Mango Fruit Processing: Options for Small-Scale Processors in Developing Countries

Abstract

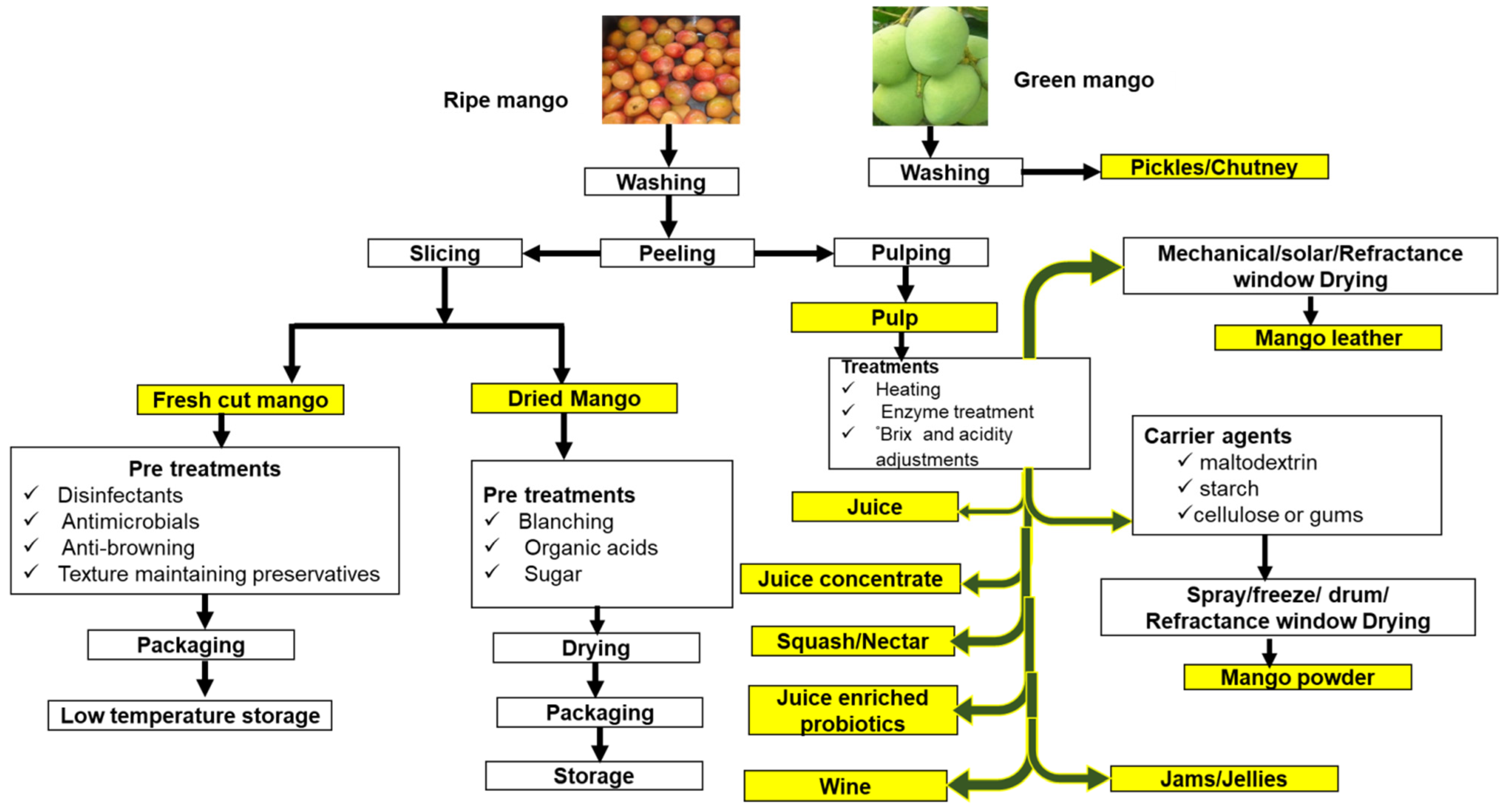

:1. Introduction

2. Fresh-Cut Mango (FCM)

3. Pulp

3.1. Mango Juice

3.2. Mango Juice Concentrate

3.3. Mango Squash

3.4. Cordials

3.5. Mango Nectar

3.6. Mango-Juice-Enriched Probiotic Dairy Drinks

3.7. Mango Wine

4. Dried Products

4.1. Mango Leather

4.2. Mango Powder

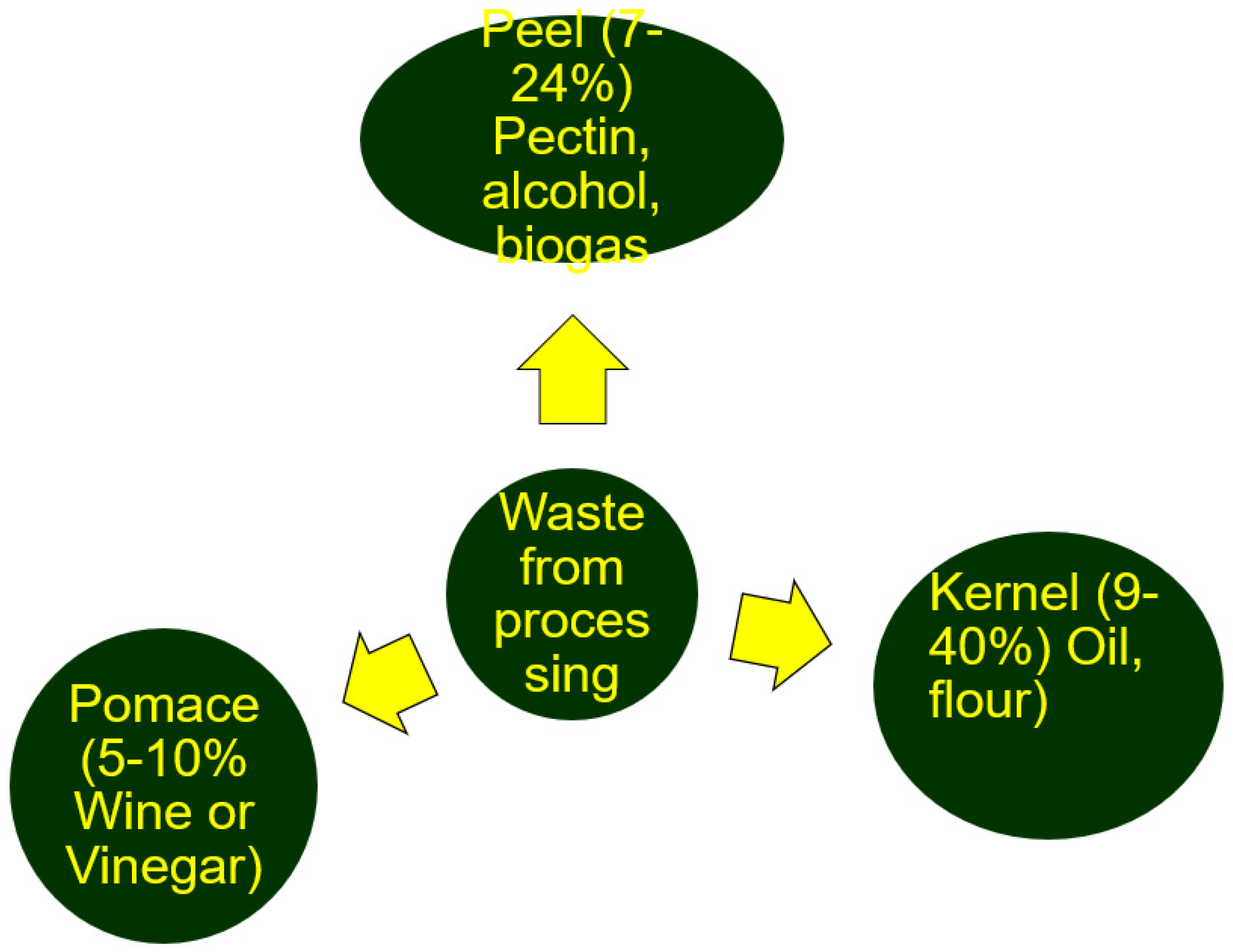

5. Utilization of Mango Processing Waste

6. Increased Value from Processed Mango Fruit

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Bank. World Development Indicators 2012; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Brooks, K.; Place, F. Global food systems: Can foresight learn from hindsight. Glob. Food Secur. 2019, 20, 66–71. [Google Scholar] [CrossRef]

- FAO. Food and Agriculture Organization of the United Nations Statistical Database (FAOSTAT); FAO: Rome, Italy, 2018. [Google Scholar]

- Maloba, S.; Ambuko, J.; Hutchinson, M.; Owino, W. Off-Season Flower Induction in Mango Fruits Using Ethephon and Potassium Nitrate. J. Agric. Sci. 2017, 9, 158–167. [Google Scholar] [CrossRef] [Green Version]

- Sheahan, M.; Barrett, C.B. Food loss and waste in Sub-Saharan Africa. Food Policy 2017, 70, 1–12. [Google Scholar] [CrossRef]

- DeeptiSalvi, E.A.; Karwe, M. Innovative processing technologies for mango products. In Handbook of Mango Fruit: Production, Postharvest Science, Processing Technology and Nutrition; John Wiley & Sons: Hoboken, NJ, USA, 2017; p. 169. [Google Scholar]

- Evans, E.A.; Ballen, F.H.; Siddiq, M. Mango production, global trade, consumption trends, and postharvest processing and nutrition. In Handbook of Mango Fruit; John Wiley & Sons: Chichester, UK, 2017; pp. 1–16. [Google Scholar]

- Siddiq, M.; Sogi, D.S.; Roidoung, S. Mango processing and processed products. In Handbook of Mango Fruit: Production, Postharvest Science, Processing Technology and Nutrition; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 195–216. [Google Scholar]

- Salinas-Roca, B.; Soliva-Fortuny, R.; Welti-Chanes, J.; Martín-Belloso, O. Combined effect of pulsed light, edible coating and malic acid dipping to improve fresh-cut mango safety and quality. Food Control 2017, 66, 190–197. [Google Scholar] [CrossRef]

- De Corato, U. Improving the shelf-life and quality of fresh and minimally-processed fruits and vegetables for a modern food industry: A comprehensive critical review from the traditional technologies into the most promising advancements. Crit. Rev. Food Sci. Nutr. 2020, 60, 940–975. [Google Scholar] [CrossRef]

- Yousuf, B.; Qadri, O.S.; Srivastava, A.K. Recent developments in shelf-life extension of fresh-cut fruits and vegetables by application of different edible coatings: A review. LWT 2018, 89, 198–209. [Google Scholar] [CrossRef]

- Leneveu-Jenvrin, C.; Apicella, A.; Bradley, K.; Meile, J.C.; Chillet, M.; Scarfato, P.; Incarnato, L.; Remize, F. Effects of maturity level, steam treatment or active packaging to maintain the quality of minimally-processed mango (Mangifera indica cv. José). J. Food Process. Preserv. 2021, 45, e15600. [Google Scholar] [CrossRef]

- Shende, D.; Kour, M.; Datta, A.K. Evaluation of sensory and physico-chemical properties of Langra variety mango leather. J. Food Meas. Charact. 2020, 14, 3227–3237. [Google Scholar] [CrossRef]

- Yildiz, G.; Aadil, R.M. Comparative analysis of antibrowning agents, hot water and high-intensity ultrasound treatments to maintain the quality of fresh-cut mangoes. J. Food Sci. Technol. 2021, 1–10. [Google Scholar] [CrossRef]

- Suriati, L.; Utama, I.S.; Harsojuwono, B.A.; Gunam, I.B.W.; Adnyana, I. Differences in Physicochemical Characters of Fresh-Cut Mango, Mangosteen and Rambutan Due to Calcium Chloride Application. J. Food Sci. Nutr. 2021, 7, 2. [Google Scholar]

- Aldana, D.S.; Aguilar, C.N.; Contreras-Esquivel, J.C.; Souza, M.P.; das Graças Carneiro-da-Cunha, M.; Nevárez-Moorillón, G.V. Use of a Mexican lime (Citrus aurantifolia Swingle) edible coating to preserve minimally processed mango (Mangifera indica L.). Hortic. Environ. Biotechnol. 2021, 62, 765–775. [Google Scholar] [CrossRef]

- Salinas-Roca, B.; Guerreiro, A.; Welti-Chanes, J.; Antunes, M.D.; Martín-Belloso, O. Improving quality of fresh-cut mango using polysaccharide-based edible coatings. Int. J. Food Sci. Technol. 2018, 53, 938–945. [Google Scholar] [CrossRef]

- Sharma, L.; Saini, C.S.; Sharma, H.K.; Sandhu, K.S. Biocomposite edible coatings based on cross linked-sesame protein and mango puree for the shelf-life stability of fresh-cut mango fruit. J. Food Process Eng. 2019, 42, e12938. [Google Scholar] [CrossRef] [Green Version]

- Zafar, T.A.; Sidhu, J.S. Composition and nutritional properties of mangoes. In Handbook of Mango Fruit: Production Postharvest Science, Processing Technology and Nutrition; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Akin-Idowu, P.E.; Adebo, U.G.; Egbekunle, K.O.; Olagunju, Y.O.; Aderonmu, O.I.; Aduloju, A.O. Diversity of mango (Mangifera indica L.) cultivars based on physicochemical, nutritional, antioxidant, and phytochemical traits in south west Nigeria. Int. J. Fruit Sci. 2020, 20 (Suppl. 2), S352–S376. [Google Scholar] [CrossRef]

- Ambuko, J.; Kemunto, N.; Hutchinson, M.; Owino, W. Comparison of the Postharvest Characteristics of Mango Fruits Produced under Contrasting Agro-Ecological Conditions and Harvested at Different Maturity Stages. J. Agric. Sci. 2017, 9, 181. [Google Scholar] [CrossRef] [Green Version]

- Lebaka, V.R.; Wee, Y.J.; Ye, W.; Korivi, M. Nutritional composition and bioactive compounds in three different parts of mango fruit. Int. J. Environ. Res. Public Health 2021, 18, 741. [Google Scholar] [CrossRef] [PubMed]

- Maldonado-Celis, M.E.; Yahia, E.M.; Bedoya, R.; Landázuri, P.; Loango, N.; Aguillón, J.; Restrepo, B.; Ospina, J.C.G. Chemical composition of mango (Mangifera indica L.) fruit: Nutritional and phytochemical compounds. Front. Plant Sci. 2019, 10, 1073. [Google Scholar] [CrossRef]

- Mirza, B.; Croley, C.R.; Ahmad, M.; Pumarol, J.; Das, N.; Sethi, G.; Bishayee, A. Mango (Mangifera indica L.): A magnificent plant with cancer preventive and anticancer therapeutic potential. Crit. Rev. Food Sci. Nutr. 2020, 61, 2125–2151. [Google Scholar] [CrossRef] [PubMed]

- Olale, K.; Walyambillah, W.; Mohammed, S.A.; Sila, A.; Shepherd, K. FTIR-DRIFTS-based prediction of β-carotene, α-tocopherol and l-ascorbic acid in mango (Mangifera indica L.) fruit pulp. SN Appl. Sci. 2019, 1, 279. [Google Scholar] [CrossRef]

- Meena, N.K.; Choudhary, K.; Negi, N.; Meena, V.S.; Gupta, V. Nutritional Composition of Stone Fruits. In Production Technology of Stone Fruits; Springer: Singapore, 2021; pp. 227–251. [Google Scholar]

- Agatonovic-Kustrin, S.; Kustrin, E.; Morton, D.W. Phenolic acids contribution to antioxidant activities and comparative assessment of phenolic content in mango pulp and peel. S. Afr. J. Bot. 2018, 116, 158–163. [Google Scholar] [CrossRef]

- Quirós-Sauceda, A.E.; Sañudo-Barajas, J.A.; Vélez-de la Rocha, R.; Domínguez-Avila, J.A.; Ayala-Zavala, J.F.; Villegas-Ochoa, M.A.; González-Aguilar, G.A. Effects of ripening on the in vitro antioxidant capacity and bioaccessibility of mango cv. ‘Ataulfo’ phenolics. J. Food Sci. Technol. 2019, 56, 2073–2082. [Google Scholar] [CrossRef] [PubMed]

- Adedeji, O.E.; Ezekiel, O.O. Chemical composition and physicochemical properties of mango juice extracted using polygalacturonase produced by Aspergillus awamori CICC 2040 on pre-treated orange peel. LWT 2020, 132, 109891. [Google Scholar] [CrossRef]

- Sakhale, B.K.; Pawar, V.N.; Gaikwad, S.S. Studies on effect of enzymatic liquefaction on quality characteristics of Kesar mango pulp. Int. Food Res. J. 2016, 23, 860–865. [Google Scholar]

- Muslim, S.; Saleem, A.; Mehmood, Z.; Iqbal, A.; Shah, F.; Khan, Z.U.; Shah, S.; Hamayun, M.; Hussain, A.; Yue, Z.; et al. An environmentally safe and healthy mango squash from natural ingredients. Fresenius Environ. Bull. 2021, 30, 2410–2415. [Google Scholar]

- Huang, B.; Zhao, K.; Zhang, Z.; Liu, F.; Hu, H.; Pan, S. Changes on the rheological properties of pectin-enriched mango nectar by high intensity ultrasound. LWT 2018, 91, 414–422. [Google Scholar] [CrossRef]

- Kumar, R.; Vijayalakshmi, S.; Rajeshwara, R.; Sunny, K.; Nadanasabapathi, S. Effect of storage on thermal, pulsed electric field and combination processed mango nectar. J. Food Meas. Charact. 2019, 13, 131–143. [Google Scholar] [CrossRef]

- Xess, R.; Singh, P.; Patel, D.; Singh, Y. Evaluation of mango (Mangifera indica L.) varieties for processing of nectar beverage on organoleptic parameters. J. Pharmacogn. Phytochem. 2018, 7, 772–774. [Google Scholar]

- Acevedo-Martínez, E.; Gutiérrez-Cortés, C.; García-Mahecha, M.; Díaz-Moreno, C. Evaluation of viability of probiotic bacteria in mango (Mangifera indica L. Cv. “Tommy Atkins”) beverage. Dyna 2018, 85, 84–92. [Google Scholar] [CrossRef]

- de Oliveira, P.M.; BRC, L.J.; Martins, E.M.F.; Martins, M.L.; Vieira, É.N.R.; de Barros, F.A.R.; Cristianini, M.; de Almeida Costa, N.; Ramos, A.M. Mango and carrot mixed juice: A new matrix for the vehicle of probiotic lactobacilli. J. Food Sci. Technol. 2020, 58, 98–109. [Google Scholar] [CrossRef] [PubMed]

- Dhillon, H.S.; Gill, M.S.; Kocher, G.S.; Panwar, H.; Arora, M. Preparation of Lactobacillus acidophilus enriched probiotic mango juice. J. Environ. Biol. 2021, 42, 371–378. [Google Scholar]

- Mayulu 2021, N.; Assa, Y.A.; Kepel, B.J.; Nurkolis, F.; Rompies, R.; Kawengian, S.; Natanael, H. Probiotic drink from fermented mango (Mangifera indica) with addition of spinach flour (Amaranthus) high in polyphenols and food fibre. Proc. Nutr. Soc. 2021, 80. [Google Scholar] [CrossRef]

- Ryan, J.; Hutchings, S.C.; Fang, Z.; Bandara, N.; Gamlath, S.; Ajlouni, S.; Ranadheera, C.S. Microbial, physico-chemical and sensory characteristics of mango juice-enriched probiotic dairy drinks. Int. J. Dairy Technol. 2020, 73, 182–190. [Google Scholar] [CrossRef]

- Wang, J.; Xie, B.; Sun, Z. Quality parameters and bioactive compound bioaccessibility changes in probiotics fermented mango juice using ultraviolet-assisted ultrasonic pre-treatment during cold storage. LWT 2021, 137, 110438. [Google Scholar] [CrossRef]

- Musyimi, S.M. Production, Optimization and Characterization of Mango Fruit Wine: Towards Value Addition of Mango Produce. Master’s Thesis, Jomo Kenyatta University of Agriculture and Technology, Nairobi, Kenya, 21 June 2017. [Google Scholar]

- Ogodo, A.C.; Ugbogu, O.C.; Agwaranze, D.I.; Ezeonu, N.G. Production and evaluation of fruit wine from Mangifera indica (cv. Peter). Appl. Microbiol. 2018, 4, 144. [Google Scholar]

- Lu, Y.; Chan, L.J.; Li, X.; Liu, S.Q. Effects of sugar concentration on mango wine composition fermented by Saccharomyces cerevisiae MERIT. ferm. Int. J. Food Sci. Technol. 2018, 53, 199–208. [Google Scholar] [CrossRef]

- Patel, V.; Tripathi, A.D.; Adhikari, K.S.; Srivastava, A. Screening of physicochemical and functional attributes of fermented beverage (wine) produced from local mango (Mangifera indica) varieties of Uttar Pradesh using novel saccharomyces strain. J. Food Sci. Technol. 2021, 58, 2206–2215. [Google Scholar] [CrossRef] [PubMed]

- Wattanakul, N.; Morakul, S.; Lorjaroenphon, Y.; Jom, K.N. Integrative metabolomics-flavoromics to monitor dynamic changes of ‘Nam Dok Mai’ mango (Mangifera indica Linn) wine during fermentation and storage. Food Biosci. 2020, 35, 100549. [Google Scholar] [CrossRef]

- Dereje, B.; Abera, S. Effect of pre-treatments and drying methods on the quality of dried mango (Mangifera Indica, L.) slices. Cogent Food Agric. 2020, 6, 1747961. [Google Scholar] [CrossRef]

- Isaac, N.; Owino, W.; Ambuko, J.; Imathiu, S. Moisture sorption properties of two varieties of dehydrated mango slices as determined by gravimetric method using Guggenheim–Anderson–de Boer model. J. Food Process. Preserv. 2021, 45, e15041. [Google Scholar] [CrossRef]

- Sulistyawati, I.; Verkerk, R.; Fogliano, V.; Dekker, M. Modelling the kinetics of osmotic dehydration of mango: Optimizing process conditions and pre-treatment for health aspects. J. Food Eng. 2020, 280, 109985. [Google Scholar] [CrossRef]

- Nyangena, I.; Owino, W.; Ambuko, J.; Imathiu, S. Effect of selected pre-treatments prior to drying on physical quality attributes of dried mango chips. J. Food Sci. Technol. 2019, 56, 3854–3863. [Google Scholar] [CrossRef] [PubMed]

- Nyangena, I.O.; Owino, W.O.; Imathiu, S.; Ambuko, J. Effect of pre-treatments prior to drying on antioxidant properties of dried mango slices. Sci. Afr. 2019, 6, e00148. [Google Scholar]

- Sarkar, T.; Chakraborty, R. Formulation, physicochemical analysis, sustainable packaging-storage provision, environment friendly drying techniques and energy consumption characteristics of mango leather production: A review. Asian J. Water Environ. Pollut. 2018, 15, 79–92. [Google Scholar] [CrossRef]

- Sarkar, T.; Salauddin, M.; Hazra, S.K.; Chakraborty, R. Effect of cutting-edge drying technology on the physicochemical and bioactive components of mango (Langra variety) leather. J. Agric. Food Res. 2020, 2, 100074. [Google Scholar] [CrossRef]

- da Silva Simão, R.; de Moraes, J.O.; de Souza, P.G.; Carciofi, B.A.M.; Laurindo, J.B. Production of mango leathers by cast-tape drying: Product characteristics and sensory evaluation. LWT 2019, 99, 445–452. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; da Silva, V.M.; Durigon, A.; Hubinger, M.D.; Laurindo, J.B. Production of mango powder by spray drying and cast-tape drying. Powder Technol. 2017, 305, 447–454. [Google Scholar] [CrossRef]

- Raghavi, L.M.; Moses, J.A.; Anandharamakrishnan, C. Refractance window drying of foods: A review. J. Food Eng. 2018, 222, 267–275. [Google Scholar] [CrossRef]

- Caparino, O.A.; Nindo, C.I.; Tang, J.; Sablani, S.S.; Chew, B.P.; Mathison, B.D.; Fellman, J.K.; Powers, J.R. Physical and chemical stability of Refractance Window®—dried mango (Philippine ‘Carabao’ var.) powder during storage. Dry. Technol. 2017, 35, 25–37. [Google Scholar] [CrossRef]

- Fongin, S.; Granados, A.E.A.; Harnkarnsujarit, N.; Hagura, Y.; Kawai, K. Effects of maltodextrin and pulp on the water sorption, glass transition, and caking properties of freeze-dried mango powder. J. Food Eng. 2019, 247, 95–103. [Google Scholar] [CrossRef]

- Tonin, I.P.; Ferrari, C.C.; da Silva, M.G.; de Oliveira, K.L.; Berto, M.I.; da Silva, V.M.; Germer, S.P.M. Performance of different process additives on the properties of mango powder obtained by drum drying. Drying Technol. 2018, 36, 355–365. [Google Scholar] [CrossRef]

- Bekele, M.; Satheesh, N.; Sadik, J.A. Screening of Ethiopian mango cultivars for suitability for preparing jam and determination of pectin, sugar, and acid effects on physico-chemical and sensory properties of mango jam. Sci. Afr. 2020, 7, e00277. [Google Scholar] [CrossRef]

- Bhardwaj, K.; Dubey, W. Exploring potential of hydro-alcoholic extract of stem of marjoram as natural preservative against food spoilage bacteria Bacillus cereus and Bacillus megaterium in homemade mango jam. Vegetos 2021, 1–11. [Google Scholar] [CrossRef]

- Aggarwal, P.; Kaur, A.; Bhise, S. Value-added processing and utilization of mango by-products. In Handbook of Mango Fruit: Production, Postharvest Science, Processing Technology and Nutrition; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 279–293. [Google Scholar]

- Cheok, C.Y.; Mohd Adzahan, N.; Abdul Rahman, R.; Zainal Abedin, N.H.; Hussain, N.; Sulaiman, R.; Chong, G.H. Current trends of tropical fruit waste utilization. Crit. Rev. Food Sci. Nutr. 2018, 58, 335–361. [Google Scholar] [CrossRef] [PubMed]

- Jahurul, M.H.A.; Zaidul, I.S.M.; Ghafoor, K.; Al-Juhaimi, F.Y.; Nyam, K.L.; Norulaini, N.A.N.; Sahena, F.; Omar, A.M. Mango (Mangifera indica L.) by-products and their valuable components: A review. Food Chem. 2015, 183, 173–180. [Google Scholar] [CrossRef]

- Mwaurah, P.W.; Kumar, S.; Kumar, N.; Panghal, A.; Attkan, A.K.; Singh, V.K.; Garg, M.K. Physicochemical characteristics, bioactive compounds and industrial applications of mango kernel and its products: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2421–2446. [Google Scholar] [CrossRef]

- Marçal, S.; Pintado, M. Mango peels as food ingredient/additive: Nutritional value, processing, safety and applications. Trends Food Sci. Technol. 2021, 114, 472–489. [Google Scholar] [CrossRef]

- Wall-Medrano, A.; Olivas-Aguirre, F.J.; Ayala-Zavala, J.F.; Domínguez-Avila, J.A.; Gonzalez-Aguilar, G.A.; Herrera-Cazares, L.A.; Gaytan-Martinez, M. Health Benefits of Mango By-products. In Food Wastes and By-products: Nutraceutical and Health Potential; Wiley: Hoboken, NJ, USA, 2020; pp. 159–191. [Google Scholar]

- Mutua, J.K.; Imathiu, S.; Owino, W.O. Evaluation of the Proximate Composition, Antioxidant Potential and Antimicrobial Activity of Mango Seed Kernel Extracts. Food Sci. Nutr. 2017, 5, 349–357. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.K.; Bansal, S.; Mangal, M.; Dixit, A.K.; Gupta, R.K.; Mangal, A.K. Utilization of food processing by-products as dietary, functional, and novel fiber: A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1647–1661. [Google Scholar] [CrossRef] [PubMed]

- Gómez, M.; Martinez, M.M. Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked goods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2119–2135. [Google Scholar] [CrossRef]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and vegetable waste: Bioactive compounds, their extraction, and possible utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef] [Green Version]

- Serna-Cock, L.; García-Gonzales, E.; Torres-León, C. Agro-industrial potential of the mango peel based on its nutritional and functional properties. Food Rev. Int. 2016, 32, 364–376. [Google Scholar] [CrossRef]

- Bonneau, A.; Boulanger, R.; Lebrun, M.; Maraval, I.; Valette, J.; Guichard, É.; Gunata, Z. Impact of fruit texture on the release and perception of aroma compounds during in vivo consumption using fresh and processed mango fruits. Food Chem. 2018, 239, 806–815. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Ma, X.W.; Zhan, R.L.; Wu, H.X.; Yao, Q.S.; Xu, W.T.; Luo, C.; Zhou, Y.G.; Liang, Q.Z.; Wang, S.B. Profiling of volatile fragrant components in a mini-core collection of mango germplasms from seven countries. PLoS ONE 2017, 12, e0187487. [Google Scholar] [CrossRef] [PubMed]

- Musharraf, S.G.; Uddin, J.; Siddiqui, A.J.; Akram, M.I. Quantification of aroma constituents of mango sap from different Pakistan mango cultivars using gas chromatography triple quadrupole mass spectrometry. Food Chem. 2016, 196, 1355–1360. [Google Scholar] [CrossRef] [PubMed]

- Oliver-Simancas, R.; Muñoz, R.; Díaz-Maroto, M.C.; Pérez-Coello, M.S.; Alañón, M.E. Mango by-products as a natural source of valuable odor-active compounds. J. Sci. Food Agric. 2020, 100, 4688–4695. [Google Scholar] [CrossRef] [PubMed]

- Oliver-Simancas, R.; Díaz-Maroto, M.C.; Pérez-Coello, M.S.; Alañón, M.E. Viability of pre-treatment drying methods on mango peel by-products to preserve flavouring active compounds for its revalorisation. J. Food Eng. 2020, 279, 109953. [Google Scholar] [CrossRef]

- Ambuko, J.; Abong, G.; Gekonge, G.; Maitha, I.; Amwoka, E. Small-scale processing of mango fruits: Putting more money in farmers’ pockets while enhancing access to nutritious fruit products. In Proceedings of the 4th All Africa Horticultural Congress, International Horticultural Society, Dakar, Senegal, 29–31 March 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Owino, W.O.; Ambuko, J.L. Mango Fruit Processing: Options for Small-Scale Processors in Developing Countries. Agriculture 2021, 11, 1105. https://doi.org/10.3390/agriculture11111105

Owino WO, Ambuko JL. Mango Fruit Processing: Options for Small-Scale Processors in Developing Countries. Agriculture. 2021; 11(11):1105. https://doi.org/10.3390/agriculture11111105

Chicago/Turabian StyleOwino, Willis O., and Jane L. Ambuko. 2021. "Mango Fruit Processing: Options for Small-Scale Processors in Developing Countries" Agriculture 11, no. 11: 1105. https://doi.org/10.3390/agriculture11111105

APA StyleOwino, W. O., & Ambuko, J. L. (2021). Mango Fruit Processing: Options for Small-Scale Processors in Developing Countries. Agriculture, 11(11), 1105. https://doi.org/10.3390/agriculture11111105