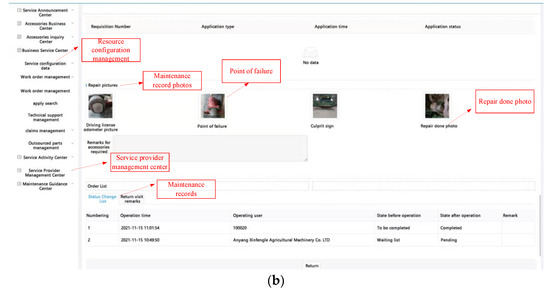

Application layer: The data was shared between the handheld terminal of agricultural machinery users, the comprehensive operation and maintenance platform, and the data monitoring vehicle terminal of the harvester. As shown in Figure 8, the mobile terminal system operated based on the service provided by the mobile device communication operator. The agricultural machinery user terminal can actively apply to the platform for repairs, harvester status information, service network viewing, path planning, service maintenance evaluation, etc., which was convenient for agricultural machinery users to understand the condition of the harvester in real-time and, at the same time, it can receive information on the operation and maintenance platform and optimal maintenance services program. Combined with the results of condition monitoring and diagnosis, and self-selected service and maintenance methods and time, it can interact with the platform information in real-time to obtain optimal service plans and provide technical guarantees for operation, maintenance, overhaul, and equipment supervision.

Figure 8.

The function of the handheld terminal for agricultural machinery users. (a) User service report for repair; (b) Service station maintenance path planning; and (c) Service evaluation after maintenance.

4. Results and Discussion

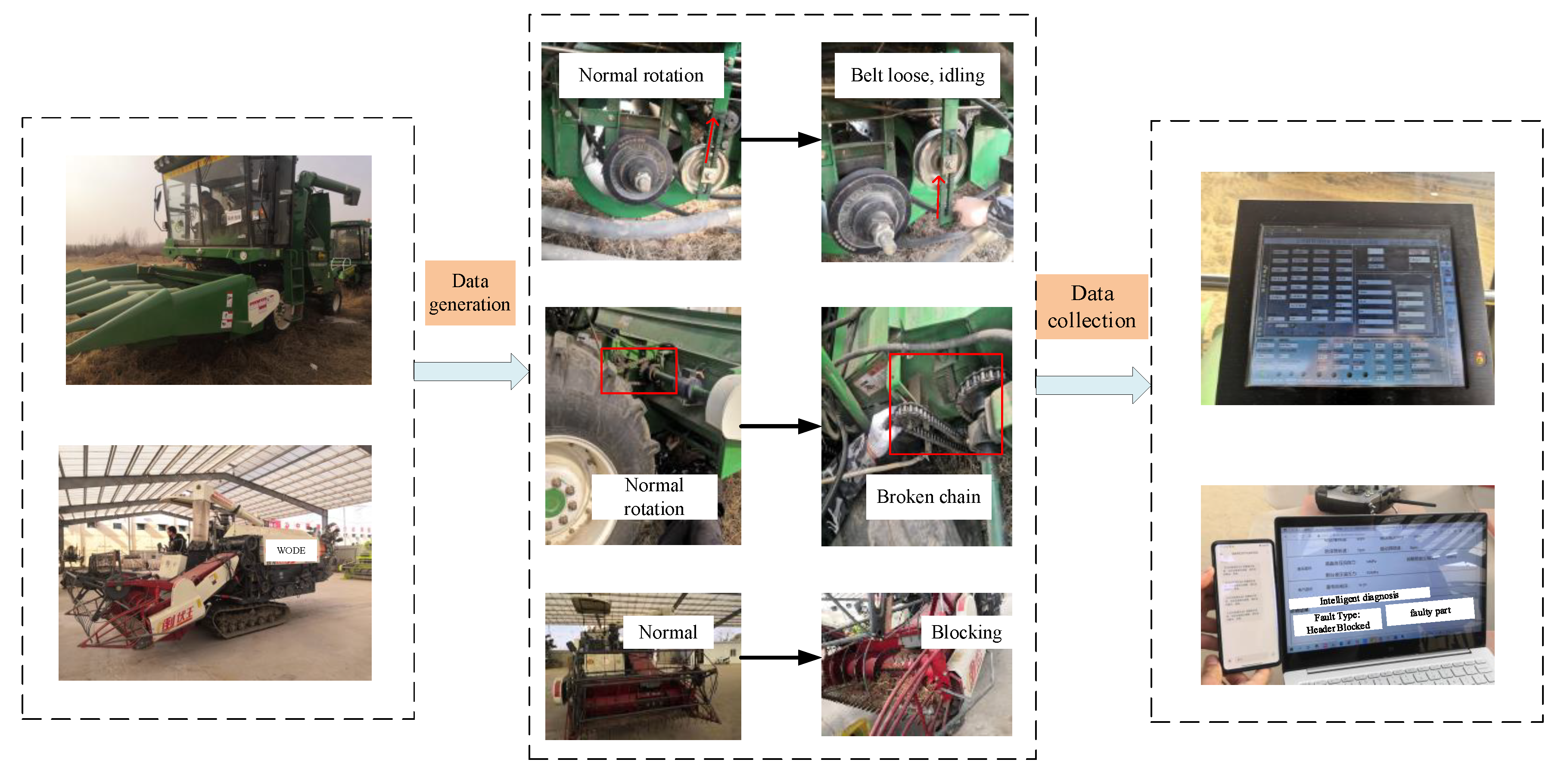

4.1. Experiment Material

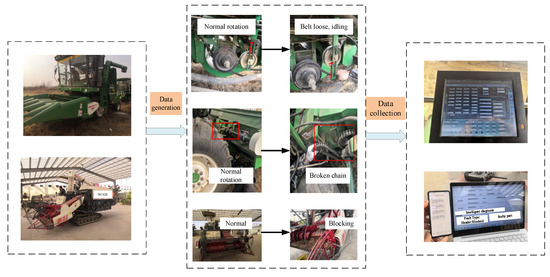

In order to test the performance of the model in the actual operating environment, a combined harvesting mechanism test was conducted in Wulian District, Rizhao City in March 2022, as shown in Figure 9. The test model is the Wuzheng 4YZP-4X corn harvester, with a variety of R1377, a grain-grass ratio of 1.06, grain moisture of 23.7%, and stem moisture of 32.4%. The cutting width of the combine is 4.75 m and the feeding amount is 6 kg/h. Due to the unpredictability and infrequent occurrence of natural failures, manual intervention was used to fail during testing, resulting in specific failures of the harvester, according to the transmission roadmap and the failure situation of the combine harvester.

Figure 9.

Fault diagnosis and monitoring test of combine harvester.

According to GB/T 8097-2008 “Test Method for Harvesting Machinery Combine Harvester”, the performance of the designed IPSO-SVM model was investigated, and the fault identification accuracy was selected as the test index.

where accuracy is the fault recognition accuracy rate of the IPSO-SVM model, %; ρ is the number of samples that are correctly diagnosed by the model; and the total is the number of samples that the model has diagnosed accumulatively.

4.2. Data Extraction and Processing

4.2.1. Data Extraction

Through the data acquisition system, the information on the main working parts of the combine harvester in the field was collected, mainly including the speed of the feeding auger, the speed of the conveyor chain rake, the speed of the threshing drum, the speed of the fan, and the speed of the drafter. Table 1 shows the working data during the failure experiment.

Table 1.

Collected data of fault diagnosis tasks.

4.2.2. Data Preprocessing

Due to the interference of the system in the test, the raw speed data collected had 0 values, abnormal values, and missing values, so it was necessary to preprocess the test data. If all attributes in a sample were 0, the sample would be deleted; for outliers exceeding the maximum speed of the corresponding part, they would be replaced by linear interpolation; for missing values, they would be filled by spline interpolation. The collected data were divided into five types of fault samples. After data preprocessing, a total of 2700 data samples were obtained, including 1650 data samples of the normal operation of combine harvesters, 178 data samples of feeding auger clogging, 163 data samples of fan clogging, 229 data samples of conveyor chain rake clogging, 180 threshing drum clogging data samples, and 300 scraper belt slip data samples. The data distribution is shown in Table 2.

Table 2.

The distribution of the number of training and test sets.

For six data types, 100 groups of samples were collected for each category, and a total of 600 samples were selected. They were then randomly divided into two parts, 60 of each data type were selected as training samples, and the remaining 40 as test samples, and normalized. Five main types of combine harvester failure data were set, and six data types were selected for data collection and testing, namely, the auger drive chain was broken, the breakaway drum was broken, the scraper was broken, the transmission chain and the drive chain of the rake were broken, and the fan pulley belt was loose and normal. The corresponding main fault parameter changes are shown in Table 3 when the above-mentioned faults occurred in the harvester.

Table 3.

Changes of main parameters of five types of combine harvesters.

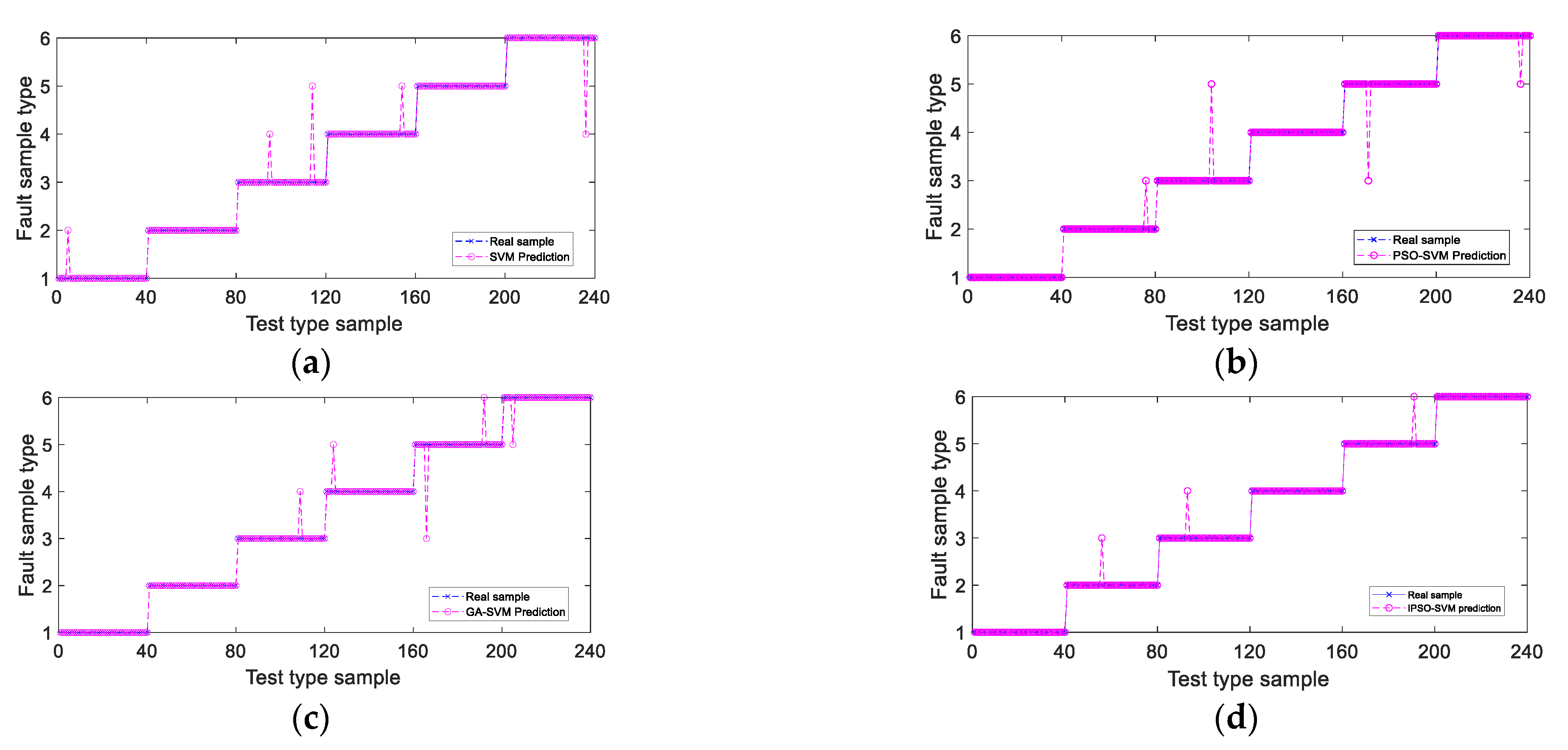

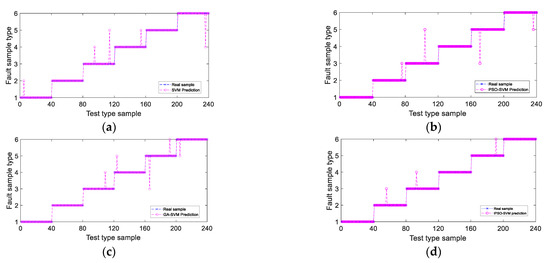

4.3. Fault Diagnosis Modeling and Verification

The sample data collected by the water combine harvester fault information in the Matlab R2018a software were selected for fault diagnosis. A total of 300 samples were selected and were randomly divided into two parts in which 30 samples were selected as training samples and the remaining 20 samples as test samples. It can be seen from Figure 10 that the diagnostic errors mainly occurred in the second to sixth types of faults. Among them, IPSO-SVM classifier diagnosis errors occurred three times, respectively, one data error of the second type of fault was wrongly divided into the third type, one data error of the third type of fault was wrongly divided into the fourth type, and one data error of the fifth type of fault was wrongly classified into the sixth category, which mainly improved the diagnostic accuracy of the fourth and sixth categories of faults compared with the GA-SVM and PSO-SVM classifiers.

Figure 10.

Classification results of four classifiers for combine harvester failures. (a) SVM diagnostic result, (b) PSO-SVM diagnostic result, (c) GA-SVM diagnostic result, and (d) IPSO-SVM diagnostic result.

The test results of the IPSO-SVM model in the experimental data test set are shown in Table 4. Two of the feed auger clogging samples were mistaken as threshing drum clogging, and one fan failure was mistaken as conveyor chain rake clogging. The reason for the identification error was that the feeding auger and the disengaging drum belonged to the same transmission structure, and the fan and the conveyor chain rake belonged to the same transmission belt transmission system.

Table 4.

The fault identification results of the IPSO-SVM model on the test set data.

The experimental results showed that the average recognition rate of the system was 97.96%. Among them, the failure recognition rate of the threshing drum was only 94.11%, which was mainly due to the accelerated rise and sudden decrease in the engine speed of the combine harvester during the data collection process and the idling process of the speed of the threshing drum, resulting in fuzzy judgment. For the fan and the feeding auger, the recognition rates were 97.30% and 96.36%, respectively. The fan was driven by the fan pulley, and the feeding auger was driven by the intermediate shaft of the header, relatively independent.

The classification accuracy was selected as the performance evaluation index, and four methods of SVM, PSO-SVM, GA-SVM, and IPSO-SVM were used to classify the faults of the selected dataset. The parameter was set to m as 20, and the maximum value of inertia weight w was 1.40; the minimum value of w was 0.4, the acceleration parameter c1 was 1.6, c2 was 1.8, the number of iterations X was 4, Y was 6, the improved IPSO optimization parameters were better than the PSO algorithm, and the IPSO optimization results were the best. When the optimal parameters c and σ were 3.281 and 0.407, respectively, the IPSO-SVM model had the best performance, and the recognition accuracy was 97.96%, better than that of the PSO-SVM model.

In this study, SVM, PSO-SVM, GA-SVM, and IPSO-SVM were used to classify the faults of the selected data set. In order to ensure the accuracy of the experimental results, 2700 data samples were selected for the experiment. The prediction accuracy of the four methods is shown in Table 5. The correct samples and the wrong samples were classified, respectively, to judge the accuracy.

Table 5.

The diagnosis results from the fault diagnosis system of the combine harvester.

It can be seen from Table 5 that the accuracy of IPSO-SVM was higher than that of the other three algorithms, and compared with PSO-SVM, the recognition accuracy of IPSO-SVM reached 97.96%. Therefore, judging from the accuracy of model classification, the classification performance of the IPSO-SVM classifier was more stable; it was not as easy to fall into the local optimal solution as the PSO-SVM classifier, which led to a decrease in classification accuracy.

4.4. Discussion

First, a combine harvester fault diagnosis and remote operation and maintenance system was developed, and the fault diagnosis of the harvester operation was carried out. At the same time, based on the smart agricultural scenario, a comprehensive operation and maintenance platform for combine harvesters was developed, and a ladder-type operation and maintenance method was realized based on fault diagnosis technology, including fault maintenance push, etc., so as to provide a basis for the further development of comprehensive operation and maintenance technology of combine harvesters.

In view of the fault diagnosis method proposed in this paper, based on the developed speed sensor for the harvester operation data monitoring and acquisition system, the application verification and comparative analysis were carried out through the data set, which effectively improved the fault diagnosis accuracy of the combine harvester, but the method as well. However, there are some problems, such as: in the diagnosis process, the fault type was wrongly judged and the problems of separation from the drum and the auger were wrongly judged to be the same fault type. The main problem was that only one factor was considered. Because the transmission structure of the combine harvester was connected, in the future research process, a variety of different sensors should be used to study the failure problems of the combine harvester, and the machine learning algorithm could be used to adjust the monitoring data types and weight ratio to achieve better discrimination.

In this study, the design of the combine harvester data acquisition system, the design of the fault diagnosis system, and the construction of the comprehensive operation and maintenance platform of the combine harvester were carried out. Based on the full-cycle operation and maintenance service technology of the combine harvester, later researchers can mainly carry out fault information transmission, service, and maintenance resource allocation and scheduling, which will be the most important part of future research.

5. Conclusions

The goal of this research was to provide a fault diagnosis system for combine harvesters, and at the same time, an operation and maintenance service platform was developed to feed back information to the manufacturer’s management center in real time, so as to provide reliable maintenance measures for agricultural machinery operators in advance, diagnose the failure of combine harvesters accurately, send failure information quickly, and push maintenance plans to agricultural machinery users.

The SVM classifier has been widely used in the research of fault diagnosis, but its classification accuracy is largely related to the selection of the penalty parameter c and the kernel function parameter g. In this paper, an improved particle swarm algorithm was proposed to optimize the SVM penalty factor and kernel function width. In the improved algorithm, the inertia weight was gradually reduced in the iteration to balance the global search ability and local search ability of the population. The fault diagnosis of the combine harvester was taken as the research object and, through the collected combined harvesting, the fault diagnosis effect was verified by using the machine operation data set, and the penalty factor c of the support vector machine and the parameter σ of the kernel function were optimized. The final fault diagnosis rate of IPSO-SVM was 95.58%. The IPSO-SVM algorithm improved the accuracy of combine harvester failure prediction, and the effectiveness of the algorithm was verified in practice.

Based on the comprehensive operation and maintenance system platform of the corn combine harvester fault diagnosis method, the simulation and comparison of IPSO-SVM with SVM, GA-SVM, and PSO-SVM were carried out. The verification showed that the accuracy of the failure prediction of the combine harvester was improved, and a new method was provided for research of the failure diagnosis of the combine harvester. However, we only used artificial faults to simulate field conditions. Compared with field operations, there may be a certain accuracy error. We will continue to carry out related technical research in a later stage.

Author Contributions

In the research of this article. Conceptualization, W.Z. and B.Z.; methodology, W.Z. and R.W.; writing—original draft, W.Z. and F.W.; funding acquisition, L.Z.; project administration, W.Z. and L.Z.; Formal analysis, W.Z. and J.W.; Investigation, K.N.; software platform, W.Z. and F.W.; data curation and software. visualization, W.Z. and F.W. All authors have read and agreed to the published version of the manuscript.

Funding

The work was sponsored by the National Key R&D Program Project (2020YFB1709603). the Intelligent Manufacturing Comprehensive Standardization Project (No. 2018GXZ1101011).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank the editor and anonymous reviewers for providing helpful suggestions for improving the quality of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Luo, Y.; Wei, L.; Xu, L.; Zhang, Q.; Liu, J.; Cai, Q.; Zhang, W. Stereo-vision-based multi-crop harvesting edge detection for precise automatic steering of combine harvester. Biosyst. Eng. 2022, 215, 115–128. [Google Scholar] [CrossRef]

- Li, R.; Cheng, Y.; Xu, J.; Li, Y.; Ding, X.; Zhao, S. Research on On-Line Monitoring System of Hydraulic Actuator of Combine Harvester. Processes 2022, 10, 35. [Google Scholar] [CrossRef]

- Craessaerts, G.; De Baerdemaeker, J.; Saeys, W. Fault diagnostic systems for agricultural machinery. Biosyst. Eng. 2010, 106, 26–36. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.; Wang, J.; Wang, C.; Sensors, Y.D.J.; Physical, A.A. Recent advances in sensor fault diagnosis: A review. Sens. Actuators A Phys. 2020, 309, 111990. [Google Scholar] [CrossRef]

- Połok, B.; Bilski, P. Intelligent diagnostic system for the rachet mechanism faults detection using acoustic analysis. Measurement 2021, 183, 109637. [Google Scholar] [CrossRef]

- Lin, Y.; Xiao, M.; Liu, H.; Li, Z.; Zhou, S.; Xu, X.; Wang, D. Gear fault diagnosis based on CS-improved variational mode decomposition and probabilistic neural network. Measurement 2022, 192, 110913. [Google Scholar] [CrossRef]

- Xue, L.; Jiang, H.; Zhao, Y.; Wang, J.; Wang, G.; Xiao, M. Fault diagnosis of wet clutch control system of tractor hydrostatic power split continuously variable transmission. Comput. Electron. Agric. 2022, 194, 106778. [Google Scholar] [CrossRef]

- Che, C.; Wang, H.; Ni, X.; Lin, R. Hybrid multimodal fusion with deep learning for rolling bearing fault diagnosis. Measurement 2021, 173, 108655. [Google Scholar] [CrossRef]

- Fu, J.; Ji, C.; Liu, H.; Wang, W.; Zhang, G.; Gao, Y.; Zhou, Y.; Abdeen, M.A. Research Progress and Prospect of Mechanized Harvesting Technology in the First Season of Ratoon Rice. Agriculture 2022, 12, 620. [Google Scholar] [CrossRef]

- Han, F.; Tian, Y.; Zou, Q.; Zhang, X. Research on the Fault Diagnosis of a Polymer Electrolyte Membrane Fuel Cell System. Energies 2020, 13, 2531. [Google Scholar] [CrossRef]

- Garramiola, F.; Poza, J.; Madina, P.; del Olmo, J.; Ugalde, G. A Hybrid Sensor Fault Diagnosis for Maintenance in Railway Traction Drives. Sensors 2020, 20, 962. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Chen, K.; Zhao, Y.; Ji, J.; Jing, P. Simulation of hydraulic transplanting robot control system based on fuzzy PID controller. Measurement 2020, 164, 108023. [Google Scholar] [CrossRef]

- Zheng, K.; Jia, G.; Yang, L.; Liu, C. A Cost-Sensitive Diagnosis Method Based on the Operation and Maintenance Data of UAV. Appl. Sci. 2021, 11, 11116. [Google Scholar] [CrossRef]

- Li, Q.; Shang, C.; Li, Z. Communication Fault Maintenance Decision of Information System Based on Inverse Symmetry Algorithm. Symmetry 2020, 12, 126. [Google Scholar] [CrossRef] [Green Version]

- Kok, Z.H.; Mohamed Shariff, A.R.; Alfatni, M.S.M.; Khairunniza-Bejo, S. Support Vector Machine in Precision Agriculture: A review. Comput. Electron. Agric. 2021, 191, 106546. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, B.; Wang, M.; Zhang, H. Damping behaviour of a prestressed composite beam designed for the thresher of a combine harvester. Biosyst. Eng. 2021, 204, 130–146. [Google Scholar] [CrossRef]

- Sun, D.; Chen, D.; Wang, S.; Wang, X. Development on electrical system performance test stand for combine harvester. IFAC-PapersOnLine 2018, 51, 363–367. [Google Scholar] [CrossRef]

- Yin, Y.; Zhang, Y.; Meng, Z.; Du, C.; Qin, W.; Guo, S. Design and Experiment of Multi-information Collection System for Grain Combine Harvesters. IFAC-PapersOnLine 2018, 51, 855–860. [Google Scholar] [CrossRef]

- Xia, M.; Shao, H.; Williams, D.; Lu, S.; Shu, L.; de Silva, C.W. Intelligent fault diagnosis of machinery using digital twin-assisted deep transfer learning. Reliab. Eng. Syst. Saf. 2021, 215, 107938. [Google Scholar] [CrossRef]

- Chenbo, X.; Guangyou, Y.; Lang, L.; Jing, L.; Xueha, C.; Zhiyan, I. Operation faults monitoring of combine harvester based on SDAE-BP. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 2020, 36, 46–53. [Google Scholar]

- Jing, L.; Guangyou, Y.; Zhiyan, M.; Xuehai, C. Fault diagnosis technology of combine harvester based on random forest. J. Chin. Agric. Mech. 2019, 40, 147–153. [Google Scholar]

- Lili, Y.; Weize, T.; Yuanyuan, X.; Caicong, W. Predicting fuel consumption of grain combine harvesters based on random forest. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 2021, 37, 275–281. [Google Scholar]

- García Nieto, P.J.; García-Gonzalo, E.; Sánchez Lasheras, F.; de Cos Juez, F.J. Hybrid PSO–SVM-based method for forecasting of the remaining useful life for aircraft engines and evaluation of its reliability. Reliab. Eng. Syst. Saf. 2015, 138, 219–231. [Google Scholar] [CrossRef]

- Lv, M.Z.; Liu, S.X.; Su, X.M.; Chen, C.Z. Intelligent Diagnosis of Health Status Based on Isomap and IPSO-SVM. Basic Clin. Pharmacol. Toxicol. 2019, 124, 298–299. [Google Scholar]

- Chen, J.; Wu, P.; Xu, K. Remote Fault Information Acquisition and Diagnosis System of the Combine Harvester Based on LabVIEW. In Proceedings of the 2015 International Conference on Applied Mechanics, Mechatronics and Intelligent Systems (AMMIS2015, Nanjing, China, 19–20 June 2015; pp. 285–292. [Google Scholar]

- Haonan, F.; Sheng, F.; Yonggang, X. Fault diagnosis of rotating machinery based on BN-1DCNN model. J. Vib. Shock 2021, 40, 302–308. [Google Scholar]

- Wen-feng, G.; Hui, C.; Dan-wei, W. Fast fault diagnosis method of marine rotating machinery with multi-sensor monitoring based on improved LSTM-SVM. J. Ship Mech. 2021, 25, 1239–1250. [Google Scholar]

- Zhang, P.; Xu, H.; Hu, Z.; Chen, Y.; Cao, M.; Yu, Z.; Mao, E. Characteristics of Agricultural Dust Emissions from Harvesting Operations: Case Study of a Whole-Feed Peanut Combine. Agriculture 2021, 11, 1068. [Google Scholar] [CrossRef]

- Xue, F.; Zhang, W.; Xue, F.; Li, D.; Xie, S.; Fleischer, J. A novel intelligent fault diagnosis method of rolling bearing based on two-stream feature fusion convolutional neural network. Measurement 2021, 176, 109226. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, X.; Zhang, J.; Wang, L.; Wang, D.; Zhang, P. Fault diagnosis of silage harvester based on a modified random forest. Inf. Process. Agric. 2022, in press. [Google Scholar] [CrossRef]

- Qiu, Z.; Shi, G.; Zhao, B.; Jin, X.; Zhou, L. Combine harvester remote monitoring system based on multi-source information fusion. Comput. Electron. Agric. 2022, 194, 106771. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, F. Fault Diagnosis of Press Bearing Based on SDAE-SVM. Digit. Manuf. Sci. 2018, 16, 203–208. [Google Scholar]

- Zhang, H.; Li, Y.N. Research on identification model of element logging shale formation based on IPSO-SVM. Petroleum 2021, in press. [Google Scholar] [CrossRef]

- Xu, H.; Chen, G. An intelligent fault identification method of rolling bearings based on LSSVM optimized by improved PSO. Mech. Syst. Signal Process. 2013, 35, 167–175. [Google Scholar] [CrossRef]

- Wen, Y.; Fashiar Rahman, M.; Xu, H.; Tseng, T.-L.B. Recent advances and trends of predictive maintenance from data-driven machine prognostics perspective. Measurement 2022, 187, 110276. [Google Scholar] [CrossRef]

- Lambinet, F.; Sharif Khodaei, Z. Measurement platform for structural health monitoring application of large scale structures. Measurement 2022, 190, 110675. [Google Scholar] [CrossRef]

- Andria, G.; Attivissimo, F.; Di Nisio, A.; Lanzolla, A.M.L.; Pellegrino, A. Development of an automotive data acquisition platform for analysis of driving behavior. Measurement 2016, 93, 278–287. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Design and Development of an Edge-Computing Platform Towards 5G Technology Adoption for Improving Equipment Predictive Maintenance. Procedia Comput. Sci. 2022, 200, 611–619. [Google Scholar] [CrossRef]

- Elsisi, M.; Tran, M.Q.; Mahmoud, K.; Mansour, D.-E.A.; Lehtonen, M.; Darwish, M.M.F. Effective IoT-based deep learning platform for online fault diagnosis of power transformers against cyberattacks and data uncertainties. Measurement 2022, 190, 110686. [Google Scholar] [CrossRef]

- Xiao-lu, X.; Tao, W.; Hong, G. Fault diagnosis of metro vehicle traction control unit based on IPSO-SVM. J. Dalian Univ. Technol. 2015, 55, 67–72. [Google Scholar]

- Min-jie, W.; Hong, A. Fault Diagnosis of Cement Calcination System Based on SVM Optimized by IPSO. Control Instrum. Chem. Ind. 2019, 46, 983–987, 1006. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).