Effect of Carbon Dioxide Loading on Removal of Heat Stable Salts from Amine Solvent by Electrodialysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

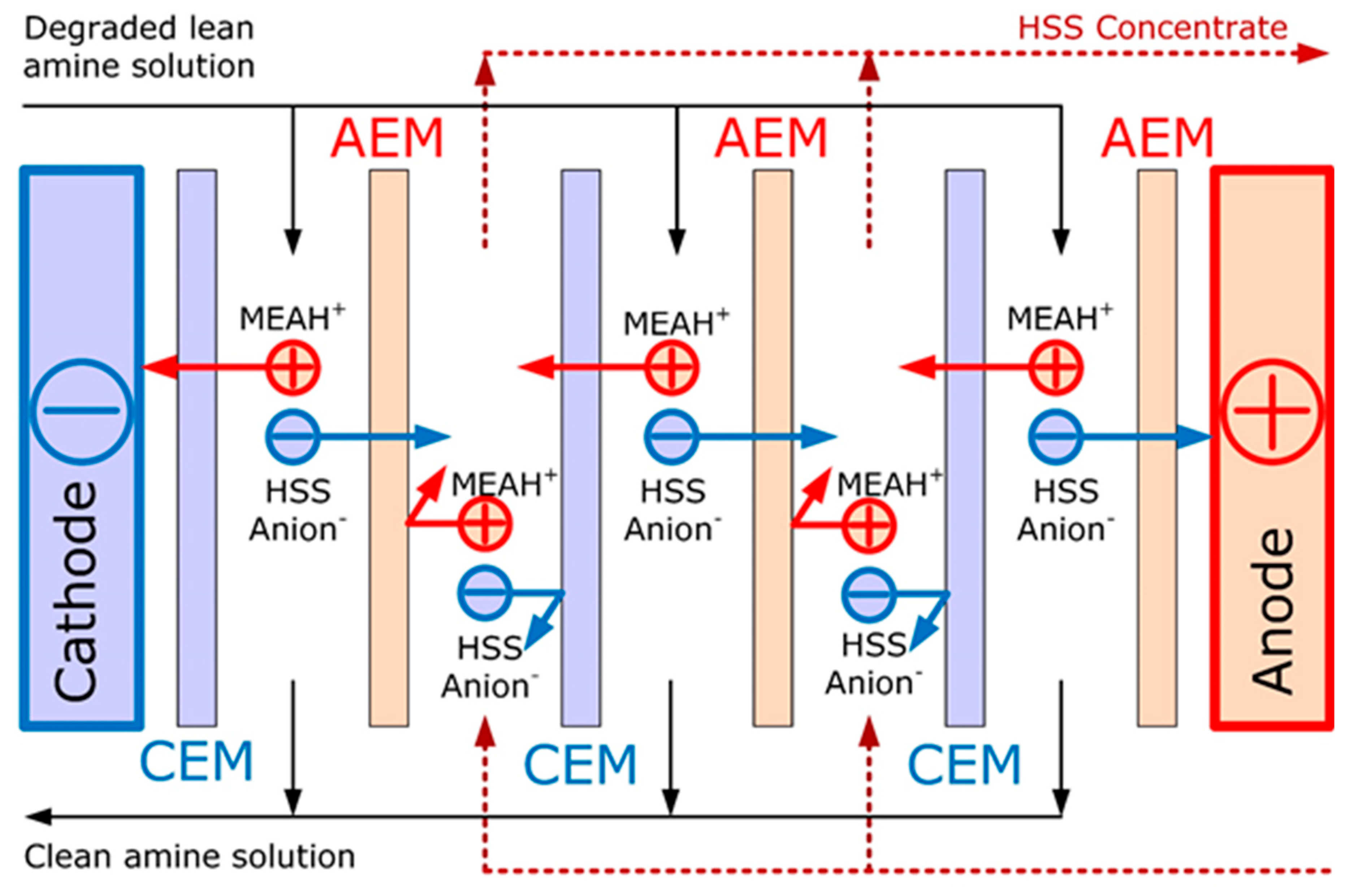

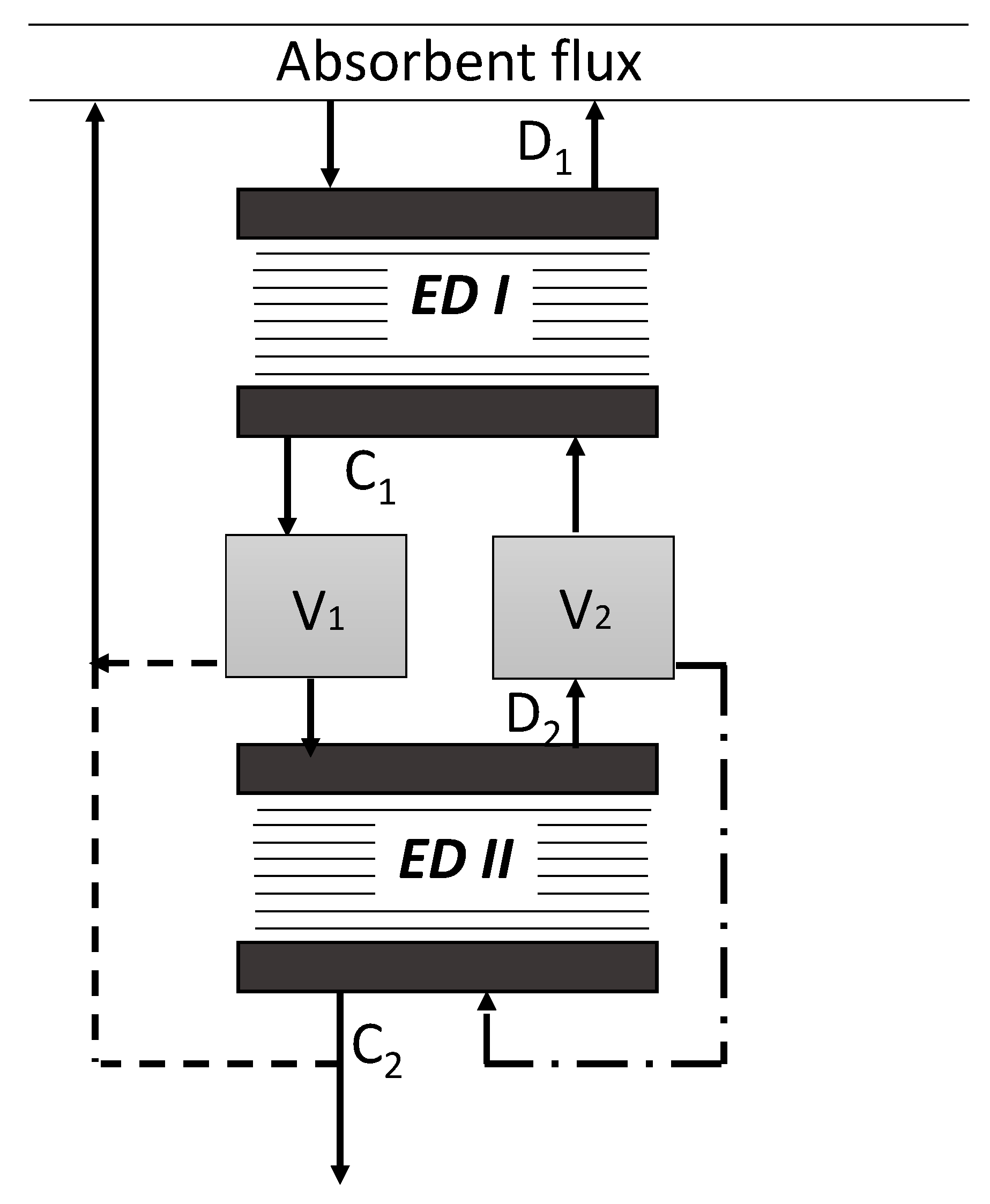

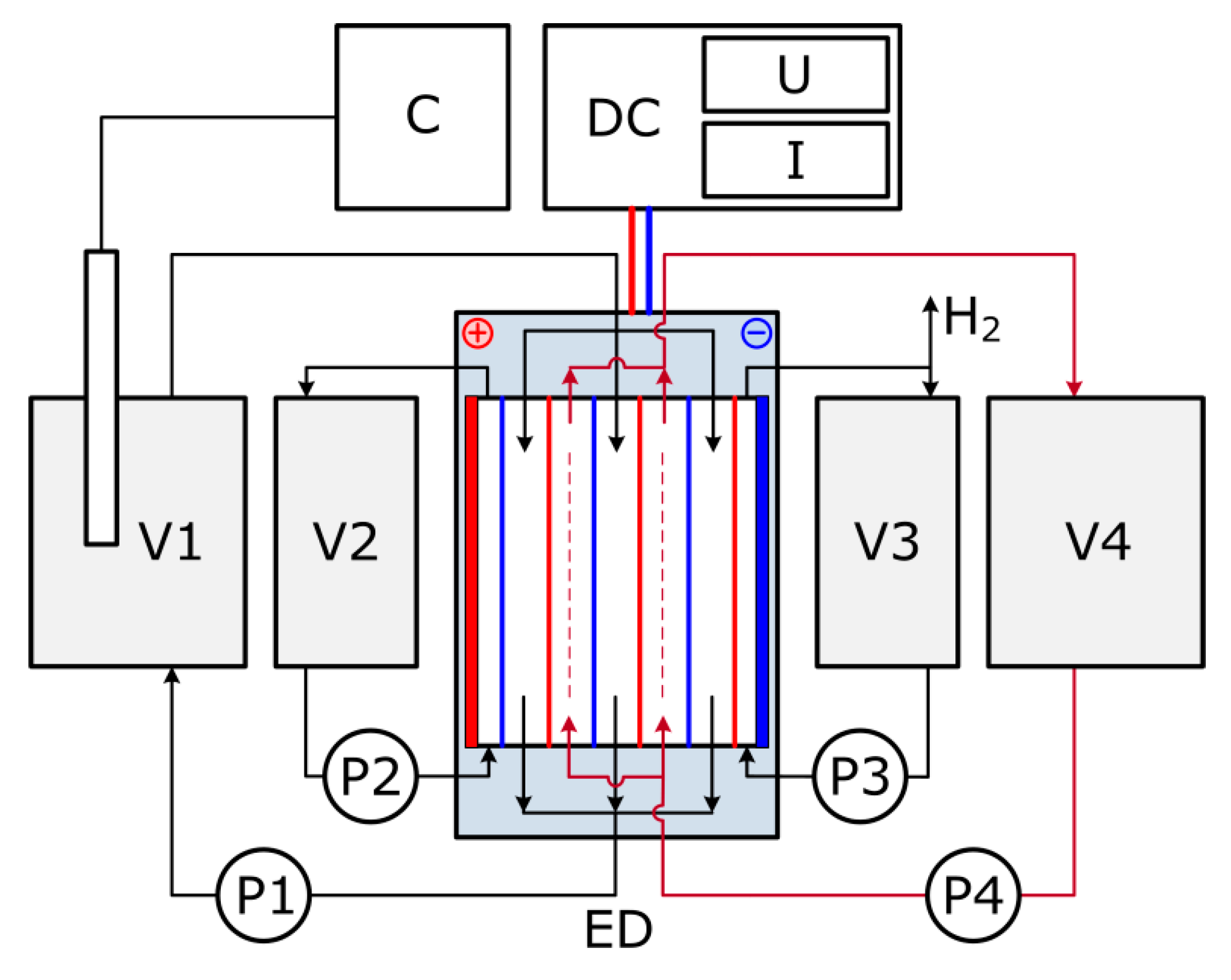

2.2. Electrodialysis Reclaiming

2.3. Analysis of Solvent Composition

2.4. Determination of Heat Consumption of Stripping Column by Aspen Plus®

3. Results and Discussion

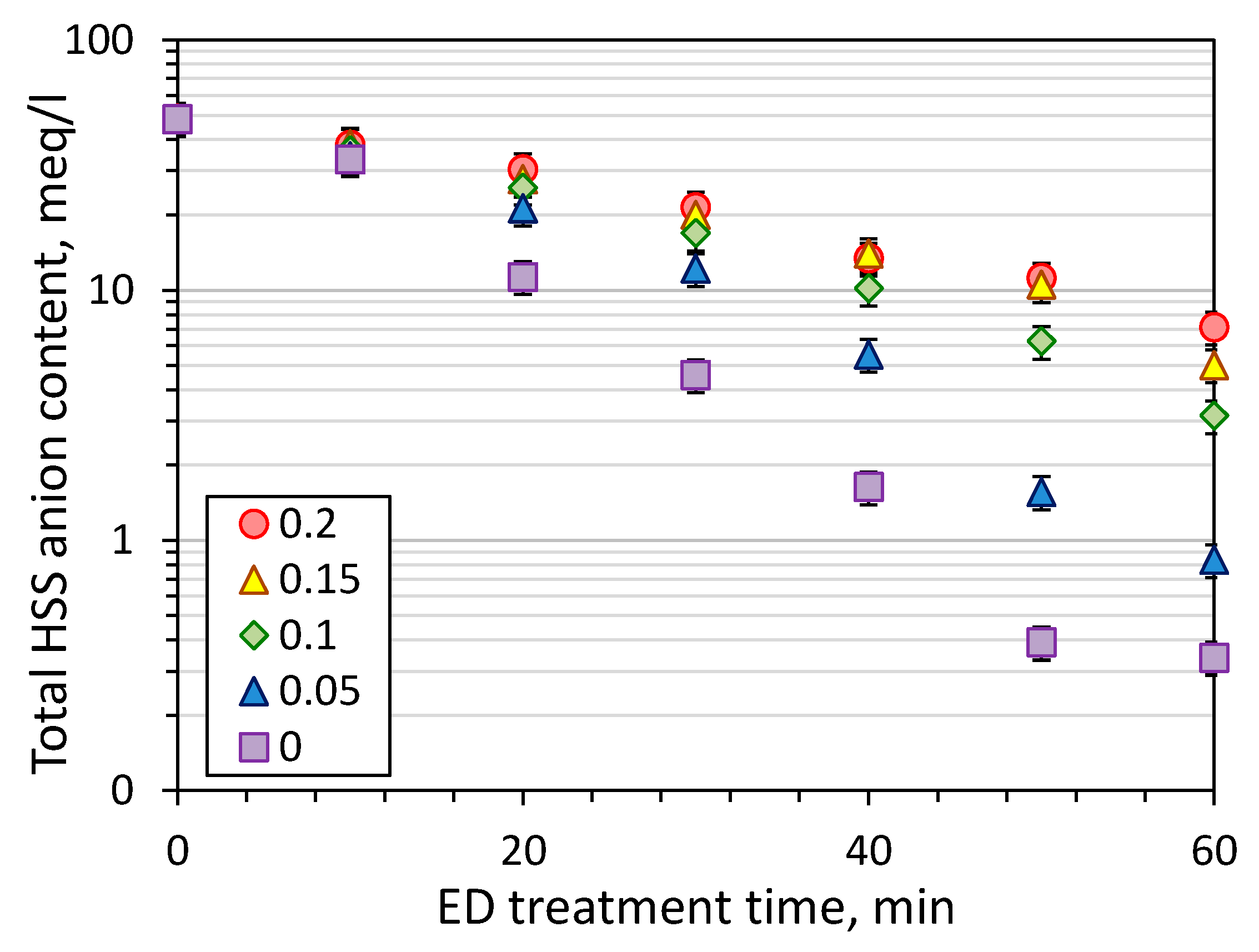

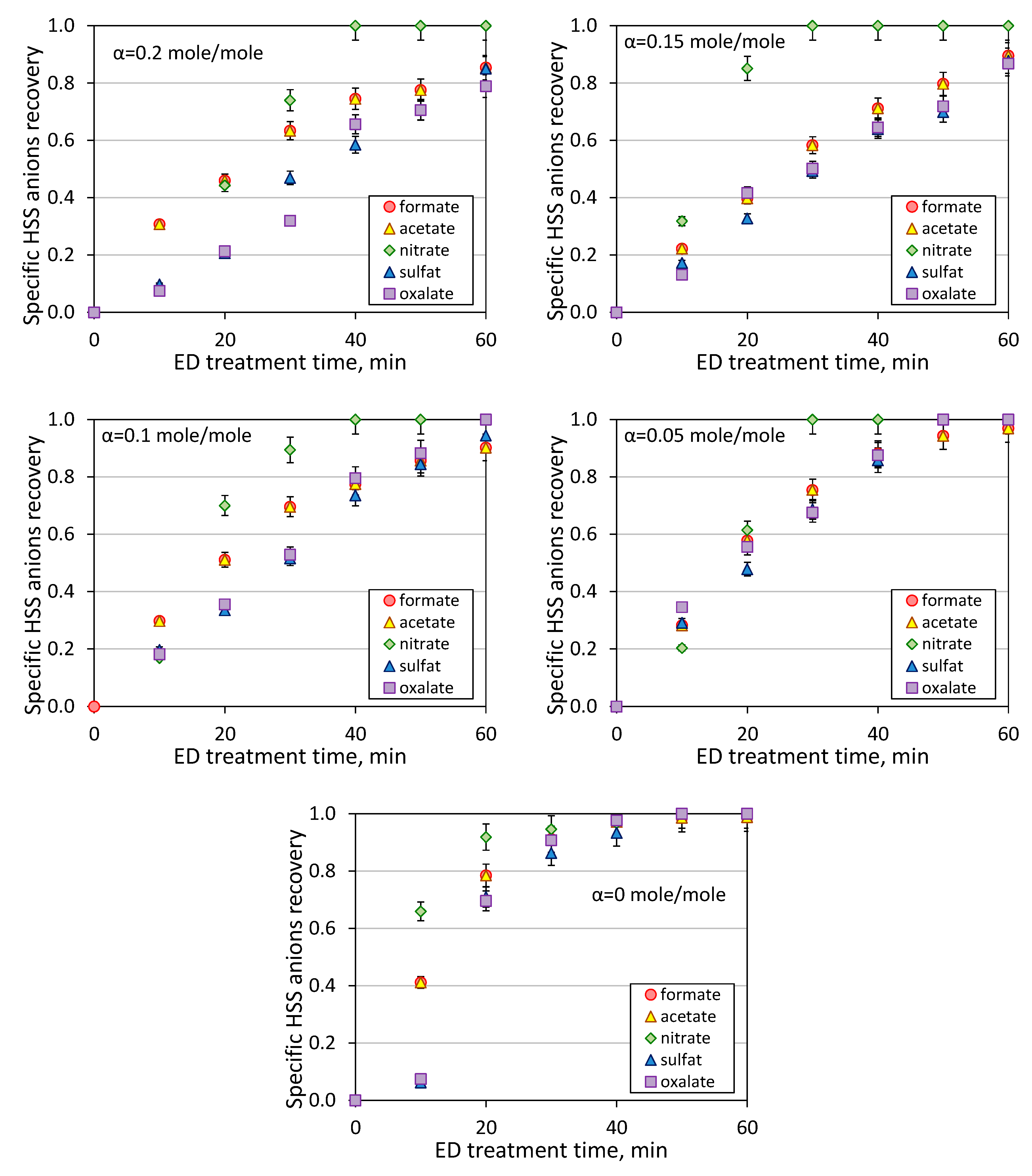

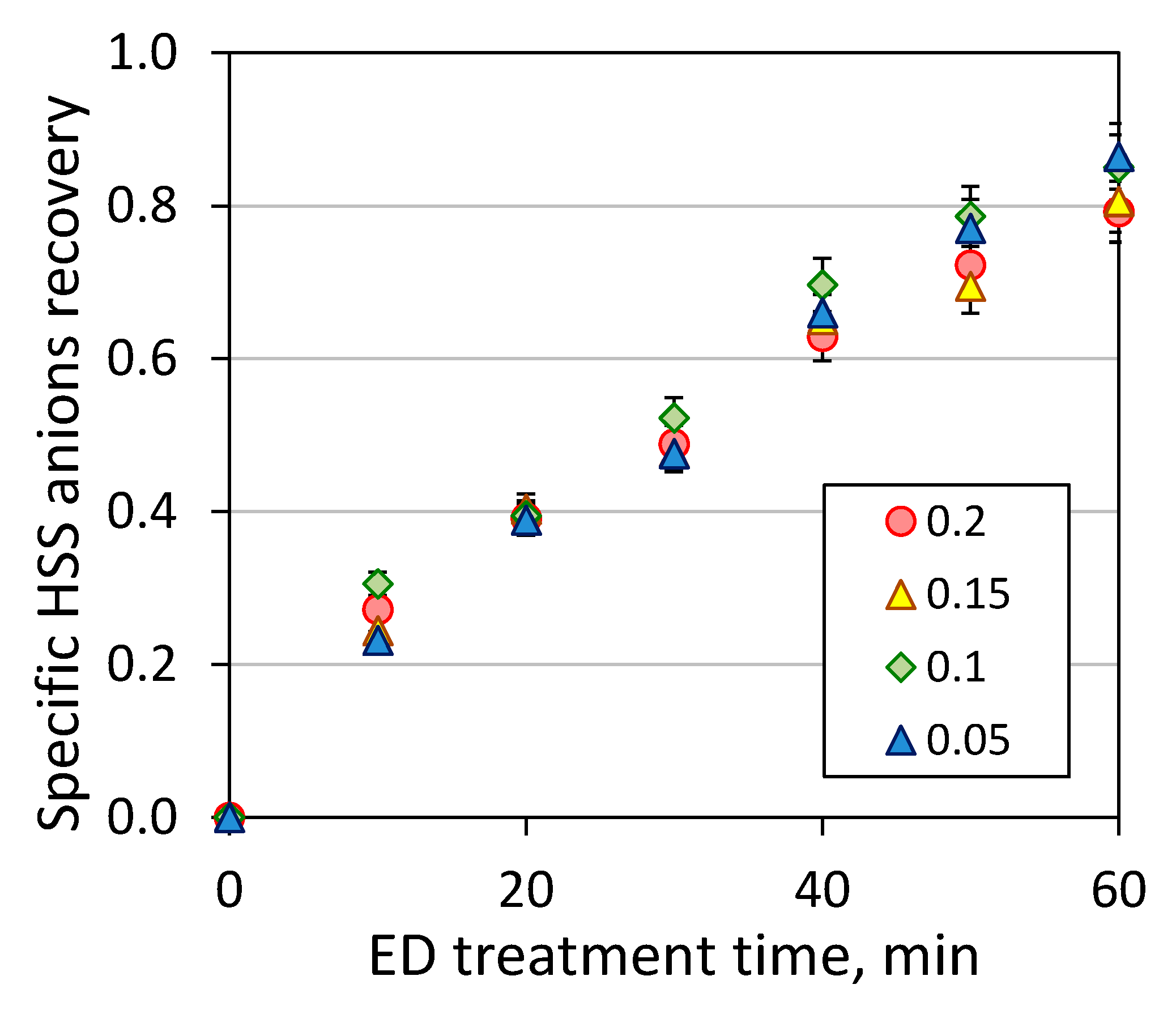

3.1. Transport of HSS Anions

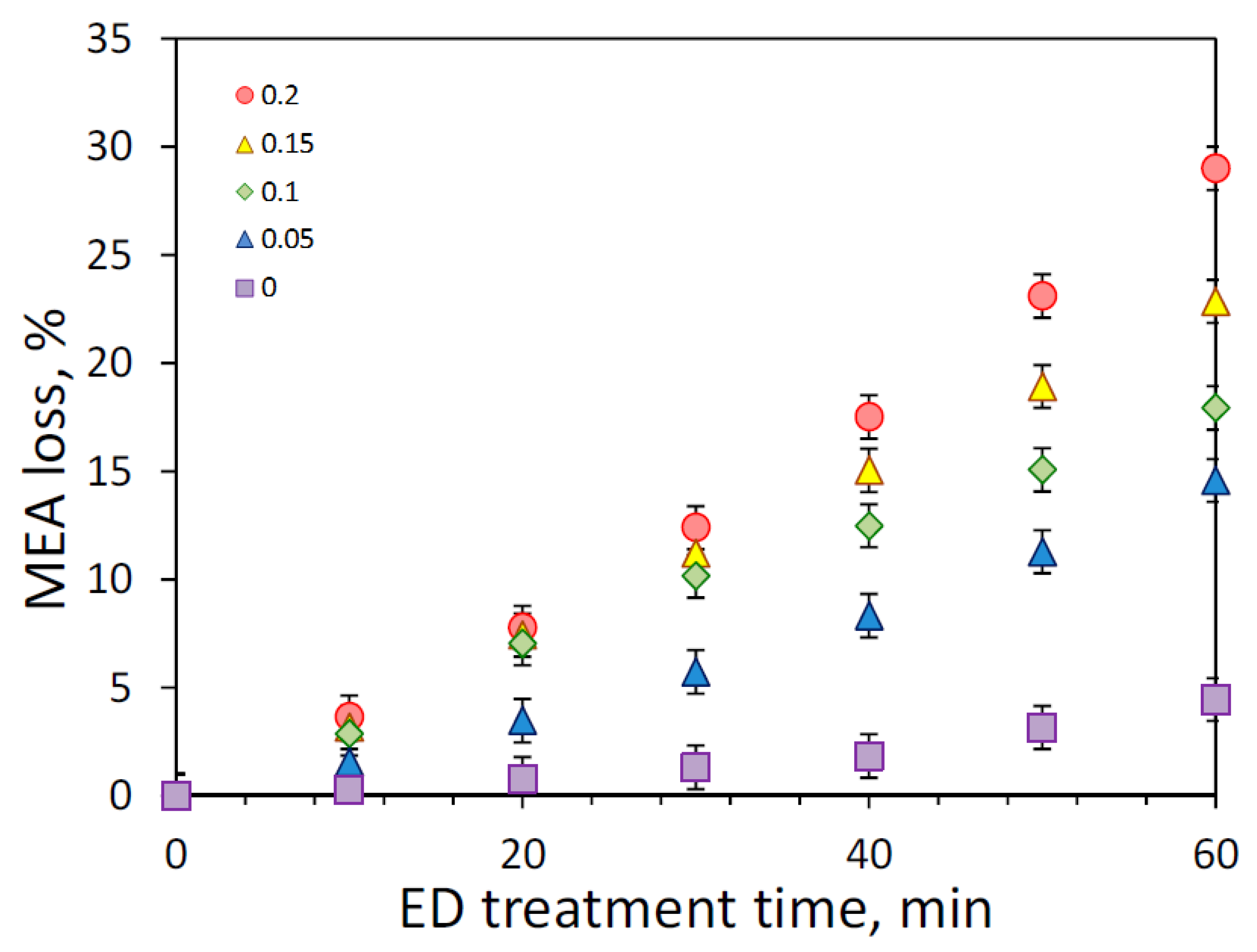

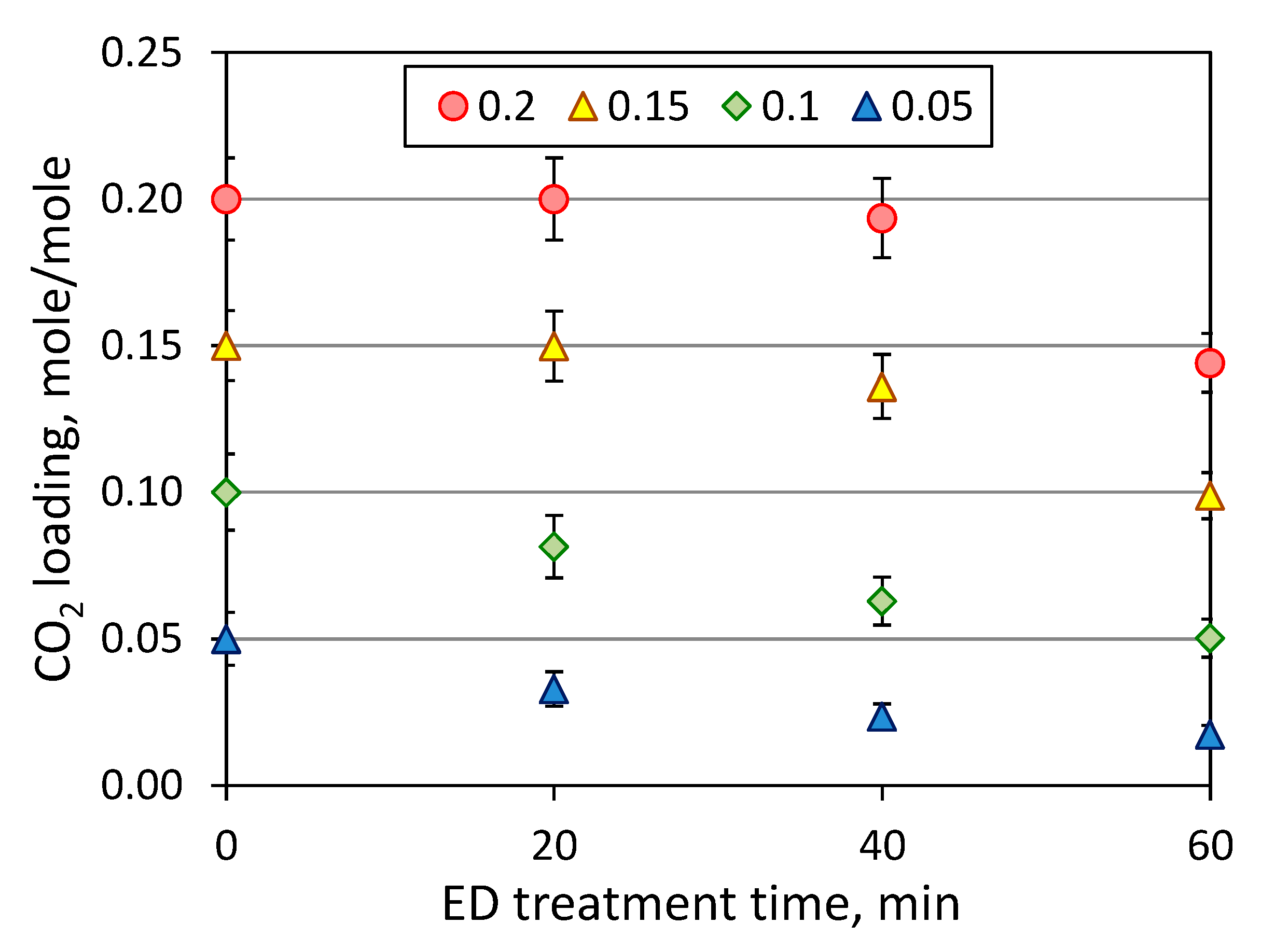

3.2. Transport of MEA and CO2

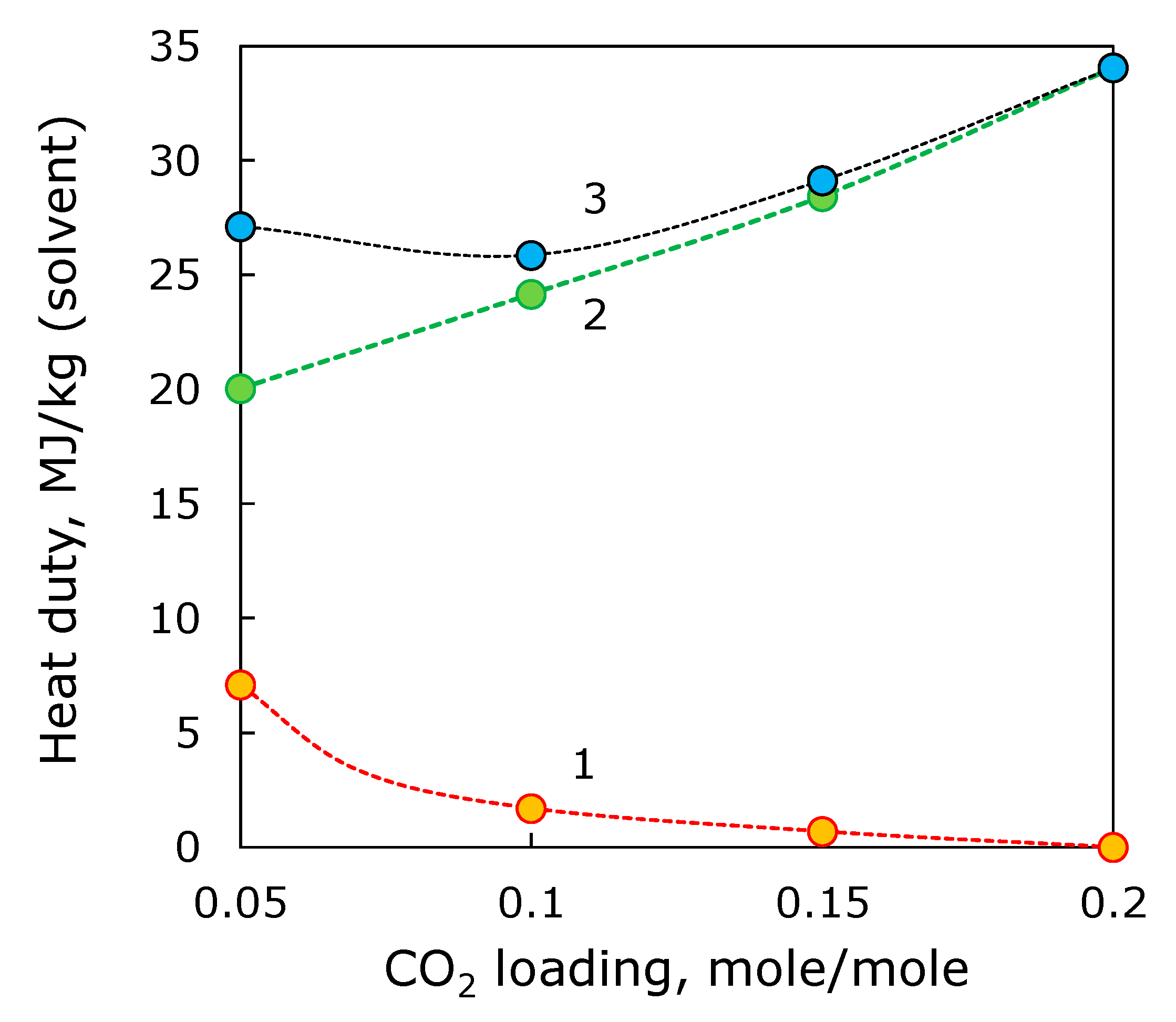

3.3. Comparison of Power Consumption: ED Reclaiming vs Addition CO2 Stripper

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liang, Z.; Liu, H.; Fu, K.; Gao, H.; Cao, F.; Zhang, R.; Sema, T.; Henni, A.; Sumon, K.; Nath, D.; et al. Recent progress and new developments in post-combustion carbon-capture technology with amine based solvents. Int. J. Greenh. Gas Con. 2015, 40, 26–54. [Google Scholar] [CrossRef]

- Wang, M.; Joel, A.S.; Ramshaw, C.; Eimer, D.; Musa, N.M. Process intensification for post-combustion CO2 capture with chemical absorption: A critical review. Appl. Energy 2015, 158, 275–291. [Google Scholar] [CrossRef]

- Supap, T.; Saiwan, C.; Idem, R.; Tontiwachwuthikul, P. Part 2: Solvent management: Solvent stability and amine degradation in CO2 capture processes. Carbon Manag. 2011, 2, 551–566. [Google Scholar] [CrossRef]

- Reynolds, A.J.; Verheyen, T.V.; Adeloju, S.B.; Meuleman, E.; Feron, P. Towards commercial scale postcombustion capture of CO2 with monoethanolamine solvent: Key considerations for solvent management and environmental impacts. Env. Sci. Technol. 2012, 46, 3643–3654. [Google Scholar] [CrossRef]

- Verma, N.; Verma, A. Amine system problems arising from heat stable salts and solutions to improve system performance. Fuel Process. Technol. 2009, 90, 483–489. [Google Scholar] [CrossRef]

- Nabokov, S.V.; Shklyar, R.L.; Petkina, N.P. The method of purification of diethanolamine solution from impurities. Patent RF 2487113, 2013. [Google Scholar]

- ElMoudir, W.; Supap, T.; Saiwan, C.; Idem, R.; Tontiwachwuthikul, P. Part 6: Solvent recycling and reclaiming issues. Carbon Manag. 2012, 3, 485–509. [Google Scholar] [CrossRef]

- Wang, T.; Hovland, J.; Jens, K.J. Amine reclaiming technologies in post-combustion carbon dioxide capture. J. Environ. Sci. 2015, 27, 276–289. [Google Scholar] [CrossRef] [PubMed]

- Strathmann, H. Electrodialysis, a mature technology with a multitude of new applications. Desalination 2010, 264, 268–288. [Google Scholar] [CrossRef]

- Lim, J.; Aguiar, A.; Scholes, C.A.; Dumée, L.F.; Stevens, G.W.; Kentish, S.E. Monoethanolamine reclamation using electrodialysis. Ind.Eng.Chem.Res. 2014, 53, 19313–19321. [Google Scholar] [CrossRef]

- Lim, J.; Aguiar, A.; Reynolds, A.; Pearson, P.; Kentish, S.E.; Meuleman, E. Remediation of monoethanolamine after exposure to brown coal flue gases. Int. J. Greenh. Gas Con. 2015, 42, 545–553. [Google Scholar] [CrossRef]

- Bazhenov, S.; Rieder, A.; Schallert, B.; Vasilevsky, V.; Unterberger, S.; Grushevenko, E.; Volkov, V.; Volkov, A. Reclaiming of degraded MEA solutions by electrodialysis: Results of ED pilot campaign at post-combustion CO2 capture pilot plant. Int. J. Greenh. Gas Control 2015, 42, 593–601. [Google Scholar] [CrossRef]

- Dumée, L.; Scholes, C.; Stevens, G.; Kentish, S. Purification of aqueous amine solvents used in post combustion CO2 capture: A review. Int. J. Greenh. Gas Control 2012, 10, 443–455. [Google Scholar] [CrossRef]

- Novitskii, E.G.; Vasilevskii, V.P.; Grushevenko, E.A.; Volkov, A.V.; Vasil’eva, V.I. The Effect of Monoethanolamine on Conductivity and Efficiency of Electrodialysis of Acid and Salt Solutions. Russ. J. Electrochem. 2017, 53, 391–397. [Google Scholar] [CrossRef]

- Kentish, S.E. Reclaiming of amine-based absorption liquids used in post-combustion capture. In Absorption-Based Post-Combustion Capture of Carbon Dioxide; Paul, H.M.F., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; pp. 425–438. [Google Scholar] [CrossRef]

- Wang, Y.; Li, W.; Yan, H.; Xu, T. Removal of heat stable salts (HSS) from spent alkanolamine wastewater using electrodialysis. J. Ind. Eng. Chem. 2018, 57, 356–362. [Google Scholar] [CrossRef]

- Cummings, A.L.; Mecum, S.M. Remove heat stable salts for better amine plant performance. Hydrocarb. Process. 1998, 77, 63–67. [Google Scholar]

- Cummings, A.L.; Mecum, S.M.; Veatch, F.C. Controlling Corrosion in Gas Treating Solutions. In Proceedings of the Gas Processors Association’ European Chapter. 18 February 1998. Available online: https://fdocuments.in/document/controlling-corrosion-in-gas-treating-solutions.html (accessed on 12 November 2019).

- Cummings, A.L.; Street, D.; Lawson, G. Contaminants and Their Effects on Operations—Yes! You can have Better Operating Amine and Glycol Systems! In Proceedings of the Brimestone Sulfur Conference, Banff, AB, Canada, May 2003; pp. 1–24. [Google Scholar]

- Melnikov, S.; Sheldeshov, N.; Zabolotsky, V.; Loza, S.; Achoh, A. Pilot scale complex electrodialysis technology for processing a solution of lithium chloride containing organic solvents. Sep. Pur. Technol. 2017, 189, 74–81. [Google Scholar] [CrossRef]

- Bdiri, M.; Dammak, L.; Larchet, C.; Hellal, F.; Porozhnyy, M.; Nevakshenova, E.; Pismenskaya, N.; Nikonenko, V. Characterization and cleaning of anion-exchange membranes used in electrodialysis of polyphenol-containing food industry solutions; comparison with cation-exchange membranes. Sep. Purif. Technol. 2019, 210, 636–650. [Google Scholar] [CrossRef]

- Golubenko, D.V.; Karavanova, Y.A.; Melnikov, S.S.; Achoh, A.R.; Pourcelly, G.; Yaroslavtsev, A.B. An approach to increase the permselectivity and mono-valent ion selectivity of cation-exchange membranes by introduction of amorphous zirconium phosphate nanoparticles. J. Membr. Sci. 2018, 563, 777–784. [Google Scholar] [CrossRef]

- Loza, S.A.; Zabolotsky, V.I.; Loza, N.V.; Fomenko, M.A. Structure, morphology, and transport characteristics of profiled bilayer membranes. Pet. Chem. 2016, 56, 1027–1033. [Google Scholar] [CrossRef]

- Zyryanova, S.V.; Pismenskaya, N.D.; Nikonenko, V.V. The Effect of Concentration and pH of NaCl Solution on the Transport Properties of Anion Exchange Membranes with Different Fixed Groups. Pet. Chem. 2018, 58, 965–974. [Google Scholar] [CrossRef]

- Grushevenko, E.A.; Bazhenov, S.D.; Vasilevskii, V.P.; Novitskii, E.G.; Volkov, A.V. Two-Step Electrodialysis Treatment of Monoethanolamine to Remove Heat Stable Salts. Russ. J. Appl. Chem. 2018, 91, 602–610. [Google Scholar] [CrossRef]

- Zagorodny, A.A. Ion Exchange Materials. Properties and Applications, 1st ed.; Elsevier BV: Oxford, UK, 2007; 496p. [Google Scholar] [CrossRef]

- Rybalkina, O.; Tsygurina, K.; Melnikova, E.; Mareev, S.; Moroz, I.; Nikonenko, V.; Pismenskaya, N. Partial Fluxes of Phosphoric Acid Anions through Anion-Exchange Membranes in the Course of NaH2PO4 Solution Electrodialysis. Int. J. Mol. Sci. 2019, 20, 3593. [Google Scholar] [CrossRef] [PubMed]

- Van der Bruggen, B.; Koninckx, A.; Vandecasteele, C. Separation of monovalent and divalent ions from aqueous solution by electrodialysis and nanofiltration. Water Res. 2004, 38, 1347–1353. [Google Scholar] [CrossRef] [PubMed]

- Kameche, M.; Innocent, C.; Xu, F.; Pourcelly, G.; Derriche, Z. Electro-transport of protons, alkali metal cations and solvent molecules through a commercial cation-exchange membrane conditioned with aqueous and organic solutions. Desalination 2004, 168, 319–327. [Google Scholar] [CrossRef]

- Innocent, C.; Huguet, P.; Bribes, J.L.; Pourcelly, G.; Kameche, M. Characterisation of cation exchange membrane in hydro-organic media by electrochemistry and Raman spectroscopy. Phys. Chem. Chem. Phys. 2001, 3, 1481–1485. [Google Scholar] [CrossRef]

- Tandon, R.; Pintauro, P.N. Solvent effects during multicomponent ion uptake into a Nafion cation-exchange membrane. J. Membr. Sci. 2009, 341, 21–29. [Google Scholar] [CrossRef]

- Chou, T.J.; Tanioka, A. Ionic behavior across charged membranes in methanol–water solutions. I: Membrane potential. J. Membr. Sci. 1998, 144, 275–284. [Google Scholar] [CrossRef]

- Novitsky, E.G.; Vasilevsky, V.P.; Bazhenov, S.D.; Grushevenko, E.A.; Vasilyeva, V.I.; Volkov, A.V. Influence of the composition of concentrate solutions on the efficiency of carbon dioxide removal from monoethanolamine aqueous solution by electrodialysis. Petr. Chem. 2014, 54, 680–685. [Google Scholar] [CrossRef]

- Bazhenov, S.; Vasilevsky, V.; Rieder, A.; Unterberger, S.; Grushevenko, E.; Volkov, V.; Schallert, B.; Volkov, A. Heat stable salts (HSS) removal by Electrodialysis: Reclaiming of MEA used in post-combustion CO2-capture. Energy Procedia 2014, 63, 6349–6356. [Google Scholar] [CrossRef]

| Anion HSS | Concentration (mg/L) |

|---|---|

| Formate (HCOO−) | 1065 |

| Acetate (CH3COO−) | 225 |

| Oxalate (C2O42−) | 392 |

| Nitrate (NO3−) | 234 |

| Sulfate (SO42−) | 390 |

| ED Variant | Initial CO2 Loading, mole (CO2)/mole (MEA) | Molar Flux, mole/(m2∙h) | MEA Loss, mole/mole СО2 (HSS) | Specific Energy Consumption, kJ/g HSS | |||

|---|---|---|---|---|---|---|---|

| MEA | СО2 | HSS mole-eq | MEA/СО2 | MEA/HSS | |||

| ED I | 0.20 | 8.50 | 2.79 | 0.384 | 3.1 | 22.1 | 140 |

| 0.15 | 7.38 | 2.5 | 0.408 | 3.0 | 18.1 | 113 | |

| 0.10 | 6.67 | 2.4 | 0.451 | 2.8 | 14.8 | 92 | |

| 0.05 | 3.64 | 1.5 | 0.524 | 2.4 | 7.0 | 69 | |

| 0 | 1.73 | - | 0.858 | - | 2.0 | 37 | |

| ED II | 0.20 | 8.97 | 4.18 | 0,904 | 2.2 | 9.9 | 80 |

| 0.15 | 8.50 | 3.84 | 0.999 | 2.2 | 8.5 | 79 | |

| 0.10 | 7.82 | 3.26 | 1.057 | 2.4 | 7.4 | 76 | |

| 0.05 | 6.38 | 2.56 | 1.178 | 2.5 | 5.4 | 76 | |

| α | ED Stage | Active Membrane Area (m2) | Specific Power Consumption (MJ/kg HSS) | Flow Rate to the Concentrate (mole/h) | ||

|---|---|---|---|---|---|---|

| MEA (MEA loss) | СО2 | HSS (mole-eq/h) | ||||

| 0.2 | EDI | 25 | 150 | 215 | 70 | 9.6 |

| EDII | 8 | 90 | 70 | 33 | 7.0 | |

| EDI + EDII | 33 | 240 | 70 | 33 | 7.0 | |

| 0.15 | EDI | 24 | 118 | 174 | 59 | 9.6 |

| EDII | 7 | 90 | 60 | 27 | 7.0 | |

| EDI + EDII | 31 | 207 | 60 | 27 | 7.0 | |

| 0.1 | EDI | 21 | 95 | 143 | 51 | 9.6 |

| EDII | 7 | 86 | 52 | 22 | 7.0 | |

| EDI + EDII | 28 | 181 | 52 | 22 | 7.0 | |

| 0.05 | EDI | 18 | 72 | 67 | 28 | 9.6 |

| EDII | 6 | 85 | 38 | 15 | 7.0 | |

| EDI + EDII | 24 | 157 | 38 | 15 | 7.0 | |

| 0 | - | 8 | 38 | 14 | - | 7.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grushevenko, E.; Bazhenov, S.; Vasilevsky, V.; Novitsky, E.; Shalygin, M.; Volkov, A. Effect of Carbon Dioxide Loading on Removal of Heat Stable Salts from Amine Solvent by Electrodialysis. Membranes 2019, 9, 152. https://doi.org/10.3390/membranes9110152

Grushevenko E, Bazhenov S, Vasilevsky V, Novitsky E, Shalygin M, Volkov A. Effect of Carbon Dioxide Loading on Removal of Heat Stable Salts from Amine Solvent by Electrodialysis. Membranes. 2019; 9(11):152. https://doi.org/10.3390/membranes9110152

Chicago/Turabian StyleGrushevenko, Evgeniia, Stepan Bazhenov, Vladimir Vasilevsky, Eduard Novitsky, Maxim Shalygin, and Alexey Volkov. 2019. "Effect of Carbon Dioxide Loading on Removal of Heat Stable Salts from Amine Solvent by Electrodialysis" Membranes 9, no. 11: 152. https://doi.org/10.3390/membranes9110152

APA StyleGrushevenko, E., Bazhenov, S., Vasilevsky, V., Novitsky, E., Shalygin, M., & Volkov, A. (2019). Effect of Carbon Dioxide Loading on Removal of Heat Stable Salts from Amine Solvent by Electrodialysis. Membranes, 9(11), 152. https://doi.org/10.3390/membranes9110152