Farmers’ Perception of Good Agricultural Practices in Rice Production in Myanmar: A Case Study of Myaungmya District, Ayeyarwady Region

Abstract

1. Introduction

2. Materials and Methods

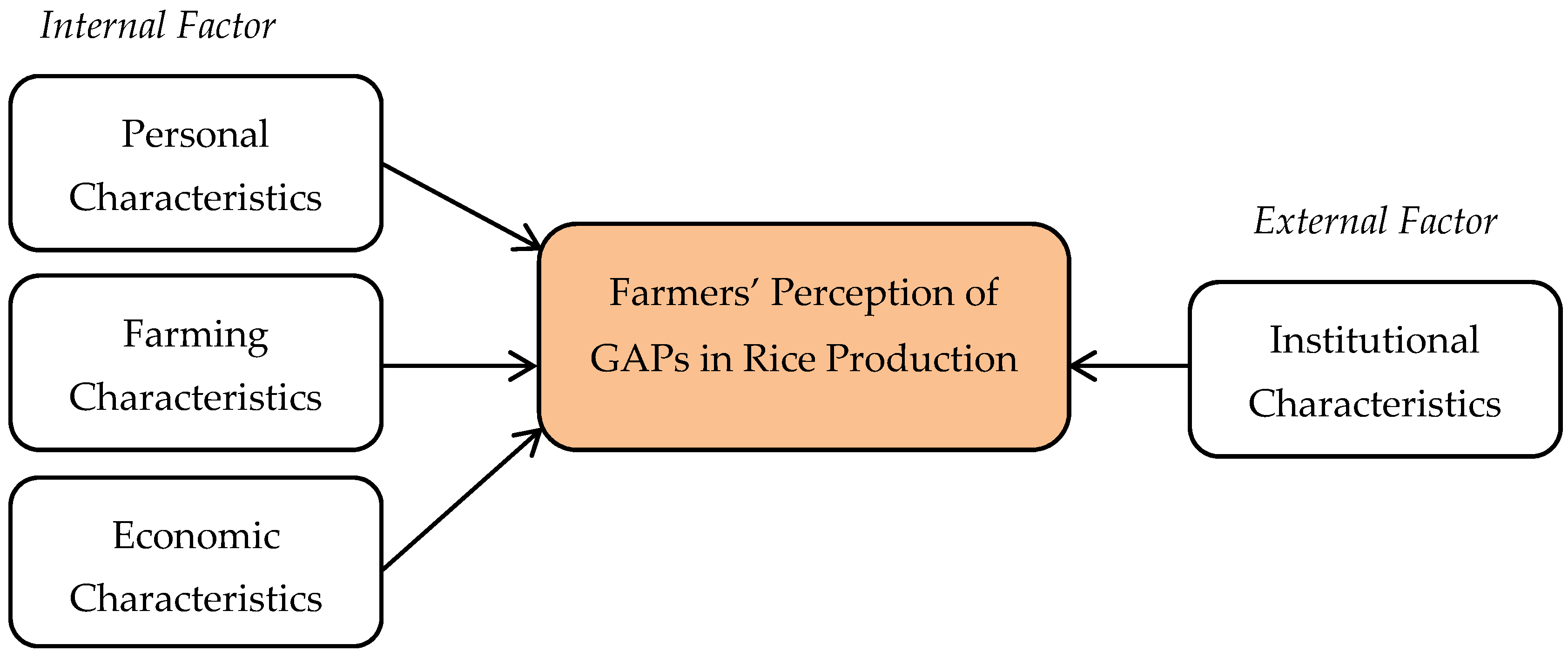

2.1. Framework and Variables

2.2. Study Area and Sampling

2.3. Data Measurement

2.4. Data Analysis

3. Results and Discussion

3.1. Farmers’ Characteristics

3.2. Farmers’ Perception of GAPs in Rice Production

3.2.1. Relative Advantage

3.2.2. Compatibility

3.2.3. Complexity

3.2.4. Trialability

3.2.5. Observability

3.2.6. Perception as a Whole

3.3. Classification of Farmers Based on Their Perception of GAPs in Rice Production

3.3.1. Common Factors of Perception of GAPs in Rice Production

CF1: Trialability of GAPs

CF2: Advantages of GAPs (Except Submerging and Harvester)

CF3: Visible Results of Using Nursery, Pest Management, Submerging, and Harvester

CF4: Compatible with Sowing, Transplanting, Inputs, and Drainage

CF5: Visible Results of Using Quality Seeds, Nursery, AWD, and Inputs

CF6: Complexity of Nursery, Population, and Harvester

CF7: Complexity of Sowing, Planning Depth, Pest Management, and Submerging

CF8: Complexity of Quality Seeds, Transplanting, AWD, and Inputs

CF9: Compatible with Quality Seeds, Seedling Number, and Pest Management

CF10: Compatible with Covering, Planting Depth, AWD, and Harvester

CF11: Complexity of Covering, Seedling Number, and Drainage

CF12: Visible results of Using Covering, Seedling Number, and Drainage

CF13: Advantages of Harvester and Benefit of Population

CF14: Visible results of Using Planting Depth

CF15: Advantages of Submerging

CF16: Compatible with Nursery

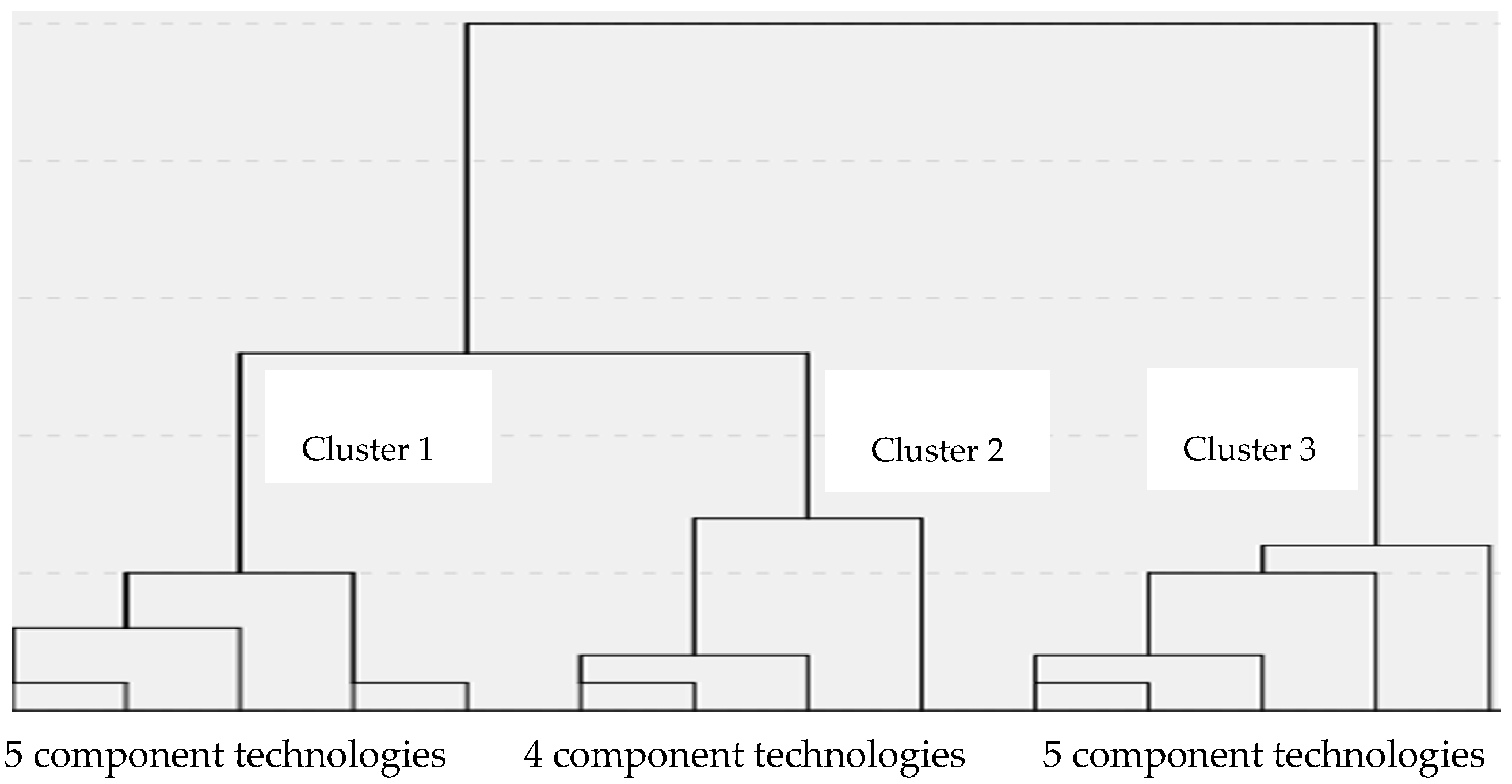

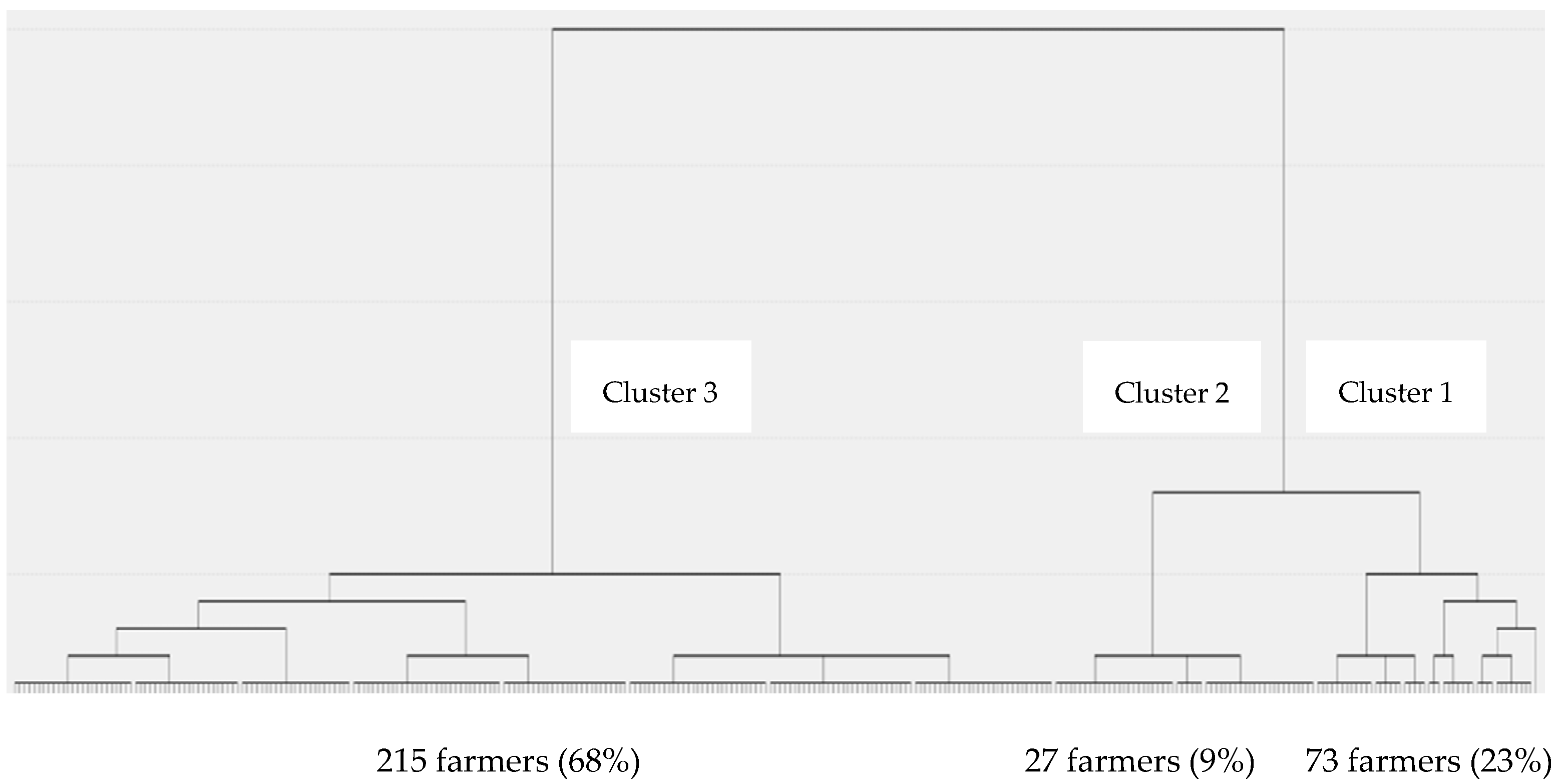

3.3.2. Results of Cluster Analysis

Cluster 1 (73 farmers: 23%)

Cluster 2 (27 farmers: 9%)

Cluster 3 (215 farmers: 68%)

3.4. Determinants of Farmers’ Perception of GAPs in Rice Production

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Raitzer, D.A.; Wong, L.C.Y.; Samson, J.N.G. Myanmar’s Agriculture Sector: Unlocking The Potential for Inclusive Growth; Asia Development Bank: Mandaluyong, Philippines, 2015; Volume 470. [Google Scholar]

- Haefele, S.M.; Johnson, D.E.; Diallo, S.; Wopereis, M.C. Improved Soil Fertility and Weed Management Is Profitable for Irrigated Rice Farmers in Sahelian West Africa. Field Crop. Res. 2000, 66, 101–113. [Google Scholar] [CrossRef]

- Becker, M.; Johnson, D.E. Improved Water Control and Crop Management Effects on Lowland Rice Productivity in West Africa. Nutr. Cycl. Agroecosystems 2001, 59, 119–127. [Google Scholar] [CrossRef]

- Poussin, J.C.; Diallo, Y.; Legoupil, J.C. Improved Collective Decision Making in Action for Irrigated Rice Farmers in the Senegal River Valley. J. Agric. Syst. 2006, 89, 299–323. [Google Scholar] [CrossRef]

- Krupnik, T.J.; Shennan, C.; Settle, W.H.; Demont, M.; Ndiaye, A.B.; Rodenburg, J. Improving Irrigated Rice Production in the Senegal River Valley Through Experiential Learning and Innovation. J. Agric. Syst. 2012, 109, 101–112. [Google Scholar] [CrossRef]

- Tanaka, A.; Saito, K.; Azoma, K.; Kobayashi, K. Factors Affecting Variation in Farm Yields of Irrigated Lowland rice in southern central Benin. Eur. J. Agron. 2013, 44, 46–53. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Bindraban, P.S.; Thiyagarajan, T.M.; Ridder, N. Modified rice cultivation in Tamil Nadu, India: Yield Gains and Farmers’ (Lack of) Acceptance. J. Agric. Syst. 2008, 98, 82–94. [Google Scholar] [CrossRef]

- DOA (Department of Agriculture). Annual Report of Rice Division; Department of Agriculture, Ministry of Agriculture and Irrigation: Nay Pyi Taw, Myanmar, 2016. [Google Scholar]

- MOAI (Ministry of Agriculture, Livestock, and Irrigation). Myanmar Agriculture in Brief; Ministry of Agriculture, Livestock, and Irrigation: Nay Pyi Taw, Myanmar, 2013. [Google Scholar]

- IRRI (International Rice Research Institute). Bridging the “GAP” Makes Farmers Wealthier. Available online: http://books.irri.org/AR2010_content.pdf (accessed on 3 February 2012).

- Mausch, K.; Milthofer, D.; Asfaw, S.; Waibel, H. Impact of EurepGAP Standard in Kenya: Comparing Smallholders to Large-scale Vegetable Producers. In Proceedings of the Conference on International Agricultural Research for Development, Bonn, Germany, 11–13 October 2006. [Google Scholar]

- Ministry of Agriculture and Cooperatives. Coffee Strategy 2009-2013 (in Thai); Ministry of Agriculture and Cooperatives: Bangkok, Thailand, 2009.

- Ryan, R.L.; Erickson, D.L.; Young, R.D. Farmers’ Motivations for Adopting Conservation Practices Along Riparian Zones in a mid-Western Agricultural Watershed. J. Environ. Plan. Manag. 2003, 46, 19–37. [Google Scholar] [CrossRef]

- Salakpetch, S. Quality Management System: Good Agricultural Practices (GAP) for On-farm Production in Thailand. In Good Agricultural Practice (GAP) in Asia and Oceania. Proceedings international seminar on Technology Development for Good Agricultural Practice in Asia and Oceania, Tsukuba, Japan, 24–28 October 2005; Hu, S., Bejosano-Gloria, G., Eds.; Food and Fertilizer Technology Center: Taipei, Taiwan, 2007. [Google Scholar]

- Van, D.M. Exclusion of Small-scale Farmers From Coordinated Supply Chain: Market Failure, policy failure, or just economies of scale? In Agro-Food Chains and Networks for Development; Ruben, R., Slingerland, M., Nijhoff, H., Eds.; Springer Netherlands: Heidelberg, Germany, 2006; pp. 209–217. [Google Scholar]

- DOA (Department of Agriculture). Phamplet for Good Agricultural Practices in Rice Production; Department of Agriculture, Ministry of Agriculture and Irrigation: Nay Pyi Taw, Myanmar, 2011. [Google Scholar]

- Banzon, A.T.; Mojica, L.E.; Angela, A.; Cielo, A.A. Adoption of Good Agricultural Practices (GAP) in the Philippines: Challenges, Issues, and Policy Imperatives. Policy Brief Ser. 2013, 2013, 1–2. [Google Scholar]

- Hobbs, J.E. Incentives for the Adoption of Good Agricultural Practices. In Background Paper for the FAO Expert Consultation on a Good Agricultural Practice Approach, Rome, Italy, 10–12 November 2003; Food and Agriculture Organization of the United Nations: Rome, Italy, 2003. [Google Scholar]

- DOA (Department of Agriculture). Annual Report of Rice Division; Department of Agriculture, Ministry of Agriculture and Irrigation: Nay Pyi Taw, Myanmar, 2017. [Google Scholar]

- Negatu, W.; Parikh, A. The Impact of Perception and Other Factors on the Adoption of Agricultural Technology in the Moret and JiruWoreda of Ethiopia. J. Agric. Econ. 1999, 21, 205–216. [Google Scholar] [CrossRef]

- Bagheri, A.; Fami, H.S.; Rezvanfar, A.; Asadi, A.; Yazdani, S. Perceptions of Paddy Farmers towards Sustainable Agricultural Technologies: Case of Haraz Catchments Area in Mazandaran Province of Iran. Am. J. Appl. Sci. 2008, 5, 1384–1391. [Google Scholar] [CrossRef]

- Emmanuel, A.-D. Farmers’ Perception of Agricultural Technologies a Case of Some Improved Crop Varieties in Ghana. Agric. For. Fish. 2014, 3, 13–16. [Google Scholar]

- Agahi, H.; Ghambarali, R.; Afsharzade, N. Wheat Farmers’ Perceptions of Sustainable Agriculture: The Case of Kermanshah Province of Iran. Eup. J. Agric. Sci. 2011, 3, 74–80. [Google Scholar]

- Smathers, W.M., Jr. Farmers’ Attitudes: Omitted Factors in Nonpoint Pollution Policy. In Perceptions, Attitudes, and Risk: Overlooked Variables in Formulating Public Policy on Soil and Water Conservation and Water Quality—An Organized Symposiym; US Department of Agriculture: Washington, DC, USA, 1982; pp. 38–49. [Google Scholar]

- Byerlee, D.; Hesse de Polanco, E. Farmers’ Stepwise Adoption of Technological Packages: Evidence from the Mexican Altiplano. Am. J. Agric. Econ. 1986, 68, 519–527. [Google Scholar] [CrossRef]

- Leathers, H.D.; Smale, M. Bayesian Approach to Explaining Sequential Adoption of Components of a Technical Package. Am. J. Agric. Econ. 1991, 73, 734–742. [Google Scholar] [CrossRef]

- Moges, D.M.; Taye, A.A. Determinants of Farmers’ Perception to Invest in Soil and Water Conservation Technologies in the North-Western Highlands of Ethiopia. Int. Soil Water Conserv. Res. 2017, 5, 56–61. [Google Scholar] [CrossRef]

- Jamal, K.; Kamarulzaman, N.H.; Abdullah, A.R.; Ismail, M.M. Adoption of Fragrant Rice Farming: The Case of Paddy Farmers in the East Coast Malaysia. UMK Procedia 2014, 1, 8–17. [Google Scholar] [CrossRef]

- Tatlidil, F.F.; Boz, I.; Tatlidil, H. Farmers’ Perception of Sustainable Agriculture and Its Determinants: A Case Study in Kahramanmaras Province of Turkey. Environ. Dev. Sustain. 2009, 11, 1091–1106. [Google Scholar] [CrossRef]

- Thompson, N.M.; Bir, C.; Widmar, D.A.; Mintert, J.R. Farmer Perceptions of Precision Agriculture Technology Benefits. J. Agric. Appl. Econ. 2019, 51, 142–163. [Google Scholar] [CrossRef]

- Rogers, E.M.; Shoemakers, F.F. Communication of Innovations: A Cross-Cultural Approach, 2nd ed.; The Free Press: New York, NY, USA, 1971. [Google Scholar]

- Alonge, A.J.; Martin, R.A. Assessment of The Adoption of Sustainable Agriculture Practices: Implications for agricultural education. J. Agric. Educ. 1995, 3, 34–42. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations, 5th ed.; Simon & Schuster: New York, NY, USA, 2003. [Google Scholar]

- Rao, S.V.N.; Rangnekar, D.V.; Dey, R.; Van Den Ban, A.W. Farmers’ Perceptions of Innovation. In Handbook for Straw Feeding Systems: Principles and Applications with Emphasis on Indian Livestock Production; Singh, K., Schiele, J.B., Eds.; Wageningen University & Research: Wageningen, The Netherlands, 1995. [Google Scholar]

- van den Ban, A.W.; Hawkins, H.S. Agricultural Extension; Blackwell Science: Oxford, UK, 1974. [Google Scholar]

- Maswadi, O.S.; Suharyani, A. The Effect of Farmer Characteristics on Perceptions of The Fermented Cocoa Beans Technology in Bengkayang Regency, West Kalimantan. J. Agric. Sci. Agritropica 2018, 1, 85–92. [Google Scholar] [CrossRef]

- Winardi, J. Motivasi Dan Pemotivasian Dalam Manajemen; Raja Persada Grafindo: Jakarta, Indonesia, 2002. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations, 4th ed.; Simon & Schuster: New York, NY, USA, 1995. [Google Scholar]

- Banmeke, T.O.A.; Ajayi, M.T. Farmers’ Perception of the Agricultural Information Resource Centre at Ago-Are, Oyo State, Nigeria. Int. J. Agric. Econ. Rural. Dev. 2008, 1, 22–29. [Google Scholar]

- Pongvinyoo, P.; Yamao, M.; Hosono, K. Factors Affecting the Implementation of Good Agricultural Practices (GAP) Among Coffee Farmers in Chumphon Province, Thailand. Am. J. Rural. Dev. 2014, 2, 34–39. [Google Scholar] [CrossRef]

- Meseret, D. Determinants of Farmers’ Perception of Soil and Water Conservation Practices on Cultivated Land in Ankesha District, Ethiopia. Agric. Sci. Eng. Technol. Res. 2014, 2, 1–9. [Google Scholar]

- Ndambiri, H.K.; Ritho, C.N.; Mbogoh, S.G. An Evaluation of Farmers’ Perceptions of and Adaptation to The Effect of Climate Change in Kenya. Int. J. Food Agric. Econ. 2013, 1, 75–96. [Google Scholar]

- Sasima, F.; Suneeporn, S.; Panya, M. Farmer’s Perceptions towards Economic Sustainability of Rice Farming in Peri-Urban Area, Bangkok, Thailand. Int. J. Agric. Technol. 2016, 12, 1759–1772. [Google Scholar]

- Pinthukas, N. Farmers’ Perception and Adaptation in Organic Vegetable Production for Sustainable Livelihood in Chiang Mai Province. Agric. Agric. Sci. Procedia 2015, 5, 46–51. [Google Scholar] [CrossRef]

- Mkuna, E.; Mugula, V.J. Farmer’s Perceptions on Climate Change Impacts in Different Rice Production Systems in Morogoro Tanzania. Int. J. Sci. Res. 2016, 6, 334–340. [Google Scholar]

- Abdul-Gafar, A.; Xu, S.; Yu, W. Perceptions of Rice Farmers towards Production Constraints: Case Study of Niger State of Nigeria and Hainan of China. J. Agric. Chem. Environ. 2016, 5, 20–30. [Google Scholar] [CrossRef]

- Ayeyarwady Regional Office. Regional Record of 2016-17; Department of Agriculture: Nay Pyi Taw, Myanmar, 2017. [Google Scholar]

- Paing Oo, S. Farmers’ Awareness of the Low Yield of Conventional Rice Production in Ayeyarwady Region, Myanmar: A Case Study of Myaungmya District. Agriculture 2020, 10, 26. [Google Scholar] [CrossRef]

- Eric, G.O.; Lagat, J.K.; Ithinji, G.K.; Mutai, B.K.; Kenneth, S.W.; Joseph, M.K. Maize Farmers’ Perceptions towards Organic Soil Management Practices in Bungoma Country, Kenya. Res. J. Environ. Earth Sci. 2013, 5, 41–48. [Google Scholar] [CrossRef]

- Hayran, S.; Gul, A.; Saridas, M.A. Farmers’ Sustainable Agriculture Perception in Turkey: The Case of Mersin Province. New Medit 2018, 3, 69–78. [Google Scholar] [CrossRef]

- Hosseini, S.J.F.; Mohammadi, F.; Mirdamadi, S.M. Factors Influencing the Economic Aspects of Sustainable Agriculture in Iran. Arch. Appl. Sci. Res. 2011, 3, 503–512. [Google Scholar]

- Shahpasand, M.R. Relationship between Awareness of Sustainable Agriculture and Fertilizer Usage by Iranian Farmers in the City of Bajestan in Khorasan Province: A Case Study. J. Agric. Sustain. 2014, 5, 104–124. [Google Scholar]

- Bagheri, A. Potato Farmers’ Perceptions of Sustainable Agriculture: The Case of Ardabil Province of Iran. Procedia Soc. Behav. Sci. 2010, 5, 1977–1981. [Google Scholar] [CrossRef]

- Acheampong, P.P.; Amengor, N.E.; Nimo-Wiredu, A.; Adogoba, D.; Frimpong, B.N.; Haleegoah, J.; Adu- Appiah, A. Does Awareness Influence the Adoption of Agricultural Technologies? The Case of Improved Sweet Potato Varieties in Ghana. In Proceedings of the 2nd GAAE Conference, Kumasi, Ghana, 9–11 August 2018. [Google Scholar]

- Mustafa, G.; Latif, I.A.; Bashir, M.K.; Shamsudin, M.N.; Daud, W.M.N.W. Determinants of Farmers’ Awareness of Climate Change. Appl. Environ. Educ. Commun. 2019, 18, 219–233. [Google Scholar] [CrossRef]

- Gujarati, D. Econometrics by Example; Palgrave Mcmilan: New York, NY, USA, 2012. [Google Scholar]

- Uddin, M.N.; Bokelmann, W.; Dunn, E.S. Determinants of Farmers’ Perception of Climate Change: A Case Study from the Coastal Region of Bangladesh. Am. J. Clim. Chang. 2017, 6, 151–165. [Google Scholar] [CrossRef]

- Allahyari, M.S.; Chizari, M.; Homaee, M. Perceptions of Iranian Agricultural Extension Professionals toward Sustainable Agriculture Concepts. J. Agric. Soc. Sci. 2008, 4, 101–106. [Google Scholar]

| Components | Benefits |

|---|---|

| GAP1(Quality seeds) | Seed rate will be reduced, and robust seedlings are produced. |

| GAP2(Sparse sowing) | Sparse sowing will provide uniform growth of seedlings. |

| GAP3(Covering) | Covering will conserve moisture and easy for uprooting. |

| GAP4(Systematic care of nursery) | Healthy and vigorous seedlings will be provided by systematic care of the nursery. |

| GAP5(Uprooting & transplanting) | The seedlings will be quickly recovered by transplanting with natural soil. |

| GAP6 (Planting depth) | Shallow transplanting will induce healthy roots and easy tillering. |

| GAP7(Seedlings per hill) | Transplanting with one to two seedlings per hill will reduce seed rate and the cost of production. |

| GAP8 (Plant population) | Using the recommended population will provide an optimum population and proper ventilation. |

| GAP9(Alternate wetting & drying) | Intermitted irrigation will reduce water utilization, methane gas emission and enhance tillering. |

| GAP10(Pests & disease management) | Safety foods are produced by using integrated pests and disease management. |

| GAP11 (Balanced inputs) | The balanced application will increase the efficiency of fertilizers and reduce environmental pollution. |

| GAP12 (Submerging) | Submerging will reduce ineffective tillers. |

| GAP13 (Drainage) | Timely drainage will induce even ripening and easy harvesting. |

| GAP14(Combine harvester) | Using combine harvester will minimize post-harvest and quality losses. |

| Variables | Description | Sign |

|---|---|---|

| Personal characteristics | ||

| Age | Age of household head | AGE |

| Gender | 1 for male; 0 otherwise | GEN |

| Marital status | 1 for married; 0 otherwise | MST |

| Education | Years of formal schooling | EDU |

| Farming experience | Years of farming experience of household head in the rice field | FEXP |

| Household size | Number of household members (persons) | HHSIZE |

| Farming characteristics | ||

| Farmland size | Size of farmland owned by household (hectares) | FSIZE |

| Active labor force | Number of household members actively involved in crop production (persons) | LAB |

| Economic Characteristics | ||

| Access to credit | 1 if household head has access to credit; 0 otherwise | CRE |

| Income from crop production | Level of annual household income from crop production: 1 for low (<6,000,000 kyats) 2 for medium (6,000,000–10,000,000 kyats) 3 for high (>10,000,000 kyats) | INC |

| Institutional characteristics | ||

| Contact with extension workers | Number of meetings per year in 2017 (times) | EXT |

| Receiving agricultural information | 1 for received; 0 otherwise | INF |

| Receiving GAPs in rice production training | 1 for received; 0 otherwise | RGAP |

| Membership in local farmers’ association | 1 for member; 0 otherwise | MLFA |

| Membership in seed growers’ association | 1 for member; 0 otherwise | MSGA |

| Characteristics | Statements |

|---|---|

| Relative advantage | The higher yield can be expected by using quality seeds. |

| Compatibility | It is compatible to use quality seeds for farmer. |

| Complexity | It is difficult for farmers to use quality seeds. |

| Trialability | You can test the characteristics of quality seeds. |

| Observability | You have a chance to observe the benefit of using quality seeds. |

| Farmers’ Characteristics | Number of Farmers = 315 | |

|---|---|---|

| Mean | Standard Deviation | |

| Age (years) | 50.25 | 12.576 |

| Gender (% of male) | 97.46 | 15.8 |

| Marital status (% of married) | 95.24 | 21.3 |

| Education (years) | 5.57 | 3.309 |

| Farming experience (years) | 25.56 | 13.706 |

| Household size (persons) | 4.51 | 1.607 |

| Farmland size (hectares) | 3.92 | 5.42 |

| Active labor force (persons) | 3.39 | 1.427 |

| Access to credit (%) | 91.74 | 27.6 |

| Income from crop production (*kyats/year) | 8,004,010 | 11,244,539 |

| Contact with extension workers (times) | 2.87 | 3.658 |

| Receiving agricultural information (%) | 87.94 | 32.6 |

| Receiving GAPs in rice production training (%) | 27 | 44.46 |

| Membership in local farmers’ association (%) | 45.71 | 49.9 |

| Membership in seed growers’ association (%) | 7.9 | 27.07 |

| Components of GAPs in Rice Production | Relative Advantage | Compatibility | Complexity | Trialability | Observability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Percentage of Farmers | Percentage of Farmers | Percentage of Farmers | Percentage of Farmers | Percentage of Farmers | |||||||||||

| a | b | a | b | a | b | a | b | a | b | ||||||

| GAP1 | 98 | 2 | 4.8 | 87 | 13 | 4.3 | 80 | 20 | 4.1 | 72 | 28 | 3.9 | 77 | 23 | 4 |

| GAP2 | 96 | 4 | 4.7 | 59 | 41 | 3.5 | 80 | 20 | 4 | 94 | 6 | 4.5 | 95 | 5 | 4.5 |

| GAP3 | 97 | 3 | 4.7 | 55 | 45 | 3.3 | 79 | 21 | 4 | 71 | 29 | 3.9 | 81 | 9 | 4.5 |

| GAP4 | 100 | 0 | 4.9 | 61 | 39 | 3.6 | 74 | 26 | 3.8 | 80 | 20 | 4.1 | 93 | 7 | 4.5 |

| GAP5 | 97 | 3 | 4.7 | 50 | 50 | 3.3 | 79 | 21 | 4 | 76 | 24 | 4 | 75 | 25 | 3.9 |

| GAP6 | 96 | 4 | 4.8 | 35 | 65 | 2.8 | 79 | 21 | 4 | 72 | 28 | 3.7 | 70 | 30 | 3.7 |

| GAP7 | 95 | 5 | 4.7 | 75 | 25 | 4 | 76 | 24 | 3.9 | 72 | 28 | 3.9 | 81 | 19 | 4.1 |

| GAP8 | 99 | 1 | 4.8 | 52 | 48 | 3.4 | 70 | 30 | 3.7 | 73 | 27 | 3.9 | 71 | 29 | 3.7 |

| GAP9 | 89 | 11 | 4.4 | 37 | 63 | 2.9 | 90 | 10 | 4.3 | 71 | 29 | 3.7 | 71 | 29 | 3.7 |

| GAP10 | 93 | 7 | 4.6 | 80 | 20 | 4.1 | 91 | 9 | 4.3 | 72 | 28 | 3.9 | 89 | 11 | 4.3 |

| GAP11 | 98 | 2 | 4.8 | 54 | 46 | 3.5 | 86 | 14 | 4.2 | 94 | 6 | 4.4 | 70 | 30 | 3.7 |

| GAP12 | 87 | 13 | 4.3 | 81 | 19 | 4.1 | 85 | 15 | 4.1 | 74 | 26 | 3.9 | 89 | 11 | 4.3 |

| GAP13 | 97 | 3 | 4.8 | 58 | 42 | 3.5 | 77 | 23 | 3.9 | 63 | 37 | 3.5 | 83 | 17 | 4.3 |

| GAP14 | 77 | 23 | 4.1 | 56 | 44 | 3.4 | 72 | 28 | 3.7 | 94 | 6 | 4.4 | 92 | 8 | 4.4 |

| Cluster | Component Technologies of GAPs in Rice Production | Mean Value | |||||

|---|---|---|---|---|---|---|---|

| Number | Name | RA | COM | CPLEX | TR | OBS | |

| 1 | 5 | GAP1, GAP7, GAP10, GAP12, and GAP13 | 4.64 | 4 | 4.06 | 3.82 | 4.2 |

| 2 | 4 | GAP2, GAP3, GAP4, and GAP14 | 4.6 | 3.45 | 3.88 | 4.23 | 4.48 |

| 3 | 5 | GAP5, GAP6, GAP8, GAP9, and GAP11 | 4.7 | 3.18 | 4.04 | 3.94 | 3.74 |

| Farmers’ Perception | Factors | ||

|---|---|---|---|

| Factor Loading | Variance Explained (%) | Eigenvalues | |

| Trialability of GAPs (CF1) | 14.879 | 10.415 | |

| Trialability of quality seeds | 0.915 | ||

| Trialability of sparse sowing | 0.933 | ||

| Trialability of covering | 0.883 | ||

| Trialability of systematic care of nursery | 0.542 | ||

| Trialability of uprooting & transplanting | 0.641 | ||

| Trialability of planting depth | 0.762 | ||

| Trialability of seedlings per hill | 0.83 | ||

| Trialability of plant population | 0.836 | ||

| Trialability of alternate wetting & drying (AWD) | 0.853 | ||

| Trialability of pest & disease management | 0.837 | ||

| Trialability of balanced inputs | 0.826 | ||

| Trialability of submerging | 0.853 | ||

| Trialability of drainage | 0.896 | ||

| Trialability of combine harvester | 0.893 | ||

| Advantages of GAPs in rice production (except Submerging & harvester) (CF2) | 6.5 | 4.55 | |

| Relative advantages of quality seeds | 0.64 | ||

| Relative advantages of sparse sowing | 0.577 | ||

| Relative advantages of covering | 0.706 | ||

| Relative advantages of systematic care of nursery | 0.668 | ||

| Relative advantages of uprooting & transplanting | 0.631 | ||

| Relative advantages of planting depth | 0.683 | ||

| Relative advantages of seedlings per hill | 0.445 | ||

| Relative advantages of plant population | 0.637 | ||

| Relative advantages of alternate wetting & drying | 0.531 | ||

| Relative advantages of pest & disease management | 0.357 | ||

| Relative advantages of balanced inputs | 0.507 | ||

| Relative advantages of drainage | 0.55 | ||

| Visible results of using nursery, pest & water management & harvester (CF3) | 5.408 | 3.786 | |

| Observability of sparse sowing | 0.864 | ||

| Observability of systematic care of nursery | 0.822 | ||

| Observability of pest & disease management | 0.808 | ||

| Observability of submerging | 0.783 | ||

| Observability of combine harvester | 0.774 | ||

| Compatible with sowing, transplanting, inputs & drainage (CF4) | 5.125 | 3.587 | |

| Compatibility of sparse sowing | 0.895 | ||

| Compatibility of uprooting & transplanting | 0.61 | ||

| Compatibility of plant population | 0.832 | ||

| Compatibility of balanced inputs | 0.837 | ||

| Compatibility of drainage | 0.887 | ||

| Visible results of using quality seeds, transplanting, AWD & inputs (CF5) | 4.552 | 3.186 | |

| Observability of quality seeds | 0.857 | ||

| Observability of uprooting & transplanting | 0.838 | ||

| Observability of alternate wetting & drying | 0.829 | ||

| Observability of balanced inputs | 0.811 | ||

| Complexity of nursery, population & harvester (CF6) | 4.543 | 3.18 | |

| Complexity of systematic care of nursery | 0.906 | ||

| Complexity of plant population | 0.901 | ||

| Complexity of combine harvester | 0.905 | ||

| Complexity of sowing, planning depth, pest management & submerging (CF7) | 4.405 | 3.084 | |

| Complexity of sparse sowing | 0.826 | ||

| Complexity of planting depth | 0.841 | ||

| Complexity of pest & disease management | 0.711 | ||

| Complexity of submerging | 0.783 | ||

| Complexity of quality seeds, transplanting, AWD & inputs (CF8) | 4.151 | 2.905 | |

| Complexity of quality seeds | 0.918 | ||

| Complexity of uprooting & transplanting | 0.903 | ||

| Complexity of alternate wetting & drying | 0.584 | ||

| Complexity of balanced inputs | 0.827 | ||

| Compatible with seeds, seedling number, pest management & submerging (CF9) | 4.056 | 2.839 | |

| Compatibility of quality seeds | 0.818 | ||

| Compatibility of seedlings per hill | 0.787 | ||

| Compatibility of pest & disease management | 0.787 | ||

| Compatibility of submerging | 0.791 | ||

| Compatible with covering, depth, AWD & harvester (CF10) | 3.944 | 2.761 | |

| Compatibility of covering | 0.832 | ||

| Compatibility of planting depth | 0.738 | ||

| Compatibility of alternate wetting & drying | 0.728 | ||

| Compatibility of combine harvester | 0.867 | ||

| Complexity of covering, seedling number & drainage (CF11) | 3.670 | 2.569 | |

| Complexity of covering | 0.801 | ||

| Complexity of seedlings per hill | 0.783 | ||

| Complexity of drainage | 0.798 | ||

| Visible results of using covering, seedling number & drainage (CF12) | 3.213 | 2.249 | |

| Observability of covering | 0.833 | ||

| Observability of seedlings per hill | 0.813 | ||

| Observability of drainage | 0.791 | ||

| Advantage of harvester & benefit of population (CF13) | 1.95 | 1.365 | |

| Relative advantages of combine harvester | 0.602 | ||

| Observability of plant population | 0.335 | ||

| Visible results of using planting depth (CF14) | 1.748 | 1.223 | |

| Observability of planting depth | 0.725 | ||

| Advantage of submerging (CF15) | 1.719 | 1.204 | |

| Relative advantages of submerging | 0.609 | ||

| Compatibility of nursery (CF16) | 1.624 | 1.137 | |

| Compatibility of systematic care of nursery | 0.702 | ||

| Total variance explained | 71.487 | ||

| * Cluster | No. of Farmers (%) | Mean Values (Standard Deviation) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Relative Advantages (3 CFs) | Compatibility (4 CFs) | Complexity (4 CFs) | Trialability (1 CF) | Observability (4 CFs) | |||||||||||||

| CF2 | CF13 | CF15 | CF4 | CF9 | CF10 | CF16 | CF6 | CF7 | CF8 | CF11 | CF1 | CF3 | CF5 | CF12 | CF14 | ||

| 1 | 73 (23%) | 0.471 (2.749) | −0.011 (1.273) | −0.011 (0.963) | 0.435 (2.315) | 0.11 (1.718) | 0.148 (1.51) | −0.01 (0.957) | −0.002 (2.045) | 0.135 (1.995) | −0.084 (1.8) | 0.014 (1.405) | −5.096 (1.773) | 1.348 (2.092) | 0.327 (2.166) | 0.046 (1.139) | −0.036 (0.932) |

| 2 | 27 (9%) | −0.574 (1.649) | 0.237 (1.164) | −0.055 (1.673) | −0.355 (2.073) | −0.419 (1.4) | 0.677 (1.375) | 0.123 (1.084) | −0.119 (1.757) | 0.51 (1.698) | 0.000 (1.657) | 0.219 (1.724) | −1.985 (2.737) | −5.192 (1.918) | −1.495 (2.396) | −0.039 (1.651) | −0.12 (1.381) |

| 3 | 215 (68%) | −0.088 (2.363) | −0.026 (1.03) | 0.011 (0.95) | −0.103 (1.818) | 0.015 (1.394) | −0.135 (1.256) | −0.012 (1.035) | 0.016 (1.597) | −0.11 (1.467) | 0.029 (1.39) | −0.032 (1.24) | 1.98 (1.526) | 0.194 (1.467) | 0.077 (1.502) | −0.011 (1.127) | 0.027 (1.051) |

| Independent Variables | GAP2 | GAP3 | GAP5 | GAP6 | GAP8 | GAP9 | GAP11 | GAP13 | GAP14 | VIF | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coef. | SE | Coef. | SE | Coef. | SE | Coef. | SE | Coef. | SE | Coef. | SE | Coef. | SE | Coef. | SE | Coef. | SE | ||

| Constant | 1.15 | 1.374 | 0.109 | 1.155 | 0.226 | 1.109 | −2.131 | 1.157 | 2.111 | 1.414 | −1.739 | 1.227 | 1.208 | 1.143 | 0.266 | 0.979 | 0.682 | 1.175 | - |

| Age | 0.015 | 0.016 | 0.007 | 0.015 | 0.01 | 0.015 | 0.023 | 0.016 | 0.005 | 0.015 | 0.006 | 0.015 | −0.002 | 0.015 | 0.009 | 0.015 | 0.009 | 0.015 | 2.7 |

| Gender | −1.682 | 1.12 | −0.552 | 0.823 | −0.663 | 0.794 | 0.027 | 0.795 | −2.416 ** | 1.196 | 0.564 | 0.88 | −0.408 | 0.814 | −0.451 | 0.209 | −1.034 | 0.881 | 1.12 |

| Marital Status | 0.002 | 0.623 | 0.142 | 0.604 | −0.16 | 0.585 | −0.124 | 0.614 | 0.897 | 0.641 | 0.581 | 0.699 | −0.159 | 0.606 | 0.145 | 0.643 | −0.05 | 0.598 | 1.17 |

| Education | −0.01 | 0.039 | 0.048 | 0.039 | −0.007 | 0.038 | 0.021 | 0.04 | −0.078 * | 0.04 | −0.01 | 0.04 | −0.071 * | 0.039 | −0.045 | 0.04 | −0.009 | 0.038 | 1.21 |

| Farming experience | −0.013 | 0.014 | 0.006 | 0.013 | −0.019 | 0.013 | −0.008 | 0.013 | −0.012 | 0.013 | 0.007 | 0.013 | −0.005 | 0.013 | −0.014 | 0.014 | 0.004 | 0.013 | 2.4 |

| Household size | −0.12 | 0.111 | −0.078 | 0.111 | −0.06 | 0.109 | 0.046 | 0.114 | −0.135 | 0.112 | 0.789 | 0.112 | −0.087 | 0.11 | −0.103 | 0.112 | 0.034 | 0.109 | 2.32 |

| Farmland size | −0.005 | 0.011 | −0.025 ** | 0.013 | −0.003 | 0.011 | −0.001 | 0.012 | −0.008 | 0.012 | −0.017 | 0.014 | −0.004 | 0.012 | 0.001 | 0.012 | −0.014 | 0.012 | 1.73 |

| Active labor force | 0.147 | 0.147 | 0.113 | 0.132 | 0.064 | 0.13 | 0.056 | 0.136 | 0.065 | 0.135 | 0.001 | 0.134 | 0.005 | 0.132 | 0.176 | 0.137 | 0.05 | 0.131 | 2.61 |

| Access to credit | −0.029 | 0.443 | −0.901 * | 0.472 | 0.555 | 0.442 | −0.023 | 0.473 | −0.669 | 0.461 | −0.389 | 0.45 | 0.179 | 0.441 | −0.275 | 0.452 | −0.648 | 0.446 | 1.09 |

| Income from crop production | −0.036 | 0.174 | 0.004 | 0.174 | 0.112 | 0.17 | 0.026 | 0.178 | 0.14 | 0.175 | 0.004 | 0.179 | −1.18 | 0.172 | −0.303 * | 0.175 | 0.084 | 0.171 | 1.53 |

| Contact with extension workers | 0.03 | 0.039 | 0.133** | 0.054 | 0.04 | 0.038 | 0.05 | 0.037 | 0.019 | 0.037 | 0.01 | 0.039 | 0.04 | 0.038 | 0.04 | 0.041 | 0.081 * | 0.045 | 1.28 |

| Receiving agricultural information | 0.602 | 0.376 | 0.371 | 0.381 | 0.056 | 0.369 | 0.127 | 0.389 | 0.791 ** | 0.395 | −0.14 | 0.379 | 0.602 | 0.378 | 0.365 | 0.383 | 0.127 | 0.373 | 1.1 |

| Receiving GAP training | −0.24 | 0.289 | 0.031 | 0.291 | −0.361 | 0.284 | −0.88 *** | 0.322 | −0.275 | 0.9 | −0.163 | 0.298 | −0.424 | 0.288 | 0.019 | 0.289 | −0.17 | 0.284 | 1.21 |

| Membership of local farmers’ association | 0.204 | 0.253 | 0.027 | 0.252 | −0.048 | 0.248 | 0.231 | 0.259 | 0.288 | 0.254 | −0.14 | 0.257 | 0.222 | 0.252 | 0.193 | 0.254 | −0.131 | 0.248 | 1.17 |

| Membership of seed growers’ association | 0.735 | 0.532 | 0.271 | 0.496 | 0.483 | 0.483 | −0.093 | 0.512 | 0.788 | 0.517 | 0.116 | 0.504 | 0.632 | 0.501 | 0.88 | 0.539 | 0.16 | 0.48 | 1.24 |

| Pseudo R2 | 0.214 | 0.475 | 0.220 | 0.377 | 0.785 | 0.221 | 0.412 | 0.635 | 0.271 | - | |||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oo, S.P.; Usami, K. Farmers’ Perception of Good Agricultural Practices in Rice Production in Myanmar: A Case Study of Myaungmya District, Ayeyarwady Region. Agriculture 2020, 10, 249. https://doi.org/10.3390/agriculture10070249

Oo SP, Usami K. Farmers’ Perception of Good Agricultural Practices in Rice Production in Myanmar: A Case Study of Myaungmya District, Ayeyarwady Region. Agriculture. 2020; 10(7):249. https://doi.org/10.3390/agriculture10070249

Chicago/Turabian StyleOo, Soe Paing, and Koichi Usami. 2020. "Farmers’ Perception of Good Agricultural Practices in Rice Production in Myanmar: A Case Study of Myaungmya District, Ayeyarwady Region" Agriculture 10, no. 7: 249. https://doi.org/10.3390/agriculture10070249

APA StyleOo, S. P., & Usami, K. (2020). Farmers’ Perception of Good Agricultural Practices in Rice Production in Myanmar: A Case Study of Myaungmya District, Ayeyarwady Region. Agriculture, 10(7), 249. https://doi.org/10.3390/agriculture10070249