Influence of Cooling and Heating Systems on Pen Fouling, Lying Behavior, and Performance of Rearing Piglets

Abstract

1. Introduction

2. Materials and Methods

2.1. Animals

2.2. Housing

2.3. Heating and Cooling

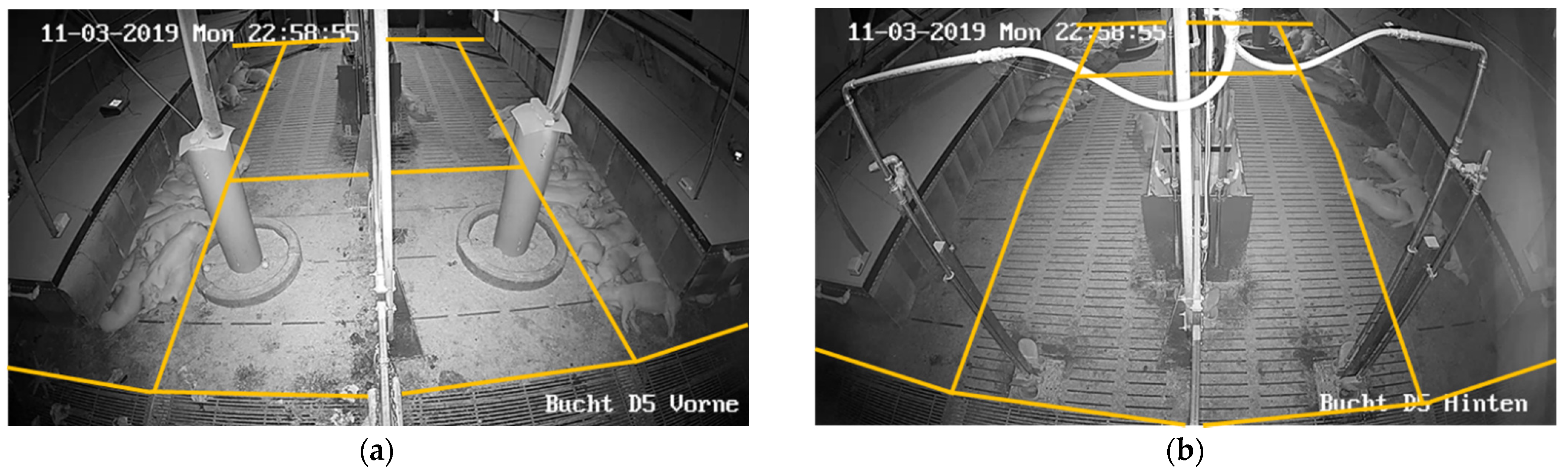

2.4. Data Collection and Aggregation

2.5. Experimental Design and Data Analysis

3. Results and Discussion

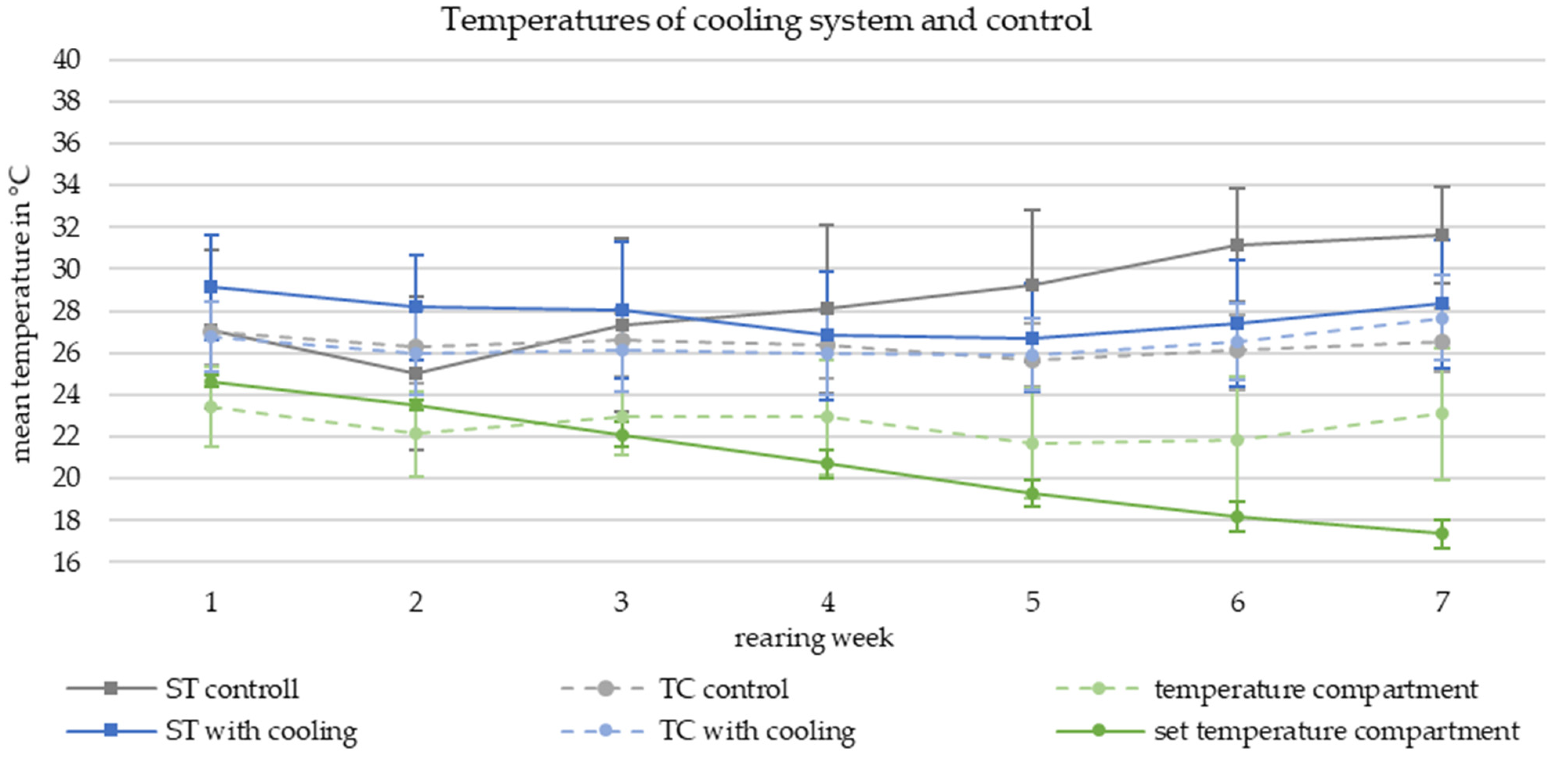

3.1. Temperature and Relative Humidity

3.2. Performance

3.3. Function of Heating and Cooling Systems

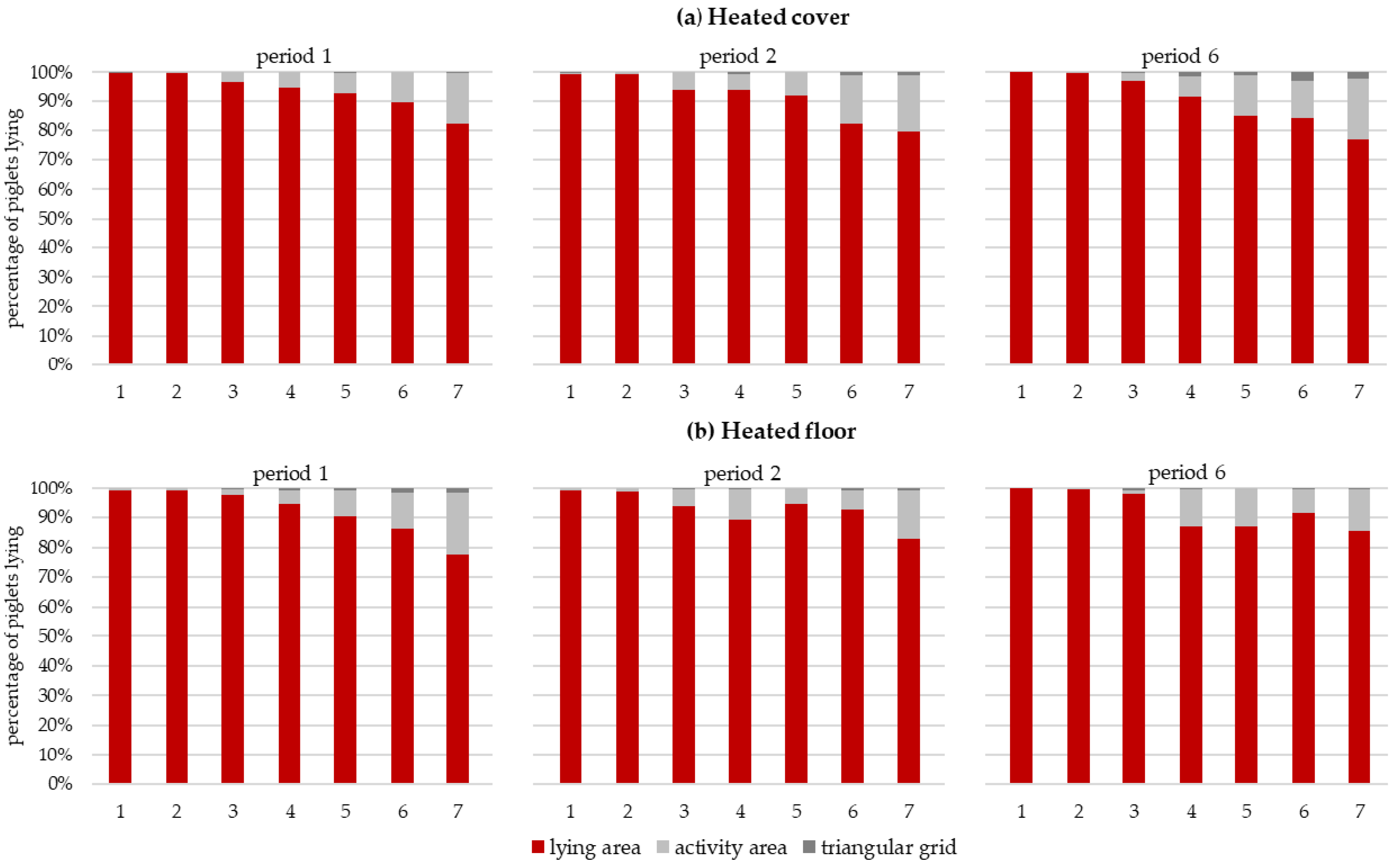

3.4. Influence of Heating on Lying Behavior

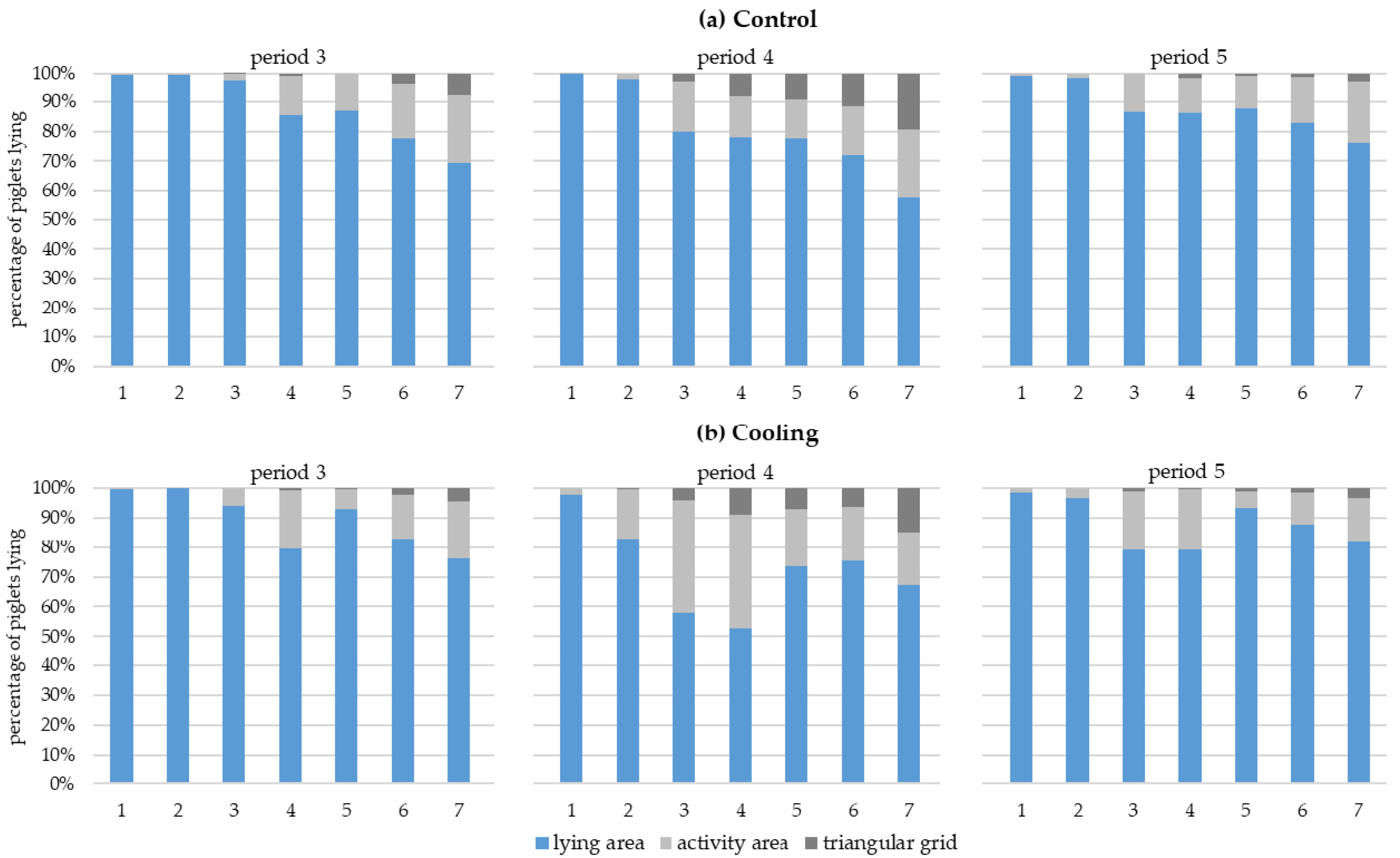

3.5. Influence of Cooling on Lying Behavior

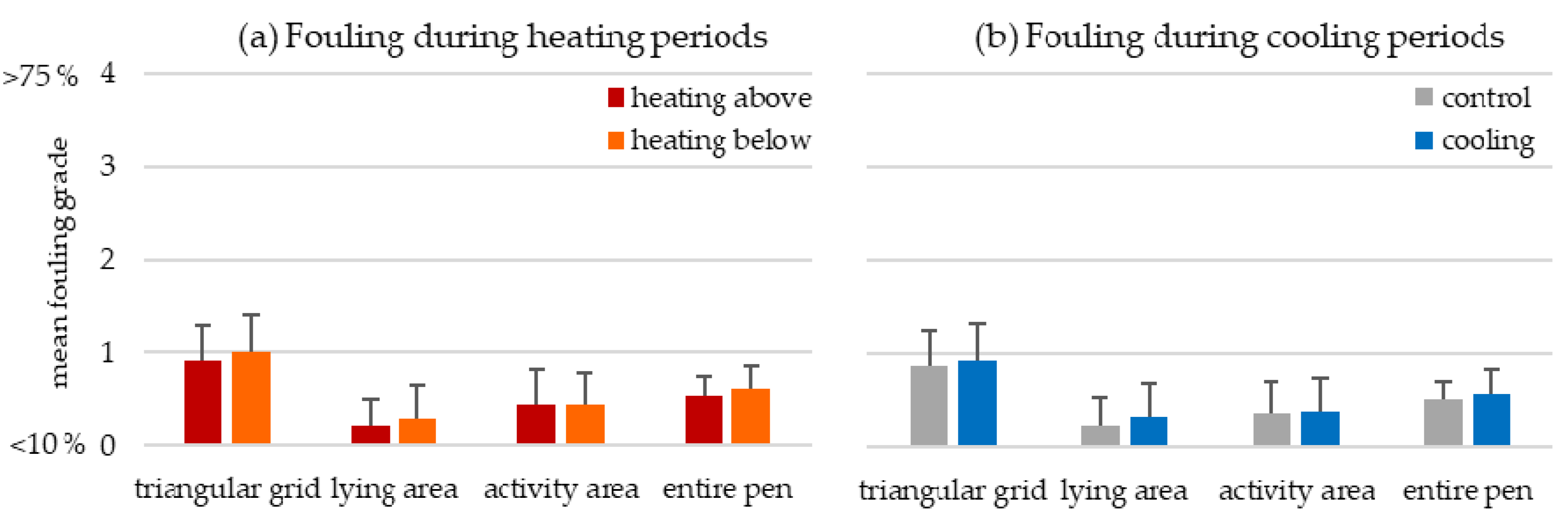

3.6. Fouling of the Pens

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Le Dividich, J.; Herpin, P. Effects of climatic conditions on the performance, metabolism and health status of weaned piglets: A review. Livest. Prod. Sci. 1994, 38, 70–79. [Google Scholar] [CrossRef]

- Jungbluth, T.; Büscher, W.; Krause, M. Technik Tierhaltung, 2nd ed.; Eugen Ulmer: Stuttgart, Germany, 2017; ISBN 978-3-8252-4243-5. [Google Scholar]

- Normenausschuss Bauwesen. Wärmeschutz Geschlossener Ställe. Wärmedämmung und Lüftung. DIN No. 18910; Beuth Verlag GmbH: Berlin, Germany, 2004. [Google Scholar]

- Le Dividich, J. Effects of environmental temperature on the growth rates of early-weaned piglets. Livest. Prod. Sci. 1981, 8, 75–86. [Google Scholar] [CrossRef]

- Hoha, G.V.; Costachescu, E.; Nica, A.; Dunea, I.B.; Pasarin, B. The influence of microclimates conditions on production performance in pigs. Lucr. Ştiinţifice Ser. Zooteh. 2013, 59, 165–169. [Google Scholar]

- Heath, M.E. The effects of rearing-temperature on body composition in young pigs. Comp. Biochem. Physiol. 1983, 76, 363–366. [Google Scholar] [CrossRef]

- Simantke, C.; Aubel, E.; Knierim, U.; Cramer, P. Optimierung der Haltungsbedingungen von Aufzuchtferkeln im Liegebereich; Bundesprogramm Ökologischer Landbau und andere Formen Nachhaltiger Landwirtschaft: Bonn, Germany, 2010. [Google Scholar]

- Kaspar, F.; Friedrich, K. Rückblick auf die Temperatur in Deutschland im Jahr 2019 und die langfristige Entwicklung. 2020. Available online: https://www.dwd.de/DE/klimaumwelt/aktuelle_meldungen/200103/temperatur_d_2019_langfristig.html?nn=344870 (accessed on 25 March 2020).

- Ross, J.W.; Hale, B.J.; Gabler, N.K.; Rhoads, R.P.; Keating, A.F.; Baumgard, L.H. Physiological consequences of heat stress in pigs. Anim. Prod. Sci. 2015, 55, 1381. [Google Scholar] [CrossRef]

- Huynh, T.T.T.; Aarnink, A.J.A. Heat stress in pigs. Pig Prog. 2005, 21, 30–32. [Google Scholar]

- Huynh, T.T.T.; Aarnink, A.J.A.; Gerrits, W.J.J.; Heetkamp, M.J.H.; Canh, T.T.; Spoolder, H.A.M.; Kemp, B.; Verstegen, M.W.A. Thermal behaviour of growing pigs in response to high temperature and humidity. App. Anim. Behav. Sci. 2005, 91, 1–16. [Google Scholar] [CrossRef]

- Aarnink, A.J.A.; Schrama, J.W.; Heetkamp, M.J.W.; Stefanowska, J.; Huynh, T.T.T. Temperature and body weight affect fouling of pig pens. J. Anim. Sci. 2006, 84, 2224–2231. [Google Scholar] [CrossRef]

- Justino, E.; Nääs, I.d.A.; Carvalho, T.M.R.; Neves, D.P.; Salgado, D.D. The impact of evaporative cooling on the thermoregulation and sensible heat loss of sows during farrowing. Eng. Agric. 2014, 1050–1061. [Google Scholar] [CrossRef]

- Jensen, P.; von Borell, E.; Broom, D.M.; Csermely, D.; Dijkhuizen, A.A.; Hylkema, S.; Edwards, S.A.; Madec, F.; Stamatatis, C. The Welfare of Intensively Keept Pigs; European Commission, Scientific Veterinary Committee: Brussels, Belgium, 1997. [Google Scholar]

- Bracke, M.B.M. Review of wallowing in pigs: Description of the behaviour and its motivational basis. App. Anim. Behav. Sci. 2011, 132, 1–13. [Google Scholar] [CrossRef]

- Parois, S.P.; Cabezón, F.A.; Schinckel, A.P.; Johnson, J.S.; Stwalley, R.M.; Marchant-Forde, J.N. Effect of floor cooling on behavior and heart rate of late lactation sows under acute heat stress. Front. Vet. Sci. 2018, 5, 223. [Google Scholar] [CrossRef]

- Silva, B.A.N.; Oliveira, R.F.M.; Donzele, J.L.; Fernandes, H.C.; Abreu, M.L.T.; Noblet, J.; Nunes, C.G.V. Effect of floor cooling on performance of lactating sows during summer. Livest. Sci. 2006, 105, 176–184. [Google Scholar] [CrossRef]

- Huynh, T.T.T.; Aarnink, A.J.A.; Spoolder, H.A.M.; Verstegen, M.W.A.; Kemp, B. Effects of floor cooling during high ambient temperatures on the lying behavior and productivity of growing finishing pigs. Am. Soc. Agric. Eng. 2004, 47, 1773–1782. [Google Scholar] [CrossRef]

- Shi, Z.; Li, B.; Zhang, X.; Wang, C.; Zhou, D.; Zhang, G. Using floor cooling as an approach to improve the thermal environment in the sleeping area in an open pig house. Biosyst. Eng. 2006, 93, 359–364. [Google Scholar] [CrossRef]

- Opderbeck, S.; Keßler, B.; Gordillio, W.; Schrade, H.; Piepho, H.-P.; Gallmann, E. Influence of a cooled, solid lying area on the pen fouling and lying behavior of fattening pigs. Agriculture 2020, 10, 307. [Google Scholar] [CrossRef]

- Bundesministeriums der Justiz und für Verbraucherschutz sowie des Bundesamts für Justiz. Verordnung zum Schutz landwirtschaftlicher Nutztiere und anderer zur Erzeugung tierischer Produkte gehaltener Tiere bei ihrer Haltung. Tierschutz-Nutztierhaltungsverordnung-TierSchNutztV, 22.8.2006.

- Kenward, M.G.; Roger, J.H. Small sample inference for fixed effects from restricted maximum likelihood. Biometrics 1997, 53, 983. [Google Scholar] [CrossRef]

- Edwards, D.; Berry, J.J. The efficiency of simulation-based multiple comparisons. Biometrics 1987, 43, 913. [Google Scholar] [CrossRef] [PubMed]

- Rohlmann, C.; Verhaagh, M.; Efken, J. Steckbriefe zur Tierhaltung in Deutschland: Ferkelerzeugung und Schweinemast; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2020; Available online: https://www.thuenen.de/de/thema/nutztiershyhaltung-und-aquakultur/haltungsverfahren-in-deutschland/konventionelle-schweinehaltung/ (accessed on 28 May 2020).

- Johnston, L.J.; Brumm, M.C.; Moeller, S.J.; Pohl, S.; Shannon, M.C.; Thaler, R.C. Effects of reduced nocturnal temperature on pig performance and energy consumption in swine nursery rooms. J. Anim. Sci. 2013, 91, 3429–3435. [Google Scholar] [CrossRef] [PubMed]

- Asse, M.; Zacharias, B. Leistungspotentiale Sind in der Ferkelaufzucht noch Nicht Ausgeschöpft. Ergebnisse aus dem Schweinereport Baden-Württemberg 2012/2013—Ferkelaufzucht: Biologische Auswertung. 2014. Available online: https://lsz.landwirtschaft-bw.de/pb/,Lde/Startseite/Wissen/Schweinereport (accessed on 19 March 2021).

- Collin, A.; van Milgen, J.; Dubois, S.; Noblet, J. Effect of high temperature and feeding level on energy utilization in piglets. J. Anim. Sci. 2001, 79, 1849–1857. [Google Scholar] [CrossRef]

- Börgermann, B.; Rus, M.; Kaufmann, O. Sensorgestützte Überprüfung des Wahlverhaltens von Mastschweinen—Welche Fußböden und Beschäftigungsangebote werden bevorzugt? Landtechnik 2007, 62, 228–229. [Google Scholar] [CrossRef]

- Christison, G.I. Dim light does not reduce fighting or wounding of newly mixed pigs at weaning. Can. J. Anim. Sci. 1996, 76, 141–143. [Google Scholar] [CrossRef]

- Taylor, N.; Prescott, N.; Perry, G.; Potter, M.; Le Sueur, C.; Wathes, C. Preference of growing pigs for illuminance. App. Anim. Behav. Sci. 2006, 96, 19–31. [Google Scholar] [CrossRef]

- Opderbeck, S.; Keßler, B.; Gordillo, W.; Schrade, H.; Piepho, H.-P.; Gallmann, E. Influence of increased light intensity on the acceptance of a solid lying area and a slatted elimination area in fattening pigs. Agriculture 2020, 10, 56. [Google Scholar] [CrossRef]

- Savary, P.; Gygax, L.; Wechsler, B.; Hauser, R. Effect of a synthetic plate in the lying area on lying behaviour, degree of fouling and skin lesions at the leg joints of finishing pigs. App. Anim. Behav. Sci. 2009, 118, 20–27. [Google Scholar] [CrossRef]

| Variable | Unit | Phase I Day 1 to 14 | Phase II Day 15 to End |

|---|---|---|---|

| ME | MJ/kg | 14.07 | 13.3 |

| Crude protein | % | 16.1 | 17.4 |

| Crude fiber | % | 4.4 | 4.5 |

| Raw fat | % | 8.4 | 5.3 |

| Lysine | % | 1.5 | 1.3 |

| Calcium | % | 0.56 | 0.52 |

| Phosphorus | % | 0.46 | 0.51 |

| Measured Variable | Unit | Number/ | Measuring Range/Accuracy | Sensor Type |

|---|---|---|---|---|

| Position | ||||

| Relative | % | two per compartment (front and back), | Range 0–100%, accuracy 5% (±2.5% for 23 °C) | MELA Feuchtesensoren IBF2.11.F100.C97.1K6 (Mohlsdorf-Teichwolframsdorf, Germany) |

| humidity | above the partition of the pens, | |||

| 1.5 m above the floor | ||||

| Room | °C | six per compartment, | Range −190–260 °C | SensorShop 24, Kabelführer (Bräunlingen, Germany) |

| temperature | two above the partition of the pens 1.5 m above the floor, | |||

| two under each cover about 0.5 m above the floor | ||||

| Surface | °C | 10 per compartment, | Range 35–400 °C | SensorShop 24, Oberflächenfühler (Bräunlingen, Germany) |

| temperature | embedded in the floor elements, 1 cm below the surface, | |||

| three each in the lying areas, | ||||

| one each in the triangular grid, | ||||

| one each in the slatted area |

| Period | Date | Pen | Treatment | Compartment | Temperature Outdoor in °C (1) | Temperature Indoor in °C (2) | Relative Humidity |

|---|---|---|---|---|---|---|---|

| (dd.mm.yy) | in % (2) | ||||||

| 1 | 20.12.18–06.02.19 | 501 | Heated floor | D5 | −1.8 ± 3.2 | 20.1 ± 1.6 | 47 ± 4 |

| 502 | Heated cover | (min. −9.4; max. 5.7) | (min. 15.1 max. 24.5) | (min. 29 max. 59) | |||

| 29.11.18–16.01.19 | 601 | Heated cover | D6 | 3.2 ± 4.1 | 21.1 ± 1.7 | 49 ± 4 | |

| 602 | Heated floor | (min. −4.7; max. 11.0) | (min. 15.0; max. 26.3) | (min. 33 max. 68) | |||

| 2 | 21.02.19–10.04.19 | 501 | Heated floor | D5 | 6.5 ± 3.9 | 20.5 ± 1.5 | 46 ± 6 |

| 502 | Heated cover | (min. −3.8; max. 17.6) | (min. 15.2; max. 25.1) | (min. 24 max. 63) | |||

| 31.01.19–30.03.19 | 601 | Heated cover | D6 | 2.0 ± 3.8 | 21.0 ± 1.9 | 44 ± 5 | |

| 602 | Heated floor | (min. −4.7; max. 16.2) | (min. 15.1; max. 26.6) | (min. 23 max. 62) | |||

| 3 | 25.04.19–12.06.19 | 501 | Cooling | D5 | 8.5 ± 4.1 | 22.0 ± 2.2 | 49 ± 7 |

| 502 | Control | (min. −0.3; max. 23.8) | (min. 15.1; max. 30.5) | (min. 26 max. 63) | |||

| 04.04.19–22.05.19 | 601 | Cooling | D6 | 8.9 ± 5.7 | 21.0 ± 1.9 | 46 ± 7 | |

| 602 | Control | (min. −1.2; max. 22.3) | (min. 14.6; max. 28.7) | (min. 22 max. 67) | |||

| 4 | 27.06.19–14.08.19 | 501 | Control | D5 | 18.5 ± 5.5 | 24.3 ± 2.3 | 50 ± 7 |

| 502 | Cooling | (min. 6.0; max. 34.0) | (min. 18.4; max. 32.3) | (min. 30 max. 70) | |||

| 05.06.19–24.07.19 | 601 | Cooling | D6 | 17.7 ± 4.8 | 24.2 ± 2.5 | 53 ± 6 | |

| 602 | Control | (min. 6.2; max. 29.6) | (min. 17.9; max. 32.2) | (min. 31 max. 69) | |||

| 5 | 29.08.19–16.10.19 | 501 | Cooling | D5 | 16.2 ± 5.3 | 21.2 ± 2.1 | 52 ± 6 |

| 502 | Control | (min. 5.4; max. 30.1) | (min. 14.0; max. 28.5) | (min. 29 max. 65) | |||

| 08.08.19–25.09.19 | 601 | Control | D6 | 18.1 ± 4.7 | 22.9 ± 2.3 | 62 ± 9 | |

| 602 | Cooling | (min. 9.1; max. 29.7) | (min. 17.3; max. 31.5) | (min. 20 max. 89) | |||

| 6 | 31.10.19–18.12.19 | 501 | Heated floor | D5 | 4.8 ± 3.6 | 19.6 ± 1.5 | 47 ± 3 |

| 502 | Heated cover | (min. −3.0; max. 15.3) | (min. 15.0; max. 25.4) | (min. 30 max. 58) | |||

| 10.10.19–27.11.19 | 601 | Heated floor | D6 | 12.4 ± 3.6 | 20.4 ± 2.2 | 49 ± 5 | |

| 602 | Heated cover | (min. 4.9; max. 24.5) | (min. 15.0; max. 27.0) | (min. 20 max. 61) |

| Period | Treatment | Weight Gain in g/d (n) (1) | Feed Intake in g/d (n) (2) | Feed Conversion Ratio in kg (n) (2) |

|---|---|---|---|---|

| 1 | Heated cover | 458 ± 90 (93) | 762 ± 13 (2) | 1.66 ± 0.01 (2) |

| Heated floor | 479 ± 78 (92) | 785 ± 20 (2) | 1.64 ± 0.00 (2) | |

| 2 | Heated cover | 448 ± 69 (92) | 719 ± 56 (2) | 1.60 ± 0.10 (2) |

| Heated floor | 455 ± 81 (93) | 730 ± 11 (2) | 1.59 ± 0.02 (2) | |

| 6 | Heated cover | 457 ± 84 (91) | 730 ± 52 (2) | 1.60 ± 0.11 (2) |

| Heated floor | 427 ± 91 (92) | 720 ± 24 (2) | 1.69 ± 0.12 (2) | |

| All heating periods | Heated cover | 454 ± 89 (276) | 737 ± 48 (6) | 1.62 ± 0.09 (6) |

| Heated floor | 413 ± 85 (277) | 745 ± 34 (6) | 1.64 ± 0.08 (6) | |

| 3 | Cooling | 441 ± 90 (95) | 718 ± 38 (2) | 1.63 ± 0.01 (2) |

| Control | 435 ± 88 (94) | 689 ± 7 (2) | 1.59 ± 0.07 (2) | |

| 4 | Cooling | 418 ± 80 (95) | 747 ± 82 (2) | 1.78 ± 0.10 (2) |

| Control | 395 ± 80 (93) | 664 ± 21 (2) | 1.69 ± 0.03 (2) | |

| 5 | Control | 400 ± 93 (93) | 700 ± 77 (2) | 1.74 ± 0.06 (2) |

| Cooling | 408 ± 82 (89) | 662 ± 52 (2) | 1.62 ± 0.07 (2) | |

| All cooling periods | Cooling | 408 ± 82 (283) | 722 ± 71 (6) | 1.72 ± 0.09 (6) |

| Cooling | 420 ± 89 (276) | 672 ± 35 (6) | 1.63 ± 0.07 (6) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Opderbeck, S.; Keßler, B.; Gordillio, W.; Schrade, H.; Piepho, H.-P.; Gallmann, E. Influence of Cooling and Heating Systems on Pen Fouling, Lying Behavior, and Performance of Rearing Piglets. Agriculture 2021, 11, 324. https://doi.org/10.3390/agriculture11040324

Opderbeck S, Keßler B, Gordillio W, Schrade H, Piepho H-P, Gallmann E. Influence of Cooling and Heating Systems on Pen Fouling, Lying Behavior, and Performance of Rearing Piglets. Agriculture. 2021; 11(4):324. https://doi.org/10.3390/agriculture11040324

Chicago/Turabian StyleOpderbeck, Svenja, Barbara Keßler, William Gordillio, Hansjörg Schrade, Hans-Peter Piepho, and Eva Gallmann. 2021. "Influence of Cooling and Heating Systems on Pen Fouling, Lying Behavior, and Performance of Rearing Piglets" Agriculture 11, no. 4: 324. https://doi.org/10.3390/agriculture11040324

APA StyleOpderbeck, S., Keßler, B., Gordillio, W., Schrade, H., Piepho, H.-P., & Gallmann, E. (2021). Influence of Cooling and Heating Systems on Pen Fouling, Lying Behavior, and Performance of Rearing Piglets. Agriculture, 11(4), 324. https://doi.org/10.3390/agriculture11040324