Development of Autofeeding Device Applicable to a Biodegradable Pot Tray

Abstract

:1. Introduction

2. Materials and Methods

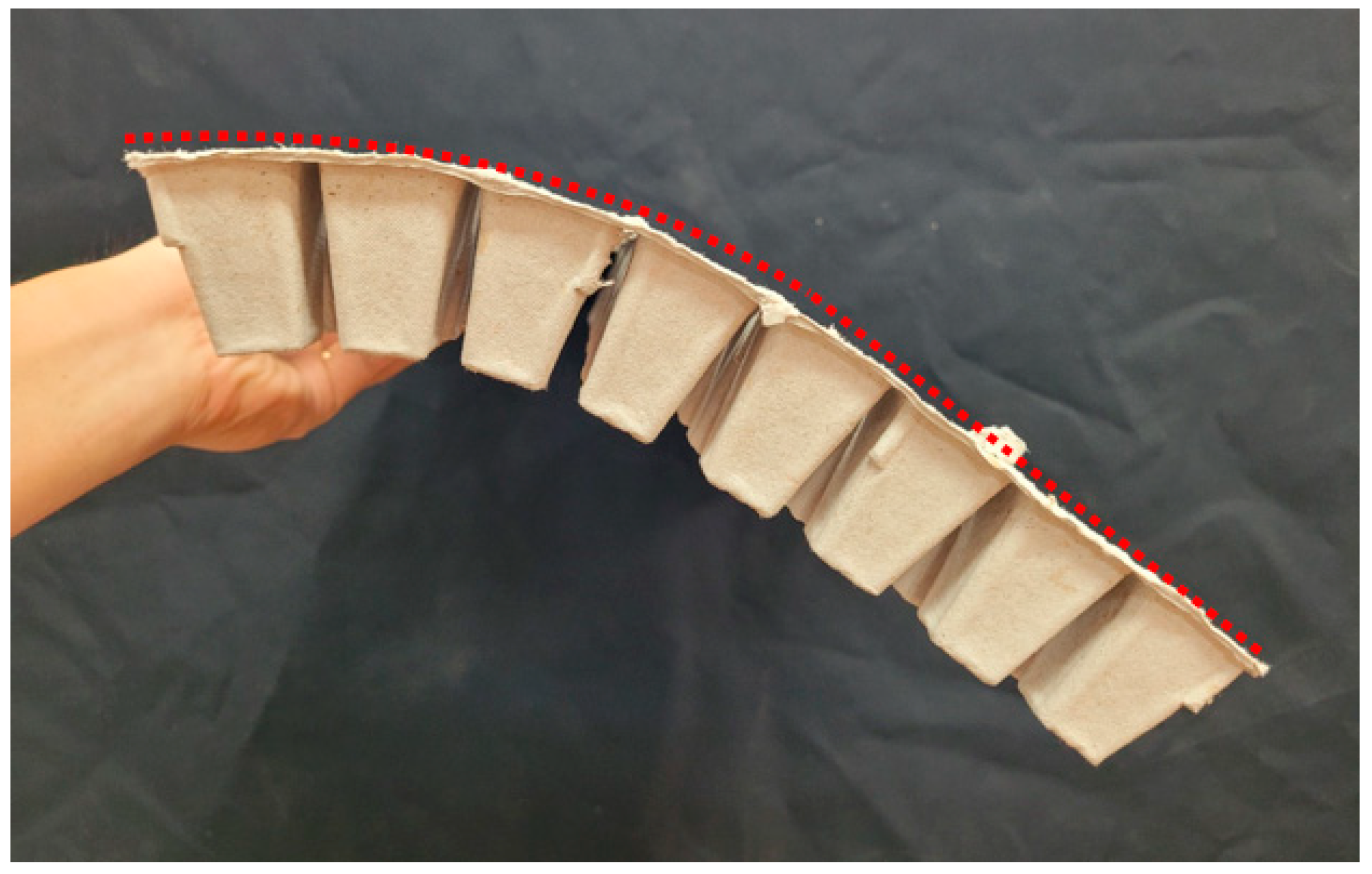

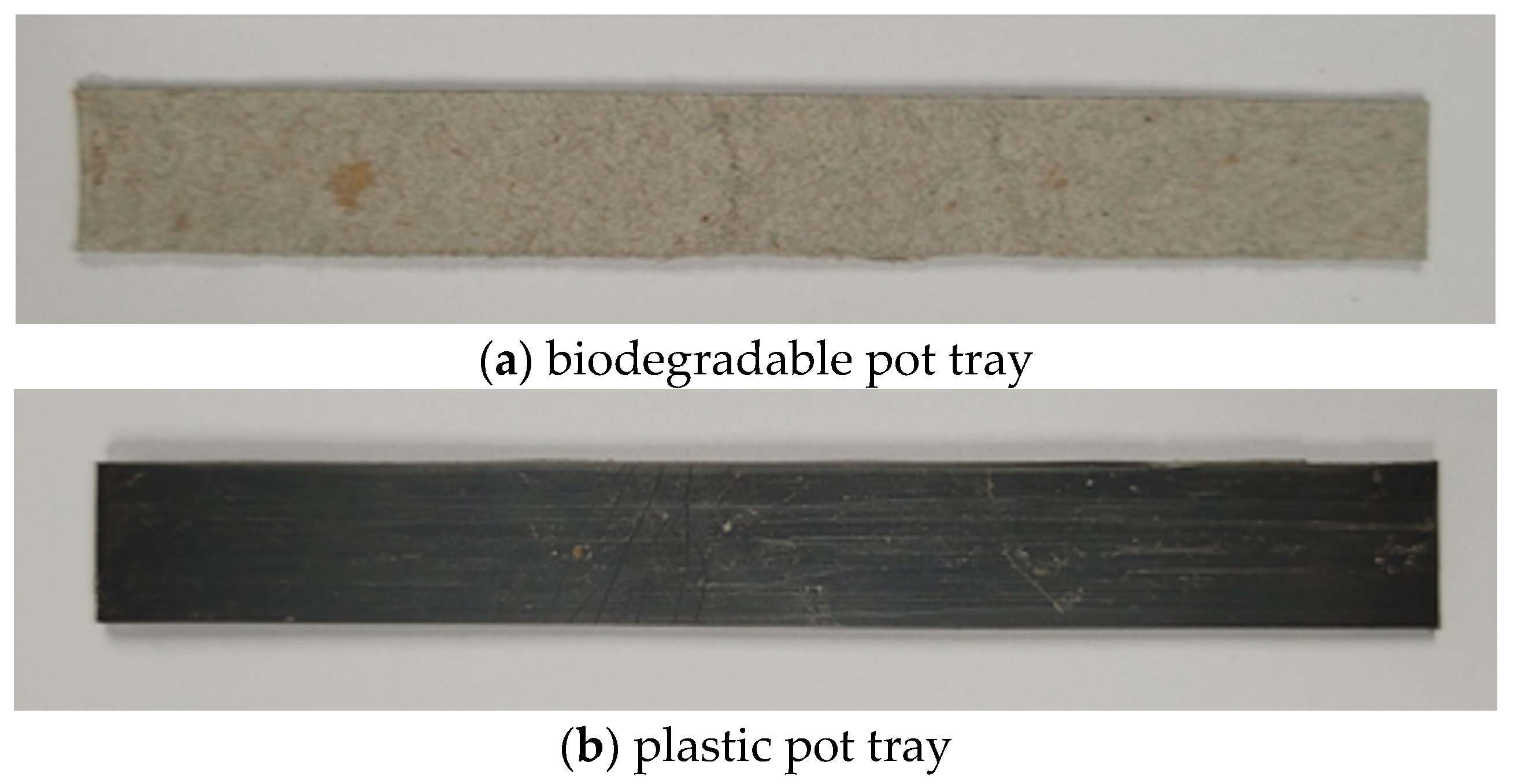

2.1. Biodegradable Pot Tray

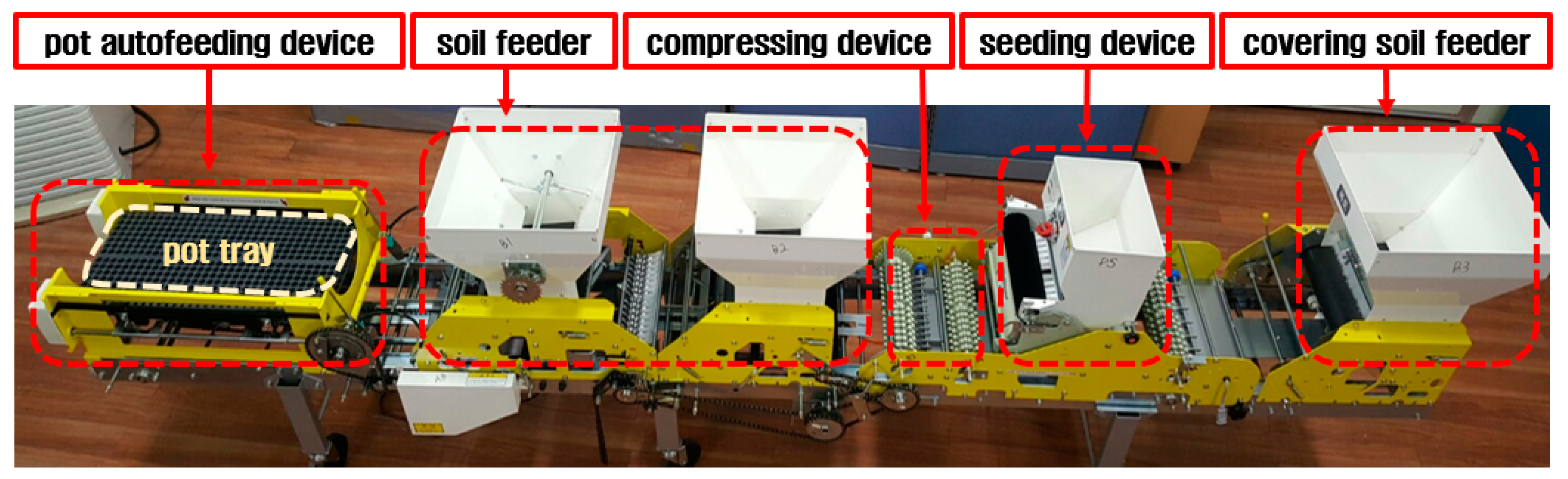

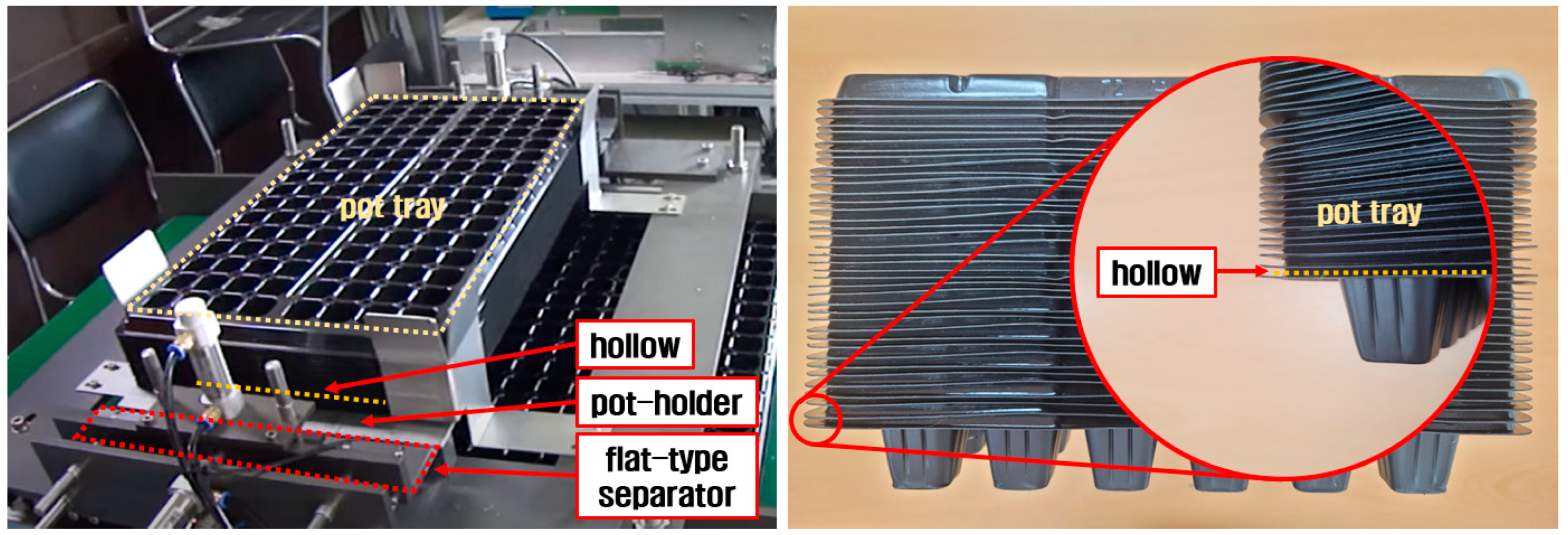

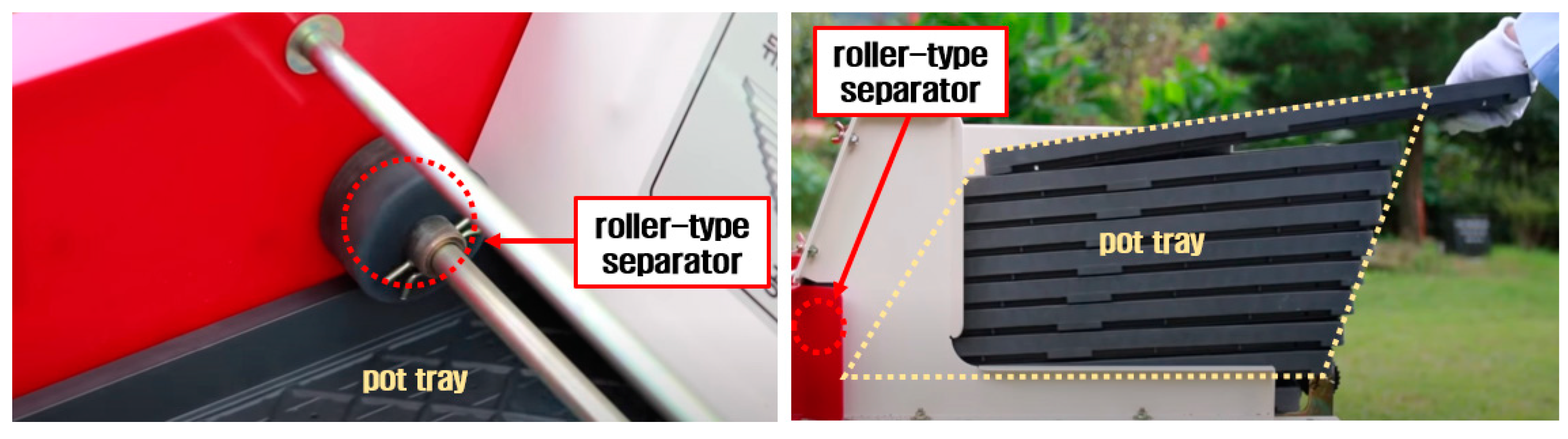

2.2. Characteristics of Current Pot Autofeeding Device

2.3. Requirements for Pot Autofeeding Device

- To minimize the manpower required in the pot tray separation process and improve work efficiency, the pot autofeeding device must be designed so that multi-stacked biodegradable pot trays can be automatically separated one by one and sent to the seeding process.

- The components of the pot autofeeding device must be designed considering the strength, dimensions, and geometry of biodegradable pot trays.

- The components of the pot autofeeding device must be designed to prevent the bending of the biodegradable pot tray during the pot tray extraction process for the smooth operation of the pot autofeeding device.

- The pot autofeeding device must be designed so that biodegradable pot trays cannot be deformed or destroyed by minimizing the load applied to the pot trays by the pot tray extraction mechanism.

2.4. Experimental Design

2.4.1. Tensile and Bending Strength

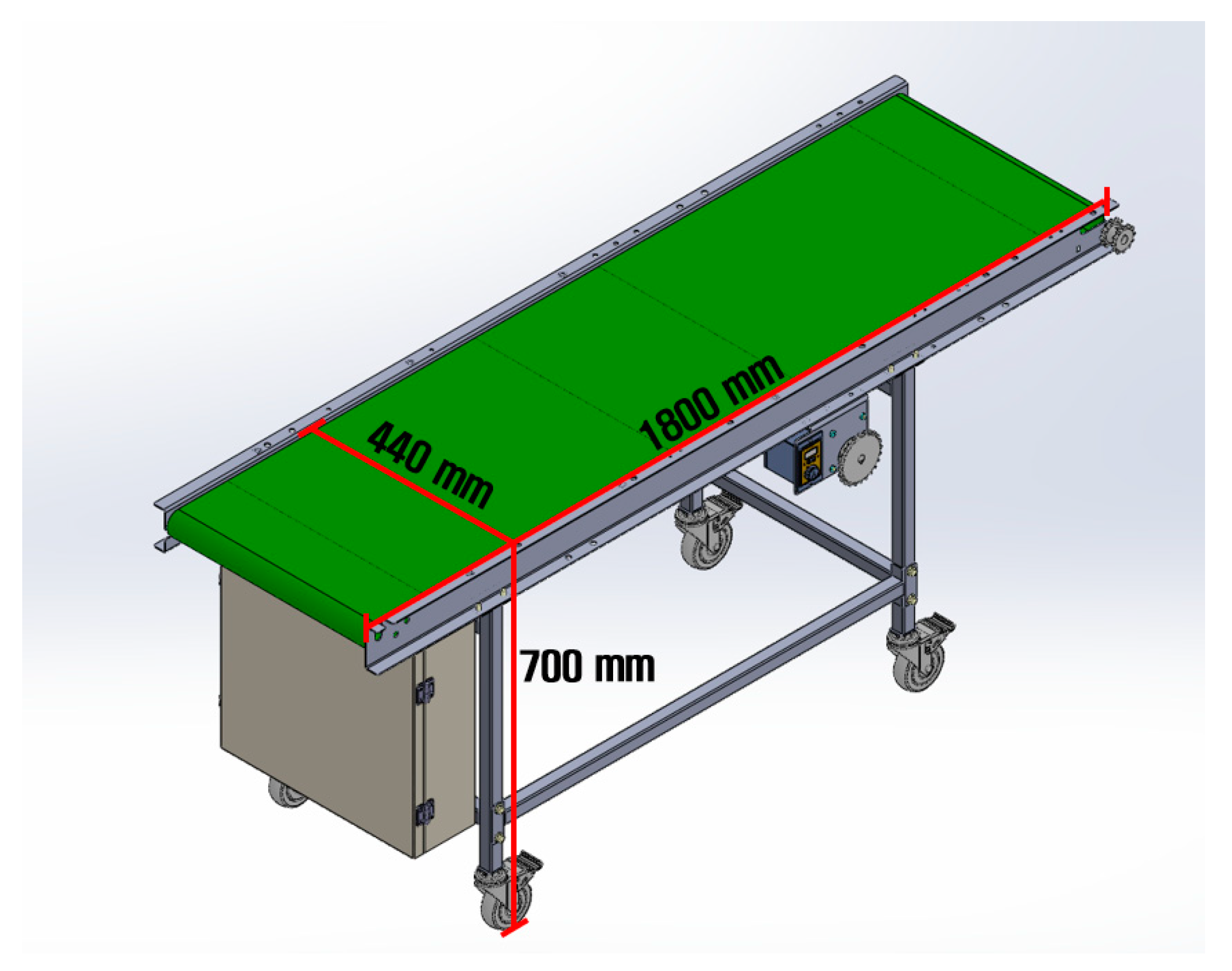

2.4.2. Performance Evaluation

3. Results and Discussion

3.1. Result of Experiment

3.2. Development of Pot Autofeeding Device

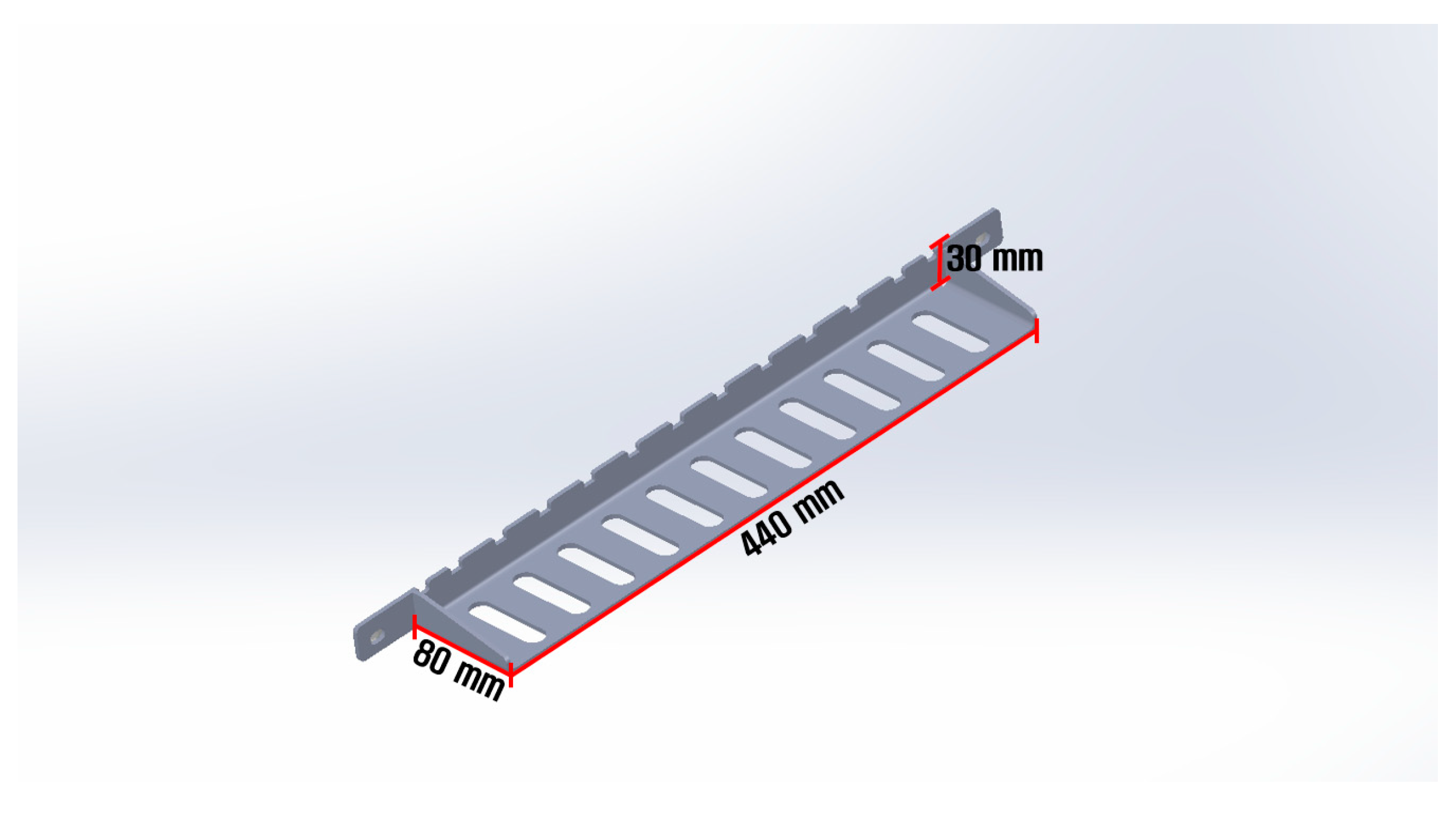

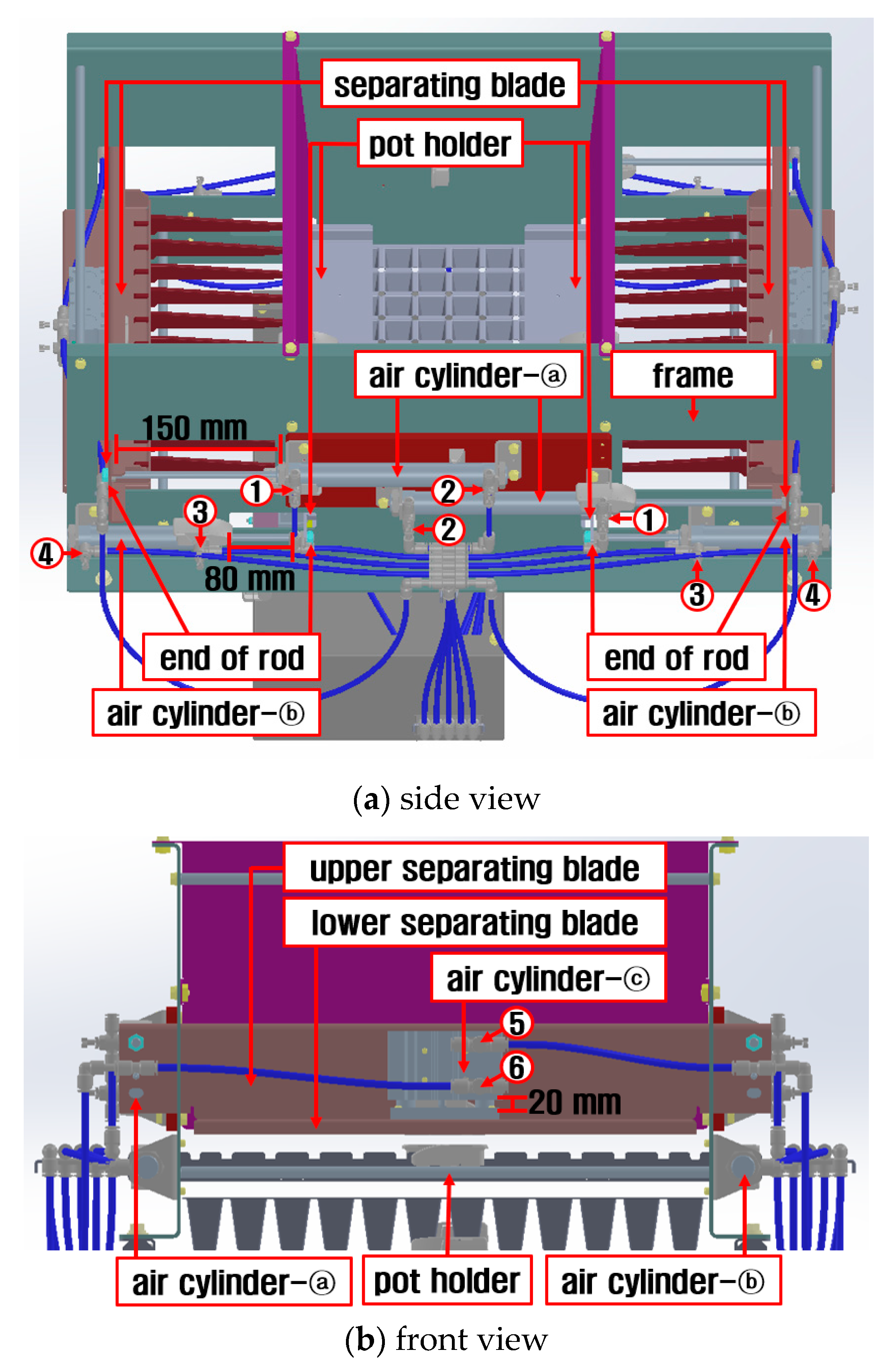

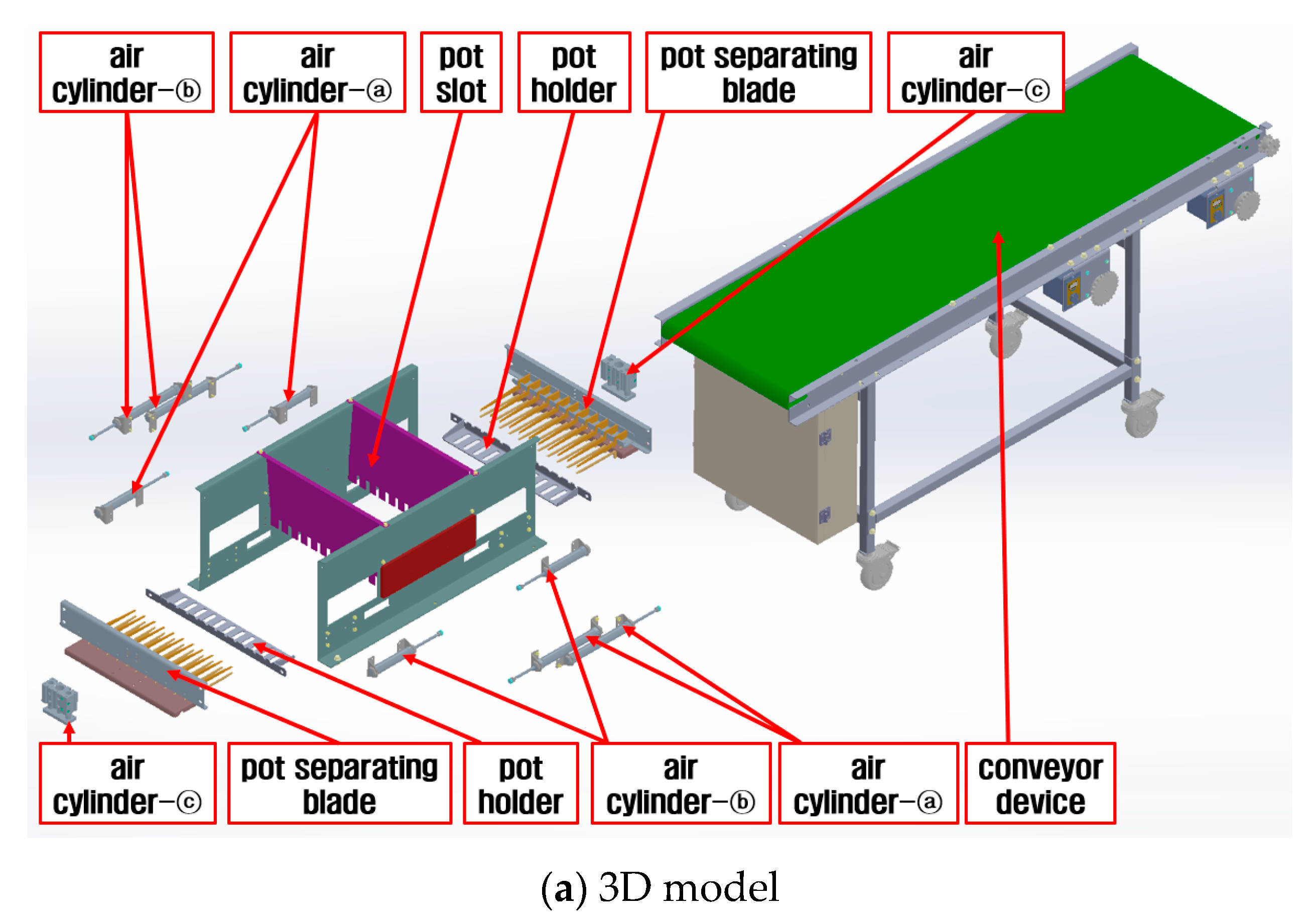

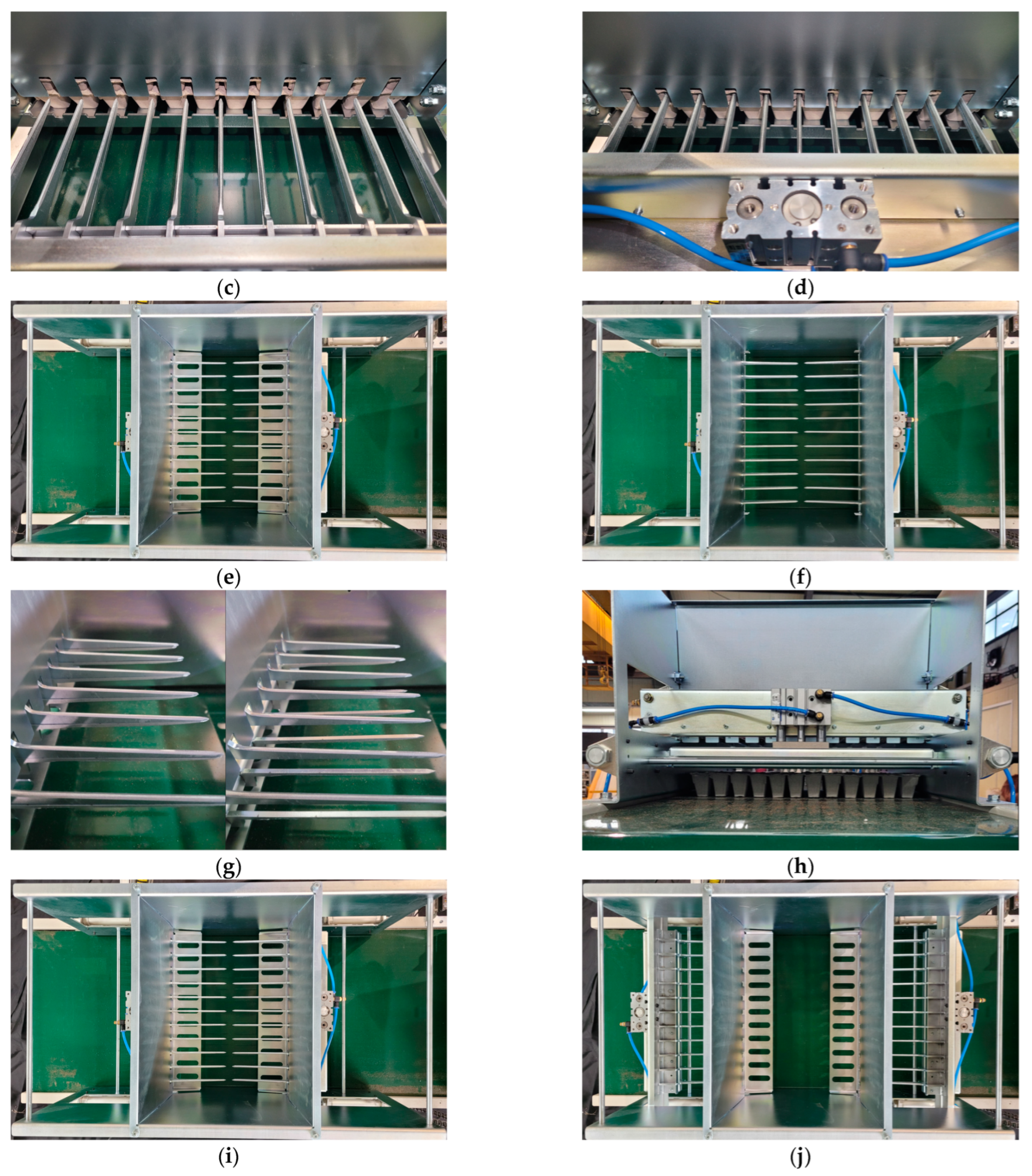

3.2.1. Design of Main Components

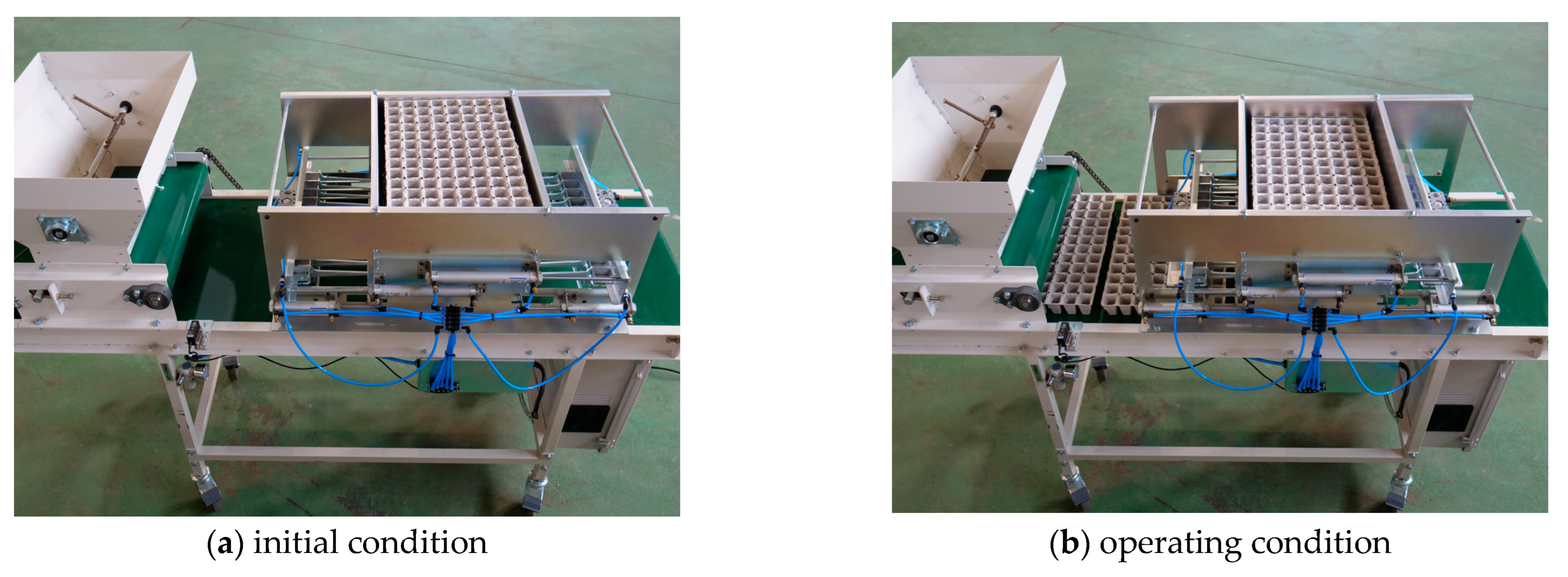

3.2.2. Operating Procedure of Developed Pot Autofeeding Device

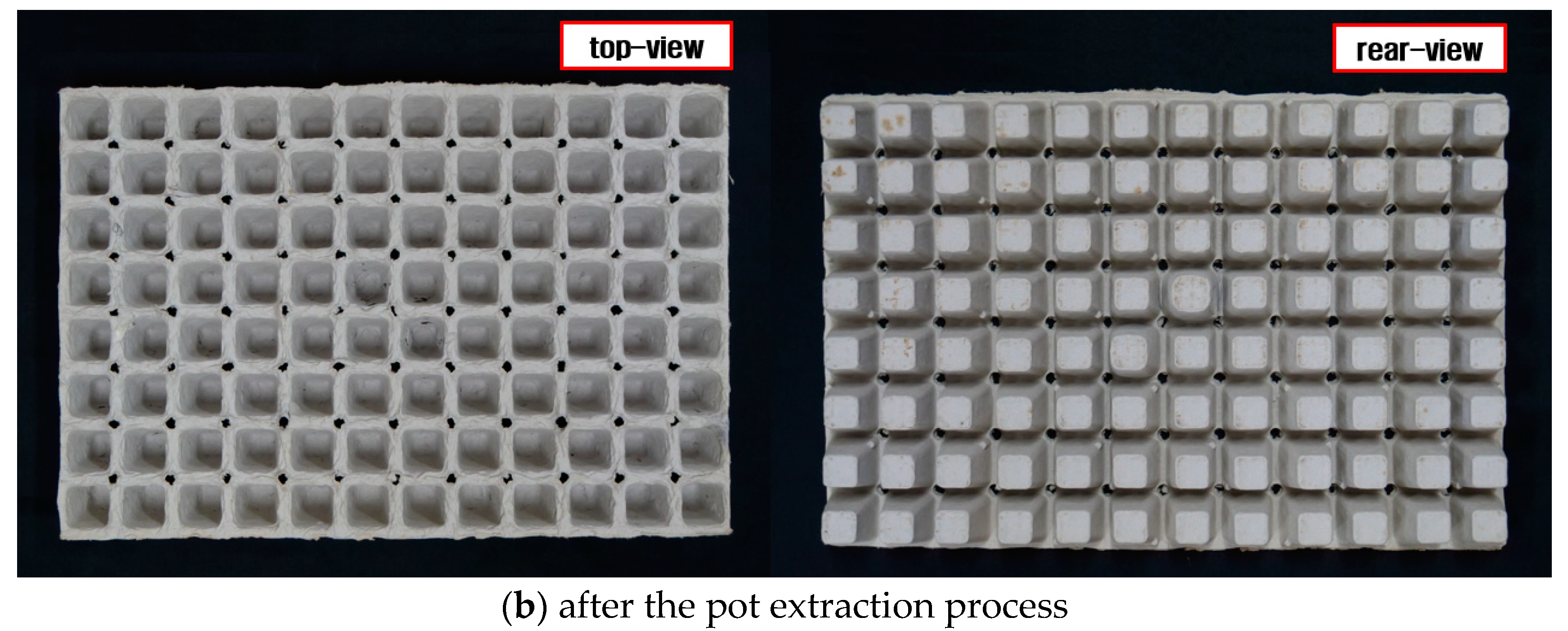

3.3. Result of Performance Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Korea Paper Association: Paper production by region. Available online: http://www.paper.or.kr/sub_5/5_1_3.php (accessed on 10 October 2022).

- Skinner, H.J. Waste problems in the pulp and paper industry. Ind. Eng. Chem. 1939, 31, 1331–1335. [Google Scholar] [CrossRef]

- Boni, M.R.; D’Aprile, L.; De Casa, G. Environmental quality of primary paper sludge. J. Hazard. Mater. 2004, 108, 125–128. [Google Scholar] [CrossRef]

- Lee, Y.H.; Jo, H.M.; Kim, S.H.; Lee, J.Y. Fundamental study of the production of paper ash made from paper sludge I: Evaluation of the characteristics of paper ash made from paper sludge in a specialty paper mill. J. Korea TAPPI 2020, 52, 113–119. [Google Scholar] [CrossRef]

- Ko, J.C.; Kim, S.H.; Park, Y.K.; Jeon, J.Y.; Kim, J.H.; Park, J.S. Pyrolysis characteristics of sludge discharged from paper mill process. J. Korra 2009, 17, 80–87. [Google Scholar]

- Song, D.B.; Lim, K.H.; Jung, D.H.; Yoon, J.H. Analysis of drying performance and cost of large-capacity sewage sludge dryer. J. Biosyst. Eng. 2021, 46, 105–111. [Google Scholar] [CrossRef]

- Takizawa, S.; Baba, Y.; Tada, C.; Fukuda, Y.; Nakai, Y. Pretreatment with rumen fluid improves methane production in the anaerobic digestion of paper sludge. Waste Manag. 2018, 78, 379–384. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Influence of industrial by-products and waste paper sludge ash on properties of recycled aggregate concrete. J. Clean. Prod. 2019, 214, 403–418. [Google Scholar] [CrossRef]

- Chen, M.; Zheng, Y.; Zhou, X.; Li, L.; Wang, S.; Zhao, P.; Lu, L.; Cheng, X. Recycling of paper sludge powder for achieving sustainable and energy-saving building materials. Constr. Build. Mater. 2019, 229, 116874. [Google Scholar] [CrossRef]

- Kang, I.K.; Oh, H.Y.; Han, D.Y.; Lim, Y.T.; Jang, M.M.; So, S.Y. An analysis of characteristics of asphalt concrete using paper sludge. Conf. AIK 2020, 40, 461. [Google Scholar]

- Schrader, J.A.; Srinivasan, G.; Grewell, D.; McCabe, K.G.; Graves, W.R. Fertilizer effects of soy-plastic containers during crop production and transplant establishment. Hortscience 2013, 48, 724–731. [Google Scholar] [CrossRef]

- Nandede, B.M.; Raheman, H.; Kumar, G.V.P. Standardization of potting mix and pot volume for the production of vegetable seedlings in paper pot. J. Plant Nutr. 2014, 37, 1214–1226. [Google Scholar] [CrossRef]

- Seo, T.C.; An, S.W.; Jang, H.W.; Nam, C.W.; Chun, H.; Kim, Y.C.; Kang, T.K.; Lee, S.H. An approach to determine the good seedling quality of grafted tomatoes (Solanum lycopersicum) grown in cylindrical paper pot through the relation analysis between DQI and short-term relative growth rate. J. Bio-Env. Control 2018, 27, 302–311. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, D.H.; Choi, G.M.; Kim, E.G.; Kim, T.H.; Kim, H.T. Analysis of plant guarding characteristics of biodegradable pot for transplant. Proc. Conf. Korean Soc. Agric. 2019, 24, 494–495. [Google Scholar]

- Lee, J.Y.; Kim, C.H.; Lee, G.S.; Jo, H.S.; Nam, H.G.; Park, H.H.; Moon, S.O. Physico-chemical characteristics of biodegradable seedling pots made of paper mill sludges. J. Korea TAPPI 2014, 46, 9–18. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, G.H.; Lee, H.M.; Madhavi, B.G.K.; Arulmozhi, E.; Bhujel, A.; Moon, B.E.; Kim, H.T. Physical properties and plant growth according to the content of additives in the biodegradable pot for mechanical transplanter. JALS 2022, 56, 129–134. [Google Scholar] [CrossRef]

- Park, H.S.; Son, K.Y.; Kang, J.R.; Seo, W.J.; Lee, S.J.; Lee, W.K. Study on properties of eco-friendly pot with biodegradable PLA/PBAT blend film. J. Environ. Sci. Int. 2015, 24, 1037–1043. [Google Scholar] [CrossRef] [Green Version]

- Jang, Y.N.; An, S.W.; Chun, H.; Lee, H.J.; Wi, S.H. The growth of cucumber seedlings grown in paper pot trays affected by nutrient management during seedling period, seedling age, and night temperature after transplanting. J. Bio-Env. Control 2019, 28, 396–403. [Google Scholar] [CrossRef]

- Seo, T.C.; An, S.W.; Kim, S.M.; Nam, C.W.; Chun, H.; Kim, Y.C.; Kang, T.K.; Kim, S.W.; Jang, K.S. Effect of the seedlings difference in cylindrical paper pot trays on initial root growth and yield of pepper. J. Bio-Env. Control 2017, 26, 368–377. [Google Scholar] [CrossRef]

- Nambu, T.; Tanimura, M. Development of automatic transplanter using chain pot for vegetable crops. Int. Symp. Transpl. Prod. Syst. 1992, 319, 541–546. [Google Scholar]

- Suggs, C.W.; Thomas, T.N.; Eddington, D.L.; Peel, H.B.; Seaboch, T.R.; Gore, J.W. Self feeding transplanter for tobacco and vegetable crops. Appl. Eng. Agric. 1987, 3, 148–152. [Google Scholar] [CrossRef]

- Kumar, G.V.P.; Raheman, H. Development of a walk-behind type hand tractor powered vegetable transplanter for paper pot seedlings. Biosyst. Eng. 2011, 110, 189–197. [Google Scholar] [CrossRef]

- Lee, M.H.; Moon, B.E.; Jo, J.M.; Choi, T.H.; Kim, H.T. Development of Automatic type transplanter for biodegradable seedling pot. Proc. Conf. Korean Soc. Agric. 2017, 22, 136. [Google Scholar]

- Jun, H.J.; Yu, S.H.; Choi, I.S.; Kim, J.G.; Lee, S.H.; Kang, T.G.; Kim, Y.K.; Choi, Y. Study on compatibility between plug tray sowing, seedlings and transplanters for planting mechanization of sesame. Proc. Conf. Korean Soc. Agric. 2018, 23, 155. [Google Scholar]

- Choudhary, V.; Machavaram, R. Need of automation in paddy nurseries for raising paddy seedlings in India: A Review. J. Biosyst. Eng. 2022, 47, 209–222. [Google Scholar] [CrossRef]

- Hwang, S.J.; Lee, J.Y.; Nam, J.S. Irrigation System for a Roller-Type Onion Pot Seeding Machine. Appl. Sci. 2019, 9, 430. [Google Scholar] [CrossRef] [Green Version]

- Hwang, S.J.; Nam, J.S. Development of automatic accumulating equipment for roller-type onion pot-seeding machine. Appl. Sci. 2019, 9, 2139. [Google Scholar] [CrossRef]

- Juvinall, R.C.; Marshek, K.M. Machine Component Design, 5th ed.; WILEY (John Wiley & Sons): Hoboken, NJ, USA, 2015; pp. 338–340. [Google Scholar]

- Malik, G.K.; Khuntia, A.; Mitra, J. Comparative effect of different plasticizers on barrier, mechanical, optical, and sorption properties of hydroxypropyl methylcellulose (HPMC)–based edible film. J. Biosyst. Eng. 2022, 47, 93–105. [Google Scholar] [CrossRef]

- Sim, J.H.; Lee, J.B.; Hwang, S.S. Effect of glazing on the flexural strength of lithium disilicate glass ceramics. Korean J. Dent. Mater. 2019, 46, 185–194. [Google Scholar] [CrossRef]

| Items | Ingredients of Biodegradable Pot Tray | ||

|---|---|---|---|

| Paper Sludge | Strength Agent | Sizing Agent | |

| Component ratio | 90.90% | 4.55% | 4.55% |

| Items | Specifications |

|---|---|

| Model/Company/Nation | AGS-50kNX/Scientific/Japan |

| Max. Load Capacity (kN) | 50 |

| Crosshead Speed Accuracy | 0.1 |

| Speed Range (mm/min) | 0.001 to 1600 |

| Max. Return Speed (mm/min) | 2200 |

| Items | Tensile Strength (N/mm2) | |

|---|---|---|

| Plastic Pot Tray | Biodegradable Pot Tray | |

| 1st Specimen | 12.91 | 0.69 |

| 2nd Specimen | 13.57 | 0.74 |

| 3rd Specimen | 11.49 | 0.66 |

| Average | 12.66 | 0.70 |

| Standard deviation | 0.87 | 0.03 |

| Items | Bending Strength (N/mm2) | |

|---|---|---|

| Plastic Pot Tray | Biodegradable Pot Tray | |

| 1st Specimen | 22.62 | 3.61 |

| 2nd Specimen | 22.20 | 4.65 |

| 3rd Specimen | 21.95 | 3.41 |

| Average | 22.26 | 3.89 |

| Standard deviation | 0.28 | 0.54 |

| Items | Specifications | |||

|---|---|---|---|---|

| Model/Company/Nation | ACS4-N LB20-S150 /KCC company/South Korea | ACS4-N LB20-S80 /KCC company/South Korea | ANGM 25-S20 /KCC company/South Korea | |

| Fluid type used | Air | Air | Air | |

| Pressure (MPa) | Max. | 1.0 | 1.0 | 1.0 |

| Min. | 0.05 | 0.05 | 0.12 | |

| Piston speed (mm/s) | Max. | 1000 | 1000 | 500 |

| Min. | 750 | 750 | 50 | |

| Stroke (mm) | 150 | 80 | 20 | |

| Inner diameter of rod (mm) | 20 | 20 | 20 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, S.-J.; Jang, M.-K.; Nam, J.-S. Development of Autofeeding Device Applicable to a Biodegradable Pot Tray. Agriculture 2022, 12, 2097. https://doi.org/10.3390/agriculture12122097

Hwang S-J, Jang M-K, Nam J-S. Development of Autofeeding Device Applicable to a Biodegradable Pot Tray. Agriculture. 2022; 12(12):2097. https://doi.org/10.3390/agriculture12122097

Chicago/Turabian StyleHwang, Seok-Joon, Moon-Kyeong Jang, and Ju-Seok Nam. 2022. "Development of Autofeeding Device Applicable to a Biodegradable Pot Tray" Agriculture 12, no. 12: 2097. https://doi.org/10.3390/agriculture12122097

APA StyleHwang, S.-J., Jang, M.-K., & Nam, J.-S. (2022). Development of Autofeeding Device Applicable to a Biodegradable Pot Tray. Agriculture, 12(12), 2097. https://doi.org/10.3390/agriculture12122097