Evolution in Configuration and Productivity of New Zealand Hill Country Sheep and Beef Cattle Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Collection for the Beef + Lamb NZ Class IV Average System

2.2. Data Collection for the Case-Study Production Systems: Farm A, Farm B, and Farm C

2.3. Modeling of Animal Feed Demand by MEB

2.4. Modeling of Herbage Supply Using GROW

2.5. Feed Conversion Efficiency

3. Results

3.1. Key Changes in System Configuration Over Time in the Average System

3.2. Key Changes of System Configuration Over Time for the Case-Study Production Systems

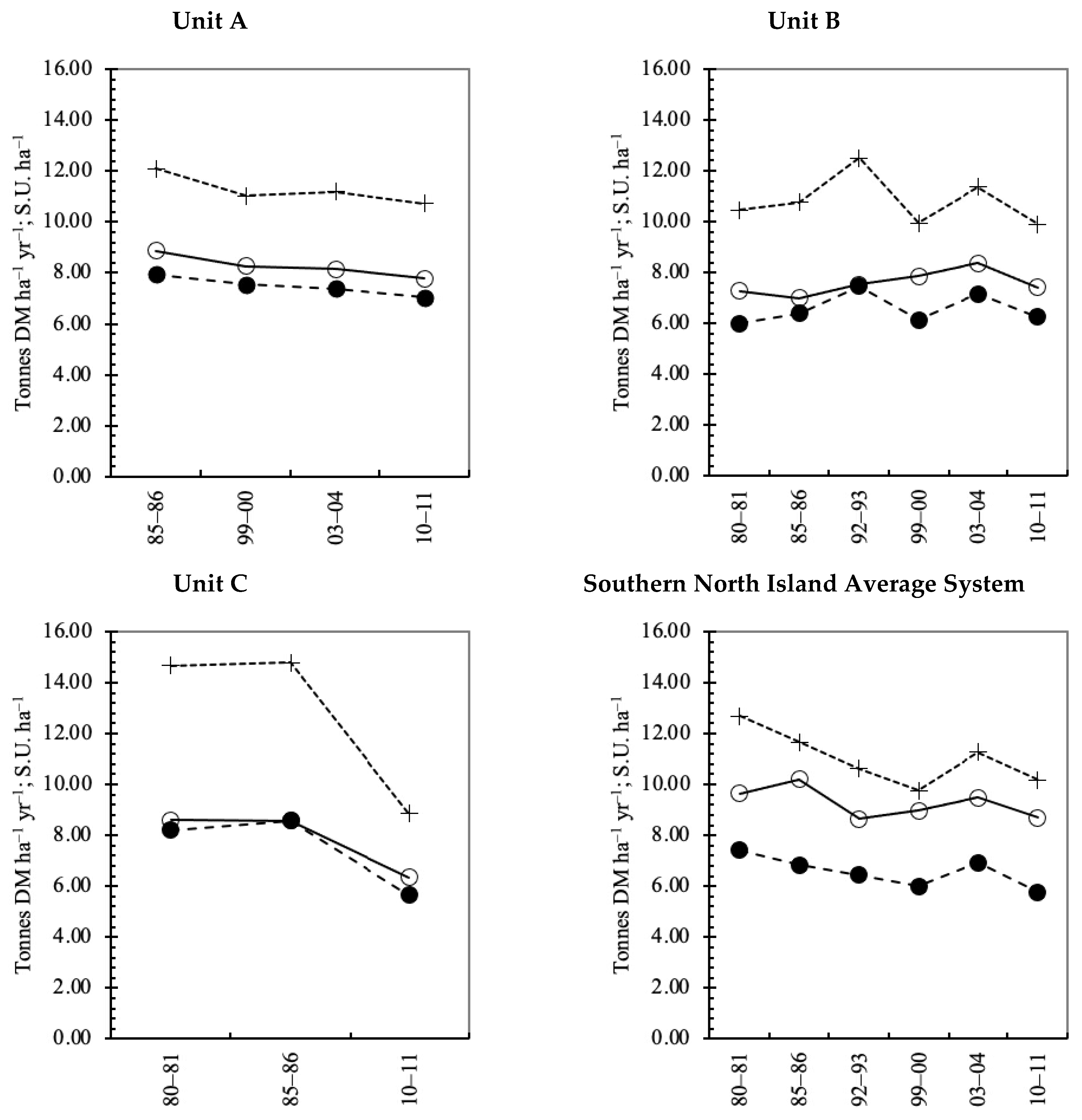

3.3. Changes over Time in Feed Demand, Herbage Supply, and Herbage Utilization

3.4. Changes over Time in Feed Conversion Efficiency and Meat Production per ha

3.5. Comparison of Feed Demand Estimates from the Excel MEB Model and FARMAX

4. Discussion

4.1. System Feed Conversion Efficiency, System Energy Requirement, and MEB as a Tool for Their Calculation

4.2. System Configuration Drivers of Feed Conversion Efficiency

4.3. Significance of Change over Time in Supplementary Feed, Fertilizer Use, and Sheep:Cattle Ratio

4.4. Model Performance

4.5. Herbage Utilization

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lopez, I.F.; Valentine, I.; Lambert, M.G.; Hedderley, D.I.; Kemp, P.D. Plant functional groups in a heterogeneous environment. J. Agric. Res. 2006, 49, 439–450. [Google Scholar] [CrossRef]

- ARC. The Nutrient Requirements of Ruminant Livestock; Commonwealth Agricultural Bureaux: Slough, UK, 1980. [Google Scholar]

- AFRC. Energy and Protein Requirements of Ruminants; CAB International: Wallingford, UK, 1993. [Google Scholar]

- Frater, P.; Howarth, S.; McEwen, G.J. Livestock feed intake assumptions in decision support tools; A stocktake of the current science and assumptions used by livestock models. J. N. Z. Grassl. 2015, 77, 19–22. [Google Scholar] [CrossRef]

- Duranton, C.; Matthew, C. Impact of introducing a herb pasture area into a New Zealand sheep and beef hill country farm system: A modelling analysis. Front. Agric. Sci. Eng. 2018, 5, 87–97. [Google Scholar] [CrossRef] [Green Version]

- Carswell, A.M.; Gongadze, K.; Misselbrook, T.H.; Wu, L. Impact of transition from permanent pasture to new swards on the nitrogen use efficiency, nitrogen and carbon budgets of beef and sheep production. Agric. Ecosyst. Environ. 2019, 283, 106572. [Google Scholar] [CrossRef] [PubMed]

- Rotz, C.A.; Kamphuis, G.H.; Karsten, H.D.; Weaver, R.D. Organic dairy production systems in Pennsylvania: A case study evaluation. J. Dairy Sci. 2007, 90, 3961–3979. [Google Scholar] [CrossRef] [PubMed]

- Basher, L.R.; Botha, N.; Dodd, M.B.; Douglas, G.B.; Lynn, I.; Marden, M.; McIvor, I.R.; Smith, W. Hill Country Erosion: A Review of Knowledge on Erosion Processes, Mitigation Options, Social Learning and Their Long-term Effectiveness in the Management of Hill Country Erosion; Landcare Research New Zealand Ltd.: Palmerston North, New Zealand, 2008. [Google Scholar]

- Matthew, C.; Horne, D.J.; Baker, R.D. Nitrogen loss: An emerging issue for the ongoing evolution of New Zealand dairy farming systems. Nutr. Cycl. Agroecosyst. 2010, 88, 289–298. [Google Scholar] [CrossRef]

- White, T.A.; Snow, V.O.; King, W.M. Intensification of New Zealand beef farming systems. Agric. Syst. 2010, 103, 21–35. [Google Scholar] [CrossRef]

- Butler, B.M.; Matthew, C.; Heerdegen, R.G. The greenhouse effect—What consequences for seasonality of pasture production. Weather Clim. 1990, 10, 55–60. [Google Scholar] [CrossRef]

- Supplement to the New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 1873 (1980–81); New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1983. [Google Scholar]

- Supplement to the New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 1893 (1981–82); New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1984. [Google Scholar]

- Supplement to the New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 1979 (1985–86); New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1988. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 1989; New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1988. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 2006; New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1989. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 2020; New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1990. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 2041; New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1991. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 2052; New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1992. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 2075; New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1993. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 2093; New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1994. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 2109; New Zealand Meat and Wool Boards’ Economic Service: Wellington, New Zealand, 1995. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. 2126; Meat and Wool Economic Service of New Zealand: Wellington, New Zealand, 1996. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. G2135; Meat and Wool Economic Service of New Zealand: Wellington, New Zealand, 1997. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. G2150; Meat and Wool Economic Service of New Zealand: Wellington, New Zealand, 1998. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. G2170; Meat and Wool Economic Service of New Zealand: Wellington, New Zealand, 1999. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. G2201; The Economic Service: Wellington, New Zealand, 2000. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. G2235; The Economic Service: Wellington, New Zealand, 2001. [Google Scholar]

- New Zealand Sheep and Beef Farm Survey. The Economic Service Publication No. G2275; Meat and Wool Innovation, Economic Service: Wellington, New Zealand, 2002. [Google Scholar]

- Gobilik, J. Considerations of Feed Demand and Supply for the Evolution and Expansion of Beef Cattle Farming in Sabah, East Malaysia. Ph.D. Thesis, Massey University, Palmerston North, New Zealand, 20 April 2017. [Google Scholar]

- Parker, W.J.; Lowe, K.I. Riverside Annual Review 1/7/80–30/6/81; Massey University: Palmerston North, New Zealand, 1981. [Google Scholar]

- Parker, W.J. Riverside Annual Review 85/86; Massey University: Palmerston North, New Zealand, 1986. [Google Scholar]

- Webby, R.W.; Bywater, A.C. Principles of feed planning and management. In Pasture and Supplements for Grazing Animals; Rattray, P.V., Brookes, I.M., Nicol, A.M., Eds.; New Zealand Society of Animal Production: Wellington, New Zealand, 2007; Volume 14, pp. 189–220. [Google Scholar]

- Nicol, A.M.; Brookes, I.M. The metabolisable energy requirements of grazing livestock. In Pasture and Supplements for Grazing Animals; Rattray, P.V., Brookes, I.M., Nicol, A.M., Eds.; New Zealand Society of Animal Production: Wellington, New Zealand, 2007; Volume 14, pp. 151–172. [Google Scholar]

- McRae, A.F. Tuapaka Beef Farm: Seasons Three and Four (and a New Direction); Massey University: Palmerston North, New Zealand, 1987. [Google Scholar]

- Machado, C.F.; Morris, S.T.; Hodgson, J.; Fathalla, M. Seasonal changes of herbage quality within a New Zealand beef cattle finishing pasture. N. Z. J. Agric. Res. 2005, 48, 265–270. [Google Scholar] [CrossRef]

- Morris, S.T.; Smeaton, D. Profitable Farming of Beef Cows; Meat and Wool New Zealand: Hamilton, New Zealand, 2009. [Google Scholar]

- National Institute of Water and Atmospheric Research (NIWA). New Zealand’s National Climate Database. Available online: https://cliflo.niwa.co.nz (accessed on 1 August 2013).

- Radcliffe, J.E., VII. Masterton (Wairarapa) and Maraekakaho (Hawke’s Bay). N. Z. J. Exp. Agric. 1975, 3, 259–265. [Google Scholar] [CrossRef] [Green Version]

- Thompson, C.S. The Weather and Climate of the Wairarapa Region; New Zealand Meteorological Service: Wellington, New Zealand, 1982. [Google Scholar]

- Beef + Lamb New Zealand Ltd. Annual Report 2011–2012. Available online: https://beeflambnz.com/sites/default/files/content-pages/2011-12-blnz-annual-report.pdf (accessed on 2 February 2014).

- Morris, S.T. Sheep and beef cattle production systems. In Ecosystem Services in New Zealand—Conditions and Trends; Dymond, J.R., Ed.; Manaaki Whenua Press: Lincoln, New Zealand, 2013; pp. 79–84. [Google Scholar]

- Morris, S.T. The New Zealand beef cattle industry—Presidential address 2012. In Proceedings of the New Zealand Society of Animal Production; New Zealand Society of Animal Production: Hamilton, New Zealand, 2013; Volume 73, pp. 1–4. Available online: http://www.nzsap.org/system/files/proceedings/ab13001.pdf (accessed on 10 October 2013).

- Morris, S.T.; Brookes, I.M.; Parker, W.J.; McCutcheon, S.N. Biological efficiency: How relevant is this concept to beef cows in a mixed livestock, seasonal pasture supply context? In Proceedings of the New Zealand Society of Animal Production; New Zealand Society of Animal Production: Palmerston North, New Zealand, 1994; Volume 54, pp. 333–336. Available online: http://www.nzsap.org/system/files/proceedings/1994/ab94082.pdf (accessed on 21 August 2013).

- Brookes, I.M.; Lowe, K.I.; Garrick, D.J. Modelling the feed requirements of cross-bred sheep. In Proceedings of the New Zealand Society of Animal Production; New Zealand Society of Animal Production: Palmerston North, New Zealand, 1998; Volume 58, pp. 161–164. Available online: http://www.nzsap.org/system/files/proceedings/1998/ab98048.pdf (accessed on 6 April 2013).

- Mackay, A.D.; Rhodes, A.P.; Power, I.; Wedderburn, M.E. Has the eco-efficiency of sheep and beef farms changed in the last 20 years? In Proceedings of the New Zealand Grassland Association; New Zealand Grassland Association: Gore, New Zealand, 2012; Volume 74, pp. 11–16. Available online: https://www.grassland.org.nz/publications/nzgrassland_publication_2263.pdf (accessed on 10 June 2013).

- Da Silva, S.C.; Hodgson, J.; Matthew, C.; Matthews, P.N.P.; Holmes, C.W. Herbage production and animal performance on perennial ryegrass/white clover dairy pastures under alternative spring grazing managements. J. Agric. Sci. Camb. 2004, 142, 97–108. [Google Scholar] [CrossRef]

- Dove, H.; Mayes, R.W. The use of plant wax alkanes as marker substances in studies of the nutrition of herbivores: A review. Aust. J. Agric. Res. 1991, 42, 913–952. [Google Scholar] [CrossRef]

- Kelly, D.N.; Murphy, C.; Sleator, R.D.; Judge, M.M.; Conroy, S.B.; Berry, D.P. Feed efficiency and carcass metrics in growing cattle. J. Anim. Sci. 2019, 97, 4405–4417. [Google Scholar] [CrossRef] [PubMed]

- National Institute of Water and Atmospheric Research (NIWA). Climate Change Scenarios for New Zealand. 2021. Available online: https://niwa.co.nz/our-science/climate/information-and-resources/clivar/scenarios (accessed on 1 June 2021).

- OECD/FAO. OECD-FAO Agricultural Outlook 2020–2029; FAO, Rome/OECD Publishing: Paris, France, 2020. [Google Scholar] [CrossRef]

- Beef + Lamb New Zealand Ltd. Economic Service Sheep and Beef Farm Survey, Taranaki/Rangitikei/Manawatu, 2020. Forecast and Quintile Analysis of Final 2018–2019 Survey Data. Available online: https://beeflambnz.com/sites/default/files/data/files/2019%20WNI.pdf (accessed on 1 June 2021).

- Nudda, A.; Buffa, G.; Atzoria, A.S.; Cappai, M.G.; Caboni, P.; Fais, G.; Pulina, G. Small amounts of agro-industrial byproducts in dairy ewes diets affects milk production traits and hematological parameters. An. Feed Sci. Technol. 2019, 251, 76–89. [Google Scholar] [CrossRef]

- Matthew, C.; Osborne, M.A.; Liu, Y.; Duan, X.; Hou, F. Winter rotation length effect on pasture production and animal performance. J. N. Z. Grassl. 2017, 79, 181–187. [Google Scholar] [CrossRef]

- Suckling, F.E.T. The effects of topdressing and oversowing hill pastures. N. Z. J. Agric. Res. 1959, 2, 153–164. [Google Scholar] [CrossRef]

- Lambert, M.G.; Clark, D.A.; Grant, D.A.; Costall, D.A.; Fletcher, R.H. Influence of fertiliser and grazing management on North Island moist hill country. 1. Herbage accumulation. N. Z. J. Agric. Res. 1983, 26, 95–108. [Google Scholar] [CrossRef] [Green Version]

- Chobtang, J.; Ledgard, S.F.; McLaren, S.J.; Donaghy, D.J. Life cycle environmental impacts of high and low intensification pasture-based milk production systems: A case study of the Waikato region, New Zealand. J. Clean. Prod. 2017, 140, 664–674. [Google Scholar] [CrossRef]

- Matthews, P.N.P.; Hodgson, J.; White, J.G.H. Livestock farming systems in New Zealand. In New Zealand Pasture and Crop Science; White, J., Hodgson, J., Eds.; Oxford University Press: Melbourne, Australia, 1999; pp. 133–151. [Google Scholar]

- McCall, D.G.; Tither, P.M. Use of the Stockpol computer decision-support program in commercial consultancy. In Proceedings of the New Zealand Grassland Association; New Zealand Grassland Association: Masterton, New Zealand, 1993; Volume 55, pp. 207–208. Available online: https://www.nzgajournal.org.nz/index.php/ProNZGA/article/view/2070/1698 (accessed on 15 November 2013).

- Payen, S.; Falconer, S.; Carlson, W.; Yanga, W.; Ledgard, S.F. Eutrophication and climate change impacts of a case study of New Zealand beef to the European market. Sci. Total Environ. 2020, 710, 136120. [Google Scholar] [CrossRef]

- Whitehead, D.; Edwards, G.R. Assessment of the application of gibberellins to increase productivity and reduce nitrous oxide emissions in grazed grassland. Agric. Ecosyst. Environ. 2015, 207, 40–50. [Google Scholar] [CrossRef]

- Gobilik, J.; Adam, L.; Punimin, A.; Harun, A.; Morris, S.T.; Matthew, C.; Yeo, B.K. Feed profile of a cut-and-carry feedlot cattle farming system in Sabah and implications for feedlot feed management. Trans. Sci. Technol. 2018, 5, 93–105. [Google Scholar]

| System Information | 1980–1981 | 1985–1986 | 1990–1991 | 1995–1996 | 2000–2001 | 2005–2006 | 2010–2011 |

|---|---|---|---|---|---|---|---|

| Production area (ha) | 398 | 396 | 408 | 433 | 469 | 493 | 498 |

| Effective area (ha) | 361 | 363 | 376 | 397 | 421 | 437 | 436 |

| Effective area (%) | 90.7 | 91.7 | 92.2 | 91.7 | 89.8 | 88.6 | 87.5 |

| Hay and silage (ha) | 6 | 7 | 5 | 10 | 8 | 8 | 9 |

| Sheep (head) | 3118 | 3139 | 2817 | 2542 | 2569 | 2798 | 2532 |

| Sheep SU | 2837 | 2874 | 2569 | 2315 | 2331 | 2538 | 2300 |

| Sheep SU ha−1 | 7.86 | 7.92 | 6.83 | 5.83 | 5.54 | 5.81 | 5.28 |

| Sheep:Cattle (SU) | 70:30 | 72:28 | 65:35 | 56:44 | 58:42 | 59:41 | 58:42 |

| Cattle (head) | 254 | 233 | 290 | 370 | 348 | 372 | 347 |

| Cattle SU | 1236 | 1129 | 1394 | 1788 | 1675 | 1784 | 1658 |

| Cattle SU ha−1 | 3.42 | 3.11 | 3.71 | 4.5 | 3.98 | 4.08 | 3.8 |

| Lambing (%) | 100.9 | 100 | 100.6 | 107.1 | 110.1 | 125.7 | 116.1 |

| Calving (%) | 84.8 | 83.3 | 85.7 | 84.5 | 83.5 | 81.6 | 80 |

| Nitrogen (T) | – | 0.2 | 0.5 | 1.2 | 2.4 | 5.5 | 2.7 |

| Phosphorus (T) | – | 2.1 | 3.7 | 6.2 | 9.4 | 8.4 | 6.7 |

| Sulfur (T) | – | 2.7 | 3.9 | 7.1 | 11.2 | 8.5 | 8.4 |

| Potassium (T) | – | 0.7 | 0.7 | 1.8 | 2.2 | 1.9 | 1.4 |

| Total Fertilizer (T) | 62.4 | 26.0 | 39.6 | 64.6 | 103.6 | 91.1 | 82.5 |

| System Information | Farm A | Farm B | Farm C | |||

|---|---|---|---|---|---|---|

| 1985–1986 | 2010–2011 | 1980–1981 | 2010–2011 | 1980–1981 | 2010–2011 | |

| Effective area (ha) | 345 | 821 | 670 | 1081 | 670 | 677 |

| Hay or silage (ha) | 0 | 0 | 0 | 0 | 63 | 33 |

| Precipitation (mm) | 1094 | 1287 | 1602 | 1348 | 1560 | 927 |

| Temperature (°C) | 12.8 | 13.4 | 12.8 | 13 | 12.6 | 13.2 |

| Sheep (head) | 3080 | 4100 | 6531 | 12,364 | 11,574 | 6750 |

| Sheep SU | 2359 | 3004 | 4815 | 8620 | 8830 | 4829 |

| Sheep SU ha−1 | 6.8 | 3.6 | 7.2 | 8.0 | 13.1 | 7.1 |

| Sheep:Cattle (SU) | 57:43 | 34:66 | 69:31 | 80:20 | 90:10 | 81:19 |

| Cattle (head) | 403 | 1288 | 453 | 441 | 221 | 238 |

| Cattle SU | 1815 | 5808 | 2192 | 2089 | 1024 | 1169 |

| Cattle SU ha−1 | 5.3 | 7.1 | 3.3 | 1.9 | 1.5 | 1.7 |

| Lambing (%) | 79 | 122 | 123 | 123 | 105 | 131 |

| Calving (%) | NB | NB | 89 | 94 | 95 | 100 |

| Nitrogen (kg ha−1yr−1) | 0 | 39.2 | 0 | 7.2 | 0 | 40 |

| Phosphorus (kg ha−1yr−1) | 20.3 | 22.9 | 22 | 25 | 29.2 | 0.0 A |

| Potassium (kg ha−1yr−1) | 0 | 0 | 0 | 0 | 0 | 0.0 A |

| Sulfur (kg ha−1yr−1) | 0 | 0 | 27 | 27 | 0 | 20 A |

| Total fertilizer (kg ha−1yr−1) | 20.3 | 62.1 | 49 | 59.2 | 29.2 | 40 |

| Lime (kg ha−1yr−1) | 0 | 0 | 0 | 454 | 1034 | 1.5 A |

| Olsen P | 16–19 | 19–29 | 12 | 18 | 14 | 25 A |

| Copper | 0 | 4 B | 0 | 0 | 0 | 0 |

| Feed Information | Average System | Farm A | Farm B | Farm C | ||||

|---|---|---|---|---|---|---|---|---|

| 1980–1981 | 2010–2011 | 1985–1986 | 2010–2011 | 1980–1981 | 2010–2011 | 1980–1981 | 2010–2011 | |

| Feed demand A | ||||||||

| Total, t DM ha−1 yr−1 | 7.43 | 5.76 C | 7.94 | 7.04 | 6.01 | 6.25 | 8.21 | 5.64 A |

| Off farm, t DM ha−1 yr−1 | ND | ND | 0 | 0 | 0 | 0.33 | 0 | 0 |

| Herbage (feed) supply B | ||||||||

| Total, t DM ha−1 yr−1 | 9.64 | 8.70 | 8.87 | 7.79 | 7.27 | 7.41 | 8.61 | 6.34 |

| Estimate of utilization (%) | 77 | 66 | 90 | 90 | 83 | 84 | 95 | 89 |

| Feed Conversion Information | Average System | Farm A | Farm B | Farm C | ||||

|---|---|---|---|---|---|---|---|---|

| 1980–1981 | 2010–2011 | 1985–1986 | 2010–2011 | 1980–1981 | 2010–2011 | 1980–1981 | 2010–2011 | |

| Feed consumption per animal class | ||||||||

| * Sheep, kg DM ha−1 | 4983 | 3299 | 3753 | 2250 | 4214 | 5091 | 7284 | 4741 |

| * Beef cattle, kg DM ha−1 | 2444 | 2430 | 4184 | 4791 | 1794 | 1049 | 908 | 888 |

| Dairy cattle, kg DM ha−1 | 0 | 36 | 0 | 0 | 0 | 0 | 0 | 15 |

| Feed conversion per product | ||||||||

| kg DM kg sheep + cattle carcass−1 | 54 | 39 | 44 | 32 | 44 | 43 | 62 | 31 |

| kg DM kg sheep carcass−1 | 65 | 47 | 76 | 48 | 46 | 41 | 100 | 46 |

| kg DM kg cattle carcass−1 | 40 | 31 | 32 | 28 | 39 | 52 | 24 | 16 |

| kg DM per kg lamb weaned | 25 | 19 | 28 | 18 | 18 | 14 | 23 | 18 |

| kg DM per lamb weaned | 574 | 611 | 672 | 661 | 417 | 450 | 649 | 490 |

| kg DM per kg calf weaned | 28 | 22 | NB | NB | 38 | 37 | 19 | 16 |

| kg DM per calf weaned | 4182 | 3239 | NB | NB | 3305 | 3498 | 2852 | 2653 |

| Carcass Information | Average System | Farm A | Farm B | Farm C | ||||

|---|---|---|---|---|---|---|---|---|

| 1985–1986 | 2010–2011 | 1980–1981 | 2010–2011 | 1980–1981 | 2010–2011 | 1980–1981 | 2010–2011 | |

| kg sheep + cattle carcass ha−1 | 137 | 147 | 181 | 219 | 137 | 148 | 146 | 222 |

| kg sheep carcass ha−1 | 76 | 70 | 49 | 47 | 91 | 128 | 73 | 104 |

| kg cattle carcass ha−1 | 61 | 77 | 132 | 172 | 46 | 20 | 74 | 188 |

| kg lamb weaned per ewe | 23 | 39 | 18 | 43 | 28 | 38 | 30 | 35 |

| kg calf weaned per cow | 125 | 137 | 0 | 0 | 140 | 159 | 140 | 171 |

| Lamb carcass weight, kg hd−1 | 13.9 A | 18.2 B | 14.7 | 16.3 | 11 | 17 | 7.8 | 12.0 |

| Steer carcass weight, kg hd−1 | 277 C | 316 C | 0 | NA | 277 | 308 | 188 | 240 |

| Bull carcass weight, kg hd−1 | 252 C | 310 C | 262 | 260 | 296 | 329 | NR | NR |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gobilik, J.; Morris, S.T.; Matthew, C. Evolution in Configuration and Productivity of New Zealand Hill Country Sheep and Beef Cattle Systems. Agriculture 2021, 11, 531. https://doi.org/10.3390/agriculture11060531

Gobilik J, Morris ST, Matthew C. Evolution in Configuration and Productivity of New Zealand Hill Country Sheep and Beef Cattle Systems. Agriculture. 2021; 11(6):531. https://doi.org/10.3390/agriculture11060531

Chicago/Turabian StyleGobilik, Januarius, Stephen Todd Morris, and Cory Matthew. 2021. "Evolution in Configuration and Productivity of New Zealand Hill Country Sheep and Beef Cattle Systems" Agriculture 11, no. 6: 531. https://doi.org/10.3390/agriculture11060531

APA StyleGobilik, J., Morris, S. T., & Matthew, C. (2021). Evolution in Configuration and Productivity of New Zealand Hill Country Sheep and Beef Cattle Systems. Agriculture, 11(6), 531. https://doi.org/10.3390/agriculture11060531