Performance Evaluation of Liquorice Harvester with Novel Oscillating Shovel-Rod Components Using the Discrete Element Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Liquorice Harvester with Oscillating Shovel-Rod Components

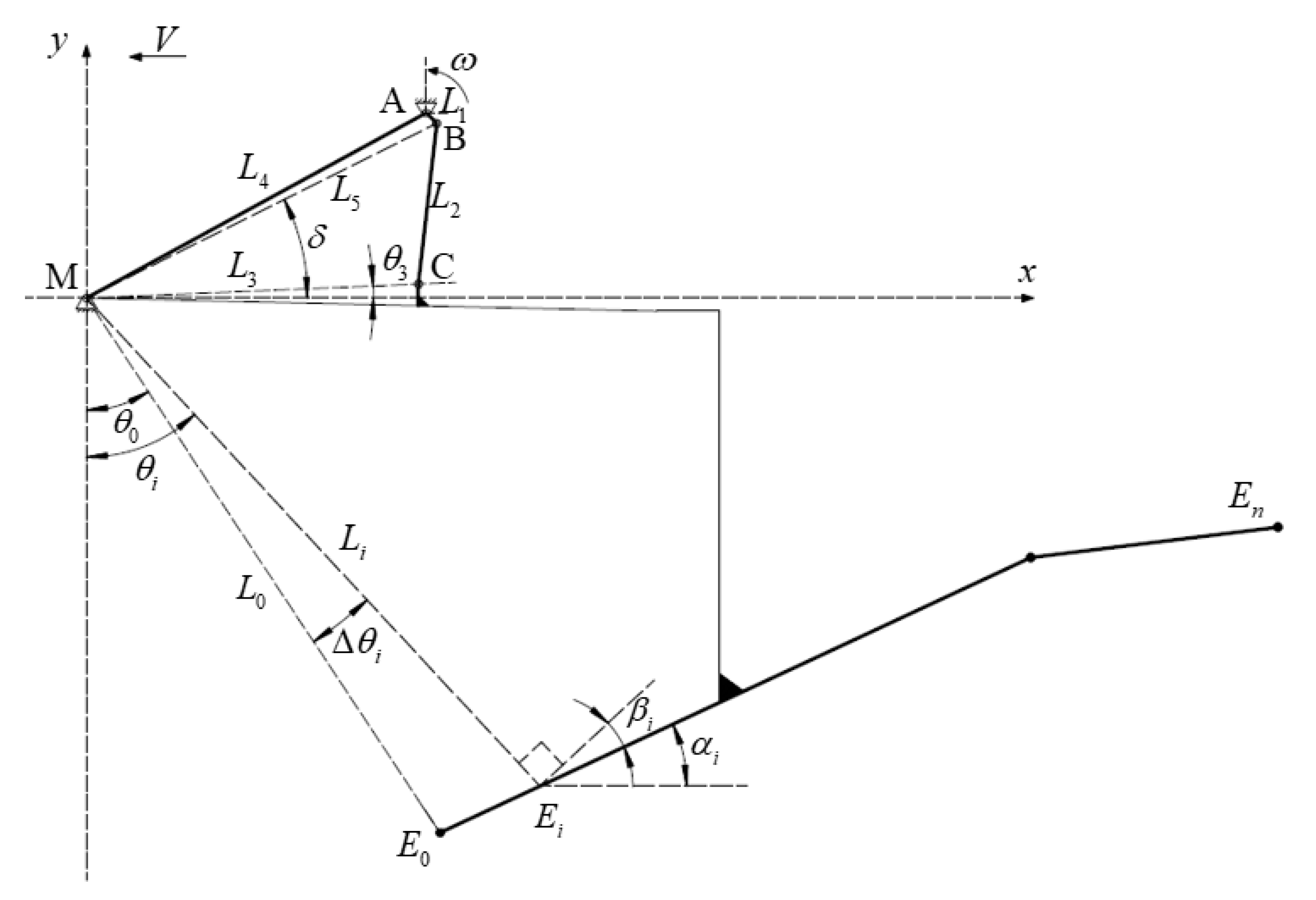

2.2. Kinematics and Dynamics Analysis

2.2.1. Throw Intensity of the Shovel-Rod

2.2.2. Total Torque

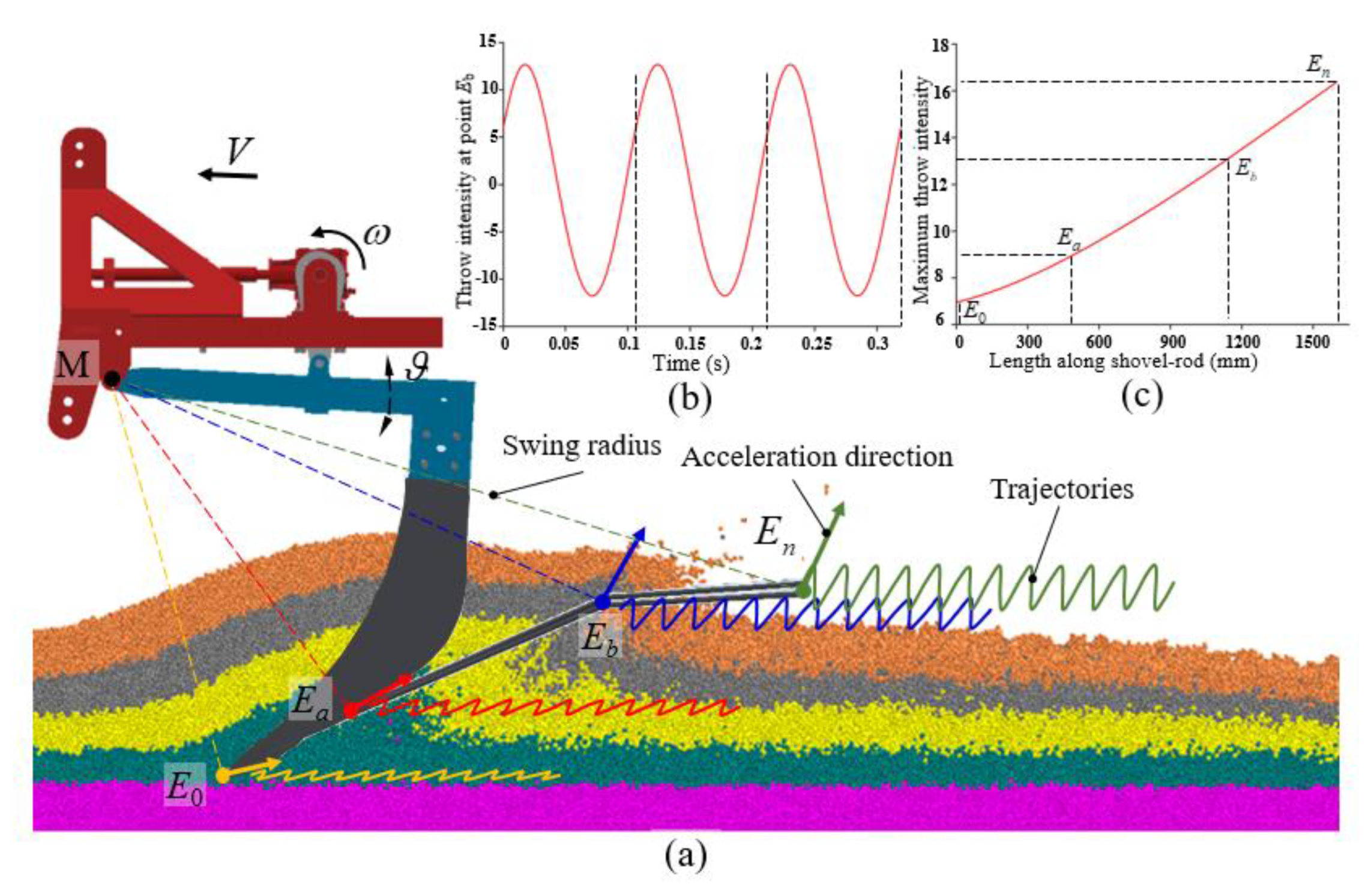

2.3. Discrete Element Models

2.3.1. DEM Model of Soil Bin

2.3.2. DEM-MBD Model

2.4. Test Design

2.4.1. Simulation Test

2.4.2. Field Test

2.5. Index Measurement

- (1)

- Draft force is extracted from the driving force dataset of translated motion by RECURDYN software. The mean value of the draft force is the average value of the draft force during the stable working section.

- (2)

- Total torque is extracted from the driving torque dataset of torque motion by RECURDYN software. The mean value of total torques is the average value of the torques during the stable working section.

- (3)

- Specific energy consumption (Pw) is the energy required by the harvester to process a unit volume of soil; Pw (kJ/m3) is calculated by Equation (12):where () represents the mean value of draft force which is calculated from the draft force dataset, N; () represents the mean value of total torque which is calculated from the total torque dataset for values greater than 0, Nm; n is the crank rotational speed, r/min; B is the working width, mm; D is the excavation depth, mm; t is the working time, s; V is the forward speed, m/s.

- (4)

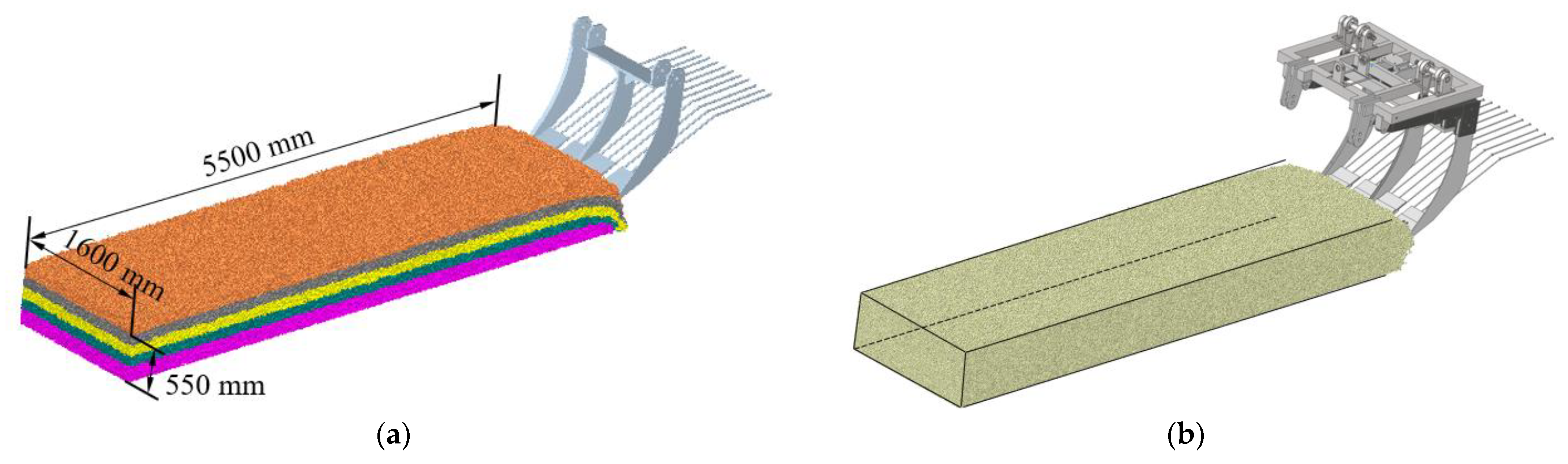

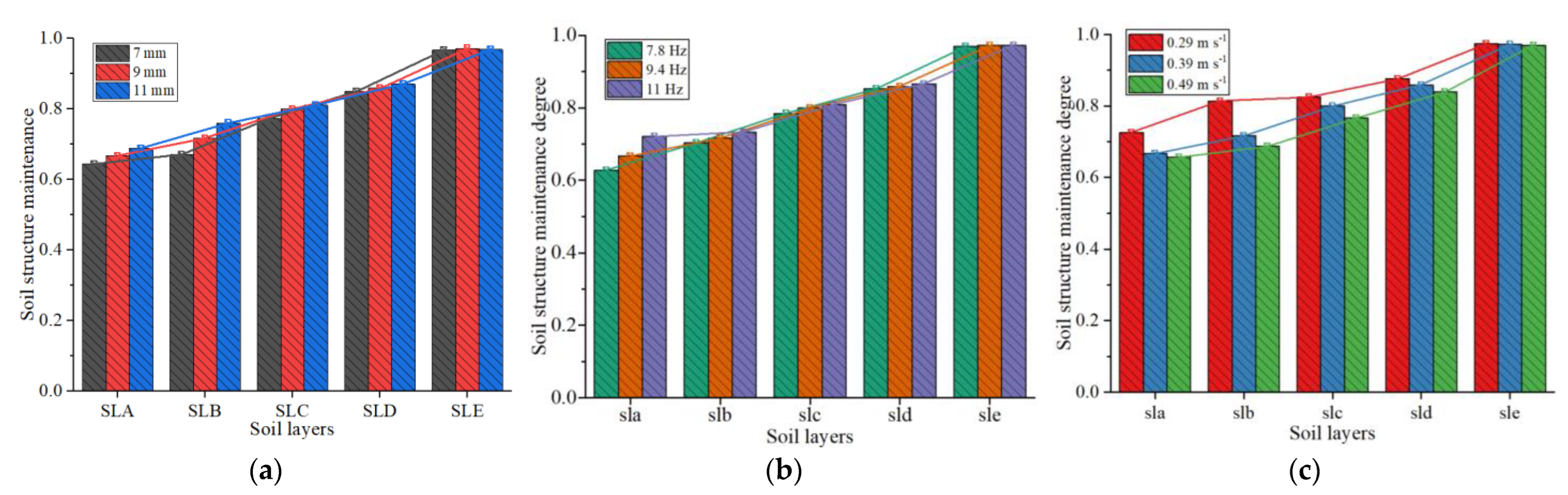

- Soil structure maintenance (Csi) is an index to assess the soil layer structural change before and after the operation (Figure 7). The virtual soil bin model was divided into five layers, including SLA (0–100 mm), SLB (100–200 mm), SLC (200–300 mm), SLD (300–400 mm) and SLE (>400 mm). The variation of soil particle mass in each layer of operational stability section was recorded by a total mass sensor, and the total mass before operation was recorded as mbi (i = 1, 2, 3, 4, 5) and after operation as mai (i = 1, 2, 3, 4, 5). Csi is calculated by Equation (13):

- (5)

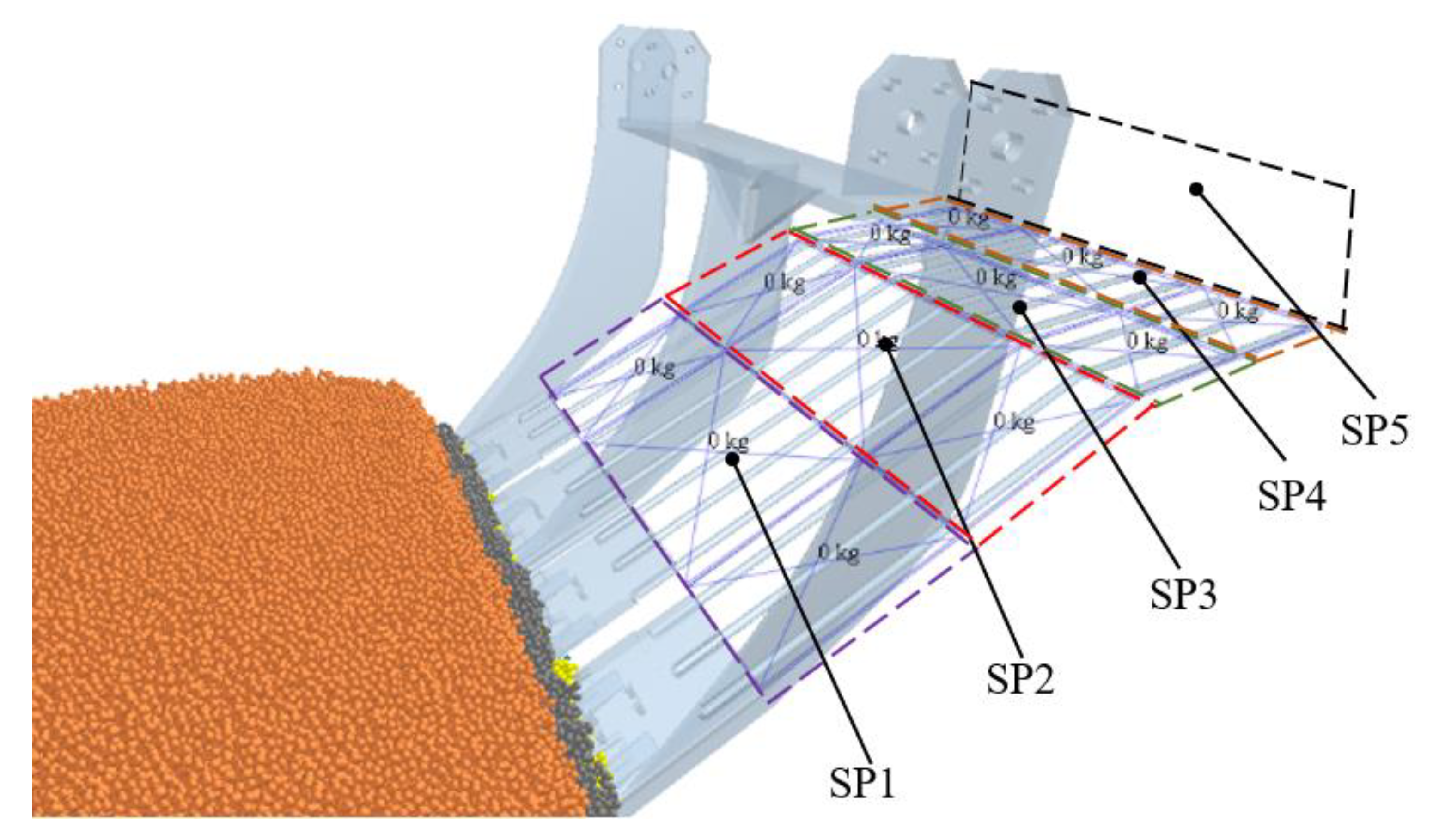

- Separation proportion (Qk) is an index to assess the ability of the liquorice harvester to separate the soil. The rods were divided into five quality monitoring areas, including SP1, SP2, SP3, SP4 and SP5 (Figure 8), which used a follower total mass sensor to record the separated soil mass in each monitoring area during the operational stability section, noted as mk (k = 1, 2, 3, 4, 5). The percentage of separated soil quality in each area to total treated mass is defined as Qk, calculated by Equation (14):

3. Results and Discussion

3.1. Analysis of Draft Force and Total Torque

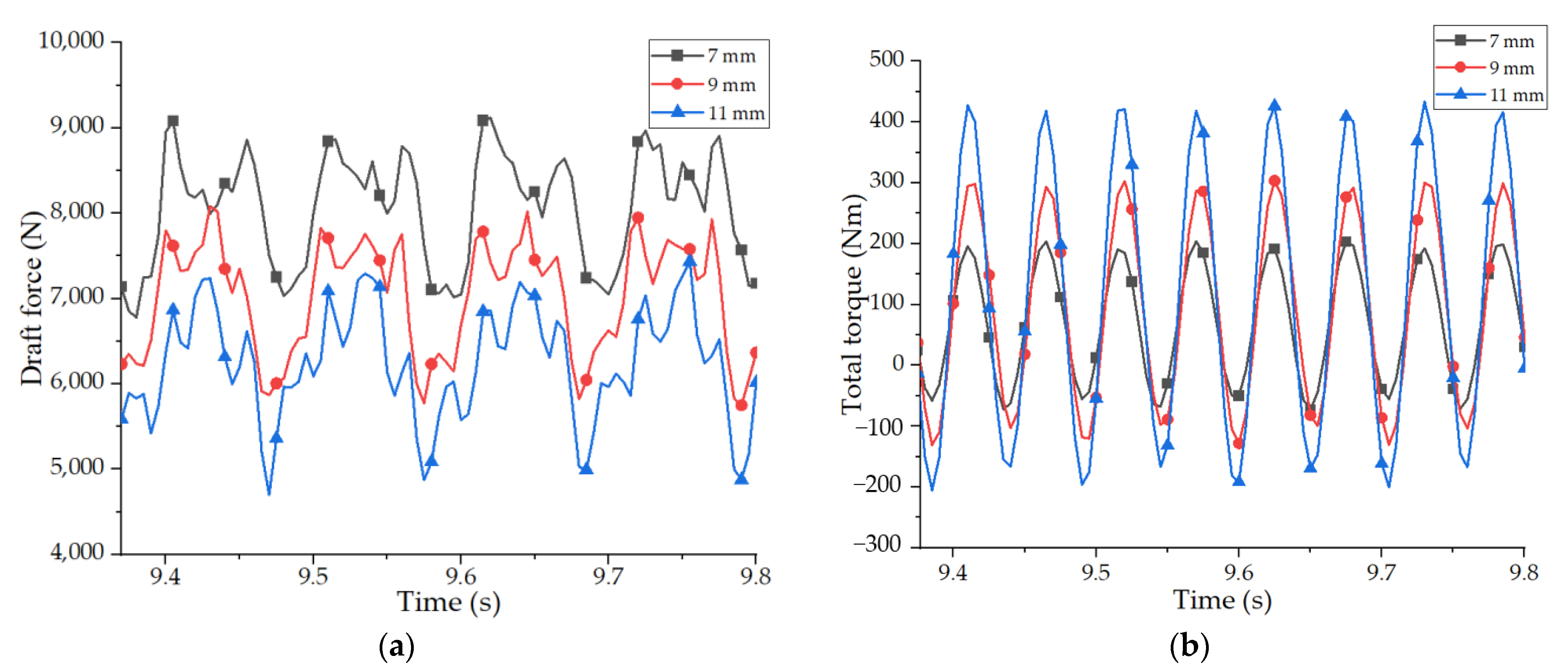

3.1.1. Amplitude

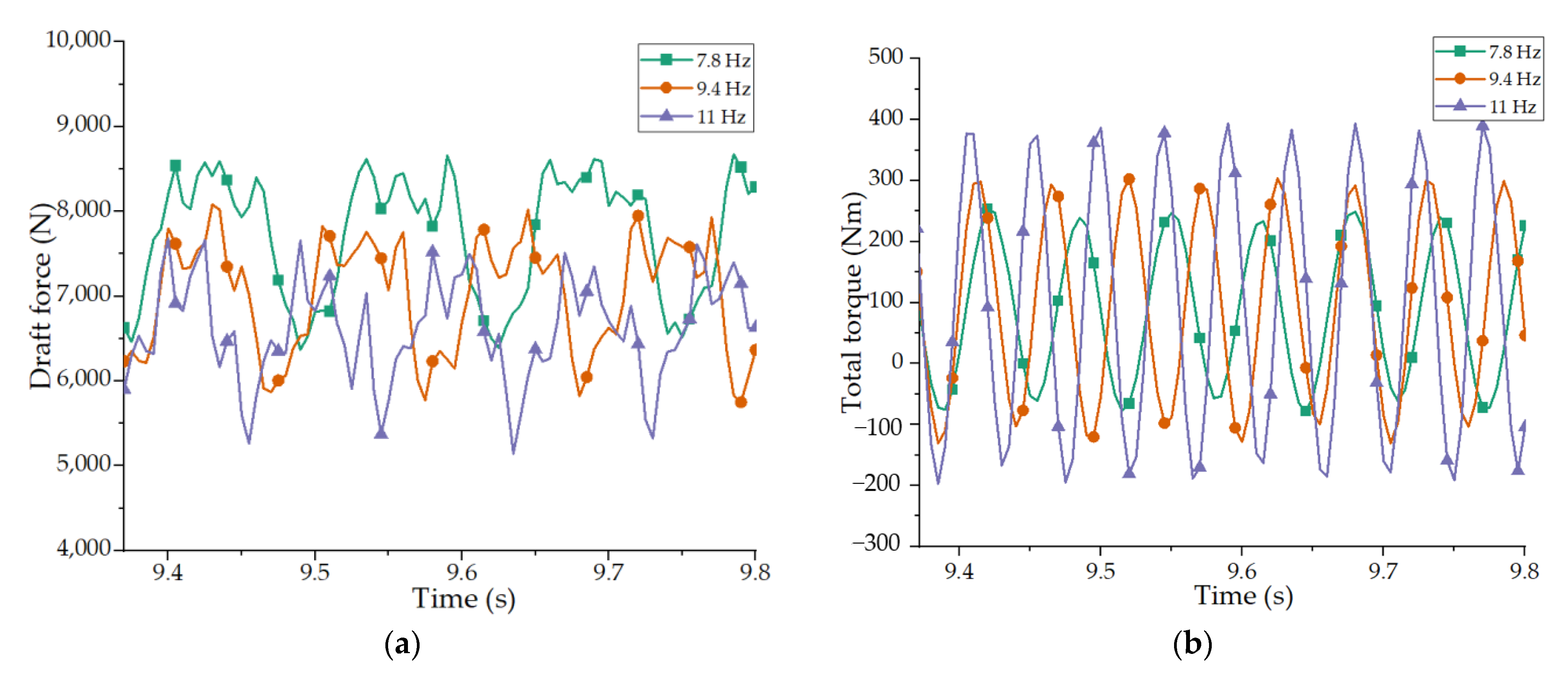

3.1.2. Vibration Frequency

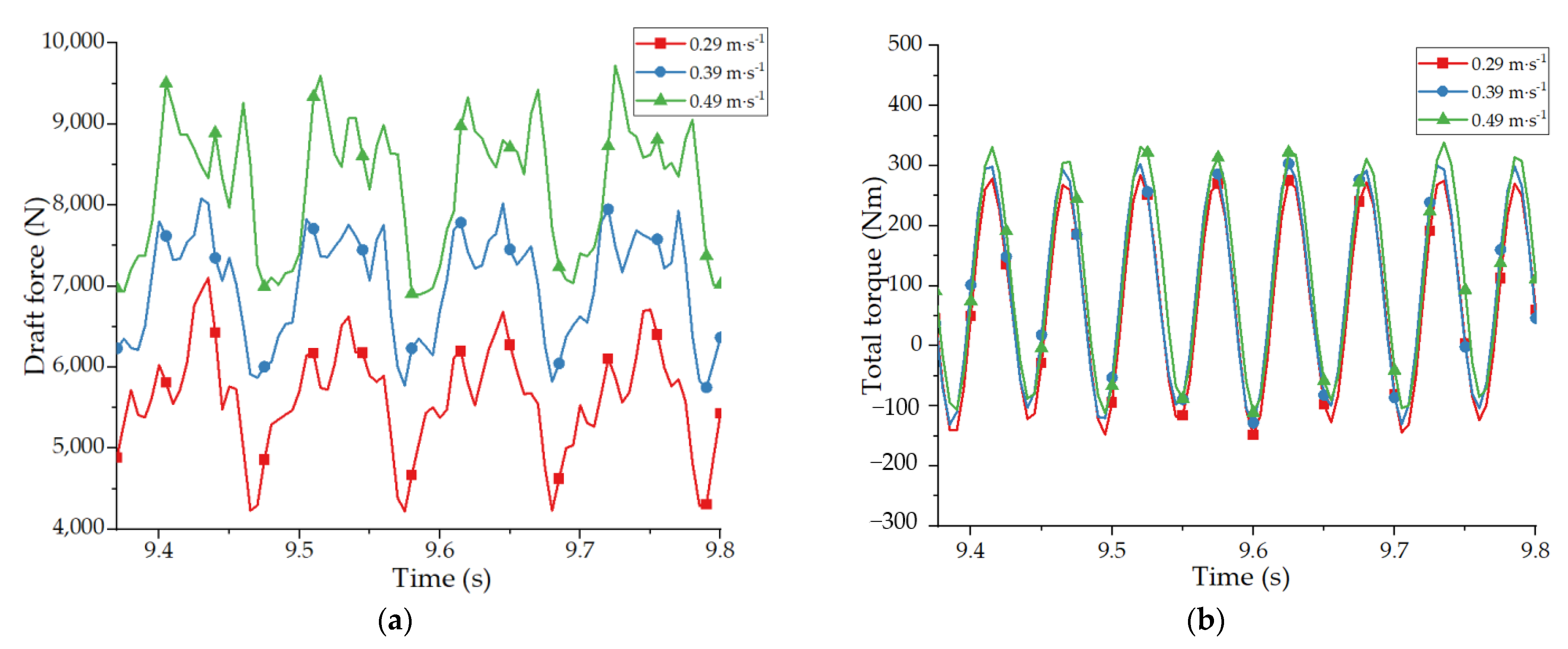

3.1.3. Forward Speed

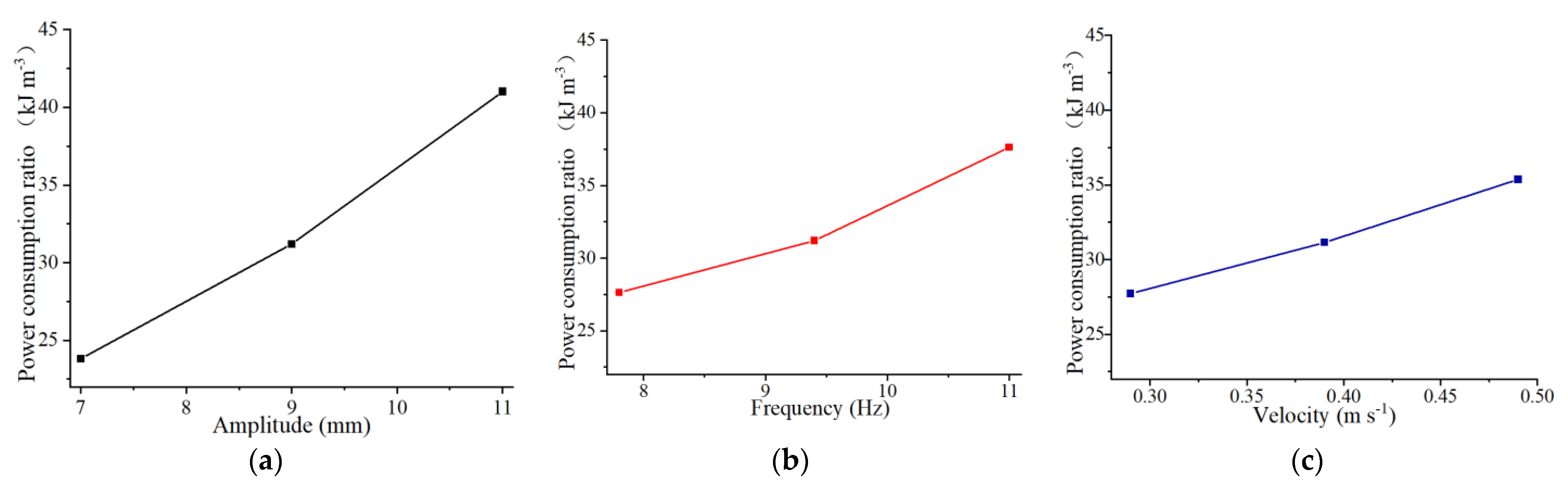

3.2. Analysis of Specific Power Consumption

3.3. Analysis of Soil Structure Maintenance

3.3.1. Amplitude

3.3.2. Vibration Frequency

3.3.3. Forward Speed

3.4. Analysis of Separation Proportion

3.4.1. Amplitude

3.4.2. Vibration Frequency

3.4.3. Forward Speed

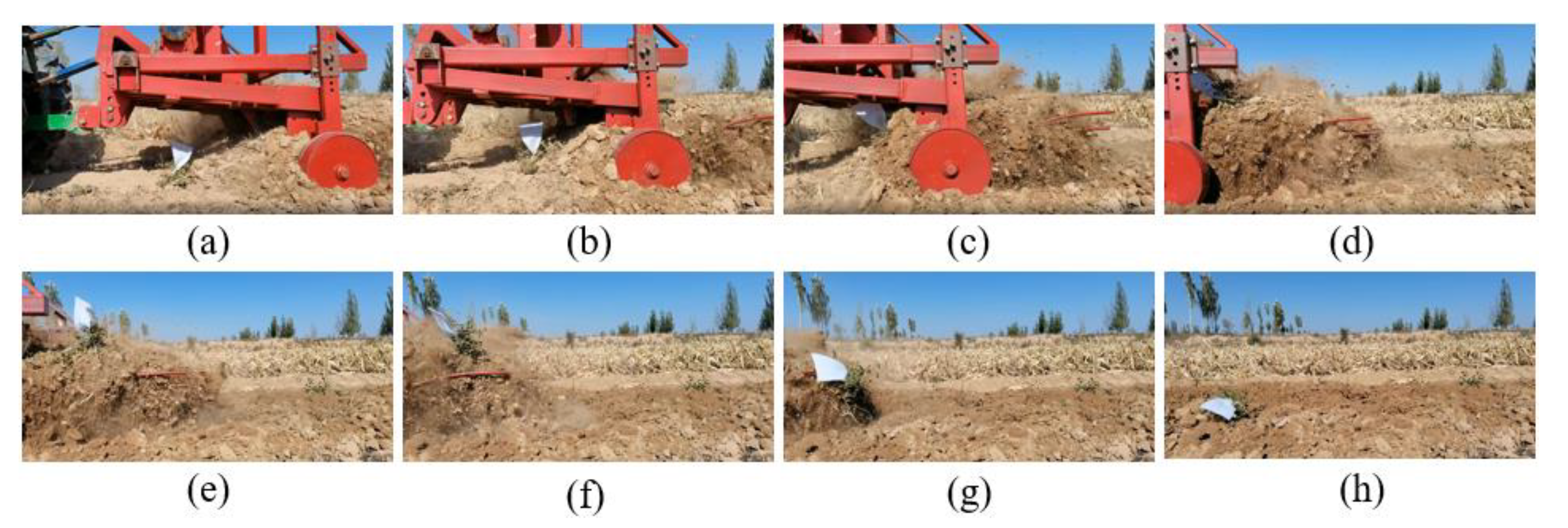

3.5. Two-Stage Cycle of Working Process

3.6. Field Test Results

4. Conclusions

- (1)

- Analysis of the throw intensity equation shows that the throw intensity of the oscillating shovel-rod components increases with the length of the rod, and the end has a higher throwing strength and throwing action. Combined with the throw intensity equation and the driving torque equation, the amplitude, vibration frequency and forward speed were determined as the key parameters.

- (2)

- The results of the coupled liquorice harvester-soil DEM-MBD simulation tests show that: As the amplitude increased, the draft force decreased by 463.35 N/mm while the total torque and specific energy consumption increased by 35.03 Nm/mm and 4.3 kJ/(m3·mm), respectively. As the vibration frequency increased, the specific energy consumption increased by 3.12 kJ/(Hz·m3) while the draft force and total torque decreased by 375.75 N/Hz and 28.44 Nm/Hz, respectively. As the forwarding speed increased, the draft force, total torque and specific energy consumption increased by 1302.72 N/ (m·s−1), 13.26 Nm/ (m·s−1) and 3.82 kJ/m3· (m·s−1), respectively. The main separation areas were SP1 and SP2, with greater than 60% soil separation proportion. The soil after the operation had a relatively minimal disturbance in all layers, with soil structure maintenance greater than 0.61.

- (3)

- The working process was assumed to be a two-stage (lifting and cutting) cycle, in which the traction resistance underwent non-sinusoidal motion and showed irregular fluctuations. The total torque curve has two peaks and two troughs in one cycle and is similar in the lifting and cutting phases. Field tests have observed that the liquorice passed smoothly through the shovel-rod components and then separated from the soil, during which the soil fell in turn at different layers.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wen, B.Q.; Li, Y.; Kan, Z.; Li, J.B.; Li, L.; Ge, J.; Ding, L.; Wang, K.; Shi, Y. Experimental study on microstructure and mechanical properties of stalk for Glycyrrhiza Glabra. J. Biomech. 2021, 118, 110198. [Google Scholar] [CrossRef]

- Lu, Y.; Yao, G.; Wang, X.; Zhang, Y.; Zhao, J.; Yu, Y.J.; Wang, H. Chemometric discrimination of the geographical origin of licorice in China by untargeted metabolomics. Food Chem. 2022, 380, 132235. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Zeng, Q.; Chen, Y.; Chen, C.; Wang, W.; Hou, J.; Li, X. Colonization by dark septate endophytes improves the growth and rhizosphere soil microbiome of licorice plants under different water treatments. Appl. Soil Ecol. 2021, 166, 103993. [Google Scholar] [CrossRef]

- Lü, J.; Sun, H.; Dui, H.; Peng, M.; Yu, J. Design and Experiment on Conveyor Separation Device of Potato Digger under Heavy Soil Condition. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 146–155. [Google Scholar] [CrossRef]

- Yang, R.; Yang, H.; Shang, S.; Xu, P.; Cui, G.; Liu, L. Design and test of poking roller shoving type potato harvester. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2016, 47, 119–126. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H.; Li, Y.; Yang, X.; Ibrahim, I.; Zhang, Z. Design and Experiment of Multi-stage Separation Buffer Potato Harvester. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2021, 52, 96–109. [Google Scholar] [CrossRef]

- Naik, M.A.; Pateriya, R.N.; Ramulu, C. Optimization of Performance Parameters of Onion Digger with Cutter Bar Topping Unit. J. Inst. Eng. Ser. 2022, 103, 71–79. [Google Scholar] [CrossRef]

- Tao, G.; Zhang, Z.; Yi, S.; Xia, C.; Ma, Y. Design and Test of Combined Swing Radix isatidi Root-soil Separation Device. Nongye Jixie Xuebao/Transactions Chinese Soc. Agric. Mach. 2022, 53, 109–119. [Google Scholar] [CrossRef]

- Yang, F.; Yang, Y.; Li, W.; Zhao, G.; Jiang, F.; Li, J. Structural Design and Experiment on Vibrating Soil Breaking Device of Mounted Yam Harvester. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2020, 51, 104–111. [Google Scholar] [CrossRef]

- Wei, Z.; Li, H.; Su, G.; Sun, C.; Liu, W.; Li, X. Development of potato harvester with buffer type potato-impurity separation sieve. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, D.; Yang, L.; Cui, T.; Jing, H.; Zhong, X. Modeling the interaction of soil and a vibrating subsoiler using the discrete element method. Comput. Electron. Agric. 2020, 174, 105518. [Google Scholar] [CrossRef]

- Shahgoli, G.; Fielke, J.; Desbiolles, J.; Saunders, C. Optimising oscillation frequency in oscillatory tillage. Soil Tillage Res. 2010, 106, 202–210. [Google Scholar] [CrossRef]

- Sun, J.; Chen, H.; Wang, Z.; Ou, Z.; Yang, Z.; Liu, Z.; Duan, J. Study on plowing performance of EDEM low-resistance animal bionic device based on red soil. Soil Tillage Res. 2020, 196, 104336. [Google Scholar] [CrossRef]

- Song, W.; Jiang, X.; Li, L.; Ren, L.; Tong, J. Increasing the width of disturbance of plough pan with bionic inspired subsoilers. Soil Tillage Res. 2022, 220, 105356. [Google Scholar] [CrossRef]

- Marani, S.M.; Shahgholi, G.; Moinfar, A. Effect of nano coating materials on reduction of soil adhesion and external friction. Soil Tillage Res. 2019, 193, 42–49. [Google Scholar] [CrossRef]

- Guan, C.; Fu, J.; Xu, L.; Jiang, X.; Wang, S.; Cui, Z. Study on the reduction of soil adhesion and tillage force of bionic cutter teeth in secondary soil crushing. Biosyst. Eng. 2022, 213, 133–147. [Google Scholar] [CrossRef]

- Liu, G.; Xia, J.; Zheng, K.; Cheng, J.; Wang, K.; Zeng, R.; Wang, H.; Liu, Z. Effects of vibration parameters on the interfacial adhesion system between soil and metal surface. Soil Tillage Res. 2022, 218, 105294. [Google Scholar] [CrossRef]

- Karki, T.B.; Gyawaly, P. Conservation Agriculture Mitigates the Effects of Climate Change. J. Nepal Agric. Res. Counc. 2021, 7, 122–132. [Google Scholar] [CrossRef]

- Geppert, C.; Contri, C.; De Boni, L.; Corcos, D.; Marini, L. Drought, nitrogen deposition and arthropod herbivory modify plant establishment dynamics after soil disturbance. Sci. Total Environ. 2021, 796, 148956. [Google Scholar] [CrossRef]

- Biney, J.K.M.; Blöcher, J.R.; Bell, S.M.; Borůvka, L.; Vašát, R. Can in situ spectral measurements under disturbance-reduced environmental conditions help improve soil organic carbon estimation. Sci. Total Environ. 2022, 838, 156304. [Google Scholar] [CrossRef]

- Deng, F.; Wang, H.; Xie, H.; Bao, X.; He, H.; Zhang, X.; Liang, C. Low-disturbance farming regenerates healthy deep soil toward sustainable agriculture-Evidence from long-term no-tillage with stover mulching in Mollisols. Sci. Total Environ. 2022, 825, 153929. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, S.; Pan, H.; Zheng, Z.; Huang, Y.; Zhu, R. Effect of soil particle size on soil-subsoiler interactions using the discrete element method simulations. Biosyst. Eng. 2019, 182, 138–150. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Li, T.; Zhao, D.; Liao, Y. Tillage practices with different soil disturbance shape the rhizosphere bacterial community throughout crop growth. Soil Tillage Res. 2020, 197, 104501. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C. Simulation of tillage forces and furrow profile during soil-mouldboard plough interaction using discrete element modelling. Biosyst. Eng. 2020, 190, 58–70. [Google Scholar] [CrossRef]

- Sadek, M.A.; Chen, Y.; Zeng, Z. Draft force prediction for a high-speed disc implement using discrete element modelling. Biosyst. Eng. 2021, 202, 133–141. [Google Scholar] [CrossRef]

- Aikins, K.A.; Ucgul, M.; Barr, J.B.; Jensen, T.A.; Antille, D.L.; Desbiolles, J.M.A. Determination of discrete element model parameters for a cohesive soil and validation through narrow point opener performance analysis. Soil Tillage Res. 2021, 213, 105123. [Google Scholar] [CrossRef]

- Makange, N.R.; Ji, C.; Torotwa, I. Prediction of cutting forces and soil behavior with discrete element simulation. Comput. Electron. Agric. 2020, 179, 105848. [Google Scholar] [CrossRef]

- Li, A.; Han, Y.; Jia, F.; Zhang, J.; Meng, X.; Chen, P.; Xiao, Y.; Zhao, H. Examination milling non-uniformity in friction rice mills using by discrete element method and experiment. Biosyst. Eng. 2021, 211, 247–259. [Google Scholar] [CrossRef]

- Katinas, E.; Chotěborský, R.; Linda, M.; Jankauskas, V. Wear modelling of soil ripper tine in sand and sandy clay by discrete element method. Biosyst. Eng. 2019, 188, 305–319. [Google Scholar] [CrossRef]

- Hou, J.; Chen, Y.; Li, Y.; Li, T.; Li, G.; Guo, H. Design and experiment of shovel-screen combined green onion digging, shaking, and soil tillage device. Trans. Chin. Soc. Agric. Eng. 2021, 37, 29–39. [Google Scholar] [CrossRef]

- Awuah, E.; Zhou, J.; Liang, Z.; Aikins, K.A.; Gbenontin, B.V.; Mecha, P.; Makange, N.R. Parametric analysis and numerical optimisation of Jerusalem artichoke vibrating digging shovel using discrete element method. Soil Tillage Res. 2022, 219, 105344. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Q.; Huang, Y.; Ji, J. An efficient method for determining DEM parameters of a loose cohesive soil modelled using hysteretic spring and linear cohesion contact models. Biosyst. Eng. 2022, 215, 283–294. [Google Scholar] [CrossRef]

- Mudarisov, S.; Farkhutdinov, I.; Khamaletdinov, R.; Khasanov, E.; Mukhametdinov, A. Evaluation of the significance of the contact model particle parameters in the modelling of wet soils by the discrete element method. Soil Tillage Res. 2022, 215, 105228. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, Y.; Chen, J.; Zhang, Z.; Huang, S. Optimization design and performance study of a subsoiler underlying the tea garden subsoiling mechanism based on bionics and EDEM. Soil Tillage Res. 2022, 220, 105375. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, H.; Liu, J.; Yang, S.X. Control method of seedbed compactness based on fragment soil compaction dynamic characteristics. Soil Tillage Res. 2020, 198, 104551. [Google Scholar] [CrossRef]

- Wan, L.; Li, Y.; Zhao, H.; Xu, G.; Song, J.; Dong, X.; Zhang, C.; Wang, J. Gradient throwing characteristics of oscillating slat shovel for rhizome crop harvesters. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2021, 37, 9–21. [Google Scholar] [CrossRef]

- Kim, Y.S.; Siddique, M.A.A.; Kim, W.S.; Kim, Y.J.; Lee, S.D.; Lee, D.K.; Hwang, S.J.; Nam, J.S.; Park, S.U.; Lim, R.G. DEM simulation for draft force prediction of moldboard plow according to the tillage depth in cohesive soil. Comput. Electron. Agric. 2021, 189, 106368. [Google Scholar] [CrossRef]

- Foldager, F.F.; Munkholm, L.J.; Balling, O.; Serban, R.; Negrut, D.; Heck, R.J.; Green, O. Modeling soil aggregate fracture using the discrete element method. Soil Tillage Res. 2022, 218, 105295. [Google Scholar] [CrossRef]

- Dong, X.; Su, C.; Zheng, H.; Han, R.; Li, Y.; Wan, L.; Song, J.; Wang, J. Analysis of soil disturbance process by vibrating subsoiling based on DEM-MBD coupling algorithm. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2022, 38, 34–43. [Google Scholar] [CrossRef]

| Parameters | Value in Each Soil Layer Depth/mm | ||||

|---|---|---|---|---|---|

| 0~100 | 100~200 | 200~300 | 300~400 | >400 | |

| Soil particle radius (mm) | 6.5 | 6.5 | 6.5 | 7.5 | 7.5 |

| Soil density (kg·m−3) | 2670 | 2800 | 2800 | 2850 | 2850 |

| Generated soil quality (kg) | 1375 | 1375 | 1375 | 1375 | 2035 |

| Poisson’s ratio of soil | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 |

| Shear modulus of soil (Pa) | 9.6 × 106 | 9.6 × 106 | 9.6 × 106 | 9.6 × 106 | 9.6 × 106 |

| Coefficient of restitution between soil and soil | 0.53 | 0.45 | 0.48 | 0.45 | 0.45 |

| Coefficient of static friction between soil and soil | 0.58 | 0.63 | 0.63 | 0.65 | 0.68 |

| Coefficient of rolling friction between soil and soil | 049 | 0.51 | 0.51 | 0.52 | 0.54 |

| Contact plasticity ratio between soil and soil | 0.26 | 0.22 | 0.2 | 0.2 | 0.18 |

| Surface energy between soil and soil | 24.9 | 25.2 | 26.5 | 26.5 | 28.7 |

| Tensile exp between soil and soil | 4 | 4 | 4 | 4 | 4 |

| Tangential stiff multiplier between soil and soil | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 |

| Density of steel (kg·m−3) | 7861 | 7861 | 7861 | 7861 | 7861 |

| Poisson’s ratio of steel | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Shear modulus of steel (Pa) | 7.9 × 1010 | 7.9 × 1010 | 7.9 × 1010 | 7.9 × 1010 | 7.9 × 1010 |

| Coefficient of restitution between soil and steel | 0.28 | 0.25 | 0.25 | 0.25 | 0.2 |

| Coefficient of static friction between soil and steel | 0.43 | 0.49 | 0.49 | 0.52 | 0.54 |

| Coefficient of rolling friction between soil and steel | 0.15 | 0.18 | 0.18 | 0.22 | 0.26 |

| Levels | Amplitude (mm) | Vibration Frequency (Hz) | Forward Speed (m·s−1) |

|---|---|---|---|

| +1 | 7 | 7.8 | 0.29 |

| 0 | 9 | 9.4 | 0.39 |

| −1 | 11 | 11 | 0.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, L.; Li, Y.; Zhang, C.; Ma, X.; Song, J.; Dong, X.; Wang, J. Performance Evaluation of Liquorice Harvester with Novel Oscillating Shovel-Rod Components Using the Discrete Element Method. Agriculture 2022, 12, 2015. https://doi.org/10.3390/agriculture12122015

Wan L, Li Y, Zhang C, Ma X, Song J, Dong X, Wang J. Performance Evaluation of Liquorice Harvester with Novel Oscillating Shovel-Rod Components Using the Discrete Element Method. Agriculture. 2022; 12(12):2015. https://doi.org/10.3390/agriculture12122015

Chicago/Turabian StyleWan, Lipengcheng, Yonglei Li, Chao Zhang, Xiang Ma, Jiannong Song, Xiangqian Dong, and Jicheng Wang. 2022. "Performance Evaluation of Liquorice Harvester with Novel Oscillating Shovel-Rod Components Using the Discrete Element Method" Agriculture 12, no. 12: 2015. https://doi.org/10.3390/agriculture12122015

APA StyleWan, L., Li, Y., Zhang, C., Ma, X., Song, J., Dong, X., & Wang, J. (2022). Performance Evaluation of Liquorice Harvester with Novel Oscillating Shovel-Rod Components Using the Discrete Element Method. Agriculture, 12(12), 2015. https://doi.org/10.3390/agriculture12122015