Design and Experiment of an Integrated Automatic Transplanting Mechanism for Picking and Planting Pepper Hole Tray Seedlings

Abstract

:1. Introduction

2. Materials and Methods

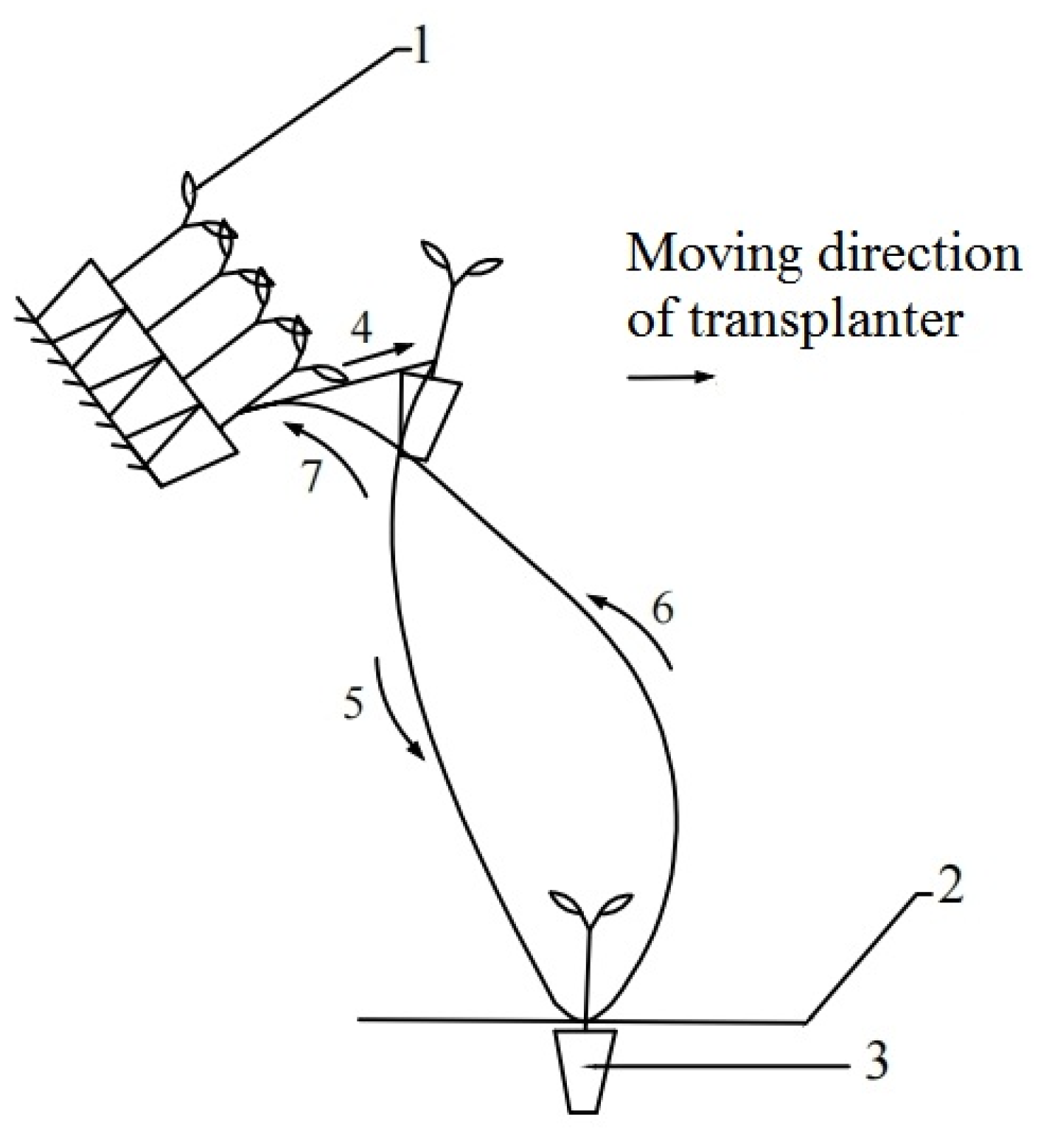

2.1. Backward Transplanting Movement Trajectory Planning

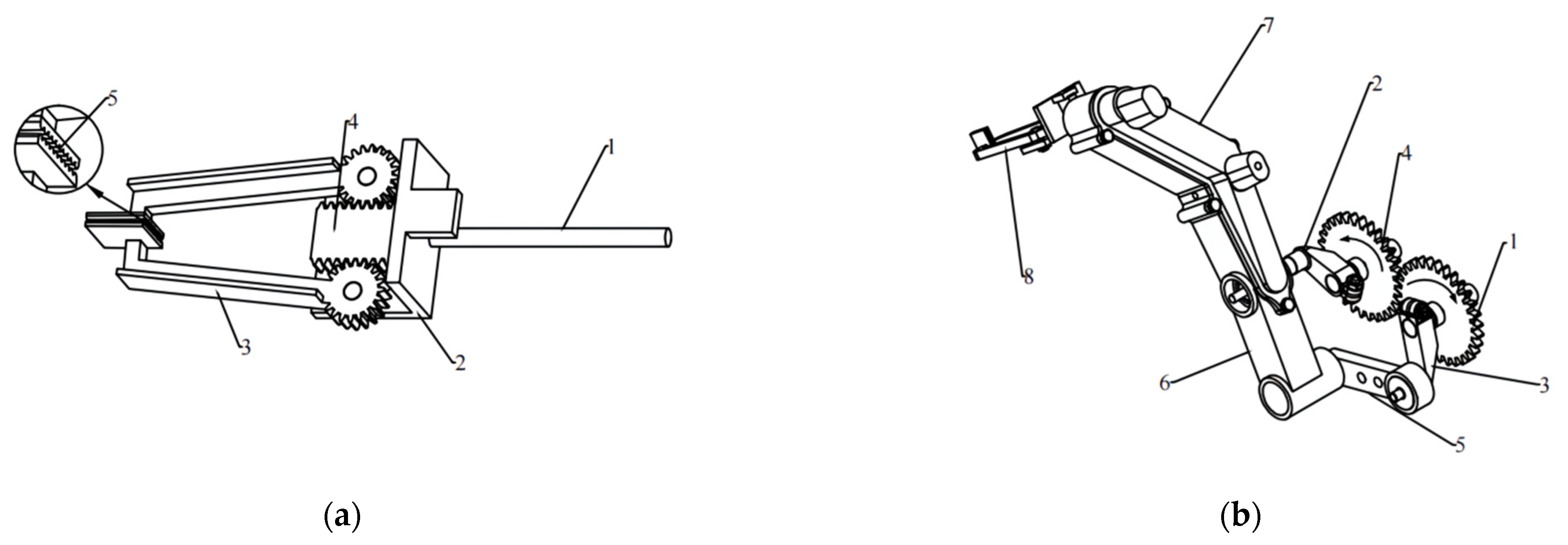

2.2. Working Principle and Mechanical Design

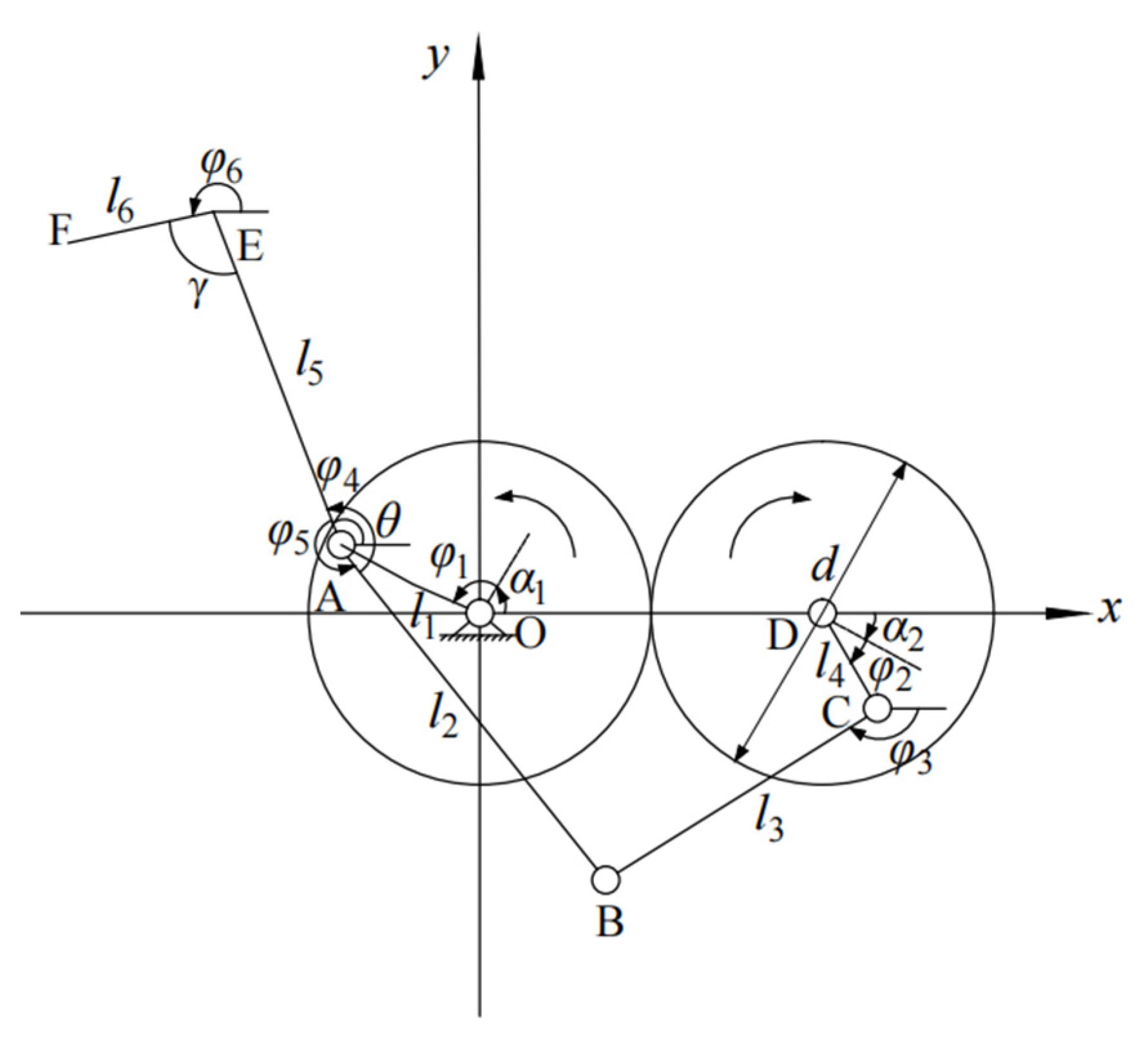

2.3. Kinematic Equation of the Integrated Automatic Transplanting Mechanism

2.4. Motion Trajectory Optimization Objective

2.5. High-Speed Photography Test Method

3. Results

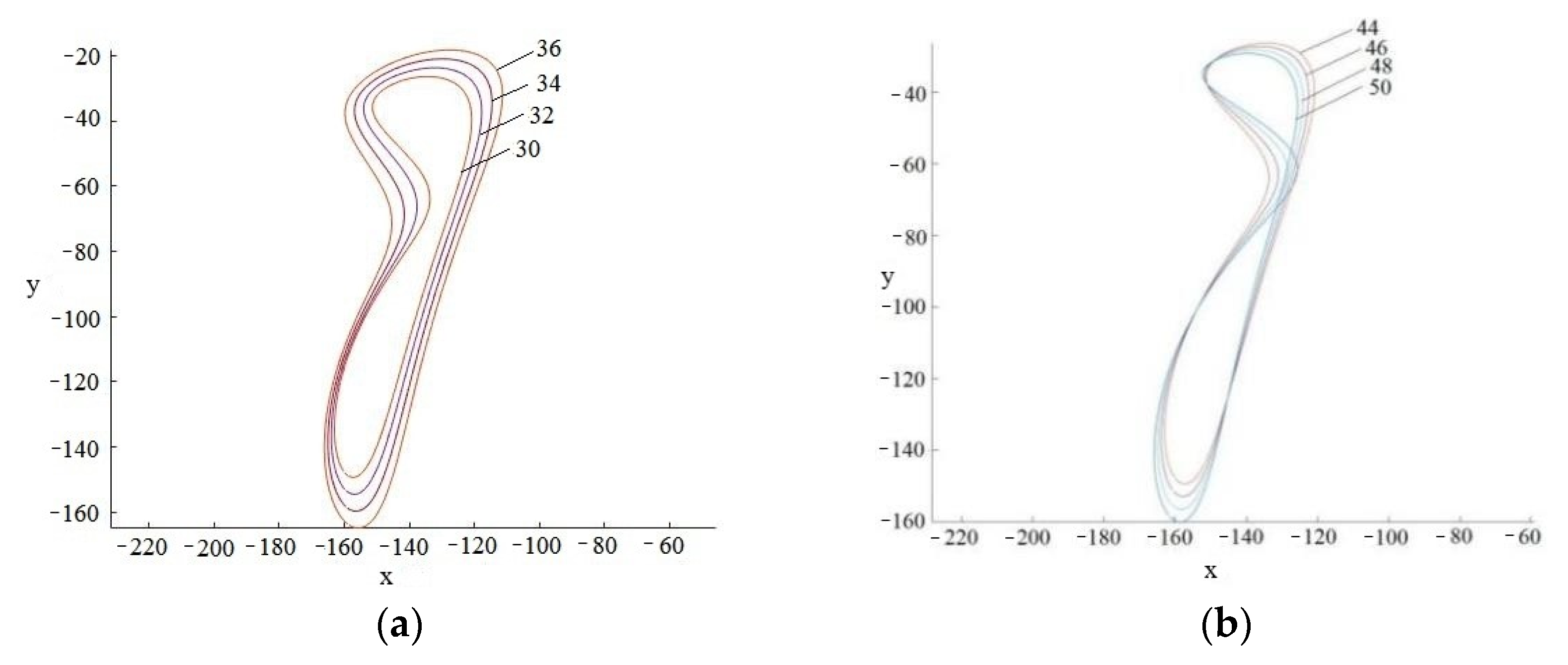

3.1. Effect of Parameter Changes on the Seedling Trajectory

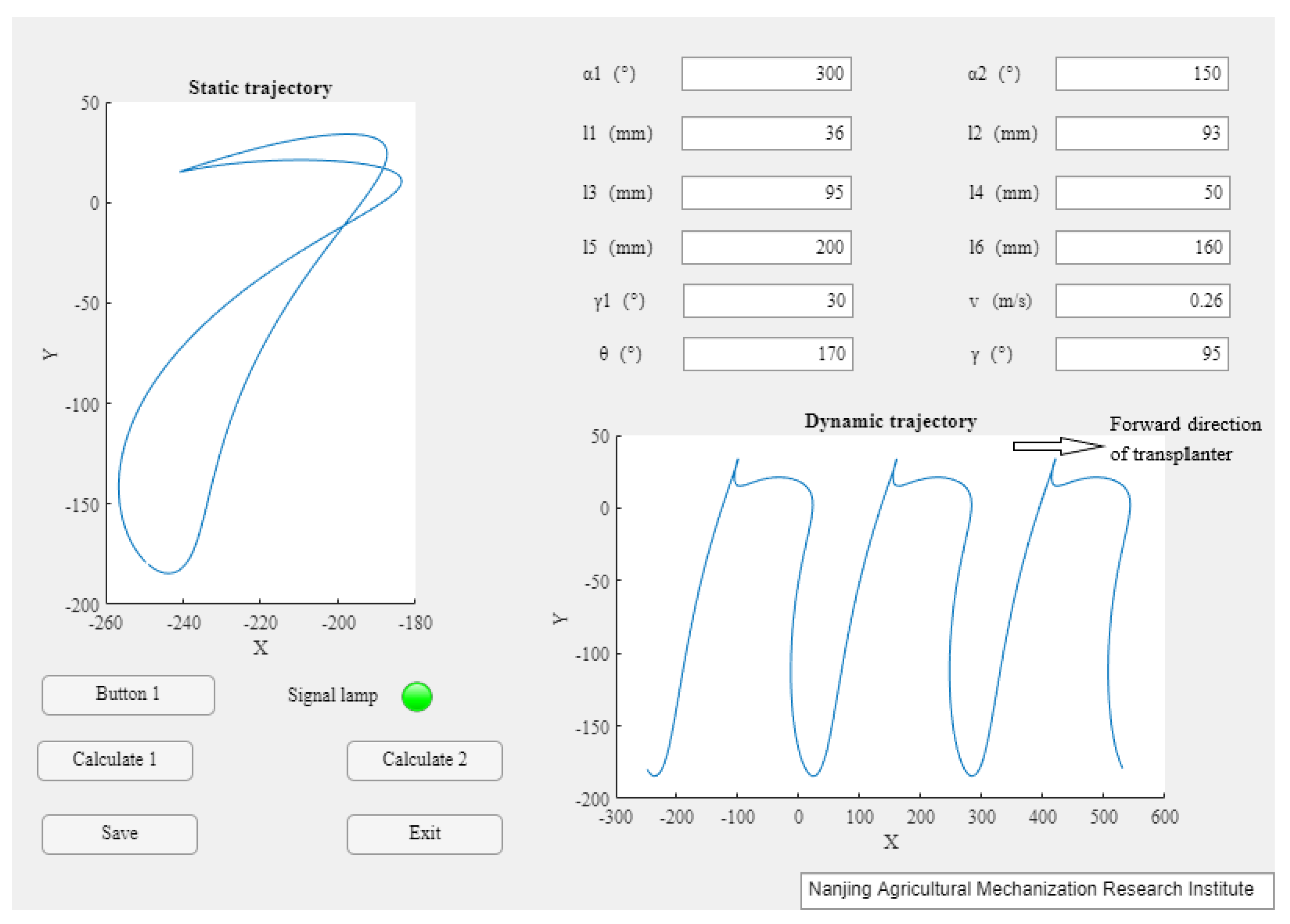

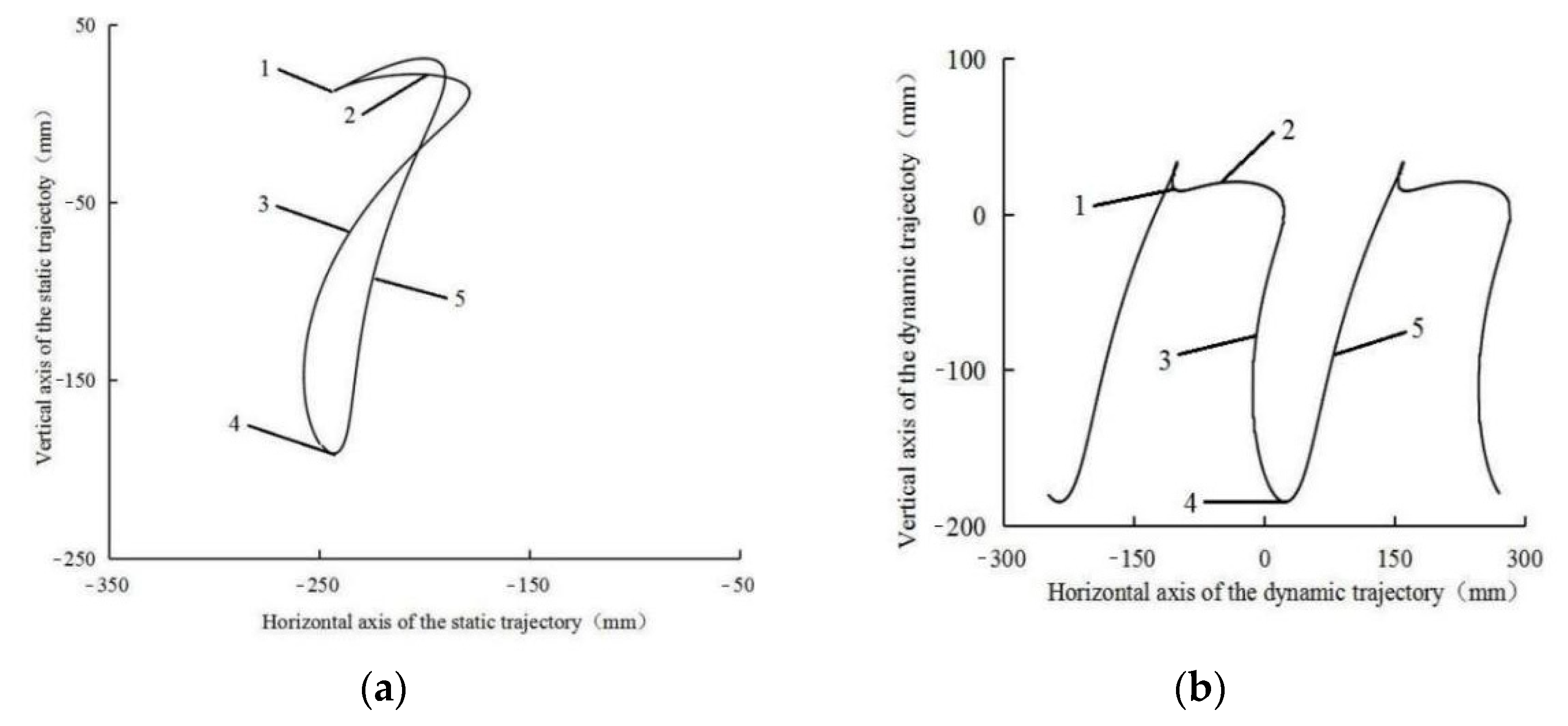

3.2. Optimization Results and Ideal Seedling Movement Trajectory

3.3. The Results of the High-Speed Photography Test

3.4. Seedling Picking and Planting Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Yang, S.; Zhang, X. The situation and thinking of Chinese characteristic vegetable industry. Chin. Veg. 2020, 6, 1–5. [Google Scholar]

- Zheng, J.; Li, X.; Liu, F.; Zhou, S.; Luo, F.; Ma, Y. Advances in Pepper Science in 2017. Chin. Veg. 2018, 5, 9–15. [Google Scholar]

- Xiao, C.; Kuang, B.; Yu, X.; Shang, Q.; Tang, E.; Li, J. Advantages and key technologies of hole dish seedling of solanaceous vegetables. Shanghai Veg. 2020, 2, 21–22. [Google Scholar]

- Yue, J.; Guo, J.; Linag, J.; Liang, S.; Zhang, C.; Liu, Y.; Liu, M. The Development Status of Transplanting Machinery at Home and Abroad. Xinjiang Agric. Mech. 2016, 5, 30–32, 36. [Google Scholar]

- Jin, X.; Li, S.; Yang, X.; Yan, H.; Wu, J.; Sun, X.; Zhang, M. Motion Analysis for Vegetable Potted Seedling Pick-up Mechanism with Double Crank Geared Linkages. J. Agric. Mech. Res. 2014, 7, 13–17. [Google Scholar]

- Zhang, M.; Ji, J.; Du, X. Status and Prospect of Transplanter at Home and Abroad. Agric. Eng. 2012, 2, 21–23. [Google Scholar]

- Zhou, M.; Xu, J.; Tong, J.; Yu, G.; Zhao, X.; Xie, J. Design and experiment of integrated automatic transplanting mechanism for taking and planting of flower plug seedlings. Trans. CSAE 2018, 34, 44–51. [Google Scholar]

- Zhao, Y.; Zhang, W.; Xin, L.; Xie, J.; Xue, X.; Shan, Y. Design and Experiment of Extensible Potted Tomatoes Seedling Transplanting Mechanism. Trans. CSAM 2019, 50, 105–112. [Google Scholar]

- Xie, S.; Yang, S.; Liu, J.; Song, L.; Xie, Q.; Duan, T. Development of the seedling taking and throwing device with oblique insertion and plug clipping for vegetable transplanters. Trans. CSAE 2020, 36, 1–10. [Google Scholar]

- Zhao, X.; Cui, H.; Dai, L.; Xu, Y.; Wang, C.; Shen, J. Optimal design and experiment of hybrid-driven five-bar flower potted-seedling transplanting mechanism. Trans. CSAE 2017, 33, 34–40. [Google Scholar]

- Zhang, Z.; Zhang, N.; Lv, Q.; Han, C.; Xu, H.; Li, H.; Bai, Z. Design and Research on the Automatic Transplanting Machine of the Top Pinch Combined Type Plug Seedling. Xinjiang Agric. Mech. 2016, 6, 16–18, 45. [Google Scholar]

- Wang, D.; Jin, X.; Ji, J.; He, Z.; Yan, H. Design and Experiment of Fully Automatic Ejection and Picking-up Seedlings Mechanism of Transplanter. J. Agric. Mech. Res. 2016, 10, 64–68. [Google Scholar]

- Wen, Y.; Zhang, J.; Zhang, Y.; Tian, J.; Yuan, T.; Tan, Y.; Li, W. Development of insertion and ejection type seedling taking device for vegetable plug seedlings. Trans. CSAE 2020, 36, 96–104. [Google Scholar]

- Liao, Q.; Zhang, Z.; Hu, Q.; Xu, B. Design and Trajectory Analysis of Pneumatic Picking-up Mechanism for Rape Paper Pot Seedling. Trans. CSAM. 2017, 48, 70–78. [Google Scholar]

- Han, L.; Mao, H.; Zhao, H.; Liu, Y.; Hu, J.; Ma, X. Design of root lump loosening mechanism using air jets to eject vegetable plug seedlings. Trans. CSAE 2019, 35, 37–45. [Google Scholar]

- Han, Z.; Yan, H.; Chen, K.; He, Y. Design and Parameter Optimization of Seedling Expeller Mechanism Based on Matlab. J. Agric. Mech. Res. 2017, 39, 142–146. [Google Scholar]

- Sun, L.; Shen, J.; Zhou, Y.; Ye, Z.; Yu, G.; Wu, C. Design of non-circular gear linkage combination driving type vegetable pot seedling transplanting mechanism. Trans. CSAE 2019, 35, 26–33. [Google Scholar]

- Li, H.; Cao, W.; Li, S.; Liu, J.; Chen, B.; Ma, X. Development of 2ZXM-2 automatic plastic film mulching plug seedling transplanter for vegetable. Trans. CSAE 2017, 33, 23–33. [Google Scholar]

- Ye, B.; Yu, G.; Chen, Z.; Zhao, Y. Kinematics modeling and parameters optimization of seedling pick-up mechanism of planetary gear train with eccentric gear and non-circular gear. Trans. CSAE 2011, 27, 7–12. [Google Scholar]

- Guo, J.; Huang, Y.; Dai, Y.; Luo, X.; Gou, H. Performance experimental study of orderly rows seedlings on a type of seedling-falling device with air blast. J. Chin. Agric. Mech. 2014, 35, 136–138. [Google Scholar]

- Ma, X.; Li, H.; Ge, Y.; Li, S.; Zhao, Y.; Yu, S. Experimental Study on Mechanical Properties of Tomato Seedling Stem. J. Agric. Mech. Res. 2020, 42, 161–167. [Google Scholar]

- Liang, L.; Guo, Y. Correlation study of biomechanical properties and morphological characteristics of crop stalks. Trans. CSAE 2008, 24, 1–6. [Google Scholar]

- Shuangyan, H.; Minjuan, H.; Wenyi, Z.; Zhan, J. Experimental and simulation study on mechanical properties of stem of pepper hole seedlings. J. Chin. Agric. Mech. 2022, 43, 9–17. [Google Scholar]

- Li, H.; Ma, X.; Cao, W.; Li, S.; Zhou, W. Design and experiment of seedling picking mechanism by stem clipping for tomato plug seedling. Trans. CSAE 2020, 36, 39–48. [Google Scholar]

- Li, H.; Cao, W.; Li, S.; Fu, W.; Liu, K. Kinematic analysis and test on automatic pick-up mechanism for chili plug seedling. Trans. CSAE 2015, 23, 20–27. [Google Scholar]

- Jiang, L.; Wu, C.; Tang, Q.; Zhang, M.; Wang, G. Kinematics model and parameter optimization of planting process of rape carpet seedling transplanter. Trans. CSAE 2018, 34, 37–46. [Google Scholar]

- Shang, T.; Yuan, R.; Tian, C.; Wang, X. Parameters matching and optimization of seedling pick-up mechanism with crank-rocker planetary gear train. J. Cent. South Tech Univ. 2016, 2, 443–449. [Google Scholar]

- Tong, J.; Yu, G.; Zhu, Y.; Ye, B.; Zheng, C.; Huang, J. Design and Experiment of Three-arms Rotary Vegetable Plug Seedling Pick-up Mechanism. Trans. CSAM 2019, 50, 113–121. [Google Scholar]

- NY/T3486-2019; Ministry of Agriculture and Rural Affairs of the People’s Republic of China, Operation Quality of Vegetable Transplanter. National Technical Committee on Agricultural Machinery of Standardization Administration. China Agriculture Press: Beijing, China, 2019.

- JB/T 10291-2013; China Machinery Industry Federation, Dryland Planting Machinery. National Technical Committee on Agricultural Machinery of Standardization Administration. AMST: Beijing, China, 2013.

| Parameter | Name | Value |

|---|---|---|

| lOA | The length of crank OA (mm) | 36 |

| lCD | The length of crank CD (mm) | 50 |

| lAB | The length of rod AB (mm) | 93 |

| lBC | The length of rod BC (mm) | 95 |

| lAE | The length of rod AE (mm) | 200 |

| lEF | The length of rod EF (mm) | 160 |

| θ | The angle of rod AE and AB (°) | 170 |

| γ | The angle of rod AE and EF (°) | 95 |

| α1 | The initial angle of the crank OA (°) | 300 |

| α2 | The initial angle of the crank CD (°) | 150 |

| Number of Hole Tray Seedlings | The Rotation Speed (r/min) | Number of Lack of Seedlings | Number of Seedlings Picking | The Success Rate of Seedling Picking (%) | Number of Seedlings Planting | The Success Rate of Seedling Planting (%) | Qualified Rate of Planting Uprightness (%) | Coefficient of Variation of Plant Spacing (%) |

|---|---|---|---|---|---|---|---|---|

| 60 | 60 | 3 | 54 | 94.7 | 48 | 84.2 | 97.8 | 11.4 |

| 60 | 70 | 2 | 53 | 91.4 | 47 | 81.0 | 95.7 | 13.8 |

| 60 | 80 | 4 | 51 | 91.1 | 44 | 78.5 | 94.9 | 14.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Hu, M.; Yan, W.; Zhang, W. Design and Experiment of an Integrated Automatic Transplanting Mechanism for Picking and Planting Pepper Hole Tray Seedlings. Agriculture 2022, 12, 557. https://doi.org/10.3390/agriculture12040557

Hu S, Hu M, Yan W, Zhang W. Design and Experiment of an Integrated Automatic Transplanting Mechanism for Picking and Planting Pepper Hole Tray Seedlings. Agriculture. 2022; 12(4):557. https://doi.org/10.3390/agriculture12040557

Chicago/Turabian StyleHu, Shuangyan, Minjuan Hu, Wei Yan, and Wenyi Zhang. 2022. "Design and Experiment of an Integrated Automatic Transplanting Mechanism for Picking and Planting Pepper Hole Tray Seedlings" Agriculture 12, no. 4: 557. https://doi.org/10.3390/agriculture12040557

APA StyleHu, S., Hu, M., Yan, W., & Zhang, W. (2022). Design and Experiment of an Integrated Automatic Transplanting Mechanism for Picking and Planting Pepper Hole Tray Seedlings. Agriculture, 12(4), 557. https://doi.org/10.3390/agriculture12040557