Environmental Impact Analysis of Natural Cork Stopper Manufacturing

Abstract

:1. Introduction

1.1. Cork and Wine

1.2. Research Context

- Co-Products:

- ○

- Thin cork planks (used to manufacture multi-piece corks).

- ○

- Thin cork planks (used to manufacture agglomerated corks).

- By-Products:

- ○

- Granules (used to manufacture agglomerated corks).

- ○

- Waste from bark and stoppers (used as biomass).

- ○

- Sawdust (used to produce colmated corks).

2. Materials and Methods

2.1. Goals and Scope

2.2. Functional Unit

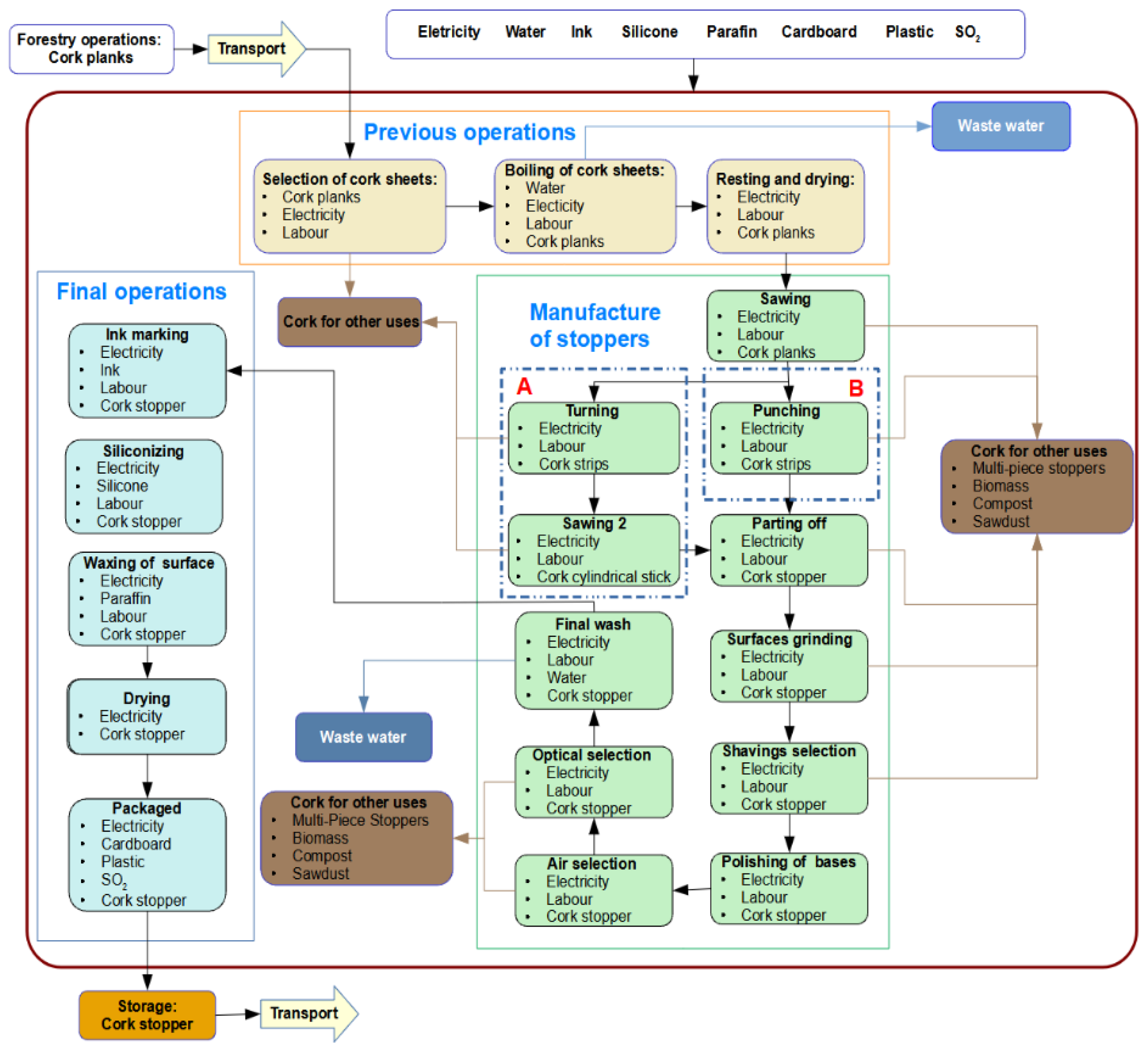

2.3. System Boundaries

- Electricity.

- Water.

- Auxiliary materials (ink, silicone, … plastic, SO2).

- Cork planks at the factory gate.

- Cork stoppers packaged.

- Treated wastewater.

- By-product 1, by-product 2, and co-product 1.

2.4. Technical Specifications

- Lot characteristics: medium load platform (365 kg).

- Number of lots studied: 10 per manufacturing technique and stopper size.

- Cork density: 166.07 kg/m3.

- Cork stopper volume: 1.99051 × 10−5 m3 (for 24 × 44 mm) and 2.33609 × 10−5 m3 (for 26 × 44 mm).

- A functional unit comprises approximately 300 units of 24 × 44 mm stoppers and 260 units of 26 × 44 mm stoppers.

2.5. Inventory

- Cork, raw {RoW}| cork forestry | Cut-off, U.

- Tap water {RER}| market group for | Cut-off, U.

- Electricity, medium voltage {ES}| market for | Cut-off, U.

- Printing ink, offset, without solvent, in 47.5% solution state {GLO}|market for | Cut-off, U.

- Silicone product {GLO}| market for | Cut-off, U.

- Paraffin {GLO}| market for | Cut-off, U.

- Carton board box production, with offset printing {GLO}| market for |Cut-off, S.

- Packaging film, low density polyethylene {GLO}| market for | Cut-off, U.

- Sulfur dioxide, at plant/RER.

2.5.1. Phase 1: Preparing Raw Cork Planks

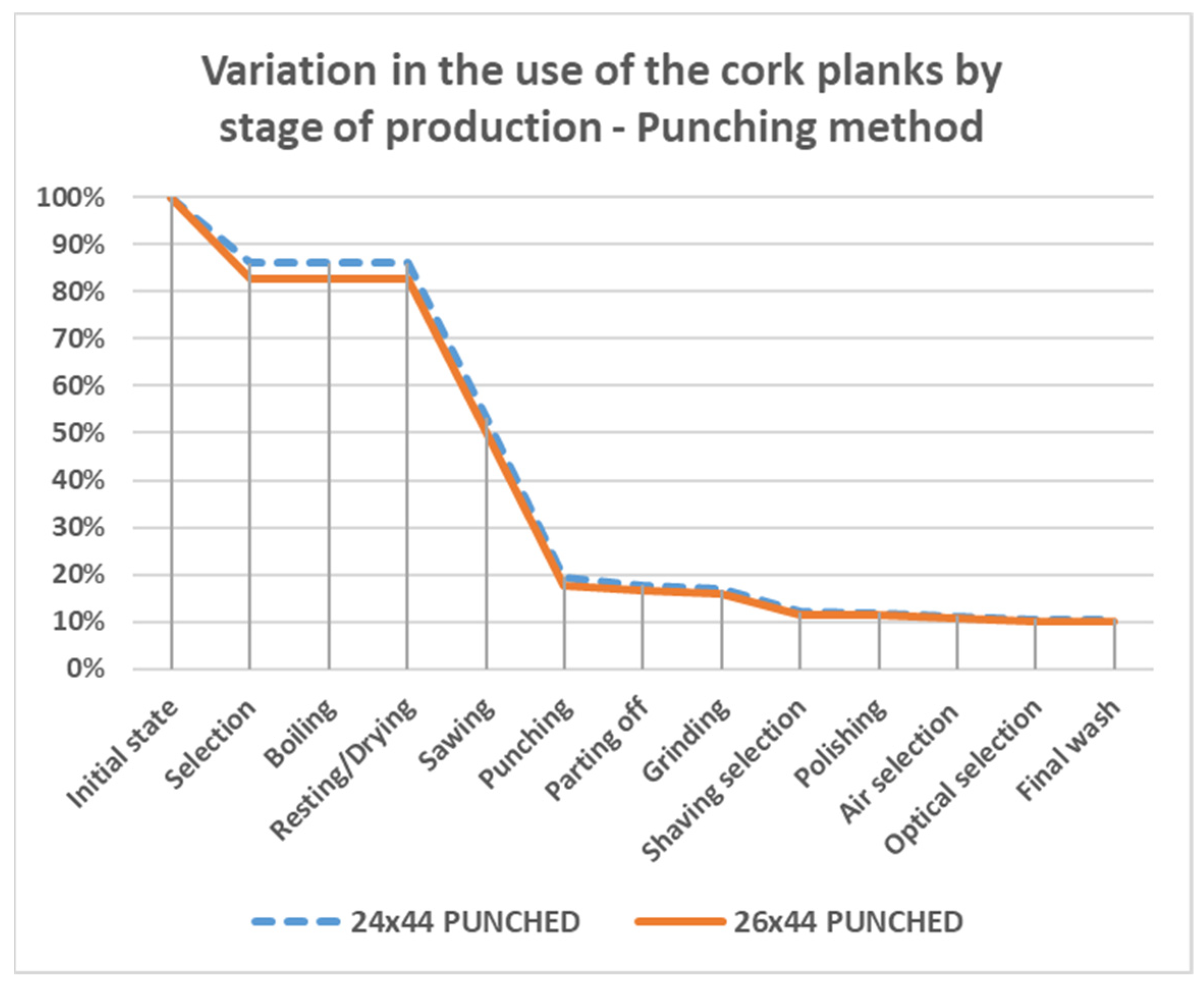

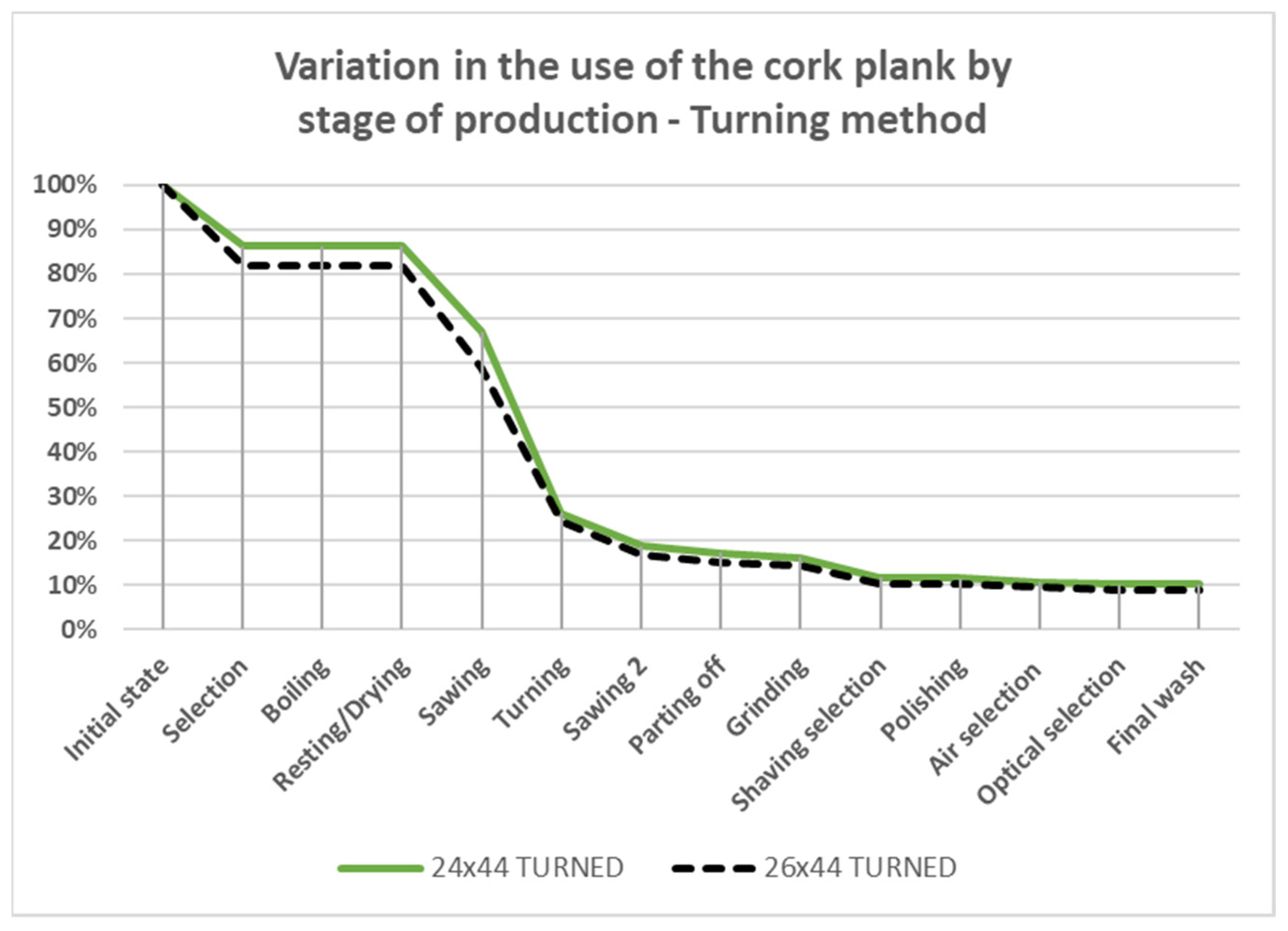

2.5.2. Phase 2: Manufacturing

2.5.3. Phase 3: Final Operations

3. Results

3.1. Environmental Impact of Raw Material Utilization, Products, By-Products, and Co-Products

3.2. Environmental Impact

3.2.1. Analysis of Global Environmental Impact

3.2.2. Environmental Impact Analysis by Phases

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dehane, B. Caracterización del crecimiento y de la calidad de corcho de los alcornocales del Noroeste de Argelia (región de Orán). Rev. Ecosistemas 2019, 28, 97–105. [Google Scholar]

- MAPA. Annual Statistics of Other Forest Uses—Estadística Anual de Otros Aprovechamientos Forestales; Ministry of Agriculture, Fisheries and Food—Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2017. [Google Scholar]

- Pereira, H. Cork: Biology, Production and Uses, 1st ed.; Elsevier Science: Berlin, Germany, 2007. [Google Scholar]

- Silva, A.; Lambri, M.; De Faveri, M. Evaluation of the performances of synthetic and cork stoppers up to 24 months post-bottling. Eur. Food Res. Technol. 2003, 216, 529–534. [Google Scholar] [CrossRef]

- Chatonnet, P.; Labadie, D.; Boutou, S. Study of chloroanisoles assay and tca assay validation in wine and cork stoppers soaked in dilute alcohol solution using SIDA-HSSPME-GC-MS/EI-SIM. OENO One 2005, 39, 137–147. [Google Scholar] [CrossRef]

- Brajkovich, M.; Tibbits, N.; Peron, G.; Lund, C.M.; Dykes, S.I.; Kilmartin, P.A.; Nicolau, L. Effect of screwcap and cork closures on SO2 levels and aromas in a Sauvignon blanc wine. J. Agric. Food Chem. 2005, 53, 10006–10011. [Google Scholar] [CrossRef]

- Conde, E.; Cadahía, E.; García-Vallejo, M.C.; Fernández de Simón, B.; González Adrados, J.R. Low molecular weight polyphenols in cork of Quercus suber. J. Agric. Food Chem. 1997, 45, 2695–2700. [Google Scholar] [CrossRef]

- Mazzoleni, V.; Caldentey, P.; Silva, A. Phenolic compounds in cork used for production of wine stoppers as affected by storage and boiling of cork slabs. Am. J. Enol. Vitic. 1998, 49, 6–10. [Google Scholar]

- Garza, J.A.V.; Caballero, H.S. El corcho, un material irremplazable. In Investigación y Ciencia; Universidad Autónoma de Aguascalientes: Aguascalientes, Mexico, 2003; pp. 48–51. [Google Scholar]

- Liu, D.; Xing, R.R.; Li, Z.; Yang, D.M.; Pan, Q.H. Evolution of volatile compounds, aroma attributes, and sensory perception in bottle-aged red wines and their correlation. Eur. Food Res. Technol. 2016, 242, 1937–1948. [Google Scholar] [CrossRef]

- Reynolds, D.; Rahman, I.; Bernard, S.; Holbrook, A. What effect does wine bottle closure type have on perceptions of wine attributes? Int. J. Hosp. Manag. 2018, 75, 171–178. [Google Scholar] [CrossRef]

- Benito Lázaro, D. Revisión y Desarrollo de Modelos de Clasificación del Corcho en Plancha. 2014. Available online: https://oa.upm.es/30795/1/PFC_DAVID_BENITO_LAZARO_1.pdf (accessed on 2 February 2018).

- Sánchez-González, M.; Pérez-Terrazas, D. Assessing the percentage of cork that a stopper should have from a mechanical perspective. Food Packag. Shelf Life 2018, 18, 212–220. [Google Scholar] [CrossRef]

- Sánchez-González, M.; Pérez-Terrazas, D. Dataset of mechanical properties from different types of wine stopper: Micro-agglomerated, natural cork and synthetic. Data Brief 2018, 21, 2103–2109. [Google Scholar] [CrossRef] [PubMed]

- Rives, J.; Fernandez-Rodriguez, I.; Rieradevall, J.; Gabarrell, X. Environmental analysis of raw cork extraction in cork oak forests in southern Europe (Catalonia—Spain). J. Environ. Manag. 2012, 110, 236–245. [Google Scholar] [CrossRef] [PubMed]

- Rives, J.; Fernandez-Rodriguez, I.; Rieradevall, J.; Gabarrell, X. Integrated environmental analysis of the main cork products in southern Europe (Catalonia—Spain). J. Clean. Prod. 2013, 51, 289–298. [Google Scholar] [CrossRef]

- Rives, J.; Fernandez-Rodriguez, I.; Gabarrell, X.; Rieradevall, J. Environmental analysis of cork granulate production in Catalonia—Northern Spain. Resour. Conserv. Recycl. 2012, 58, 132–142. [Google Scholar] [CrossRef]

- Demertzi, M.; Silva, R.P.; Neto, B.; Dias, A.C.; Arroja, L. Cork stoppers supply chain: Potential scenarios for environmental impact reduction. J. Clean. Prod. 2016, 112, 1985–1994. [Google Scholar] [CrossRef]

- Ardente, F.; Cellura, M. Economic allocation in life cycle assessment: The state of the art and discussion of examples. J. Ind. Ecol. 2012, 16, 387–398. [Google Scholar] [CrossRef]

- Ayer, N.W.; Tyedmers, P.H.; Pelletier, N.L.; Sonesson, U.; Scholz, A. Co-product allocation in life cycle assessments of seafood production systems: Review of problems and strategies. Int. J. Life Cycle Assess. 2007, 12, 480. [Google Scholar] [CrossRef]

- Lauri, L.; Roope, H.; Atsushi, T.; Tuovi, V.; Olli, D. Environmental product declaration of timber products: The impact of allocation method to the impact categories. J. Clean. Prod. 2020, 256, 120386. [Google Scholar] [CrossRef]

- Thomassen, M.A.; de Boer, I.J.M. Evaluation of indicators to assess the environmental impact of dairy production systems. Agric. Ecosyst. Environ. 2005, 111, 185–199. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G. Economic allocation: Examples and derived decision tree. Int. J. Life Cycle Assess. 2004, 9, 23. [Google Scholar] [CrossRef] [Green Version]

- Rives, J.; Fernandez-Rodriguez, I.; Rieradevall, J.; Gabarrell, X. Environmental analysis of the production of natural cork stoppers in southern Europe (Catalonia–Spain). J. Clean. Prod. 2011, 19, 259–271. [Google Scholar] [CrossRef]

- PwC/Ecobilan. Evaluation of the Environmental Impacts of Cork Stoppers versus Aluminum and Plastic Closures: Analysis of the Life Cycle of Cork, Aluminium and Plastic Wine Closures, Report Prepared for Corticeira Amorim, SGPS, SA by PricewaterhouseCoopers/ECOBILAN. October 2008. Available online: https://documents.pub/document/amorim-lca-final-report.html?page=1 (accessed on 1 January 2022).

| Inventory | Punching 24 × 44 mm | Turning 24 × 44 mm | Punching 26 × 44 mm | Turning 26 × 44 mm | |

|---|---|---|---|---|---|

| Item | Unit | ||||

| Phase 1 | |||||

| Cork planks | kg | 9.552 | 9.905 | 9.871 | 11.152 |

| Electricity | kWh | 0.079 | 0.080 | 0.081 | 0.092 |

| Water | L | 19.497 | 20.217 | 20.148 | 22.763 |

| Phase 2 | |||||

| Electricity | kWh | 0.624 | 0.412 | 0.515 | 0.333 |

| Water | L | 0.003 | 0.003 | 0.002 | 0.002 |

| Phase 3 | |||||

| Electricity | kWh | 0.055 | 0.054 | 0.044 | 0.043 |

| Ink | g | 0.190 | 0.190 | 0.190 | 0.190 |

| Silicon | g | 1.210 | 1.210 | 1.030 | 1.030 |

| Paraffin | g | 6.050 | 6.050 | 5.160 | 5.160 |

| Cardboard | g | 34.200 | 34.200 | 34.200 | 34.200 |

| Plastic | g | 4.300 | 4.300 | 4.300 | 4.300 |

| SO2 | g | 0.860 | 0.860 | 0.860 | 0.860 |

| Cork Stopper Size/Production Method/Usage | ||||

|---|---|---|---|---|

| Item | 24 × 44 mm Punching | 26 × 44 mm Punching | 24 × 44 mm Turning | 26 × 44 mm Turning |

| Cork stoppers | 10.47% ± 0.93% | 10.10% ± 0.91% | 10.13% ± 0.91% | 8.97% ± 0.82% |

| Materials for Co-Products and by-Products | ||||

| Thin plank | 6.16% ± 0.58% | 7.41% ± 0.69% | 6.05% ± 0.57% | 7.12% ± 0.66% |

| Granules | 72.75% ± 1.98% | 72.65% ± 1.99% | 72.57% ± 1.99% | 73.22% ± 1.96% |

| Biomass | 6.64% ± 0.62% | 6.50% ± 0.61% | 6.91% ± 0.64% | 6.77% ± 0.63% |

| Sawdust | 3.98% ± 0.38% | 3.35% ± 0.32% | 4.34% ± 0.43% | 3.93% ± 0.38% |

| Cork Stopper Size/€ per kg | ||

|---|---|---|

| Item | 24 × 44 mm | 26 × 44 mm |

| Cork stoppers | 53.80 | 64.70 |

| Co-products and by-products/€ per kg | ||

| Thin plank | 2.05 | |

| Granules | 1.45 | |

| Biomass | 0.06 | |

| Sawdust | 0.27 | |

| Item | 24 × 44 mm Punching | 26 × 44 mm Punching | 24 × 44 mm Turning | 26 × 44 mm Turning |

|---|---|---|---|---|

| Cork stoppers | 82.49% | 84.29% | 82.05% | 82.60% |

| Co-products and by-products | ||||

| Thin plank | 1.85% | 1.96% | 1.87% | 2.06% |

| Granules | 15.45% | 13.59% | 15.84% | 15.11% |

| Biomass | 0.06% | 0.05% | 0.06% | 0.06% |

| Sawdust | 0.16% | 0.12% | 0.18% | 0.15% |

| 24 × 44 mm | 26 × 44 mm | |||

|---|---|---|---|---|

| Punching | Turning | Punching | Turning | |

| Cork stop × 10 rs | 1.36 × 100 | 1.43 × 100 | 1.38 × 100 | 1.49 × 100 |

| Co-products and by-products | ||||

| Thin plank | 3.05 × 10−2 | 3.25 × 10−2 | 3.16 × 10−2 | 3.72 × 10−2 |

| Granul × 10 s | 2.54 × 10−1 | 2.76 × 10−1 | 2.19 × 10−1 | 2.73 × 10−1 |

| Biomass | 9.88 × 10−4 | 1.04 × 10−3 | 8.05 × 10−4 | 1.08 × 10−3 |

| Sawdust | 2.63 × 10−3 | 3.13 × 10−3 | 1.93 × 10−3 | 2.71 × 10−3 |

| Punching | Turning | ||||

|---|---|---|---|---|---|

| Operation | Size: 24 × 44 mm | Size: 26 × 44 mm | Operation | Size: 24 × 44 mm | Size: 26 × 44 mm |

| Phase 1: Initial Operations | |||||

| Selection | 1.19 × 10−1 | 1.26 × 10−1 | Selection | 1.22 × 10−1 | 1.39 × 10−1 |

| Boiling | 9.16 × 10−1 | 9.36 × 10−1 | Boiling | 9.44 × 10−1 | 1.02 × 100 |

| Resting/Drying | 1.16 × 10−1 | 1.23 × 10−1 | Resting/Drying | 1.19 × 10−1 | 1.36 × 10−1 |

| Phase 2: Manufacturing | |||||

| Cutting | 1.13 × 10−2 | 1.38 × 10−2 | Cutting 1 | 1.19 × 10−2 | 1.38 × 10−2 |

| Punching | 1.49 × 10−2 | 1.84 × 10−2 | Turning | 2.02 × 10−2 | 2.59 × 10−2 |

| Cutting 2 | 2.34 × 10−2 | 2.91 × 10−2 | |||

| Parting off | 3.48 × 10−3 | 4.64 × 10−3 | Parting off | 3.51 × 10−3 | 4.45 × 10−3 |

| Grinding | 2.31 × 10−2 | 2.88 × 10−2 | Grinding | 2.24 × 10−2 | 2.77 × 10−2 |

| Shaving | 3.24 × 10−3 | 4.11 × 10−3 | Shavings selection | 3.09 × 10−3 | 3.94 × 10−3 |

| Polishing | 3.61 × 10−3 | 4.54 × 10−3 | Polishing | 3.42 × 10−3 | 4.35 × 10−3 |

| Optical selection | 2.22 × 10−3 | 2.84 × 10−3 | Optical selection | 2.09 × 10−3 | 2.71 × 10−3 |

| Visual selection | 1.98 × 10−3 | 2.52 × 10−3 | Visual selection | 1.85 × 10−3 | 2.41 × 10−3 |

| Final wash | 8.59 × 10−2 | 9.87 × 10−2 | Final wash | 8.40 × 10−2 | 9.82 × 10−2 |

| Phase 3: Final Operations | |||||

| Ink printing | 2.85 × 10−3 | 3.24 × 10−3 | Ink printing | 2.53 × 10−3 | 3.14 × 10−3 |

| Siliconizing | 5.78 × 10−3 | 6.80 × 10−3 | Siliconizing | 5.55 × 10−3 | 6.66 × 10−3 |

| Waxing | 8.50 × 10−3 | 1.01 × 10−2 | Waxing | 8.20 × 10−3 | 9.88 × 10−3 |

| Drying | 1.22 × 10−3 | 1.47 × 10−3 | Drying | 1.15 × 10−3 | 1.42 × 10−3 |

| Packaging | 1.91 × 10−3 | 2.30 × 10−3 | Packaging | 1.80 × 10−3 | 2.21 × 10−3 |

| Construction and Demolition of Building Infrastructures and Machinery Manufacturing and Maintenance | |||||

| 1.51 × 10−2 | 1.54 × 10−2 | 1.50 × 10−2 | 1.51 × 10−2 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flor-Montalvo, F.J.; Martínez-Cámara, E.; García-Alcaraz, J.L.; Jiménez-Macías, E.; Latorre-Biel, J.-I.; Blanco-Fernández, J. Environmental Impact Analysis of Natural Cork Stopper Manufacturing. Agriculture 2022, 12, 636. https://doi.org/10.3390/agriculture12050636

Flor-Montalvo FJ, Martínez-Cámara E, García-Alcaraz JL, Jiménez-Macías E, Latorre-Biel J-I, Blanco-Fernández J. Environmental Impact Analysis of Natural Cork Stopper Manufacturing. Agriculture. 2022; 12(5):636. https://doi.org/10.3390/agriculture12050636

Chicago/Turabian StyleFlor-Montalvo, Francisco Javier, Eduardo Martínez-Cámara, Jorge Luis García-Alcaraz, Emilio Jiménez-Macías, Juan-Ignacio Latorre-Biel, and Julio Blanco-Fernández. 2022. "Environmental Impact Analysis of Natural Cork Stopper Manufacturing" Agriculture 12, no. 5: 636. https://doi.org/10.3390/agriculture12050636

APA StyleFlor-Montalvo, F. J., Martínez-Cámara, E., García-Alcaraz, J. L., Jiménez-Macías, E., Latorre-Biel, J.-I., & Blanco-Fernández, J. (2022). Environmental Impact Analysis of Natural Cork Stopper Manufacturing. Agriculture, 12(5), 636. https://doi.org/10.3390/agriculture12050636