Abstract

Ammonia emissions are both an environmental and health issue. Biological preparations (also known as biopreparations) have attracted interests as a tool to reduce ammonia emissions from livestock. However, little is known about their effectiveness in modulating evaporating NH3 from manure. The aim of this study was to evaluate the effectiveness of one biopreparation product (MycroZyme© Micron Bio-Systems Ltd., Bridgwater, UK) by studying the dynamics of NH3 gas evolution, taking into account factors such as manure storage time (fresh or stored) and the application method (sprayed or mixed). Experimental studies were performed with control manure (manure without biopreparation) and manure treated with the biopreparation. Data showed that the use of biopreparation slowed down the ammonia emission from manure, so the ammonia concentration in the wind tunnel decreased on average from 21.69 ± 0.9 to 14.43 ± 1.5 ppm. The effect of the biopreparation on ammonia evaporation was higher in the presence of more intensive ammonia emission conditions; i.e., when the manure was fresh, there was no crust on the surface, and the airflow over the manure was intense, and there was a large gradient of ammonia concentration on the manure surface. Based on the obtained results, recommendations were made to reduce ammonia emissions in litter-less cowsheds, where liquid manure is stored.

1. Introduction

Dairy cattle manure is one of the most polluting wastes in the agricultural sector. Intensive dairy farming produces large amounts of manure with high concentrations of organic matter, including nitrogen [1,2,3]. Indeed, the livestock farming sector is the main source of atmospheric forms of nitrogen, such as ammonia, worldwide [4]. Livestock emits 83–91% of total ammonia emissions to the environment (i.e., about 8–9 million tonnes per year) [4,5,6,7]. It is therefore important to have a good understanding of the key factors influencing such emissions in order to develop effective strategies to reduce air pollution.

Ammonia is considered an atmospheric pollutant that reacts in the atmosphere due to its high solubility in water to form ammonium (NH4+) compounds [6]. These compounds can have significant adverse effects on the biodiversity of natural and semi-natural ecosystems due to acidity and eutrophication in both terrestrial and aquatic environments. Ammonia can also be dangerous to human health [4,6,7,8]. In addition, during the evaporation of NH3 from livestock manure, farmers lose valuable nutrient nitrogen resources because the loss of ammonia-N reduces the quality of manure fertilizers, and agricultural systems often require additional nitrogen supplementation using mineral nitrogen fertilizers [6,7]. Therefore, animal manure needs to be properly treated and disposed of in order to minimise the risk to the environment and at the same time to recover nutrients [9].

Several technological [4,6], chemical [6,8], and biological [4,7,8,9,10,11,12,13] preparations are known to reduce the release of NH3 from manure. The technological and chemical methods help in reducing the release of NH3 from manure, but they have several shortcomings, such as the high costs for equipment, difficulties in implementing, and potential cause creation of by-products. Air pollution can be reduced by a variety of preventive (aeration, alkali, temperature sanitation, etc.), technological (scrubbers, biofilters, ozonation, irradiation), and chemical (synthetic essential oils, terpenes, glycols, ethylene oxide, etc.) methods. Chemicals are camouflage and therefore only change the threshold of discomfort but do not eliminate the causes of unpleasant odours. The harmfulness of deodorizing compounds has not been established [11]. Other chemicals that are designed to disinfect a contaminated object are toxic and destroy both pathogenic and probiotic microflora, and their residual products can remain toxic for long periods of time [12]. Therefore, innovative farming needs to find the most natural ways to reduce harmful emissions to the environment. Recently, there has been an increasing focus on biological preparations, also called biopreparations, that are based on bacterial cultures or enzymes being environmentally friendly and not requiring special equipment for their use [10,11,12,13]. According to the known mode of the action, biopreparations are divided into several groups that include agents that improve the biodegradability of manure and consist of strains of microorganisms and/or enzymes, acidifying additives that lower the pH of manure, absorbent additives, and urease inhibitors [4]. Various biopreparations consisting of microorganisms and enzymes of different compositions are most widely used on farms [9,10,11,12,13]. However, little is known about the effectiveness of these additives in evaporating NH3 from manure. Therefore, the aim of this research was to determine the influence of one commercially available biopreparation product on the evaporation of ammonia from manure, focusing mainly on the effects of application method, manure storage time, and ventilation intensity. Based on the findings of the study, the overarching goal was to develop recommendations for the use of biological preparations in cattle housing. We hypothesized that the use of the biopreparation can reduce ammonia emissions from manure, and this effect will depend on the duration of application as well as on the application method.

2. Materials and Methods

2.1. Experimental Conditions

The research was carried out at the Institute of Mechanics, Energy and Biotechnology Engineering, the Thermal Energy Processes and Emissions Laboratory at Vytautas Magnus University, Lithuania. Liquid cattle manure used for the research was collected from the site near the milking room in a semi-deep cowshed, using the technique described in detail by our team earlier [10]. Briefly, manure samples were collected in 40 L chambers in the cowshed. To ensure the homogeneity of the manure in the chambers, the manure was thoroughly mixed in the barn with a manual mixer and then loaded into the chambers.

The biopreparation product used in this experiment was a probiotic composition (MycroZyme©) purchased from Micron Bio-Systems Ltd., Bridgwater, UK, and containing strains of Bacillus subtilis, Bacillus licheniformis, and Bacillus amyloliquefaciens in 7 billion bacterial colony forming units (CFU) per mL). Before use, the biopreparation was diluted (5 mL in 100 mL water) with water free of active chlorine based on the protocol of the company.

2.2. Methodology and Equipment for Measuring Ammonia Emissions from Manure

We performed eight trials to determine ammonia emissions from the stored manure without or with treatment using the biopreparation. In each trial, the first storage tank of liquid cattle manure with a capacity of 25 L was sprayed with the 100 mL diluted solution of the biopreparation. The second storage tank (chamber No. 2) with the same capacity (25 L) of liquid cattle manure was not sprayed and served as control. Ammonia emissions trials from the manure treated with biopreparations or not were performed in a wind tunnel bench, using the method described in detail earlier [10]. The manure was stored in both chambers under the same aerobic conditions at a constant temperature of 18.7 ± 0.2 °C. Periodically, every 10 days, each manure chamber was placed in a wind tunnel, and ammonia emissions from the manure were determined. The manure was mixed with a wooden spatula before each test. Each emission test was performed for up to 1.5 h. The test was performed at a constant air flow above the manure and at a constant ambient temperature. The air velocity in the 100 mm diameter duct was determined before each test at 0.1 ± 0.02 ms−1. To analyse the influence of air ventilation velocity on ammonia emissions, studies were performed at air velocities of 0.1 and 0.7 m s−1 as described earlier [10]. The pH of the manure and the dry matter content of the manure were determined before the tests. Laboratory tests were performed for 3 months.

An analyser GME700 (laser spectroscopy) was used to measure the ammonia (NH3) gas concentration (Supplementary Figure S1). The measuring range of NH3 was from 0 to 2000 ppm. Air temperature and humidity were measured by temperature and humidity sensors connected to the “Almemo 2590-9” system. Measuring range was for temperature from 30 to 60 °C, relative humidity from 5 to 98%, and the accuracy of the device was ±0.1%.

2.3. Statitical Analysis

Data were tested for normality (Bonferroni test), and descriptive statistics was performed, including the means and the indicators of the variance for all variables measured. The reliability of statistical data was assessed according to the Student’s t-test. The standard error and the cut-off for the minimum confidence interval were calculated at the statistical significance level of p < 0.05.

The dependency of the obtained variables over time was analysed using polynomial regression analyses. The goodness of the fit was evaluated by the determination coefficient (R2).

3. Results and Discussion

3.1. Ammonia Gas Emissions from Cattle Manure Mixed or Sprayed with Biopreparation with Various Storage Times

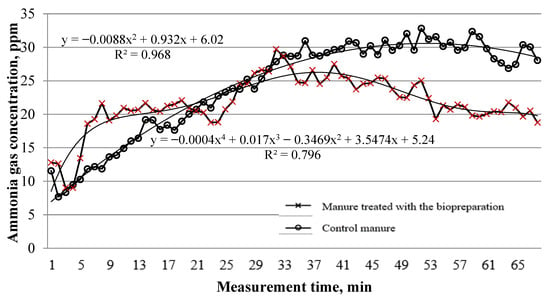

Data of the changes in ammonia emissions from fresh manure either mixed and homogenized with biopreparation or without being mixed with biopreparation (control) are shown in Figure 1. In the control manure, there was an increase of the ammonia concentration in the wind tunnel from initially 10–15 ppm to around 25 ppm after 33 min, the time when a plateau was reached, as supported by the quadratic regression. However, when the biopreparation were mixed, the polynomial regression revealed a cubic term, indicating in the first 10 min a greater emission but decreasing trend of ammonia release up to 20 ppm after 33 min, likely suggesting an effect of the biopreparation starting after around 33 min of the activity.

Figure 1.

Ammonia concentration when fresh liquid cattle manure was mixed and homogenized with biopreparation or not (control) as measured in the wind tunnel up to 67 min.

When biopreparation was sprayed onto the fresh manure, there was a different curve of ammonia emission, which is shown in Figure 2. Accordingly, after spraying the manure on the surface with the biopreparation, a significant difference again with a cubic term in the values of ammonia concentration in the wind tunnel was found. As expected, the control manure performed the same as in the first case of mixed biopreparation shown in Figure 1.

Figure 2.

Change in the ammonia concentration in the wind tunnel with time after addition of manure sprayed with biopreparation (biologically treated manure) or the manure without additives (control).

Our data showed that there were significant (1.5-fold) reductions in ammonia emissions from the manure sprayed with the biopreparation on the fresh manure. As a whole, the ammonia concentrations ranged from 7 to 33 ppm during the testing. At the beginning of the testing, an increase in ammonia emissions was observed from both manures, which persisted for most of the study period, and then, the emissions from the control manure (manure without additives) stabilised. After 21–25 min, the ammonia emission from the manure sprayed with the biopreparation decreased polynomially, and after one hour in the wind tunnel, the concentration was less than 12 ppm. Based on the results of this measurement, it can be stated that spraying manure with the biopreparation reduced ammonia emissions, and therefore, the concentration in the wind tunnel decreased on average from 21.69 ± 0.9 to 14.43 ± 1.5 ppm. During the tests (within 70 min), the average ammonia concentration in the wind tunnel after the loading of the control manure was 24.3 ppm and after the loading of the manure treated with the biopreparation was 14.5 ppm, i.e., 40% lower.

The difference in ammonia emissions from the control manure and the manure treated with the biopreparation after certain periods confirms the results obtained previously in the manure of broilers [13] and laying hens [14] and shows the effectiveness of the biopreparation in influencing the targeted processes in manure and in reducing ammonia gas release into the environment. Rational use of the selected measures [15] can effectively reduce odours and ammonia gas emissions from the cattle manure. The ammonia reshuffle into simple compounds occurs in two stages. The first stage is nitrification, in which ammonia is oxidized to nitrite (nitritation), and then, nitrite is oxidized to nitrate (nitratation), whereas the second step is denitrification, in which nitrate is decomposed to nitrogen gas [16]. An explanation of the stronger effect of spraying biopreparation on the ammonia emission than of mixing can be the direct effect of the bacterial strains in the biopreparation on the pH in the surface of the manure. Bacterial probiotics are known to decrease in pH by producing lactic acid [17]. A lower pH can inhibit the urease activity [18] and hence degradation of manure ammonium nitrogen into ammonia gas.

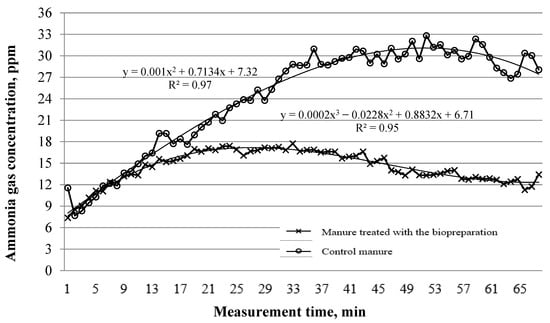

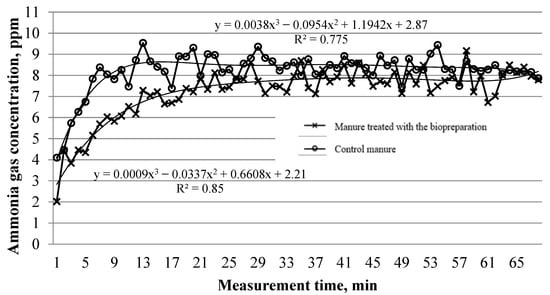

After 10 days, another trial of ammonia emissions was performed without mixing the manure in both chambers, maintaining a constant air velocity of 0.1 ms−1 in the air duct. The results are presented in Figure 3.

Figure 3.

Change in ammonia concentration in the wind tunnel with the addition of the manure treated with the biopreparation and the control manure without additives (10 days after the addition of the biopreparation without mixing the manure).

Taking into account the changes in the manure treated with the biopreparation and the control manure presented in Figure 3, a uniform and insignificant change in gas concentration was found in both test manures when evaluated in parallel during the evaluation of the intensity of ammonia gas dispersion after 10 days. The ammonia emissions from both types of manure changed insignificantly: in the wind tunnel, the concentration varied from 9 to 15 ppm in the case of the control manure and from 7 to 11 ppm in the case of the manure treated with the biopreparation; i.e., the ammonia emissions were 23.2% lower. After 10 days of application of the biological preparation to the cattle manure, the ammonia emissions from the biologically treated manure decreased on average by two times, and regarding the manure without additives, the ammonia emissions were reduced by 1.89 times. Thus, no significant difference was observed between the determined ammonia emission values.

Manure was mixed in both chambers, and comparative studies of ammonia emissions were performed. The results are shown in Figure 4. After mixing the manure, the intensity of the ammonia emissions differed less from the two types of manure. In the wind tunnel, the average ammonia concentration over 70 min was 18.1 ppm for the control manure and 15.3 ppm for the manure treated with the biopreparation; i.e., the intensity of the ammonia emissions differed by 15.4%.

Figure 4.

Change in ammonia concentration in the wind tunnel with the addition of the manure treated with the biopreparation and the control manure without additives (10 days after the addition of the biopreparation by mixing the manure).

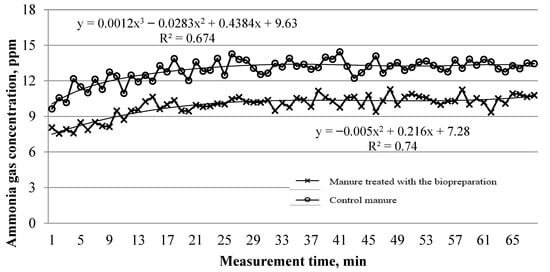

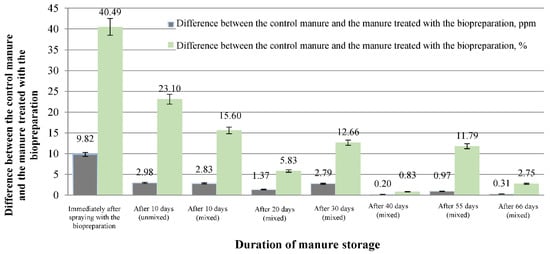

Forty-four days after the first spraying of the biopreparation on the manure surface, the manure was re-sprayed with the biopreparation, and 10 days after the second spraying, comparative ammonia emissions studies were performed by testing the control manure and the manure treated with the biopreparation. Studies were performed by increasing the ventilation intensity of the chamber so that the air velocity in the air duct was increased to 0.7 m/s (Figure 5).

Figure 5.

Change in ammonia concentration in the wind tunnel with the addition of the manure treated with the biopreparation and the control manure without additives (55 days after the addition of the biopreparation, the manure is mixed).

The manure was mixed in both chambers prior to the ammonia emissions studies. At the beginning of the study, the ammonia emission from the manure in both chambers increased, and after 13–15 min, the emission process stabilised and continued to change slightly: in the wind tunnel, the average ammonia concentration was 8.2 ppm with the addition of the control manure and 7.3 ppm with the addition of the manure treated with the biopreparation, a difference of 11.0%.

Rather similar results were obtained after 66 days of the storage of the manure, which are shown in Figure 6. The values of ammonia emissions overlapped each other, and after 10 min, the ammonia gas concentrations in the wind tunnel are stabilized at a level around 11–12 ppm.

Figure 6.

Change in ammonia concentration in the wind tunnel with the addition of the manure treated with the biopreparation and the control manure without additives (66 days after the addition of the biopreparation).

The fact that the concentration of ammonia is lower, and the effect of biopreparation on ammonia release is less can be explained with the building of the crust on the surface of the manure with time. As the manure dries, a crust forms on its outer layer, which acts as a protection against ammonia diffusion [19].

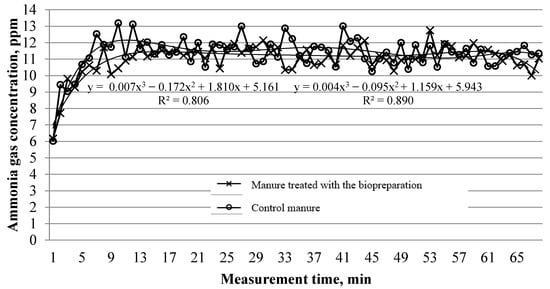

A summary of the changes in the ammonia in ppm and % relative to the control for various storage times is shown in Figure 7. According to the summarised indicators of ammonia emissions from the manure treated with the biopreparation and the control manure, differences were found only in certain periods. Significant reduction of the ammonia emissions from the manure treated with the biopreparation is achieved immediately after spraying of the biopreparation and by increasing air velocity after 55 days of manure storage, and a reduction in ammonia emissions from manure without additives was found after 10 days and also by increasing the chamber ventilation intensity. Comparing the ammonia emissions from the manure without additives and the manure treated with the biopreparation, the largest difference was found only after spraying the biopreparation and also without mixing the manure. The smallest differences in ammonia concentration were observed after 40 days of manure storage, and this could be explained by the decrease in the efficacy of the biopreparation.

Figure 7.

Difference between the average ammonia concentration values in the wind tunnel (ppm and %) after the addition of the control manure without additives and the manure treated with the biopreparation in the tunnel, depending on manure storage time 35.

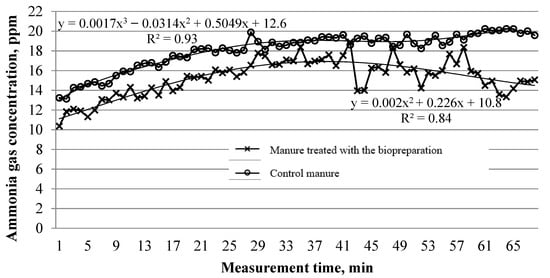

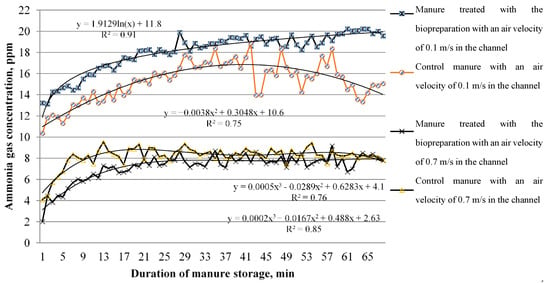

3.2. Ammonia Gas Emissions in an Environment of Variable Ventilation Intensity

The diffusion of ammonia into the environment is influenced by air velocity. During intensive ventilation, the concentration of ammonia in the air above the manure is low, which promotes more intensive evaporation of ammonia [18]. However, with a strong air flow, the top layer of manure can dry out more intensively, which in turn reduces the evaporation of ammonia [19,20,21]. Figure 8 shows changes in the ammonia emissions from the manure treated with the biopreparation and the manure without additives with two different air velocities. Throughout the study, the concentration of ammonia in the biologically treated manure chamber increased and reached higher values than in the previous study after 55 days of manure storage (Figure 5). The increasing concentration of ammonia gas may have been influenced by other factors such as intensified activity of urobacteria for urease production or changes in chemical composition of the manure [22,23].

Figure 8.

Change in ammonia concentration in the wind tunnel with the addition of the manure treated with the biopreparation and the control manure without additive at two different ventilation velocities.

In the present study, the values of ammonia gas concentration in the wind tunnel with the manure treated with the biopreparation and the control manure without additives varied 80% in parallel throughout the whole study period. However, the ammonia gas concentration values were on average 16±1 ppm for low (v = 0.1 m/s) and 7 ± 2 for the high (v = 0.7 m/s) air velocity. Theoretical studies have shown that the process of evaporation of ammonia from manure is determined by many variable and interrelated factors, one of the most important of which is air velocity. As the air velocity varies within the recommended limits in cowsheds (up to 2 m s−1 in summer), ammonia emissions change even more significantly. As the air velocity increases from 0.1 to 2.0 m s−1, the ammonia emissions increase by as much as 10 times. As air velocity increases, its effect on emissions decreases. In the air velocity range 0–0.5 m s−1, as the air velocity increases by 0.1 m s−1, the ammonia emissions increase on average by 39.4%, and in the air velocity range 1.5–2.0 m s−1, the emissions increase, respectively, by only 4.7%.

The obtained results confirm the statements of other researchers [24,25,26,27,28]: as the ventilation intensity increases, the ammonia concentration in the room decreases, and the emission increases disproportionately. Therefore, according to previous scientific studies, a 4.5-fold increase in ventilation intensity decreases the NH3 concentration in the chamber by 1.9–2.4-fold, and the emission increases by 1.7–2.5-fold (p < 0.05). However, in order to accurately compare the actual emission values with the results of the studies by other authors, all factors (air flow, the content of dry matter in manure, the chemical composition of manure, the protein content of manure, temperature, manure storage time, and the drying of manure surface) must be considered, on which the effect of ventilation intensity on gaseous emissions from manure depends.

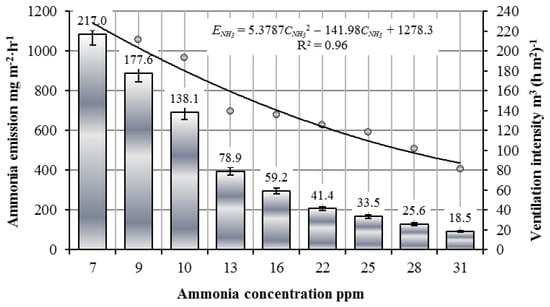

As the ventilation intensity increases, the ammonia concentration in the chamber decreases, and the emission increases rapidly [29]. As the ventilation intensity increases from 18.5 m3 (h m2)−1 to 217.0 m3(h m2)−1, the ammonia concentration decreases from 31 ppm to 7 ppm, and the emission increases from 406.4 mg m−2⋅h−1 to 1124.2 mg m−2⋅h−1. The researchers found a reliable correlation between the intensity of ammonia emission from manure and the concentration of ammonia above manure, which is expressed as a function of a second-order polynomial (R2 = 0.96) (Figure 9).

Figure 9.

Dependence of ammonia emission (line) from the liquid cattle manure on ammonia concentration at different ventilation intensities (column).

As the ventilation intensity increases, the ammonia concentration in the chamber decreases, and the emission increases rapidly. Studies with manure stored for various periods, of which the surface had unevenly dried before crushing and formed a crust, showed different ammonia emissions from the manure as well as different effects of ventilation intensity on ammonia emissions.

4. Conclusions and Recommendations

In conclusion, the study showed that spraying manure with the biopreparation product reduced ammonia emissions by as much as 40%. The effect of the biopreparation on ammonia evaporation was higher in the presence of more intensive ammonia emission; i.e., when the manure is fresh, there is no crust on the surface, the air flow over the manure is intense, and there is a large gradient of ammonia concentration on the manure surface. Nevertheless, the process of ammonia evaporating from the manure is very complex. It depends on many factors: temperature, air velocity, ventilation intensity, pH, farming system (pastures, livestock housing, waste management), nitrogen content in feed and manure, carbon-to-nitrogen ratio in manure, and manure surface area. In order to make the most efficient use of the biopreparation, more detailed, experimental studies are needed to assess the influence of various different parameters on the interaction processes between the manure and the biopreparations.

Based on the findings of this research, the following recommendations can be made to reduce ammonia emissions in litter-less cowsheds, where liquid manure is stored:

- The smallest differences in ammonia emission from both types of manure were obtained after 40 days, and an almost identical trend of ammonia emission from both chambers was found. This indicates the longest possible duration of efficacy of the biopreparation solution.

- To reduce ammonia emissions and air pollution in barns, it is recommended to spray manure with a biopreparation. The effect of the biopreparation will be higher during the warm period, especially at temperatures above 20 °C.

- After estimating the intensity of ammonia emissions from manure of different humidity, it is recommended to use the biopreparation in more liquid manure, from which gas emissions are significantly higher. It is recommended to use the biopreparation to reduce ammonia emissions in litter-less cowsheds where liquid manure accumulates. Its use is in line with the innovative tendencies of modernisation of cowsheds to implement technologies designed for liquid manure in litter-less cowsheds.

- By controlling the microclimatic factors in the manure environment, it is possible to influence the processes that take place on the manure surface and slow down the ammonia evaporation process from the manure, intensifying the crust formation and reducing the ammonia concentration gradient in the vertical above the manure. A greater effect of the biopreparation on the evaporation of ammonia can be obtained when the manure is not mixed.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/agriculture12101626/s1, Figure S1: Ammonia gas concentration measurement system with laser analyser GME700.

Author Contributions

Conceptualization, R.B. and R.M.; methodology, R.B. and R.M.; software, R.M.; validation, R.M.; investigation, R.M.; data curation, R.M.; writing—original draft preparation, R.M.; writing—review and editing, R.M.; visualization, R.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to internal laboratory restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rico, C.; García, H.; Rico, J.L. Physical–anaerobic–chemical process for treatment of dairy cattle manure. Bioresour. Technol. 2011, 102, 2143–2150. [Google Scholar] [PubMed]

- Haselmann, A.; Zehetgruber, K.; Fuerst-Waltl, B.; Zollitsch, W.; Knaus, W.; Zebeli, Q. Feeding forages with reduced particle size in a total mixed ration improves feed intake, total-tract digestibility, and performance of organic dairy cows. J. Dairy Sci. 2019, 102, 8839–8849. [Google Scholar] [PubMed]

- Khiaosa-ard, R.; Zebeli, Q. Cattle’s variation in rumen ecology and metabolism and its contributions to feed efficiency. Livest. Sci. 2014, 162, 66–75. [Google Scholar]

- Van der Stelt, B.; Temminghoff, E.J.M.; Van Vliet, P.C.J.; Van Riemsdijk, W.H. Volatilization of ammonia from manure as affected by manure additives, temperature and mixing. Bioresour. Technol. 2007, 98, 3449–3455. [Google Scholar] [PubMed]

- Sanz, A.; Misselbrook, T.H.; Sanz, M.J.; Vallejo, A. Use of an inverse dispersion technique for estimating ammonia emission from surface-applied slurry. Atmos. Environ. 2010, 44, 999–1002. [Google Scholar]

- McIlroy, J.P.; McGeough, K.L.; Laughlin, R.J.; Carolan, R. 2019. Abatement of ammonia emissions from dairy cow house concrete floor surfaces through additive application. Biosyst. Eng. 2019, 188, 320–330. [Google Scholar]

- Martínez-Lagos, J.; Salazar, F.; Alfaro, M.; Misselbrook, T. Ammonia volatilization following dairy slurry application to a permanent grassland on a volcanic soil. Atmos. Environ. 2013, 80, 226–231. [Google Scholar] [CrossRef]

- Hagenkamp-Korth, F.; Haeussermann, A.; Hartung, E.; Reinhardt-Hanisch, A. Reduction of ammonia emissions from dairy manure using novel urease inhibitor formulations under laboratory conditions. Biosyst. Eng. 2015, 130, 43–51. [Google Scholar]

- Zubair, M.; Wang, S.; Zhang, P.; Ye, J.; Liang, J.; Nabi, M.; Zhou, Z.; Tao, X.; Chen, N.; Sun, K.; et al. Biological nutrient removal and recovery from solid and liquid livestock manure: Recent advance and perspective. Bioresour. Technol. 2020, 301, 122823. [Google Scholar]

- Borowski, S.; Gutarowska, B.; Durka, K.; Korczyński, M.; Opaliński, S.; Kołacz, R. Biological deodorization of organic fertilizers. Przemysł Chem. 2010, 89, 318–323. [Google Scholar]

- Gutarowska, B.; Matusiak, K.; Borowski, S.; Rajkowska, A.; Brycki, B. Removal of odorous compounds from poultry manure by microorganisms on perlite—Bentonite carrier. J. Environ. Manag. 2014, 141, 70–76. [Google Scholar] [CrossRef]

- Naujokienė, V.; Bagdonienė, I.; Bleizgys, R.; Rubežius, M. Biotreatment Effect on Dynamics of Cattle Manure Composition and Reduction of Ammonia Emissions from Agriculture. Agriculture 2021, 11, 303. [Google Scholar] [CrossRef]

- Eglite, S.; Ilgaza, A.; Butka, M. Reduction of ammonia emissions by applying probiotics on litter in a commercial breeding poultry house. J. Artic. Agron. Res. 2021, 19 (Suppl. 2), 1015–1022. [Google Scholar]

- Ali, M.; Zubair, M.; Rosyidi, A.; Amin, M. Screening of ammonia-degrading bacteria to reduce ammonia content in the manure of laying hens. Earth Environ. Sci. 2020, 441, 012138. [Google Scholar] [CrossRef]

- Zhua, X.; Burgerb, M.; Doaneb, T.A.; Horwathb, W.R. Ammonia oxidation pathways and nitrifier denitrification are significant sources of N2O and NO under low oxygen availability. PNAS. Agric. Sci. 2013, 110, 6328–6333. [Google Scholar]

- Tang, R.Y.; Wu, Z.L.; Wang, G.Z.; Liu, W.C. The effect of Bacillus amyloliquefaciens on productive performance of laying hens. Italian. J. Anim. Sci. 2018, 17, 436–441. [Google Scholar] [CrossRef]

- Emerson, K.; Russo, R.C.; Lund, R.E.; Thurston, R.V. Aqueous ammonia equilibrium calculations: Effect of pH and temperature. J. Fish. Res. Bd. Can. 1975, 32, 2379–2383. [Google Scholar] [CrossRef]

- Ahring, B.K. Perspectives for anaerobic digestion. Adv. Biochem. Eng./Biotechnol. 2003, 81, 1–30. [Google Scholar]

- Brose, G. Emission von klimarelevanten gasen, ammoniak und geruch aus einem milchviehstall mit schwerkraftlüftung. Ph.D. Thesis, Universität Hohenheim, Stuttgart, Germany, 2000; p. 136. [Google Scholar]

- Zhang, G.; Bjerg, B.; Strøm, J.S.; Morsing, S.; Kai, P.; Tong, G.; Ravn, P. Emission effects of three different ventilation control strategies-A scale model study. Biosyst. Eng. 2008, 100, 96–104. [Google Scholar]

- Demmers, T.G.M.; Burgess, L.R.; Short, J.L.; Phillips, V.R.; Clark, J.A.; Wathes, C.M. First experiences with methods to measure ammonia emissions from naturally ventilated cattle buildings in the UK. Atmos. Environ. 1998, 32, 285–293. [Google Scholar] [CrossRef]

- Aguerre, M.J.; Wattiaux, M.A.; Powell, J.M. Emissions of ammonia, nitrous oxide, methane, and carbon dioxide during storage of dairy cow manure as affected by dietary forage–to–concentrate ratio and crust formation. J. Dairy Sci. 2012, 95, 7409–7416. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Bai, Z.; Winiwarter, W.; Ledgard, S.; Luo, J.; Liu, J.; Guo, Y.; Ma, L. Reducing Ammonia Emissions from Dairy Cattle Production via Cost-Effective Manure Management Techniques in China. Environ. Sci. Technol. 2019, 53, 11840–11848. [Google Scholar] [CrossRef]

- Philippe, F.; Cabaraux, J.; Nicks, B. Ammonia emissions from pig houses: Influencing factors and mitigation techniques. Ecosyst. Environ. 2011, 141, 245–260. [Google Scholar] [CrossRef]

- Samer, M.; Ammon, C.; Loebsin, C.; Fiedler, M.; Berg, W.; Sanftleben, P.; Brunsch, R. Moisture balance and tracer gas technique for ventilation rates measurement and greenhouse gases and ammonia emissions quantification in naturally ventilated buildings. Build. Environ. 2012, 50, 10–20. [Google Scholar] [CrossRef]

- Blanes–Vidal, V.; Hansen, M.N.; Pedersen, S.; Rom, H.B. Emissions of ammonia, methane and nitrous oxide from pig houses and slurry: Effects of rooting material, animal activity and ventilation flow. Agric. Ecosyst. Environ. 2008, 124, 237–244. [Google Scholar] [CrossRef]

- Kang, J.H.; Lee, S.J. Improvement of natural ventilation in a large factory building using a louver ventilator. Build. Environ. 2008, 43, 2132–2141. [Google Scholar] [CrossRef]

- Bagdonienė, I. Ammonia emissions from cattle manure in the environment of changing microclimate factors. Ph.D. Thesis, Alexandras Stulginskis University Academy, Kaunas, Lithuania, 2013; p. 91. [Google Scholar]

- Bagdonienė, I.; Bleizgys, R. Ammonia emissions from dairy cattle manure under variable ventilation rates. Ann. Anim. Sci. 2014, 14, 141–151. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).