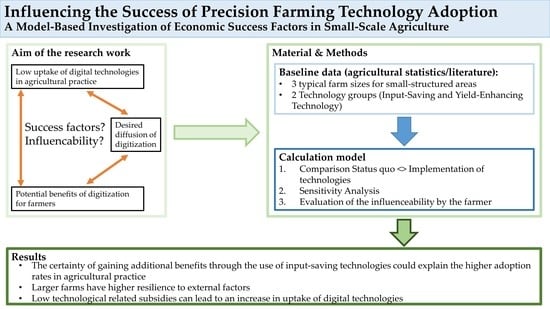

Influencing the Success of Precision Farming Technology Adoption—A Model-Based Investigation of Economic Success Factors in Small-Scale Agriculture

Abstract

1. Introduction

2. Materials and Methods

2.1. Planning Data

2.2. Technology Selection

2.3. Economic Modeling of a Farm, Evaluation and Sensitivity Analysis

3. Results

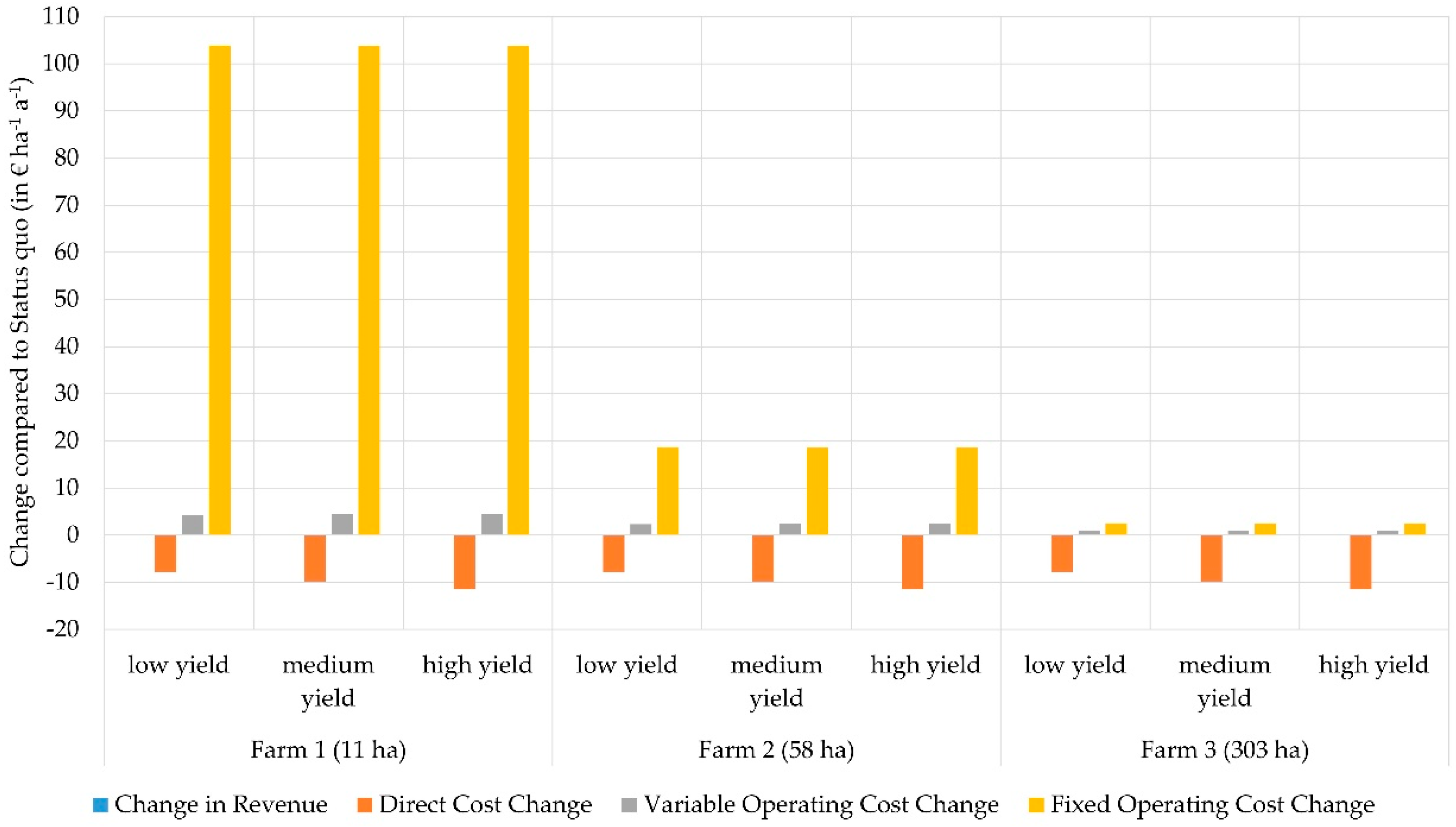

3.1. Input-Saving Technologies (IST)

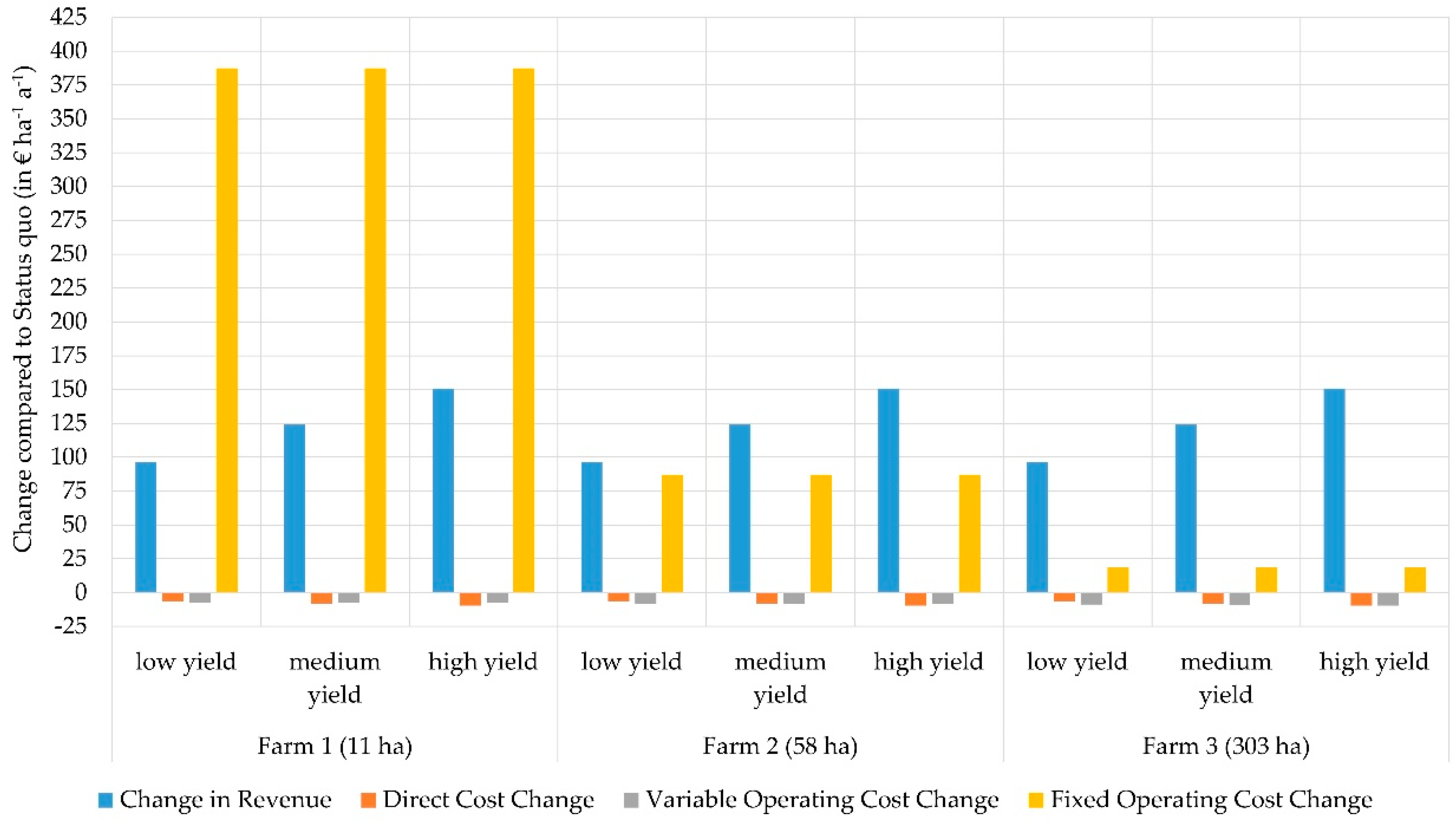

3.2. Yield-Enhancing Technologies (YET)

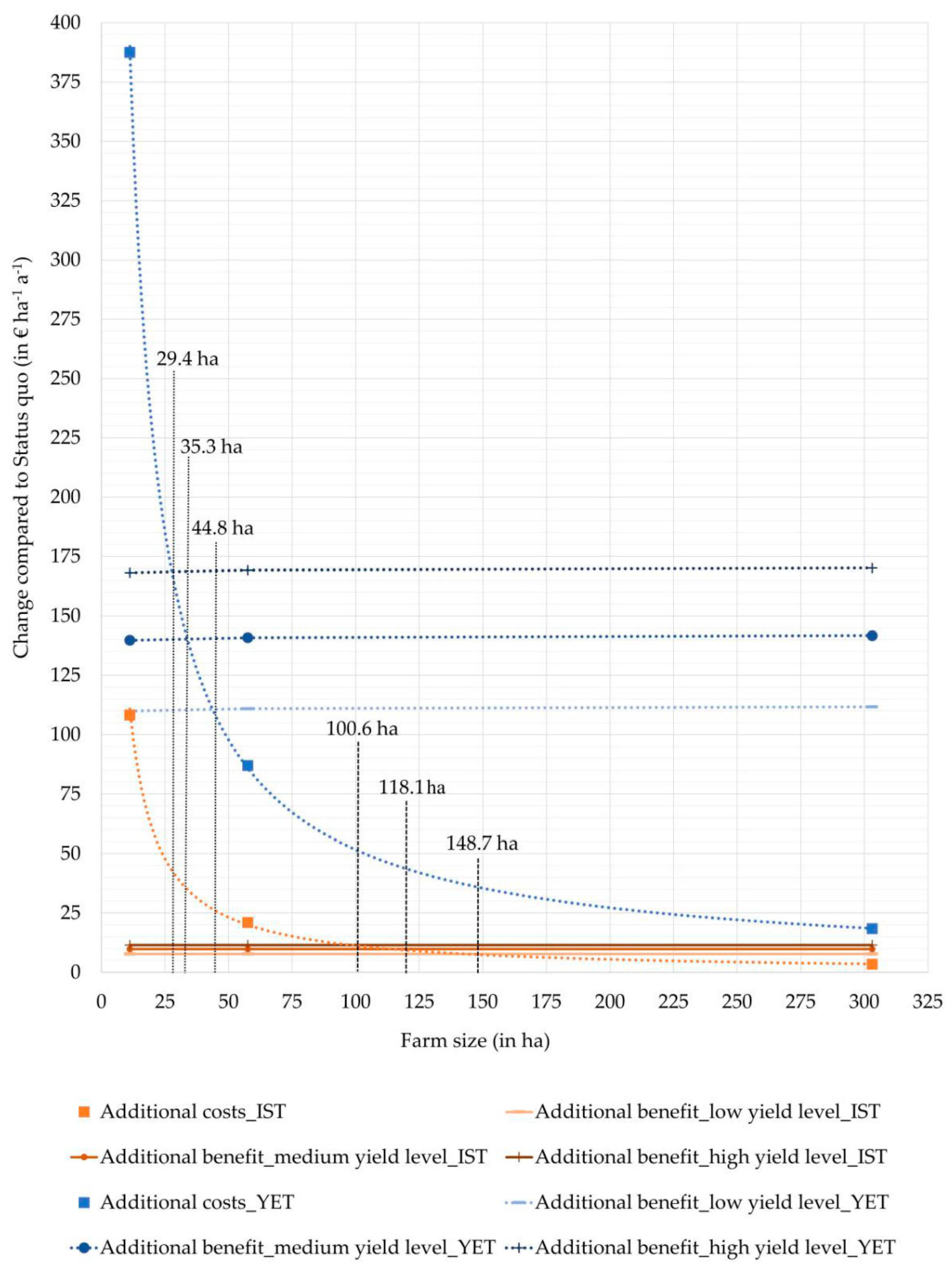

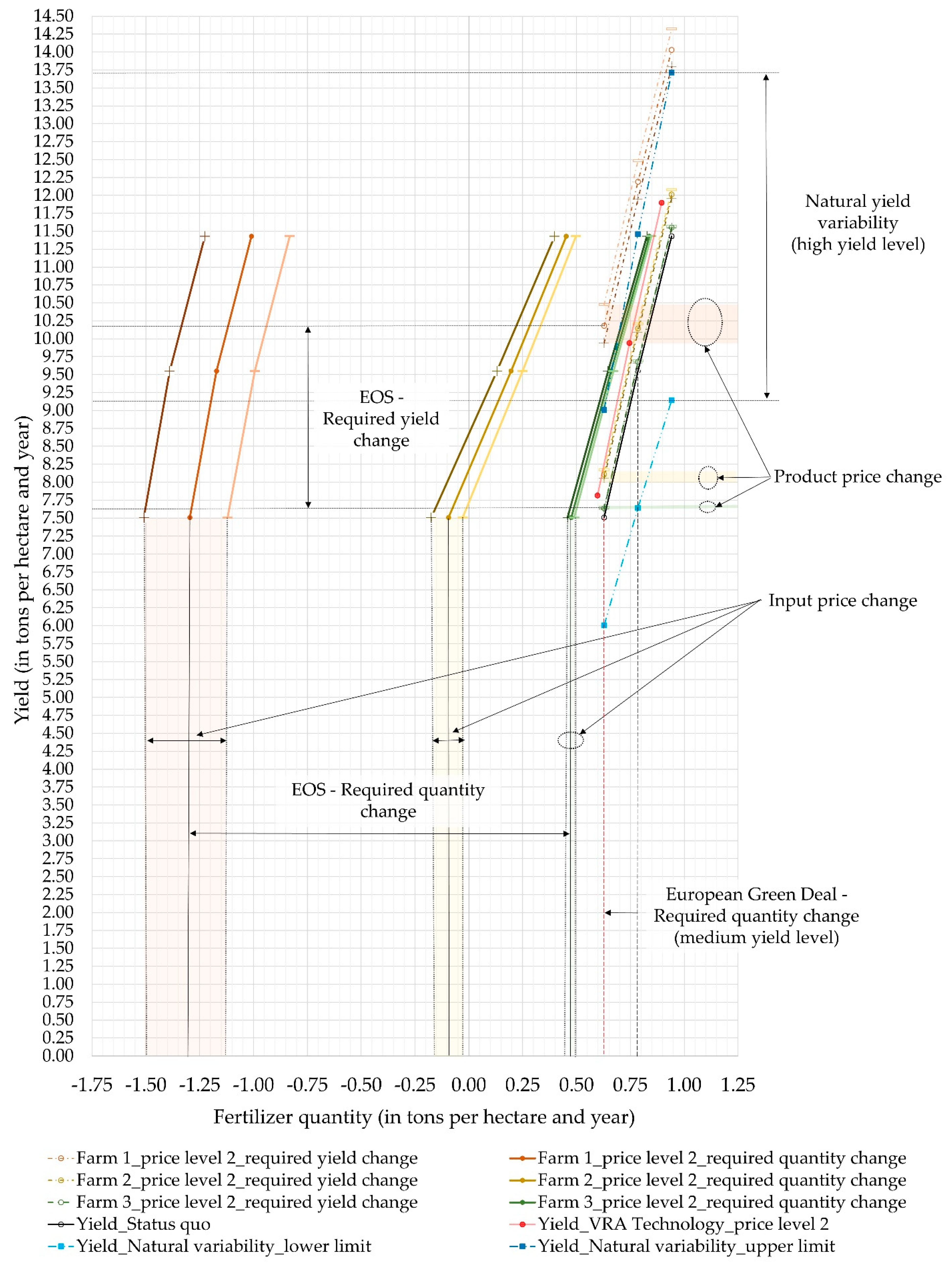

3.3. Sensitivity Analysis

3.3.1. Required Changes in Total Costs and Revenues

3.3.2. High Level of Influence—Farm Size

3.3.3. Limited Level of Influence—Acquisition, Learning Costs and Depreciation Period

3.3.4. No Influence—Price Changes, Natural Yield Variability and Regulations

4. Discussion

4.1. Yield-Enhancing Technologies Compared to Input-Saving Technologies

4.2. Sensitivity Analysis—Influenceable Factors

4.3. Sensitivity Analysis—Non-Influenceable Factors

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Farm 1 | Farm 2 | Farm 3 | |

|---|---|---|---|

| Farm size (ha) | 11 | 58 | 303 |

| Power main tractor/second tractor in kW | 67/45 | 102/83 | 200/120 |

| Size Classes (Farms) from … to under … ha | Number of Farms | Share | Utilized Agricultural Area (in ha) | Share |

|---|---|---|---|---|

| <5 | 72 | 0.67% | 149 | 0.04% |

| 5–10 | 2523 | 23.42% | 18,239 | 4.45% |

| 10–20 | 2902 | 26.94% | 42,940 | 10.49% |

| 20–50 | 2884 | 26.77% | 94,021 | 22.97% |

| 50–100 | 1526 | 14.17% | 107,002 | 26.14% |

| 100–200 | 684 | 6.35% | 92,188 | 22.52% |

| 200–500 | 170 | 1.58% | 46,112 | 11.26% |

| 500–1000 | 8 | 0.07% | 5451 | 1.33% |

| >1000 | 3 | 0.03% | 3305 | 0.81% |

| total | 10,772 | 100% | 409,407 | 100% |

| Average arable farm size in BW: | 38.01 ha | |||

| Average arable farm size in Germany: | 71.66 ha | |||

| Share (in %) | Yield (t/ha) | Product Price (€/t) | ||||

|---|---|---|---|---|---|---|

| Low | Average | High | Average | |||

| Barley | 25.0 | 5.4 | 6.9 | 7.9 | 6.9 | 181.0 |

| Triticale | 5.0 | 3.9 | 5.9 | 7.9 | 6.7 | 148.0 |

| Wheat | 30.0 | 5.9 | 7.9 | 9.9 | 7.5 | 166.0 |

| Grain Corn | 15.0 | 7.3 | 9.8 | 11.4 | 10.1 | 164.0 |

| Canola | 15.0 | 2.9 | 3.4 | 4.3 | 3.9 | 360.0 |

| Soybean | 5.0 | 3.0 | 3.9 | 5.0 | ** | 350.0 |

| Sugar beet | 5.0 | 50.0 | 60.0 | 70.0 | 75.3 | 32.0 |

| Yield Level | |||||

|---|---|---|---|---|---|

| Low | Medium | High | |||

| Farm 1 | Required Yield | Category 1 * | 10.48 | 12.48 | 14.32 |

| Category 2 ** | 10.18 | 12.19 | 14.03 | ||

| Category 3 *** | 9.94 | 11.95 | 13.79 | ||

| Required Input Quantity | Category 1 | −1.51 | −1.39 | −1.23 | |

| Category 2 | −1.30 | −1.17 | −1.01 | ||

| Category 3 | −1.12 | −0.99 | −0.83 | ||

| Farm 2 | Required Yield | Category 1 | 8.17 | 10.21 | 12.08 |

| Category 2 | 8.11 | 10.14 | 12.01 | ||

| Category 3 | 8.05 | 10.09 | 11.96 | ||

| Required Input Quantity | Category 1 | −0.17 | 0.13 | 0.40 | |

| Category 2 | −0.09 | 0.20 | 0.45 | ||

| Category 3 | −0.03 | 0.25 | 0.50 | ||

| Farm 3 | Required Yield | Category 1 | 7.65 | 9.69 | 11.57 |

| Category 2 | 7.63 | 9.68 | 11.55 | ||

| Category 3 | 7.62 | 9.66 | 11.54 | ||

| Required Input Quantity | Category 1 | 0.46 | 0.65 | 0.83 | |

| Category 2 | 0.48 | 0.66 | 0.84 | ||

| Category 3 | 0.49 | 0.67 | 0.85 | ||

| Status quo | Fertilizer Quantity | 0.63 | 0.78 | 0.94 | |

| Yield | 7.51 | 9.55 | 11.43 | ||

| Technology-induced changes | Fertilizer Quantity | 0.60 | 0.75 | 0.89 | |

| Yield | 7.81 | 9.94 | 11.90 | ||

| Natural yield variability | Lower Limit | 6.01 | 7.64 | 9.14 | |

| Upper Limit | 9.01 | 11.46 | 13.71 | ||

References

- Tey, Y.S.; Brindal, M. Factors influencing the adoption of precision agricultural technologies: A review for policy implications. Precis. Agric. 2012, 13, 713–730. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture-Trends and Challenges; FAO: Rome, Italy, 2017. [Google Scholar]

- Valin, H.; Sands, R.D.; van der Mensbrugghe, D.; Nelson, G.C.; Ahammad, H.; Blanc, E.; Bodirsky, B.; Fujimori, S.; Hasegawa, T.; Havlik, P.; et al. The future of food demand: Understanding differences in global economic models. Agric. Econ. 2014, 45, 51–67. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food security: The challenge of feeding 9 billion people. Science 2010, 327, 812–818. [Google Scholar] [CrossRef]

- Värnik, R.; Aste, R.; Ariva, J. Sustainable Intensification in Crop Farming—A Case from Estonia. In Precision Agriculture: Technology and Economic Perspectives; Pedersen, S.M., Lind, K.M., Eds.; Springer: Cham, Switzerland, 2017; pp. 201–221. ISBN 978-3-319-68713-1. [Google Scholar]

- Bongiovanni, R.; Lowenberg-Deboer, J. Precision Agriculture and Sustainability. Precis. Agric. 2004, 5, 359–387. [Google Scholar] [CrossRef]

- Zambon, I.; Cecchini, M.; Egidi, G.; Saporito, M.G.; Colantoni, A. Revolution 4.0: Industry vs. Agriculture in a Future Development for SMEs. Processes 2019, 7, 36. [Google Scholar] [CrossRef]

- Daberkow, S.G.; McBride, W.D. Farm and Operator Characteristics Affecting the Awareness and Adoption of Precision Agriculture Technologies in the US. Precis. Agric. 2003, 4, 163–177. [Google Scholar] [CrossRef]

- Balafoutis, A.T.; Beck, B.; Fountas, S.; Tsiropoulos, Z.; Vangeyte, J.; van der Wal, T.; Soto-Embodas, I.; Gómez-Barbero, M.; Pedersen, S.M. Smart Farming Technologies–Description, Taxonomy and Economic Impact. In Precision Agriculture: Technology and Economic Perspectives; Pedersen, S.M., Lind, K.M., Eds.; Springer: Cham, Switzerland, 2017; pp. 21–77. ISBN 978-3-319-68713-1. [Google Scholar]

- Heege, H.J. (Ed.) Precision in Crop Farming: Site Specific Concepts and Sensing Methods: Applications and Results; Springer: Dordrecht, The Netherlands, 2013; ISBN 9789400767607. [Google Scholar]

- Chen, W.; Bell, R.W.; Brennan, R.F.; Bowden, J.W.; Dobermann, A.; Rengel, Z.; Porter, W. Key crop nutrient management issues in the Western Australia grains industry: A review. Soil Res. 2009, 47, 1. [Google Scholar] [CrossRef]

- Michalski, A.; Czajewski, J. Instrumentatio nnotes-The accuracy of the global positioning systems. IEEE Instrum. Meas. Mag. 2004, 7, 56–60. [Google Scholar] [CrossRef]

- Paustian, M.; Theuvsen, L. Adoption of precision agriculture technologies by German crop farmers. Precis. Agric. 2017, 18, 701–716. [Google Scholar] [CrossRef]

- Reichardt, M.; Jürgens, C.; Klöble, U.; Hüter, J.; Moser, K. Dissemination of precision farming in Germany: Acceptance, adoption, obstacles, knowledge transfer and training activities. Precis. Agric. 2009, 10, 525–545. [Google Scholar] [CrossRef]

- Bramley, R.G.V. Lessons from nearly 20 years of Precision Agriculture research, development, and adoption as a guide to its appropriate application. Crop Pasture Sci. 2009, 60, 197. [Google Scholar] [CrossRef]

- Lowenberg-DeBoer, J.; Erickson, B. Setting the Record Straight on Precision Agriculture Adoption. Agron. J. 2019, 111, 1552–1569. [Google Scholar] [CrossRef]

- Gabriel, A.; Gandorfer, M. Landwirte-Befragung 2020 Digitale Landwirtschaft Bayern. 2020. Available online: https://www.lfl.bayern.de/mam/cms07/ilt/dateien/ilt6_praesentation_by_2390_27082020.pdf (accessed on 24 September 2022).

- Groher, T.; Heitkämper, K.; Walter, A.; Liebisch, F.; Umstätter, C. Status quo of adoption of precision agriculture enabling technologies in Swiss plant production. Precis. Agric. 2020, 21, 1327–1350. [Google Scholar] [CrossRef]

- Aubert, B.A.; Schroeder, A.; Grimaudo, J. IT as enabler of sustainable farming: An empirical analysis of farmers' adoption decision of precision agriculture technology. Decis. Support Syst. 2012, 54, 510–520. [Google Scholar] [CrossRef]

- Tamirat, T.W.; Pedersen, S.M.; Lind, K.M. Farm and operator characteristics affecting adoption of precision agriculture in Denmark and Germany. Acta Agric. Scand. Sect. B Soil Plant Sci. 2018, 68, 349–357. [Google Scholar] [CrossRef]

- Kernecker, M.; Knierim, A.; Wurbs, A.; Kraus, T.; Borges, F. Experience versus expectation: Farmers’ perceptions of smart farming technologies for cropping systems across Europe. Precis. Agric. 2020, 21, 34–50. [Google Scholar] [CrossRef]

- Schimmelpfennig, D. Farm Profits and Adoption of Precision Agriculture. 2016. Available online: https://www.researchgate.net/publication/309565269_Farm_Profits_and_Adoption_of_Precision_Agriculture (accessed on 24 September 2022).

- Mondal, P.; Basu, M. Adoption of precision agriculture technologies in India and in some developing countries: Scope, present status and strategies. Prog. Nat. Sci. 2009, 19, 659–666. [Google Scholar] [CrossRef]

- Bovensiepen, G.; Hombach, R. Quo Vadis, Agricola? Smart Farming: Nachhaltigkeit und Effizienz Durch den Einsatz Digitaler Technologien. 2016. Available online: https://www.pwc.de/de/handel-und-konsumguter/assets/smart-farming-studie-2016.pdf (accessed on 24 September 2022).

- Robertson, M.; Isbister, B.; Maling, I.; Oliver, Y.; Wong, M.; Adams, M.; Bowden, B.; Tozer, P. Opportunities and constraints for managing within-field spatial variability in Western Australian grain production. Field Crops Res. 2007, 104, 60–67. [Google Scholar] [CrossRef]

- Kutter, T.; Tiemann, S.; Siebert, R.; Fountas, S. The role of communication and co-operation in the adoption of precision farming. Precis. Agric. 2011, 12, 2–17. [Google Scholar] [CrossRef]

- Gandorfer, M.; Meyer-Aurich, A. Economic Potential of Site-Specific Fertiliser Application and Harvest Management. In Precision Agriculture: Technology and Economic Perspectives; Pedersen, S.M., Lind, K.M., Eds.; Springer: Cham, Switzerland, 2017; pp. 79–92. ISBN 978-3-319-68713-1. [Google Scholar]

- Robertson, M.J.; Llewellyn, R.S.; Mandel, R.; Lawes, R.; Bramley, R.G.V.; Swift, L.; Metz, N.; O’Callaghan, C. Adoption of variable rate fertiliser application in the Australian grains industry: Status, issues and prospects. Precis. Agric. 2012, 13, 181–199. [Google Scholar] [CrossRef]

- Waltmann, M.; Gindele, N.; Doluschitz, R. Informatik in der Land-, Forst- und Ernährungswirtschaft, (S. 275-280): Fokus: Digitalisierung für Landwirtschaftliche Betriebe in Kleinstrukturierten Regione-ein Widerspruch in Sich?: Referate der 39. GIL-Jahrestagung 18.-19. Februar 2019 Wien, Österreich; Meyer-Aurich, A., Gandorfer, M., Barta, N., Gronauer, A., Kantelhardt, J., Floto, H., Eds.; Gesellschaft für Informatik e.V: Bonn, Germany, 2019; ISBN 9783885796817. [Google Scholar]

- Jensen, H.G.; Jacobsen, L.-B.; Pedersen, S.M.; Tavella, E. Socioeconomic impact of widespread adoption of precision farming and controlled traffic systems in Denmark. Precis. Agric. 2012, 13, 661–677. [Google Scholar] [CrossRef]

- Lambert, D.M.; Lowenberg-DeBoer, J.; Griffin, T.W.; Peone, J.; Payne, T.; Daberkow, S.G. Adoption, Profitability, and Making Better Use of Precision Farming Data; Dept. of Agricultural Economics, Purdue University: West Lafayette, Indiana, 2004. [Google Scholar]

- Jochinke, D.C.; Noonon, B.J.; Wachsmann, N.G.; Norton, R.M. The adoption of precision agriculture in an Australian broadacre cropping system—Challenges and opportunities. Field Crops Res. 2007, 104, 68–76. [Google Scholar] [CrossRef]

- Lawes, R.A.; Robertson, M.J. Whole farm implications on the application of variable rate technology to every cropped field. Field Crops Res. 2011, 124, 142–148. [Google Scholar] [CrossRef]

- Finger, R.; Swinton, S.M.; El Benni, N.; Walter, A. Precision Farming at the Nexus of Agricultural Production and the Environment. Annu. Rev. Resour. Econ. 2019, 11, 313–335. [Google Scholar] [CrossRef]

- European Commission. Farm to Fork Strategy-for a Fair, Healthy and Environmentally-Friendly Food System. 2020. Available online: https://food.ec.europa.eu/horizontal-topics/farm-fork-strategy_en (accessed on 24 September 2022).

- Statistisches Landesamt BW. Landwirtschaftszählung 2020 in Baden-Württemberg-Aus der Reihe Statistische Daten; Statistisches Landesamt Baden-Württemberg: Stuttgart, Germany, 2021.

- Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V. Leistungs-Kostenrechnung Pflanzenbau. Available online: https://daten.ktbl.de/dslkrpflanze/postHv.html (accessed on 24 September 2022).

- Schimmelpfennig, D.; Ebel, R. Sequential Adoption and Cost Savings from Precision Agriculture. J. Agric. Resour. Econ. 2016, 41, 97–115. [Google Scholar]

- Karatay, Y.N.; Meyer-Aurich, A. Profitability and downside risk implications of site-specific nitrogen management with respect to wheat grain quality. Precis. Agric. 2020, 21, 449–472. [Google Scholar] [CrossRef]

- Whelan, B.M.; McBratney, A.B. The “Null Hypothesis” of Precision Agriculture Management. Precis. Agric. 2000, 2, 265–279. [Google Scholar] [CrossRef]

- Robertson, M.J.; Lyle, G.; Bowden, J.W. Within-field variability of wheat yield and economic implications for spatially variable nutrient management. Field Crops Res. 2008, 105, 211–220. [Google Scholar] [CrossRef]

- Statistisches Landesamt BW. Ertragsentwicklung Ausgewählter Feldfrüchte 1988–2021. Available online: https://www.statistik-bw.de/Landwirtschaft/Ernte/Feldfruechte-LR-1988.jsp (accessed on 24 September 2022).

- Morari, F.; Zanella, V.; Sartori, L.; Visioli, G.; Berzaghi, P.; Mosca, G. Optimising durum wheat cultivation in North Italy: Understanding the effects of site-specific fertilization on yield and protein content. Precis. Agric. 2018, 19, 257–277. [Google Scholar] [CrossRef]

- Basso, B.; Cammarano, D.; Fiorentino, C.; Ritchie, J.T. Wheat yield response to spatially variable nitrogen fertilizer in Mediterranean environment. Eur. J. Agron. 2013, 51, 65–70. [Google Scholar] [CrossRef]

- Colaço, A.F.; Bramley, R. Do crop sensors promote improved nitrogen management in grain crops? Field Crops Res. 2018, 218, 126–140. [Google Scholar] [CrossRef]

- Basso, B.; Dumont, B.; Cammarano, D.; Pezzuolo, A.; Marinello, F.; Sartori, L. Environmental and economic benefits of variable rate nitrogen fertilization in a nitrate vulnerable zone. Sci. Total Environ. 2016, 545–546, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Gandorfer, M.; Rajsic, P. Modeling Economic Optimum Nitrogen Rates for Winter Wheat When Inputs Affect Yield and Output-Price. Agric. Econ. Rev. 2008, 9, 54–63. [Google Scholar]

- Long, D.S.; Engel, R.E.; Carlson, G.R. Method for Precision Nitrogen Management in Spring Wheat: II. Implementation. Precis. Agric. 2000, 2, 25–38. [Google Scholar] [CrossRef]

- Bongiovanni, R.G.; Robledo, C.W.; Lambert, D.M. Economics of site-specific nitrogen management for protein content in wheat. Comput. Electron. Agric. 2007, 58, 13–24. [Google Scholar] [CrossRef]

- Meyer-Aurich, A.; Griffin, T.W.; Herbst, R.; Giebel, A.; Muhammad, N. Spatial econometric analysis of a field-scale site-specific nitrogen fertilizer experiment on wheat (Triticum aestuvum L.) yield and quality. Comput. Electron. Agric. 2010, 74, 73–79. [Google Scholar] [CrossRef]

- Meyer-Aurich, A.; Weersink, A.; Gandorfer, M.; Wagner, P. Optimal site-specific fertilization and harvesting strategies with respect to crop yield and quality response to nitrogen. Agric. Syst. 2010, 103, 478–485. [Google Scholar] [CrossRef]

- Yost, M.A.; Kitchen, N.R.; Sudduth, K.A.; Massey, R.E.; Sadler, E.J.; Drummond, S.T.; Volkmann, M.R. A long-term precision agriculture system sustains grain profitability. Precis. Agric. 2019, 20, 1177–1198. [Google Scholar] [CrossRef]

- Havlin, J.L.; Heiniger, R.W. A variable-rate decision support tool. Precis. Agric. 2009, 10, 356–369. [Google Scholar] [CrossRef]

- European Commission. Price Dashboard No 116-January 2022 Edition. 2022. Available online: https://ec.europa.eu/info/sites/default/files/food-farming-fisheries/farming/documents/commodity-price-dashboard_2022-02_en.pdf (accessed on 24 September 2022).

- Statistisches Bundesamt. Allgemeine Preisstatistik. Available online: https://www.bmel-statistik.de/preise/allgemeine-preisstatistik#c9447 (accessed on 24 September 2022).

- Koch, B.; Khosla, R.; Frasier, W.M.; Westfall, D.G.; Inman, D. Economic Feasibility of Variable-Rate Nitrogen Application Utilizing Site-SpecificManagement Zones. Agron. J. 2004, 96, 1572–1580. [Google Scholar] [CrossRef]

- Shockley, J.M.; Dillon, C.R.; Stombaugh, T.S. A Whole Farm Analysis of the Influence of Auto-Steer Navigation on Net Returns, Risk, and Production Practices. J. Agric. Appl. Econ. 2011, 43, 57–75. [Google Scholar] [CrossRef]

- Mees, M.; Hedtrich, J. Investitionszyklen bei GPS-Gestützter Technik. Available online: https://llh.hessen.de/unternehmen/unternehmensfuehrung/analyse-strategie-und-finanzen/investitionszyklen-bei-gps-gestuetzter-technik/ (accessed on 24 September 2022).

- Sørensen, C.G.; Rodias, E.; Bochtis, D. Auto-Steering and Controlled Traffic Farming–Route Planning and Economics. In Precision Agriculture: Technology and Economic Perspectives; Pedersen, S.M., Lind, K.M., Eds.; Springer: Cham, Switzerland, 2017; pp. 129–145. ISBN 978-3-319-68713-1. [Google Scholar]

- Treiber-Niemann, H.; Schwaiberger, R.; Fröba, N.; Kloepfer, F. (Eds.) Parallelfahrsysteme; KTBL: Darmstadt, Germany, 2013; ISBN 9783941583849. [Google Scholar]

- Achilles, W.; Anter, J.; Belau, T.; Blankenburg, J. (Eds.) Faustzahlen Für Die Landwirtschaft; Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V. (KTBL): Darmstadt, Germany, 2018; ISBN 9783945088593. [Google Scholar]

- van Henten, E.J.; Goense, D.; Lokhorst, C. Precision Agriculture’09; Wageningen Academic Publishers: Wakhningen, The Netherlands, 2009; ISBN 978-90-8686-113-2. [Google Scholar]

- Drücker, H. (Ed.) Precision Farming-Sensorgestützte Stickstoffdüngung; KTBL: Darmstadt, Germany, 2016. [Google Scholar]

- Reckleben, Y.; Schneider, M.; Wagner, P.; Schwarz, J.; Hüter, J. Teilflächenspezifische Stickstoffdüngung; Kuratorium für Technik und Bauwesen in der Landwirtschaft: Darmstadt, Germany, 2007; ISBN 9783939371519. [Google Scholar]

- Godwin, R.; Richards, T.; Wood, G.; Welsh, J.; Knight, S. An Economic Analysis of the Potential for Precision Farming in UK Cereal Production. Biosyst. Eng. 2003, 84, 533–545. [Google Scholar] [CrossRef]

- Miller, N.J.; Griffin, T.W.; Ciampitti, I.A.; Sharda, A. Farm adoption of embodied knowledge and information intensive precision agriculture technology bundles. Precis. Agric. 2019, 20, 348–361. [Google Scholar] [CrossRef]

- Faria, A.; Fenn, P.; Bruce, A. A count Data Model of technology adoption. J. Technol. Transf. 2003, 28, 63–79. [Google Scholar] [CrossRef]

- Vecchio, Y.; Agnusdei, G.P.; Miglietta, P.P.; Capitanio, F. Adoption of Precision Farming Tools: The Case of Italian Farmers. Int. J. Environ. Res. Public Health 2020, 17, 869. [Google Scholar] [CrossRef]

- Khanna, M.; Epouhe, O.F.; Hornbaker, R. Site-Specific Crop Management: Adoption Patterns and Incentives. Appl. Econ. Perspect. Policy 1999, 21, 455–472. [Google Scholar] [CrossRef]

- Ministerium für Ernährung, Ländlichen Raum und Verbraucherschutz-Baden-Württemberg. Betriebswirtschaftliche Ausrichtung-Ergebnisse der Landwirtschaftszählung. 2020. Available online: https://www.landwirtschaft-bw.info/pb/,Lde/3650826_3651462_5405915_5378885_5378985_5401010_5401663 (accessed on 13 October 2022).

- Statistisches Bundesamt. Land- und Forstwirtschaft, Fischerei-Betriebswirtschaftliche Ausrichtung und Standardoutput Agrarstrukturerhebung. 2017. Available online: https://www.destatis.de/DE/Themen/Branchen-Unternehmen/Landwirtschaft-Forstwirtschaft-Fischerei/Landwirtschaftliche-Betriebe/Publikationen/Downloads-Landwirtschaftliche-Betriebe/betriebswirtschaftliche-ausrichtung-standardoutput-2030214169004.pdf?__blob=publicationFile (accessed on 13 October 2022).

| Variable | Lower Limit | Upper Limit | Influenceability | References |

|---|---|---|---|---|

| Changes on revenue side | ||||

| Natural yield variability | ±20% | No | [39,40,41,42,43,44] | |

| Yield change through technology use | 0% | 4% | Yes | [10,11,32,44,45,46] |

| Technologically induced product price change | 0% | 5% | Yes | [11,27,32,43,47,48,49,50,51,52] |

| Price fluctuations on the market | ±10% | No | [39,53,54,55] | |

| Changes on direct cost side | ||||

| Technologically induced input savings | 1% | 5% | Yes | [10,11,32,56,57,58] |

| Input price changes | ±10% | No | [33,39,53,55] | |

| European Green Deal (amount of fertilizer) | −20% | No | [35] | |

| Changes on variable operating cost side | ||||

| Reduction in variable labor costs | 0% | 4.2% | Yes | [10,11,32,57,58,59] |

| Changes on fixed operating cost side | ||||

| Farm size (in ha) | 11 | 303 | Yes | Assumption, [36] |

| Learning costs (deviation from mean) | −50% | +300% | Partially | Assumption based on expert interviews |

| Investment costs IST (in €) | 5150 | 16,150 | Partially | [25,32,58,60,61] |

| Investment costs YET Farm 1 (in €) | 22.986 | 40.850 | Partially | [10,25,37,61,62,63,64] |

| Investment costs YET Farm 2 (in €) | 28.105 | 51.554 | Partially | [10,25,37,61,62,63,64] |

| Investment costs YET Farm 3 (in €) | 31.390 | 58.424 | Partially | [10,25,37,61,62,63,64] |

| Useful life/depreciation period (deviation from mean) | −50% | +150% | Partially | [32,61] |

| Fixed Technology Costs ha−1 a−1 | |||||||

|---|---|---|---|---|---|---|---|

| Input-Saving Technology | Yield-Enhancing Technology | ||||||

| Farm 1 | Farm 2 | Farm 3 | Farm 1 | Farm 2 | Farm 3 | ||

| Aquisition costs | low | 46.2 | 8.9 | 1.7 | 263.0 | 68.8 | 15.2 |

| medium | 92.7 | 18.0 | 3.4 | 372.2 | 98.3 | 21.9 | |

| high | 144.8 | 28.1 | 5.3 | 473.9 | 129.0 | 29.0 | |

| Learning costs | low | 92.0 | 17.8 | 3.4 | 367.9 | 97.5 | 21.7 |

| medium | 92.7 | 18.0 | 3.4 | 372.2 | 98.3 | 21.9 | |

| high | 95.4 | 18.5 | 3.5 | 389.4 | 101.7 | 22.5 | |

| Depreciation period | low | 175.1 | 33.9 | 6.4 | 729.4 | 193.8 | 43.2 |

| medium | 92.7 | 18.0 | 3.4 | 372.2 | 98.3 | 21.9 | |

| high | 65.2 | 12.6 | 2.4 | 253.2 | 66.5 | 14.8 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munz, J.; Schuele, H. Influencing the Success of Precision Farming Technology Adoption—A Model-Based Investigation of Economic Success Factors in Small-Scale Agriculture. Agriculture 2022, 12, 1773. https://doi.org/10.3390/agriculture12111773

Munz J, Schuele H. Influencing the Success of Precision Farming Technology Adoption—A Model-Based Investigation of Economic Success Factors in Small-Scale Agriculture. Agriculture. 2022; 12(11):1773. https://doi.org/10.3390/agriculture12111773

Chicago/Turabian StyleMunz, Johannes, and Heinrich Schuele. 2022. "Influencing the Success of Precision Farming Technology Adoption—A Model-Based Investigation of Economic Success Factors in Small-Scale Agriculture" Agriculture 12, no. 11: 1773. https://doi.org/10.3390/agriculture12111773

APA StyleMunz, J., & Schuele, H. (2022). Influencing the Success of Precision Farming Technology Adoption—A Model-Based Investigation of Economic Success Factors in Small-Scale Agriculture. Agriculture, 12(11), 1773. https://doi.org/10.3390/agriculture12111773