Estimation of the Cooling Rate of Six Olive Cultivars Using Thermal Imaging

Abstract

1. Introduction

2. Material and Methods

2.1. Experimental Material

2.2. Biometrical Data and Oil Content

2.3. Biothermal Data and Mathematical Calcuation

2.4. Data Analysis

3. Results and Discussion

3.1. Biometrical Data, Moisture and Oil Content in the Fruit

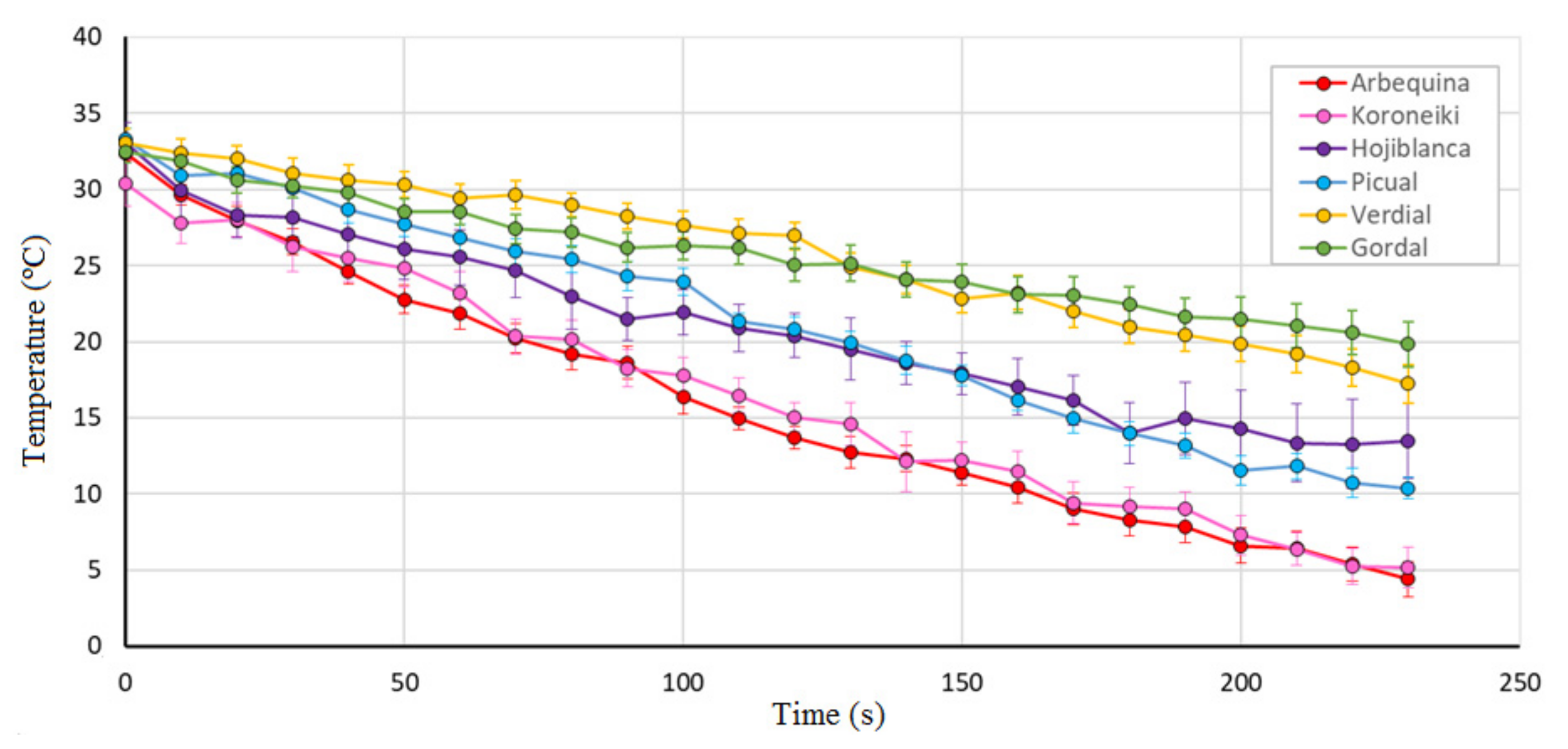

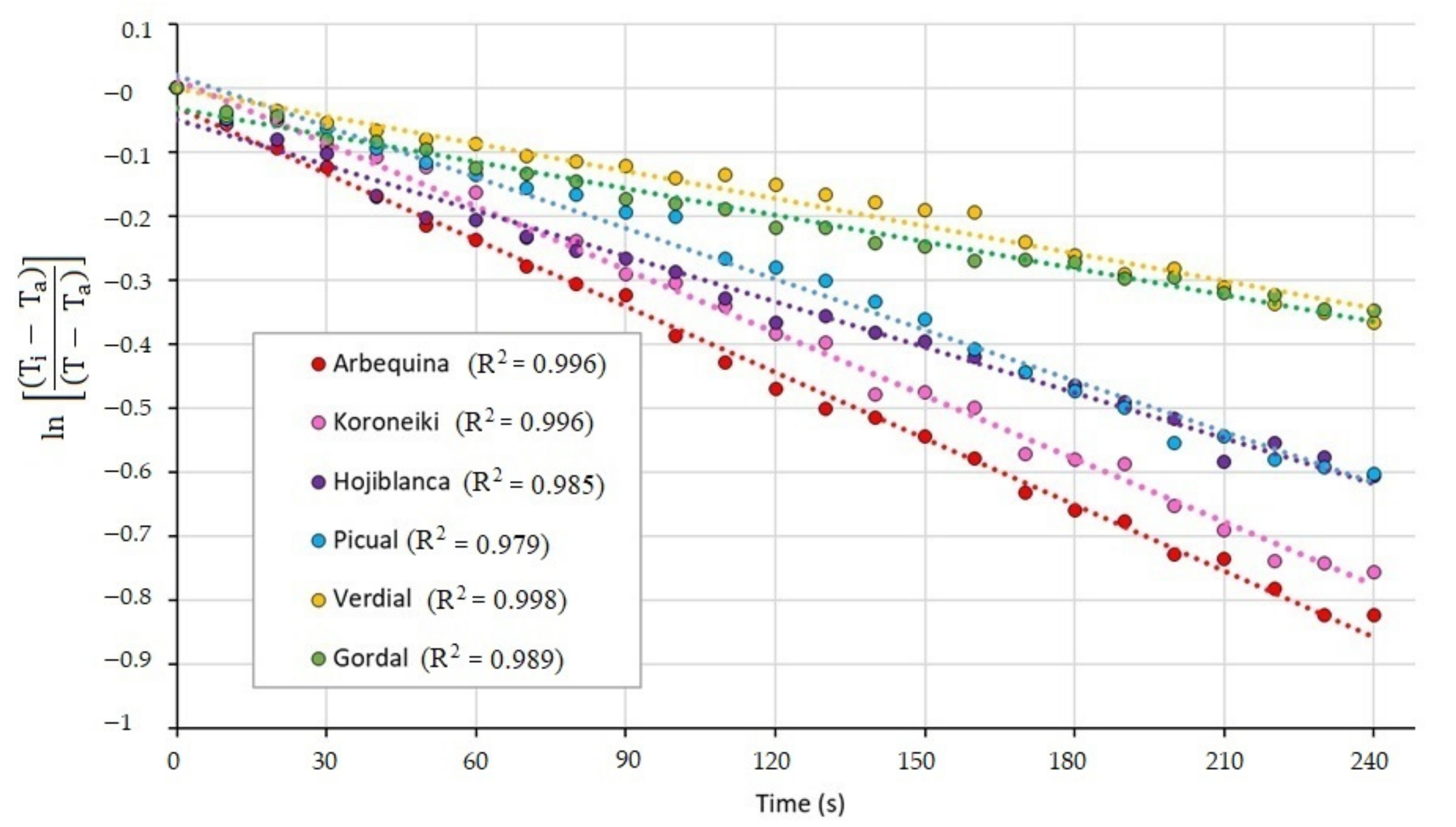

3.2. Cooling Curves

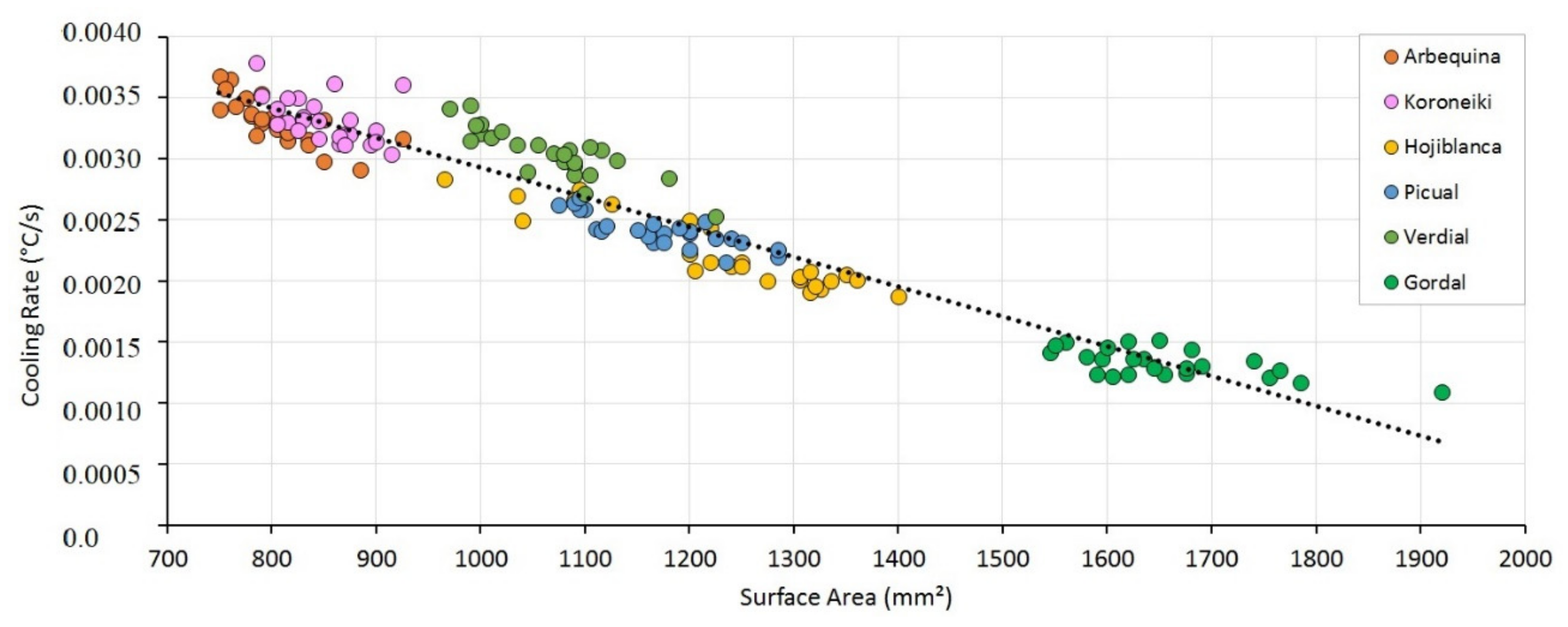

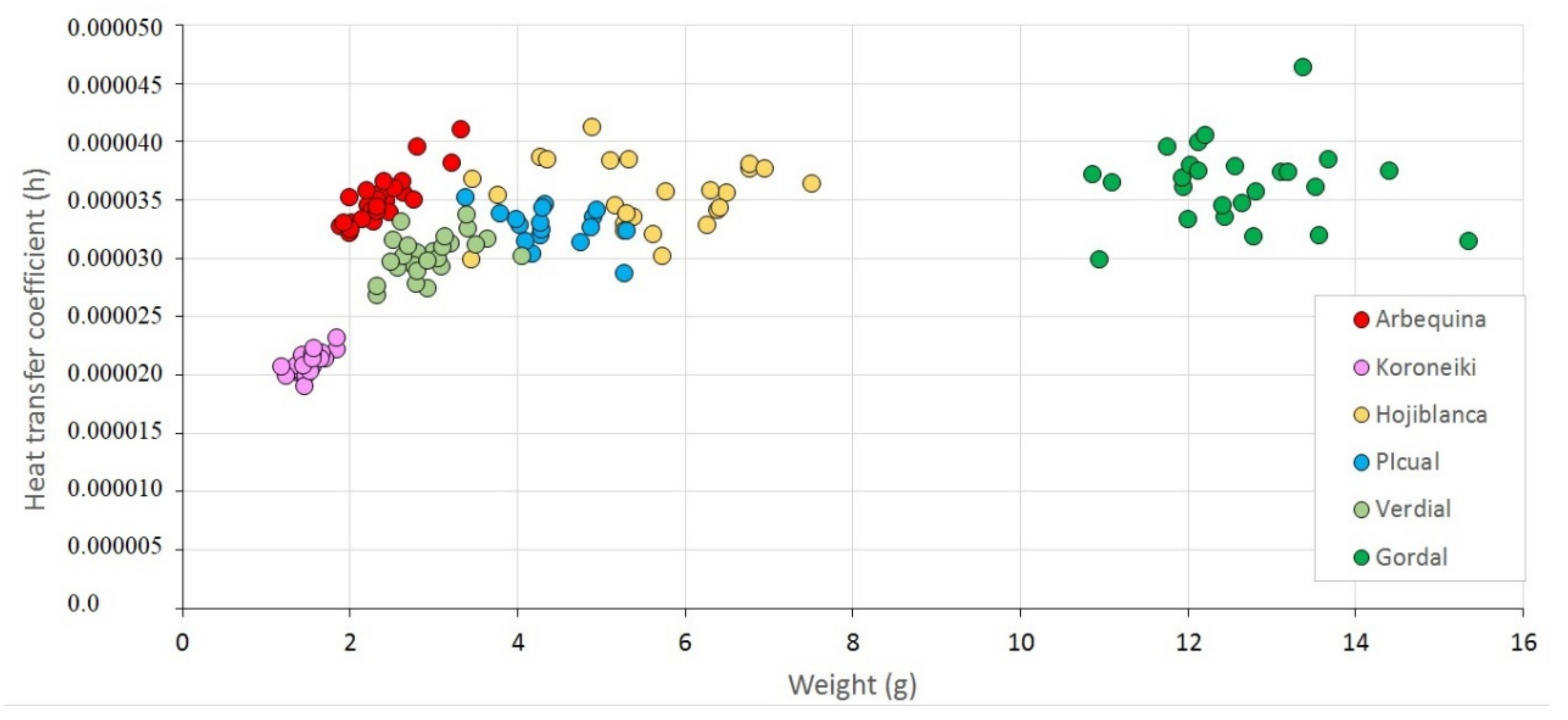

3.3. Influence of Cooling Rate with the Biometrical Data

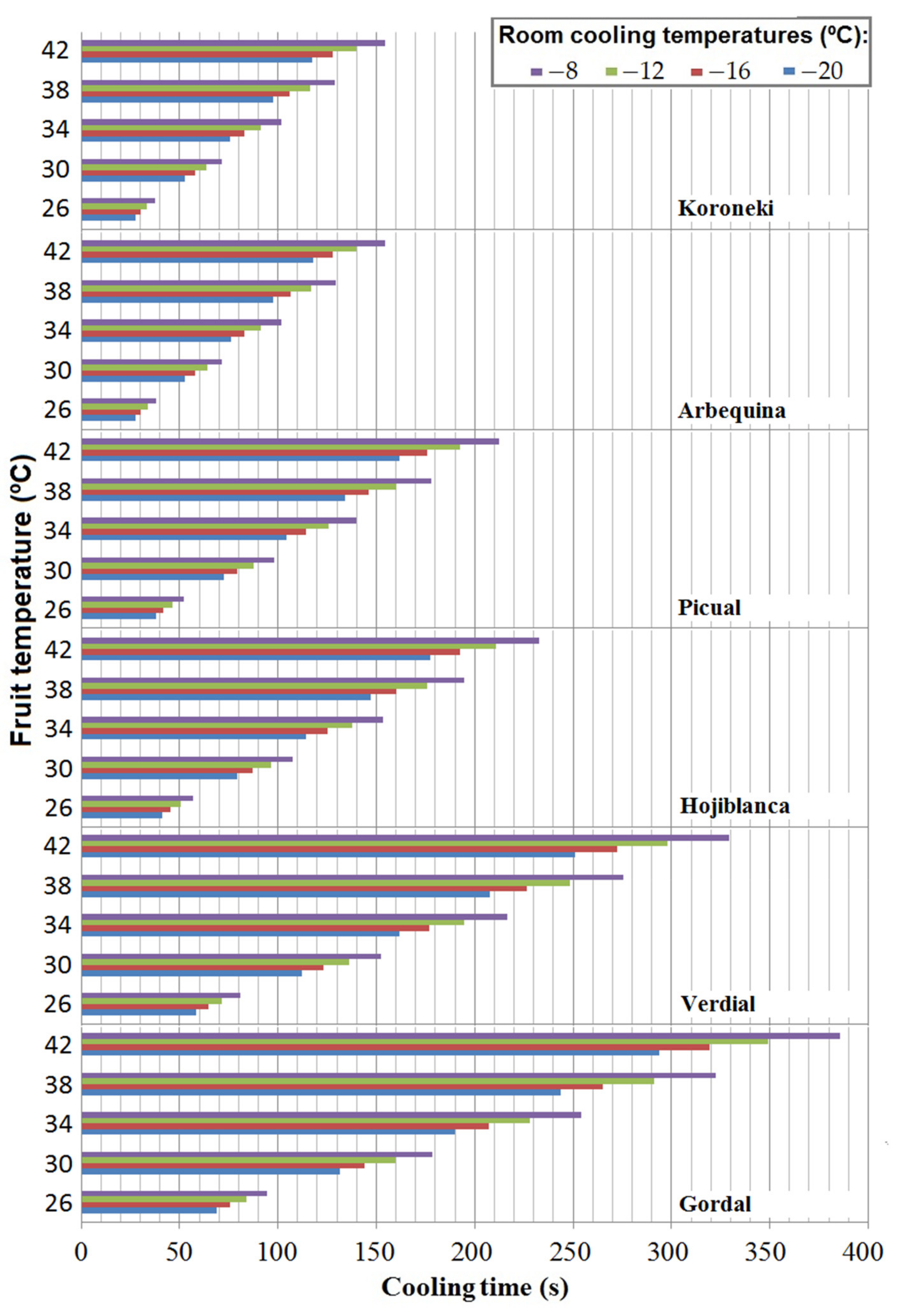

3.4. Simulation of Cooling Time

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fraga, H.; Pinto, J.G.; Santos, J.A. Climate change projections for chilling and heat forcing conditions in European vineyards and olive orchards: A multi-model assessment. Clim. Chang. 2019, 152, 179–193. [Google Scholar] [CrossRef]

- Mihailescu, E.; Soares, M.B. The Influence of Climate on Agricultural Decisions for Three European Crops: A Systematic Review. Front. Sustain. Food Syst. 2020, 4, 64. [Google Scholar] [CrossRef]

- Lorite, I.; Gabaldón-Leal, C.; Ruiz-Ramos, M.; Belaj, A.; De La Rosa, R.; León, L.; Santos, C. Evaluation of olive response and adaptation strategies to climate change under semi-arid conditions. Agric. Water Manag. 2018, 204, 247–261. [Google Scholar] [CrossRef]

- Cabezas, J.; Ruiz-Ramos, M.; Soriano, M.; Gabaldón-Leal, C.; Santos, C.; Lorite, I. Identifying adaptation strategies to climate change for Mediterranean olive orchards using impact response surfaces. Agric. Syst. 2020, 185, 102937. [Google Scholar] [CrossRef]

- Galán, C.; García-Mozo, H.; Vázquez, L.; Ruiz, L.; De La Guardia, C.D.; Trigo, M.M. Heat requirement for the onset of the Olea europaea L. pollen season in several sites in Andalusia and the effect of the expected future climate change. Int. J. Biometeorol. 2005, 49, 184–188. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Mozo, H.; Oteros, J.; Galan, C. Phenological changes in olive (Ola europaea L.) reproductive cycle in southern Spain due to climate change. Ann. Agric. Environ. Med. 2015, 22, 421–428. [Google Scholar] [CrossRef]

- Gabaldón-Leal, C.; Ruiz-Ramos, M.; De La Rosa, R.; León, L.; Belaj, A.; Rodríguez, A.; Santos, C.; Lorite, I.J. Impact of changes in mean and extreme temperatures caused by climate change on olive flowering in southern Spain. Int. J. Climatol. 2017, 37, 940–957. [Google Scholar] [CrossRef]

- Sola-Guirado, R.R.; Ceular-Ortiz, D.; Gil-Ribes, J.A. Automated system for real time tree canopy contact with canopy shakers. Comput. Electron. Agric. 2017, 143, 139–148. [Google Scholar] [CrossRef]

- Sola-Guirado, R.R.; Aragon-Rodriguez, F.; Castro-Garcia, S.; Gil-Ribes, J. The vibration behaviour of hedgerow olive trees in response to mechanical harvesting with straddle harvester. Biosyst. Eng. 2019, 184, 81–89. [Google Scholar] [CrossRef]

- Connor, D.J.; Gómez-Del-Campo, M.; Rousseaux, M.C.; Searles, P.S. Structure, management and productivity of hedgerow olive orchards: A review. Sci. Hortic. 2014, 169, 71–93. [Google Scholar] [CrossRef]

- Rallo, L.; Barranco, D.; De La Rosa, R.; Leon, L. New olive cultivars and selections in Spain: Results after 25 years of breeding. Acta Hortic. 2018, 1199, 21–26. [Google Scholar] [CrossRef]

- Caponio, F.; Gomes, T.; Summo, C.; Pasqualone, A. Influence of the type of olive-crusher used on the quality of extra virgin olive oils. Eur. J. Lipid Sci. Technol. 2003, 105, 201–206. [Google Scholar] [CrossRef]

- Biedermann, M.; Bongartz, A.; Mariani, C.; Grob, K. Fatty acid methyl and ethyl esters as well as wax esters for evaluating the quality of olive oils. Eur. Food Res. Technol. 2008, 228, 65–74. [Google Scholar] [CrossRef]

- Jabeur, H.; Zribi, A.; Abdelhedi, R.; Bouaziz, M. Effect of olive storage conditions on Chemlali olive oil quality and the effective role of fatty acids alkyl esters in checking olive oils authenticity. Food Chem. 2015, 169, 289–296. [Google Scholar] [CrossRef] [PubMed]

- Di Serio, M.G.; Giansante, L.; Di Loreto, G.; Faberi, A.; Ricchetti, L.; Di Giacinto, L. Ethyl esters versus fermentative organoleptic defects in virgin olive oil. Food Chem. 2017, 219, 33–39. [Google Scholar] [CrossRef]

- Jiménez, M.R.; Casanova, L.; Suárez, M.P.; Rallo, P.; Morales-Sillero, A. Internal fruit damage in table olive cultivars under superhigh-density hedgerows. Postharvest Biol. Technol. 2017, 132, 130–137. [Google Scholar] [CrossRef]

- Dourou, A.-M.; Brizzolara, S.; Meoni, G.; Tenori, L.; Famiani, F.; Luchinat, C.; Tonutti, P. The inner temperature of the olives (cv. Leccino) before processing affects the volatile profile and the composition of the oil. Food Res. Int. 2020, 129, 108861. [Google Scholar] [CrossRef] [PubMed]

- Veneziani, G.; Esposto, S.; Taticchi, A.; Urbani, S.; Selvaggini, R.; Di Maio, I.; Sordini, B.; Servili, M. Cooling treatment of olive paste during the oil processing: Impact on the yield and extra virgin olive oil quality. Food Chem. 2017, 221, 107–113. [Google Scholar] [CrossRef]

- García, J.M.; Gutiérrez, F.; Barrera, M.J.; Albi, M.A. Storage of Mill Olives on an Industrial Scale. J. Agric. Food Chem. 1996, 44, 590–593. [Google Scholar] [CrossRef]

- Kiritsakis, A.; Nanos, G.D.; Polymenopulos, Z.; Thomai, T.; Sfakiotakis, E.M. Effect of fruit storage conditions on olive oil quality. J. Am. Oil Chem. Soc. 1998, 75, 721–724. [Google Scholar] [CrossRef]

- Clodoveo, M.; Delcuratolo, D.; Gomes, T.; Colelli, G. Effect of different temperatures and storage atmospheres on Coratina olive oil quality. Food Chem. 2006, 102, 571–576. [Google Scholar] [CrossRef]

- Kalua, C.M.; Bedgood, D.R.; Bishop, A.G.; Prenzler, P.D. Changes in Virgin Olive Oil Quality during Low-Temperature Fruit Storage. J. Agric. Food Chem. 2008, 56, 2415–2422. [Google Scholar] [CrossRef] [PubMed]

- Gowen, A.; Tiwari, B.; Cullen, P.; McDonnell, K.; O’Donnell, C. Applications of thermal imaging in food quality and safety assessment. Trends Food Sci. Technol. 2010, 21, 190–200. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, C.; Zhao, J.; Ouyang, Q. Recent advances in emerging imaging techniques for non-destructive detection of food quality and safety. TrAC Trends Anal. Chem. 2013, 52, 261–274. [Google Scholar] [CrossRef]

- Guzmán, E.; Baeten, V.; Pierna, J.A.F.; García-Mesa, J.A. Determination of the olive maturity index of intact fruits using image analysis. J. Food Sci. Technol. 2015, 52, 1462–1470. [Google Scholar] [CrossRef] [PubMed]

- ASHRAE. Chapter 9: Methods of Precooling Fruits and Vegetables. In American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) Handbook; ASHRAE Research: Peachtree Corners, GA, USA, 2006. [Google Scholar]

- Barranco, D.; Fernandez-Escobar, R.; Rallo, L. El Cultivo del Olivo, 6th ed.; Ediciones Mundi-Prensa: Madrid, Spain, 2008. [Google Scholar]

- Cuesta, F.; Alvarez, M. Mathematical modeling for heat conduction in stone fruits. Int. J. Refrig. 2017, 80, 120–129. [Google Scholar] [CrossRef]

- Al-Widyan, M.I.; Rababah, T.M.; Mayyas, A.; Al-Shbool, M.; Yang, W. Geometrical, thermal and mechanical properties of olive fruits. J. Food Process. Eng. 2010, 33, 257–271. [Google Scholar] [CrossRef]

- Wang, S.; Tang, J.; Cavalieri, R. Modeling fruit internal heating rates for hot air and hot water treatments. Postharvest Biol. Technol. 2001, 22, 257–270. [Google Scholar] [CrossRef]

- Vichi, S.; Boynuegri, P.; Caixach, J.; Romero, A. Quality losses in virgin olive oil due to washing and short-term storage before olive milling. Eur. J. Lipid Sci. Technol. 2015, 117, 2015–2022. [Google Scholar] [CrossRef]

- Edeogu, I.; Feddes, J.; Leonard, J. Comparison between vertical and horizontal air flow for fruit and vegetable precooling. Can. Agric. Eng. 1997, 39, 107–112. Available online: https://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/agdex3973/$FILE/736-14.pdf (accessed on 15 December 2020).

- Arenas-Castro, S.; Gonçalves, J.F.; Moreno, M.; Villar, R. Projected climate changes are expected to decrease the suitability and production of olive varieties in southern Spain. Sci. Total Environ. 2020, 709, 136161. [Google Scholar] [CrossRef] [PubMed]

- Benlloch-González, M.; Sánchez-Lucas, R.; Bejaoui, M.A.; Benlloch, M.; Fernández-Escobar, R. Global warming effects on yield and fruit maturation of olive trees growing under field conditions. Sci. Hortic. 2019, 249, 162–167. [Google Scholar] [CrossRef]

- Boletín Oficial de la Junta de Andalucía. Resolución de 15 de Junio de 2020, de la Dirección General de Medio Natural, Biodiversidad y Espacios Protegidos, por la que se Suspende en La Temporada 2020–2021 La Recogida Nocturna de Aceituna en Olivares Superintensivos. BOJA 2020, 123, 598–602. [Google Scholar]

- Becker, B.R.; Misra, A.; Fricke, B.A. Bulk refrigeration of fruits and vegetables. Part II: Computer algorithm for heat loads and moisture loss. Int. J. HVAC&R Res. 1996, 2, 215–230. [Google Scholar]

| Cultivar | Weight (g) | Height (mm) | Width (mm) | Surface (mm²) | Specific Surf. Area (mm²/g) | Moisture Content (%) | Oil Content (%) * | Specific Heat (J/kg °C) |

|---|---|---|---|---|---|---|---|---|

| Arbequina | 2.38 ± 0.37 e* | 16.0 ± 0.8 e | 15.6 ± 0.8 b | 80.4 ± 4.2 e | 332.6 ± 17.5 b | 64.6 | 16.7 (47.2) | 3.343 |

| Koroneiki | 1.50 ± 0.16 f | 17.0 ± 0.8 e | 12.8 ± 0.6 | 85.1 ± 3.9 e | 421.2 ± 14.7 a | 65.1 | 15.7 (45.0) | 3.356 |

| Hojiblanca | 5.52 ± 1.09 b | 24.6 ± 2.3 bc | 20.1 ± 1.1 b | 123.0 ± 11.4 bc | 269.2 ± 20.9 d | 58.8 | 17.5 (42.5) | 3.194 |

| Picual | 4.40 ± 0.48 c | 23.5 ± 1.2 c | 18.3 ± 0.7 c | 117.3 ± 6.2 c | 287.6 ± 13.3 c | 58.3 | 21.8 (52.2) | 3.181 |

| Verdial | 2.95 ± 0.42 d | 21.3 ± 1.2 d | 16.2 ± 0.8 b | 106.7 ± 6.2 d | 344.2 ± 18.8 b | 47.1 | 25.8 (48.9) | 2.875 |

| Gordal | 12.60 ± 1.04 a | 33.1 ± 1.7 a | 24.7 ± 1.3 a | 165.6 ± 8.5 a | 184.0 ± 9.1 e | 63.1 | 16.5 (47.1) | 3.306 |

| Cultivar | Cooling Rate (°C/min) | Half Cooling Time (s) |

|---|---|---|

| Arbequina | 0.19 ± 0.01 a | 198 ± 12 c |

| Koroneiki | 0.20 ± 0.01 a | 200 ± 19 c |

| Hojiblanca | 0.13 ± 0.02 b | 327 ± 43 b |

| Picual | 0.15 ± 0.01 b | 247 ± 18 b |

| Verdial | 0.18 ± 0.01 c | 481 ± 32 a |

| Gordal | 0.08 ± 0.01 c | 571 ± 56 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plasquy, E.; Garcia, J.M.; Florido, M.C.; Sola-Guirado, R.R. Estimation of the Cooling Rate of Six Olive Cultivars Using Thermal Imaging. Agriculture 2021, 11, 164. https://doi.org/10.3390/agriculture11020164

Plasquy E, Garcia JM, Florido MC, Sola-Guirado RR. Estimation of the Cooling Rate of Six Olive Cultivars Using Thermal Imaging. Agriculture. 2021; 11(2):164. https://doi.org/10.3390/agriculture11020164

Chicago/Turabian StylePlasquy, Eddy, José M. Garcia, Maria C. Florido, and Rafael R. Sola-Guirado. 2021. "Estimation of the Cooling Rate of Six Olive Cultivars Using Thermal Imaging" Agriculture 11, no. 2: 164. https://doi.org/10.3390/agriculture11020164

APA StylePlasquy, E., Garcia, J. M., Florido, M. C., & Sola-Guirado, R. R. (2021). Estimation of the Cooling Rate of Six Olive Cultivars Using Thermal Imaging. Agriculture, 11(2), 164. https://doi.org/10.3390/agriculture11020164