Rapeseed Oil in New Application: Assessment of Structure of Oleogels Based on their Physicochemical Properties and Microscopic Observations

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Oleogels Preparation

2.3. Methods

2.3.1. Test for Strength and Spreadability of Oleogels at 20 ± 3 °C

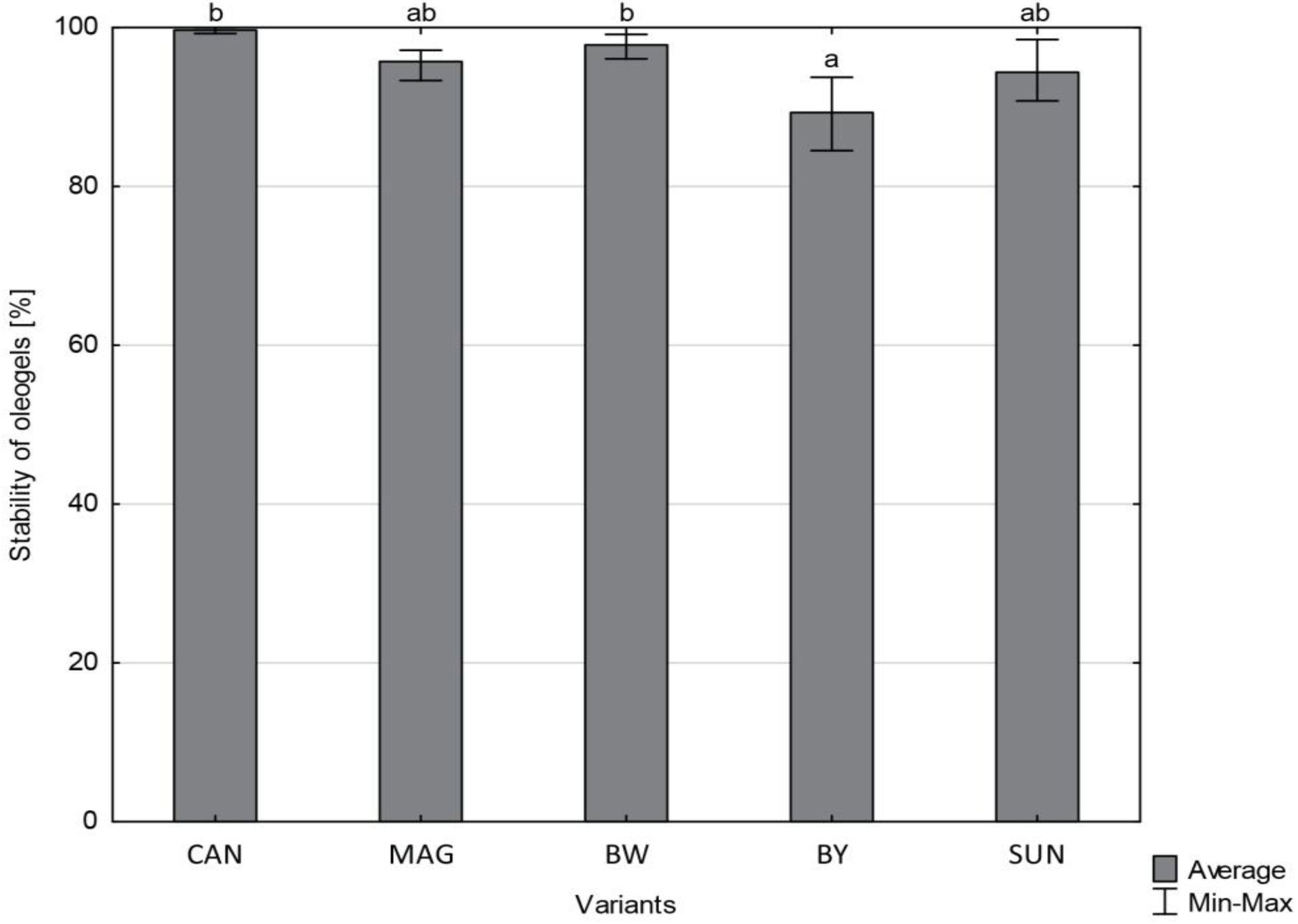

2.3.2. Stability of Oleogel–Centrifuge Method

2.3.3. Color

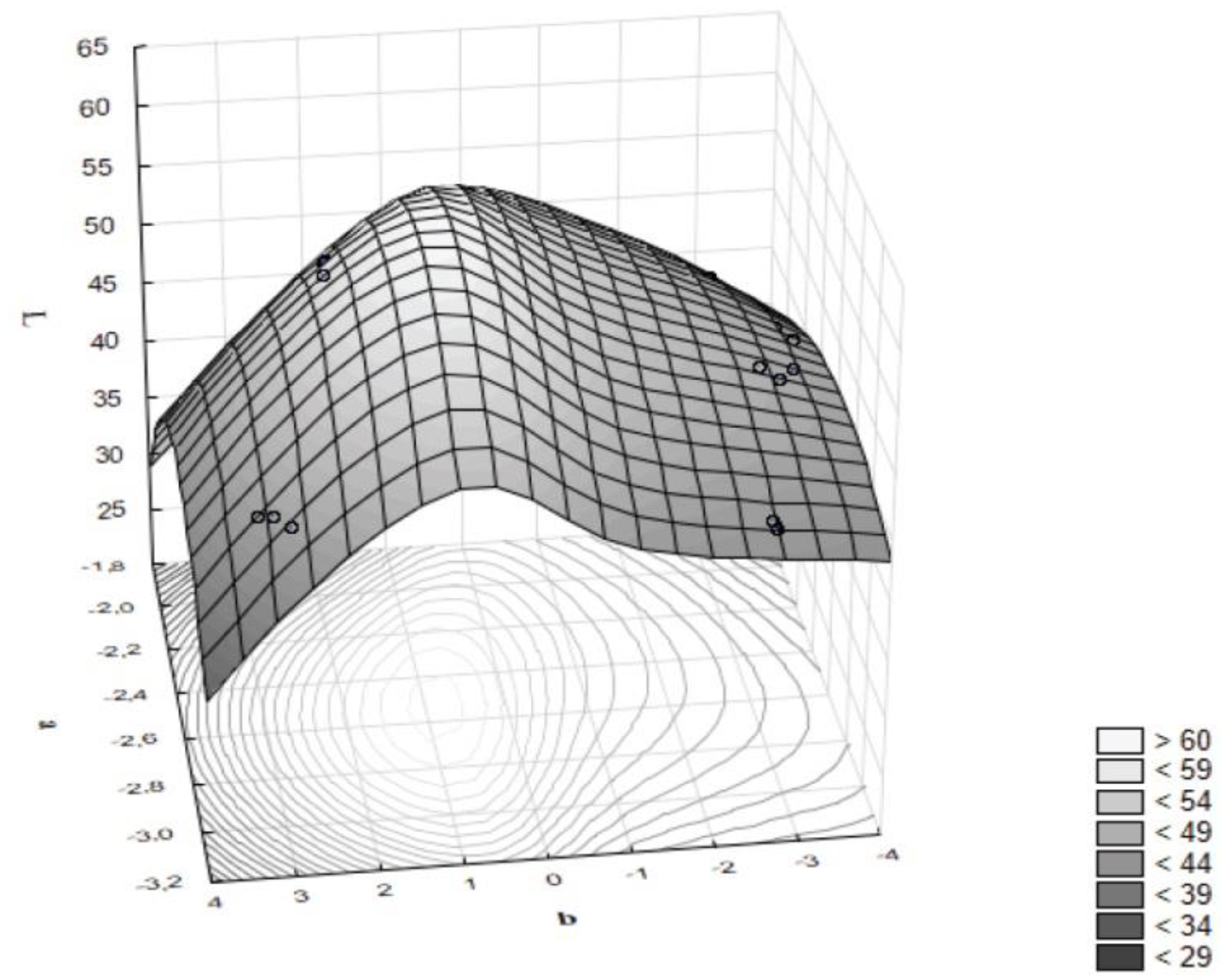

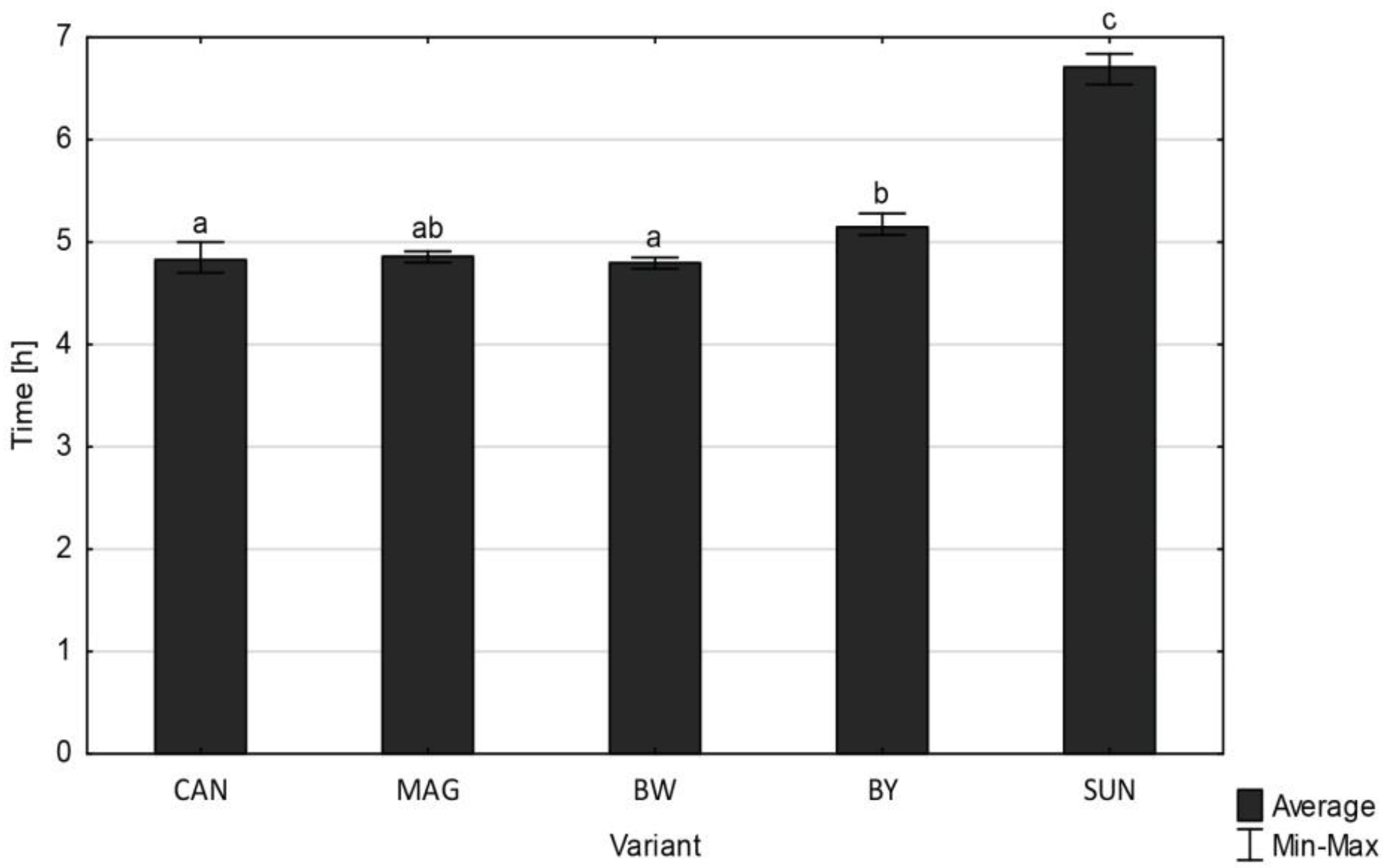

2.3.4. Oxidation Stability Index: The Rancimat Method

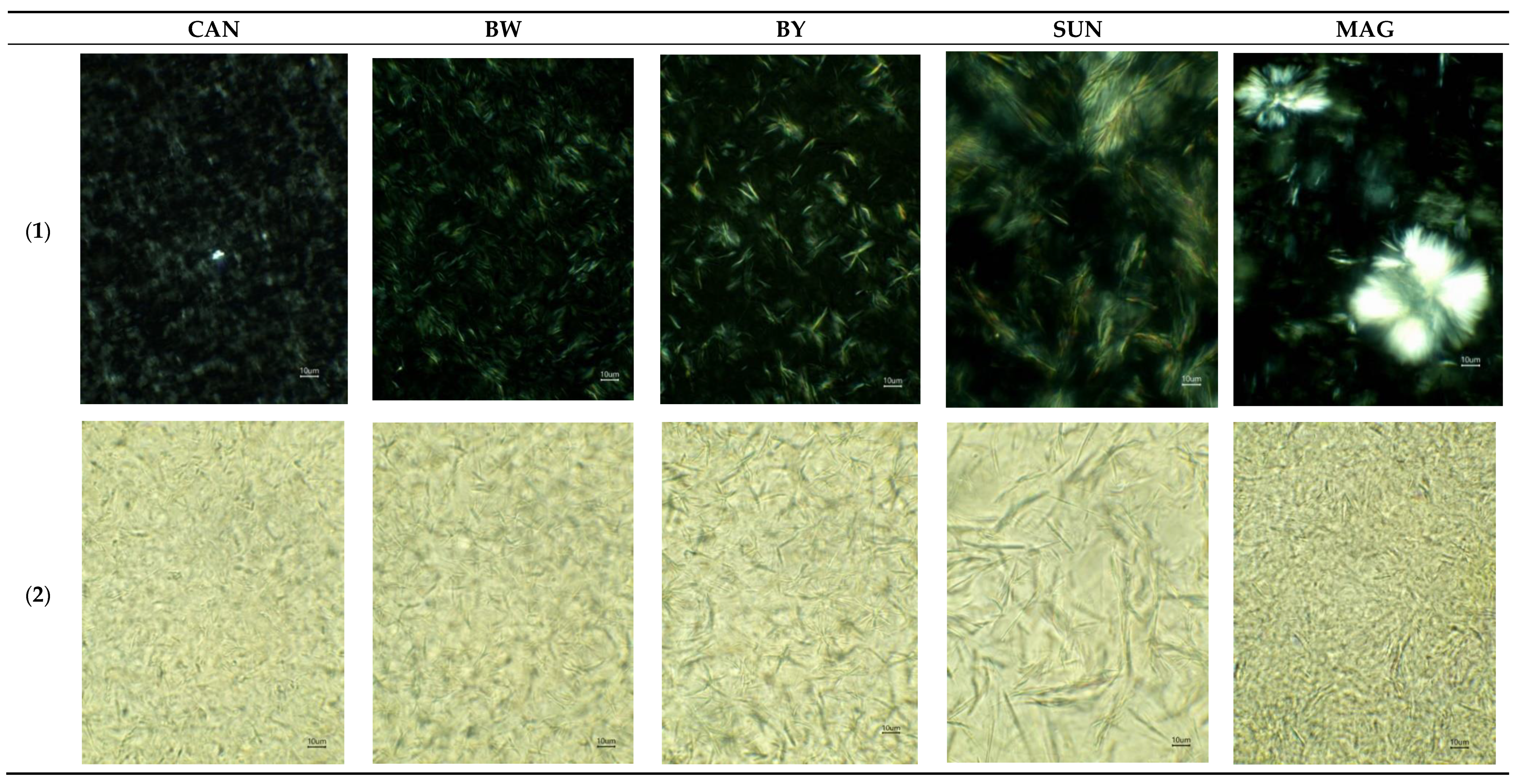

2.3.5. Analysis of Oleogel Morphology

2.3.6. Statistical Analysis

3. Results and Discussion

3.1. Oleogel Strengh and Spreadability Test

3.2. Oleogel Stability, Determined by the Centrifugal Method

3.3. Oleogels Color

3.4. The Rancimat Test

3.5. Analysis of Microscopic Images

3.6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- USDA (United States Department of Agriculture). Oilseeds: World Markets and Trade. Global Market Analysis; Foreign Agricultural Service; United States Department of Agriculture: Washington, DC, USA, 2020; pp. 1–39.

- Unger, E.H. Commercial processing of canola and rapeseed: Crushing and oil extraction. In Canola and Rapeseed: Production, Chemistry, Nutrition and Processing Technology; Shahidi, F., Ed.; Springer: Boston, MA, USA, 1990; pp. 235–249. [Google Scholar]

- Warner, D.; Lewis, K. Evaluation of the Risks of Contaminating Low Erucic Acid Rapeseed with High Erucic Rapeseed and Identification of Mitigation Strategies. Agriculture 2019, 9, 190. [Google Scholar] [CrossRef]

- McCarthy, A.; O’Callaghan, Y.C.; O’Brien, N.M. Protein Hydrolysates from Agricultural Crops—Bioactivity and Potential for Functional Food Development. Agriculture 2013, 3, 112–130. [Google Scholar] [CrossRef]

- Lin, L.; Allemekinders, H.; Dansby, A.; Campbell, L.; Durance-Tod, S.; Berger, A.; Jones, P.J.H. Evidence of health benefits of canola oil. Nutr. Rev. 2013, 71, 370–385. [Google Scholar] [CrossRef]

- Kanwu Study Group; Rasmussen, B.M.; Vessby, B.; Uusitupa, M.; Berglund, L.; Pedersen, E.; Riccardi, G.; Rivellese, A.; Tapsell, L.; Hermansen, K. Effects of dietary saturated, monounsaturated, and n−3 fatty acids on blood pressure in healthy subjects. Am. J. Clin. Nutr. 2006, 83, 221–226. [Google Scholar] [CrossRef] [PubMed]

- Mozaffarian, D.; Clarke, R. Quantitative effects on cardiovascular risk factors and coronary heart disease risk of replacing partially hydrogenated vegetable oils with other fats and oils. Eur. J. Clin. Nutr. 2009, 63, S22–S33. [Google Scholar] [CrossRef] [PubMed]

- FDA US (Food and Drug Administration). Qualified Health Claims–Qualified Health Claims: Letter of Enforcement Discretion: Unsaturated Fatty Acids from Canola Oil and Reduced Risk of Coronary Heart Disease. 2006 (Docket No. 2006Q-0091). Available online: http://www.fda.gov/Food/LabelingNutrition/LabelClaims (accessed on 3 May 2020).

- Shahbandeh, M. Production Volume of Rapeseed Oil Worldwide from 2012/13 to 2019/20. Statista Farming Report. Available online: https://www.statista.com/statistics/613487/rapeseed-oil-production-volume-worldwide (accessed on 25 April 2020).

- Jang, A.; Bae, W.; Hwang, H.-S.; Lee, H.G.; Lee, S. Evaluation of canola oil oleogels with candelilla wax as an alternative to shortening in baked goods. Food Chem. 2015, 187, 525–529. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.R.; Dewettinck, K. Edible oil structuring: An overview and recent updates. Food Funct. 2016, 7, 20–29. [Google Scholar] [CrossRef]

- Callau, M.; Sow-Kébé, K.; Nicolas-Morgantini, L.; Fameau, A.-L. Effect of the ratio between behenyl alcohol and behenic acid on the oleogel properties. J. Colloid Interface Sci. 2020, 560, 874–884. [Google Scholar] [CrossRef] [PubMed]

- Delbecq, F.; Nguyen, R.; Van Hecke, E.; Len, C. Design and physicochemical properties of long and stiff fatty low molecular weight oleogelators. J. Mol. Liq. 2019, 295, 111708. [Google Scholar] [CrossRef]

- Hwang, H.-S.; Kim, S.; Singh, M.; Moser, J.K.; Liu, S.X. Organogel Formation of Soybean Oil with Waxes. J. Am. Oil Chem. Soc. 2011, 89, 639–647. [Google Scholar] [CrossRef]

- Patel, A.R.; Babaahmadi, M.; Lesaffer, A.; Dewettinck, K. Rheological Profiling of Organogels Prepared at Critical Gelling Concentrations of Natural Waxes in a Triacylglycerol Solvent. J. Agric. Food Chem. 2015, 63, 4862–4869. [Google Scholar] [CrossRef] [PubMed]

- Giacomozzi, A.; Palla, C.; Carrín, M.E.; Martini, S. Physical Properties of Monoglycerides Oleogels Modified by Concentration, Cooling Rate, and High-Intensity Ultrasound. J. Food Sci. 2019, 84, 2549–2561. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Lo, Y.M.; Yan, M.; Li, P.; Cao, Y. Characterization of thermo-oxidative behavior of ethylcellulose oleogels. Food Chem. 2020, 305, 125470. [Google Scholar] [CrossRef] [PubMed]

- Blake, A.I.; Co, E.D.; Marangoni, A.G. Structure and Physical Properties of Plant Wax Crystal Networks and Their Relationship to Oil Binding Capacity. J. Am. Oil Chem. Soc. 2014, 91, 885–903. [Google Scholar] [CrossRef]

- Wijarnprecha, K.; Aryusuk, K.; Santiwattana, P.; Sonwai, S.; Rousseau, D. Structure and rheology of oleogels made from rice bran wax and rice bran oil. Food Res. Int. 2018, 112, 199–208. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Lim, J.; Lee, J.; Hwang, H.-S.; Lee, S. Utilization of Oleogels as a Replacement for Solid Fat in Aerated Baked Goods: Physicochemical, Rheological, and Tomographic Characterization. J. Food Sci. 2017, 82, 445–452. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Lan, Y.; Cui, L.; Monono, E.; Rao, J.; Chen, B. Formation, characterization, and potential food application of rice bran wax oleogels: Expeller-pressed corn germ oil versus refined corn oil. Food Chem. 2020, 309, 125704. [Google Scholar] [CrossRef]

- Hughes, N.E.; Marangoni, A.G.; Wright, A.J.; Rogers, M.A.; Rush, J.W. Potential food applications of edible oil organogels. Trends Food Sci. Technol. 2009, 20, 470–480. [Google Scholar] [CrossRef]

- Mert, B.; Demirkesen, I. Evaluation of highly unsaturated oleogels as shortening replacer in a short dough product. Food Sci. Technol. 2016, 68, 477–484. [Google Scholar] [CrossRef]

- Hwang, H.-S.; Singh, M.; Lee, S. Properties of Cookies Made with Natural Wax-Vegetable Oil Organogels. J. Food Sci. 2016, 81, C1045–C1054. [Google Scholar] [CrossRef]

- Franco, D.; Martins, A.J.; López-Pedrouso, M.; Cerqueira, M.A.; Purriños, L.; Pastrana, L.M.; Vicente, A.A.; Zapata, C.; Lorenzo, J.M. Evaluation of linseed oil oleogels to partially replace pork backfat in fermented sausages. J. Sci. Food Agric. 2019, 100, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Onacik-Gür, S.; Żbikowska, A. Effect of high-oleic rapeseed oil oleogels on the quality of short-dough biscuits and fat migration. J. Food Sci. Technol. 2019, 57, 1609–1618. [Google Scholar] [CrossRef]

- Cegla-Nemirovsky, Y.; Aserin, A.; Garti, N. Oleogels from Glycerol-Based Lyotropic Liquid Crystals: Phase Diagrams and Structural Characterization. J. Am. Oil Chem. Soc. 2015, 92, 439–447. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Krishnan-Ghosh, Y. First report of phase selective gelation of oil from oil/water mixtures. Possible implications toward containing oil spills. Chem. Commun. 2001, 185–186. [Google Scholar] [CrossRef]

- Abdallah, D.J.; Weiss, R.G. n-Alkanes Geln-Alkanes (and Many Other Organic Liquids). Langmuir 2000, 16, 352–355. [Google Scholar] [CrossRef]

- Hwang, H.-S.; Singh, M.; Moser, J.K.; Bakota, E.L.; Liu, S.X. Preparation of Margarines from Organogels of Sunflower Wax and Vegetable Oils. J. Food Sci. 2014, 79, C1926–C1932. [Google Scholar] [CrossRef]

- Rocha, J.C.B.; Lopes, J.D.; Mascarenhas, M.C.N.; Arellano, D.B.; Guerreiro, L.M.R.; Cunha, R.L. Thermal and rheological properties of organogels formed by sugarcane or candelilla wax in soybean oil. Food Res. Int. 2013, 50, 318–323. [Google Scholar] [CrossRef]

- Martins, A.J.; Cerqueira, M.A.; Fasolin, L.H.; Cunha, R.L.; Vicente, A. Beeswax organogels: Influence of gelator concentration and oil type in the gelation process. Food Res. Int. 2016, 84, 170–179. [Google Scholar] [CrossRef]

- Da Pieve, S.; Calligaris, S.; Co, E.; Nicoli, M.C.; Marangoni, A.G. Shear Nanostructuring of Monoglyceride Organogels. Food Biophys. 2010, 5, 211–217. [Google Scholar] [CrossRef]

- Yılmaz, E.; Öğütcü, M.; Yilmaz, E. Properties and Stability of Hazelnut Oil Organogels with Beeswax and Monoglyceride. J. Am. Oil Chem. Soc. 2014, 91, 1007–1017. [Google Scholar] [CrossRef]

- Onacik-Gür, S.; Zbikowska, A.; Przybysz, M.; Kowalska, M. Assessment of physical properties of structured oils and palm fat. Mater. Plast. 2017, 54, 800–805. [Google Scholar] [CrossRef]

- Mielicki, J. Zarys Wiadomości O Barwie; Fundacja Rozwoju Polskiej Kolorystyki Publisher: Łódź, Poland, 1997. [Google Scholar]

- Wrolstad, R.E.; Smith, D.E. Color Analysis. In Food Analysis; Nielsen, S.S., Ed.; Springer: Boston, MA, USA, 2010; pp. 57–586. [Google Scholar]

- Codex Alimentarius International Food Standards. Standard for Named Vegetable Oils CXS 210-1999. 1999. Available online: http://www.fao.org/fao-who-codexalimentarius/codex-texts/list-standards/en/ (accessed on 6 June 2020).

- Kanya, T.C.S.; Rao, L.J.; Sastry, M.C.S. Characterization of wax esters, free fatty alcohols and free fatty acids of crude wax from sunflower seed oil refineries. Food Chem. 2007, 101, 1552–1557. [Google Scholar] [CrossRef]

- Tada, A.; Masuda, A.; Sugimoto, N.; Yamagata, K.; Yamazaki, T.; Tanamoto, K. Analysis of constituents of ester-type gum bases used as natural food additives. Shokuhin Eiseigaku Zasshi J. Food Hyg. Soc. Jpn. 2007, 48, 179–185. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Doan, C.D.; Tavernier, I.; Bin Sintang, M.D.; Danthine, S.; Van De Walle, D.; Rimaux, T.; Dewettinck, K. Crystallization and Gelation Behavior of Low- and High Melting Waxes in Rice Bran Oil: A Case-Study on Berry Wax and Sunflower Wax. Food Biophys. 2016, 12, 97–108. [Google Scholar] [CrossRef]

- Hwang, H.-S.; Kim, S.; Evans, K.O.; Koga, C.; Lee, Y. Morphology and networks of sunflower wax crystals in soybean oil organogel. Food Struct. 2015, 5, 10–20. [Google Scholar] [CrossRef]

- Bonvehí, J.S.; Bermejo, F.O. Detection of adulterated commercial Spanish beeswax. Food Chem. 2012, 132, 642–648. [Google Scholar] [CrossRef]

| KERRYPNX | Structuring Agent | ||||

|---|---|---|---|---|---|

| Parameter | Beeswax White | Beeswax Yellow | Candelilla Wax | Sunflower Wax | Monoacylglycerols |

| Melting temperature [°C] | 61–66 | 68.50–72.50 | 74–80 | 63 | |

| Color | White | yellow | yellow | pale-yellowish | white-ivory |

| Acid value [mg KOH/g] | 17–24 | 17–22 | 12–22 | 2–8 | 1.40 |

| Ester value [mg KOH/g] | 70–80 | 70–80 | - | 67–93 | - |

| Variant * | Oleogel Strengh [N] | Firmness [N] | Work of Shear [N∙mm] | Stickness [N] | Work of Adhesion [N∙mm] |

|---|---|---|---|---|---|

| CAN | 5.52 ± 0.33 d | 12.68 ± 1.06 b | 35.57 ± 3.88 b | −10.06 ± 0.83 a | −5.01 ± 0,48 d |

| MAG | 0.77 ± 0.15 a | 6.47 ± 0.46 a | 18.29 ± 1.34 a | −7.50 ± 0.31 a | −3,81 ± 0,42 a |

| BW | 1.60 ± 0.31 b | 5.60 ± 0.42 a | 13.00 ± 1.05 a | −6.22 ± 0.39 a | −2.92 ± 0.18 a,b |

| BY | 0.73 ± 0.15 a | 4.39 ± 0.42 a | 9.74 ± 1.44 a | −4.87 ± 0.41 a | −2.68 ± 0.34 b |

| SUN | 3.33 ± 0.42 c | 15.78 ± 3.12 b | 46.62 ± 8.60 b | −20.37 ± 4.53 a | −7.54 ± 0.26 c |

| Parameter | ||||

|---|---|---|---|---|

| Variant of Oleogel | L* | a* | b* | ∆E |

| CAN | 45.06 ± 0.21 b | −3.11 ± 0.02 a | −2.70 ± 0.02 b | 53.04 ± 0.21 d |

| MAG | 47.99 ± 0.19 c | −2.58 ± 0.03 b | −3.25 ± 0.21 a,b | 50.15 ± 0.21 b |

| BW | 46.04 ± 0.09 a | −2.19 ± 0.18 c | −3.41 ± 0.37 a | 52.09 ± 0.08 c |

| BY | 46.26 ± 0.30 a | −3.02 ± 0.04 a | 3.09 ± 0.18 d | 51.65 ± 0.30 c |

| SUN | 55.68 ± 0.54 d | −2.39 ± 0.07 b,c | 2.09 ± 0.05 c | 42.20 ± 0.54 a |

| Variant of Oleogel | Average [nm] | Min [nm] | Max [nm] |

|---|---|---|---|

| CAN | 8.49 ± 2.53 a | 5.18 | 13.31 |

| MAG | 15.50 ± 5.19 b | 9.14 | 23.04 |

| BW | 10.09 ± 4.02 a | 6.40 | 18.22 |

| BY | 17.77 ± 8.60 b | 9.14 | 33.42 |

| SUN | 27.41 ± 10.42 c | 18.42 | 51.26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kupiec, M.; Zbikowska, A.; Marciniak-Lukasiak, K.; Kowalska, M. Rapeseed Oil in New Application: Assessment of Structure of Oleogels Based on their Physicochemical Properties and Microscopic Observations. Agriculture 2020, 10, 211. https://doi.org/10.3390/agriculture10060211

Kupiec M, Zbikowska A, Marciniak-Lukasiak K, Kowalska M. Rapeseed Oil in New Application: Assessment of Structure of Oleogels Based on their Physicochemical Properties and Microscopic Observations. Agriculture. 2020; 10(6):211. https://doi.org/10.3390/agriculture10060211

Chicago/Turabian StyleKupiec, Milena, Anna Zbikowska, Katarzyna Marciniak-Lukasiak, and Małgorzata Kowalska. 2020. "Rapeseed Oil in New Application: Assessment of Structure of Oleogels Based on their Physicochemical Properties and Microscopic Observations" Agriculture 10, no. 6: 211. https://doi.org/10.3390/agriculture10060211

APA StyleKupiec, M., Zbikowska, A., Marciniak-Lukasiak, K., & Kowalska, M. (2020). Rapeseed Oil in New Application: Assessment of Structure of Oleogels Based on their Physicochemical Properties and Microscopic Observations. Agriculture, 10(6), 211. https://doi.org/10.3390/agriculture10060211