Effects of Operating Parameters on Ionic Liquid Membrane to Remove Humidity in a Green Continuous Process

Abstract

1. Introduction

2. Materials and Methods

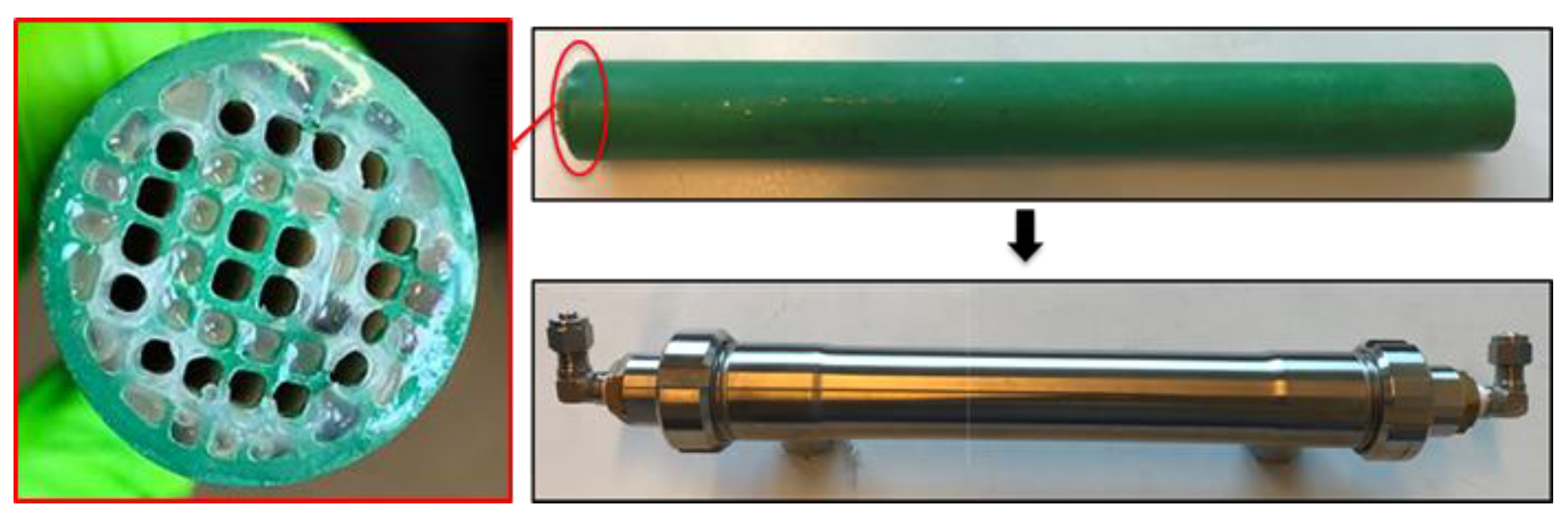

2.1. Ionic Liquid Membrane (ILM)

2.2. Ionic Liquids (ILs)

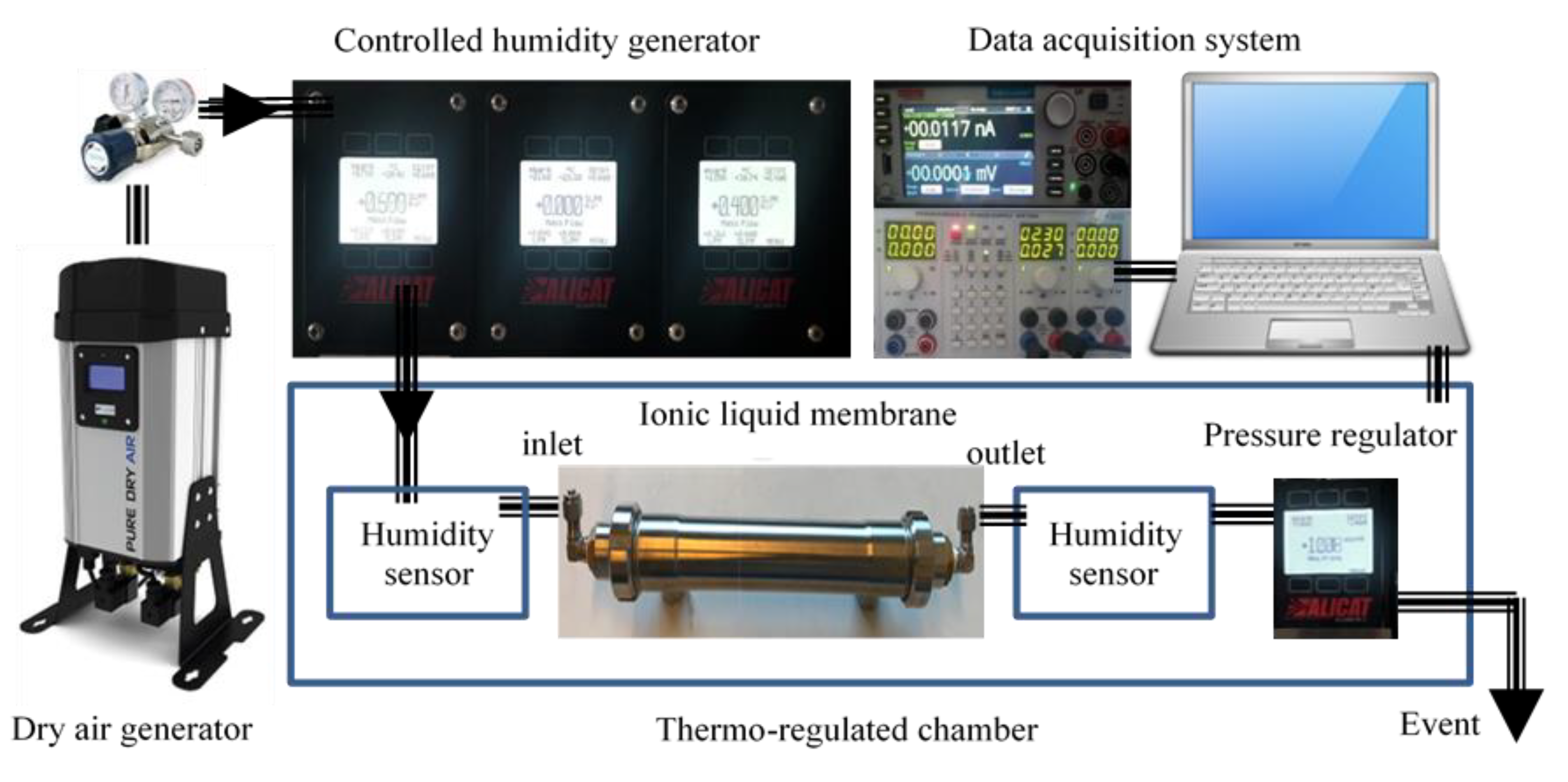

2.3. Experimental Set-Up

2.4. Analysis of the Results

3. Results and Discussion

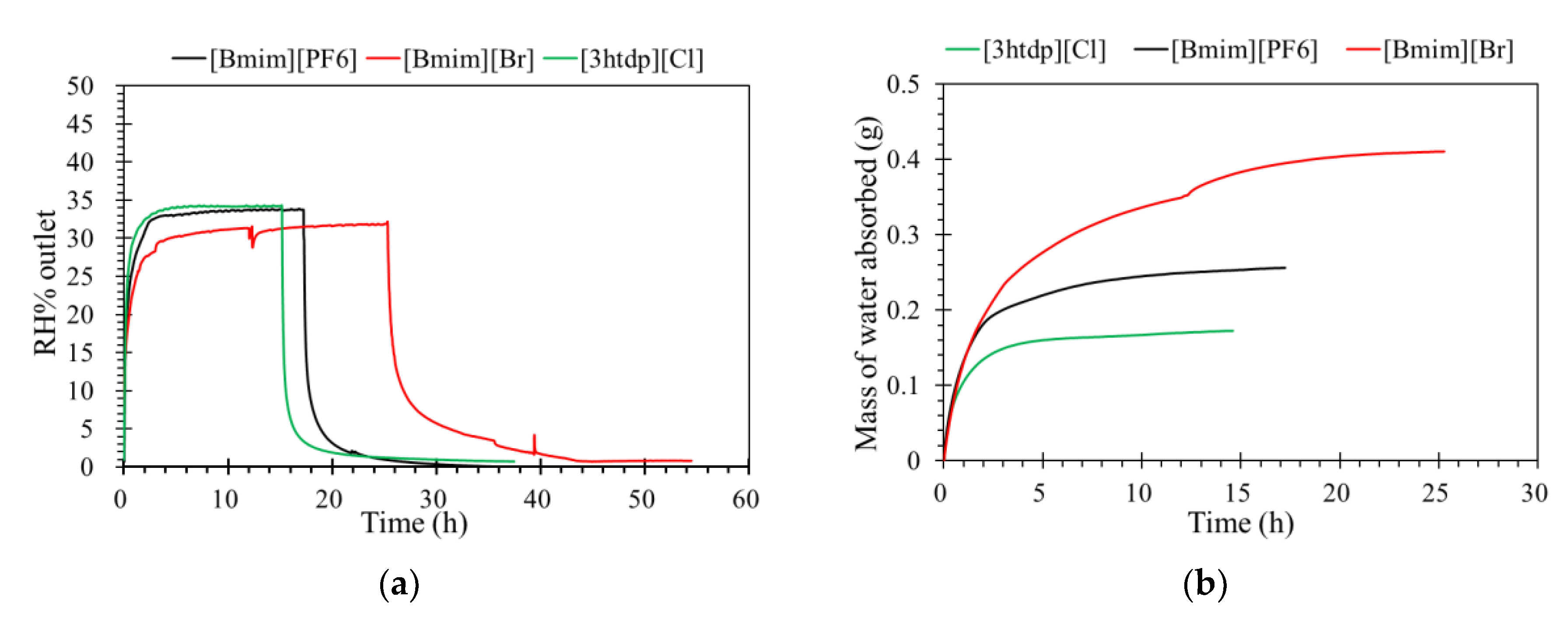

3.1. Selection of Ionic Liquids

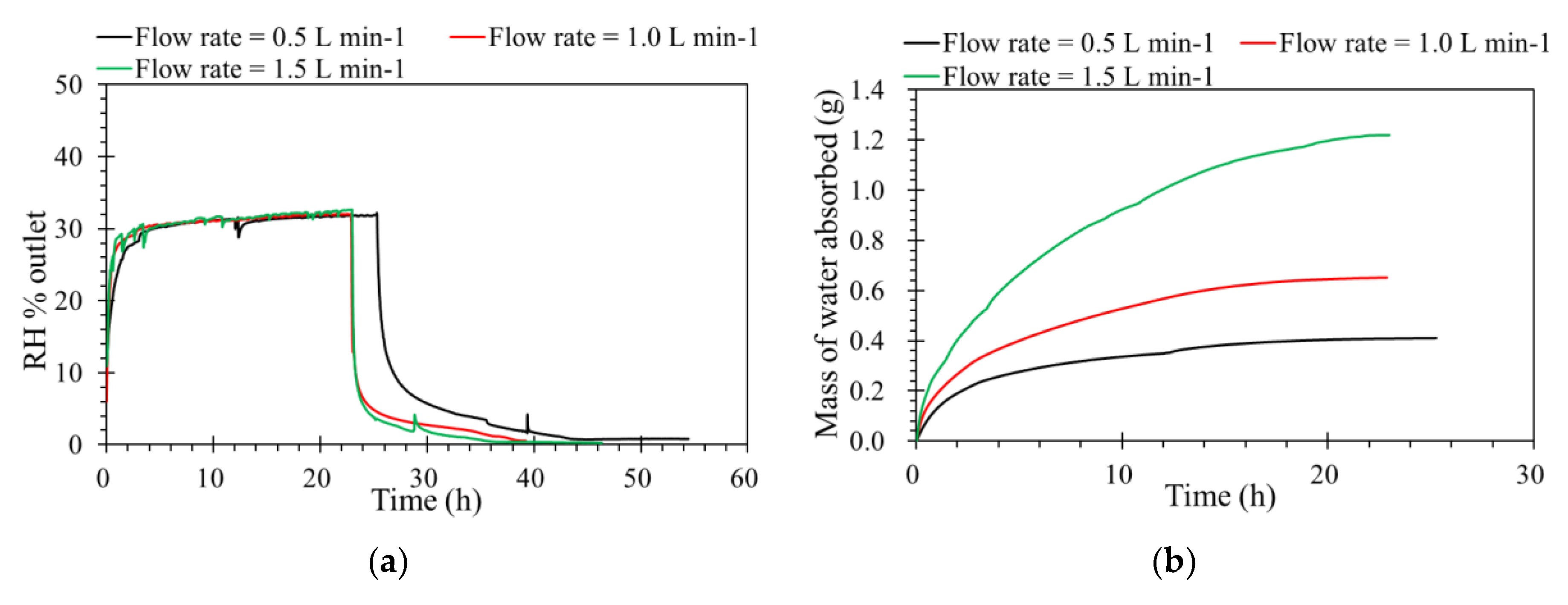

3.2. Inlet Flow Rates

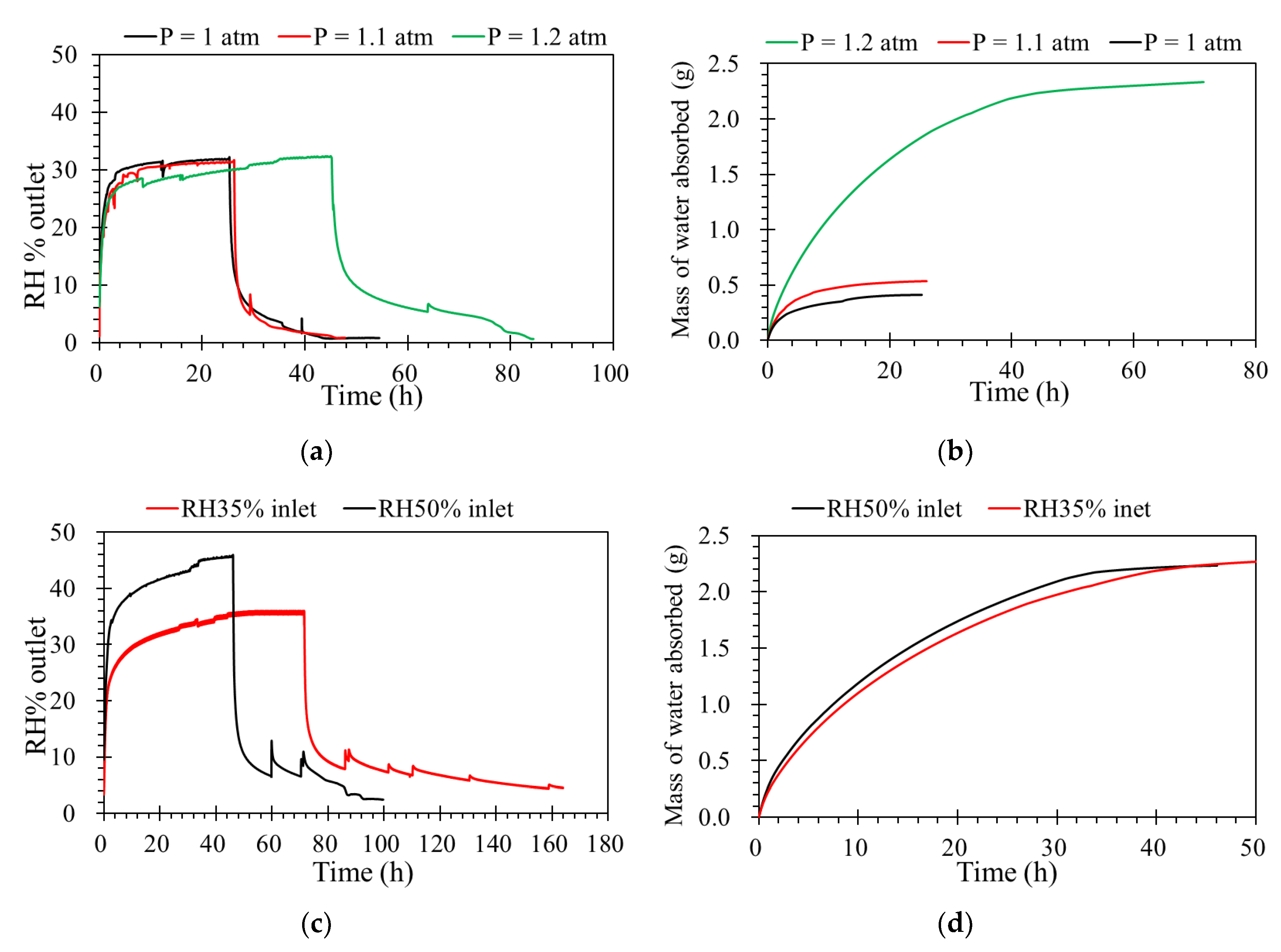

3.3. Pressures and Relative Humidity

3.4. Temperature

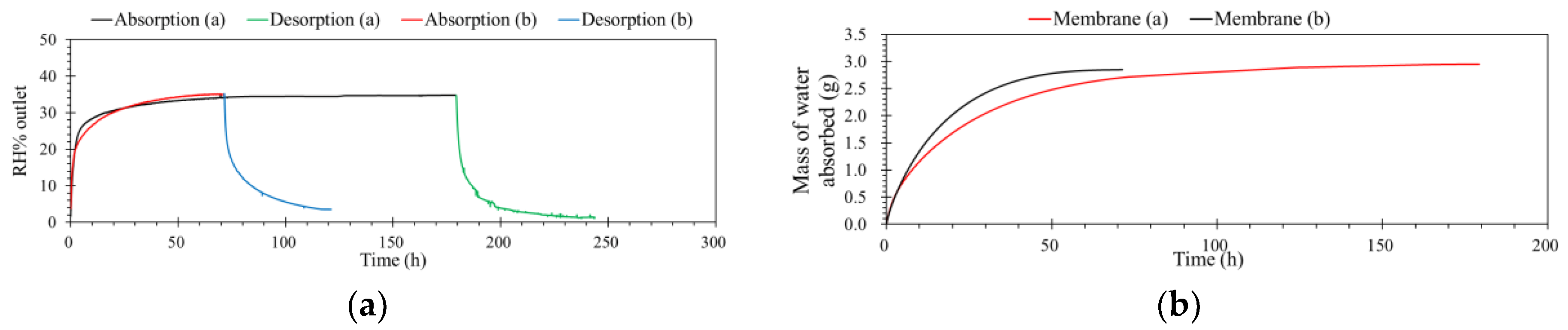

3.5. Comparison of ILM Performance with Different Operating Conditions

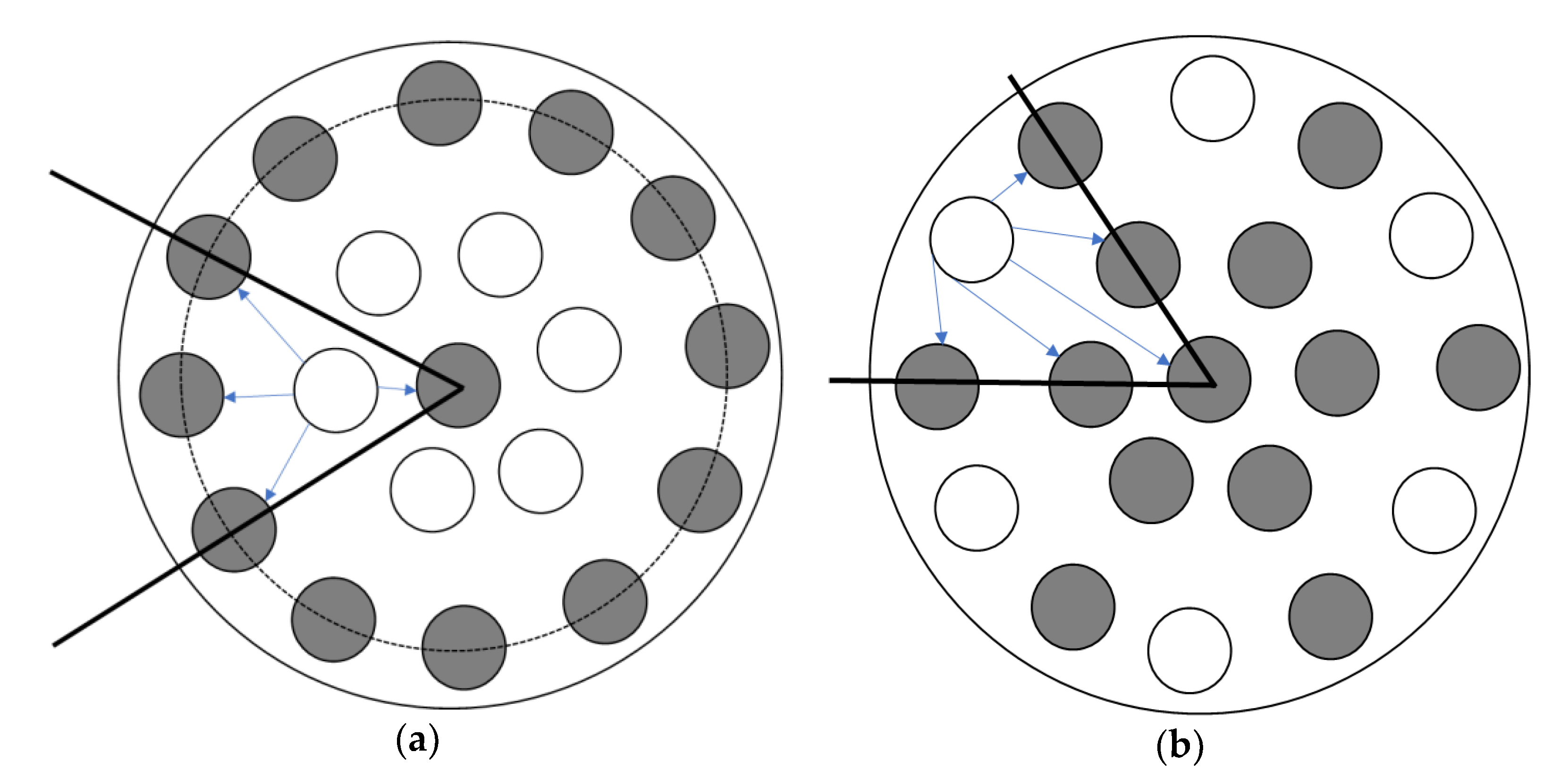

3.6. Position of Gas Channels

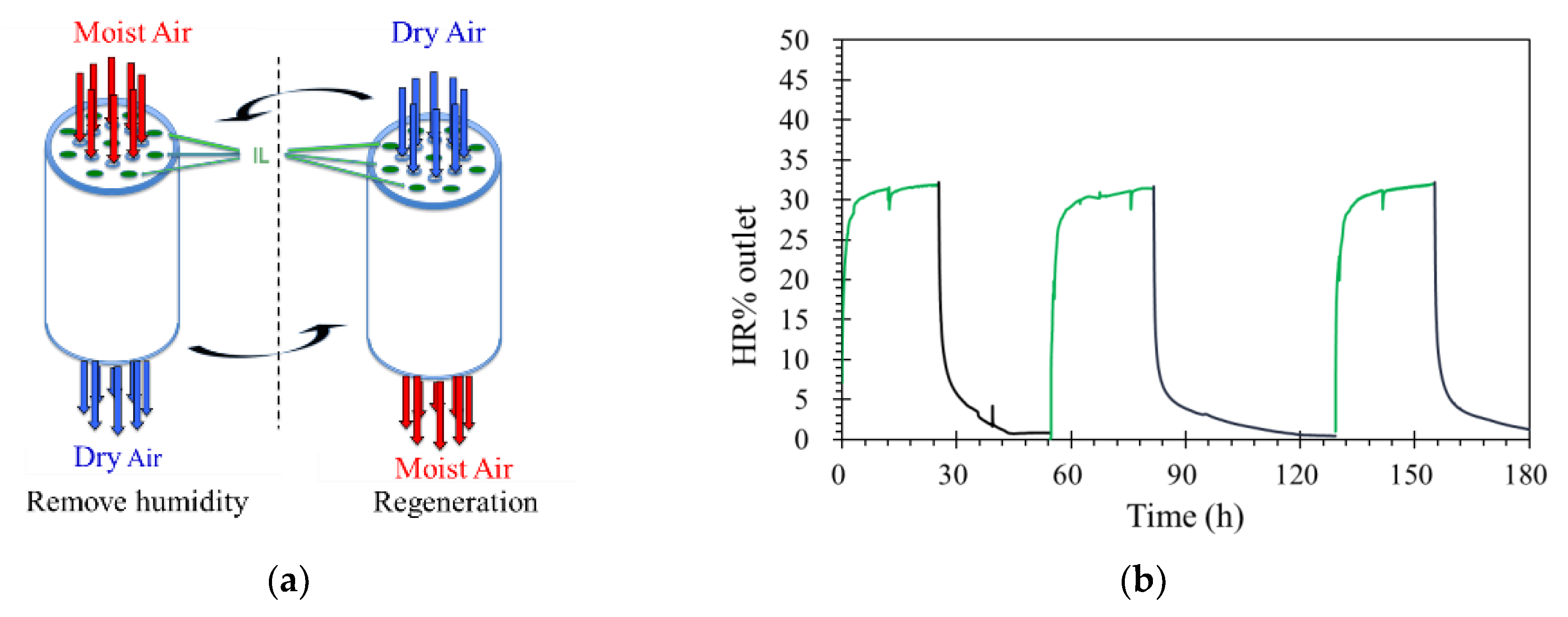

3.7. Regeneration

4. Conclusions

5. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Akhtar, F.H.; Kumar, M.; Peinemann, K.V. Pebax®1657/Graphene oxide composite membranes for improved water vapor separation. J. Membr. Sci. 2017, 525, 187–194. [Google Scholar] [CrossRef]

- Cvjetko Bubalo, M.; Radošević, K.; Radojčić Redovniković, I.; Halambek, J.; Gaurina Srček, V. A brief overview of the potential environmental hazards of ionic liquids. Ecotoxicol. Environ. Saf. 2014, 99, 1–12. [Google Scholar] [CrossRef]

- Huddleston, J.G.; Willauer, H.D.; Swatloski, R.P.; Visser, A.E.; Rogers, R.D. Room temperature ionic liquids as novel media for ‘clean’ liquid–liquid extraction. Chem. Commun. 1998, 0, 1765–1766. [Google Scholar] [CrossRef]

- Armand, M.; Endres, F.; MacFarlane, D.R.; Ohno, H.; Scrosati, B. Ionic-liquid materials for the electrochemical challenges of the future. Nat. Mater. 2009, 8, 621–629. [Google Scholar] [CrossRef] [PubMed]

- Dupont, J.; Souza, R.F.; Suarez, P.A.Z. Ionic Liquid (Molten Salt) Phase Organometallic Catalysis. Chem. Rev. 2002, 102, 3667–3692. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Luo, F.; Wu, H.; Liu, Y.; Zhang, C.; Chen, J. One-Step Ionic-Liquid-Assisted Electrochemical Synthesis of Ionic-Liquid-Functionalized Graphene Sheets Directly from Graphite. Adv. Funct. Mater. 2008, 18, 1518–1525. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Li, L.; Hu, Y.; Liu, J.; Xu, Y.; Luo, C.; Zheng, C. NO Removal from Flue Gas Using Conventional Imidazolium-Based Ionic Liquids at High Pressures. Energy Fuels 2018, 32, 6039–6048. [Google Scholar] [CrossRef]

- Kudasheva, A.; Kamiya, T.; Hirota, Y.; Ito, A. Dehumidification of air using liquid membranes with ionic liquids. J. Membr. Sci. 2016, 499, 379–385. [Google Scholar] [CrossRef]

- Lynam, J.G.; Chow, G.I.; Coronella, C.J.; Hiibel, S.R. Ionic liquid and water separation by membrane distillation. Chem. Eng. J. 2016, 288, 557–561. [Google Scholar] [CrossRef]

- Anguille, S.; Moulin, P. Device for Extraction of Pollutants By Multichannel Tubular Membrane. EP 2015/064462, 25 June 2015. [Google Scholar]

- Yan, X.; Favard, A.; Anguille, S.; Seguin, J.L.; Bendahan, M.; Mouin, P. Membrane SF: Hybrid membrane process to remove emerging pollutants. In Proceedings of the Euromembrane 2018 Conference, Valence, Spain, 9–13 July 2018; pp. 86–87, ISBN 978-84-09-03247-1. [Google Scholar]

- Favard, A.; Yan, X.; Anguille, S.; Moulin, P.; Seguin, J.L.; Aguir, K.; Bendahan, M. Ionic liquids filter for humidity effect reduction on metal oxide gas sensor response. Sens. Transducers. 2018, 222, 6–11. [Google Scholar]

- Wang, C.; Yin, L.; Zhang, L.; Xiang, D.; Gao, R. Metal oxide gas sensors: Sensitivity and influencing factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef]

- Eslamimanesh, A.; Mohammadi, A.H.; Richon, D.; Naido, P.; Ramjugerath, D. Application of gas hydrate formation in separation processes: A review of experimental studies. J. Chem. Thermodyn. 2012, 46, 62–71. [Google Scholar] [CrossRef]

- Mara, G.F.; Luis, M.N.B.F.S.; Ana, M.F.; Joao, A.P.C.; Isabel, M.M. An overview of the mutual solubilities of water-imidazolium-based ionic liquids systems. Fluid Phase Equilib. 2007, 261, 449–454. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, L.; Ye, Y.; Chen, L.; Qi, Z.; Freund, H.; Sundmacher, K. An overview of mutual solubilities of ionic liquids and water predicted by COSMO-RS. Ind. Eng. Chem. Res. 2012, 51, 6256–6264. [Google Scholar] [CrossRef]

- Kamimura, A.; Shiramatsu, Y.; Murata, K.; Kawamoto, T. Solubility-switchable Ionic Liquids: A Control of Hydrophilicity and Hydrophobicity Using a Protective Group. Chem. Lett. 2018, 47, 1079–1081. [Google Scholar] [CrossRef]

- Restolho, J.; Mata, J.L.; Colaço, R.; Saramago, B. Moisture absorption in ionic liquid films. J. Phys. Chem. C. 2013, 117, 10454–10463. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, Y.; Sun, X.; Zhang, Z.; Mu, T. Water sorption in ionic liquids: Kinetics, mechanisms and hydrophilicity. Phys. Chem. Chem. Phys. 2012, 14, 12252–12262. [Google Scholar] [CrossRef]

- Francesco, F.D.; Calisi, N.; Creatini, M.; Melai, B.; Salvo, P.; Chiappe, C. Water sorption by anhydrous ionic liquids. Green Chem. 2011, 13, 1712–1717. [Google Scholar] [CrossRef]

- Zhang, Q.G.; Wang, N.N.; Yu, Z.W. The hydrogen bonding interactions between the ionic liquid 1-ethyl-3-methylimidazolium ethyl sulfate and water. J. Phys. Chem. B. 2010, 114, 4747–4754. [Google Scholar] [CrossRef]

- Cammarata, L.; Kazarian, S.G.; Salter, P.A.; Welton, T. Molecular states of water in room temperature ionic liquids. Phys. Chem. Chem. Phys. 2001, 3, 5192–5200. [Google Scholar] [CrossRef]

- Dahi, A.; Fatyeyeva, K.; Langevin, D.; Chappey, C.; Rogalsky, S.P.; Tarasyuk, O.P.; Benamor, A.; Marais, S. Supported ionic liquid membranes for water and volatile organic compounds separation: Sorption and permeation properties. J. Membr. Sci. 2014, 458, 164–178. [Google Scholar] [CrossRef]

- Kelkar, M.S.; Shi, W.; Maginn, E.J. Determining the Accuracy of Classical Force Fields for Ionic Liquids: Atomistic Simulation of the Thermodynamic and Transport Properties of 1-Ethyl-3-methylimidazolium Ethylsulfate ([emim][ EtSO4]) and Its Mixtures with Water. Ind. Eng. Chem. Res. 2008, 47, 9115–9126. [Google Scholar] [CrossRef]

- Tran, C.D.; De Paoli Lacerda, S.H.; Oliveira, D. Absorption of Water by Room-Temperature Ionic Liquids: Effect of Anions on Concentration and State of Water. Appl. Spectrosc. 2003, 57, 152–157. [Google Scholar] [CrossRef] [PubMed]

- Bowen, T.C.; Noble, R.D.; Falconer, J.L. Fundamentals and applications of pervaporation through zeolite membranes. J. Membr. Sci. 2004, 245, 1–33. [Google Scholar] [CrossRef]

- Liang, C.Z.; Chung, T.S. Robust thin film composite PDMS/PAN hollow fiber membranes for water vapor removal from humid air and gases. Sep. Purif. Technol. 2018, 202, 345–356. [Google Scholar] [CrossRef]

- Kumar, P.; Ismail, A.F. Fouling control on microfiltration/ultrafiltration membranes: Effects of morphology, hydrophilicity, and charge. J. Appl. Polym. Sci. 2015, 132, 42042. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, Y.; Sun, J.; Liu, Y.; Zhang, Y.; Du, W.; Lan, J. An experimental study of membranes for capturing water vapor from flue gas. J. Energy Inst. 2018, 91, 339–348. [Google Scholar] [CrossRef]

- Hantoko, D.; Su, H.; Yan, M.; Kanchanatip, E.; Susanto, H.; Wang, G.; Zhang, S.; Xu, Z. Thermodynamic study on the integrated supercritical water gasification with reforming process for hydrogen production: Effects of operating parameters. Int. J. Hydrogen Energy 2018, 43, 17620–17632. [Google Scholar] [CrossRef]

- Wang, M.; Li, M.; Chang, N.; Gao, L.; Wang, M.; Zhang, Y. Vapor separation of methanol-dimethyl carbonate mixture on SAPO-34 zeolite membrane. J. Membr. Sci. 2018, 565, 311–321. [Google Scholar] [CrossRef]

- Park, S.; Jung, D. Effect of operating parameters on dynamic response of water-to-gas membrane humidifier for proton exchange membrane fuel cell vehicle. Int. J. Hydrogen Energy 2013, 38, 7114–7125. [Google Scholar] [CrossRef]

- Finotello, A.; Bara, J.E.; Camper, D.; Noble, R.D. Room-Temperature Ionic Liquids: Temperature Dependence of Gas Solubility Selectivity. Ind. Eng. Chem. Res. 2008, 47, 3453–3459. [Google Scholar] [CrossRef]

- Hayduk, W.; Buckley, W.D. Temperature coefficient of gas solubility for regular solutions. Can. J. Chem. Eng. 1971, 49, 667–671. [Google Scholar] [CrossRef]

- Swarnkar, S.K.; Murthy, S.S.; Gardas, R.L.; Venkatarathnam, G. Performance of a vapor absorption refrigeration system operating with ionic liquid-ammonia combination with water as cosolvent. Appl. Therm. Eng. 2014, 72, 250–257. [Google Scholar] [CrossRef]

| Effective length (cm) | 25 |

| Channels size (mm) | 2 |

| Total number of channels | 52 |

| Number of channels with IL | 32 |

| Surface area (m2) | 4.0 × 10−2 |

| Molecular weight cut-off (Da) | 1000 |

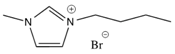

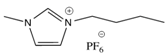

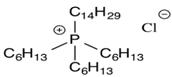

| Content | [bmim]Br | [bmim][PF6] | [3htdp]Cl |

|---|---|---|---|

| Name | 1-butyl-3-methylimidazolium Bromide | 1-butyl-3-methylimidazolium Hexafluorophosphate | Trihexyl(tetradecyl)phosphonium Chloride |

| Chemical structure |  |  |  |

| Molar mass (g·mol−1) | 219.13 | 284.19 | 519.32 |

| Water affinity | hydrophilic | hydrophobic | hydrophobic |

| Mass of IL used (g) | 49.0 | 53.4 | 34.1 |

| Mass of water absorbed by per gram of IL (g) | 0.14 | 0.033 | 0.055 |

| Operating Conditions | Mass of Water Absorbed (g) | y (%) | |

|---|---|---|---|

| Flow rate (L·min−1) | 0.5 | 0.42 | 0.86 |

| 1.0 | 0.65 | 1.33 | |

| 1.5 | 1.22 | 2.59 | |

| Pressure (atm) | 1.0 | 0.42 | 0.86 |

| 1.1 | 0.53 | 1.08 | |

| 1.2 | 2.33 | 4.76 | |

| Feed concentration (%) | 35 | 2.34 | 4.78 |

| 50 | 2.33 | 4.76 | |

| Temperature (°C) | 25 | 2.00 | 4.08 |

| 32 | 0.41 | 0.84 | |

| 39 | 0.43 | 0.88 | |

| Content | Membrane (a) | Membrane (b) |

|---|---|---|

| Total channels | 19 | |

| Channels with IL | 13 | |

| Channels without IL | 6 | |

| Mass of IL (g) | 38.7 | 38.4 |

| Total mass of water absorbed by ILM (g) | 2.95 | 2.85 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Favard, A.; Anguille, S.; Bendahan, M.; Moulin, P. Effects of Operating Parameters on Ionic Liquid Membrane to Remove Humidity in a Green Continuous Process. Membranes 2019, 9, 65. https://doi.org/10.3390/membranes9050065

Yan X, Favard A, Anguille S, Bendahan M, Moulin P. Effects of Operating Parameters on Ionic Liquid Membrane to Remove Humidity in a Green Continuous Process. Membranes. 2019; 9(5):65. https://doi.org/10.3390/membranes9050065

Chicago/Turabian StyleYan, Xueru, Alexandre Favard, Stéphane Anguille, Marc Bendahan, and Philippe Moulin. 2019. "Effects of Operating Parameters on Ionic Liquid Membrane to Remove Humidity in a Green Continuous Process" Membranes 9, no. 5: 65. https://doi.org/10.3390/membranes9050065

APA StyleYan, X., Favard, A., Anguille, S., Bendahan, M., & Moulin, P. (2019). Effects of Operating Parameters on Ionic Liquid Membrane to Remove Humidity in a Green Continuous Process. Membranes, 9(5), 65. https://doi.org/10.3390/membranes9050065