Abstract

Reducing tillage has become necessary in irrigated, arid cropping systems in southwestern USA, to address soil degradation and erosion problems associated with intensive soil tillage. A study was conducted in arid southwestern USA, to compare a reduced tillage method (strip tillage) to two conventional tillage methods (plow tillage and raised bed tillage) for irrigated upland cotton (Gossypium hirsutum) production. Strip tillage (ST) was established in a single pass by a strip tillage equipment, while the plow tillage (PT) consisted of plowing, disking the soil twice, subsoiling and harrowing. The raised bed tillage (BT) consisted of all the tillage operations under PT method, with an additional tillage event to shape the beds. Crop and soil parameters were assessed during the growing seasons. Soil physical and biological measurements were assessed at the beginning of the trial before planting, and at the end of each cropping season. Results show no significant differences in cotton yield and fiber quality parameters under the tillage systems tested. Out of the soil physical measurements assessed, the cone index (CI) significantly differed with tillage systems during the mid-season assessments, with BT generally having better CI than ST and PT. Other physical measurements were not significant with tillage, but significantly declined over time irrespective of tillage treatments. Out of the soil biological measurements assessed, the total fungal biomass and the arbuscular mycorrhizae fungi biomass were significant with tillage, with ST and BT having higher measurements than PT. In contrast to soil physical measurements that declined, most of the soil biological measurements improved over time. Comparing some soil biological measurements at the beginning to the end of the trial across the tillage treatments, the total microbial biomass increased from 714 to 3565 ng/g, the total bacterial biomass increased from 321 to 1478 ng/g, and the total fungal biomass increased from 84 to 436 ng/g. This study shows that ST can perform adequately for sustainable cotton production in an irrigated arid region of United States.

1. Introduction

Cotton production in the southwestern United States is accompanied by intensive, yearly soil tillage leading to soil quality degradation and widespread wind erosion that characterize this region [1].

Most of the cotton fields are prepared in the early spring with full inversion tillage using primary and secondary tillage equipment and multiple field passes, to create a suitable, bare soil seedbed for planting. Unfortunately, the interval between the land preparation and waiting for an optimal temperature for planting cotton often coincide with the period of high wind velocities, leading to massive wind erosion from the bare, tilled landscapes that are waiting to be planted. Wind erosion is a major land degradation concern in the desert southwest [2,3]. The need for reduced tillage has become necessary in this region for long-term resource conservation and for improvement of soil health.

Several studies have highlighted the beneficial effects of reduced tillage on soil properties in cotton production systems [4,5,6]. Karamanos et al. [4] reported that no tillage and minimum tillage led to improved soil water status, foliage growth, and yield of cotton compared to the conventional tillage. Other observed benefits reported under reduced tillage in cotton production systems in south-central Texas included increased soil organic carbon and soil organic nitrogen by 24% and 27%, respectively, compared to conventional tillage at 0–0.05 m soil layer [5], thus elucidating the potential of reduced tillage to sequester carbon in cotton production systems. Reduced soil erosion is another remarkable benefit that can accrue to an agricultural production system as demonstrated by Yoo and Touchton [6], who found that soil losses were lower in reduced tillage systems with winter cover crops compared to the conventional tillage systems. Lascano et al. [7] demonstrated that the water conservation benefits in strip tillage was due to the winter cover crop residue under cotton, in a semiarid agroecosystem. This research reported that the strip tillage coupled with residue resulted in increased water use efficiency by cotton plants, leading to about 35% increase in lint yield. Smart and Bradford [8] showed that reduced tillage method could lead to higher net economic benefits for cotton producers in southern Texas, operating in irrigated and dryland conditions. In this same study, they determined that the reduced tillage net return was approximately USD110/acre greater than the conventional tillage system over a 3-year period.

While the reduced tillage systems benefits have been demonstrated in literature, farmers in the irrigated desert southwest have not widely adopted these systems. One primary issue affecting the adoption of reduced tillage is the lack of research trials conducted in specific production regions of the southwest, which will assure farmers about the success of various reduced tillage methods in their regions [9]. Another constraint is the necessity to procure new equipment for cultural operations in some reduced tillage systems, such as specific strip tillage equipment or a no tillage planter, which are required components to implement some reduced tillage methods [10].

However, with increasing degradation being experienced in soils of southwestern United States, and due to the climate change occurring within this region as manifested by recurring droughts, the necessity for improved tillage practices for conserving the soil has become imperative. This study was conducted in southwestern NM to help with the adoption of reduced tillage in cotton production systems within the region. The objectives of this study were to:

- i.

- Evaluate the performance of three tillage methods (bed, plow, and strip tillage) for cotton growth, yields and fiber quality,

- ii.

- Evaluate differences of selected soil quality indicators between the tillage treatments,

- iii.

- Evaluate the temporal changes of selected soil quality indicators under the tillage treatments.

2. Materials and Methods

2.1. Experimental Site and Land Preparation

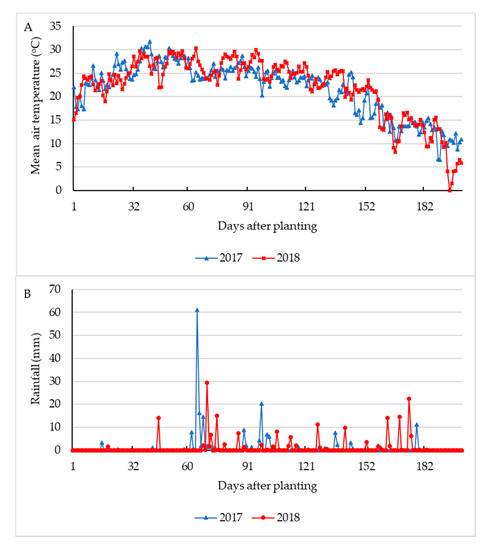

This study was conducted at the New Mexico State University Leyendecker Plant Science Research Center, in Las Cruces, NM (32.20595N and -106.74951W) in 2017 and 2018. The elevation of the study site is 1176 m above the sea level, and the mean annual precipitation is 250 mm. The average minimum and maximum temperatures are 5.8 °C in December/January and 27 °C in July during the cotton growing season. The average daily temperature and rainfall during the growing seasons are presented in Figure 1A,B.

Figure 1.

Mean air temperature (A) and rainfall (B) during the growing season at the trial site in 2017 and 2018.

The test crop was upland cotton (Gossypium hirsutum L.). The cotton cultivar tested (NuMex COT 17 GLS) is a full-season, non-transgenic, glandless cotton cultivar, adapted to NM environments [11]. Prior to the establishment of the tillage trial, the field used for the study had been in 4 years of alfalfa (Medicago sativa L.) production. During the fall preceding the establishment of the tillage trial (fall of 2016), the alfalfa was terminated after the last cut, and was disked into the soil to prepare the field for a winter crop. Winter wheat (Triticum aestivum L.) was then planted as a winter crop across the entire field, prior to the establishment of the tillage treatments in the spring of 2017. The winter wheat crop was harvested in March of 2017, by cutting and baling the harvested product, but leaving about 0.2 m tall stubble in the field.

The standing stubble was left to dry down for a month before establishing different tillage treatments. In the fall of 2017, after the harvest of cotton, the cotton stalks were mowed and left on the soil surface. At beginning of February 2018, a winter wheat cover crop was seeded and allowed to grow as cover crop till middle of April 2018. The cover crop was about 0.15 m tall by the time of termination and a Roundup herbicide (Roundup PowerMax®, Bayer Environmental Science, 2 T. W. Alexander Drive, Research Triangle Park, Durham, NC, USA) was used to terminate the winter cover crops before the establishment of the tillage treatments in 2018.

The tillage treatments tested in this study included plow tillage (PT), which consisted of five tillage passes encompassed of plowing with a moldboard plow, disking the soil twice, and then subsoiling and harrowing. The second tillage treatment tested was raised bed tillage (BT) which consisted of the same five tillage passes as used in PT, but with an extra tillage pass to form raised beds using a bed shaper, giving a total of six tillage passes. Although the BT and PT methods are traditionally the conventional tillage methods used for cotton production within the study region, the BT method is used more by farmers, as they believe that this method produces better cotton yield and reduces the incidence of soil borne pathogens [12]. The third tillage treatment tested in this study was the strip tillage (ST), which involved a single pass tillage system which creates 0.2 m wide planting strips by using the Orthman Manufacturing 1tRIPr® Strip Tillage Equipment (Orthman Manufacturing Inc., Lexington, NE, USA). The soil-engaging portion of the strip tillage equipment consisted of two offset coulters that were approximately 0.3 m in diameter, preceded by an adjustable narrow shank, which was set to penetrate the soil up to 0.25 m deep at the time of land preparation to break any subsurface compaction that might be present within the soil.

Cotton was planted on May 15 in 2017, and on May 3 in 2018, at a seeding rate of 11.2 kg/ha, using a John Deere planter with a between-row spacing of 1 m. Cotton harvest took place on December 1 in 2017, and on November 19 in 2018. The dimensions of the experimental plot were 12 × 4 m.

Furrow irrigation was used for the BT treatment plots, while flood irrigation was used for both the PT and ST treatments to reflect traditional irrigation practices for these site preparation treatments in cotton production. The trials were irrigated six times each year with the total of 457.2 mm of irrigation water during the growing season. Additionally, a total of 194.8 mm of rain fell in 2017, while a total of 193 mm fell in 2018 during the respective growing seasons. Staple LX® (DuPont, Wilmington, DE, USA) herbicide was applied at a rate of 146 mL ha−1 at the beginning of each season to control yellow nutsedge (Cyperus esculentus L.). During the mid-season, Intensity® (Loveland Products Inc. Loveland, CO, USA) herbicide was applied at a rate of 877 mL ha−1 to control post-emergence grass weeds. The BT and PT plots were cultivated twice during the growing seasons and some manual weeding also took place in all tillage treatments prior to the closure of the cotton canopy.

Fertilizer was applied based on the recommendations of the chemical soil test results.

The soil type of the trial plots is Glendale series, described as thermic Typic Torrifluvents according to USDA soil classification [13].

2.2. Measurements

Field measurements assessed included cotton plant population counts and plant height (m). Cotton plant population after crop establishment was estimated per hectare by counting the number of plants in two rows, 3 m long, within each treatment plot, while the average plant height (m) at harvest was estimated using a meterstick, by measuring five random cotton plants within each treatment plot. At maturity, 25 open bolls were randomly collected from each plot (no more than two bolls/plant) and ginned using a 20-saw laboratory gin for lint percentage and fiber quality evaluation. The cotton fiber samples were then sent to the Louisiana State University Fiber Quality Laboratory for fiber quality analysis. Quantitative field yield was assessed for each plot by hand-harvesting all the seed cotton in two rows, that were 6 m long.

Soil quality measurements that were assessed in the field included the field infiltration rate (FIR) using a Turf Tech double ring infiltrometer (Turf-Tec International, Tallahassee, FL, USA) and the cone index (CI) which was measured up to 0.3 m depth using a FieldScout SC 900 Soil Compaction Meter (Spectrum Technologies Inc., Aurora, IL, USA). The FIR was measured at two random locations within each plot, while the CI was assessed within each plot at three random locations within the planting rows. The averages for these respective measurements were calculated for each plot.

Soil samples used for laboratory analyses were collected from 0–0.15 m soil depth at five random locations within a plot and composited. The samples from each plot were air dried in the laboratory and used for multiple soil measurements, including the mean weight diameter of dry aggregates (MWD) using a RoTap sieve shaker [14], the wet aggregate stability (WAS) using Cornell Rainfall Simulator® (Cornell University, Ithaca, NY, USA) [15], and the permanganate oxidizable carbon (POXC) using the technique developed by Weil et al. [16]. In order to study the soil microbial community, soil samples were collected from each plot at 0–0.15 m soil depth and were analyzed for phospholipid fatty acid analysis (PLFA) [17] at Ward Laboratories (Kearney, NE). From the results, multiple soil biological indicators were assessed including the total microbial biomass (TMB), total bacterial biomass (TBB), total fungal biomass (TFB), total arbuscular mycorrhizae fungi (AMF), diversity index (DI), and fungi to bacteria ratio (FBR). Inverse Simpson index was used to calculate the diversity index of the soil microbial communities from the PLFA analysis. Simpson diversity index accounts for the richness and evenness of species with the community being evaluated. The following measurements—FIR, MWD, WAS, and POXC—were assessed at three separate timings (before planting in 2017 and 2018 and at harvest in 2018) during the experimental period. The PLFA analysis was assessed before planting and at harvest in 2017 and 2018. The cone index was measured before planting, at mid-season, and at harvest in both 2017 and 2018. The experimental plots were maintained utilizing the same tillage treatments over the 2 years of the study.

The experimental design was a repeated measure, randomized complete block, with treatments replicated three times. Analysis of variance was performed to assess statistically significant differences between treatments, trial years, and sampling times for crop and soil measurements. A post-hoc comparison test (Bonferroni test) was performed when a significant F ratio was detected. For the CI, comparisons were not made between time periods because of the sensitivity of CI to soil moisture conditions. Therefore, CI values were analyzed within each given time period of measurement, in which case, only the tillage treatments were compared. Data analyses were performed using SPSS software package version 25 [18].

3. Results

3.1. Cotton Growth, Yield, and Fiber Quality

Analysis of variance results show no significant tillage effects on plant population or plant height at harvest (Table 1).

Table 1.

Population and height of cotton plants measured under the tillage treatments in Las Cruces (2017 and 2018).

Cotton plant populations ranged from 74,163 plants/ha in ST to 86,111 plants/ha in BT, while plant height ranged from 1.14 m in PT to 1.26 in BT. While the effect of year was not significant for plant population, it was significant for plant height with 2017 having taller plants than 2018 at p < 0.01 (Table 1). Seed cotton, lint, and cottonseed yields were not significantly different with tillage treatments over the 2 years of trial, and the year effect was also not significant for the yield parameters (Table 2).

Table 2.

Yield parameters of cotton under the tillage treatments tested in Las Cruces (2017 and 2018).

Lint percentage was not significantly different with tillage treatments but was significantly higher in 2017 compared to 2018 at p < 0.05 (Table 2). The boll weight was not different between the tillage treatments and during both years (Table 2).

Fiber quality parameters including micronaire, fiber length, uniformity index, fiber strength, fiber elongation, and short fiber content were not significantly different with tillage treatments (Table 3). However, micronaire, fiber length, uniformity index, and fiber elongation were significantly different between both years of trial with 2017 measurements except micronaire that were greater than the 2018 measurements for these quality parameters at p < 0.01 (Table 3).

Table 3.

Fiber quality parameters of cotton under the tillage treatments in Las Cruces (2017 and 2018).

3.2. Soil Measurements

Soil penetration resistance as assessed by the CI was significantly different at 0–0.1 m in the pre-plant measurement after the tillage operations in 2017, with the PT treatment having higher CI than BT and ST treatments (Table 4). However, this difference was not repeated in the pre-plant measurement during 2018 at the same depth. CI was not significant at 0.1–0.2 m and 0.2–0.3 m in the pre-plant measurement during both trial years. For the mid-season measurements in 2017, the CI was statistically different between tillage treatments at all depths of measurement, with the BT treatment having the lowest CI at all depths compared to the PT (Table 4).

Table 4.

Penetration resistance measurements under the tillage treatments tested in Las Cruces (2017 and 2018).

In 2018, only 0.1–0.2 m and 0.2–0.3 m depths were significantly affected by tillage with the PT treatment having higher CI values than the BT and ST. The CI measurements taken after the harvest during both years were not significantly affected by the tillage treatments, and these measurements were generally much higher than the measurements taken at pre-plant and mid-season periods (Table 4). In 2017 at harvest, the penetrometer equipment used was not able to pass through to the 0.2–0.3 m soil layer due to mechanical impedance that exceeded the capacity of the equipment; therefore, no measurement was recorded for 0.2–0.3 m layer (Table 4).

The field infiltration rate (FIR), mean weight diameter of the dry aggregates (MWD), wet aggregate stability (WAS), and permanganate oxidizable carbon (POXC) were not significantly affected by the tillage treatments; however, they were all significantly affected by the sampling time (Table 5). The general trend for these measurements indicated less favorable indicator measurements at the end of the trial in 2018 harvest samples compared to 2017 pre-plant samples.

Table 5.

Soil measurements under the tillage treatments tested in Las Cruces (2017 and 2018).

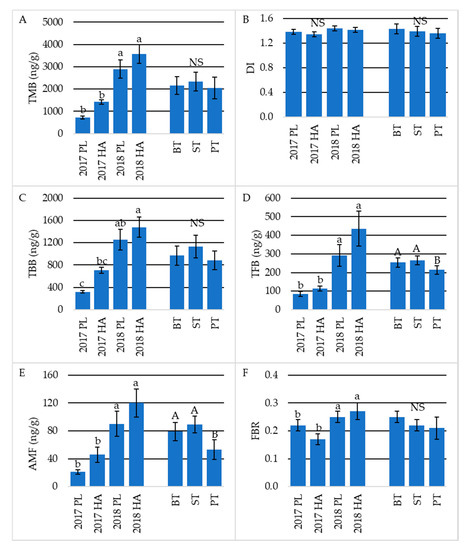

Out of the soil microbial indicator measurements, only the TFB and the AMF showed significant tillage effects, with PT treatment having lower TFB and AMF than the ST and BT treatments (Figure 2D,E). The TMB, TBB, TFB, AMF, and FBR were all significant with sampling time (Figure 2A,C–F). Generally, the measurement values for these soil microbial indicators were significantly lower at the beginning of the tillage experiment in 2017 pre-plant samples compared to the 2018 samples at harvest. However, DI was not significantly affected by the time of sampling (Figure 2B).

Figure 2.

(A–F) Soil biological measurements. (A) Total microbial biomass (TMB); (B) diversity index (DI); (C) total bacteria biomass (TBB); (D) total fungal biomass (TFB); (E) arbuscular mycorrhizae fungi biomass (AMF); (F) fungi to bacteria ratio (FBR) as a function of tillage treatments and time in Las Cruces, NM (2017 and 2018). a, b, c, A, B—bars with different upper or lowercase letters indicate significant differences at p < 0.05 for a given measurement; NS—no statistical significance, PL—measurement before planting; HA—measurement at harvest; BT—bed tillage; ST—strip tillage; PT—plow tillage; error bars indicate the standard error of mean for respective measurements.

In this trial, there was no significant interaction effect between the year and the tillage treatments for crop growth, yield, and fiber quality measurements. There were also no significant interaction effects between the sampling time and the tillage treatments for all the soil measurements.

4. Discussion

The nonsignificant difference in plant populations under the tillage treatments indicates that plant establishment has not been negatively impacted by the reduced tillage treatment (ST). Some of the previous observations made in some studies have shown lower cotton plant population in reduced tillage compared to the conventional tillage systems. In the irrigated, desert, southwestern USA, cotton can produce optimum yields over a wide range of plant populations (62,000–111,000 plants/ha) [19]. The lowest plant population in this trial which was under the ST (74,163) was still well within the range specified for adequate cotton yield.

From this study, tillage effect was not significant for yield and fiber quality measurements indicating that all the tillage treatments tested have been effective for successful production of cotton in the study region. This is particularly important since the strip tillage could impart significant benefits into the farming system through the potential to improve soil quality in the long term and protect the land from wind erosion which is a common agricultural issue in the desert southwestern USA. Previous research conducted in semiarid locations in southern Texas have shown the beneficial effects of reduced tillage on cotton production, demonstrating a greater net economic benefit for reduced tillage compared to the conventional tillage systems [8]. As the yield and fiber quality parameters were not affected by the tillage methods that were tested, farmers in the arid southwest can successfully transition to reduced tillage methods such as strip tillage without negative impact on yields. Additionally, the cost of production will be much reduced in strip tillage systems due to reduced field passes for land preparation. Consequently, the net economic benefit to farmers using reduced tillage systems for cotton production in the irrigated southwest would be higher compared to the conventional systems of planting on beds or planting on the flat that is currently being practiced [8].

Another important outcome of this study is the comparison between BT and PT treatments. Since there were no significant differences in yield parameters between these two tillage methods, there appears to be no justification in using a raised bed for cotton production in this region. In fact, the seed cotton, lint, and seed yields were quantitatively higher in the PT treatments than BT, though not statistically different (Table 2). Eliminating bed shaping which is an extra operation that takes place in BT treatment when compared to PT, will result in cost savings for farmers. Although, studies have shown that planting cotton on beds may be more profitable than planting on flat due to improved seed germination, higher yields, better weed control, water savings, and better soil drainage [20]. However, in this study, we did not see any advantage of raised beds over planting on the flat in terms of plant establishment and yield. There might be some specific local conditions in the field that might make planting on raised beds more desirable, for example, in soils with very poor drainage that can make cotton plants more susceptible to soil-borne pathogens.

While the tillage effect was not significant for yield and fiber quality parameters in our research, the year effect was very strong for some of the fiber quality parameters including the micronaire, fiber length, uniformity index, and fiber elongation. This was expected as previous research has shown that fiber quality parameters can be influenced by a variety of complex factors including farm management practices, along with the yearly weather, especially the temperature and precipitation, irrigation practices, and soil nutrients/properties [21,22,23,24].

Significant tillage differences for CI measurements were pronounced during the mid-season measurements in which more favorable values were observed in the BT treatments compared to ST and PT in 2017 (Table 4). However, cotton root growth will not be affected during the mid-season of 2017, since CI values for all the tillage treatments were lower than 2000 kPa, which is regarded as threshold beyond which root growth will be impeded by compaction [25]. In contrast, the mid-season 2018 CI measurements of the PT treatment were highest at 0.1–0.3 m depth, where it exceeded 2000 KPa indicating a compacted soil layer. Generally, the trend of soil compaction irrespective of tillage treatments, showed CI progressively increasing from the beginning to the end of the season. By the end of the season, the CI especially, at 0.1–0.3 m soil depth, already exceeded 2000 kPa, thereby leading to very compacted soils by the end of the season. This observation confirms a study that showed that the soil penetration resistance increased from spring to fall in irrigated cotton, irrespective of the tillage system [26]. The high CI at the end of the season is often a justification for intensive tillage practices in the following spring before planting. However, with strip tillage, there is an opportunity to combine intensive tillage within the seed rows with no tillage between the seed rows, leaving most of the soil surface covered with cover crop stubble, capable of protecting the soil surface from erosion and degradation. This contrasts with the plow or bed tillage in which the whole soil surface is finely tilled and left bare, exposing the soil particles to losses from wind erosion during the early spring season.

We did not observe any significant tillage effect on FIR, MWD, WAS, and POXC, possibly due to the short-term nature of this study. A previous study at the same location of this trial did not find any significant tillage impact on soil structural parameters and POXC when no-tillage, strip tillage, and plow tillage were compared under corn silage system over a period of 2 years [27]. The significant differences over time observed in the soil measurements including FIR, MWD, WAS, and POXC showed a generally less favorable measurement at the end of the trial in 2018 compared with the baseline measurements at the beginning of the trial in 2017. This could probably be attributed to the preceding 4 years of alfalfa crop production prior to the establishment of cotton production before the implementation of the tillage treatments in the trial plots. Previous studies have shown that alfalfa production and residue can improve soil properties including saturated hydraulic conductivity, soil aggregation, and soil organic carbon [28,29]. Improvement in soils planted to alfalfa is as a result of the absence of yearly tillage and the extensive root network of alfalfa plants. It is possible that due to the soil transitioning out of alfalfa production and being exposed to tillage, these measurements were degraded over time due to the annual soil disturbances taking place. The reduction in soil measurements during the progression of 2 years of cotton production was more drastic for FIR (54% reduction) compared to MWD (4% reduction), WAS (25% reduction), and POXC (8% reduction). A previous study has shown the strong effects that alfalfa root systems can have on soil hydraulic properties [29]. Therefore, soil disturbances resulting from tillage will probably have more impact on soil hydraulic properties compared to the other soil indicator measurements. It is expected that these measurements will attain new stable levels under each tillage system over time, with ST probably achieving a more favorable indicator status compared to intensively tilled PT and BT [30].

The TFB and the AMF were the only biological measurements that were significant with tillage treatment and showed that PT had lower fungal population compared to the BT and ST systems. The higher fungal biomass in the ST treatment may be as a result of greater amounts of residue at the soil surface compared to the PT treatment. Previous studies have shown significantly reduced fungal AMF colonization in conventionally tilled soils compared to the reduced and no-tillage soils in corn rotation [31,32]. A meta-analysis study on tillage and cover crop effects on AMF colonization showed that less intensive tillage led to increased AMF colonization of summer annual cash crop roots by about 30%. In our study, the TFB was 23% more in ST compared to PT while the AMF was 68% more in ST than PT. This highlights the importance of reduced tillage in sustaining the AMF colonization in arid soils. The reason for higher AMF colonization in ST may be due to less disruption of fungal hyphae by this tillage practice in contrast to the PT, where full-width yearly tillage occurred [33].

The TFB and AMF were significantly higher on BT than PT despite that these treatments experienced similar yearly intensive tillage operations. A study previously showed higher colonization of AMF in raised beds compared to flat seedbed under wheat production [34]. The authors suggested that the higher colonization in raised beds was probably due to the development of higher AMF hyphal network and better exploitation of soil pool resources.

Most of the microbial parameters measured showed significant increases over the period of trial. When compared with the baseline measurements, TMB increased by 5 times, TBB increased by 4.6 times, TFB increased by 5.2 times, AMF increased by 5.7 times, and FBR increased 1.2 times. These increases suggest that the soil microbial parameters improved in the soil irrespective of tillage treatments. These results were rather surprising when compared to other soil measurements assessed such as POXC, MWD, and WAS whose values were reduced and less favorable when the baseline measurements were compared to the final measurements taken at the end of the trial. This highlights the difficulties associated with assessing soil quality in short-term tillage trials. The results from short-term trials may not necessarily represent a full picture of the directional changes in soil quality that may become apparent over a longer period. However, when all the soil measurements assessed in this study are considered, only the total fungal biomass and AMF showed significant differences between the tillage treatments, while the other measurements were unaffected by the tillage treatments. Fungal measurements could probably serve as an early indicator of carbon sequestration in the soil, as some studies have shown that quantitative and qualitative improvement in the soil organic matter is generally observed in agroecosystems favoring a fungal-dominated community [35]. This information may be beneficial for soil quality assessment since land managers are often seeking for measurements that can show early changes in soil quality over a short period of time and from this study, both the total fungal population and AMF were able to show the distinction between tillage treatments.

It is expected that the strip tillage system will become more beneficial for crop production and soil quality in the long term due to highly reduced soil disturbance and more surface residue. These factors will allow more soil organic matter sequestration and better establishment of soil microbial population.

5. Conclusions

A trial conducted over 2 years to compare plow tillage and raised bed tillage to strip tillage, showed no significant differences in cotton yields and fiber quality parameters across the tillage treatments. Additionally, soil physical measurements and POXC were not significantly different with tillage treatments. Out of all the biological measurements assessed, only the total fungal biomass and the AMF gave significant difference with tillage treatments, with strip tillage and bed tillage having higher measurement values than the plow tillage. Sampling time significantly impacted most of the soil measurements, with the physical measurements and POXC having final measurements (measurements at the end of second trial year) that were lower and less favorable than the initial measurements at the beginning of the experiment. However, the biological measurements were opposite, being higher and more favorable at the end of the second trial year. In this experiment, the total fungal population and the AMF were sensitive enough to soil disturbances to distinguish between the tillage systems, thus these measurements may serve as potential soil quality indicators for evaluating performance of tillage systems in the short term. This study shows that the strip tillage system can be used to produce cotton successfully in the irrigated arid agroecosystems and can provide economic benefits by minimizing the overall production costs for farmers in the region due to reduced tillage costs. It can also benefit the environment, help with soil moisture conservation, and improve soil quality due to its potential to reduce wind erosion by maintaining a more stable residue cover on the soil surface. Longer term studies are needed in the arid southwestern USA, to adequately monitor soil quality changes and document the benefits of reduced tillage systems to production costs, potential cotton yield, and the overall ecosystem.

Author Contributions

Conceptualization, O.J.I.; methodology, O.J.I., M.D. and R.S.; software, O.J.I.; formal analysis, O.J.I., S.S. and R.S.; investigation, S.S. and M.O.; resources, O.J.I. and M.D.; data curation, S.S. and O.J.I.; writing—original draft preparation, O.J.I.; writing—review and editing, L.B. and M.D.; supervision, O.J.I., M.D., L.B. and R.S.; project administration, O.J.I.; funding acquisition, O.J.I. and M.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the New Mexico Agricultural Experiment Station and the USDA Hatch grant.

Acknowledgments

Special thanks to Dave Lowry, the Farm Manager at the Leyendecker Plant Science Center, Las Cruces, NM, and the farm crew members who helped with plot layout and routine management of this trial.

Conflicts of Interest

The authors declare no conflict of interest and the funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Nordstrom, K.F.; Hotta, S. Wind Erosion from Cropland in the USA: A Review of Problems, Solutions and Prospects. Geoderma 2004, 121, 157–167. [Google Scholar] [CrossRef]

- Huszar, P.C.; Piper, S.L. Estimating the off-Site Costs of Wind Erosion in New Mexico. J. Soil Water Conserv. 1986, 41, 414–416. [Google Scholar]

- Piper, S. Measuring Particulate Pollution Damage from Wind Erosion in the Western United States. J. Soil Water Conserv. 1989, 44, 70–75. [Google Scholar]

- Karamanos, A.J.; Bilalis, D.; Sidiras, N. Effects of Reduced Tillage and Fertilization Practices on Soil Characteristics, Plant Water Status, Growth and Yield of Upland Cotton. J. Agron. Crop. Sci. 2004, 190, 262–276. [Google Scholar] [CrossRef]

- Wright, A.L.; Hons, F.M.; Lemon, R.G.; McFarland, M.L.; Nichols, R.L. Microbial Activity and Soil C Sequestration for Reduced and Conventional Tillage Cotton. Appl. Soil Ecol. 2008, 38, 168–173. [Google Scholar] [CrossRef]

- Yoo, K.H.; Touchton, J.T. Runoff and Soil Loss by Crop Growth Stage under Three Cotton Tillage Systems. J. Soil Water Conserv. 1989, 44, 225–228. [Google Scholar]

- Lascano, R.J.; Baumhardt, R.L.; Hicks, S.K.; Heilman, J.L. Soil and Plant Water Evaporation from Strip-Tilled Cotton: Measurement and Simulation. Agron. J. 1907, 86, 987–994. [Google Scholar] [CrossRef]

- Smart, J.R.; Bradford, J.M. No-Tillage and Reduced Tillage Cotton Production in South Texas. In Proceedings of the Beltwide Cotton Conference, Nashville, TN, USA, 9–12 January 1996; pp. 1397–1401. [Google Scholar]

- Mitchell, J.; Klonsky, K.; Shrestha, A.; Fry, R.; DuSault, A.; Beyer, J.; Harben, R. Adoption of Conservation Tillage in California: Current Status and Future Perspectives. Aust. J. Exp. Agric. 2007, 47, 1383–1388. [Google Scholar] [CrossRef]

- Bossange, A.V.; Knudson, K.M.; Shrestha, A.; Harben, R.; Mitchell, J.P. The Potential for Conservation Tillage Adoption in the San Joaquin Valley, California: A Qualitative Study of Farmer Perspectives and Opportunities for Extension. PLoS ONE 2016, 11, e0167612. [Google Scholar] [CrossRef]

- Zhang, J.; Idowu, O.J.; Wedegaertner, T. Registration of Glandless ‘NuMex COT 17 GLS’ Upland Cotton Cultivar with Fusarium Wilt Race 4 Resistance. J. Plant Regist. 2020, 14, 1–9. [Google Scholar] [CrossRef]

- Chohan, S.; Perveen, R.; Abid, M.; Tahir, M.N.; Sajid, M. Cotton Diseases and Their Management. In Cotton Production and Uses; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2020; pp. 239–270. [Google Scholar]

- USDA; NRCS. Soil Survey Staff Keys to Soil Taxonomy, 8th ed.; U.S. Gov. Print. Office: Washington, DC, USA, 1998.

- Idowu, O.J.; Kircher, P. Soil Quality of Semi-Arid Conservation Reserve Program Lands in Eastern New Mexico. Arid Land Res. Manag. 2015, 30, 153–165. [Google Scholar] [CrossRef]

- Ogden, C.B.; Van Es, H.M.; Schindelbeck, R.R. Miniature Rain Simulator for Field Measurement of Soil Infiltration. Soil Sci. Soc. Am. J. 1997, 61, 1041–1043. [Google Scholar] [CrossRef]

- Islam, K.; Stine, M.A.; Gruver, J.B.; Samson-Liebig, S.E.; Weil, R.R. Estimating Active Carbon for Soil Quality Assessment: A Simplified Method for Laboratory and Field Use. Am. J. Altern. Agric. 2003, 18, 3–17. [Google Scholar] [CrossRef]

- Willers, C.; Van Rensburg, P.J.; Claassens, S. Phospholipid Fatty Acid Profiling of Microbial Communities-A Review of Interpretations and Recent Applications. J. Appl. Microbiol. 2015, 119, 1207–1218. [Google Scholar] [CrossRef]

- IBM Corp. Released IBM SPSS Statistics for Windows, Version 25.0; IBM Corp: Armonk, NY, USA, 2017. [Google Scholar]

- Norton, E.R.; Silvertooth, J.C.; Stedman, S.W. Plant Population Evaluation for Upland Cotton; Series P-99; College of Agriculture, University of Arizona: Tucson, AZ, USA, 1995; pp. 25–28. [Google Scholar]

- Farooq, O.; Mubeen, K.; Khan, A.A.; Ahmad, S. Sowing Methods for Cotton Production. In Cotton Production and Uses; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2020; pp. 45–57. [Google Scholar]

- Johnson, R.M.; Downer, R.G.; Bradow, J.M.; Bauer, P.J.; Sadler, E. Variability in Cotton Fiber Yield, Fiber Quality, and Soil Properties in a Southeastern Coastal Plain. Agron. J. 2002, 94, 1305–1316. [Google Scholar] [CrossRef]

- Cassman, K.G.; Kerby, T.A.; Roberts, B.A.; Bryant, D.C.; Higashi, S.L. Potassium Nutrition Effects on Lint Yield and Fiber Quality of Acala Cotton. Crop. Sci. 1990, 30, 672–677. [Google Scholar] [CrossRef]

- Zhang, D.; Luo, Z.; Liu, S.; Li, W.; Tang, W.; Dong, H. Effects of Deficit Irrigation and Plant Density on the Growth, Yield and Fiber Quality of Irrigated Cotton. Field Crop. Res. 2016, 197, 1–9. [Google Scholar] [CrossRef]

- Bradow, J.M.; Davidonis, G.H. Effects of Environment on Fiber Quality. In Physiology of Cotton; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2010; pp. 229–245. [Google Scholar]

- Hamza, M.A.; Anderson, W.K. Soil Compaction in Cropping Systems—A Review of the Nature, Causes and Possible Solutions. Soil Till. Res. 2005, 82, 121–145. [Google Scholar] [CrossRef]

- Coates, W.E. Reduced Tillage Systems for Irrigated Cotton: Is Soil Compaction a Concern? Appl. Eng. Agric. 2001, 17, 273–279. [Google Scholar] [CrossRef]

- Idowu, O.J.; Sultana, S.; Darapuneni, M.; Beck, L.; Steiner, R. Short-term Conservation Tillage Effects on Corn Silage Yield and Soil Quality in an Irrigated, Arid Agroecosystem. Agronomy 2019, 9, 455. [Google Scholar] [CrossRef]

- Angers, D.A. Changes in Soil Aggregation and Organic Carbon under Corn and Alfalfa. Soil Sci. Soc. Am. J. 1992, 56, 1244–1249. [Google Scholar] [CrossRef]

- Rasse, D.P.; Smucker, A.J.M.; Santos, D.; Rasse, D. Alfalfa Root and Shoot Mulching Effects on Soil Hydraulic Properties and Aggregation. Soil Sci. Soc. Am. J. 2000, 64, 725–731. [Google Scholar] [CrossRef]

- Busari, M.A.; Kukal, S.S.; Kaur, A.; Bhatt, R.; Dulazi, A.A. Conservation Tillage Impacts on Soil, Crop and the Environment. Int. Soil Water Conserv. Res. 2015, 3, 119–129. [Google Scholar] [CrossRef]

- Kabir, Z.; O’Halloran, I.; Fyles, J.; Hamel, C. Seasonal Changes of Arbuscular Mycorrhizal Fungi as Affected by Tillage Practices and Fertilization: Hyphal Density and Mycorrhizal Root Colonization. Plant Soil 1997, 192, 285–293. [Google Scholar] [CrossRef]

- Curaqueo, G.; Acevedo, E.; Cornejo, P.; Seguel, A.; Rubio, R.; Borie, F. Tillage Effect on Soil Organic Matter, Mycorrhizal Hyphae and Aggregates in a Mediterranean Agroecosystem. Rev. Cienc. Suelo Nutr. Veg. 2010, 10, 12–21. [Google Scholar] [CrossRef]

- Jansa, J.; Wiemken, A.; Frossard, E. The Effects of Agricultural Practices on Arbuscular Mycorrhizal Fungi. Geol. Soc. London Spéc. Publ. 2006, 266, 89–115. [Google Scholar] [CrossRef]

- Sharma, M.P.; Reddy, U.G.; Adholeya, A. Response of Arbuscular Mycorrhizal Fungi on Wheat (Triticum aestivum L.) Grown Conventionally and on Beds in a Sandy Loam Soil. Indian J. Microbiol. 2011, 51, 384–389. [Google Scholar] [CrossRef]

- Six, J.; Frey, S.D.; Thiet, R.K.; Batten, K.M. Bacterial and Fungal Contributions to Carbon Sequestration in Agroecosystems. Soil Sci. Soc. Am. J. 2006, 70, 555–569. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).