Abstract

Conventional redesign methodologies applied on the grain harvester headers for the mechanical harvesting of chickpeas cause its progress to not be as rapid and technological. This paper presents a hybrid modeling-optimization methodology to design harvester reels for efficient chickpea harvesting. The five fabricated headers were tested in both real and virtual modeling environments to optimize the operational parameters of the reel for minimum losses. Harvesting losses data gathered from chickpea fields over ten years of trials were fed into a fuzzy logic model, which in turn was merged with simulated annealing to develop a simulator. To this end, simulated annealing was used to produce combinations of reel diameter and number of bats, to be fed into the fuzzy model until achieving a minimum harvesting loss. The proposed model predicts the reel structure measured in-field evaluation, which fits well with the previously established mathematical model. A significant improvement in harvesting performance, 71% pod harvesting, validates the benefits of the proposed fuzzy-simulated annealing approach to optimize the design of grain harvester headers.

1. Introduction

Agricultural robots, autonomous field modules, and digitalized equipment have taken over conventional harvesting methodology. Crops are harvested mechanically or automatically with high efficiency. However, there are other crops, such as some legumes in which progress is not as rapid and technological. This fact leads to low investment in the development of machinery for its handling, and therefore, there are unresolved problems. Labor shortage, the migration of youth people to large cities, the decline in the number of professional farmers due to aging or low incomes are extreme difficulties for planting pulses in rural areas.

Chickpea (Cicer arietinum L.) is one of the legumes with over 14 million tons of world production, and with special importance in dry or semi-dry lands in countries such as India, Turkey, Pakistan, Myanmar or Iran [1]. Chickpea production improves the fertility of the farm’s agro-system [2], fixes atmospheric N through symbiosis with bacteria in nodules of the root system [3] to conserve soil and water, and helps economically vulnerable farmers. Weed infestation, pods near the ground, low height of the plant, and uneven ripening are difficulties for efficient harvesting of rain-fed chickpeas [4]. These crudities in conjunction with the inappropriate design of conventional grain headers for mechanical harvesting of chickpeas cause high shattering losses and manually harvesting of the crop by the laborers in some developing countries.

Time-consuming and costly conventional design methodologies based on developments and trials in conjunction with a short harvesting period represent critical difficulties for redesigning concepts and reaching optimal solutions of special crop harvesters. During the last few decades, some models have been developed to predict the harvesting losses with good accuracy based on machine operational parameters [5,6,7,8,9]. However, these models, because of low knowledge and field data, would not be useful to redesign chickpea harvester reels. On the other hand, mathematical models or statistical analysis would not predict the next design and generation. Fuzzy modeling is a black-box-type framework for modeling and identification of nonlinear systems and mechanisms. Fuzzy modeling techniques have proven useful for predicting inefficiencies in agricultural machinery [10,11,12] and identifying the most relevant parameters in optimization [13,14].

The computer-aided design approach merged mathematical algorithms and computational models to study complex system behaviors [15,16,17]. New strategies have been introduced where field data and simulation models are synergistically combined, an overall framework referred to as model-based system testing [18,19]. In 2017, Golpira and Golpira [20] merged conventional design methodologies with metaheuristic modeling combining genetic algorithms with fuzzy logic to develop a hybrid computational algorithm that predicted the optimal sizing of a grain harvester platform. The main drawback found in this work, however, stemmed from the fact that a succession of platforms was fabricated according to the design output by a single optimization methodology, whose simplicity could not model such a complex operation as chickpea retrieval. In this sense, other types of approaches could complement fuzzy logic such as simulated annealing (SA) which is an optimization technique that can statistically guarantee the finding of an optimal solution to an engineering problem [21,22]. SA finds the optimal solutions using point-by-point interactions rather than a generic search over a population of individuals [23]. SA is an effective optimization methodology for problems with an unclear mathematical model. SA is based on random evaluations of the cost function [24], allowing transitions out of local minima.

The main aim of this study is to develop a computer-based model for the optimization of chickpea harvester reels. It is intended to merge fuzzy modeling and SA with the use of extensive field data from five prototype chickpea harvesters to develop a data-driven model for the static design of the reel structure. The fuzzy SA model was used to adjust the reel diameter and the number of bats on which the harvester losses are minimized.

2. Materials and Methods

2.1. Chickpea Harvester Reels and Harvesting Test

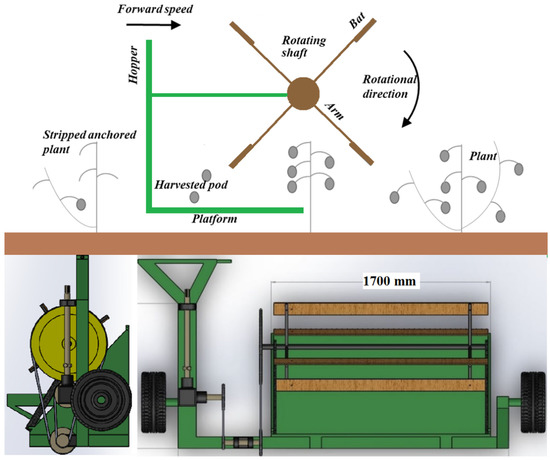

From 2008 to 2017, 5 different configurations of the reel were iteratively designed and modified to reduce harvesting losses. Figure 1 provides a schematic drawing of the main parts of a reel, specifying the location of the bats and the reel diameter. The main components of this harvester are: a transversely elongated frame fixed to a platform; protruding fingers extending forwardly on the platform; a reel driving system; a belt drive; and two front wheels pivoted to the frame.

Figure 1.

Schematic drawing of the main parts that comprise the proposed bat-type reel (up) and the chickpea harvester, Model 2017 (down).

Table 1 shows the combination of three types of transmission systems, five reels types, and three attachment systems fabricated for five prototype chickpea harvesters with the harvesting losses associated with each one. Model 1 had a stripper header in which a platform with forward-opening fingers produced a mechanism to strip the plants by moving them through V-shaped slots. The fixed-bat reel swept the pods across the platform and pushed the top of the chickpeas over the header. A chain and sprocket system produced different reel speeds, ranging from 30 rpm to 110 rpm [25]. Model 2 experienced a considerable redesign of functional parameters [26]. The vertically adjustable platform, with 1.4 m working width and 27 V-shaped slots, was carried in front of the machine, and it was transversely elongated relative to the direction of travel. The supporting platform was made with beams 6 mm thick and 700 mm wide. A derailleur sprocket system provided power for the ground-driven reel and operated new pneumatic conveyors. In Model 3 some adjustments were made to the power system, the number, and the diameter of the blades [27]. In Model 4, a few more parameters were adjusted over the previous model, performed different reel speeds and kinematic indices provided by a variable transmission system, in which a gearbox coupled to a pulley and a belt transferred the power take-off of a tractor to the axis of the reel. Finally, Model 5 was slightly modified having the actual prototype that reduced the total losses from 47% in 2009 to 29% in 2017 and had a field capacity of 0.42 ha/h considering a forward speed of 3 km/h and a 1.4 m working width.

Table 1.

Functional operators of the developed prototype chickpea harvesters and the field losses performed in harvesting tests.

All the design modifications in the different prototypes were taken based on the results of various field trials. The field experiments were performed in three locations: (1) the Dooshan farm of the University of Kurdistan; (2) the Sanandaj Agricultural Research Center; and (3) the Saral farm of Kurdistan Agricultural Research Center from 2007 to 2017, using common chickpea varieties Kabuli and Red desi and the typical field of chickpea. One hectare of chickpeas was plowed and disk-harrowed. Plant and row spacings were 0.5 m and 0.5 m, respectively. Weeds were removed manually by the laborer before evaluation. Harvested pods were manually removed from the collection container by the laborer. The chickpea harvester was tested at a fixed ground speed of 3 km h−1. The platform was adjusted at 5 cm (above the ground) based on previous measurements of seed distribution along with chickpea height. The reels were adjusted so that the bats passed approximately 5 cm above the fingers. Reels distance ahead of the teeth was fixed at 5 cm. The tilt angle of the platform, or the angle that the platform made with the ground above a horizontal transverse axis, was adjusted to 0 degrees. The length of test plots was 15 m and was laid out in a factorial experiment based on a completely randomized design with 3 replications and 6 treatments.

Before harvesting, pre-harvest losses were estimated by collecting the pods and seeds lying on the ground from a sample area 1.0 m long × 1.0 m (2 rows) wide from each plot. Samples were threshed, cleaned, and weighed to determine an average pre-harvest loss for the entire plot area. Plant from this sample area, randomly located near the prototype harvester entry point end of each plot, were also harvested manually and threshed to determine harvestable yield for the plot area. Further, the major branches, pods per plant, and location of all pods of 10 plants in this sample area were recorded. The moisture content of the seeds was checked by oven drying at 105 °C for 72 h. Mean values of different measurements were recorded for the crop properties. An additional sample area measuring 0.6 m long × 1.5 m (3 rows) wide, was randomly located near the middle of the plot, established within each plot to determine harvesting losses.

After harvesting, the pods and seeds in the sample area were collected, manually threshed, and weighed to determine harvesting losses. Harvester loss was calculated by subtracting the average pre-harvest loss from harvesting loss. Samples were threshed, cleaned, and weighed to determine an average pre-harvest loss for the entire plot area. Harvester loss was calculated as a percentage of harvestable yield by dividing seed loss by hand harvest yield and multiplying the result by 100.

2.2. Modeling-Optimization Approach

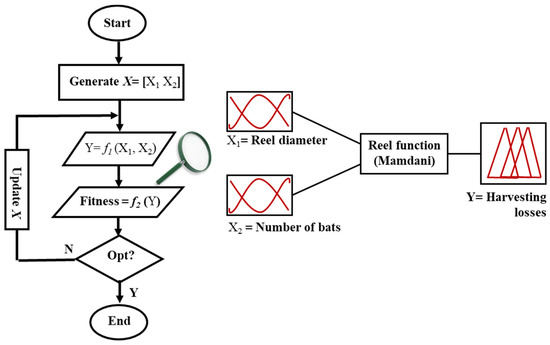

The fuzzy model fed with harvesting losses data acquired in the evaluation of five prototypes of chickpea harvesters in field tests carried out over 10 years, was merged with SA to optimize the reel structure. Fuzzy modeling helps to quantify expert knowledge and facilitates optimized design through SA. The SA optimization paradigm can be compared to a physical process by which a material changes state while minimizing its energy. The algorithm was used to simulate the annealing process by repeatedly reducing the value of temperature until it reaches a heuristic solution [28]. SA exploits functions domain and reaches an area where at least one global minimum is present. A general description of the proposed optimization strategy can be explained by the following steps summarized in the flowchart in Figure 2:

Figure 2.

Flowchart representation of the optimization procedure for designing the harvester reel.

- Step 1: SA randomly defines state S1 = [X1, X2] and sets a primary temperature (T).

- Step 2: A neighbor state of S1, named S2, is defined according to the stochastic pre-specified algorithm.

- Step 3: S1 and S2 are fed into fuzzy models to calculate Y1 and Y2, i.e., harvesting losses.

- Step 4: Calculation of fitness values S1 and S2, i.e., E (Y1) and E (Y2).

- Step 5: if E(Y2) < E(Y1) then set S2 = S1, otherwise keep S1 as the optimum solution with the probability of ΔE/T.

- Step 6: Decrease T and go to Step 2, noting that by decreasing T in several iterations, the probability of ΔE/T converges to 1, leading to the optimum solution.

- Step 7: Continue iterating until the termination condition is met.

Based on the estimation of losses from field experiments conducted over the years with prototype Models 2009, 2013, 2014, 2015, and 2017 the fuzzy model for harvester Model 2021 was developed. Fuzzy modeling characterizes by fuzzification, generating of fuzzy associative memory (FAM), defuzzification, and settles by validation to be appropriate for optimization purposes. In rule-based fuzzy systems, the relationships between variables are represented utilizing if–then rules. The output of a rule-based fuzzy model is computed by specific algorithms such as the max–min [29] or relational composition [30]. Both the antecedent and consequent are fuzzy prepositions in the linguistic fuzzy model. Linguistic presentation in the form of rules and logic structure provides a transparent representation of a system. Qualitative relationship between input and output is expressed by fuzzy rules. Finally, to obtain a crisp value the output of the fuzzy system should be defuzzified. The number of inputs, number of fuzzy sets, and number of rules are important factors in modeling a fuzzy set.

2.2.1. Fuzzification

A linguistic fuzzy model in which both the antecedent and the consequent propositions are based on fuzzy logic was used for describing the key actuators of chickpea harvesters. The fuzzy model developed in this research considers two input parameters: the reel diameter (d) and the number of bats (n), and its main purpose is to minimize the harvesting losses of the harvester. In addition, 59 field data of harvesting losses for reels configurations were fed into the metaheuristic model.

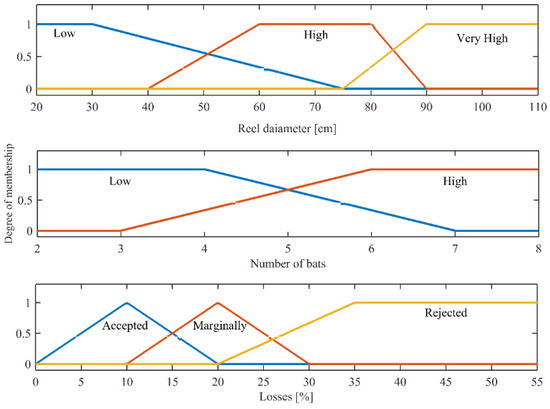

2.2.2. Rules

The fuzzified inputs and outputs, named antecedent and consequent in the rule-based system, are defined by membership functions (MFs). The two inputs of reel diameter and number of bats were tied to the output of harvesting losses via 59 fuzzy rules. While the fuzzification functions for the reel diameter and number of bats relied on a trapezoid shape, the functions for losses followed a combination of trapezoid and triangular functions as plotted in Figure 3. Fuzzification relies on the pre-specified losses levels, i.e., accepted, marginally accepted, and rejected. Each input variable is varied in a defined range while the others are considered constant. Any significant change in harvesting losses in response to desired variable variation leads to the definition of an MF. For instance, for reel diameter more than 80 cm, pod losses increase impact velocity which in turn increases pod losses and reduces harvesting efficiency. Table 2 summarizes the designer knowledge based on which the MFs are defined. Desired zones are those whose behavior is accepted in field experiments.

Figure 3.

Fuzzy membership functions for the inputs reel diameter and number of bats, and output functions for the harvesting losses model.

Table 2.

Membership function definition procedure for the optimization of the reel functional operators.

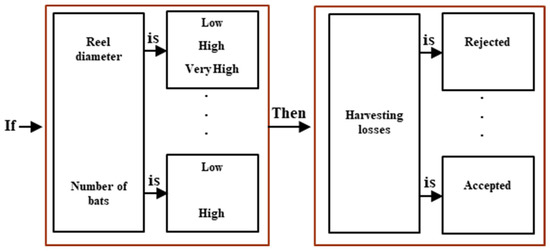

The field data incorporation with the defined MFs was employed to generate a set of if–then rules, called FAM bank. FAM bank contained a set of linguistic relationships between design variables and harvesting losses. If–then rules were enounced to compose the rule-base of the fuzzy system. Data gathered from field evaluations in the form of if–then rules were employed to develop a fuzzy model, as described in Figure 4. Each reel was a redesigned version of the previous one, where its functional operators were optimized for reducing losses. Two design parameters comprising the number of bats and the reel diameter fed the fuzzy model to calculate harvesting losses. The result was a fuzzy-based model that determines harvesting losses in a mapping function featuring three levels: accepted, marginally accepted, and rejected. Computation of rules performed via fuzzy conjunctions (Mamdani method).

Figure 4.

The set if–then conditions to establish the rule-base of the fuzzy system.

2.2.3. Defuzzification

While fuzzification converts crisp input data to fuzzy values, using membership functions, defuzzification regenerates crisp values as the output of the model. The max–min inference scheme based on the center of gravity was employed to defuzzify the output values, providing a crisp output value of harvesting losses for crisp inputs of reel diameter and number of bats. Mamdani inference method does not require any discretization and thus can work with analytically defined MFs.

3. Results and Discussion

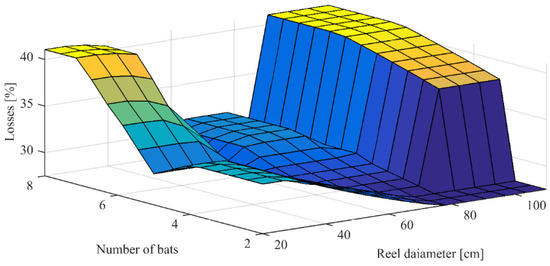

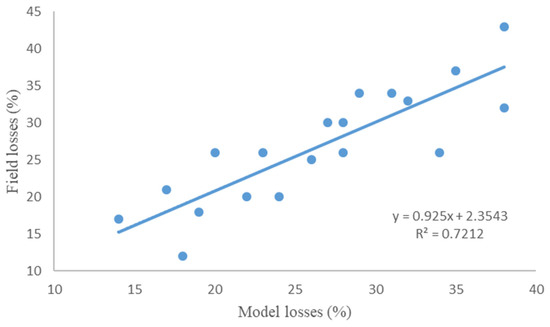

Figure 5 describes a non-concave surface for the relationship between shattering losses and the input variables number of bats and reel diameter. The outcomes of the field tests for evaluating the shattering losses in Model 2017 were applied for validating the fuzzy model. The validation results for the developed model are shown in Figure 6, where the predicted losses are plotted against the real losses with a coefficient of determination R2 = 0.72. This plot reveals that the proposed model represents the reel to a sufficient level of accuracy. Several works apply regression equations to estimate losses in machinery based on various functional parameters such as cutting speed, spacing, length, etc. [31,32,33]. However, in less linear optimization problems, as in the one posed in this paper, fuzzy logic models address the problem with greater flexibility and efficiency [34,35].

Figure 5.

Relationship between shattering losses and reel functional operators, number of bats and reel diameter in the fuzzy model.

Figure 6.

Comparison of the field-registered platform losses versus the model-predicted losses on a 20-point validation set.

While agricultural research often deals with fuzzy logic with control of the functional operators of the grain combine harvesters [36,37,38], in the proposed data-driven simulator fuzzy modeling was applied for machine design and optimization. The extraction of the membership function to the outputs shows harvesting performance to be 71%, and for that minimum value, the best configuration is four bats with a 70 cm reel diameter. Although the harvesting losses of 29% were previously reported for harvesting of irrigated chickpeas by conventional grain combine harvesters [39], in the present research rain-fed varieties of Kabuli and Desi, in which the height of the plant often does not reach 30 cm above the ground, were tried. It is noteworthy that, the physical and mechanical properties of the crop, the plant varieties, height, and distances in rows are hidden in the field gathering data. These results were confirmed by [40] both in kinematic analysis and field experiments results. Finally, the optimized reel was assembled on the redesigned prototype chickpea harvester model 2021 as shown in Figure 7.

Figure 7.

The prototype chickpea harvester model 2021.

Using hybrid models such as fuzzy logic and SA, interesting results have been obtained in other engineering fields [41,42,43,44], in a manner analogous to those obtained in this work. In the same way that complex models exist for farmers’ decision-making [45], machinery optimization models are of great use for the industrial manufacturing sector [46,47] in the adjustment of machines in the field [48] or the choice of an agricultural machinery service [49,50]. In this sense, synergies between the agronomic and industrial sectors are key for efficient crop mechanization [51]. Therefore, data collected in numerous campaigns with the variation of several operational machine parameters are very useful for shortening product development times with models such as those presented in this work.

4. Conclusions

A virtual concept for the optimization of the chickpea harvester reel is presented. The integration of the conventional prototyping methodology, field evaluation data, and metaheuristic modeling support a data-driven simulator. The model-based system testing fed with harvesting losses data acquired in the evaluation of five prototypes of chickpea harvesters in field tests merged fuzzy logic with SA to optimize reel structure. The modeling-optimization approach guaranteed the optimal design of the reel with four bats and a diameter of 70 cm which increases harvesting performance to more than 70%. Field evaluation results demonstrated satisfactory efficiency from a statistical standpoint yielding a high coefficient of determination when correlating the proposed fuzzy model with actual harvester losses. To the best of the authors’ knowledge, the developed model is the unique hybrid fuzzy SA model for the optimization of the combine harvester reels. Field evaluation of the new reel and prototype chickpea harvester was considered for increasing the harvesting performance of the machine and simulator.

Author Contributions

Conceptualization, H.G.; methodology, H.G.; formal analysis, H.G. and R.R.S.-G.; original draft preparation, H.G.; writing—review and editing, R.R.S.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received financial support from the University of Kurdistan under grant agreement CRC96-00213-2, the Iran National Science Foundation (INSF) under grant agreement 89003097, and the Incubator Center of the University of Kurdistan under grant agreement 2/24111.

Conflicts of Interest

The authors declare no conflict of interest.

References

- FAOSTAT. Chickpea Production in 2019, Crops/Regions/World list/Production Quantity (Pick Lists). Retrieved 7 October 2021. 2020. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 7 January 2022).

- European Parliament’s Committee on Agriculture and Rural Development (COMAGRI). Measures at Farm Level to Reduce Greenhouse Gas Emissions from EU Agriculture 2014. Available online: https://www.europarl.europa.eu/RegData/etudes/note/join/2014/513997/IPOL-AGRI_NT(2014)513997_EN.pdf (accessed on 5 June 2021).

- Kanouni, H.; Sadeghzadeh Ahari, D.; Saeid, A.; Shobeiri, S.S.; Mahdieh, M.; Haji Hasani, M.; Beheshti Danalou, M. Investigation of grain yield stability of Desi type chickpea across different environments and introducing promising lines. J. Agric. Sci. Sustain. Prod. 2021, 31, 295–312. [Google Scholar] [CrossRef]

- Niazi, A.; Golpira, H.; Akhijahani, H.S. Evaluation of a chickpea harvesting header with porous plate. J. Agric. Mach. 2021. (In Farsi) [Google Scholar] [CrossRef]

- Zareei, S.; Abdollahpour, S. Modeling the optimal factors affecting combine harvester header losses. Agric. Eng. Int. CIGR J. 2016, 18, 60–65. [Google Scholar]

- Hirai, Y.; Inoue, E.; Mori, K.; Hashiguchi, K. Investigation of mechanical interaction between a combine harvester reel and crop stalks. Biosyst. Eng. 2002, 83, 307–317. [Google Scholar] [CrossRef]

- Hirai, Y.; Inoue, E.; Mori, K.; Hashiguchi, K. Analysis of reaction forces and posture of a bunch of crop stalks during reel operations of a combine harvester. CIGR E-J. 2002, IV, 1–18. [Google Scholar]

- Oduori, M.F.; Mbuya, T.O.; Sakai, J.; Inoue, E. Modeling of crop stem deflection in the context of combine harvester reel design and operation. Agric. Eng. Int. CIGR J. 2012, 14, 21–28. [Google Scholar]

- Oduori, M.F.; Mbuya, T.O.; Sakai, J.; Inoue, E. Kinematics of the tined combine harvester reel. Agric. Eng. Int. CIGR J. 2012, 14, 53–60. [Google Scholar]

- Craessaerts, G.; Saeys, W.; Missotten, B.; De Baerdemaeker, J. Identification of the cleaning process on combine harvesters, Part II: A fuzzy model for prediction of the sieve losses. Biosyst. Eng. 2010, 106, 97–102. [Google Scholar] [CrossRef]

- Chai, X.; Xu, L.; Li, Y.; Qiu, J.; Li, Y.; Lv, L.; Zhu, Y. Development and experimental analysis of a fuzzy grey control system on rapeseed cleaning loss. Electronics 2020, 9, 1764. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, M.S.; Huang, R.L. Research on application of fuzzy neural network in combine harvester. In Proceedings of the 2008 Fifth International Conference on Fuzzy Systems and Knowledge Discovery, Jinan, China, 18–20 October 2008; Volume 3, pp. 231–235. [Google Scholar]

- Dimitrov, V.; Borisova, L.; Nurutdinova, I. Development and analysis of fuzzy expert data for technological adjustment of a grain harvester header. E3S Web Conf. 2020, 175, 05027. [Google Scholar] [CrossRef]

- Manuja, R.; Bindra, S.S.; Gupta, S. Combinational fuzzy expert system (CFES) for academic performance appraisal. Adv. Appl. Math. Sci. 2019, 18, 691–703. [Google Scholar]

- Torenbeek, E. Advanced Aircraft Design: Conceptual Design, Analysis and Optimization of Subsonic Civil Airplanes; John Wiley & Sons: Hoboken, NJ, USA, 2013; Available online: https://doi-org.ezp.semantak.com/10.1002/9781118568101.ch7 (accessed on 5 June 2021).

- Más, F.R.; Zhang, Q.; Hansen, A.C. Mechatronics and Intelligent Systems for Off-Road Vehicles; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar] [CrossRef]

- Zhu, J.H.; Zhang, W.H.; Xia, L. Topology optimization in aircraft and aerospace structures design. Arch. Comput. Methods Eng. 2016, 23, 595–622. [Google Scholar] [CrossRef]

- Cornelis, B.; Forrier, B.; Cumbo, R.; Risaliti, E.; Janssens, K.; Tamarozzi, T.; Desmet, W. Virtual sensing strategies utilizing various model complexities: Industrial applications. In Commercial Vehicle Technology 2020/2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 512–523. [Google Scholar] [CrossRef]

- Schwich, S.; Schattenberg, J.; Frerichs, L. Development of a Machine Learning-Based Assistance System for Computer-Aided Process Optimization within a Self-Propelled Sugar Beet Harvester. Available online: https://elibrary.asabe.org/abstract.asp?JID=5&AID=51512&CID=virt2020&T=1 (accessed on 5 June 2021).

- Golpira, H.; Golpîra, H. Soft simulator for redesigning of a chickpea harvester header. Comput. Electron. Agric. 2017, 135, 252–259. [Google Scholar] [CrossRef]

- Savsani, V.; Rao, R.; Vakharia, D. Optimal weight design of a gear train using particle swarm optimization and simulated annealing algorithms. Mech. Mach. Theory 2010, 45, 531–541. [Google Scholar] [CrossRef]

- Ingber, L. Simulated annealing: Practice versus theory. Math. Comput. Model. 1993, 18, 29–57. [Google Scholar] [CrossRef] [Green Version]

- Suman, B.; Kumar, P. A survey of simulated annealing as a tool for single and multiobjective optimization. J. Oper. Res. Soc. 2006, 57, 1143–1160. [Google Scholar] [CrossRef]

- Aguiare Oliveira Junior, H.; Ingber, L.; Petraglia, A.; Petraglia, M.R.; Machado, M.A.S. Fuzzy Modeling with Fuzzy Adaptive Simulated Annealing. In Stochastic Global Optimization and Its Applications with Fuzzy Adaptive Simulated Annealing; Springer: Berlin/Heidelberg, Germany, 2012; pp. 139–148. [Google Scholar] [CrossRef]

- Golpira, H.; Tavakoli, T.; Baerdemaeker, J. Design and development of a chickpea stripper harvester. Span. J. Agric. Res. 2013, 11, 929–934. [Google Scholar] [CrossRef] [Green Version]

- Golpira, H. Conceptual design of a chickpea harvesting header. Span. J. Agric. Res. 2013, 11, 635–641. [Google Scholar] [CrossRef] [Green Version]

- Golpira, H. Redesign and evaluation of a chickpea harvester. J. Biosyst. Eng. 2015, 40, 102–109. [Google Scholar] [CrossRef] [Green Version]

- Chopard, B.; Tomassini, M. Simulated Annealing. In An Introduction to Metaheuristics for Optimization; Springer International Publishing: Cham, Switzerland, 2018; pp. 59–79. [Google Scholar] [CrossRef]

- Babuška, R. Fuzzy Modeling for Control; Springer Science & Business Media: Berlin, Germany, 2012; Volume 12. [Google Scholar]

- Babuska, R. Fuzzy Systems, Modeling and Identification; Lecture Notes; Delft University of Technology, Department of Electrical Engineering: Delft, The Netherlands, 2002. [Google Scholar]

- Junsiri, C.; Cinsuwan, W. Prediction equations for header losses of combine harvesters when harvesting Thai Hom Mali rice. Songklanakarin J. Sci. Technol. 2009, 31, 613–620. [Google Scholar]

- Fadavi, R.; Abdollahpour, S.; Moghaddam, M. Design, construction and evaluation of grain harvester combine’s header loss based on statistical analysis and modeling the optimal factors. J. Exp. Biol. 2017, 5, 537–544. [Google Scholar] [CrossRef]

- Doungpueng, K.; Saengprachatanarug, K.; Posom, J.; Chuan-Udom, S. Selection of proper combine harvesters to field conditions by an effective field capacity prediction model. Int. J. Agric. Biol. Eng. 2020, 13, 125–134. [Google Scholar] [CrossRef]

- Omid, M.; Lashgari, M.; Mobli, H.; Alimardani, R.; Mohtasebi, S.; Hesamifard, R. Design of fuzzy logic control system incorporating human expert knowledge for combine harvester. Expert Syst. Appl. 2010, 37, 7080–7085. [Google Scholar] [CrossRef]

- Liang, Z.; Li, Y.; Xu, L. Grain sieve loss fuzzy control system in rice combine harvesters. Appl. Sci. 2019, 9, 114. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Cao, M.; Wang, B.; Hu, Z.; Xu, H.; Wang, S.; Yu, Z. Design and Test of a Tangential-Axial Flow Picking Device for Peanut Combine Harvesting. Agriculture 2022, 12, 179. [Google Scholar] [CrossRef]

- Petre, I. Combine Harvesters: Theory, Modeling and Design; CRC Press Inc.: Boca Taton, FL, USA, 2015; pp. 3–25. [Google Scholar]

- Redenius, J.; Belau, S.; Irmer, D.; Ruckelshausen, A.; Middelberg, R.; Spiekermann, S.; Hertzberg, J. Virtual Harvesting as a Key Element in the Development of a Novel LiDAR Based Combine Harvester Steering System; VDI-Berichte: Düsseldorf, Germany, 2019; Volume 2361, pp. 173–178. [Google Scholar]

- Siemens, M.C. Effect of guard spacing, guard attachments and reel type on chickpea harvesting losses. Appl. Eng. Agric. 2006, 22, 651–657. [Google Scholar] [CrossRef]

- Golpira, H.; Rovira-Más, F.; Golpira, H.; Saiz-Rubio, V. Mathematical model-based redesign of chickpea harvester reel. Span. J. Agric. Res. 2021, 19, e0203. [Google Scholar] [CrossRef]

- Pandey, A.; Parhi, D.R. Autonomous mobile robot navigation in cluttered environment using hybrid Takagi-Sugeno fuzzy model and simulated annealing algorithm controller. World J. Eng. 2016, 13, 431–440. [Google Scholar] [CrossRef]

- Bagheri Tolabi, H.; Hosseini, R.; Shakarami, M.R. A robust hybrid fuzzy–simulated annealing–intelligent water drops approach for tuning a distribution static compensator nonlinear controller in a distribution system. Eng. Optim. 2016, 48, 999–1018. [Google Scholar] [CrossRef]

- Craessaerts, G.; de Baerdemaeker, J.; Missotten, B.; Saeys, W. Fuzzy control of the cleaning process on a combine harvester. Biosyst. Eng. 2010, 106, 103–111. [Google Scholar] [CrossRef]

- Kim, D.; Druot, T.Y.; Liem, R.P. Data-Driven Operation-Based Aircraft Design Optimization. Available online: https://hal-enac.archives-ouvertes.fr/hal-02868096/document (accessed on 5 June 2021).

- Qureshi, M.R.N.; Singh, R.K.; Hasan, M.A. Decision support model to select crop pattern for sustainable agricultural practices using fuzzy MCDM. Environ. Dev. Sustain. 2018, 20, 641–659. [Google Scholar] [CrossRef]

- Zareiforoush, H.; Minaei, S.; Alizadeh, M.R.; Banakar, A.; Samani, B.H. Design, development and performance evaluation of an automatic control system for rice whitening machine based on computer vision and fuzzy logic. Comput. Electron. Agric. 2016, 124, 14–22. [Google Scholar] [CrossRef]

- Petrović, D.V.; Tanasijević, M.; Stojadinović, S.; Ivaz, J.; Stojković, P. Fuzzy Model for Risk Assessment of Machinery Failures. Symmetry 2020, 12, 525. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A fuzzy control strategy for the forward speed of a combine harvester based on KDD. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar] [CrossRef]

- Miodragović, R.; Tanasijević, M.; Mileusnić, Z.; Jovančić, P. Effectiveness assessment of agricultural machinery based on fuzzy sets theory. Expert Syst. Appl. 2012, 39, 8940–8946. [Google Scholar] [CrossRef]

- Osuch, A.; Osuch, E.; Rybacki, P.; Przygodziński, P.; Kozłowski, R.; Przybylak, A. A decision support method for choosing an agricultural machinery service workshop based on fuzzy logic. Agriculture 2020, 10, 76. [Google Scholar] [CrossRef] [Green Version]

- Sola-Guirado, R.; Blanco-Roldan, G.; Gil-Ribes, J. New harvester machine for traditional olive orchards: Agronomic and industrial engineering. DYNA 2018, 93, 60–66. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).