1. Introduction

The development of livestock systems has focused primarily on increasing technical and economic efficiency over the last few decades, which has led to intensive livestock housing systems and an associated reduction of animal welfare.

One consequence of this development is that most pigs in conventional systems are kept on fully slatted floors [

1]. The requirements for animal welfare in German pig farming have increased during the last few years. One possibility of improving the welfare of conventionally kept pigs could be to offer a solid lying area. Pigs prefer solid surfaces to partial and fully slatted areas for lying [

2]. Furthermore, fully slatted floors pose a higher risk for injury to the legs and can cause lameness in pigs [

3,

4]. The main problem when using solid surfaces is the high risk of fouling of the solid surface, as is known from practical experiences and several studies [

5,

6]. This increased fouling could lead to poor indoor air quality and increased workload because the surfaces usually have to be cleaned by hand.

If it is possible, pigs separate their elimination area from the lying area [

7,

8]. The division of functional areas by the pigs and their behavior is influenced by various factors. In addition to the floor design, the temperature, air speed, stocking density, and light intensity influence the choice of the lying or elimination area.

More pigs lie in the slatted area when the temperature is increased [

5,

9]. Furthermore, the elimination behavior and, consequently, the fouling of the lying area are affected by the temperature. The fouling of the lying area increases with increased ambient temperature [

6,

10].

Moreover, Larsen et al. [

11] showed that pens with high stocking density had a higher risk of fouling.

The air speed in the different areas of the pens also has an influence on the division of the functional areas. Randell et al. [

12] showed that the fouling of the solid lying area was much higher when the fresh air first passed into the lying area before entering the elimination area.

Another effect that has the potential to lead the behavior of pigs is the light intensity. Different light intensities were tested in some studies: 5 lx and 100 lx [

13] and 2.4 lx, 4 lx, 40 lx and 400 lx [

14]. The pigs showed more resting behavior in areas with dimmer light intensities. The results of Taylor et al. [

14] showed that the piglets used the areas with high light intensity (40 lx and 400 lx) mainly for elimination.

The division of the functional areas also can be influenced by the design of the pen. Pigs prefer wet, cool areas with low activity for their elimination behavior [

12,

15]. Therefore, pigs prefer to eliminate near walls or corners and open pen partitions may lead to more elimination because of territorial function [

16,

17,

18]. The position of the feeder and drinker also influence the pigs’ behavior [

19,

20].

In the present study, the influence of a highly increased light intensity over the slatted area on the elimination and lying behavior of fattening pigs was investigated. This was tested in two different pen designs with a solid lying area during different seasons. The hypothesis was that a higher number of pigs lie in the lying area in pens with a spotlight over the slatted area. Furthermore, lower fouling of the lying area and, consequently, lower fouling of the animals was expected. The focus of the study was on the light intensity factor because it can be integrated easily into existing pig husbandry systems and is low-priced.

2. Materials and Methods

This study was carried out as part of the project “Label-Fit” scheduled for three and a half years from January 2017 to July 2020. The aim of this project was to implement the requirements of the entry-level of the label “The German Animal Welfare Association – For more Animal Welfare” (“Deutscher Tierschutzbund – Für mehr Tierwohl”) in the conventional pig holding farming systems in Germany. The main requirements of the entry-level are: 1.1 m² per pig (0.6 m² solid lying area), straw or comparative material for employment, maximum 3:1 animal:feeding place ratio for automatic dry feeder, maximum 8:1 animal:feeding place ratio for mash feeder, maximum 12:1 animal:drinking place ratio, and no tail docking. The focus of this contribution is the design of the solid comfort lying area. For this purpose, four fattening compartments have been rebuilt according to the requirements of the label at the federal pig research and training center “Bildungs- und Wissenszentrum LSZ Boxberg.” The housing and management of the animals were conducted in accordance with German legislation (TierSchNutztVO, 2017) for farm animals. Animals were visually inspected for health issues daily.

The influence of different pen structures (arrangement of the slatted floors and feeder), different floor structures (concrete slatted floor, triangular grid), and increased light intensity were examined in two fattening compartments. This study shows the results of increased light intensity over the slatted area on the use of the functional areas (lying and elimination area) by the pigs.

2.1. Animals

A total of 648 crossbred long-tailed pigs, eighteen pigs per pen and fattening period (50% females and 50% castrated males, German Hybrid x German Piétrain) were used for this study. The pigs were allocated to four pens in each compartment over four (pen design B) and five (pen design A) fattening periods, respectively (

Table 1). The eleven-week-old pigs were fattened over seventeen weeks. The average live weight at the beginning was 30 ± 4.4 kg per pig and 116.8 ± 10.5 kg per pig at the end of the fattening period. The daily weight gain was 963 ± 127 g per pig.

2.2. Housing and Experimental Pen Design

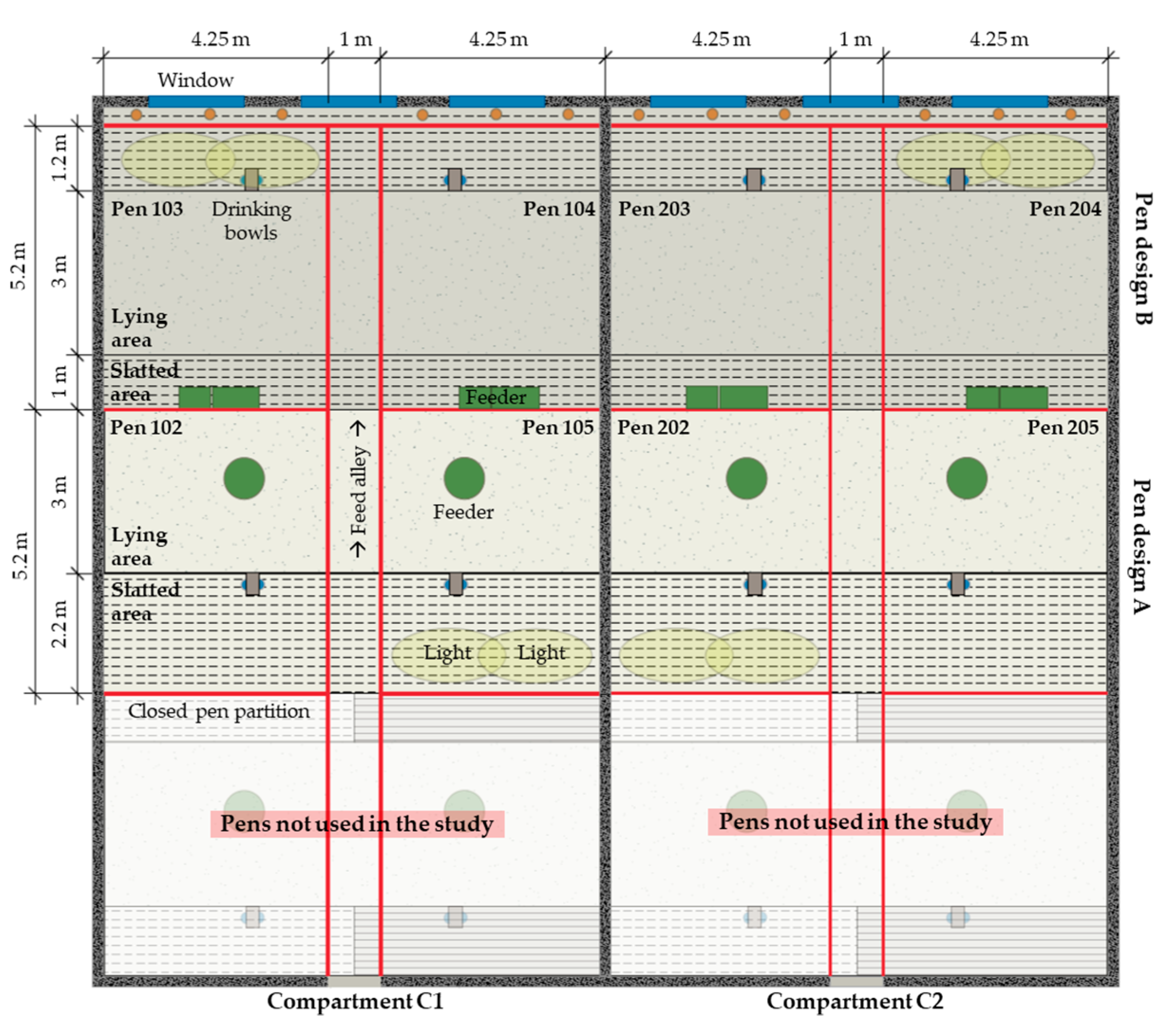

There were six pens within each fattening compartment, of which only four were used for this study (

Figure 1). The two compartments (C1 and C2) were temperature-controlled forced mechanical ventilated with an air supply from outside through the attic and a porous ceiling. The set temperature decreased from 25°C (day 0) to 22.5°C (day 15) to 19°C (day 60) and stayed at 18°C (day 120) until the end of the fattening period. The minimum ventilation rate was 10% until day 15 and then 25% until the end.

Two pen designs (pen design A and B), different in the placement of the slatted floors and feeder, were tested. All pens had a size of 4.25 × 5.2 m, including a lying area of 4.25 × 3 m (58% of the total pen area, 0.6 m² per pig). The slatted floor in pen design A was located on one side (2.2 × 4.25 m) and the slatted area in pen design B was on both sides (1/1.2 × 4.25 m) of the lying area (42% of the total pen area, 0.5 m² per pig) (

Figure 1). The floor in the lying area was solid concrete with a maximum perforation of 3% and the concrete slatted floor had < 15% perforation with a slat width of 17 mm and 83 mm between the slats. Food and straw were spread over the lying area and the slatted area was wetted before the animals entered the pens. The lying area was cleaned by hand during the first five days in case of fouling. The lying area was cleaned up after the weekly scoring, if necessary, during the entire fattening period to prevent a bad indoor climate.

All pigs were fed ad libitum with a two-phase feeding. In the beginning, the diet contained 13.3 MJ/kg and 170 g/kg crude protein. From a live weight of over 80 kg, the diet contained 10.8 MJ/kg and 145 g/kg crude protein. Animals in pen design A were fed by a round tube mash automat type “Optimat” (Schauer Agrotonic GmbH, Prambachkirchen, Austria) located in the middle of the lying area. The animal:feeding place ratio was 2.25:1. Animals in pen design B were fed by plateau combination feeder (L. Verbakel BV, Sint-Oedenrode, The Netherlands) with an animal:feeding place ratio of 3.6:1. These feeders were located on the partition wall in the smaller slatted area (

Figure 1). All pigs had free access to water from two drinking bowls “Suevia 95S” (Suevia Haiges GmbH, Kirchheim/Neckar, Germany), which were located on the slatted floor. The pigs had free access to hay, one wooden beam and two hamper ropes in each pen for environmental enrichment. Approximately 30 g/pig chopped straw was spread automatically on the lying area by the automatic straw distribution system “Spotmix Welfare” (Schauer Agrotonic GmbH, Prambachkirchen, Austria) twice a day (11 a.m. and 3 p.m.).

Four pens of each treatment in two compartments (C1 and C2) were used to investigate the effect of a strong increase of the light intensity over the slatted area on the lying and elimination behavior. A total of eight pens, four of each pen design (Pen design A: 102/105 and 202/205; pen design B: 103/104 and 203/204) were examined (

Figure 1).

In each compartment, one pen per pen design remained unchanged and the other received a brighter light intensity over the slatted (designated elimination) area. Two LED spotlights (LED Fluter 30 W, 2400 lm floodlight, cool white) were set up over the slatted area for this purpose (

Figure 2). The fattening compartments were illuminated by a total of six fluorescent tubes (warm white light), one above each pen. In addition, there were three windows on the front of each compartment.

The spotlights and the compartment lighting were switched on from 7 a.m. to 6 p.m. The spotlights were hung 1.4 m above the slatted area. The spotlights were limited by a sheet to ensure that only the slatted area was illuminated (

Figure 2). The spotlights were exchanged between the two pens in each compartment after each fattening period to counteract an effect of the location of the pen within the compartments. The average light intensity on pig eye-height for the illuminated area was extremely bright with about 850 lx.

2.3. Data Collection and Aggregation

The temperature and relative humidity inside the compartments was recorded continuously during the fattening periods. The sensors were located 1.5 m above the floor in the feed alley between the two pens of the same pen design.

The first animals were slaughtered from week thirteen, so the number of animals in the stables decreased every week. From the fourteenth week, the number of animals per pen was mostly reduced and, therefore, no longer suitable for data analysis. Consequently, the lying and elimination behavior was recorded during the first thirteen weeks of the fattening period. A video recording device was installed (video cameras, HIKVision DS-2CD2125FWD-1) for 24 h per day during this time. The percentage of lying animals was recorded every 15 min during the first fattening period to determine the activity and respectively, the resting pattern rhythms. Based on this data, three time slots per day with the highest probability of lying pigs were chosen: 5–6 a.m. (morning), 10.30–11.30 a.m. (noon), and 8–9 p.m. (evening). The lying behavior was recorded during these three time slots using scan sampling as an observation method three days a week (Thursday, Wednesday, and Saturday). Usually, 114 observations per period and pen, failures in data due to defects or contamination of the camera were possible.

For recording the lying behavior, screenshots of the first moment in every time slot when all pigs were lying were used. The screenshot of the pen was segmented in twelve parts, i.e., six parts on the lying area and six parts on the slatted area. The number of pigs lying in each part was recorded. Pigs lying on the line were assigned to the part in which more than half of the body or the head was located. Lying was defined as: pigs lying on side or belly with legs stretched out or folded underneath. The percentage of pigs lying on the solid floor was calculated for each pen and time of sampling for the statistical analysis of the lying behavior.

The fouling of the lying surface and of the animals by feces and urine was also recorded directly in the compartments every week to investigate whether the lying area as such is well accepted. Weekly scores were used to monitor the fouling of the pen (usually thirteen observations per fattening period and pen during the first thirteen fattening weeks; failures in data were possible). Consequently, the pen was segmented into twelve parts. The scores for the fouled area were as follows: grade 0 (0–10% fouling), 1 (> 10–25% fouling), 2 (> 25–50% fouling), 3 (> 50–75% fouling), and 4 (> 75–100% fouling). Only fouling caused by feces and urine was considered.

The fouling of the animals was also scored weekly at the same time as the pen fouling from the second to the thirteenth fattening week (usually twelve observations per fattening period and pen; failures in data were possible). Each side of each pig was scored to achieve this: 0 (not fouled), 1 (slightly fouled), 2 (one body part fouled), 3 (two or more body parts fouled), and 4 (completely fouled). An average grade over both sides of the body was then calculated. These average grades were divided into three categories: 0 (not fouled, average grade 0–1), 1 (slightly fouled, average grade 1.5–2.5), and 2 (heavily fouled, average grade 3–4).

The weekly scores were carried out mainly by the same person. One person exclusively executed the evaluation of the lying behavior by video analysis.

Each dataset was aggregated for statistical analysis. The measurements of the lying behavior were summarized over three fattening phases. Fattening phase 1 includes measurements from weeks 1–4, fattening phase 2 from weeks 5–8, and fattening phase 3 from weeks 9–13. Means were calculated for each time of day (morning, noon, and evening) for each fattening phase. Thus, there were nine means for each pen and fattening period used in the data analysis. Only a weekly average score of the fouling of the lying area was used (grade between 0–4) for the analysis of pen fouling. An average value for the fouling of the animals was calculated out of the amounts of the three categories for every week.

Because the compartment temperature might have an important influence on the lying behavior and fouling, a deviation from the set temperature was considered. Consequently, an average compartment and set temperature were calculated for the time before data collection. Averages over the hour before were calculated for the analysis of the influence on the lying behavior. Averages over the three days before were used for the fouling of the pen and animals. The difference between the compartment and set temperatures resulted in the deviation from the set temperature.

2.4. Experimental Design and Data Analysis

The two compartments and the eight pens represented the spatial and fattening periods temporal repetitions of the experimental treatment in the experimental design. Thus, the measurements in the pens were considered statistically independent. The two pen designs A and B were analyzed separately. The pigs were allocated to the pens randomly but with a consideration of an equal distribution of sex and weight over all the pens. The experiment ran over five fattening periods in pen design A and four periods in pen design B.

The lying behavior was analyzed with a linear mixed model (GLIMMIX procedure, SAS 9.4®). The factors phase (1–3), time of day (morning, noon, evening), and spotlight (with and without) and their interactions were taken as fixed effects. The design effect for the period (pen design A: 1–5, pen design B: 1–4) was also set as a fixed effect. The deviation from the set temperature was used as a covariate because of the expected influence on the lying behavior. In addition, the interactions of the covariate with the spotlight were also tested. The method of Kenward and Roger [

21] was used for computing the denominator degrees of freedom for the tests of fixed effects. The random effects for period*compartment and period*compartment*pen were assumed to be serially correlated across levels of phase and time of day, thus, accounting for the repeated measures nature of the data. The anisotropic power covariance structure was assumed for both random effects, allowing for separate autocorrelations for phase and time of day.

The fouling of pen and animals was also analyzed with a linear mixed model (GLIMMIX procedure, SAS 9.4®). In these analyses, the factors of week (1–13) and spotlight (with and without) and their interaction were taken as fixed effects. The fattening period (pen design A: 1–5, pen design B: 1–4) was set as a fixed design effect. The deviation from the set temperature was used as a covariate because of the expected influence on the fouling. In addition, the interactions of the covariate with and without the spotlight were also tested. The method of Kenward and Roger [

21] was used for computing the denominator degrees of freedom for the tests of fixed effects. The effect of the week (1–13) was also considered as a random effect for the interactions period*compartment, period*compartment*pen and period*compartment*spotlight. The anisotropic power covariance structure was used to estimate the random effects.

For both models, the approximate normal distribution and homogeneity of variance of the studentized residuals were confirmed graphically using QQ-plots and plots of residuals versus predicted values, respectively, for both models. The data of pen and animal fouling were not normally distributed and were transformed by taking the square root. No fixed or design effects were removed from the models. Comparisons of means were conducted using the Edwards-Berry procedure for controlling the family-wise type I error rate at a level of α = 5% [

22]. Furthermore, estimated effects with adjusted

p < 0.1 were considered to be suggestive of real effects.

4. Discussion

Both pen designs proved to be functional and no adjustments needed to be made. The design of the experiment was sufficient to evaluate the treatment “spotlight” statistically within the two pen designs. The limitation of this study is, that randomization of the pen designs was not possible, and therefore, the data of the two pen designs were only compared descriptively and the differences between the two designs were not evaluated statistically. The defined time slots for the evaluation of the lying behavior of the animals were well chosen with usually more than 97% of pigs lying during the observation.

However, the time period around noon rather reflects the resting behavior and changes very quickly, whereas the animals seem to sleep more and lay over a longer period of time during the mornings and evenings. No differences were found when the data set included only morning and evening observations. A more frequent recording of the lying behavior in future studies, for example, with automatic image/video analysis, could give more detailed and dense information on the pig behavior and short-term changes [

23].

On the first day, the pigs were put on their elimination and sleeping areas. Especially on these days, cleaning the lying area can still have a strong influence on the division of the areas. This effect was observed during the study. Subjectively, the cleaning of the pen by hand during the first days led to a positive influence of the division of the functional areas and to a reduction of the fouling of the solid lying area over a longer period of time or even completely. Subjectively, even the weekly cleaning after the scoring sometimes had a positive effect on the fouling. We chose these cleaning intervals because we wanted to make the experiment as practical as possible in order to be able to transfer the results into practice.

Low relative humidity was measured in both compartments over the fattening periods. This low relative humidity could have a positive effect on the animals’ behavior because a high relative humidity has the potential to reinforce the effects of the temperature on the pigs [

6]. Furthermore, low humidity reduces the urination of the pigs on the solid area [

6]. On the other hand, low humidity could result in an increased dust content of the ambient air [

24] and, consequently, a higher risk of disease transmission through the dust [

24,

25]. A high level of fouling can lead to higher ammonia concentrations. The high ammonia concentrations and the low humidity could worsen the indoor climate. This decline of the indoor climate can lead to the impaired welfare of the pigs. Welfare indicators were also collected during the weekly scoring. However, as this study was about improving the acceptance of the lying area, these indicators and the data on the gas measurements have not yet been evaluated.

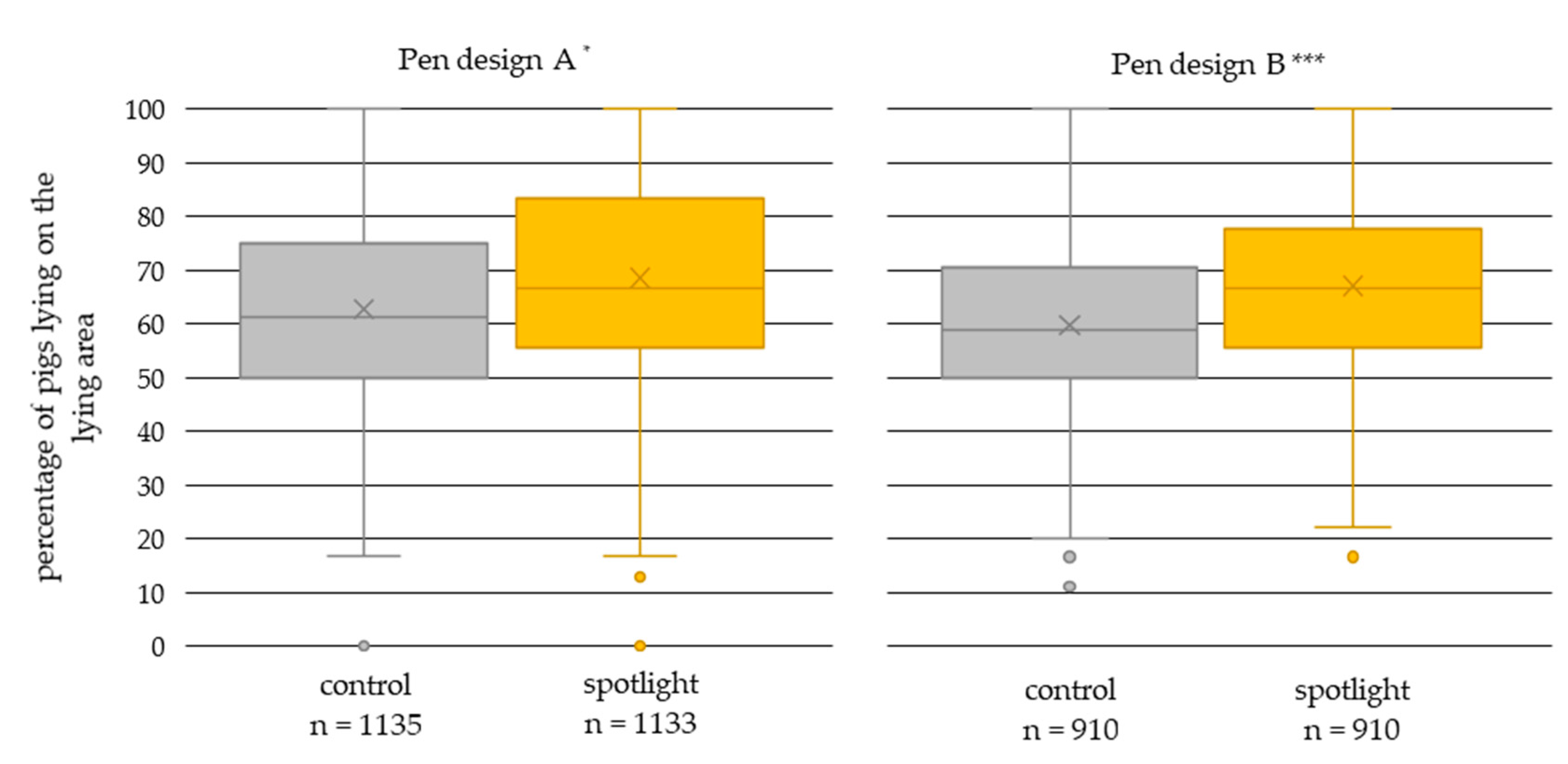

A significant effect of the increased light intensity on the lying behavior was found for both pen designs. A higher percentage of pigs lay on the solid lying area when there were spotlights over the slatted area. These results led to the conclusion that pigs avoid areas with high light intensity for lying and prefer the dimmer areas. This effect could already be shown in earlier studies by Christison [

13] and Taylor et al. [

14]. Christison [

13] showed that weaning pigs lay slightly more often in low light intensity (5 lx) than in brighter areas (100 lx). The study of Taylor et al. [

14] showed that pigs prefer to stay in darker areas (4 lx and less) compared to higher illuminances (40 and 400 lx). Furthermore, the piglets showed more resting behavior in dimmer areas than in brighter.

In this study, no significant effect of the increased light intensity was found for the fouling of the lying area or the animals. However, the fouling of the lying areas in pens with spotlights was slightly lower than in control pens (fouling grades: A: 1.24 to 1.33 and B: 0.86 to 1.2). Taylor et al. [

14] showed that increased light intensity led to higher activity and elimination behavior in these areas. Based on the results of this and further studies, it cannot be concluded that the brighter light leads to more elimination behavior in these areas or that these areas are avoided for lying. Another possible reason for the slightly reduced fouling of the lying area could be the pigs’ preference for a separate elimination area from the resting or sleeping area [

16,

17,

26]. Therefore, if they avoid brighter areas for resting, they use these brighter areas for defecation to keep the lying area clean.

If the fouling of the animals is seen as a consequence of the fouling of the lying area, then it is obvious that it is not significantly affected by the light, because there were no significant differences in the fouling of the lying area. If the fouling of the animals is considered due to wallowing, then it is effected mainly by other parameters, such as thermoregulation, skincare, health or sexual behavior [

27], and the light intensity has no noteworthy influence.

In relation to the results of this and earlier studies, it seems that it could further improve the acceptance if the lying area is dimmed additionally. An extremely large difference between the illuminated and other areas was chosen in this study to find a possible effect. In future studies, the effect of a less increased light intensity should be tested. Taylor et al. [

14] showed that a light intensity of 400 lx (about 850 lx in this study) at pig eye-height led to more elimination and less resting behavior.

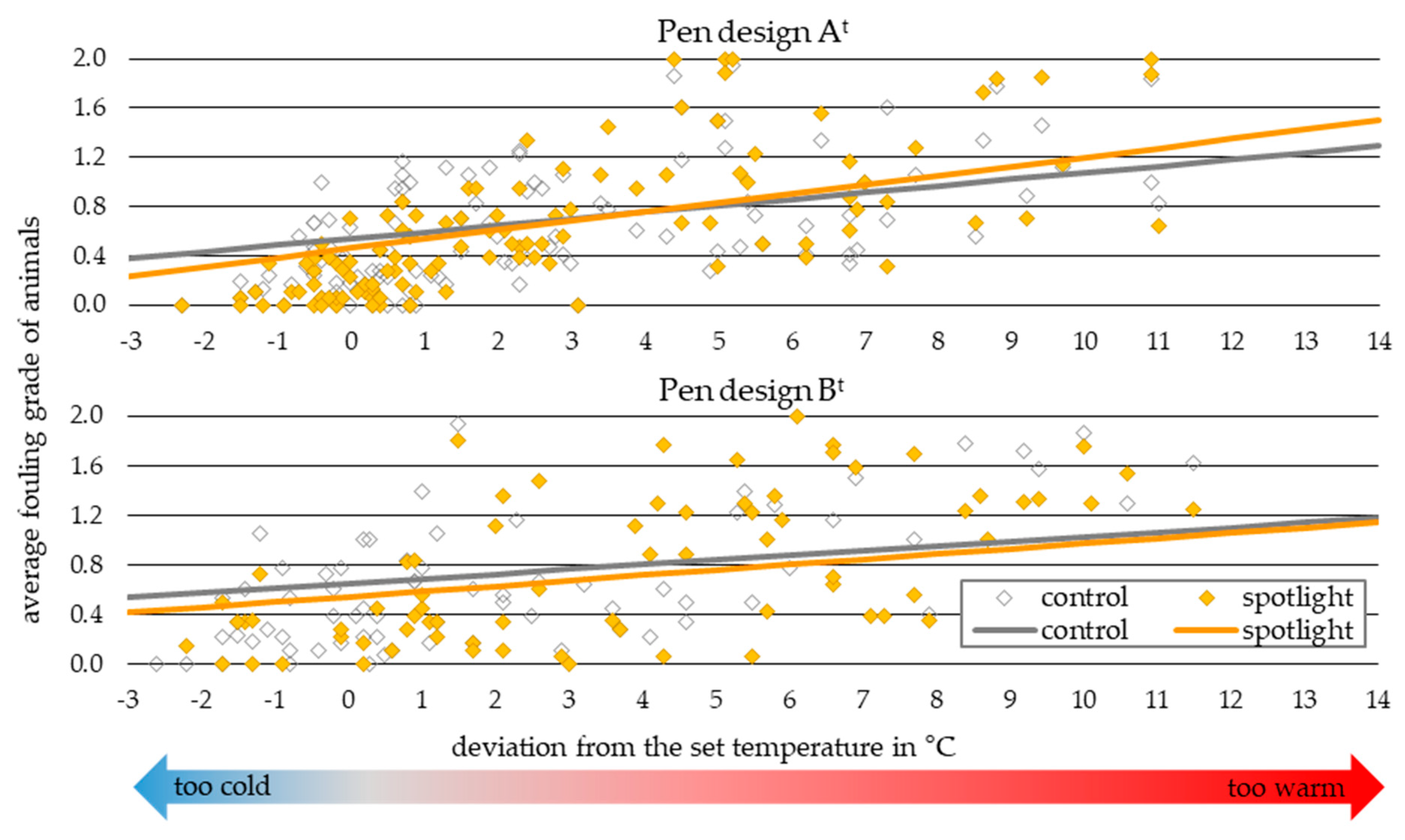

The temperature is one of the most important factors that influence the behavior of pigs. Under thermoneutral conditions, pigs prefer to rest on a solid floor, and with increased temperatures, the percentage of pigs lying on a slatted area will also increase [

5]. In this study, the temperature was examined by using the deviation from the set temperature (average compartment minus set temperature). The lying behavior in pen design B is affected by the deviation from the set temperature. The number of pigs which lay on the solid lying area decreased when temperature and, consequently, the deviation from the set temperature, increased. The effect that more pigs lay on the slatted floor with increasing temperature has been shown in many studies [

5,

6,

9,

28]. Spoolder et al. [

28] determined that 1.39% more pigs lay on the slatted floor with every degree increase from 16 to 30°C. The critical temperature at which young sows (60 kg) started lying on the slatted floor was 18.8°C in the study of Huynh et al. [

6]. The change in lying behavior and the increase in the number of pigs lying on the slatted area could be caused by the lower surface temperature of the slatted floor or by the pigs spreading over the whole pen when the temperature rises. With increased temperature, pigs need more space for lying because they expand their body surface by lying on the side and lay less against other pigs [

5,

28]. The thermoneutral zone must be observed to prevent these changes in the behavior. The thermoneutral zone of pigs depends on their bodyweight. The thermal tolerance of pigs with a bodyweight of 25–23 kg is 19–21°C, 10–17°C for pigs between 50–70 kg, and 5–17°C for pigs heavier than 85 kg [

29]. Aarnink et al. [

5] supposed that the influence of the bodyweight on the thermoneutral zone is an indirect effect of the higher heat production. Pigs with a higher bodyweight have larger feed intake and, therefore, they will produce more heat, which results in a higher sensitivity to high temperatures. High temperatures could lead to changes in behavior, especially for fattening pigs with a higher bodyweight.

Nevertheless, in this study, not only the lying behavior was affected by the temperature. The fouling of the animals in all pens was affected by the deviation from the set temperature. The higher the deviation from the set temperature, the higher the fouling of the animals. This higher fouling of the animals can have different causes. It could be a consequence of the higher number of pigs lying in the elimination area because of spreading over the pen; or it could be a consequence of the higher fouling of the lying areas because the pigs lie on the cooler slatted floor or because of wallowing for thermoregulation [

5,

6,

10,

27,

30,

31]. In the study of Aarnink et al. [

5], the excretion on the solid floor increased above a certain inflection temperature. The fouling of the solid floor increased from an ambient temperature of 24°C and alredy above 26°C 50% of the solid floor was fouled by excrement. The excrement on the lying area could explain the higher fouling of the animals with increased temperatures. Even though the fouling of the lying area was not affected significantly by temperature, it increased when the deviation from the set temperature increased. On the other hand, fouling could be a result of wallowing. The most important effect of wallowing is the temperature increase because it is a method of thermoregulation [

27].

Another significant effect, which could be explained by the temperature, is the effect of the fattening period on the lying behavior. Fewer pigs lay on the lying area in pen design B during the warmer periods 1 and 4 (mean temperature over 25°C) than during the colder seasons (mean temperature about 20°C) (period 1: 58%; period 2: 65%; period 3: 72%; period 4: 56%). The temperature in periods 1 and 4 was clearly higher than during periods 2 and 3 (

Table 1).

Furthermore, the lying behavior changes depending on the age and body size of the pigs. More pigs lay on the solid area in pen design B during the last fattening phase than during the beginning and middle (beginning: 59%, middle: 62%, end: 68%). The increased body size and the resulting small number of pigs that can lie on the slatted floor could cause this change. Another reason could be that the optimal temperature decreased with increased age and bodyweight. If the optimum is not achieved during the last phase of the fattening, the pigs spread over the pen and need more space of the lying area [

5,

28,

29].

Since randomization of the pen arrangement within the compartments could not be implemented, the differences between two pen designs, A and B, cannot be evaluated statistically. The different arrangements of the slatted floor and feeders were chosen based on findings in previous studies and the practical experiences of the project members. In the current study, the pigs eliminated mainly on the slatted floor near the drinkers and in pen design B next to the feeders on the slatted floor. No differences in pen structure were found in the fouling or lying behavior between the two pen designs. The subjective contemplation suggests that pen design B showed a better performance regarding pen and animal fouling. This could be due either to the arrangements of the slatted floor (both sides of the lying area) or the location of the feeding system (on the edge on the slatted floor). The location of the drinker and feeder could influence the behavior of the pigs in different ways. Aarnink et al. [

32] showed that pigs eliminated on the slatted floor where no drinkers or feeders were located, while the pigs in the studies of Vermeer et al. [

20] and Simsonsen [

7] eliminated near the drinkers. In the current study, pigs eliminated on the slatted floor near the drinkers and next to the feeders. As pigs prefer to eliminate near corners and walls [

16,

17,

18], the slatted floor on both sides of the pen could lead to clean lying areas. Because the feeder was located on the wall, the pigs had the opportunity to eliminate as far as possible away from the feeding area, and they seemed to prefer this [

7,

32].