Design Matching and Dynamic Performance Test for an HST-Based Drive System of a Hillside Crawler Tractor

Abstract

1. Introduction

2. Materials and Methods

2.1. Main Performance and Technical Parameters of the Drive System

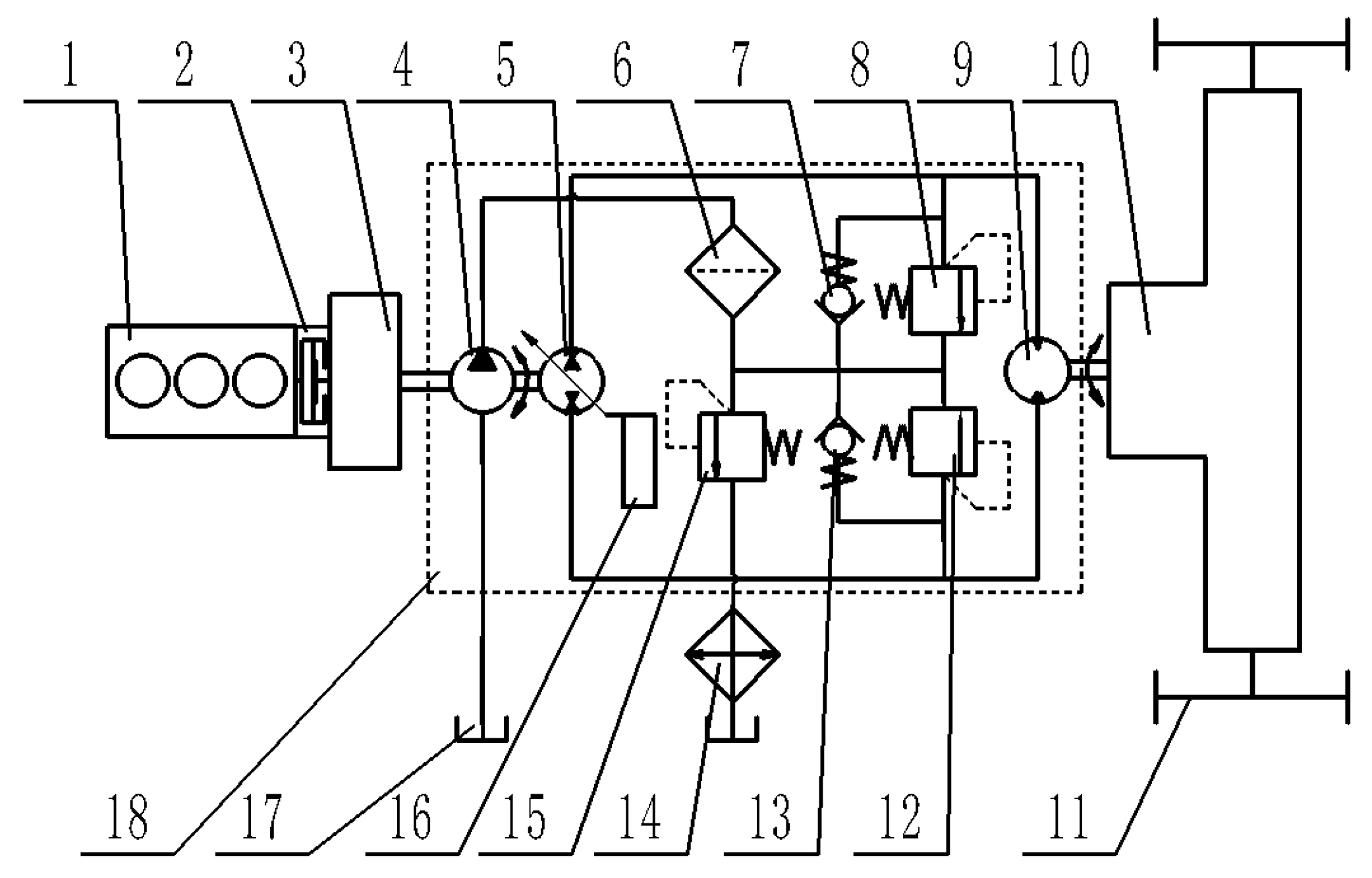

2.2. Structure of the Drive System

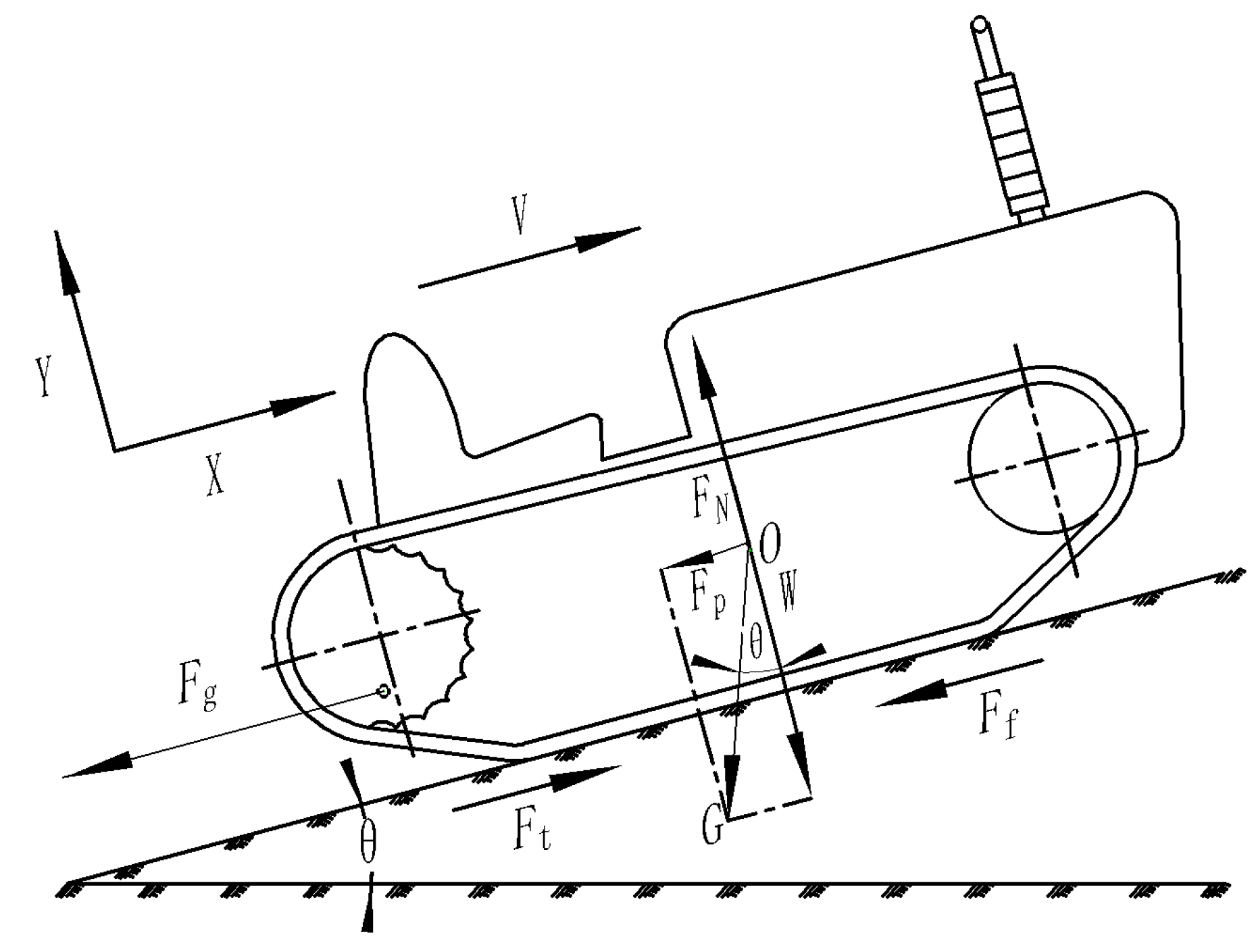

2.3. Force Analysis of the Hillside Crawler Tractor

2.4. Motion Analysis of the Hillside Crawler Tractor

2.5. Parameter Matching of the Key Components of the Drive System

2.5.1. Engine Matching

2.5.2. Matching of the HST

2.5.3. Matching of the Drive Rear Axle

2.6. Performance Check of the Drive System

2.6.1. Drive Force Check

2.6.2. System Pressure Check

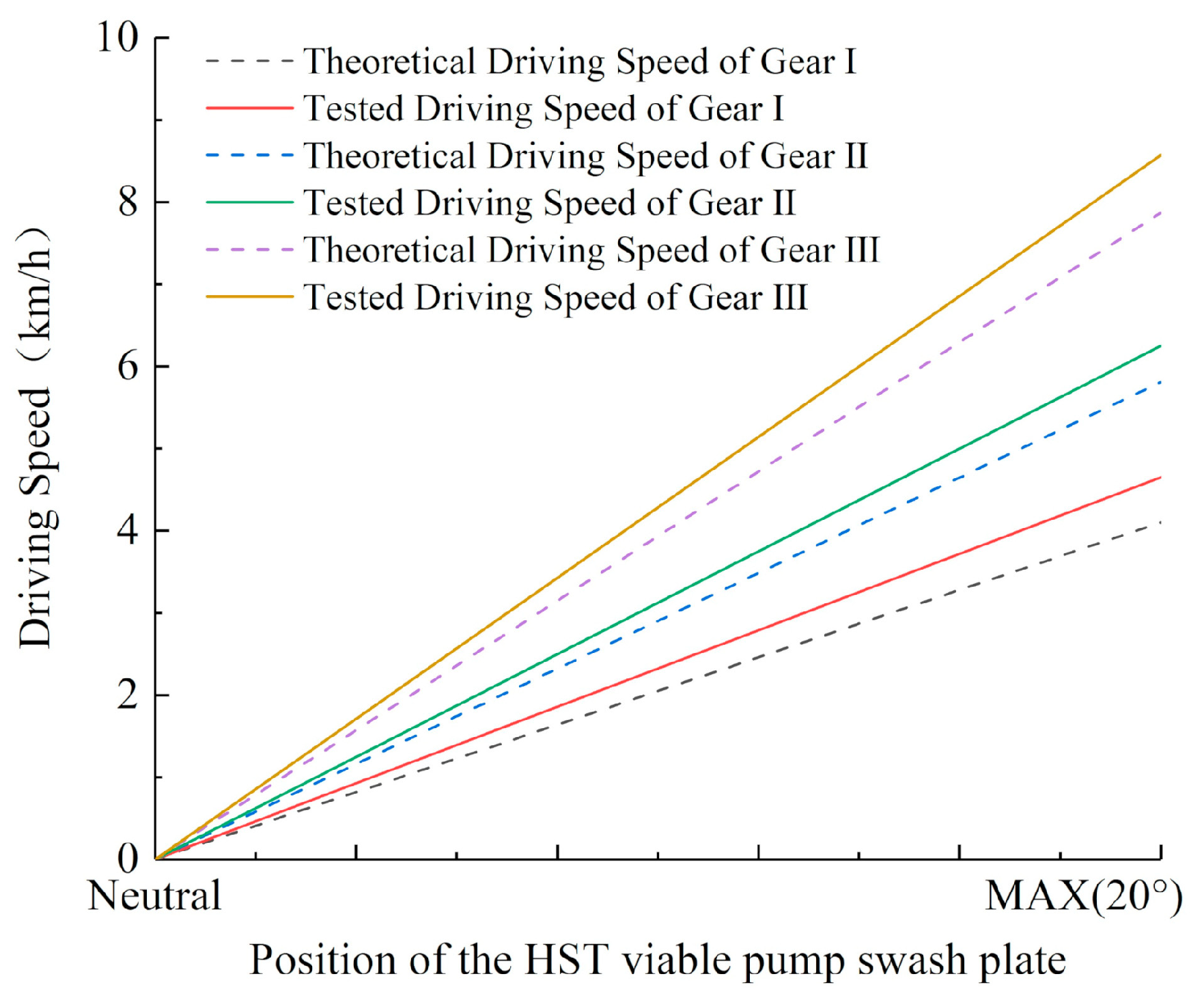

2.6.3. Driving Speed Check

2.7. Building the Drive System Test Bench

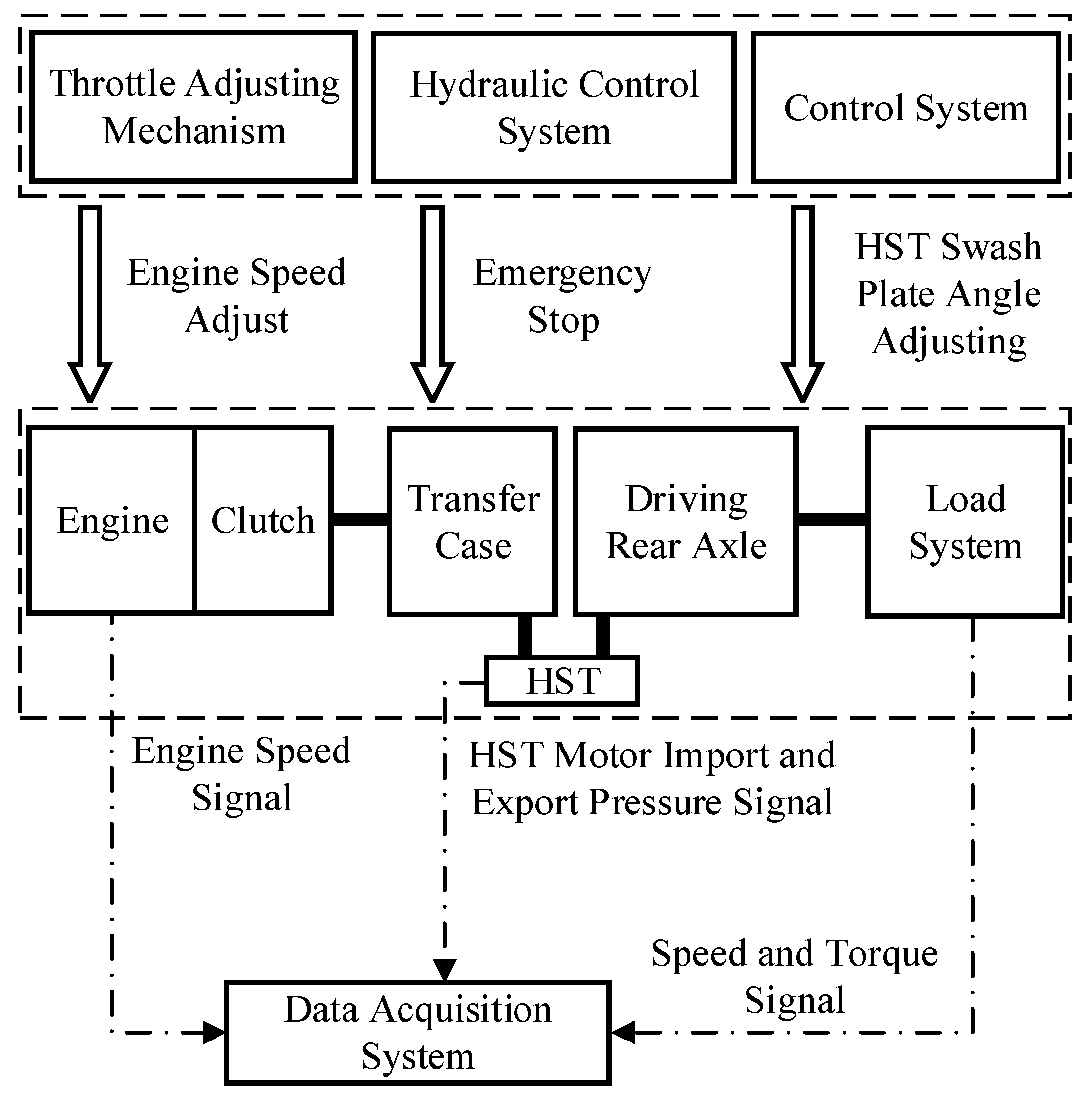

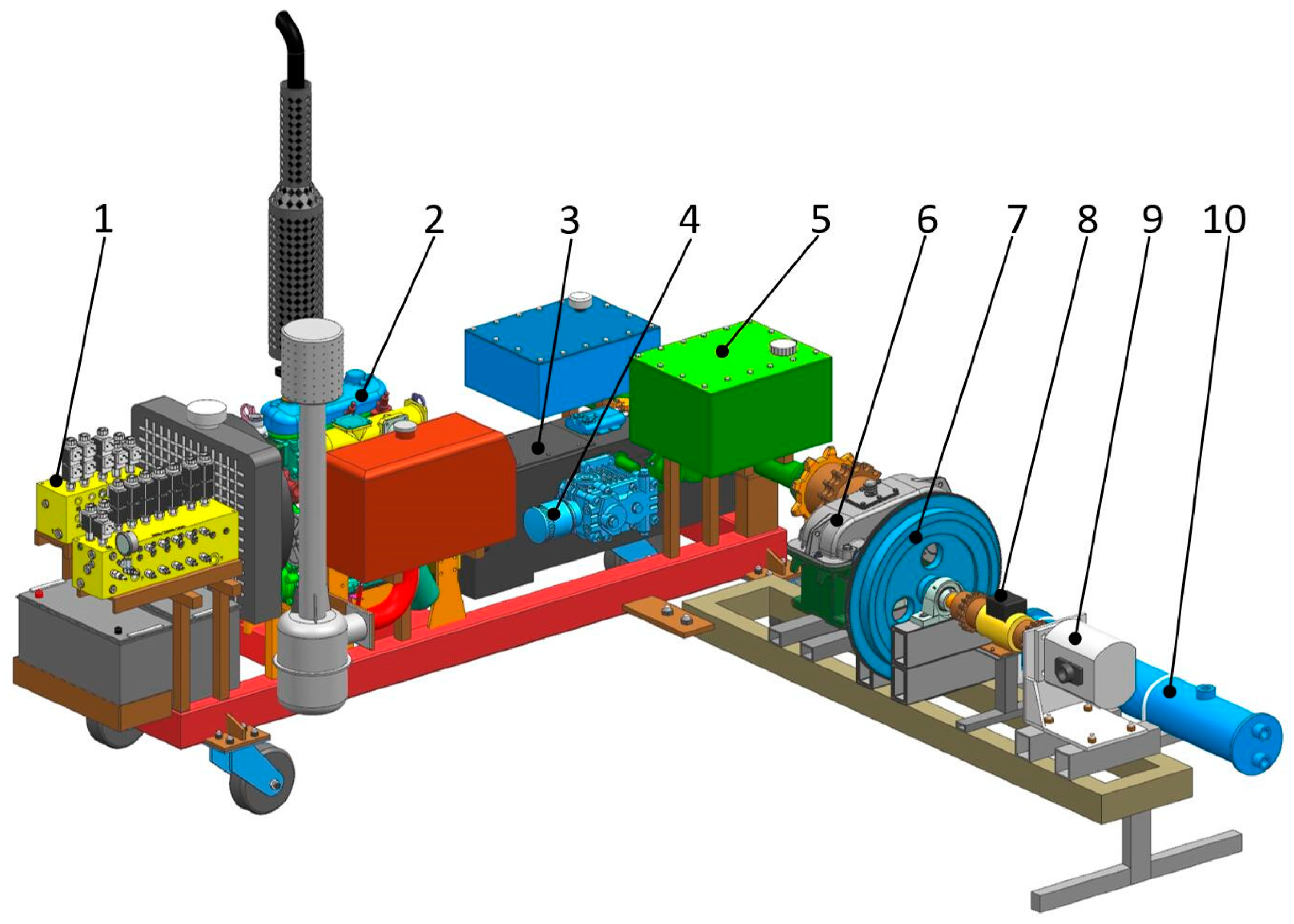

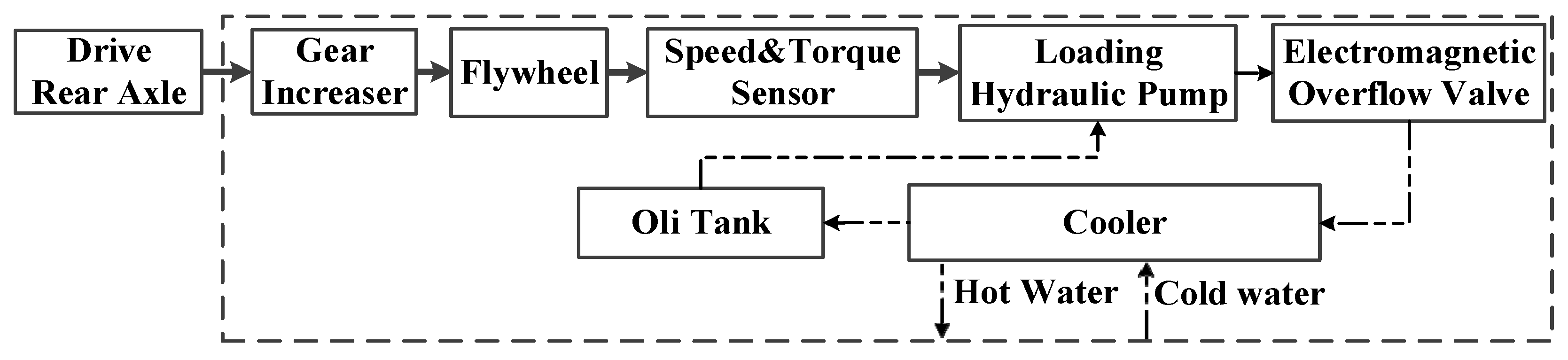

General Scheme of the Drive System Test Bench

2.8. Dynamic Performance Test of the Drive System

2.8.1. Traction Performance Test

- Put the drive rear axle in the neutral position, start the engine, and warm up the engine without load for 8–12 min to allow the engine to be in a hot initial state;

- Operate the clutch and put the drive rear axle at Gear I/II;

- Adjust the engine speed to 1700 r/min, and then adjust the swash plate angle of the HST variable pump to the maximum (20°) through the control system of the test bench;

- When the engine speed is stable, adjust the load torque of the load system, increase it by 10 N·m until it reaches 80 N·m, and then decrease it to a minimum; and

- Record the change of the load torque, the engine speed, the driving speed, and the pressure difference between the inlet and outlet of the hydraulic motor.

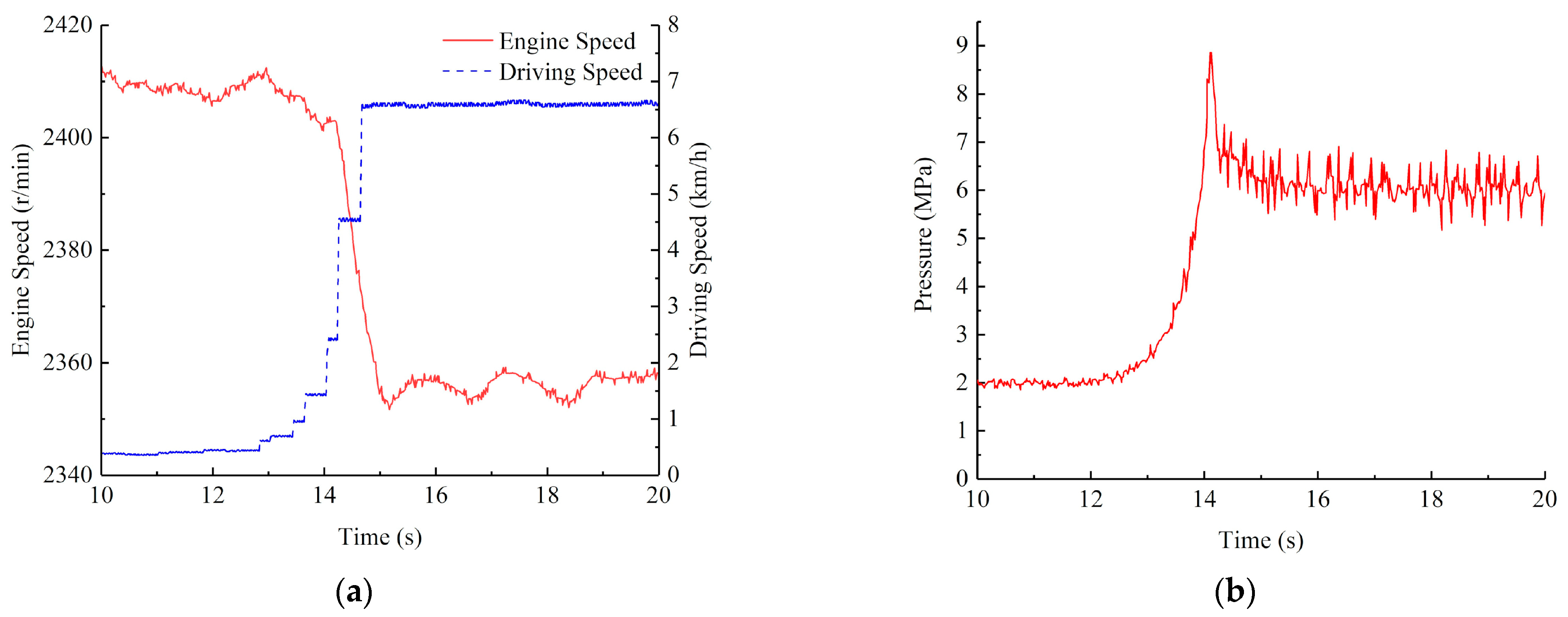

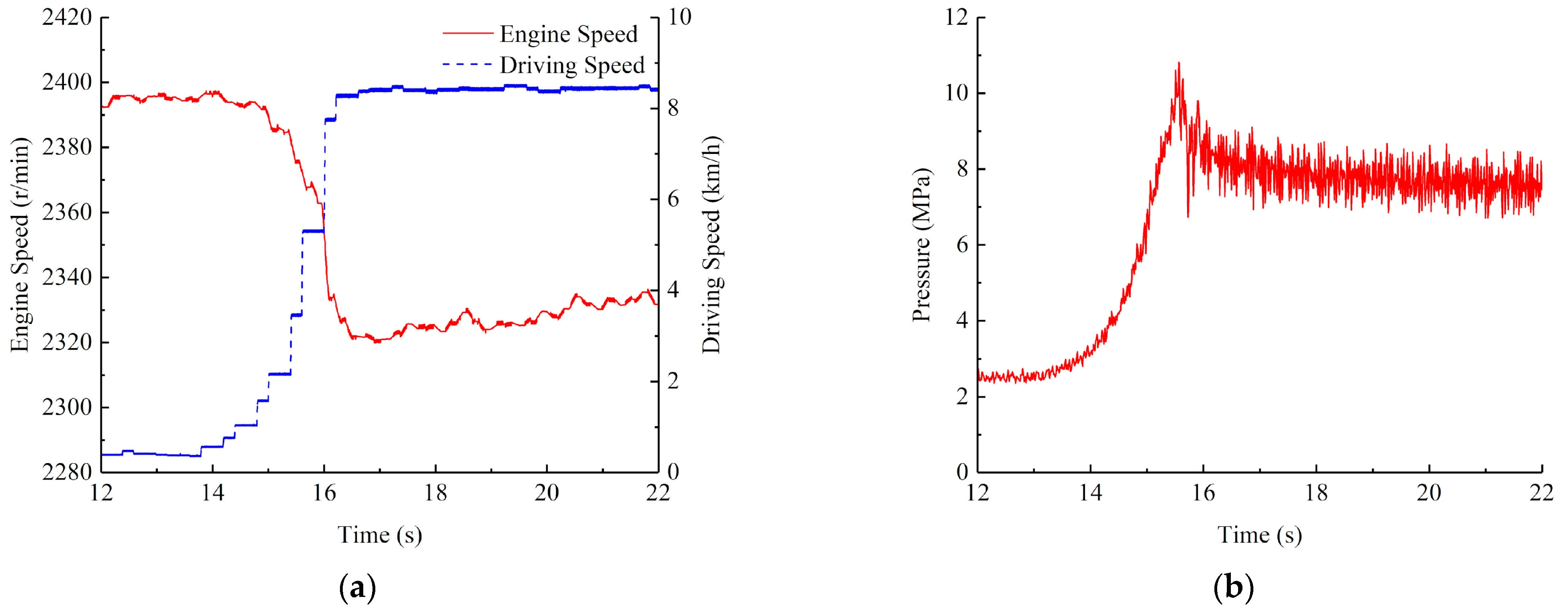

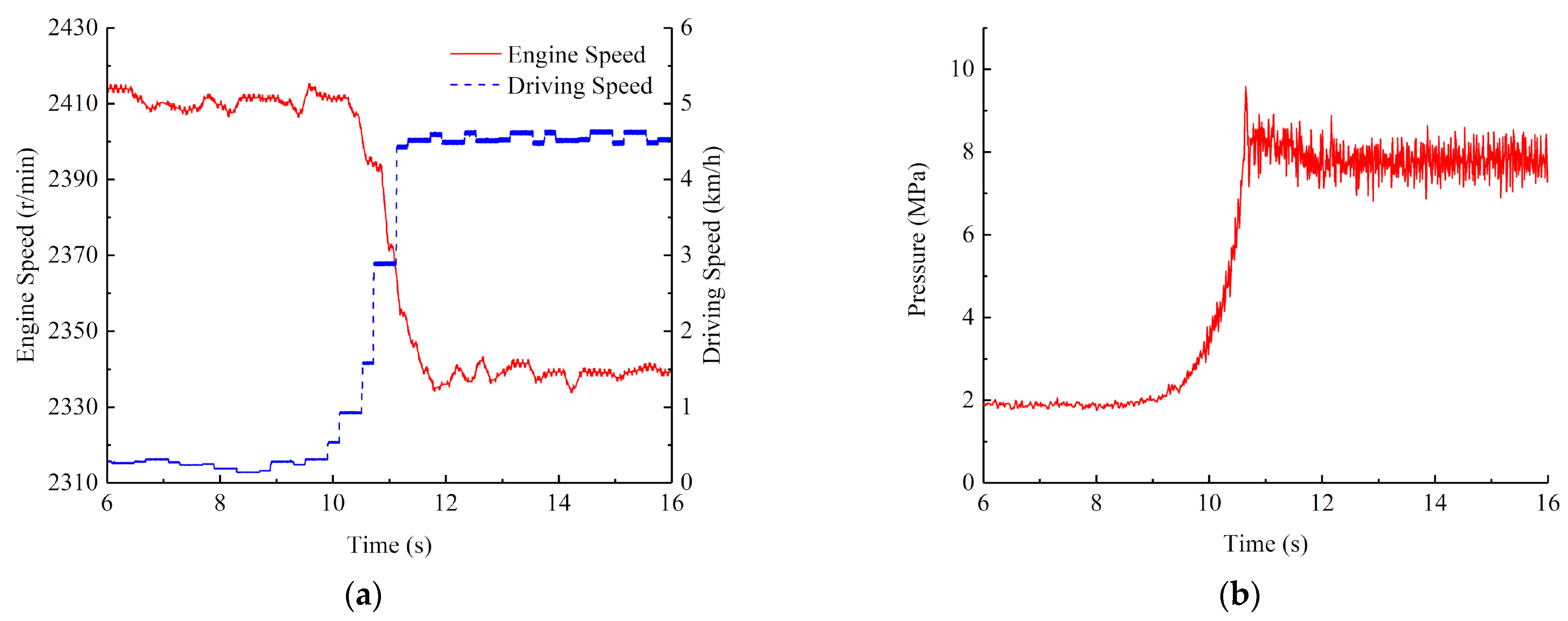

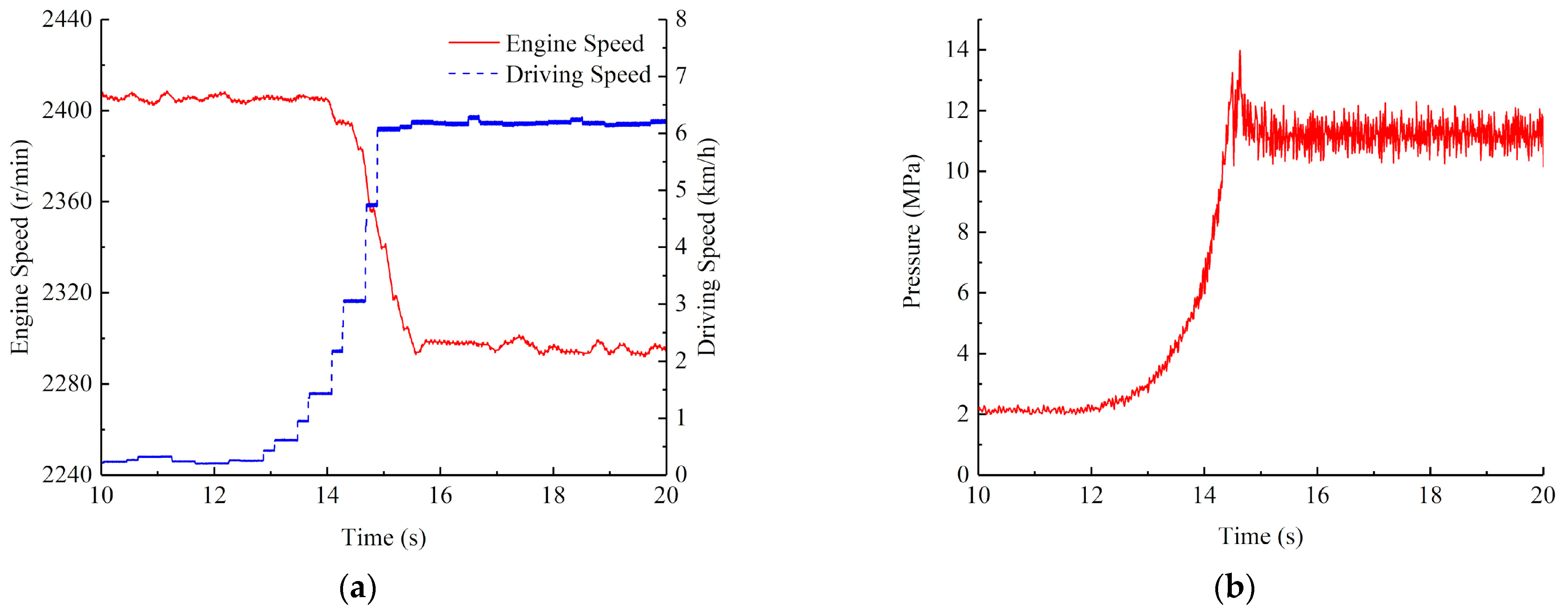

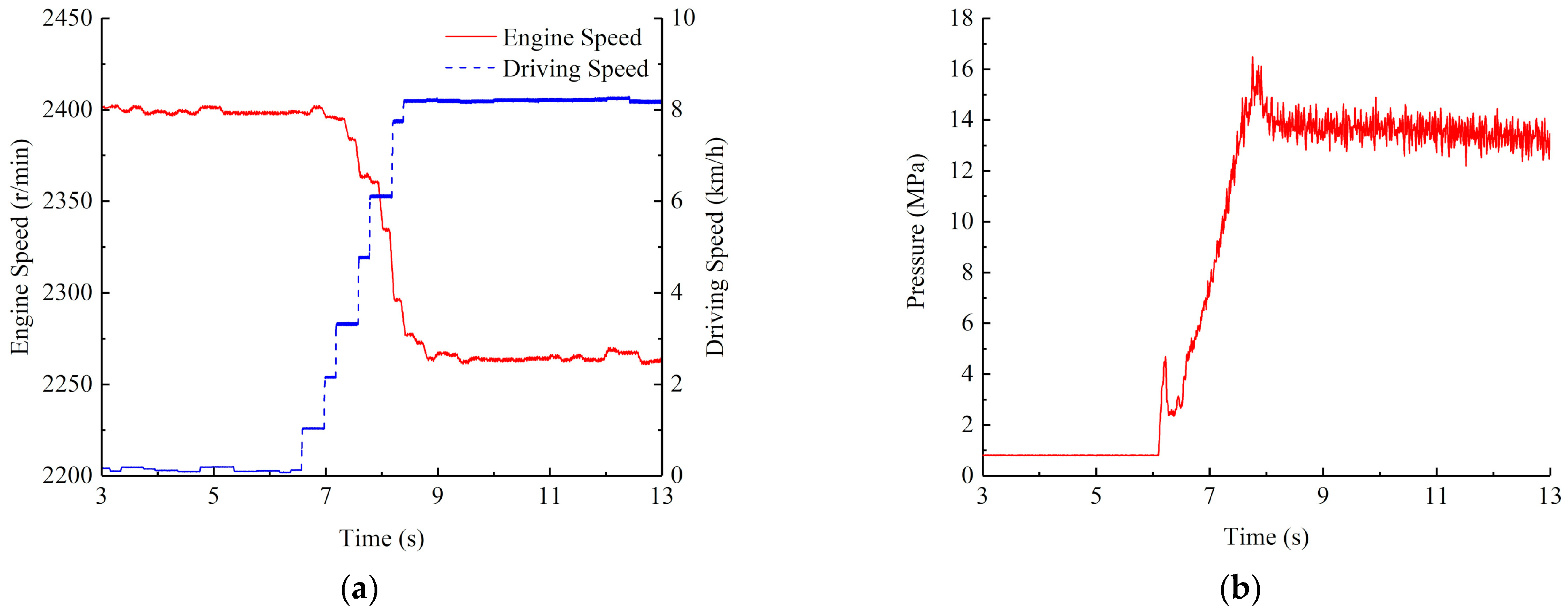

2.8.2. Starting Acceleration Performance Test

- Adjust the engine speed to 2400 r/min;

- Operate the clutch and put the drive rear axle at Gear I/II/III;

- Adjust the load torque to 27.6 N·m and 82.6 N·m according to the two different conditions of flat and slope, respectively;

- Adjust the swash plate angle of the HST variable pump from 0° to the maximum within 3 s through the control system of the test bench; and

- Record the change of the engine speed, the driving speed and the pressure difference between the inlet and outlet of the hydraulic motor.

3. Results and Discussion

3.1. Test Results of the Traction Performance

3.2. Test Results of the Initial Acceleration Performance

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luo, X.W. How to Develop the Agricultural Mechanization in Hilly Regions. Agric. Mach. Sci. Technol. Dev. 2011, 2, 17–20. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.J.; Yang, F.Z.; Pan, G.T.; Liu, H.Y.; Liu, Z.J.; Zhang, J.Q. Design and testing of a small remote-control hillside tractor. Trans. ASABE 2014, 57, 363–370. [Google Scholar] [CrossRef]

- Luo, X.W.; Liao, J.; Hu, L.; Zhang, Y.; Zhou, Z.Y. Improving agricultural mechanization level to promote agricultural sustainable development. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–11. (In Chinese) [Google Scholar] [CrossRef]

- Sun, J.B.; Meng, C.; Zhang, Y.Z. Design and physical model experiment of an attitude adjustment device for a crawler tractor in hilly and mountainous regions. Inf. Process. Agric. 2020, 7, 466–478. [Google Scholar] [CrossRef]

- Wang, Y.J.; Liu, Y.C.; Yang, F.Z. Development and test of tiny remotely controlled electric tractor for greenhouses. Trans. Chin. Soc. Agric. Eng. 2012, 28, 23–29. (In Chinese) [Google Scholar]

- Molari, G.; Bellentani, L.; Guarnieri, A. Performance of an agricultural tractor fitted with rubber tracks. Biosys. Eng. 2012, 111, 57–63. [Google Scholar] [CrossRef]

- Dasgupta, K.; Mandal, S.K.; Pan, S. Dynamic analysis of a low speed high torque hydrostatic drive using steady-state characteristics. Mech. Mach. Theory 2012, 52, 1–17. [Google Scholar] [CrossRef]

- Kim, D.M.; Kim, S.C.; Noh, D.K.; Jang, J.S. Jerk phenomenon of the hydrostatic transmission through the experiment and analysis. Int. J. Automot. Technol. 2015, 16, 783–790. [Google Scholar] [CrossRef]

- Jivkov, V.; Draganov, V. Theoretical Study and Experimental Validation of a Hydrostatic Transmission Control for a City Bus Hybrid Driveline with Kinetic Energy Storage. Energies 2018, 11, 2200. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.L.; Qin, X.Q.; Xu, M. Research Status and Development Trend on Vehicle Hydrostatic Transmission Hydraulic System. Mach. Hydraul. 2015, 43, 149–155. (In Chinese) [Google Scholar] [CrossRef]

- Li, S.; Chen, J.F.; Dong, H. Selection and design of HST for medium and small horsepower tractors. Agric. Dev. Equip. 2018, 5, 81–82. [Google Scholar] [CrossRef]

- Kim, W.S.; Kim, Y.-J.; Kim, Y.-S.; Baek, S.-Y.; Baek, S.-M.; Lee, D.-H.; Nam, K.-C.; Kim, T.-B.; Lee, H.-J. Development of Control System for Automated Manual Transmission of 45-kW Agricultural Tractor. Appl. Sci. 2020, 10, 2930. [Google Scholar] [CrossRef]

- Wang, G.; Song, Y.; Wang, J.; Chen, W.; Cao, Y.; Wang, J. Study on the Shifting Quality of the CVT Tractor under Hydraulic System Failure. Appl. Sci. 2020, 10, 681. [Google Scholar] [CrossRef]

- Murakami, N.; Ito, A.; Will, J.D. Development of a teleoperation system for agricultural vehicles. Comput. Electron. Agric. 2008, 63, 81–88. [Google Scholar] [CrossRef]

- Wan, I.; Yong, W.L.; Razali, M.H. Development of autonomous bio-production vehicle for agriculture. Int. J. Agric. Sci. 2010, 2, 21–27. [Google Scholar] [CrossRef][Green Version]

- Takai, R.; Yang, L.L.; Noguchi, N. Development of a crawler-type robot tractor using RTK-GPS and IMU. Eng. Agric. Environ. Food 2014, 7, 143–147. [Google Scholar] [CrossRef]

- Karl-Erik, R. Hydrostatic Drives in Heavy Mobile Machinery-New Concepts and Development Trends. SAE Trans. 1998, 107, 232–238. [Google Scholar]

- Comellas, M.; Pijuan, J. Analysis of a hydrostatic transmission driveline for its use in off-road multiple axle vehicles. J. Terramech. 2012, 49, 245–254. [Google Scholar] [CrossRef]

- Xiao, L.; Zhi Gu APP. Top 10 grain harvesters in China International Agricultural Machinery Exhibition 2019. Farm. Mach. 2019, 11, 40–42. (In Chinese) [Google Scholar] [CrossRef]

- Yang, H.Y.; Wang, H.B.; Zhang, L.X.; Zhao, Y.K. Application of hydraulic drive system in wheeled grain combine harvester. Tractor. Farm. Transp. 2019, 46, 10–12. (In Chinese) [Google Scholar]

- Bhamodkar, M.A.; Bhende, S.M.; Khambalkar, V.P. Hydrostatic drive system for sorghum harvester. New Agric. 2006, 2, 207–214. [Google Scholar]

- Chen, S.Y.; Du, Y.F.; Xie, B.; Song, Z.H.; Mao, E.R.; Chen, Y. Design and performance analysis of drive system for high clearance self-propelled corn detasseling machine. Trans. Chin. Soc. Agric. Eng. 2016, 32, 10–17. (In Chinese) [Google Scholar] [CrossRef]

- Zou, F.; Kang, J.J.; Xiao, M.H. Hydrostatic driving system for self-propelled sprayer. Int. Agric. Eng. J. 2017, 26, 11–17. [Google Scholar]

- Zhao, J.H.; Xu, L.Y.; Zhang, J.Q. Research and application status of hydrostatic driving technology of Non-road vehicles. Tractor. Farm. Transp. 2018, 45, 8–13. (In Chinese) [Google Scholar]

- Luoyang Tractor Research Institute, Ministry of Machinery and Electronics Industry, China. Tractor Design Manual, 1st ed.; China Machine Press: Beijing, China, 1994; Volume 1. (In Chinese)

- Luoyang Tractor Research Institute, Ministry of Machinery and Electronics Industry, China. Mechanical Engineering Manual, 1st ed.; China Machine Press: Beijing, China, 1978; Volume 70. (In Chinese)

- Wang, M.H. Thoughts on accelerating the development of Agricultural Mechanization in southern and hilly areas. South. Agric. Mach. 2015, 8, 3–7. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y. Hydrostatic Driving of Vehicles and Walking Machinery; Chemical Industry Press: Beijing, China, 2014; pp. 272–290. (In Chinese) [Google Scholar]

- Xu, L.Y.; Liu, M.N.; Zhou, Z.L. Design of drive system for series hybrid electric tractor. Trans. Chin. Soc. Agric. Eng. 2014, 30, 11–18. (In Chinese) [Google Scholar] [CrossRef]

- Chen, L.Q.; Zhan, Q.F.; Wang, W.W.; Huang, X.; Zheng, Q. Design and Experiment of Electric Drive System for Pure Electric Tractor. Trans. Chin. Soc. Agric. Mach. 2018, 49, 388–394. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, L.J.; Wei, Y.Y.; Liu, Q.H. Hierarchical control of engine-variable pump-variable motor drive system. J. B Univ. Aeronaut. Astronaut. 2015, 41, 1416–1421. (In Chinese) [Google Scholar] [CrossRef]

- Lu, Y.X. Technical Handbook for Hydraulics and Pneumatics; China Machine Press: Beijing, China, 2002; pp. 470–541. (In Chinese) [Google Scholar]

- Xie, B.; Zhang, C.; Chen, S.; Mao, E.R.; Du, Y.F. Transmission Performance of Two-wheel Drive Electric Tractor. Trans. Chin. Soc. Agric. Mach. 2015, 46, 8–13. (In Chinese) [Google Scholar] [CrossRef]

- Luo, Q.G.; Zhang, Y.F.; Yuan, W. Comprehensive Evaluation of Power-train Performance for Tracked Vehicles. Acta Armamentarii 2005, 26, 413–417. (In Chinese) [Google Scholar] [CrossRef]

- Wei, L.; Liu, H.; Chen, H.; Xu, Y.; Zhao, Z. Research on parameter optimisation of tracked vehicle transmission system based on genetic algorithm. Int. J. Autom. Logist. 2021, 3, 169. [Google Scholar] [CrossRef]

| Operation Items | Ploughing | Rotary Tillage | Harrow, Suppress | Seeding | Cultivation and Plant Protection | Transplanting and Ditching |

|---|---|---|---|---|---|---|

| Speed range (km/h) | 3.5–7 | 2–3 | 4–8 | 5–9 | 3–7 | 0.5–2.5 |

| Name | Parameter | Name | Parameter |

|---|---|---|---|

| Total weight (kg) | Approximately 1300 | Number of shares | 2 |

| Working speed (km/h) | 0–8 | Maximum working gradient (°) | 15 |

| Radius of the driving wheel (mm) | 103 | Ploughing depth (mm) | 250 |

| Working Condition | Task Type | Resistance Coefficient | Maximum Speed (km/h) | Rolling Resistance (N) | Traction Resistance (N) | Driving Resistance (N) | Drive Torque (N·m) | Power (kW) |

|---|---|---|---|---|---|---|---|---|

| Flat ground | Driving | 0.06 | 8.0 | 764.4 | 0 | 1656.2 | 170.6 | 3.68 |

| Seeding | 0.07 | 7.0 | 891.8 | 1875.0 | 3658.6 | 376.8 | 7.11 | |

| Ploughing | 0.07 | 6.0 | 891.8 | 4500.0 | 6283.6 | 647.2 | 10.47 | |

| Slope | Driving | 0.06 | 6.0 | 764.4 | 0 | 4953.6 | 510.2 | 8.26 |

| Seeding | 0.07 | 5.0 | 861.4 | 1875.0 | 6952.6 | 713.9 | 9.62 | |

| Ploughing | 0.07 | 4.5 | 861.4 | 4500.0 | 9550.6 | 983.7 | 11.94 |

| Model | Rated Power (kW) | Rated Speed (r/min) | Maximum Torque (N·m) | Displacement (L) |

|---|---|---|---|---|

| ZN390B | 26.5 | 2400 | 2400 | 1.908 |

| Specifications | Parameter |

|---|---|

| Variable pump displacement (mL/r) | 0–28 |

| Motor displacement (mL/r) | 28 |

| Charge pump Displacement (mL/r) | 7 |

| Maximum input speed (r/min) | 3000 |

| Output speed (r/min) | 0–3000 |

| Rated pressure (MPa) | 21 |

| Maximum pressure (MPa) | 32 |

| Theoretical rated output torque (N·m) | 93.6 |

| Maximum output torque (N·m) | 151.6 |

| Operating temperature range (°C) | −20–80 |

| Theoretical total efficiency (%) | ≥73 |

| Type | Maximum Input Speed (r/min) | Transmission Ratio | Gear Speed Ratio | Steering Mode | Lubricating Oil |

|---|---|---|---|---|---|

| XL-80 | 23.36 | ||||

| 2400 | 0.8 | 16.46 | Jaw clutch | Anti-wear (68#) | |

| 12.16 |

| Gear | Gear I | Gear II | Gear III |

|---|---|---|---|

| Theoretical set speed (km/h) | 0–4 | 0–6 | 0–8 |

| Driving speed after checking (km/h) | 0–4.1 | 0–5.81 | 0–7.87 |

| Name | Type | Main Parameter | Numerical Value |

|---|---|---|---|

| Gear Increaser I | Actual transmission ratio | 14.75 | |

| ZLY-125 | Nominal input speed (R/min) | 1500 | |

| Nominal output speed (R/min) | 107 | ||

| Gear Increaser II | Actual transmission ratio | 6.3 | |

| ZLY-125 | Nominal input speed (R/min) | 1500 | |

| Nominal output speed (R/min) | 240 | ||

| Loading Hydraulic Pump | CBG2040-BFPR | Nominal displacement (mL/r) | 40 |

| Rated pressure (MPa) | 20 | ||

| Flywheel | ZS1105 | Mass (kg) | 25 |

| Outer diameter (mm) | 450 | ||

| Cooler | GLC-2.6 | Cooling area (m2) | 2.6 |

| Heat transfer coefficient (W/(m2 °C)) | 330 | ||

| Speed & Torque sensor | TL-303 | Range (N·m) | −200–+200 |

| measurement accuracy | 0.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Zhang, G.; Chu, G.; Niu, H.; Zhang, Y.; Yang, F. Design Matching and Dynamic Performance Test for an HST-Based Drive System of a Hillside Crawler Tractor. Agriculture 2021, 11, 466. https://doi.org/10.3390/agriculture11050466

Liu Z, Zhang G, Chu G, Niu H, Zhang Y, Yang F. Design Matching and Dynamic Performance Test for an HST-Based Drive System of a Hillside Crawler Tractor. Agriculture. 2021; 11(5):466. https://doi.org/10.3390/agriculture11050466

Chicago/Turabian StyleLiu, Zhijie, Guoqiang Zhang, Guoping Chu, Hanlin Niu, Yazhou Zhang, and Fuzeng Yang. 2021. "Design Matching and Dynamic Performance Test for an HST-Based Drive System of a Hillside Crawler Tractor" Agriculture 11, no. 5: 466. https://doi.org/10.3390/agriculture11050466

APA StyleLiu, Z., Zhang, G., Chu, G., Niu, H., Zhang, Y., & Yang, F. (2021). Design Matching and Dynamic Performance Test for an HST-Based Drive System of a Hillside Crawler Tractor. Agriculture, 11(5), 466. https://doi.org/10.3390/agriculture11050466