Risk Factor Assessment of the Smallholder Baby Vegetable Production in Eswatini

Abstract

:1. Introduction

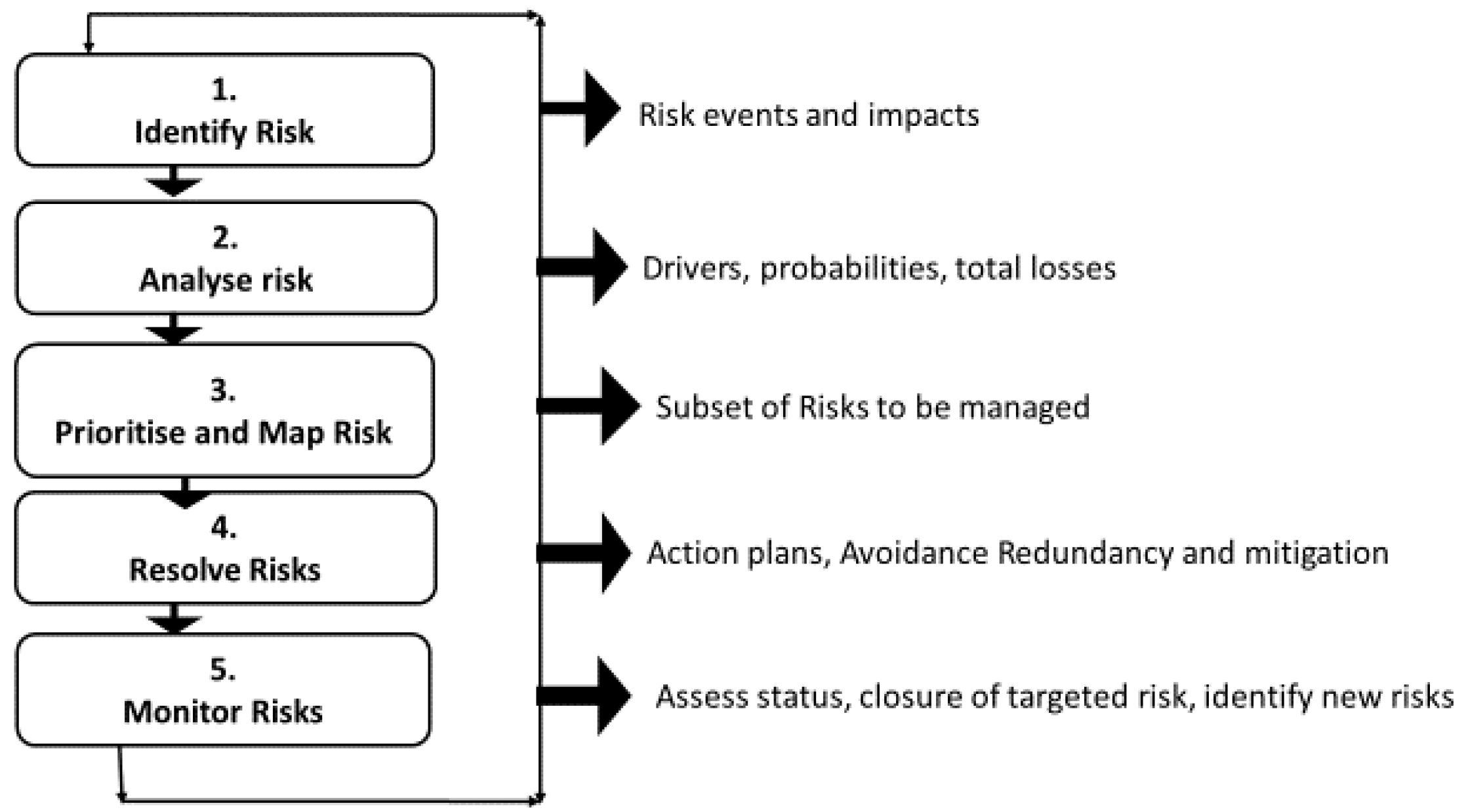

2. Materials and Methods

3. Results

3.1. Loading Risk Factors for Smallholder Irrigation Production

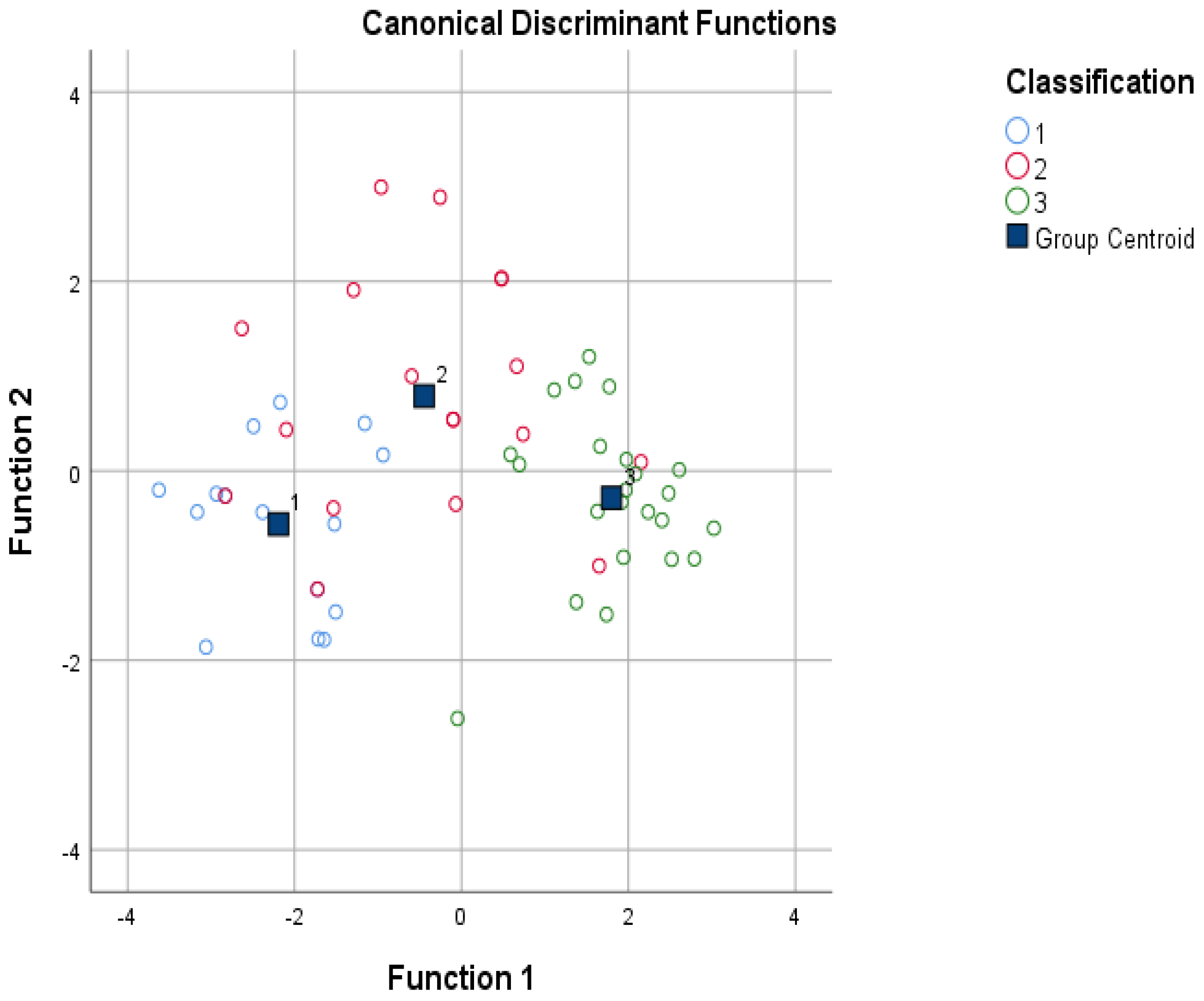

Group Classification Using Risk Experiences

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Orr, A.; Donovan, J.; Stoian, D. Smallholder value chains as complex adaptive systems: A conceptual framework. J. Agribus. Dev. Emerg. Econ. 2018, 8, 14–33. [Google Scholar] [CrossRef]

- Lindahl, F.W. Accounting standards and Olson’s theory of collective action. J. Account. Public Policy 1987, 6, 59–72. [Google Scholar] [CrossRef]

- Hardaker, J.B.; Huirne, R.B.M.; Anderson, J.R.; Lien, G. Coping with Risk in Agriculture, 2nd ed.; CABI Publishing: Wallingford, UK, 2004. [Google Scholar] [CrossRef]

- Byerlee, D.; Kyaw, D.; Thein, U.S.; Kham, L.S. Agribusiness Models for Inclusive Growth in Myanmar: Diagnosis and Ways Forward. MSU International Development Working Paper 133 No. 1096-2016-May. 2014, pp. 36–38. Available online: https://www.canr.msu.edu/resources/agribusiness-models-for-inclusive-growth-in-myanmar-diagnosis-and-ways-forward (accessed on 1 September 2021).

- Arumugam, N.; Mohamed, A.F.; Chiew, F.E.; Mohamed, Z. Determinants of fresh fruits and vegetables (FFV) farmers ‘participation in contract farming in peninsular malaysia. Int. J. Agric. Manag. Dev. 2011, 1, 65–71. [Google Scholar]

- Key, N.; Runsten, D. Contract farming, smallholders, and rural development in Latin America: The organisation of agro-processing firms and the scale of outgrower production. World Dev. 1999, 27, 381–401. [Google Scholar] [CrossRef]

- Arumugam, N.; Fatimah, M.; Chiew, E.E.F.; Zainalabidin, M. Supply chain analysis of fresh fruits and vegetables (FFV): Prospects of contract farming. Agric. Econ. 2010, 56, 435–442. [Google Scholar] [CrossRef] [Green Version]

- Maertens, M.; Swinnen, J. Agricultural Trade and Development: A Value Chain Perspective (No. ESRD-2015-04); WTO Staff Working Paper; World Trade Organization (WTO): Geneva, IL, USA, 2015. [Google Scholar] [CrossRef]

- Smith, D.; Newby, J.; Cramb, R. Developing Value-Chain Linkages to Improve Smallholder Cassava Production in Southeast Asia; The University of Queensland: Brisbane, Australia, 2018; pp. 1–9. [Google Scholar]

- Stepanuk, Z. Concept of Risk and Monitoring of Classification Significance of Risk. Caucasus 2017, 6, 26–29. [Google Scholar]

- Islam, D.I.; Rahman, A.; Sarker, N.I.; Sarker, S.R.; Jianchao, L. Factors Influencing Rice Farmers’ Risk Attitudes and Perceptions in Bangladesh amid Environmental and Climatic Issues. Pol. J. Environ. Stud. 2020, 30, 177–187. [Google Scholar] [CrossRef]

- Offord, D.R.; Kraemer, H.C. Risk factors and prevention. Evid.-Based Ment. Health 2000, 3, 70–71. [Google Scholar] [CrossRef] [Green Version]

- Behzadi, G.; O’Sullivan, M.J.; Olsen, T.L.; Zhang, A. Agribusiness supply chain risk management: A review of quantitative decision models. Omega 2018, 79, 21–42. [Google Scholar] [CrossRef]

- Ali, J.; Kapoor, S. Farmers’ perception on risks in fruits and vegetables production: An empirical study of Uttar Pradesh. Agric. Econ. Res. Rev. 2008, 21, 317–326. [Google Scholar]

- Tittonell, P.; Vanlauwe, B.; de Ridder, N.; Giller, K. Heterogeneity of crop productivity and resource use efficiency within smallholder Kenyan farms: Soil fertility gradients or management intensity gradients? Agric. Syst. 2007, 94, 376–390. [Google Scholar] [CrossRef]

- Poole, N.D.; Chitundu, M.; Msoni, R. Commercialisation: A meta-approach for agricultural development among smallholder farmers in Africa? Food Policy 2013, 41, 155–165. [Google Scholar] [CrossRef]

- Gollin, D.; Rogerson, R. Productivity, transport costs and subsistence agriculture. J. Dev. Econ. 2014, 107, 38–48. [Google Scholar] [CrossRef]

- Schoneveld, G.C.; van der Haar, S.; Ekowati, D.; Andrianto, A.; Komarudin, H.; Okarda, B.; Jelsma, I.; Pacheco, P. Certification, good agricultural practice and smallholder heterogeneity: Differentiated pathways for resolving compliance gaps in the Indonesian oil palm sector. Glob. Environ. Chang. 2019, 57, 101933. [Google Scholar] [CrossRef]

- Kan, M.; Shan, S.; Zhang, H.; Lao, S.; Chen, X. Multi-View Discriminant Analysis. IEEE Trans. Pattern Anal. Mach. Intell. 2016, 38, 188–194. [Google Scholar] [CrossRef]

- Ogbanje, C.E.; Chedibelu, S.; Nweze, N.J. Discriminant function analysis of factors affecting off-farm diversification among small-scale farmers in North Central Nigeria. J. Econ. Sustain. Dev. 2014, 5, 127–135. [Google Scholar]

- Lekshmi, P.S.; Chandrakandan, K.; Balasubramani, N. Discriminating Factors of High and Low Adopters of Shrimp Farmers in Nagapattinam of Tamil Nadu. Indian Res. J. Extn. Edu. 2013, 13, 120–125. [Google Scholar]

- Khemais, Z.; Nesrine, D.; Mohamed, M. Credit Scoring and Default Risk Prediction: A Comparative Study between Discriminant Analysis & Logistic Regression. Int. J. Econ. Financ. 2016, 8, 39. [Google Scholar] [CrossRef]

- Fakayode, S.; Rahji, M.; Adeniyi, S. Economic analysis of risks in fruit and vegetable farming in Osun state, Nigeria. Bangladesh J. Agric. Res. 2012, 37, 473–491. [Google Scholar] [CrossRef] [Green Version]

- Ariyo, O.S.; Arogundade, O.; Abdul-Rafiu, A.M. Discriminant and classification analysis of health status of bell pepper (Capsicum annuum). Res. J. Math. Stat. 2011, 3, 77–81. [Google Scholar]

- National Marketing Board (NAMBOARD). Annual Report 2019. Available online: https://www.namboard.co.sz/reports (accessed on 8 October 2021).

- Fisher, R.A. The use of multiple measurements in taxonomic problems. Ann. Eugen. 1936, 7, 179–188. [Google Scholar] [CrossRef]

- Ali, M.; Abedullah, D. Nutritional and economic benefits of enhanced vegetable production and consumption. J. Crop Prod. 2002, 6, 145–176. [Google Scholar] [CrossRef]

- Filina, L.; Filin, S. An analysis of influence of lack of the electricity supply to reefer containers serviced at sea ports on storing conditions of cargoes contained in them. Pol. Marit. Res. 2008, 15, 96–102. [Google Scholar] [CrossRef] [Green Version]

- Galawe, N.J. Endogenous and Exogenous Risk Factors in the Success of South African Small-Medium Enterprises. Ph.D. Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2017. [Google Scholar]

- Kusunose, Y.; Mason-Wardell, N.; Tembo, S. The Role of Liquidity in Preventing Dis-investment in Crop Inputs: Evidence from Zambia. J. Afr. Econ. 2020, 29, 375–396. [Google Scholar] [CrossRef]

- Kenea, T.; Umer, A.; Ambisa, Z. Constraints of agricultural input supply and its impact on small scale farming: The case of Ambo District, West Shewa, Ethiopia. Int. J. Agric. Econ. 2019, 4, 80–86. [Google Scholar] [CrossRef]

- Mdemu, M.V.; Mziray, N.; Bjornlund, H.; Kashaigili, J.J. Barriers to and opportunities for improving productivity and profitability of the Kiwere and Magozi irrigation schemes in Tanzania. Int. J. Water Resour. Dev. 2017, 33, 725–739. [Google Scholar] [CrossRef] [Green Version]

- Moyo, M.; Van Rooyen, A.; Chivenge, P.; Bjornlund, H. Irrigation development in Zimbabwe: Understanding productivity barriers and opportunities at Mkoba and Silalatshani irrigation schemes. Int. J. Water Resour. Dev. 2017, 33, 740–754. [Google Scholar] [CrossRef] [Green Version]

- Elik, A.; Yanik, D.K.; Istanbullu, Y.; Guzelsoy, N.A.; Yavuz, A.; Gogus, F. Strategies to Reduce Post-Harvest Losses for Fruits and Vegetables. Int. J. Sci. Technol. Res. 2019, 5, 29–39. [Google Scholar] [CrossRef]

- Nagaraj, N.; Chandrakanth, M.G.; Chengappa, P.G.; Roopa, H.S.; Chandakavate, P.M. Contract farming and its implications for input-supply, linkages between markets and farmers in Karnataka. Agric. Econ. Res. Rev. 2008, 21, 307–316. [Google Scholar]

- Harris, S.R. Production is Only Half the Battle; Training Manual; Food and Agriculture Organization of United Nations: Bridgetown, Barbados, 1988; pp. 1–156. [Google Scholar]

- de Oliveira, L.G.; Batalha, M.O. Conditioning factors to market fruits and vegetables from family farms to supermarket supply chains. Ciência Rural 2021, 51, 1–8. [Google Scholar] [CrossRef]

- Tray, B.; Garnevska, E.; Shadbolt, N. Linking smallholder producers to high-value markets through vegetable producer cooperatives in Cambodia. Int. Food Agribus. Manag. Rev. 2021, 24, 905–920. [Google Scholar] [CrossRef]

- Dlamini-Mazibuko, B.P.; Ferrer, S.; Ortmann, G. Factors affecting the choice of marketing outlet selection strategies by smallholder farmers in Swaziland. Afr. J. Sci. Technol. Innov. Dev. 2019, 11, 569–577. [Google Scholar] [CrossRef]

- Reardon, T.; Barrett, C.; Berdegué, J.A.; Swinnen, J. Agrifood Industry Transformation and Small Farmers in Developing Countries. World Dev. 2009, 37, 1717–1727. [Google Scholar] [CrossRef]

- Wang, H.; Dong, X.; Rozelle, S.; Huang, J.; Reardon, T. Producing and Procuring Horticultural Crops with Chinese Characteristics: The Case of Northern China. World Dev. 2009, 37, 1791–1801. [Google Scholar] [CrossRef]

- Hu, D.; Reardon, T.; Rozelle, S.; Timmer, P.; Wang, H. The Emergence of Supermarkets with Chinese Characteristics: Challenges and Opportunities for China’s Agricultural Development. Dev. Policy Rev. 2004, 22, 557–586. [Google Scholar] [CrossRef]

- Stringer, R.; Sang, N.; Croppenstedt, A. Producers, Processors, and Procurement Decisions: The Case of Vegetable Supply Chains in China. World Dev. 2009, 37, 1773–1780. [Google Scholar] [CrossRef]

- Reddy, G.P.; Murthy, M.R.K.; Meena, P.C. Value chains and retailing of fresh vegetables and fruits, Andhra Pradesh. Agric. Econ. Res. Rev. 2010, 23, 455–460. [Google Scholar]

- Ahmad, B.; Hassan, S.; Bakhsh, K. Factors affecting yield and profitability of carrot in two districts of Punjab. Int. J. Agric. Biol. 2005, 7, 794–798. [Google Scholar]

- Alamerie, K.; Ketema, M.; Gelaw, F. Risks in vegetables production from the perspective of smallholder farmers: The case of Kombolcha Woreda, Oromia region, Ethiopia. Agric. For. Fish. 2014, 3, 1–5. [Google Scholar] [CrossRef]

- Gurses, A.P.; Dietz, A.S.; Nowakowski, E.; Andonian, J.; Schiffhauer, M.; Billman, C.; Abashian, A.M.; Trexler, P.; Osei, P.; Benishek, L.E.; et al. Human factors–based risk analysis to improve the safety of doffing enhanced personal protective equipment. Infect. Control Hosp. Epidemiol. 2019, 40, 178–186. [Google Scholar] [CrossRef]

| Risk Variable | Clustered Production (n = 15) | Semi-Dependent Production (n = 19) | Independent Scheme (n = 23) | Group Total (n = 57) | ||||

|---|---|---|---|---|---|---|---|---|

| Mean Rank | Std. Dev | Mean Rank | Std. Dev | Mean Rank | Std. Dev | Mean Rank | Std. Dev | |

| Market Risks | ||||||||

| Product Payments | 1.67 | 1.234 | 3.74 | 1.727 | 4.78 | 0.850 | 3.61 | 1.790 |

| High Input Price | 2.40 | 1.056 | 3.63 | 1.257 | 3.87 | 1.546 | 3.40 | 1.450 |

| Produce Collection Failure | 4.20 | 0.862 | 3.11 | 1.595 | 2.96 | 1.551 | 3.33 | 1.492 |

| Fluctuating Product Prices | 3.47 | 1.407 | 3.58 | 0.902 | 2.65 | 1.369 | 3.18 | 1.297 |

| Drop In Produce Price | 3.80 | 1.014 | 3.26 | 1.195 | 1.35 | 0.714 | 2.63 | 1.447 |

| Wage Rate Changes | 3.27 | 1.280 | 2.74 | 0.933 | 2.26 | 1.389 | 2.68 | 1.270 |

| Product Demand | 3.87 | 1.302 | 2.37 | 1.422 | 1.48 | 1.123 | 2.40 | 1.580 |

| Production Risks | ||||||||

| Yield Changes | 2.60 | 1.242 | 3.79 | 0.976 | 3.96 | 1.296 | 3.54 | 1.297 |

| Labour Availability | 4.13 | 0.915 | 3.11 | 1.524 | 1.87 | 1.325 | 2.88 | 1.582 |

| Pest and Diseases | 2.33 | 0.900 | 2.89 | 1.329 | 2.13 | 1.517 | 2.44 | 1.337 |

| Risk Variable | Wilks’ Lambda | F | Sig. |

|---|---|---|---|

| Market Risks | |||

| Fluctuating Product Prices | 0.887 | 3.445 | 0.039 * |

| Produce Collection Failure | 0.876 | 3.839 | 0.028 * |

| High Input Price | 0.821 | 5.893 | 0.005 * |

| Product Demand | 0.629 | 15.920 | 0.000 * |

| Product Payments | 0.507 | 26.302 | 0.000 * |

| Drop In Produce Price | 0.437 | 34.716 | 0.000 * |

| Production Risks | |||

| Yield Changes | 0.804 | 6.571 | 0.003 * |

| Labour Availability | 0.657 | 14.069 | 0.000 * |

| Variables | Structural Matrix | Coefficients | ||

|---|---|---|---|---|

| Function 1 | Function 2 | Function 1 | Function 2 | |

| Market Risk | ||||

| Fluctuating Produce Price (FPD) | −0.661 * | 0.447 | −0.833 | 0.720 |

| Product Payments (PP) | 0.571 * | 0.443 | 0.672 | 0.342 |

| Product Demand (PD) | −0.449 * | −0.289 | 0.002 | −0.609 |

| Wage Rate (WR) | −0.202 * | −0.060 | −0.340 | −0.313 |

| Input Price Prices (IPP) | 0.250 | 0.358 * | −0.023 | −0.114 |

| Product Collection Failure (PCF) | −0.197 | −0.315 * | 0.146 | −0.328 |

| Product Price (Py) | −0.185 | 0.306 * | 0.270 | 0.295 |

| Production Risks | ||||

| Labour Availability (LA) | −0.433 * | −0.024 | 0.059 | 0.097 |

| Yield Changes (YC) | 0.259 | 0.409 * | 0.342 | 0.106 |

| Pest and Diseases (PDs) | −0.066 | 0.401 * | −0.280 | 0.343 |

| Parameter | Results |

|---|---|

| Box’s M | 259.2 |

| F approx. (p-value) | 1.686 (0.000) *** |

| Eigenvalue | 2.839 |

| % of variation | 89.1 |

| Canonical correlation | 0.855 |

| Wilks’ Lambda | 0.2 (0.000) *** |

| Chi-squared, p-value | 80.40 (0.000) *** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dlamini, D.D.; Zuwarimwe, J.; Francis, J.; Mchau, G.R.A. Risk Factor Assessment of the Smallholder Baby Vegetable Production in Eswatini. Agriculture 2022, 12, 643. https://doi.org/10.3390/agriculture12050643

Dlamini DD, Zuwarimwe J, Francis J, Mchau GRA. Risk Factor Assessment of the Smallholder Baby Vegetable Production in Eswatini. Agriculture. 2022; 12(5):643. https://doi.org/10.3390/agriculture12050643

Chicago/Turabian StyleDlamini, Daisy Delsile, Jethro Zuwarimwe, Joseph Francis, and Godwin R. A. Mchau. 2022. "Risk Factor Assessment of the Smallholder Baby Vegetable Production in Eswatini" Agriculture 12, no. 5: 643. https://doi.org/10.3390/agriculture12050643

APA StyleDlamini, D. D., Zuwarimwe, J., Francis, J., & Mchau, G. R. A. (2022). Risk Factor Assessment of the Smallholder Baby Vegetable Production in Eswatini. Agriculture, 12(5), 643. https://doi.org/10.3390/agriculture12050643