Techno-Economic Assessment in a Fluidized Bed Membrane Reactor for Small-Scale H2 Production: Effect of Membrane Support Thickness

Abstract

:1. Introduction

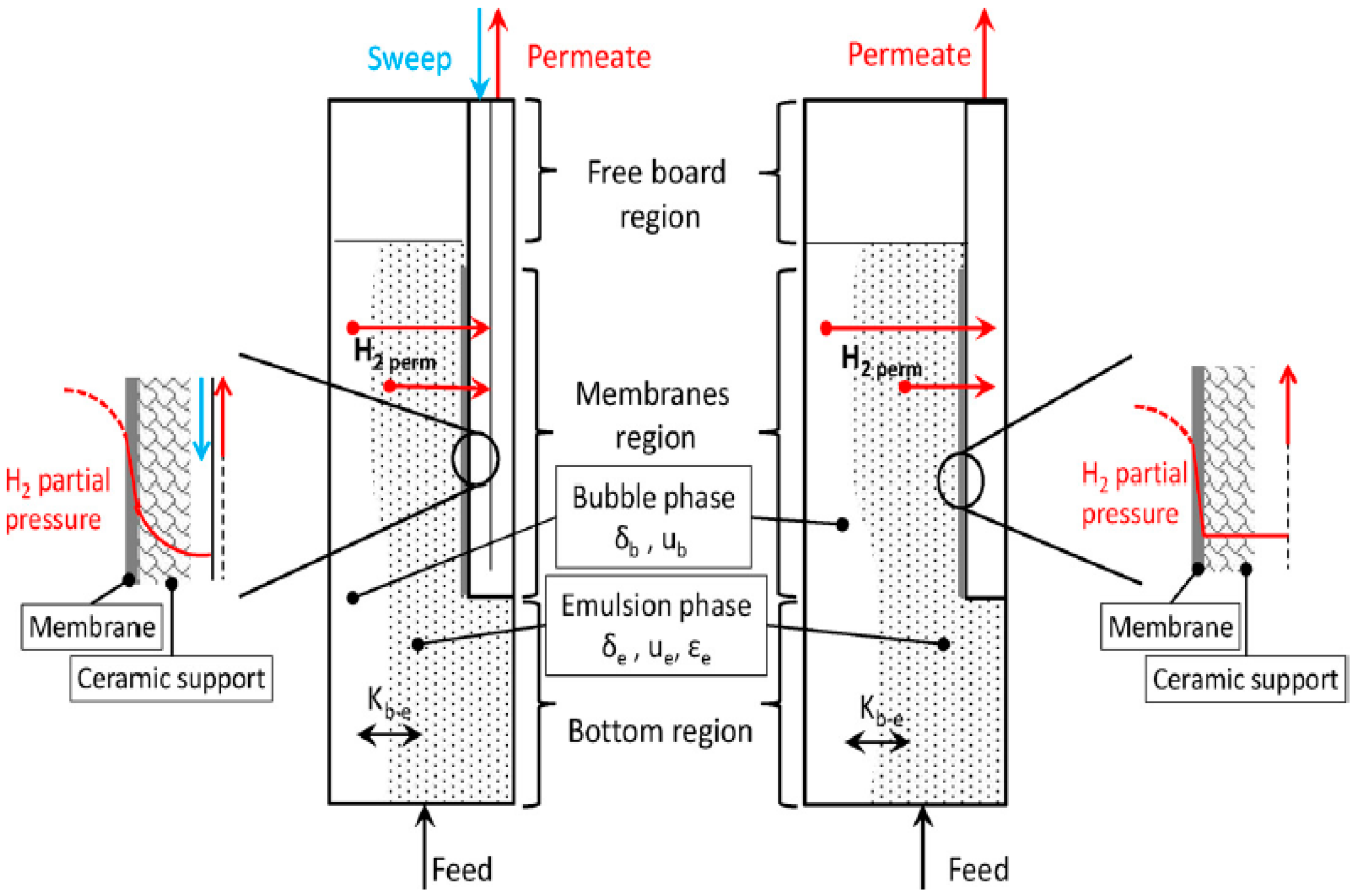

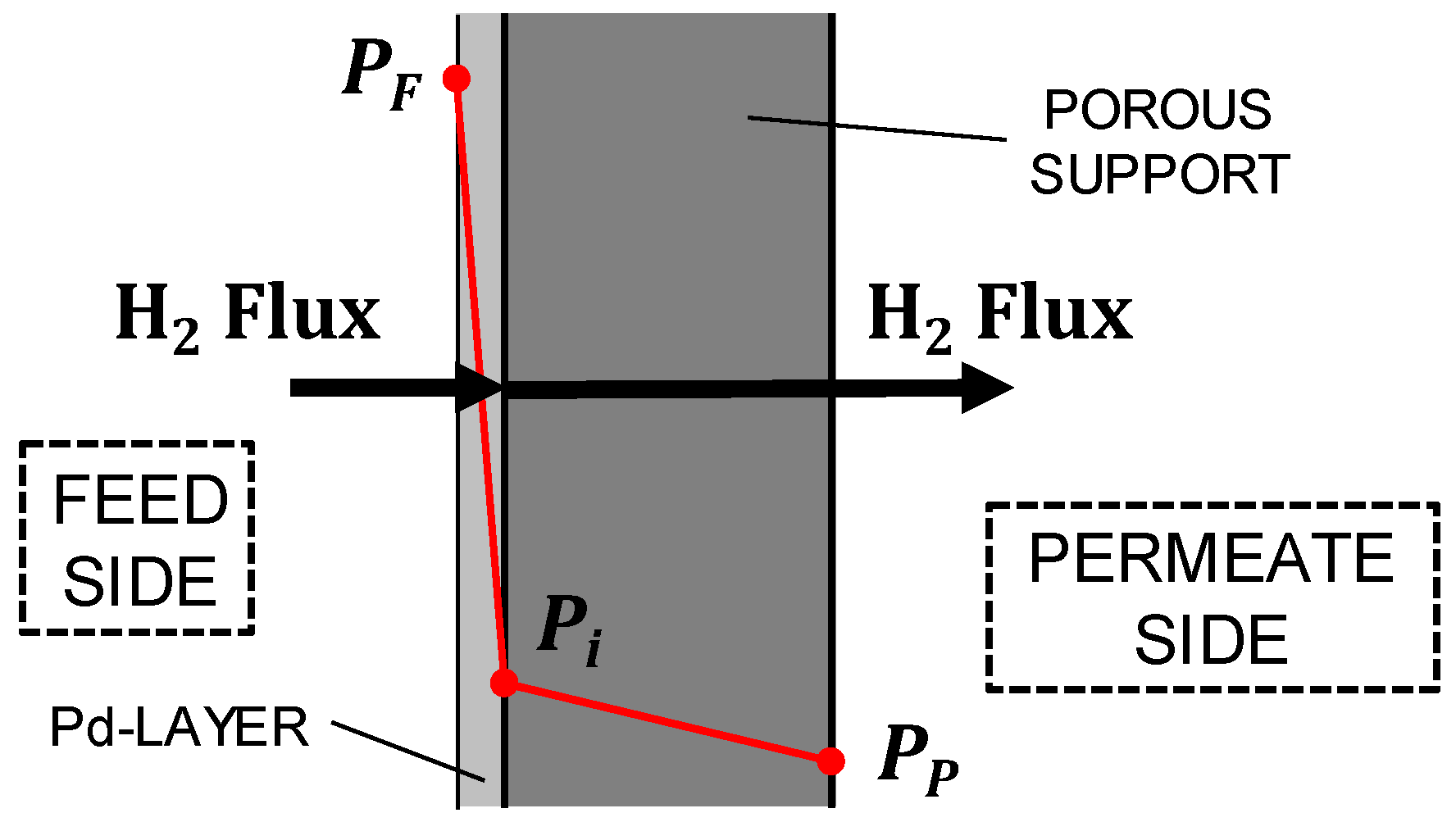

2. Materials and Methods

Modelling of Pd Membranes:

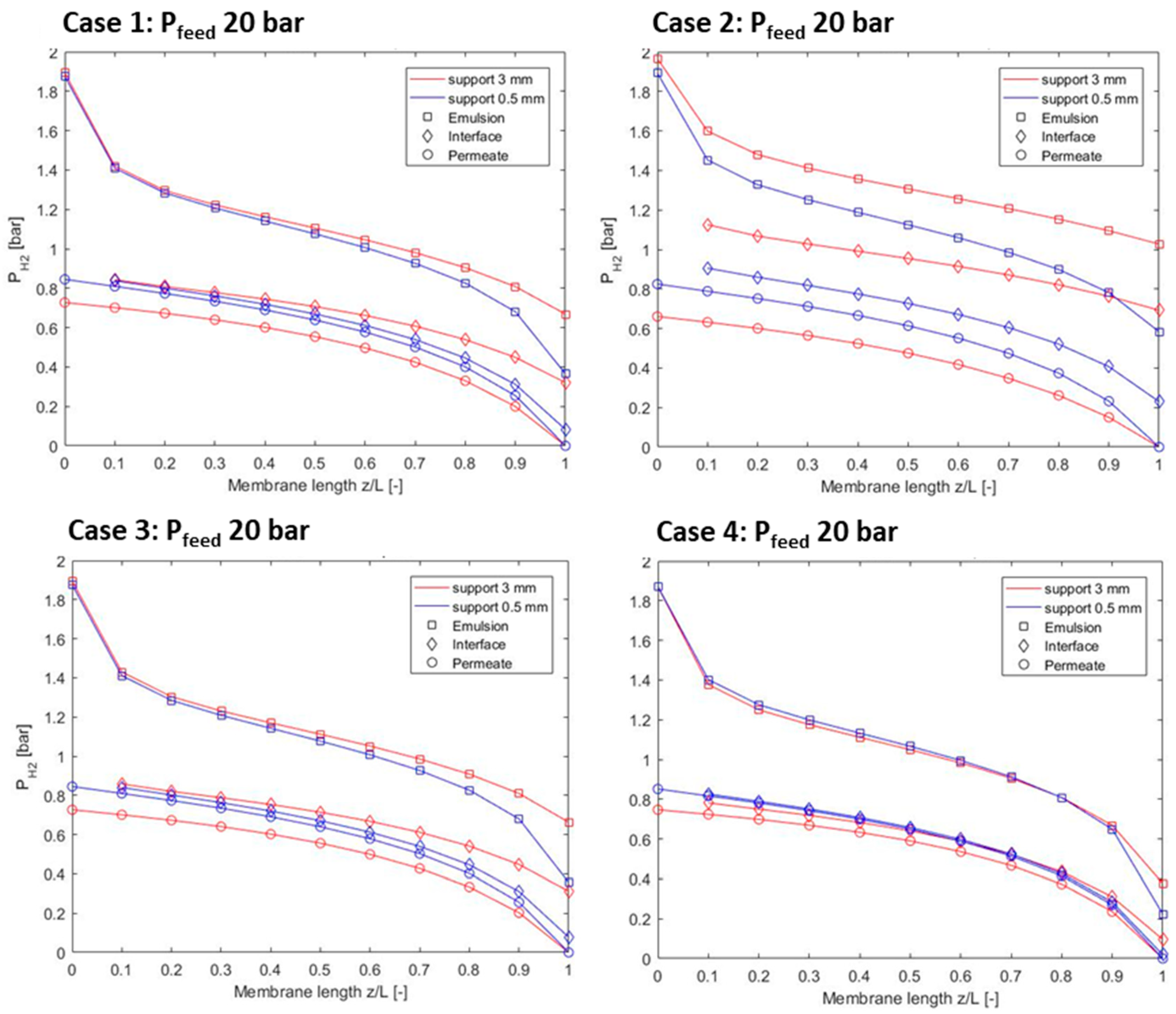

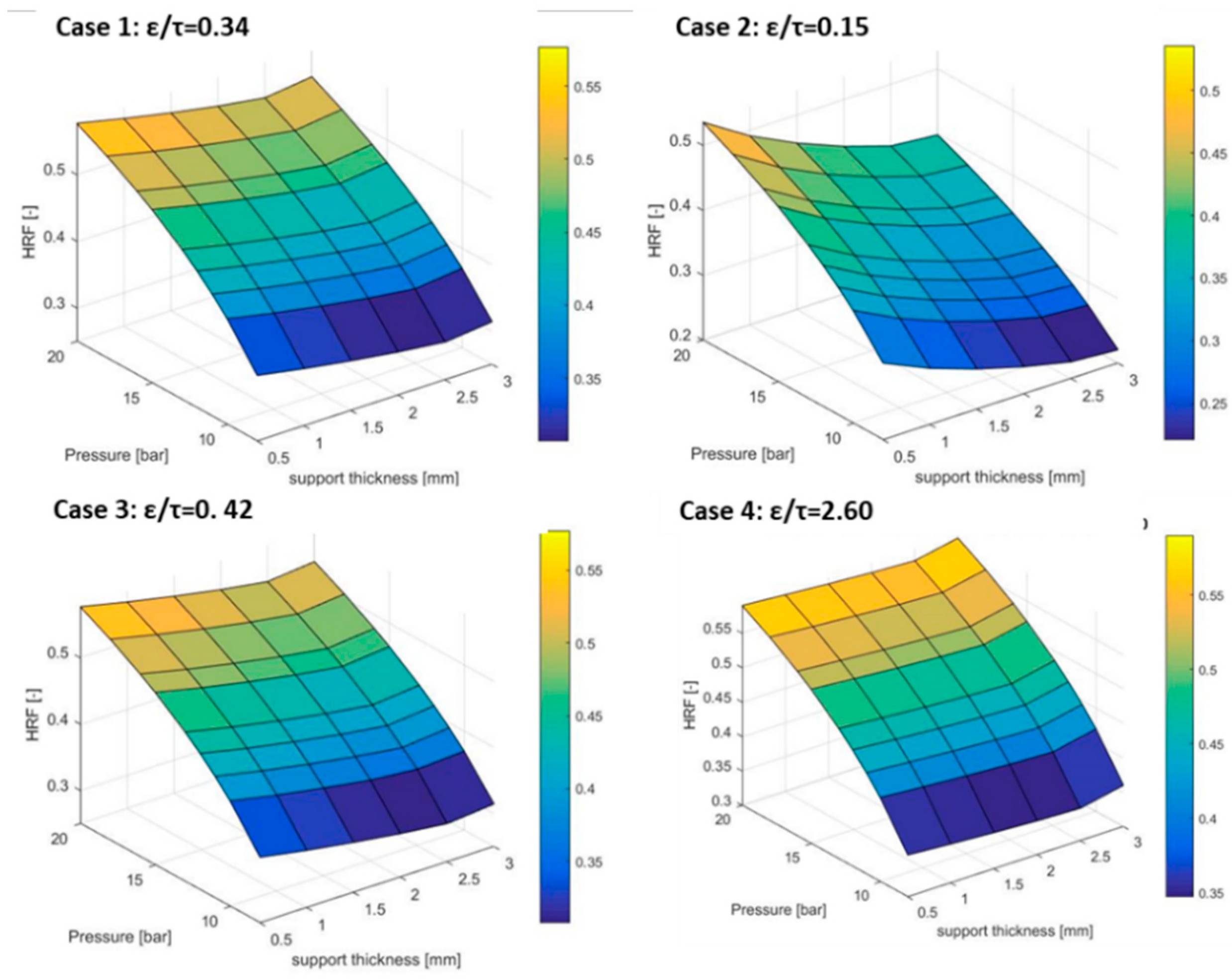

3. Results

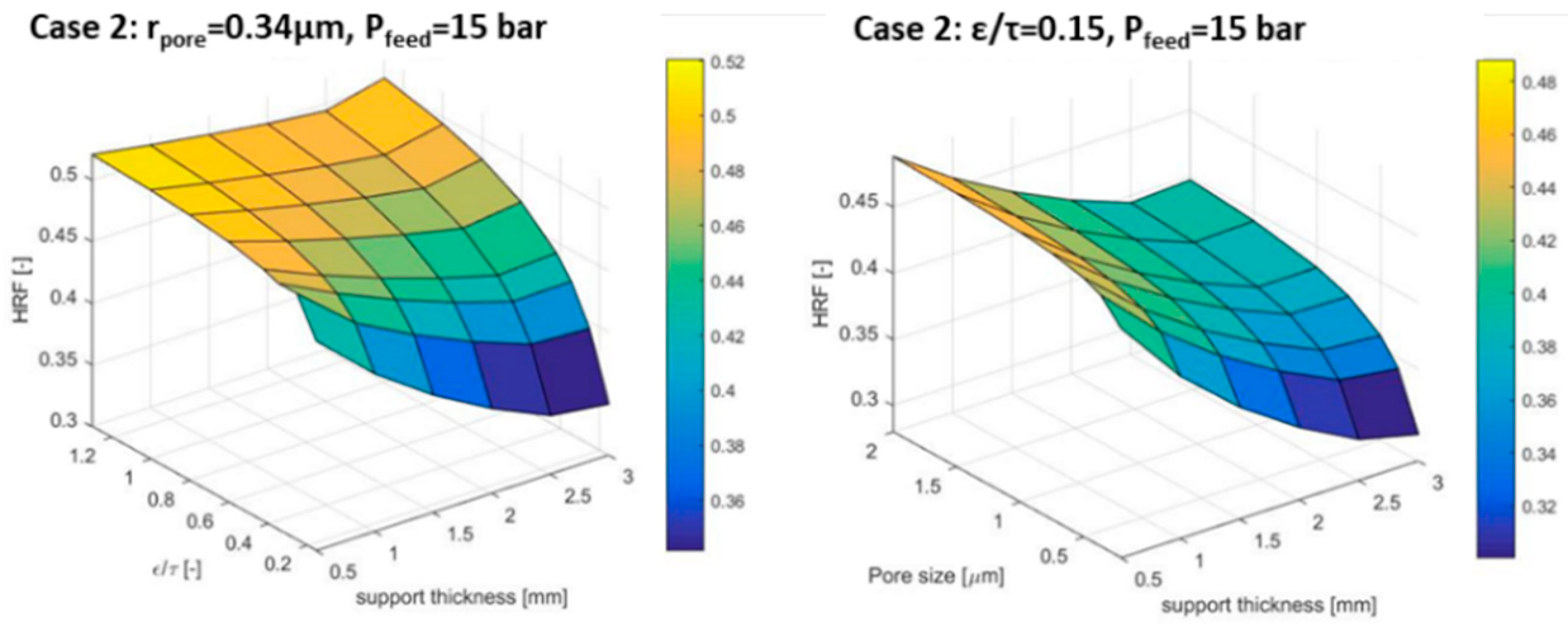

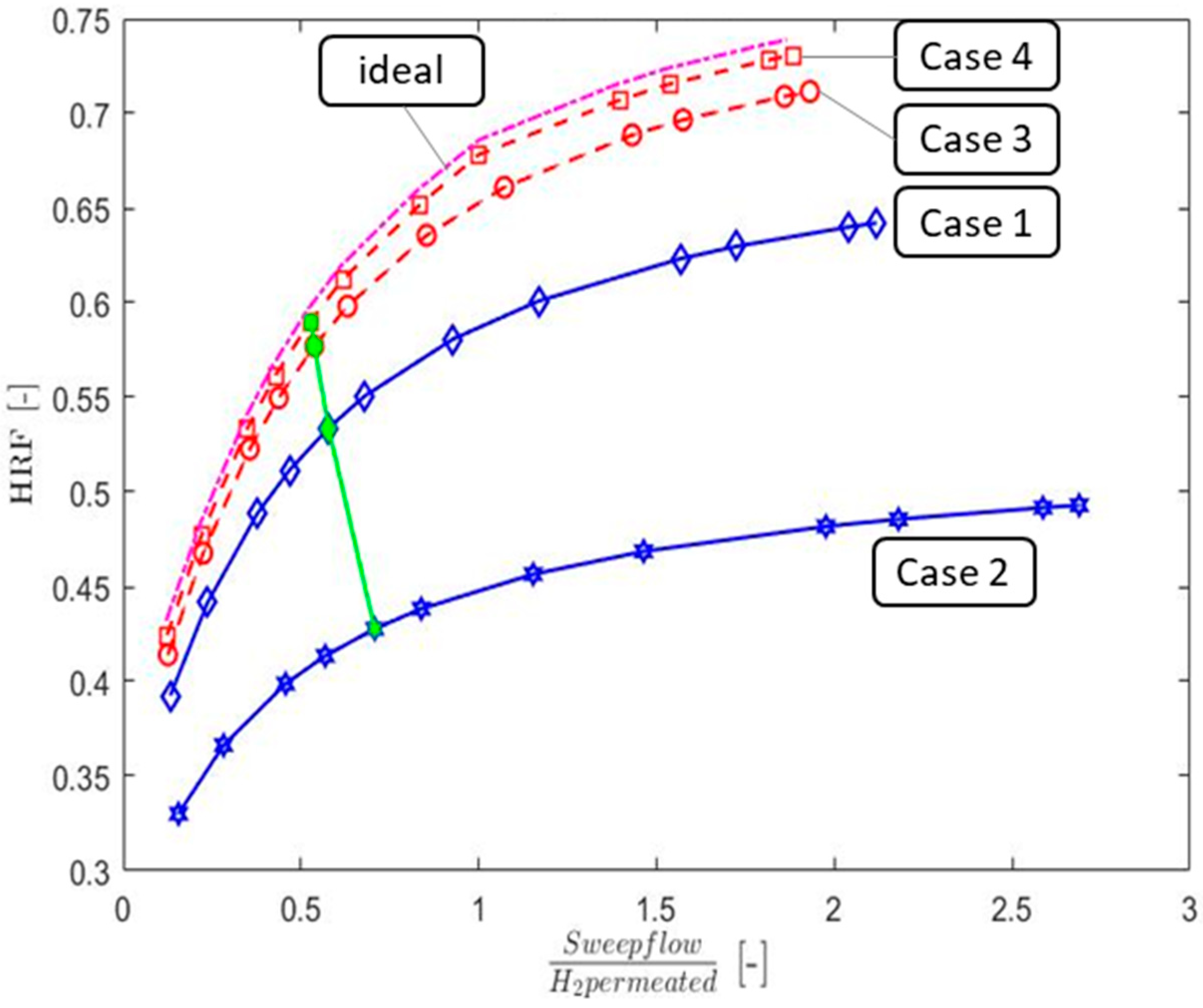

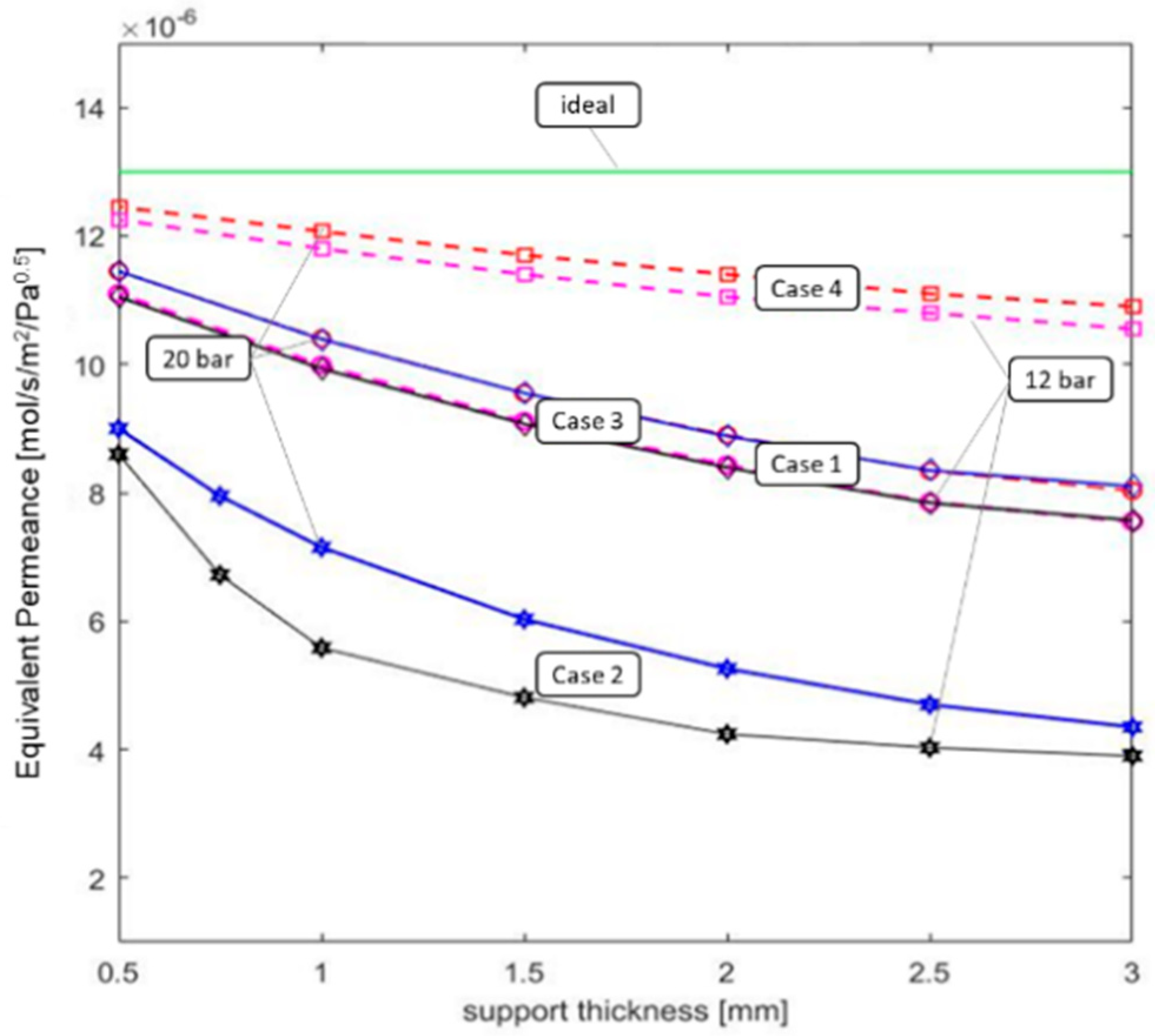

- Case 2 is the one that has the highest penalties in terms of partial pressures with thicker membranes, while Case 4 has very limited differences; Case 2 have roughly the same pore radius of Case 4, while 10 times lower ε/τ;

- Case 1 and Case 3 have pretty similar with limited impact of the support thickness on the partial pressure trend. Case 1 and Case 3 share similar ε/τ with larger pore diameters for the alumina support (Case 1);

- Case 4 shows the highest HRF thanks to the lower resistance introduced by the support, hence a lower driving force requested. Case 1 and Case 3 have almost the same HRF and trend;

- The support thickness can affect the HRF by more than 20%, ranging from 40% of Case 2 to 60% of Case 4;

- The permeate pressure is an important factor to justify the higher HRF, with 3 mm supports compared to the one for 2.5 mm supports. As the calculations are performed at constant outer diameter and sweep inlet pressure, the thicker the membrane, the lower the final permeate pressure as a consequence of the higher pressure drops in the permeate side. In the 20 bar case, the permeate pressure can go even below the atmospheric one (this is not a design condition for a real plant, but it serves for the purpose of this analysis).

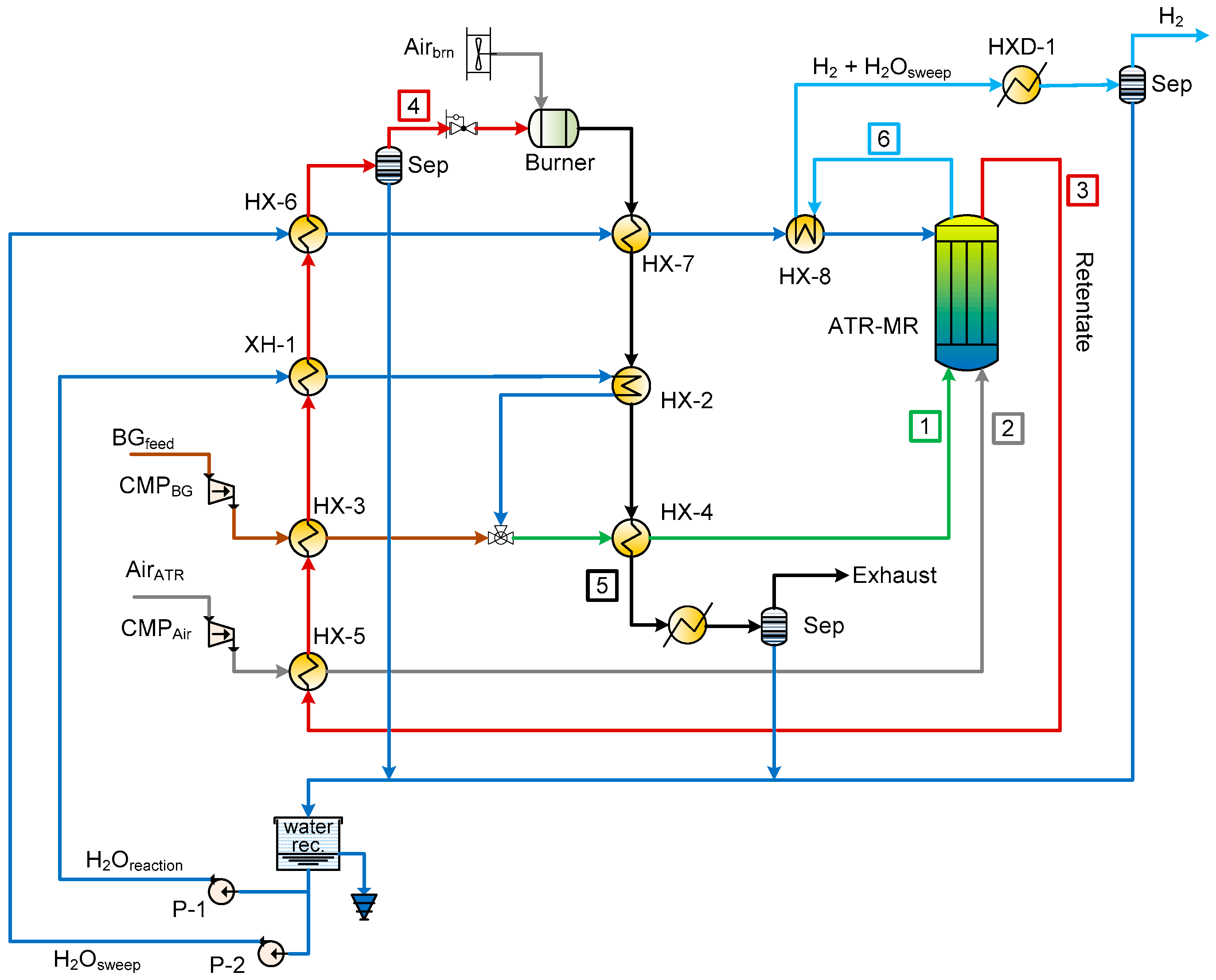

4. Case Study

5. Economic Analysis and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Amem | Membrane area, m2 |

| B | Viscous permeability |

| D | Knudsen diffusion |

| d | Diameter |

| Ea | Energy activation, kJ/mol |

| k0 | Pre exponential factor, mol/smPan |

| M | Molar mass |

| n | Exponential factor, - |

| N | Molar flux |

| Pe | Permeability, mol/sm2Pan |

| p | Pressure, bar |

| Partial pressure, bar | |

| r | radius |

| R | Universal gas constant |

| t | Support thickness [m] |

| T | Temperature, °C |

| Acronyms | |

| ACM | Aspen Custom Modeler |

| ATR | Auto-thermal reformer |

| ATR-MR | Auto-thermal membrane reformer |

| BG | Biogas |

| BSR | Biogas steam reforming |

| CAPEX | Capital expenditure |

| C&OC | Owner’s and contingencies costs |

| CCF | Capital charge factor |

| CP | Concentration polarization |

| DGM | Dusty-gas model |

| EU | Europe |

| HRF | Hydrogen recovery factor, - |

| HX | Heat exchanger |

| IC | Indirect costs, € |

| ID/OD | Inner/outer diameter, mm |

| LCOH | Levelized cost of hydrogen, €/kg |

| LF | Landfill |

| LHV | Low heating value |

| LT | Low temperature |

| NBS/NRC | National Bureau of Standards/Nuclear Regulatory Commission |

| NG | Natural gas |

| O&M | Operation and maintenance costs, € |

| OPEX | Operating expenditure |

| OX | Oxidation |

| PSS | Porous stainless steel |

| S/C | Steam to carbon molar ratio, - |

| SMR | Steam methane reforming |

| TEC | Total equipment cost, € |

| TIC | Installation costs, € |

| TPC | Total plant cost, € |

| WGS | Water gas shift |

| Subscripts | |

| F | feed |

| perm | ATR-MR permeate side |

| ret | ATR-MR retentate side |

| mem | Membrane |

| Greek letters | |

| ε | Porosity |

| τ | tortuosity |

| ηel,ref | Average electric efficiency of the power generating park, % |

Appendix A

References

- Ball, M.; Wietschel, M. The Hydrogen Economy: Opportunities and Challenges; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- IRENA. Hydrogen From Renewable Power: Technology Outlook for the Energy Transition; IRENA: Abu Dhabi, United Arab Emirates, 2018. [Google Scholar]

- Sumbramani, V.; Basile, A.; Verizoglu, N.T. Compendium of Hydrogen Energy: Hydrgoen Production and Purification; Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrogen Energy 2015, 40, 11094–11111. [Google Scholar] [CrossRef]

- Hydrogen Price Target. Available online: https://www.iea.org/hydrogen2019/ (accessed on 20 July 2019).

- Parkinson, B.; Balcombe, P.; Speirs, J.F.; Hawkes, A.D.; Hellgardt, K. Levelized cost of CO2 mitigation from hydrogen production routes. Energy Environ. Sci. 2019, 12, 19–40. [Google Scholar] [CrossRef]

- European Biogas Association. EBA Annual Report 2018; European Biogas Association: Brussels, Belgium, 2019. [Google Scholar]

- Uemiya, S.; Sato, N.; Ando, H.; Matsuda, T. Steam reforming of methane in a hydrogen-permeable membrane reactor. Appl. Catal. A Gen. 1991, 67, 223–230. [Google Scholar] [CrossRef]

- Adris, A.M.; Grace, J.R. Characteristics of Fluidized-Bed Membrane Reactors: Scale-up and Practical Issues. Ind. Eng. Chem. Res. 1997, 36, 4549–4556. [Google Scholar] [CrossRef]

- Lu, G.Q.; Diniz da Costa, J.C.; Duke, M.; Giessler, S.; Socolow, R.; Williams, R.H.; Kreutz, T. Inorganic membranes for hydrogen production and purification: A critical review and perspective. J. Colloid Interface Sci. 2007, 314, 589–603. [Google Scholar] [CrossRef] [PubMed]

- Gallucci, F.; Fernandez, E.; Corengia, P.; van Sint Annaland, M. Recent advances on membranes and membrane reactors for hydrogen production. Chem. Eng. Sci. 2013, 92, 40–66. [Google Scholar] [CrossRef]

- Tosti, S.; Basile, A.; Bettinali, L.; Borgognoni, F.; Gallucci, F.; Rizzello, C. Design and process study of Pd membrane reactors. Int. J. Hydrogen Energy 2008, 33, 5098–5105. [Google Scholar] [CrossRef]

- Roses, L.; Gallucci, F.; Manzolini, G.; Campanari, S.; van Sint Annaland, M. Comparison between fixed bed and fluidized bed membrane reactor configurations for PEM based micro-cogeneration systems. Chem. Eng. J. 2011, 171, 1415–1427. [Google Scholar] [CrossRef]

- Gallucci, F.; van Sint Annaland, M.; Kuipers, J.A.M. Autothermal reforming of methane with integrated CO2 capture in novel fluidized bed membrane reactors. Asia-Pac. J. Chem. Eng. 2009, 4, 334–344. [Google Scholar] [CrossRef]

- Deshmukh, S.A.R.K.; Volkers, S.; van Sint Annaland, M.; Kuipers, J.A.M. Heat Transfer in a Membrane Assisted Bubbling Fluidized Bed with Immersed Horizontal tubes. Int. J. Chem. React. Eng. 2005. [Google Scholar] [CrossRef]

- Foresti, S.; Di Marcoberardino, G.; Manzolini, G.; De Nooijer, N.; Gallucci, F.; van Sint Annaland, M. A comprehensive model of a fluidized bed membrane reactor for small-scale hydrogen production. Chem. Eng. Process. Process Intensif. 2018, 127, 136–144. [Google Scholar] [CrossRef]

- Fernandez, E.; Coenen, K.; Helmi, A.; Melendez, J.; Zuñiga, J.; Pacheco Tanaka, D.A.; Van Sint Annaland, M.; Gallucci, F. Preparation and characterization of thin-film Pd-Ag supported membranes for high-temperature applications. Int. J. Hydrogen Energy 2015, 40, 13463–13478. [Google Scholar] [CrossRef]

- Nordio, M.; Soresi, S.; Manzolini, G.; Melendez, J.; Van Sint Annaland, M.; Pacheco Tanaka, D.A.; Gallucci, F. Effect of sweep gas on hydrogen permeation of supported Pd membranes: Experimental and modeling. Int. J. Hydrogen Energy 2019, 44, 4228–4239. [Google Scholar] [CrossRef]

- Basile, A.; Campanari, S.; Manzolini, G.; Iulianelli, A.; Longo, T.; Liguori, S.; De Falco, M.; Piemonte, V. Methane steam reforming in a Pd-Ag membrane reformer: An experimental study on reaction pressure influence at middle temperature. Int. J. Hydrogen Energy 2011, 36, 1531–1539. [Google Scholar] [CrossRef]

- Fernandez, E.; Helmi, A.; Coenen, K.; Melendez, J.; Viviente, J.L.; Pacheco Tanaka, D.A.; van Sint Annaland, M.; Gallucci, F. Development of thin Pd–Ag supported membranes for fluidized bed membrane reactors including WGS related gases. Int. J. Hydrogen Energy 2015, 40, 3506–3519. [Google Scholar] [CrossRef]

- Di Marcoberardino, G.; Foresti, S.; Binotti, M.; Manzolini, G. Potentiality of a biogas membrane reformer for decentralized hydrogen production. Chem. Eng. Process. Process Intensif. 2018, 129, 131–141. [Google Scholar] [CrossRef]

- Pinacci, P.; Drago, F. Influence of the support on permeation of palladium composite membranes in presence of sweep gas. Catal. Today 2012, 193, 186–193. [Google Scholar] [CrossRef]

- Marcoberardino, G.D.; Gallucci, F.; Manzolini, G.; van Sint Annaland, M. Definition of validated membrane reactor model for 5 kW power output CHP system for different natural gas compositions. Int. J. Hydrogen Energy 2016, 41, 19141–19153. [Google Scholar] [CrossRef]

- Zhao, C.; Xu, H.; Goldbach, A. Duplex Pd/ceramic/Pd composite membrane for sweep gas-enhanced CO2 capture. J. Membr. Sci. 2018, 563, 388–397. [Google Scholar] [CrossRef]

- Boon, J.; Pieterse, J.A.Z.; Dijkstra, J.W.; van Sint Annaland, M. Modelling and systematic experimental investigation of mass transfer in supported palladium-based membrane separators. Int. J. Greenh. Gas Control 2012, 11, 122–129. [Google Scholar] [CrossRef]

- Li, X.; Li, A.; Lim, C.J.; Grace, J.R. Hydrogen permeation through Pd-based composite membranes: Effects of porous substrate, diffusion barrier and sweep gas. J. Membr. Sci. 2016, 499, 143–155. [Google Scholar] [CrossRef]

- Zhao, C.; Caravella, A.; Xu, H.; Brunetti, A.; Barbieri, G.; Goldbach, A. Support mass transfer resistance of Pd/ceramic composite membranes in the presence of sweep gas. J. Membr. Sci. 2018, 550, 365–376. [Google Scholar] [CrossRef]

- Zeng, G.; Goldbach, A.; Xu, H. Impact of support mass flow resistance on low-temperature H2 permeation characteristics of a Pd95Ag5/Al2O3 composite membrane. J. Membr. Sci. 2009, 326, 681–687. [Google Scholar] [CrossRef]

- Li, H.; Dijkstra, J.W.; Pieterse, J.A.Z.; Boon, J.; Van Den Brink, R.W.; Jansen, D. WGS-mixture separation and WGS reaction test in a bench-scale multi-tubular membrane reactor. Energy Procedia 2011, 4, 666–673. [Google Scholar] [CrossRef] [Green Version]

- Fernandez, E.; Helmi, A.; Medrano, J.A.; Coenen, K.; Arratibel, A.; Melendez, J.; de Nooijer, N.C.A.; Spallina, V.; Viviente, J.L.; Zuñiga, J.; et al. Palladium based membranes and membrane reactors for hydrogen production and purification: An overview of research activities at Tecnalia and TU/e. Int. J. Hydrogen Energy 2017, 42, 13763–13776. [Google Scholar] [CrossRef] [Green Version]

- Nooijer, N.; Arratibel Plazaola, A.; Meléndez Rey, J.; Fernandez, E.; Pacheco Tanaka, D.; van Sint Annaland, M.; Gallucci, F. Long-Term Stability of Thin-Film Pd-Based Supported Membranes. Processes 2019, 7, 106. [Google Scholar] [CrossRef]

- Nayebossadri, S.; Fletcher, S.; Speight, J.D.; Book, D. Hydrogen permeation through porous stainless steel for palladium-based composite porous membranes. J. Membr. Sci. 2016, 515, 22–28. [Google Scholar] [CrossRef]

- Zhu, B.; Duke, M.; Dumée, L.F.; Merenda, A.; des Ligneris, E.; Kong, L.; Hodgson, P.D.; Gray, S. Short review on porous metal membranes—Fabrication, commercial products, and applications. Membranes 2018, 8, 83. [Google Scholar] [CrossRef] [PubMed]

- Peters, T.A.; Tucho, W.M.; Ramachandran, A.; Stange, M.; Walmsley, J.C.; Holmestad, R.; Borg, A.; Bredesen, R. Thin Pd–23%Ag/stainless steel composite membranes: Long-term stability, life-time estimation and post-process characterisation. J. Membr. Sci. 2009, 326, 572–581. [Google Scholar] [CrossRef]

- Hwang, K.R.; Oh, D.K.; Lee, S.W.; Park, J.S.; Song, M.H.; Rhee, W.H. Porous stainless steel support for hydrogen separation Pd membrane; fabrication by metal injection molding and simple surface modification. Int. J. Hydrogen Energy 2017, 42, 14583–14592. [Google Scholar] [CrossRef]

- Caravella, A. Dusty-Gas Model (DGM). In Encyclopedia of Membranes; Springer: Berlin, Germany, 2016. [Google Scholar]

- Gallucci, F.; Van Sint Annaland, M.; Kuipers, J.A.M. Pure hydrogen production via autothermal reforming of ethanol in a fluidized bed membrane reactor: A simulation study. Int. J. Hydrogen Energy 2010, 35, 1659–1668. [Google Scholar] [CrossRef]

- Trimm, D.L.; Lam, C.-W. The Combustion of Methane on Platinum-Alumina Fibre Catalysts-1. Chem. Eng. Sci. 1979, 35, 1405–1413. [Google Scholar] [CrossRef]

- Numaguchi, T.; Kikuchi, K. Intrinsic Kinetics and Design Simulation in a Complex Reaction Network; Steam-Methane Reforming. Chem. Eng. Sci. 1988, 43, 2295–2301. [Google Scholar] [CrossRef]

- Nam, S.E.; Lee, K.H. Hydrogen separation by Pd alloy composite membranes: Introduction of diffusion barrier. J. Membr. Sci. 2001, 192, 177–185. [Google Scholar] [CrossRef]

- Peters, T.A.; Stange, M.; Klette, H.; Bredesen, R. High pressure performance of thin Pd-23%Ag/stainless steel composite membranes in water gas shift gas mixtures; influence of dilution, mass transfer and surface effects on the hydrogen flux. J. Membr. Sci. 2008, 316, 119–127. [Google Scholar] [CrossRef]

- Rothenberger, K.S.; Cugini, A.V.; Howard, B.H.; Killmeyer, R.P.; Ciocco, M.; Morreale, B.; Enick, R.; Bustamante, F.; Mardilovich, I.; Ma, Y. High pressure hydrogen permeance of porous stainless steel coated with a thin palladium film via electroless plating. J. Membr. Sci. 2004, 244, 55–68. [Google Scholar] [CrossRef]

- Mardilovich, P.P.; She, Y.; Ma, Y.H.; Rei, M.-H. Defect-free palladium membranes on porous stainless-steel support. AIChE J. 1998, 44, 310–322. [Google Scholar] [CrossRef]

- Huang, Y.; Dittmeyer, R. Preparation of thin palladium membranes on a porous support with rough surface. J. Membr. Sci. 2007, 302, 160–170. [Google Scholar] [CrossRef]

- Veldsink, J.W.; van Damme, R.M.J.; Versteeg, G.F.; van Swaaij, W.P.M. The use of the dusty-gas model for description of mass transport with chemical reaction in porous media. Chem. Eng. J. 1995, 115–125. [Google Scholar] [CrossRef]

- Nooijer, N.D.; Gallucci, F.; Pellizzari, E.; Melendez, J.; Tanaka, D.A.P.; Manzolini, G.; van Sint Annaland, M. On concentration polarisation in a fluidized bed membrane reactor for biogas steam reforming: Modelling and experimental validation. Chem. Eng. J. 2018, 348, 232–243. [Google Scholar] [CrossRef]

- AspenTech Aspen Plus. Available online: https://www.aspentech.com/en/products/engineering/aspen-plus (accessed on 20 July 2019).

- Di Marcoberardino, G.; Vitali, D.; Spinelli, F.; Binotti, M.; Manzolini, G. Green Hydrogen Production from Raw Biogas: A Techno-Economic Investigation of Conventional Processes Using Pressure Swing Adsorption Unit. Processes 2018, 6, 19. [Google Scholar] [CrossRef]

- Peng, D.Y.; Robinson, D.B. New Two-Constant Equation of State. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Rackett, H.G. Equation of state for saturated liquids. J. Chem. Eng. Data 1970, 15, 514–517. [Google Scholar] [CrossRef]

- Haar, L.; Gallagher, J.; Kell, G.S. NBS/NRC Steam Tables: Thermodynamic and Transport Properties and Computer Programs for Vapor and Liquid States of Water in S.I. Units; Hemisphere Publishing Corporation: Washington, DC, USA, 1984. [Google Scholar]

- Tecnalia FERRET WP3—Public Report on Production Costs and Scale Up of the Membrane Production, 2017.

- Manzolini, G.; Sanchez Fernandez, E.; Rezvani, S.; Macchi, E.; Goetheer, E.L.V.; Vlugt, T.J.H. Economic assessment of novel amine based CO2 capture technologies integrated in power plants based on European Benchmarking Task Force methodology. Appl. Energy 2015, 138, 546–558. [Google Scholar] [CrossRef]

- Di Marcoberardino, G.; Liao, X.; Dauriat, A.; Binotti, M.; Manzolini, G. Life Cycle Assessment and Economic Analysis of an Innovative Biogas Membrane Reformer for Hydrogen Production. Processes 2019, 7, 86. [Google Scholar] [CrossRef]

- Jenkins, S. Chemical Engineering Plant Cost INdex: 2018 Annual Value. Available online: https://www.chemengonline.com/2019-cepci-updates-january-prelim-and-december-2018-final/ (accessed on 20 July 2019).

- Spallina, V.; Pandolfo, D.; Battistella, A.; Romano, M.C.; Van Sint Annaland, M.; Gallucci, F. Techno-economic assessment of membrane assisted fluidized bed reactors for pure H2 production with CO2 capture. Energy Convers. Manag. 2016, 120, 257–273. [Google Scholar] [CrossRef]

| Support Material | Advantages | Disadvantages |

|---|---|---|

| Ceramic supports |

|

|

| Metallic supports |

|

|

| Pore Size | Porosity/Tortuosity | Support Geometry | Surface Area | Manufacturer | Reference |

|---|---|---|---|---|---|

| 0.5 μm | - | Thickness 1 mm | 7.07 cm2 | Mott metallurgical corporation | [40] |

| 2 μm | - | Thickness 0.48 mm | 6.8 cm2 | AccuSep PALL corporation USA | [41] |

| 0.2 μm | ε = 20–23% | OD 6.4 mm ID 3.2 mm | 9 cm2 | Mott Metallurgical Corporation | [42] |

| 3 μm | ε = 17% | OD 15.9 and 12.7 mm Thickness 1.6 mm | - | Mott Metallurgical Corporation | [43] |

| 0.5 μm 1–2 μm | - | OD 10 mmID 6 mm | - | GKN Sinter Metal Filters GmbH Radevormwald | [44] |

| 0.45 μm | ε/τ = 1.12 | OD 21 mm Thickness 1 mm | - | Mott Metallurgical Corporation | [32] |

| 0.30 μm | ε/τ = 2.89 | ||||

| 0.87 μm | ε/τ = 0.42 | ||||

| 0.24 μm | ε/τ = 2.60 |

| Pore Size | Porosity | Tortuosity | Thickness | Surface Area | Manufacturer | Reference |

|---|---|---|---|---|---|---|

| 0.16 μm | ε = 35% | τ = 1.25 | 14 mm OD 10 mm ID | 21 cm2 | Provided by ECN | [27] |

| 0.16 μm | ε = 35% | τ = 1.25 | 14 mm OD 10 mm ID | 21 cm2 | Provided by ECN | [27] |

| 3.4 μm | ε = 43% | τ = 1.25 | 14 mm OD 10 mm ID | 21 cm2 | Provided by ECN | [27] |

| 0.36 μm | ε/τ = 0.15 | 1.5 mm | 29/36.4 cm2 | - | [16] | |

| Feed Stream Conditions | Value | Membrane Characteristics | Value |

|---|---|---|---|

| Natural gas feed (kmol/h) | 0.055 | Membrane thickness (μm) | 5 |

| Steam feed (kmol/h) | 0.165 | Permeance (kmol s−1 m−2 Pa−n) | 1.3 × 10−5 |

| Air feed (kmol/h) | 0.062 | Ea (J/mol) | 10,171 |

| Sweep gas (kmol/h) | 0.058 | n | 0.5 |

| Temperature (°C) | 400 | Membrane length (m) | 0.4 |

| Pressure (bar) | 8–20 | Outer diameter support (mm) | 10 |

| S/C ratio | 3 | Inner diameter support range (mm) | 4–9 |

| Membrane area (m2) | 0.14 | ||

| Reactor conditions | |||

| Temperature (°C) | 500 | ||

| Pressure (vessel/permeate side) (bar) | 8–20/1.3 |

| Cases | Support Type | OD [mm] | ID Range [mm] | ε/τ | rp [μm] |

|---|---|---|---|---|---|

| Case 1 [27] | α-Al2O3 | 10 | 4–9 | 0.344 | 3.4 |

| Case 2 [16] | α-Al2O3 | 10 | 4–9 | 0.15 | 0.34 |

| Case 3 [32] | 316 L | 10 | 4–9 | 0.42 | 0.87 |

| Case 4 [32] | 316 L | 10 | 4–9 | 2.6 | 0.24 |

| Stream | Flow | T (°C) | p (bar) | Composition (% Molar Basis) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Molar (mol/s) | Mass (g/s) | CH4 | H2 | CO | CO2 | H2O | O2 | N2 | |||

| 1 | 1.16 | 27.35 | 535 | 20 | 24.9 | - | - | 19.2 | 45.4 | 1.5 | 9.0 |

| 2 | 0.32 | 9.32 | 520 | 20 | - | - | - | - | - | 21 | 79 |

| 3 | 1.24 | 35.51 | 550 | 20 | 6.4 | 5.4 | 2.0 | 32.9 | 24.3 | - | 29.1 |

| 4 | 0.9 | 28.29 | 30.1 | 20 | 8.6 | 7.4 | 2.7 | 41.1 | 0.2 | - | 39.9 |

| 5 | 2.32 | 70.76 | 335 | 1.1 | - | - | - | 20.2 | 9.6 | 4.7 | 65.5 |

| 6 | 1.15 | 11.56 | 550 | 1.1 | - | 50.0 | - | - | 50.0 | - | - |

| Parameters | Case 1: (rpore = 3.4 μm) ε/τ = 0.344 | Case 2: (rpore = 0.36 μm) ε/τ = 0.15 | Case 3: (rpore = 0.87 μm) ε/τ = 0.42 | Case 4: (rpore = 0.24 μm) ε/τ = 2.60 |

|---|---|---|---|---|

| Thickness (mm) | 2 | 2 | 0.5 | 0.5 |

| Nmem (–) | 267 | 438 | 223 | 203 |

| Amem (m2) | 3.36 | 5.50 | 2.80 | 2.55 |

| Vvessel (m3) | 0.25 | 0.41 | 0.22 | 0.20 |

| mcat (kg) | 165 | 175 | 135 | 120 |

| HRF (%) | 62.40 | 62.80 | 62.40 | 62.50 |

| Plant Component | Cost (M €) |

| Compressor | A |

| Heat exchanger | B |

| Reactor | C |

| Bare erected cost (BEC) | A + B + C |

| Direct costs as percentage of BEC Includes piping/valves, civil works, instrumentation, steel structure, erections, etc. | |

| Total installation cost (TIC) | 80% BEC |

| Total direct plant cost (TDPC) | BEC + TIC |

| Indirect costs (IC) | 14% TDPC |

| Engineering procurement and construction (EPC) | TDPC + IC |

| Contingencies and owner’s costs (C&OC) | |

| Contingency | 5% EPC |

| Owner’s cost | 10% EPC |

| Total C&OC | 15% EPC |

| Total plant cost (TPC) | EPC + C&OC |

| Components | Amount | Scaling Parameter | S0 | C0 (k€) | f | Year Cost | CEPCI |

|---|---|---|---|---|---|---|---|

| Reactor | 1 | Weight (lb) | 130,000 | 70.32 | 0.3 | 2007 | 525.4 |

| Heat Exchanger | 8 | Exchange area (m2) | 2 | 15.5 | 0.59 | 2007 | 525.4 |

| Biogas compressor | 1 | Power (kW) | 5 | 3.3 | 0.82 | 2006 | 499.6 |

| Air compressor | 1 | Power (MW) | 0.68 | 3.42 | 0.67 | 2009 | 521.9 |

| Water demineralizer | 1 | Water flow rate (lH2O/h) | 90 | 2.1 | 0.68 | 2011 | 585.7 |

| Water pump | 2 | Water flow rate (lH2O/h) | 90 | 1.2 | 0.7 | 2011 | 585.7 |

| O&M—Fixed | |

| Labor costs | 60,000 € |

| Maintenance costs | 2.5% TOC |

| Insurance | 2.0% TOC |

| O&M—Variable | |

| Catalyst cost | 258 €/kg/y |

| Filler particles | 12 €/kg/y |

| Membrane replacement ceramic | 360 €/m2/y |

| Membrane replacement SS | 2040 €/m2/y |

| Deionization Resin | 90 €/y |

| Lifetime | 5 Years |

| Process water | 0.35 €/m3 |

| Biogas cost | 1.50 €/GJLHV |

| Electricity cost | 0.12 €/kWh |

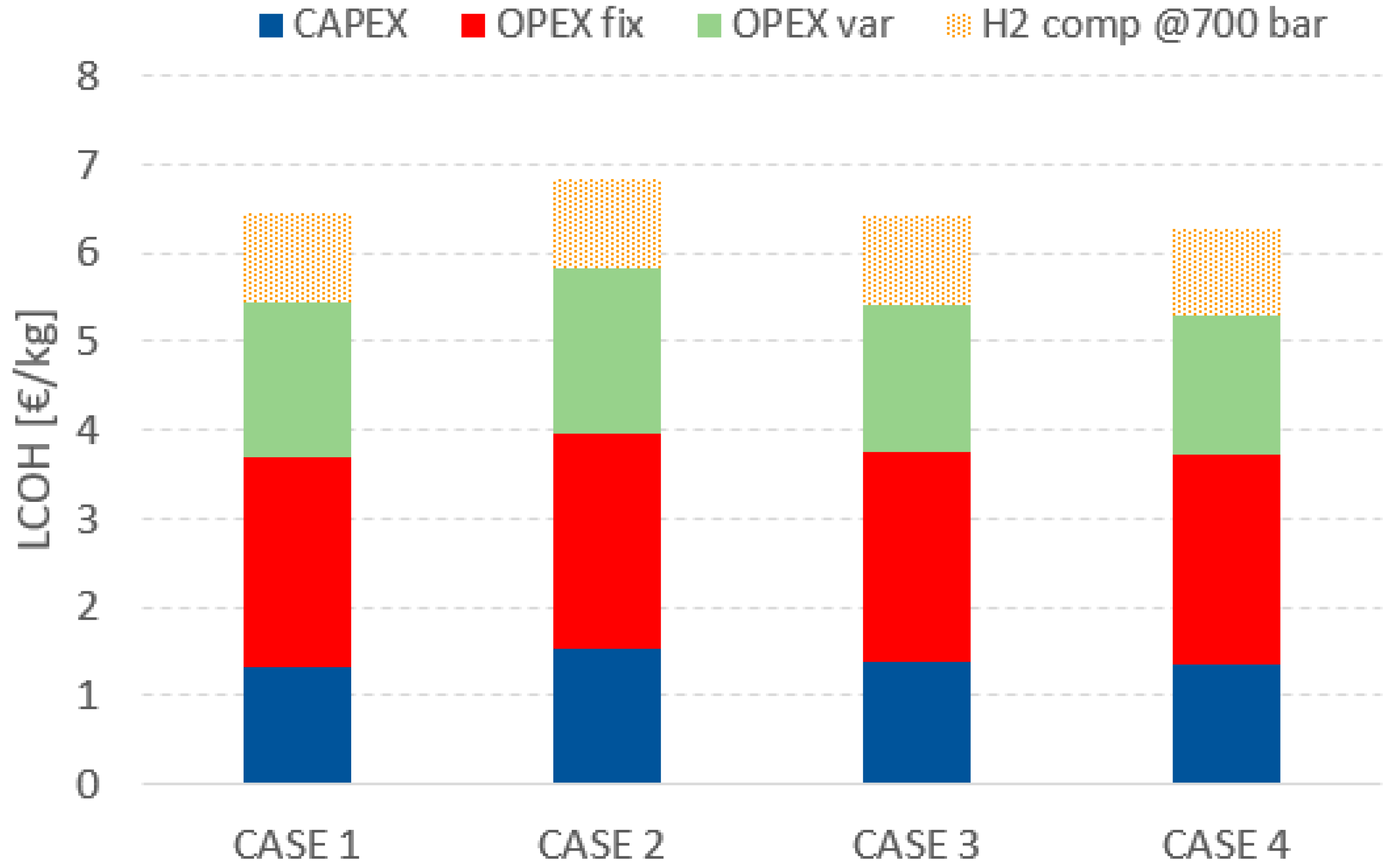

| Components | Ceramic | Stainless Steel | ||

|---|---|---|---|---|

| Case 1: (rpore = 3.4 μm) ε/τ = 0.34 | Case 2: (rpore = 0.36 μm) ε/τ = 0.15 | Case 3: (rpore = 0.87 μm) ε/τ = 0.42 | Case 4: (rpore = 0.24 μm) ε/τ = 2.60 | |

| CAPEX | ||||

| Reactor cost (k€) | 29.5 | 34.2 | 28.4 | 27.6 |

| Membranes (k€) | 22.8 | 37.4 | 28.6 | 26.0 |

| Heat exchangers (k€) | 73.9 | 73.9 | 73.9 | 73.9 |

| Biogas compressors (k€) | 3.9 | 3.9 | 3.9 | 3.9 |

| Balance of plant (k€) | 0.3 | 0.3 | 0.3 | 0.3 |

| H2 compr @20 bar (k€) | 4.4 | 4.4 | 4.4 | 4.4 |

| TPC @20 bar (k€) | 318.2 | 363.7 | 329.0 | 321.1 |

| H2 compr @700 bar (k€) | 22.1 | 22.1 | 22.1 | 22.1 |

| TPC @700 bar (k€) | 370.3 | 415.8 | 381.2 | 373.3 |

| OPEX | ||||

| Catalyst + filler | 22.2 | 23.6 | 18.2 | 16.2 |

| Biogas | 9.1 | 9.1 | 9.1 | 9.1 |

| Water cost | 0.2 | 0.2 | 0.2 | 0.2 |

| Electricity @20 bar | 18.5 | 18.5 | 18.5 | 18.5 |

| Membranes | 4.6 | 7.5 | 5.7 | 5.2 |

| Deionization resin | 0.45 | 0.45 | 0.45 | 0.45 |

| O&Mvar. total @ 20 bar | 55.0 | 59.3 | 52.1 | 49.6 |

| Electric energy @ 700 bar | 21.6 | 21.6 | 21.6 | 21.6 |

| O&Mvar. total @ 700 bar | 76.7 | 81.0 | 73.8 | 71.3 |

| O&Mfix @ 20 bar | 74.32 | 76.36 | 74.81 | 74.45 |

| O&Mfix @ 700 bar | 76.66 | 78.71 | 77.15 | 76.80 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Marcoberardino, G.; Knijff, J.; Binotti, M.; Gallucci, F.; Manzolini, G. Techno-Economic Assessment in a Fluidized Bed Membrane Reactor for Small-Scale H2 Production: Effect of Membrane Support Thickness. Membranes 2019, 9, 116. https://doi.org/10.3390/membranes9090116

Di Marcoberardino G, Knijff J, Binotti M, Gallucci F, Manzolini G. Techno-Economic Assessment in a Fluidized Bed Membrane Reactor for Small-Scale H2 Production: Effect of Membrane Support Thickness. Membranes. 2019; 9(9):116. https://doi.org/10.3390/membranes9090116

Chicago/Turabian StyleDi Marcoberardino, Gioele, Jasper Knijff, Marco Binotti, Fausto Gallucci, and Giampaolo Manzolini. 2019. "Techno-Economic Assessment in a Fluidized Bed Membrane Reactor for Small-Scale H2 Production: Effect of Membrane Support Thickness" Membranes 9, no. 9: 116. https://doi.org/10.3390/membranes9090116

APA StyleDi Marcoberardino, G., Knijff, J., Binotti, M., Gallucci, F., & Manzolini, G. (2019). Techno-Economic Assessment in a Fluidized Bed Membrane Reactor for Small-Scale H2 Production: Effect of Membrane Support Thickness. Membranes, 9(9), 116. https://doi.org/10.3390/membranes9090116