1. Introduction

In conventional production systems based on fast-growing broilers, the three most important constraints (bottlenecks) for the maximum production results of broilers on a farm are the genetics or potential and quality of the day-old chicks, the nutrition or feed quality, and the health or care of the chickens. Local independent farmers often do not have a significant influence on the first two, except through the choice of the chicken and feed suppliers available on the market. While large vertically integrated poultry production systems can control all aspects, that is the choice of the hybrids and the quality of the chickens in their own incubators, the quality of the nutrition program in their feed mills, as well as farm fattening and the entire production chain optimization to maximize their profit [

1,

2,

3]; the economy of a single independent farm can be controlled the most at the farm’s gate—the price, quantity, and quality of the broiler fattening inputs and outputs. In practice, the farmer usually has two options: to control or to trust his/her partners—the local production contractors/integrators and input suppliers.

The current genetic potential of the two most bred fast-growing chicken hybrids in Serbia (Cobb 500 and Ross 308), according to the published data of their producers, is very similar. Although these hybrids, in optimal conditions of six-week fattening for both sexes, reach an average body weight of 2952 g for Cobb 500 and 2918 g for Ross 308, with a similar feed conversion ratio (FCR) of 1.61 for both breeds [

4,

5], in Serbia, in the last four years, these fattened broilers were delivered to slaughterhouses with an average body weight of 2400 g [

6]. The reason may be suboptimal conditions of breeding and/or nutrition [

7], but also the frequent practice of producers to depopulate the fattening flock from day 35 by picking and selling the heaviest chickens. On the other hand, the increase and much better use of the genetic potential of broilers, i.e., the reduction in the yield gap in a country [

8], represents the greatest potential for increasing the production of broiler meat, both locally and globally. Beside genetics, the quality and potential of day-old chicks delivered to the farm are affected by a number of factors, such as the parent flock (age, health status, nutrition, environment, and management of the parent farm), incubation, and transport methods [

9]. Therefore, in addition to the choice of hybrid, the choice of a reliable local supplier of day-old chicks is also important.

The quality of the feed and the nutrition of the broilers, the second most important factor in fattening, can also differ in integrated, internal feed mills, and commercial, market-oriented feed factories. The nutritionist employed by the integrator knows which genotype, under what conditions and the purpose of the fattening, will be fed, and usually needs and produces only a few formulations. In the case of the feed factories (especially when it comes to feed for retail), they have many clients who use different hybrids and grow them under different conditions and goals, and feed producers are usually not familiar with this [

10]. Therefore, the largest industrial feed mills in Serbia have more options in the market program for broiler fattening. Most often, these are three qualitatively and price-wise different nutrition programs: an economical, standard, and premium feed program for broiler fattening. Since economical and premium programs can be very different from different manufacturers or can even be custom-made (including the optimization of nutrition, if the client has reliable farm data and the feed producer has state-of-the-art software tools and an experienced nutritionist, as shown by Steed et al. [

11]), the focus of this study was on standard programs, which have the widest application, attractiveness in terms of the price–quality ratio, and are more suitable for performing realistic comparisons of different producers and the impact of their feed on fattening results. Additionally, the minimum quality requirements for these mixtures for broiler fattening are regulated in Serbia by the Rulebook on the quality of animal feed [

12] and all products on the market within this (standard quality) category comply with these (minimum or minimum/maximum) nutrient limits. On the other hand, manufacturers use so-called closed recipes (specifications of the ingredients used on the product declaration without stating the quality, quantity, and processing), which limits the possibility of characterizing and comparing the market feed for broilers.

Although Serbia is a major producer of maize, soybeans, and sunflowers, which are the main components of quality mixtures for broiler fattening, Milošević et al. [

13] point out that the price of the inputs for broiler fattening, especially feed, is significantly higher than in the EU countries, and especially in relation to Brazil and the USA, stating that in observed years it was approx. 30 €/100 kg of feed and was 10–30% more expensive. The price of feed for broilers follows the trends of the stock market prices, primarily maize and soybean, which have been changing mostly upwards in recent decades. Therefore, the feed in broiler fattening, especially the price–quality ratio, is becoming more important than ever for the economic success of commercial broiler fattening. Concern for the future is also shown in the latest global survey of poultry and feed industry stakeholders [

14], especially regarding the availability of raw materials, commodity costs, mycotoxins, antibiotic bans, and other difficulties in maintaining feed quality. It should be emphasized that GMO feed and the use of antibiotics as growth promoters has been banned in Serbia, and therefore it is more challenging to produce the best-performed broiler feed, as shown by Bean-Hodgins et al. [

15].

The average purchase prices of broilers in Serbia, according to the Statistical Office of the Republic of Serbia [

6] for the years 2017, 2018, and 2019 were 112, 105, and 96 RSD/kg live weight, respectively (0.95, 0.89, and 0.81 €/kg; 1 € ≈ 118 RSD). Due to the sensitivity of the Serbian market, as a small and open market for imports, as well as the insufficient organization and market impact of broiler producers, frequent and unpredictable fluctuations in the prices of fattened chickens are noticeable, usually by ±10% of the average price, which significantly complicates the ability to plan and control the broiler production economy.

Therefore, to show how local farmers can open and light these two “black boxes” in their production, we considered it important and useful to design and perform independent testing of the most commonly used hybrids and broiler feeds in the Serbian market, and especially to cross-test these two key production factors. Additionally, due to the frequent variability of the purchase prices of fattened chickens and at least two thirds of the share of feed in the production cost, the test results of the different feeds in terms of the profitability of the nutrition per broiler depending on the duration of fattening (35 or 42 days) and market conditions (90, 100, or 110% of the current price of kg live weight of broilers) were analyzed.

The main aim of this study was to design and evaluate a simple tool as a combination of comparative biological tests and feed characterizations to help local broiler producers from one region or country choose the most cost-effective feeding and fattening strategies for their farm, in these changing market conditions.

2. Materials and Methods

2.1. Trial Design, Used Broilers and Feed

The effects of two different hybrids and three different feeds, most common on the Serbian market, on broiler production performance was determined by a 2 × 3 factorial experimental design. Before and after the biological trial, the characterization of the tested feed was designed and performed.

The test was performed in the period of April/May 2018 on broilers of the Cobb 500 and Ross 308 proveniences, currently the two most commonly used broiler hybrids in Serbia. All chickens were procured from the same local producer and incubated in the same incubator. The biological trial was performed on a total of 1800 day-old broiler chickens of both sexes (900 per tested hybrid) divided by a randomized block system into a total of 6 experimental treatments, with 6 replicates per group and 50 chickens in each replicate/box. At the start of the trial, an individual initial visual inspection and an initial measurement of the chickens were performed. At the beginning of and during the trial, the common vaccination program of chickens, required by national regulations and technologically recommended, was performed.

Complete mixtures for broiler fattening were purchased on the market under the same market conditions from three different manufacturers who are well-known and established animal feed companies in Serbia with large production capacities and a long tradition (producers A, B, and C). The selected commercial feed and diet program was an average, standard option of the broiler fattening feed supplied to the local market: a starter mixture with 22% crude protein (CP) to be used until day 21 of broiler fattening, a grower mixture with 19% CP until day 35, and the finisher with 17% CP until day 42 of the fattening. All the used mixtures were analyzed in the laboratory before their use in the biological trial.

The study was performed at the Institute of Animal Husbandry, Belgrade—Zemun, Serbia, in the accredited Laboratory for Chemistry and Microbiology and at the Experimental Farm for Broiler Fattening in the period April/May 2018. The trial was reported and approved by the Ethics Commission of the Institute of Animal Husbandry Belgrade—Zemun according to the required procedure. The experiment complied with the principles of the Serbian Law 41/2009 concerning animal welfare and Rulebook 39/10 for the handling and protection of animals used for experimental purposes, as well as the EU Council Directive 98/58/EC concerning the protection of farmed animals and Directive 2010/63/EU on the protection of animals used for scientific purposes.

2.2. Housing and Feeding of Broilers in the Trial

The chickens were kept in a floor system, in a single building/room with group boxes measuring 1.9 × 1.95 m for a maximum of 50 broilers (stocking density 15 heads/m2) on a chopped straw litter. Food and water were given to the chickens ad libitum from one standard bell feeder and two round feeders per box. The lighting program during the first 10 days and the last three days of fattening was 23 h of light (L) and 1 h of darkness (D), and from day 11 to 38, in 24 h, 16L/4D/2L/2D. The temperature in the building was regulated by an automatic switching on of heating (set temperature) and air circulation by setting a timer (without the possibility of cooling the intake air) according to the ambiental recommendations of the manufacturers of the used hybrids.

The basic indicators of the ambient conditions (temperature and humidity) in the facility (at the level of the chickens) were registered and recorded every hour during the biological trial, and the average weekly values are shown in

Table 1.

2.3. Feed Characterization

In order to clearly and completely compare the tested feeds and obtain a rational conclusion about their value, the characterization of the feeds before and after the biological trial was designed.

The characterization of the feed before the biological trial was performed on the basis of the market price and producer declarations, laboratory analyses, and calculations of the chemical and nutritional composition, as well as microbiological analyses.

The characterization of the feed after the biological trial was performed on the basis of the absolute and relative comparison of body weight, the feed conversion ratio, and the other production results of the broilers fed the tested feeds, as well as the calculated economic parameters of fattening success related to feed (average price/cost of the feed consumed per broiler, gross profit after deduction of the feed costs), where comparisons were made for two scenarios of fattening duration (35-day fattening and 42-day fattening) and three market price scenarios (90, 100, and 110% of the current price per kg of the live weight of the fattened broilers).

2.4. Testing during the Broiler Biological Trial

The health conditions of the broilers were monitored and determined daily, and deaths in the trial were immediately recorded, measured, and included in the calculation of the feed conversion ratio. Mortality was calculated at the box level.

The individual body weight of all the chickens was measured on arrival (day zero, a few hours after hatching), at the end of the first week, during feed changes, and at the end of the test (days 7, 21, 35, and 42). For the first two measurements, a calibrated scale CHYO MK-2000B (Chyo Balance Corp., Kyoto, Japan) with an accuracy of 0.01 g was used, and for the other measurements, a specialized scale for measuring poultry BAT 1 (Veit Electronics, Moravany, Czech Republic) with an accuracy of 1 g was used. Simultaneously with the recording of body weight, the consumption of feed per box was determined for the time interval between the two weightings.

On the basis of all the measurements, the individual weight gain of the chickens was calculated, as well as the mortality and feed conversion ratio (kg of feed/kg gain) at the box level for the different observed periods of fattening.

For the two production scenarios, broiler fattening up to 35 days and broiler fattening up to 42 days, the European Production Efficiency Factor (EPEF) was calculated, a common aggregate performance indicator of broiler fattening based on average weight, vitality, the feed conversion ratio, and fattening duration [

16].

2.5. Statistical Data Processing

Body weight and weight gain were determined and analyzed for each trial chicken, while a box was used as the experimental unit for all the other production parameters. The obtained results were processed with the statistical software package STATISTICA, version 8 (StatSoft Inc., Tulsa, OK, USA), using the Factorial ANOVA procedure. The degree of statistical significance of the differences in production performance between the groups was determined using the Tukey test. Significant differences were considered to be values with p < 0.05.

3. Results

3.1. Feed Characterization before the Trial

The properties of all the purchased feeds within the standard broiler diet program of the three different industrial feed manufacturers in Serbia, which could be determined without a biological trial, based on declarations, chemical and microbiological analysis, and calculations, are shown in

Table 2.

The table shows the main identified specifics of the broiler feed produced in three different feed companies in Serbia, all three among the leading producers in terms of capacity and market reputation. It must be pointed out that manufacturers use so-called closed recipes with the declaration of all used components and their groups (oil industry by-products: soybean meal, sunflower meal, etc.) without the obligation to state the specific ingredient quantity, quality, or processing methods. The exact composition of purchased broiler feed cannot be determined from declarations. However, in Serbia, non-GMO domestic maize and soybean (meal, cake, and full fat) are most often used for broiler feed as two basic ingredients of diets.

According to chemical and microbiological analysis, it was determined that all feeds were correct, and according to the form (crumble, pellet) and additives used, they can be classified as quality feeds.

In general, the feeds and nutrition program A, characterized by the lowest market price of all the feeds, showed a lower crude protein (CP) content in the starter, but also 0.4 and 1% higher CP in the grower and finisher than the declared minimum. There were also relatively lower contents of soluble sugars in the feeds compared to the other two manufacturers, but also higher calculated values of the metabolic energy of the starter and grower.

The feeds and diet program B was characterized by a CP content equal to or about 0.5% above the declared minimum. The most noticeable was the very low content of crude fat in the feeds, especially in the starter and grower, about 2.5% less than prescribed (and declared) for this type of feed, which caused the low metabolic energy content of these feeds.

The feeds and the general diet program C was mostly characterized by a significantly higher soluble sugar content compared to the other two manufacturers (and up to twice as high), with the normal metabolic energy values in the feeds almost in the middle between the respective feeds of the other two manufacturers. Protein analysis showed (up to 0.5%) lower values in the starter, within the permitted limits, and about 0.6% higher content in the grower and finisher than the declared minimum.

By comparing the results of the feed analysis with the regulated and declared values, as well as by comparing the manufacturers, it was determined that the biggest differences related to the price of the mixtures and the chemical composition of some nutrients.

3.2. Biological Trial

The average body weights during the biological trial of fattening the two hybrids with feed from the three different manufacturers most commonly used on the Serbian market are shown in

Table 3.

The quality of the two purchased broiler hybrids was checked visually at the beginning of the test (according to the recommendations of the hybrid manufacturer) and by initial weighing. The visual quality of both hybrids was equally good and without differences between them, except for the body weight of the Ross 308 day-old chicks, which was 0.5 g higher (p < 0.0001) and somewhat more uniform compared to the Cobb 500 hybrid.

However, the achieved average body weights recorded in all the measurements during the 42-day fattening did not differ significantly (

p > 0.05) between the two tested hybrids. The body weights achieved in the 35-day fattening were comparable to the current technological targets of the tested hybrids declared by the breeders (lagging behind by 2–4%); in the final weeks of fattening, the lagging behind reached 10%, partly due to the increased stocking density (from 33 kg/m

2 to 40 kg/m

2 at the end of the week). Additionally, the tested broiler feed and feeding strategies were standard, different from those recommended by breeding companies, so they were not best adapted to a particular broiler hybrid and led to a reduction in final body weight [

18].

The achieved body weight of the broilers in fattening was under the greatest influence of the diet comprising mixtures of the different manufacturers. Chickens fed mixtures of producer A had a significantly lower body weight in all measurements during the test (p < 0.01) compared to the diet comprising feeds B and C, which did not differ from each other (p > 0.05).

The results of mortality monitoring during the biological trial are shown in

Table 4.

In general, the Cobb 500 hybrids and one feed (manufacturer C) showed higher broiler mortality during the biological trial, but the differences were not statistically significant (p > 0.05), nor was the interaction of the tested hybrids and the feed used observed. However, all feeds produced by the C manufacturer had a high level of soluble sugars, which is positive in term of easy energy availability in feed for young chicks, but could be detrimental to the gut microbiota in feed for older broilers.

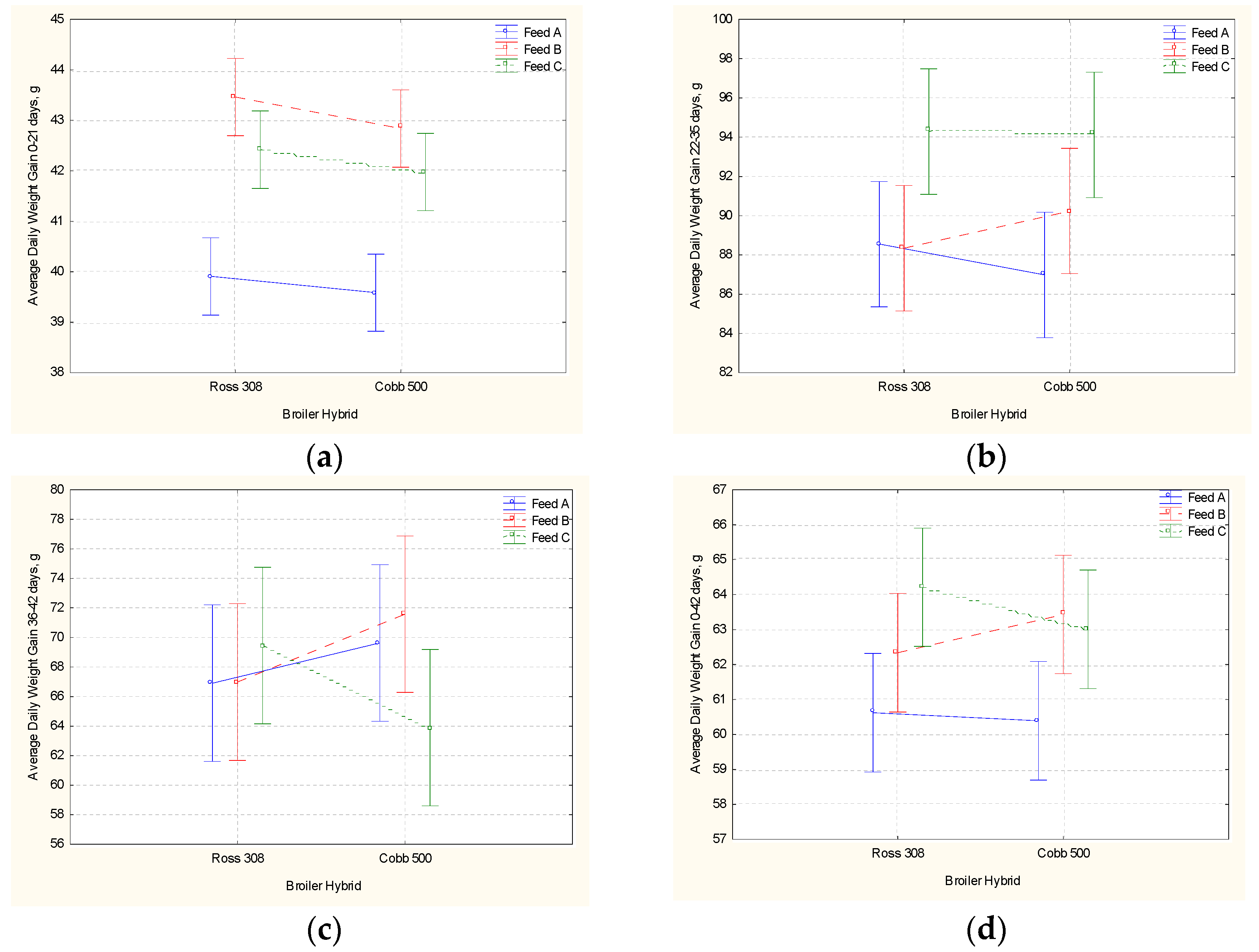

Figure 1 shows the achieved average daily weight gains during the biological trial, individually for all six applied treatments and by feeding periods, during the feeding period with starter feed (a), grower feed (b), finisher mixtures (c), as well as during the entire six-week period of fattening (d).

Similar to body weight, the graphs with the average values of the daily gain of the different broiler hybrids fed different market feeds even show a visually noticeable positive impact on the weight gain of the feeds used during the starter (feed B and feed C) and grower period (feed C), and consequently during the whole fattening. Broilers fed starter and grower A realized a significantly lower gain during the test (p < 0.05).

It is also noticeable that the tested hybrids fed with the same feed did not differ (p > 0.05) in the expressed growth rate measured by daily gain in the observed periods, as a biological response to nutrition.

The conversion of feed per kilogram of broiler growth in the test (

Table 5) differed only during the feeding of broilers with starter feeds from the different manufacturers. In the first week, as in the next two weeks, until day 21 of fattening, the broilers fed starter B showed the best feed conversion ratio, significantly lower compared to starter A in the first week, and starter A and starter C during the first three weeks of fattening (

p < 0.01). During the period of grower and finisher feeding, as well as for the complete biological trial, none of the applied treatments significantly affected the conversion of feed in the broilers.

It should be noted that the only significant interaction effect of the tested feed and hybrids in general on the broiler production performance during the test was registered during the first week in the starter conversion ratio (p = 0.0067) but was not determined and confirmed in the analysis of the whole starter period (p = 0.9899).

The production index (EPEF) for the two fattening scenarios (for the five-week and six-week fattening) was calculated based on the achieved production results of the broilers in the trial and, since no significant interaction between the two factors was observed in the trial results, the influence of the factors is shown individually in

Table 6.

The biological trial also showed in the production index, as a summary of the broiler production performance in fattening, that both broiler hybrids were of similar quality, but that market feed from different producers could significantly affect the manifestation of broiler potential and success measured by this parameter. The broilers fed with mixtures of producer A achieved a significantly lower EPEF in both scenarios of fattening duration compared to the feed of producer B, and also in fattening up to day 35 when compared to the feed of producer C.

It should be noted that in all treatments, a better EPEF was achieved with shorter fattening.

3.3. Post-Test Feed Characterization

Comparisons and analysis of the feeds based on the absolute and relative production parameters achieved in the fattening and a calculation of the impact of the feed on the economic success of the fattening in various scenarios of the end of the fattening and the price of the final product are shown in

Table 7.

At the production level, it is easy to see that the feed and nutrition programs of manufacturers B and C were obviously better and very similar in terms of the production performance of the broilers in the biological trial, but were about 8% more expensive than feed A, which was poorer in terms of performance in the test. However, a complete picture of the tested feeds was obtained only when the success of the tested feeds in economic terms was analyzed, and the results of this analysis were very interesting when looking at different scenarios of fattening duration and market conditions.

In particular, the feed and standard nutrition program for broiler fattening of producer A, which served as the basis for feed comparison, has the best prices on the market, but also gives poorer production results of broilers in fattening in both fattening scenarios. The production performance as a result of feed A was proportionally poorer compared to the other two feeds almost to the same extent, as the price of the feed was lower (up to 8% lower production parameters with 8–9% cheaper food). However, if the economics of fattening are observed, it is recommended to use this food in six-week fattening, as it can be economically more profitable than feed B by 2–7%, depending on the purchase price of the broiler live weight, and compared to feed C can be equal to or up to 4% more profitable.

Regarding the individual mixtures (

Figure 1), the results showed that the broilers in the biological trial reacted best to the starter mixture of manufacturer B, as well as to the grower of manufacturer C, and when fed the finisher feeds, the chickens reacted very similarly to mixtures of all three manufacturers. In general, the feed and nutrition programs of producers B and C were very comparable both in price and in the results of the biological trial. However, even relatively small differences between feeds B and C in the individual production results of the fed broilers (1–3% by day 35 of fattening and up to 1% in six-week fattening) caused significant differences in the economic analysis. The results of the analysis indicated that in five-week fattening, it is most profitable to use feed from producer C, which was 2–5% more profitable than feed B and 2–4% more profitable than feed A.

It is also interesting to analyze the production indices (EPEF) and gross profits in the five-week and six-week fattening. It can be noticed that higher production indices were achieved in the five-week fattening compared to the six-week fattening, which may have been due to the increase in stocking density in the final week (from 33 kg/m2 to 40 kg/m2 at the end of the week) and the consequent deterioration of welfare conditions in the trial. It is also noticeable that the gross profit per fattened chicken in shorter and longer fattening (observed in absolute values) remained almost the same at the current purchase price of the broiler live weight, or by 10% lower price, but not if the purchase price of the broilers on the market increases.

4. Discussion

4.1. Chickens and Feed Quality

Biological testing of broiler production performance showed that both broiler hybrids have similar genetic potential and quality, but that market feed of the same quality class from different domestic producers can affect the expression of broiler potential.

The average body weight, daily gain, and FCR recorded during the 42-day fattening, as well as the EPEF did not differ (

p > 0.05) between the two tested broiler hybrids. However, the characterization of commercial feed for broilers before biological testing revealed differences in the chemical composition of some nutrients, which significantly affected the production performance in biological testing. Broilers fed a feed program of producer A achieved significantly lower starting and overall results compared to the feed of producers B and C. The test confirmed the claims of breeder companies that every additional gram gained by a seven-day-old chick in fattening can result in a 6–7 g weight gain on day 35 of fattening [

19,

20]. Broilers fed the starter of manufacturer B, which were the heaviest in the test on day 7, were 12 g heavier than the broilers fed mixtures of producer A, 92 g heavier on day 35 (7.7 g per measured gram more in a seven-day-old chicken compared to feed A), and 99 g heavier on day 42 of the fattening.

The starter of manufacturer B was a feed with less fat and fibers and also with slightly more protein and soluble sugars compared to the other starter feeds used. The nutritional strategy that feed for young chicks, who are limited in the digestibility of fat, proteins, and complex carbohydrates due to relatively immature digestive organs and enzyme systems [

21], should contain highly digestible ingredients and/or higher levels of nutrients [

22,

23,

24] is obviously effective but more expensive.

Particularly interesting were the results of the chickens fed the feed program of producer C, which, despite slightly poorer results with the starter feed compared to feed B (8 g heavier on day 7 compared to the broilers fed starter A), had the highest weight on days 35 and 42 in the trial, especially after consuming the grower (141 g heavier than the broilers fed grower A, or an additional 18 g per gram of body weight difference on day 7). These results clearly show that for the expression of the maximum genetic potential of modern broiler hybrids, each feeding and fattening period is equally valuable.

It should be noted that feed differences related to the chemical composition of some nutrients and the overall quality can be controlled, intentional, related to specific market strategies, and can experience the specifics of the production processes of a particular feed factory, but it can also be uncontrolled and unintentional due to failures in quality control or the formulation or production of mixtures [

25,

26,

27]. Additionally, the challenges for feed producers today and tomorrow, among other things, are the price and shortage of certain feed ingredients, as well as strict regulations regarding health and sustainability [

28,

29,

30]. Moreover, the last global Poultry Nutrition and Feed Survey [

14] showed that respondents (stakeholders) believe that climate change in the future will be responsible for reducing raw material availability, contributing to high commodity costs, and increasing mycotoxin contamination, and will make it difficult to maintain feed quality.

In any case, when it comes to closed recipes and the manufacturer’s internal know how and strategy used to deal with fluctuations in the price and quality of the ingredients on the market, only a biological trial can reliably show customers whether these variations in feed quality among producers mean better or worse nutrition for their birds.

4.2. Farm Economy and Feed Quality

On the market, we generally expect that feeds from different producers with the same quality have the same price or that a better feed has a higher price, but often we can find feeds with the same price and different quality or feeds that differ in price but not in quality. Results in this test show that the feed and nutrition programs of manufacturers B and C were obviously better and very similar in terms of the production performance of the broilers in the biological trial, but was about 8% more expensive than feed A. However, a complete picture of the tested feeds was obtained only when the farm economy was included in analysis, and the results were very interesting when looking at different production and market scenarios.

If the economics of fattening is observed, it is recommended to use feed A in six-week fattening, as it can be economically more profitable than feed B by 2–7%, depending on the purchase price of the broiler live weight, and compared to feed C, can be equal to or up to 4% more profitable. Additionally, even relatively small differences between feeds B and C in the individual production results of the fed broilers (1–3% by day 35 of fattening and up to 1% in six-week fattening) caused significant differences in economic analysis.

By combining all the results of the trials and analyses, feed C and shorter fattening can be chosen as the most profitable solution, for example, in the conditions of lower purchase prices of chickens and at the maximum occupancy of the facility. If the market under these conditions requires a higher weight of the chickens, the most optimal diet is feed A in fattening up to 42 days, or feed C with depopulation of the heaviest chickens from day 35. On the contrary, in the case of a rise in the purchase price of the fattened chickens, longer fattening with feeds A or C is preferable, and feed B is also acceptable.

Finally, it seems that this combination of comparative biological test and post-test feed characterization could serve as an example of how to develop a relatively simple and reliable tool to help local producers from one region or country choose the most cost-effective feeding and fattening strategies for his farm, especially in changing market conditions, as well as if there is no independent consultant on the local market (out of feed or hybrid producers), specialized broiler nutrition optimization services for a particular feed producer [

11,

31], and/or an integrator company using one of the specialized software packages for production optimization [

32] that is reliable enough, experienced enough, and even impartial enough to be an adequate replacement of the biological trial.