Research on Characteristics of Airway Pressure Loss in Seeding-Wheel-Type Pneumatic Seeder

Abstract

:1. Introduction

2. Structure and Fluid Analysis

2.1. The Structure and Working Principle of Seeding-Wheel-Type Pneumatic Seeder

2.2. Fluid Domain Modeling

2.3. Analysis of Pressure Loss in Airway

2.3.1. Aerodynamic Analysis of Variable-Section Panhandle Area

2.3.2. Aerodynamic Analysis of Variable Diameter Transition

2.3.3. Aerodynamic Analysis of Long and Narrow Air Pipe

- Scheme 1.

- The diameter of airway section II is equal to the diameter of section I, that is, the diameter of airway section II is 10 mm, so there is only one instance of local pressure loss in this area, but the pressure loss along the path is higher.

- Scheme 2.

- The diameter of the airway section II is unequal to that of section I, so this will result in twice the local pressure loss. However, due to the larger diameter of the airway section II, the pressure loss along the path will be lower.

- Scheme 3.

- The optimal value can be found between Scheme 1 and Scheme 2. However, based on theoretical analysis alone, it is impossible to determine which scheme is better, and numerical analysis and experimental methods are still needed for research.

2.3.4. Aerodynamic Analysis of Bending Area of Air Pipe

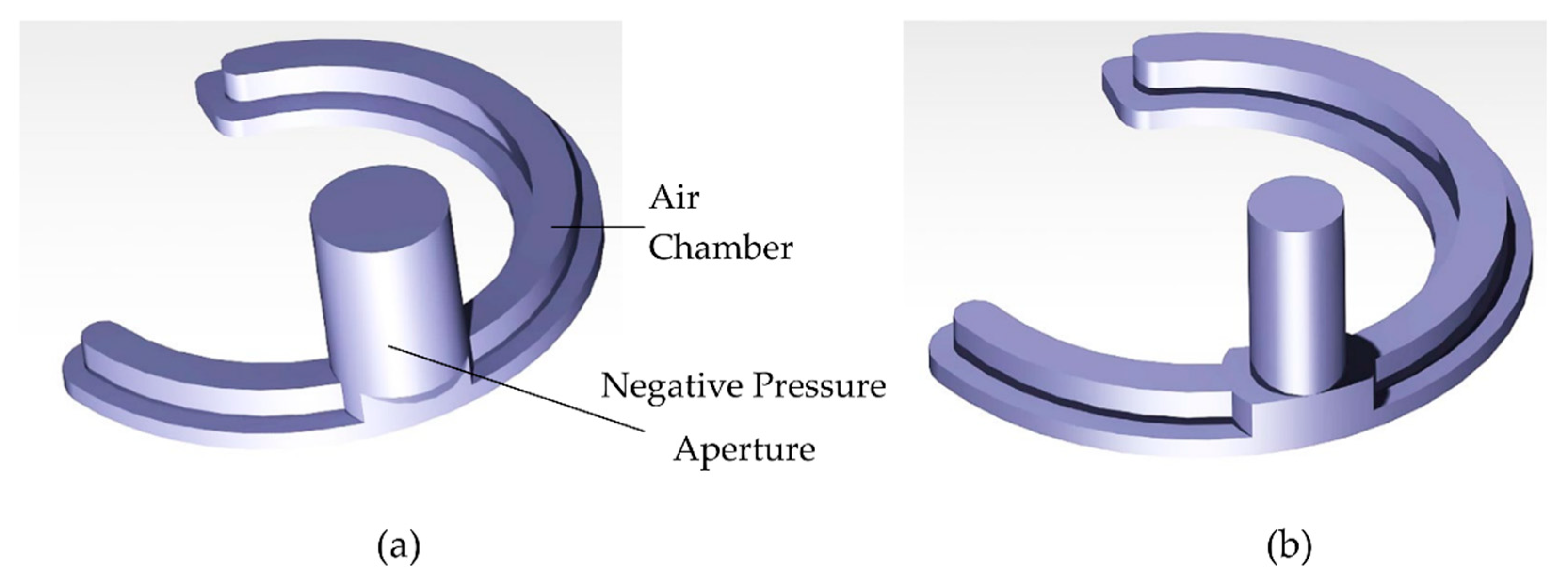

2.3.5. Aerodynamic Analysis of Air Chamber Confluence Area

2.3.6. Aerodynamic Analysis of Connection Area of Negative Pressure Aperture and Air Chamber

3. Simulation Analysis

3.1. Flow Field Static Simulation Analysis of Seeding Device

3.2. Analysis of Simulation Results

3.2.1. Analysis of Variance and Range

3.2.2. Analysis of Airflow Velocity Difference of Various Seed-Sucking Holes

3.2.3. Airflow Trajectory Analysis

3.3. Study on Negative Pressure Characteristics of Locally Connected Seed-Sucking Holes

4. Prototype Test Verification

4.1. Prototyping and Testing Methods

4.2. Results and Analysis

5. Conclusions

- A functional model of pressure loss in variable-section panhandle areas, the bending area of the air pipe, air chamber confluence area, and connection area of the negative pressure aperture and air chamber were established and it was concluded that the airway structural factors that may have a significant influence on the pressure loss are the diameter of the horizontal air pipe, the angle of the air pipe, and the diameter of the negative pressure aperture.

- It was concluded that the optimal parameter combination was as follows: the diameter of the horizontal air pipe was 15 mm, the angle of the air pipe was 105°, and the diameter of the negative pressure aperture was 34 mm. Under these parameters, the average airflow velocity of the seed-sucking hole was 102.59, the minimum airflow velocity of the seed-sucking hole was 101.58, and the airflow velocity standard deviation of the seed-sucking hole was 0.54. The position of the seed-sucking hole has no significant influence on its airflow velocity.

- A dynamic simulation test was carried out and it was concluded that there is a sharp decline when the opening angle of the air-passing aperture is 1.326°. In addition, it triggers the casting action of seeds when the opening angle of the air-passing aperture is 0.929°.

- Compared with the simulation results, the tested measurement results are generally lower, but the difference is not significant, which proves that the position of the seed-sucking holes has little influence on the airflow velocity, and the overall pneumatic distribution is uniform.

- This paper mainly explores the distribution law of the internal flow field when the seed-sucking hole is open, and the interaction between the flow field and the seeds can be further explored by CFD-DEM coupling technology in the future, which will help us to study the mechanism and effect of the flow field on seeds more accurately.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dowlati, M.; Namjoo, M. Development and Evaluation of a Pneumatic Dibble Punch Planter for Precision Planting. AMA Agric. Mech. Asia Afr. 2016, 47, 53–59. [Google Scholar]

- Kroulík, M.; Hula, J.; Rybka, A.; Honzík, I. Seed passage speed through short vertical delivery tubes at precise seeding. Agron. Res. 2016, 14, 442–449. [Google Scholar]

- Soza, E.L.; Agnes, D.W.; Agostinelli, F. Variability of wheat seeds distribution by one seeder on three tillage systems, impact in the establish and growth crop. Rev. Fac. Agron. 2010, 30, 123–132. [Google Scholar]

- Liu, J.; Wang, Q.; Li, H.; He, J.; Lu, C.; Wang, C. Numerical Analysis and Experiment on Pneumatic Loss Characteristic of Pinhole-Tube Wheat Uniform Seeding Mechanism. Trans. Chin. Soc. Agric. Mach. 2020, 51, 29–37. [Google Scholar]

- Tu, J.; Yeoh, G.; Liu, C.; Wang, X. Computational Fluid Dynamics, 2nd ed.; Northeastern University Press: Shenyang, China, 2014; pp. 1–17. [Google Scholar]

- John, D.; Anderson, J.R. Introduction to Computational Fluid Dynamics, 1st ed.; Tsinghua University Press: Beijing, China, 2010; pp. 1–28. [Google Scholar]

- Ben Amara, H.; Bouadila, S.; Fatnassi, H.; Arici, M.; Allah Guizani, A. Climate assessment of greenhouse equipped with south-oriented PV roofs: An experimental and computational fluid dynamics study. Sustain. Energy Technol. Assess. 2021, 45, 100–101. [Google Scholar] [CrossRef]

- Panigrahi, S.S.; Singh, C.B.; Fielke, J. Strategies to mitigate dead-zones in on-farm stored grain silos fitted with aeration ducting modelled using computational fluid dynamics. Biosyst. Eng. 2021, 205, 93–104. [Google Scholar] [CrossRef]

- Yazgi, A.; Degirmencioglu, A. Optimisation of the seed spacing uniformity performance of a vacuum-type precision seeder using response surface methodology. Biosyst. Eng. 2007, 97, 347–356. [Google Scholar] [CrossRef]

- Yazgi, A.; Degirmencioglu, A. Measurement of seed spacing uniformity performance of a precision metering unit as function of the number of holes on vacuum plate. Measurement 2014, 56, 128–135. [Google Scholar] [CrossRef]

- Ghafori, H.; Hemmat, A.; Borghaee, A.M.; Minaei, S. Physical properties and conveying characteristics of corn and barley seeds using a suction-type pneumatic conveying system. Afr. J. Agric. Res. 2011, 6, 5972–5977. [Google Scholar] [CrossRef]

- Yang, S. Study on Maize Seed-Metering Mechanism of Side Positive Pressure and Gas Supply System. Ph.D. Thesis, China Agricultural University, Beijing, China, 28 May 2015. [Google Scholar]

- Yang, S.; Zhang, D.; Diao, P.; Guo, Z.; Song, J.; Zhang, X. Design and experiment of side positive pressure seed metering device. Trans. Chin. Soc. Agric. Eng. 2015, 31, 8–13. [Google Scholar]

- Yang, S.; Zhang, D.; Gao, Z.; Liu, X. Flow Field Simulation and Working Parameters Analysis of Side Positive Pressure Maize Seeding Device. Trans. Chin. Soc. Agric. Mach. 2014, 45, 35–39. [Google Scholar]

- Zhan, Z.; Li, Y.; Chen, J.; Xu, L. Numerical analysis and laboratory testing of seed spacing uniformity performance for vacuum-cylinder preci-sion seeder. Biosyst. Eng. 2010, 106, 344–351. [Google Scholar] [CrossRef]

- Zhan, Z.; Li, Y.; Chen, J.; Han, Z. Dynamic analysis on seeds pick-up process for vacuum-cylinder seeder. Trans. Chin. Soc. Agric. Eng. 2011, 27, 112–116. [Google Scholar]

- Zhan, Z.; Li, Y. Numerical Analysis on the Inner Flow Field of Vacuum-cylinder Precision Seeder. In Proceedings of the 2010 International Conference on Agricultural Engineering, Shanghai, China, 18 November 2010. [Google Scholar]

- Lei, X.L.; Liao, Y.T.; Zhang, Q.S.; Wang, L.; Liao, Q.X. Numerical simulation of seed motion characteristics of distribution head for rapeseed and wheat. Comput. Electron. Agr. 2018, 150, 98–109. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Liao, Q. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat. Comput. Electron. Agric. 2016, 131, 29–39. [Google Scholar] [CrossRef]

- Shi, S.; Liu, H.; Wei, G.; Zhou, J.; Jian, S.; Zhang, R. Optimization and Experiment of Pneumatic Seed Metering Device with Guided Assistant Filling Based on EDEM-CFD. Trans. Chin. Soc. Agric. Mach. 2020, 51, 54–66. [Google Scholar]

- Liu, J.; Wang, Q.; Li, H.; He, J.; Lu, C. Design and seed suction performance of pinhole-tube wheat precision seeding device. Trans. Chin. Soc. Agric. Eng. 2019, 35, 10–18. [Google Scholar]

- Logachev, K.I.; Ziganshin, A.M.; Popov, E.N.; Averkova, O.A.; Kryukova, O.S.; Gol’Tsov, A.B. Experiment determining pressure loss reduction using a shaped round exhaust hood. Build. Environ. 2021, 190, 107572. [Google Scholar] [CrossRef]

- Borzenko, E.I.; Ryl’Tsev, I.A.; Schrager, G.R. Pressure Losses in Power-Law Fluid Flow through a Tube of Variable Cross-Section. Fluid Dynam. 2021, 56, 1–9. [Google Scholar] [CrossRef]

- Mo, S.; Zuo, C.; Jia, F. Calculation of Local Pressure Loss Coefficient for Flow Distribution Baffle and Cross Flow in Steam Generator. At. Energy Sci. Technol. 2015, 49, 1039–1044. [Google Scholar]

- Bernardi, C.; Dib, S.; Girault, V.; Hecht, F.; Murat, F.; Sayah, T. Finite element methods for Darcy’s problem coupled with the heat equation. Numer. Math. 2018, 139, 315–348. [Google Scholar] [CrossRef]

- Que, X.; Su, L.; Yang, W.; Hu, C. Research on influencing factors of fire hose’s pressure loss and its calculation method. J. Univ. Shanghai Sci. 2006, 28, 561–565. [Google Scholar]

- Li, Z.; Wang, D.; Liu, G.; Yang, M.; Wang, Z. Experimental study on sowing seeds by air-stream metering mechanism. Trans. Chin. Soc. Agric. Eng. 2009, 25, 89–93. [Google Scholar]

- Zinurov, V.E.; Dmitriev, A.V.; Badretdinova, G.R.; Galimova, A.R.; Dmitrieva, O.S. Analysis of various mathematical models of turbulence when calculating the gas dynamics in a classifier with coaxially arranged pipes. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1089, 012002. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, K.; Guo, X.; Li, J.; Fu, H. Quick evaluation of the pipeline equivalent sand-grain roughness based on the surface roughness parameters. J. Hydraul. Eng. 2018, 49, 178–185. [Google Scholar]

- Uralov, B.; Choriev, R.; Maksudova, L.; Sapaeva, M.; Shernaev, A.; Nurmatov, P. Substantiation of the influence of the channel shape and the roughness of machine canals on the pressure loss of irrigation pumping stations. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1030, 12148. [Google Scholar] [CrossRef]

- Han, Z.; Wang, G. Fundamentals of Engineering Fluid Dynamics, 2nd ed.; Beijing Institute of Technology Press: Beijing, China, 2016; pp. 71–97. [Google Scholar]

- Mao, Z.; Zhao, K.; Zhao, X.; Luo, S. Experimental study on local flow resistance at junctions of circular pipes. J. Hydraul. Eng. 2007, 38, 812–818. [Google Scholar]

- Shen, Y.; Wang, J.; Cao, K. Loss property analysis of throttle with large aperture. J. Air Force Eng. Univ. 2001, 2, 10–12. [Google Scholar]

- Salikov, V.; Antonyuk, S.; Heinrich, S.; Sutkar, V.S.; Deen, N.G.; Kuipers, J.A.M. Characterization and CFD-DEM modelling of a prismatic spouted bed. Powder Technol. 2015, 270, 622–636. [Google Scholar] [CrossRef] [Green Version]

- Tao, Z.; Xiao-jun, Z.; Fei, P.; Shao-song, M. Analysis of effect of near-wall treatments on numerical computation of turbulent flow. J. Nav. Univ. Eng. 2013, 25, 104–108. [Google Scholar]

- Kun, H.; Tingting, H.; Haifeng, M. ANSYS CFD Introductory Guide Fundamentals and Applications of Computational Fluid Dynamics, 1st ed.; China Machine PRESS: Beijing, China, 2019; pp. 47–58. [Google Scholar]

- Richard, W.; Richard, M.L. Analysis of variance in soil research: Examining the assumptions. Eur. J. Soil. Sci. 2019, 70, 990–1000. [Google Scholar]

- Guarella, P.; Pellerano, A.; Pascuzzi, S. Experimental and Theoretical Performance of a Vacuum Seeder Nozzle for Vegetable Seeds. J. Agric. Eng. Res. 1996, 64, 29–36. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Liu, H.; Wu, G. Mathematical modeling and validation of seeder’s suction-boundary on pneumatic-roller type metering. Trans. Chin. Soc. Agric. Eng. 2016, 32, 12–20. [Google Scholar]

- Liu, F. Discrete Element Modelling of the Wheat Particles and Short Straw in Cleaning Devices. Ph.D. Thesis, Northwest A&F University, Xi’an, China, 5 June 2018. [Google Scholar]

- Shi, S.; Zhang, D.; Yang, L.; Cui, T.; Zhang, R.; Yin, X. Design and experiment of pneumatic maize precision seed-metering device with combined holes. Trans. Chin. Soc. Agric. Eng. 2014, 30, 10–18. [Google Scholar]

| Level | Factor | ||

|---|---|---|---|

| A Diameter of Horizontal Air Pipe | B Angle of Air Pipe | C Diameter of Negative Pressure Aperture | |

| 1 | 10 | 90 | 21.5 |

| 2 | 15 | 105 | 27.75 |

| 3 | 20 | 120 | 34 |

| Number | Factor | Average Airflow Velocity of Seed-Sucking Hole /(m·s−1) | Minimum Airflow Velocity of Seed-Sucking Hole /(m·s−1) | Airflow Velocity Standard Deviation of Seed-Sucking Hole /(m·s−1) | ||

|---|---|---|---|---|---|---|

| A | B | C | ||||

| 1 | 1 | 1 | 1 | 101.46 | 99.66 | 0.86 |

| 2 | 1 | 2 | 2 | 102.42 | 101.17 | 0.68 |

| 3 | 1 | 3 | 3 | 102.31 | 101.05 | 0.89 |

| 4 | 2 | 1 | 2 | 102.02 | 100.39 | 0.78 |

| 5 | 2 | 2 | 3 | 102.59 | 101.58 | 0.54 |

| 6 | 2 | 3 | 1 | 101.62 | 100.29 | 0.73 |

| 7 | 3 | 1 | 3 | 102.12 | 100.45 | 0.72 |

| 8 | 3 | 2 | 1 | 101.75 | 100.78 | 0.67 |

| 9 | 3 | 3 | 2 | 102.02 | 100.99 | 0.77 |

| Items | Average Airflow Velocity of Seed-Sucking Hole /(m·s−1) | Minimum Airflow Velocity of Seed-Sucking Hole /(m·s−1) | Airflow Velocity Standard Deviation of Seed-Sucking Hole /(m·s−1) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | |

| K1 | 102.06 | 101.87 | 101.61 | 100.63 | 100.17 | 100.24 | 0.81 | 0.79 | 0.75 |

| K2 | 102.08 | 102.25 | 102.15 | 100.75 | 101.18 | 100.85 | 0.68 | 0.63 | 0.74 |

| K3 | 101.96 | 101.87 | 102.34 | 100.74 | 100.78 | 101.03 | 0.72 | 0.80 | 0.72 |

| R | 0.12 | 0.38 | 0.73 | 0.12 | 1.01 | 0.79 | 0.13 | 0.17 | 0.03 |

| Optimal level combination | A2B2C3 | A2B2C3 | A2B2C3 | ||||||

| Source of Difference | SS | df | MS | F | Significance | |

|---|---|---|---|---|---|---|

| Average airflow velocity of seed-sucking hole | A | 0.02 | 2 | 0.01 | 11.75 | |

| B | 0.23 | 2 | 0.17 | 118.91 | ** | |

| C | 0.87 | 2 | 0.43 | 442.65 | ** | |

| Error | 0.00 | 2 | 0.00 | |||

| Sum | 1.13 | 8 | ||||

| Minimum airflow velocity of seed-sucking hole | A | 0.03 | 2 | 0.01 | 1.37 | |

| B | 1.55 | 2 | 0.78 | 72.45 | * | |

| C | 1.01 | 2 | 0.5 | 47.05 | * | |

| Error | 0.02 | 2 | 0.01 | |||

| Sum | 2.61 | 8 | ||||

| Airflow velocity standard deviation of seed-sucking hole | A | 0.03 | 2 | 0.01 | 2.9 | |

| B | 0.05 | 2 | 0.03 | 5.87 | ||

| C | 0.00 | 2 | 0.00 | 0.28 | ||

| Error | 0.01 | 2 | 0.00 | |||

| Sum | 0.09 | 8 | ||||

| Group | Simulation Time (s) | Opening Angle of Air-Passing Aperture (°) | Negative Pressure of Seed-Sucking Hole (Pa) |

|---|---|---|---|

| 41 | 0.12 | 2.518 | −6101.03 |

| 42 | 0.123 | 2.121 | −5974.7 |

| 43 | 0.126 | 1.723 | −5768.42 |

| 44 | 0.129 | 1.326 | −5179.11 |

| 45 | 0.132 | 0.929 | −3831.63 |

| 46 | 0.135 | 0.532 | −1072.76 |

| 47 | 0.138 | 0.135 | −5.13 |

| 48 | 0.141 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Wen, Z.; Wang, Q.; Li, H.; Zhang, Z.; Liu, J. Research on Characteristics of Airway Pressure Loss in Seeding-Wheel-Type Pneumatic Seeder. Agriculture 2022, 12, 2021. https://doi.org/10.3390/agriculture12122021

Zhang X, Wen Z, Wang Q, Li H, Zhang Z, Liu J. Research on Characteristics of Airway Pressure Loss in Seeding-Wheel-Type Pneumatic Seeder. Agriculture. 2022; 12(12):2021. https://doi.org/10.3390/agriculture12122021

Chicago/Turabian StyleZhang, Xirui, Zhentuo Wen, Qingjie Wang, Hongwen Li, Zhifu Zhang, and Junxiao Liu. 2022. "Research on Characteristics of Airway Pressure Loss in Seeding-Wheel-Type Pneumatic Seeder" Agriculture 12, no. 12: 2021. https://doi.org/10.3390/agriculture12122021

APA StyleZhang, X., Wen, Z., Wang, Q., Li, H., Zhang, Z., & Liu, J. (2022). Research on Characteristics of Airway Pressure Loss in Seeding-Wheel-Type Pneumatic Seeder. Agriculture, 12(12), 2021. https://doi.org/10.3390/agriculture12122021