Implementation of a Fuzzy Logic Controller for the Irrigation of Rose Cultivation in Mexico

Abstract

:1. Introduction

1.1. Conditions for Growing Roses

- In production, the environmental temperature (T) is approximately 17–25 °C, with a minimum vegetative temperature close to 15 °C and a maximum of 32 °C.

- During the growth period, T should be above 20–24 °C, with relative humidity (RH) around 98–100%.

- RH ranges between 70–75% demand a higher light intensity since higher intensity results in higher yields. In summer months, when brighter and longer days prevail, flower production is greater when compared to winter crop output.

- During winter, it is recommended to raise (T), irradiate with artificial lighting (implementation of lamps), and install thermal blankets to preserve heat at night.

1.2. Evapotranspiration

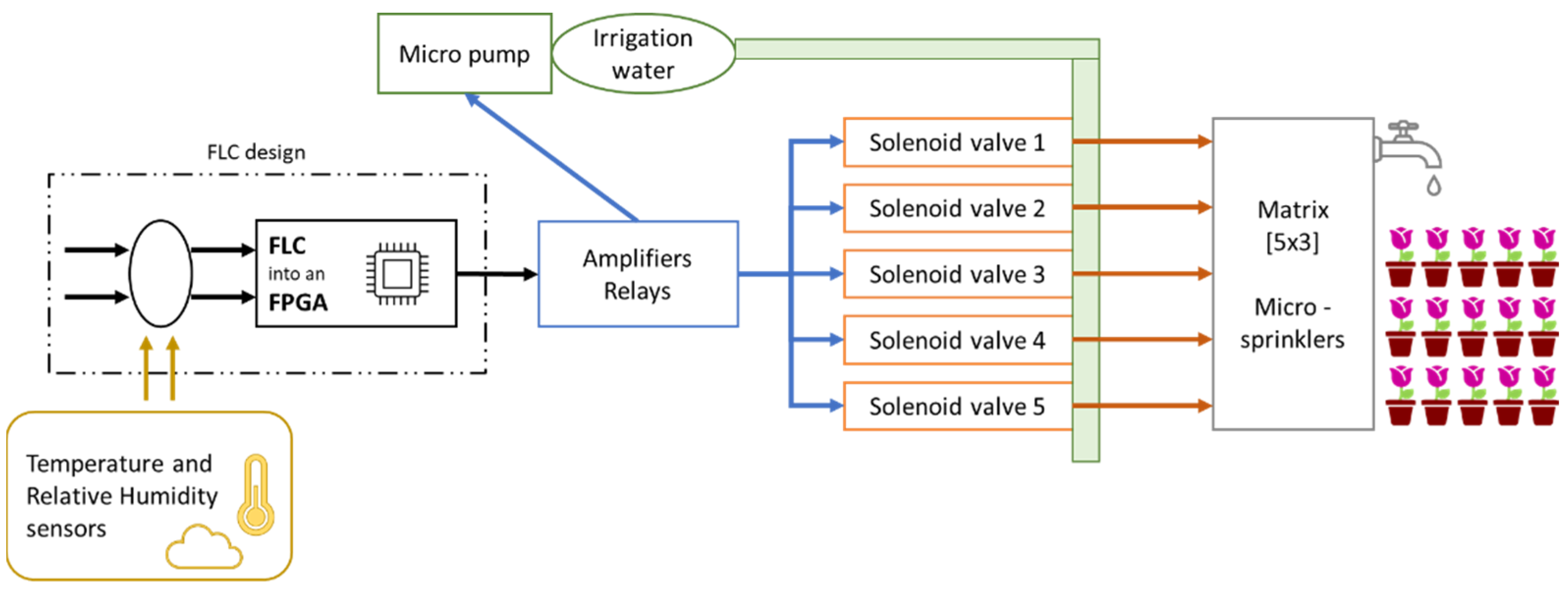

2. Materials and Methods

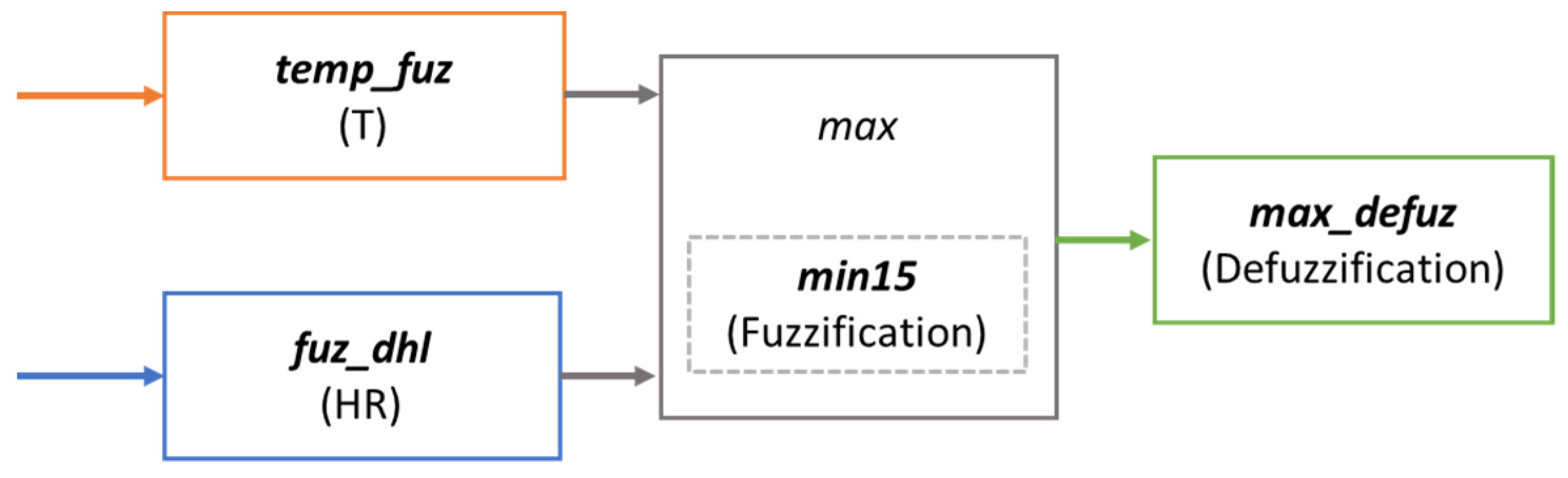

2.1. FLC Modeling

(d − EHR)/(d − c), c ≤ EHR ≤ d; 0, d ≤ HER}

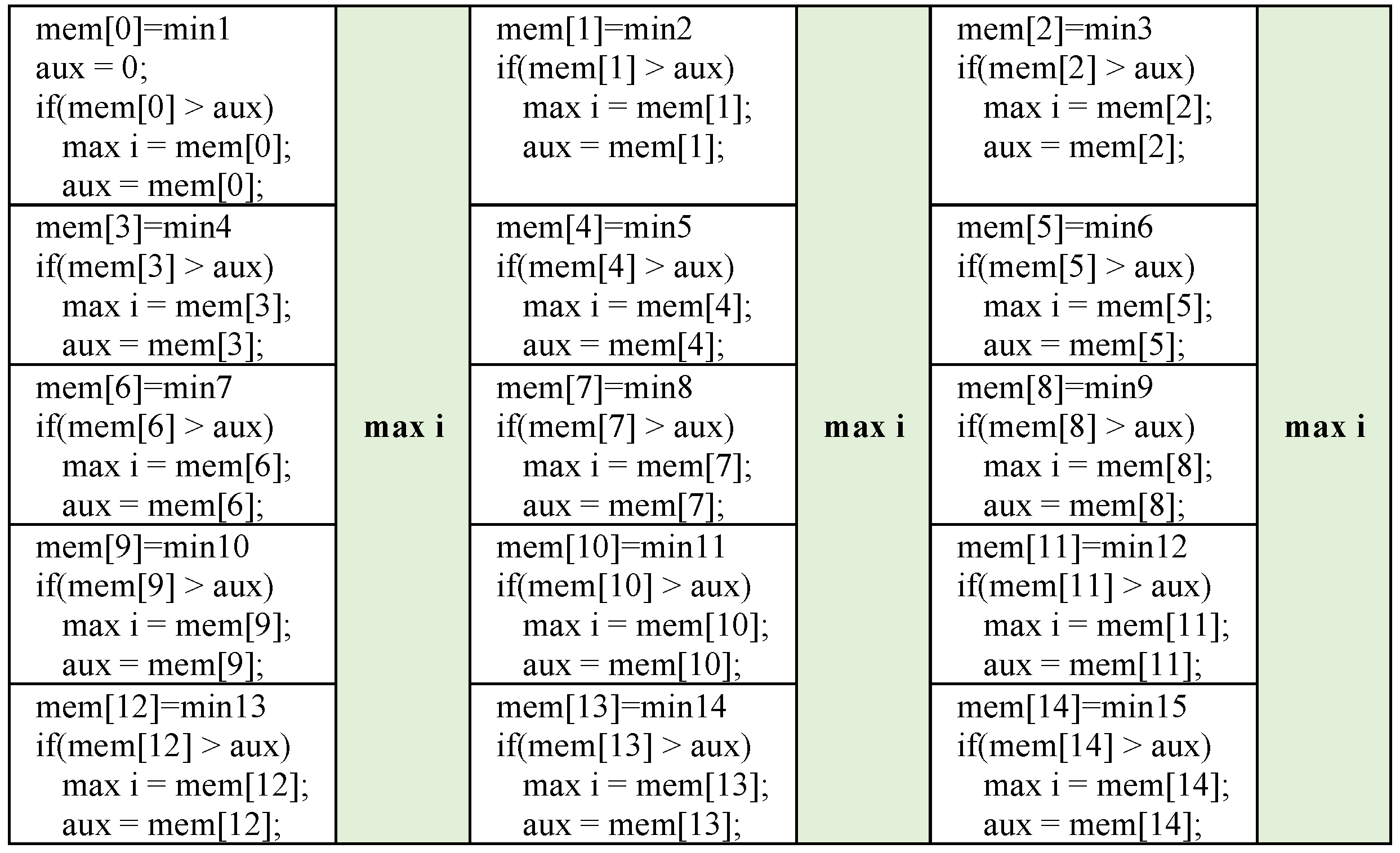

2.2. FLC Implementation

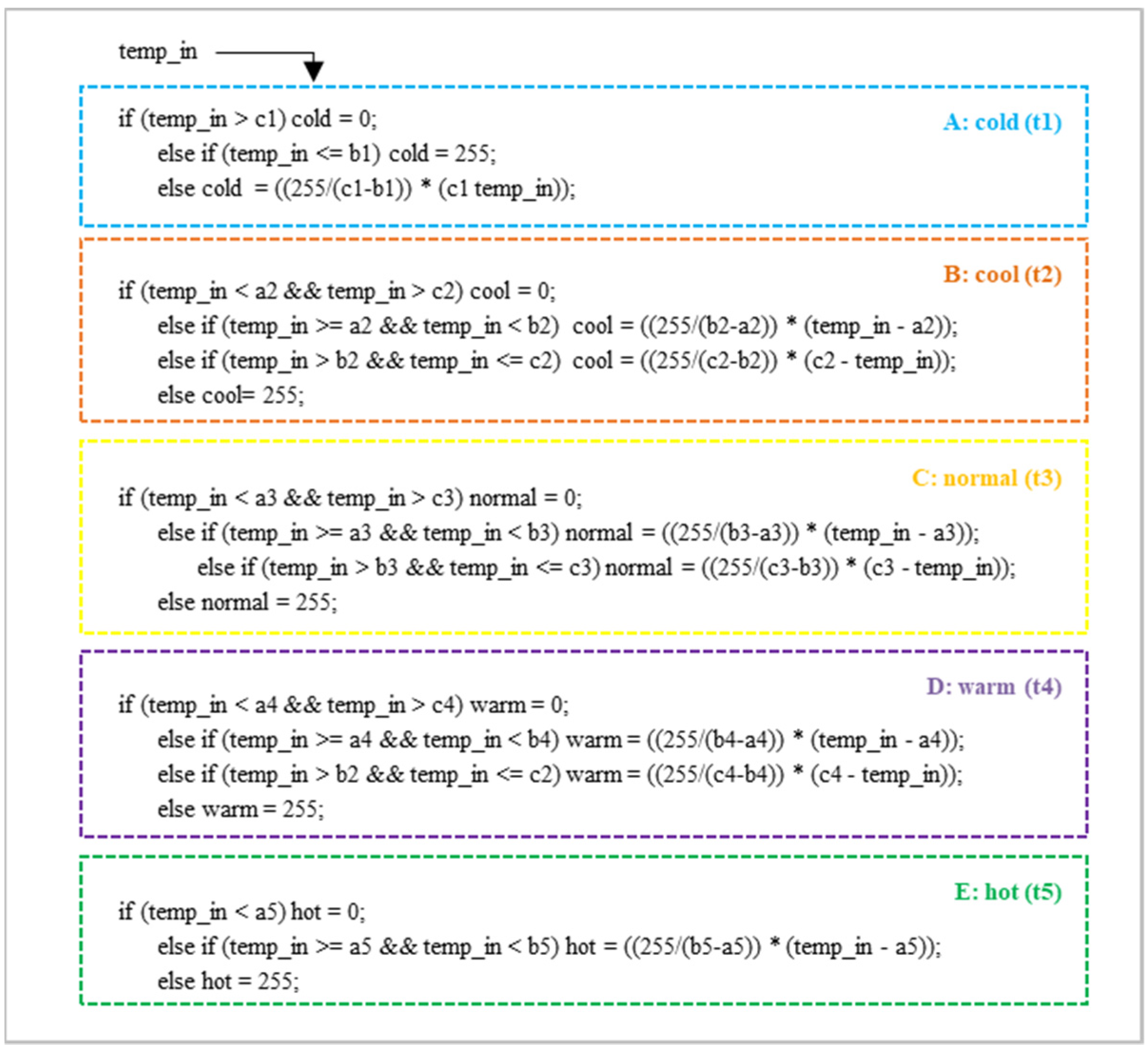

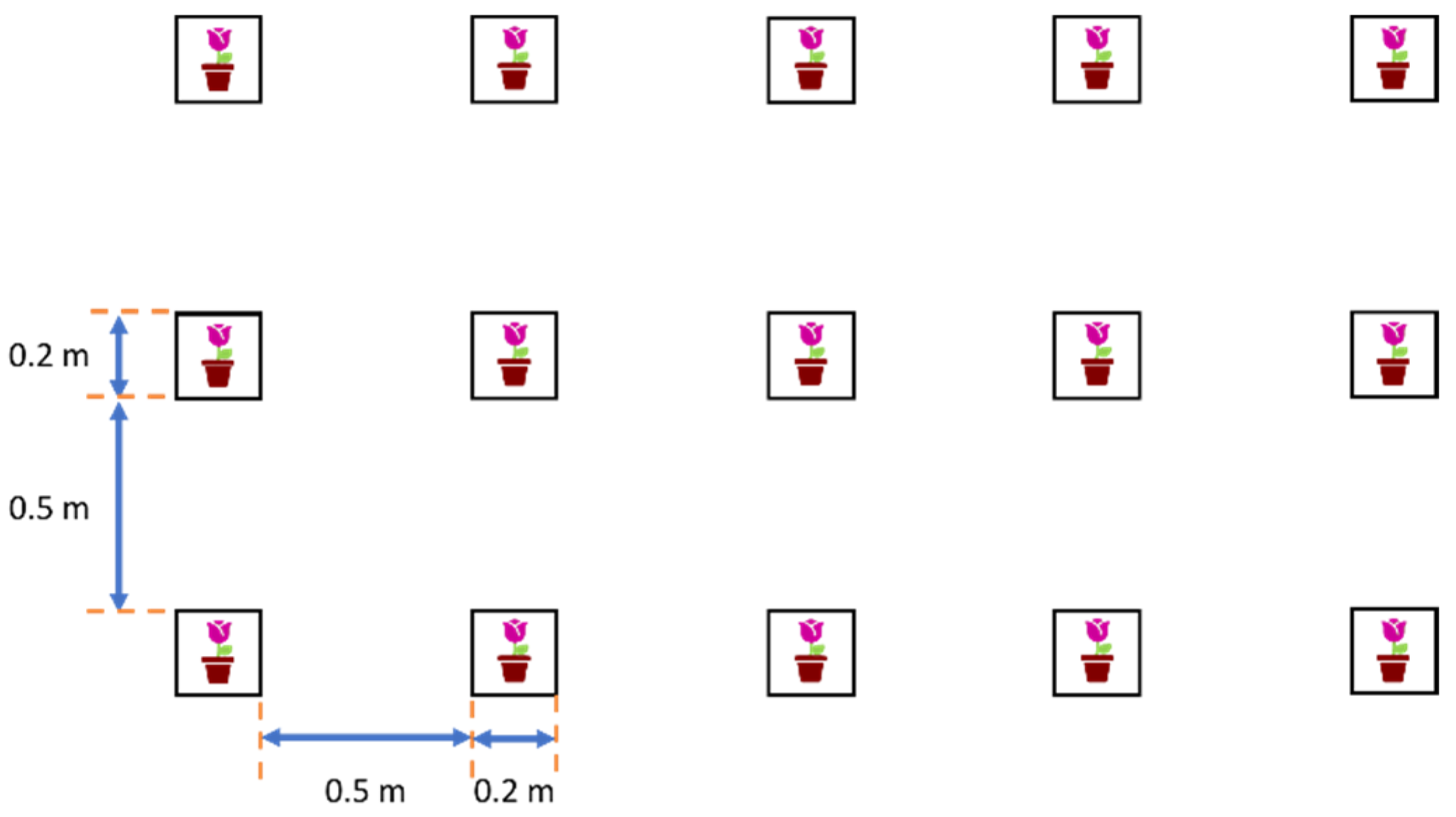

2.3. Module I: temp_fuz

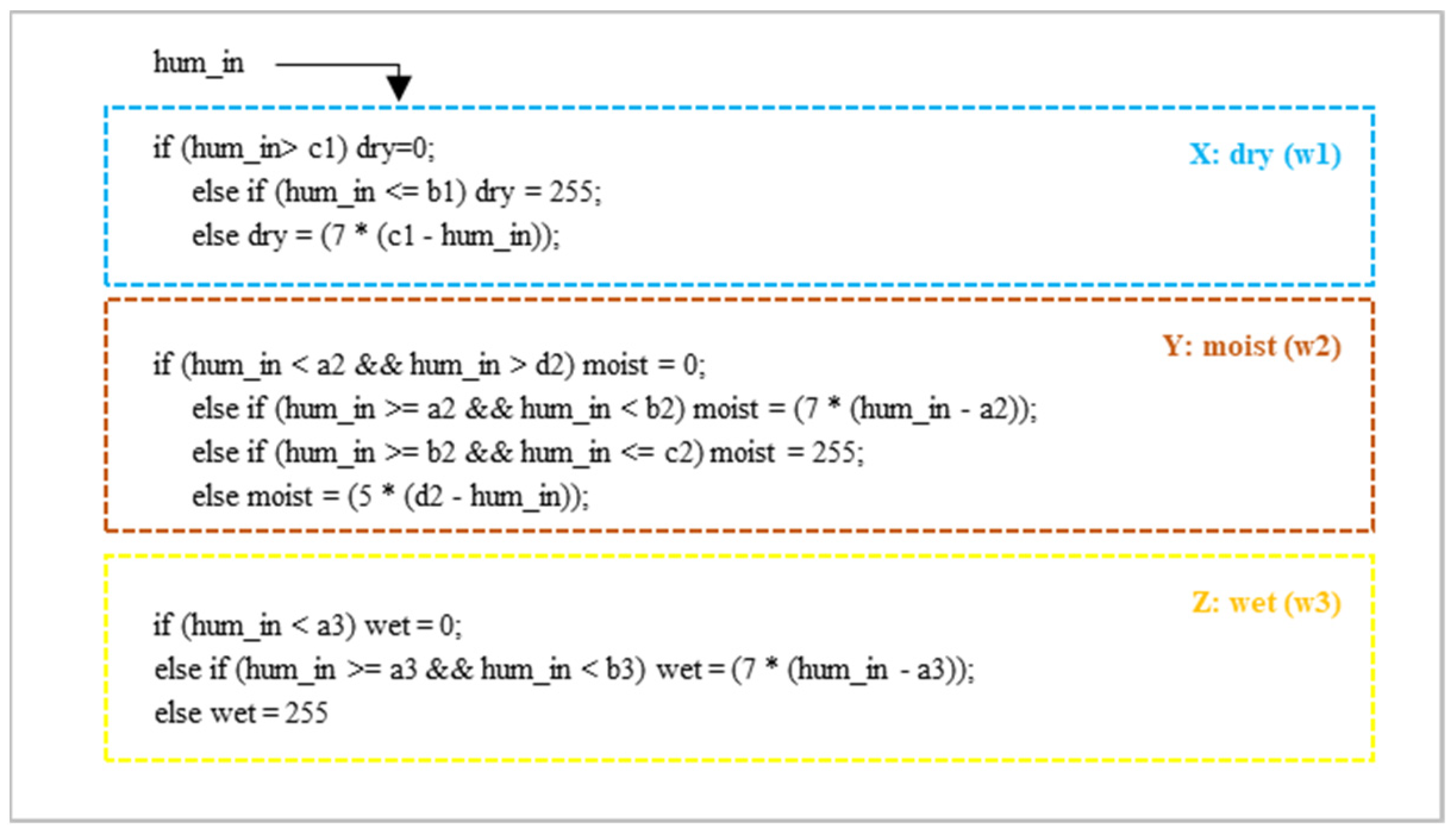

2.4. Module II: fuz_dhl

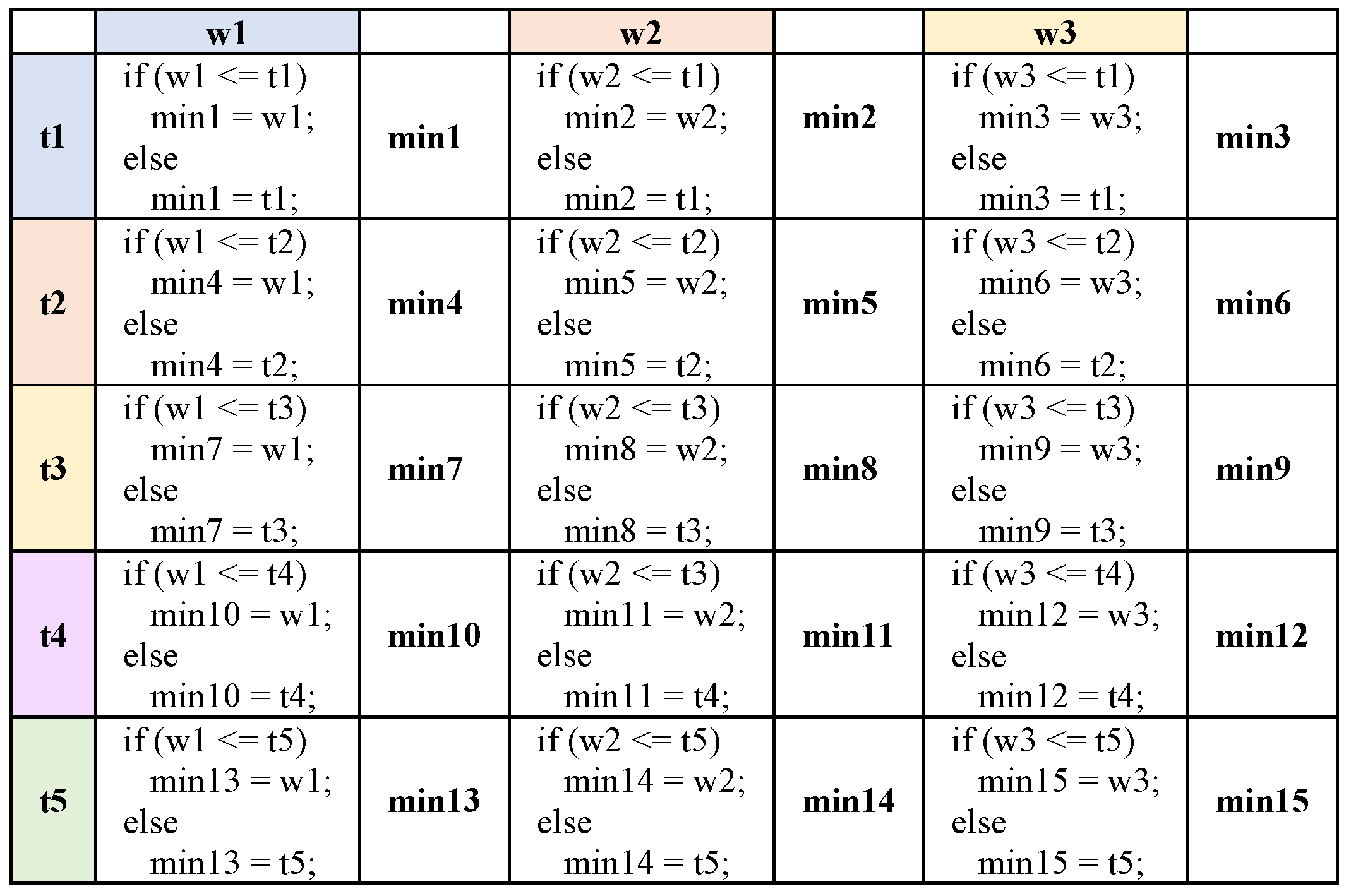

2.5. Module III: min15

2.6. Module IV: max_def

3. Results

FLC Implementation into an FPGA

- Sprinkling;

- Drip;

- Micro spray;

- Underground drainage.

- It is adaptable for any given plant, adjusting the parameters to the specific conditions required.

- It is immune to noise variations since it is implemented in a single integrated circuit.

- It uses a system of two sensors to measure the temperature and relative humidity of the air, thereby saving resources by going from more complex irrigation systems to a simple one.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Servicio de Información Agroalimentaria y Pesquera. Anuario Estadístico de la Producción Agrícola. 2020. Available online: https://nube.siap.gob.mx/cierreagricola/ (accessed on 20 April 2021).

- Lara Valencia, L.A.; Valencia Gonzalez, Y.; Vital de Brito, J.L. Uso de lógica difusa para la administración de un sistema disipador de energía en estructuras compuesto por amortiguadores magnetoreológicos. Fac. Ing. Univ. Antioquia 2015, 74, 151–164. [Google Scholar]

- Keswani, B.; Mohapatra, A.G.; Mohanty, A.; Khanna, A.; Rodrigues, J.J.P.C.; Gupta, D.; Albuquerque, V.H.C. Adapting weather conditions based IoT enabled smart irrigation technique in precision agriculture mechanisms. Neural Comput. Appl. 2019, 31, 277–292. [Google Scholar] [CrossRef]

- Yager, R.R. Alternative Structures for Knowledge Representation in Fuzzy Logic Controllers; Machine Intelligence Institute: Berkeley, CA, USA, 1993. [Google Scholar]

- Muthuvijayalakshmi, M.; Kumar, E.; Venkatesan, P. TB Disease Diagnosis Using Fuzzy Max-Min Composition Technique. CiiT Int. J. Fuzzy Syst. 2014, 6, 1–5. Available online: http://www.ciitresearch.org/dl/index.php/fs/article/view/FS022014001 (accessed on 21 June 2021).

- Lujiao, T. Takagi-Sugeno and Mamdani Fuzzy Control of a Resort Management System; Blekinge Institute of Technology: Karlshamn, Sweden, 2011. [Google Scholar]

- Alma, G.G. Producción y Comercialización de Rosa en México. In Ciencias Sociales: Economía y Humanidades: Handbook TI; ECORFAN: Toluca, México, 2015. [Google Scholar]

- Gómez Gómez, A.A.; Carrillo Ángeles, R.Y. Producción y Comercialización de Flores Mexicanas; ECORFAN: Spain, 2014; Available online: https://www.ecorfan.org/spain/libros/LIBRO_FLORES.pdf (accessed on 21 June 2021).

- Velázquez, D. Proyecto de Exportación de Rosas de Invernadero de Coatepec de Harinas, Estado de México a San Petersburgo, Rusia Para el año 2017; Universidad Autónoma del Estado de México: Toluca, Mexico, 2017. [Google Scholar]

- Haramaki, C. Studies on the Floral Malformation of the Greenhouse Rose Variety Better Times; Ohio State University: Columbus, OH, USA, 1957. [Google Scholar]

- Pérez, R. Plagas y Enfermedades Importantes del Rosal; Universidad Autónoma Agraria: Saltillo, Mexico, 2002. [Google Scholar]

- Yong, A. El cultivo del rosal y su propagación. Cultiv. Trop. 2004, 25, 53–67. [Google Scholar]

- García Blanco, A. ¿Cuánta Agua Necesita Mi Jardín? Cienc. Desarro. 2019. Available online: https://www.cyd.conacyt.gob.mx/?p=articulo&id=480#:~:text=Ladensidaddebecalcularsea,aguadiarios (accessed on 21 June 2021).

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Evapotranspiración del Cultivo. Guías Para la Determinación de los Requerimientos de agua de los Cultivos; FAO: Rome, Italy, 2006. [Google Scholar]

- González Osuna, C.d.J. Sistema Basado en Arquitectura Híbrida FPGA-µC Para la Medición Remota de Variables Fisiológicas en Plantas; Universidad Autónoma de Querétaro: Querétaro, Mexico, 2013. [Google Scholar]

- Hanitha, D.; Anusha, B.; Durga Prakash, M. FPGA Implementation of Automatic Irrigation and Pesticide Control System. Int. J. Reconfigurable Embed. Syst. 2016, 5, 136–140. [Google Scholar] [CrossRef]

- Zhiyong, L.; Yongli, D. An irrigation control system based on an fpga. In Proceedings of the 2012 International Conference on Instrumentation, Measurement, Computer, Communication and Control, Harbin, China, 8–10 December 2012; pp. 159–163. [Google Scholar] [CrossRef]

- Best, S.; León, L.; Méndez, A.; Flores, F.; Aguilera, H. Adopción y Desarrollo de tecnologías en Agricultura de Precisión. Chillán, Chile, 2014. Available online: http://www.gisandbeers.com/RRSS/Publicaciones/Tecnologia-Agricultura-Precision.pdf (accessed on 21 June 2021).

- Mazari Hiriat, M. El agua como recurso. In ¿Cómo ves? Revista de Divulgación de la Ciencia; UNAM: Mexico City, México, 2019. [Google Scholar]

- Saade, J.J.; Diab, H.B. Defuzzification Methods and New Techniques for Fuzzy Controllers. Iran. J. Electr. Comput. Eng. 2004, 31, 161–174. [Google Scholar]

- Sharma, S.; Patel, M. Implementation of fuzzy controller in verilog. Int. J. Sci. Res. Dev. 2016, 4, 743–745. [Google Scholar]

| Temperature (T) | |||||||||||

| °C | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |||

| Decimal | 0 | 36 | 73 | 109 | 146 | 182 | 219 | 255 | |||

| Relative Humidity (%) | |||||||||||

| % | 70 | 71 | 72 | 73 | 74 | 75 | 76 | 77 | 78 | 79 | 80 |

| Decimal | 0 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 255 |

| Valve Opening (%) | |||||||||||

| Valve Opening | (0) | (50) | (100) | ||||||||

| Time (h) | 0 | 4.7 | 9.4 | ||||||||

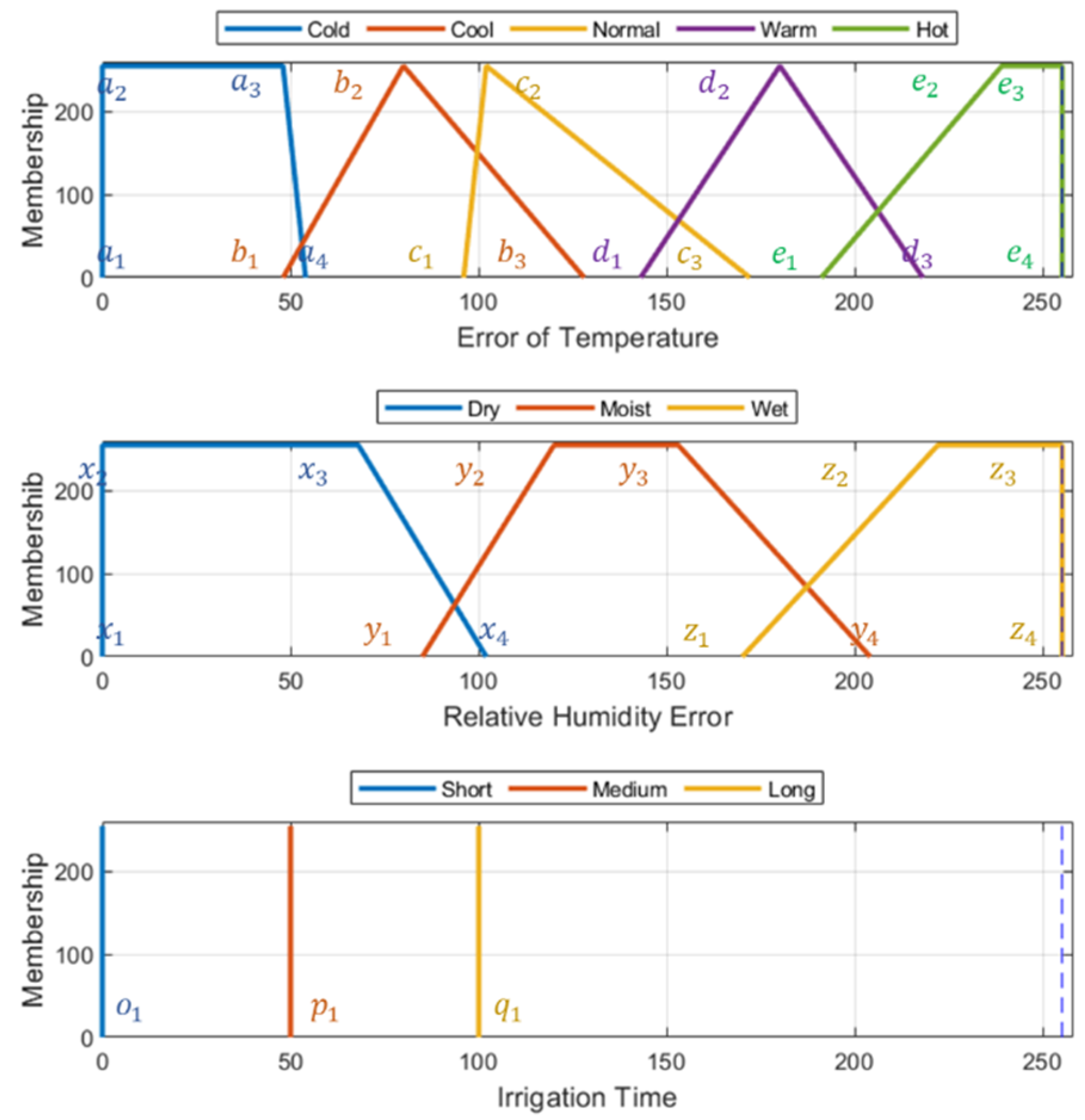

| Error of Temperature (°C) | ||

| Variable | Linguistic Representation | Decimal Associated Values |

| A(ErT) | Cold | {a1 = 0, a2 = 0, a3 = 48, a4 = 54} |

| B(ErT) | Cool | {b1 = 48, b2 = 80, b3 = 128} |

| C(ErT) | Normal | {c1 = 96, c2 = 102, c3 = 172} |

| D(ErT) | Warm | {d1 = 143, d2 = 180, d3 = 218} |

| E(ErT) | Hot | {e1 = 191, e2 = 239, e3 = 255, e4 = 255} |

| Relative Humidity Error (%) | ||

| Variable | Linguistic Representation | Decimal Associated Values |

| X(ERH) | Dry | {x1 = 0, x2 = 0, x3 = 68, x4 = 102} |

| Y(ERH) | Moist | {y1 = 85, y2 = 120, y3 = 153, y4 = 204} |

| Z(ERH) | Wet | {z1 = 170, z2 = 222, z3 = 255, z4 = 255} |

| Irrigation Time (s) | ||

| Variable | Linguistic Representation | Decimal Associated Values |

| O(TIr) | Short | {o1 = 0} |

| P(TIr) | Medium | {p1 = 50} |

| Q(TIr) | Long | {q1 = 100} |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urbieta Parrazales, R.; Zagaceta Álvarez, M.T.; Aguilar Cruz, K.A.; Palma Orozco, R.; Fernández Muñoz, J.L. Implementation of a Fuzzy Logic Controller for the Irrigation of Rose Cultivation in Mexico. Agriculture 2021, 11, 576. https://doi.org/10.3390/agriculture11070576

Urbieta Parrazales R, Zagaceta Álvarez MT, Aguilar Cruz KA, Palma Orozco R, Fernández Muñoz JL. Implementation of a Fuzzy Logic Controller for the Irrigation of Rose Cultivation in Mexico. Agriculture. 2021; 11(7):576. https://doi.org/10.3390/agriculture11070576

Chicago/Turabian StyleUrbieta Parrazales, Romeo, María T. Zagaceta Álvarez, Karen A. Aguilar Cruz, Rosaura Palma Orozco, and José L. Fernández Muñoz. 2021. "Implementation of a Fuzzy Logic Controller for the Irrigation of Rose Cultivation in Mexico" Agriculture 11, no. 7: 576. https://doi.org/10.3390/agriculture11070576

APA StyleUrbieta Parrazales, R., Zagaceta Álvarez, M. T., Aguilar Cruz, K. A., Palma Orozco, R., & Fernández Muñoz, J. L. (2021). Implementation of a Fuzzy Logic Controller for the Irrigation of Rose Cultivation in Mexico. Agriculture, 11(7), 576. https://doi.org/10.3390/agriculture11070576