Short Review on Predicting Fouling in RO Desalination

Abstract

1. Introduction

2. Membrane Fouling Indices

2.1. Silt Density Index

2.2. Modified Fouling Index

2.3. Indices Derived from

2.4. Indices Derived from

2.5. Fouling Potential Parameter ()

3. Predictive Models

4. Conclusions and Perspective of Future

- (a)

- Most conventional indexes, and are not appropriate.

- (b)

- There are very few studies about indices or parameters applied directly to spiral wound membranes and feedwater with high salinity. Most of the studies are applied at the laboratory scale with well-controlled operating conditions, flat membrane systems and at low salinity. However, it is preferable for fouling potential to be determined with RO membranes and under operating conditions similar to those of full-scale desalination plants.

- (c)

- Currently, the effect of Cake-Enhanced Osmotic Pressure (CEOP) has not been taken extensively into account in measuring fouling potential. However, CEOP can contribute to a significant loss of performance, even more than the hydraulic resistance brought about by cake formation.

Conflicts of Interest

References

- Misdan, N.; Ismail, A.; Hilal, N. Recent advances in the development of (bio)fouling resistant thin film composite membranes for desalination. Desalination 2016, 380, 105–111. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, Y.; He, M.; Su, Y.; Zhao, X.; Elimelech, M.; Jiang, Z. Antifouling membranes for sustainable water purification: strategies and mechanisms. Chem. Soc. Rev. 2016, 45, 5888–5924. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Li, Y.; Ladewig, B.P. A review of reverse osmosis membrane fouling and control strategies. Sci. Total Environ. 2017, 595, 567–583. [Google Scholar] [CrossRef] [PubMed]

- She, Q.; Wang, R.; Fane, A.G.; Tang, C.Y. Membrane fouling in osmotically driven membrane processes: A review. J. Membr. Sci. 2016, 499, 201–233. [Google Scholar] [CrossRef]

- Tang, C.Y.; Chong, T.; Fane, A.G. Colloidal interactions and fouling of NF and RO membranes: A review. Adv. Colloid Interface Sci. 2011, 164, 126–143. [Google Scholar] [CrossRef] [PubMed]

- Karabelas, A.; Sioutopoulos, D. New insights into organic gel fouling of reverse osmosis desalination membranes. Desalination 2015, 368, 114–126. [Google Scholar] [CrossRef]

- Shirazi, S.; Lin, C.J.; Chen, D. Inorganic fouling of pressure-driven membrane processes—A critical review. Desalination 2010, 250, 236–248. [Google Scholar] [CrossRef]

- Matin, A.; Khan, Z.; Zaidi, S.; Boyce, M. Biofouling in reverse osmosis membranes for seawater desalination: Phenomena and prevention. Desalination 2011, 281, 1–16. [Google Scholar] [CrossRef]

- Hoek, E.M.; Allred, J.; Knoell, T.; Jeong, B.H. Modeling the effects of fouling on full-scale reverse osmosis processes. J. Membr. Sci. 2008, 314, 33–49. [Google Scholar] [CrossRef]

- Ruiz-García, A.; Ruiz-Saavedra, E. 80,000 h operational experience and performance analysis of a brackish water reverse osmosis desalination plant. Assessment of membrane replacement cost. Desalination 2015, 375, 81–88. [Google Scholar] [CrossRef]

- Kang, G.D.; Cao, Y.M. Development of antifouling reverse osmosis membranes for water treatment: A review. Water Res. 2012, 46, 584–600. [Google Scholar] [CrossRef] [PubMed]

- Shahkaramipour, N.; Tran, T.N.; Ramanan, S.; Lin, H. Membranes with Surface-Enhanced Antifouling Properties for Water Purification. Membranes 2017, 7, 13. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.P.; Arnot, T.C.; Mattia, D. A review of reverse osmosis membrane materials for desalination—Development to date and future potential. J. Membr. Sci. 2011, 370, 1–22. [Google Scholar] [CrossRef]

- Lawler, J. Incorporation of Graphene-Related Carbon Nanosheets in Membrane Fabrication for Water Treatment: A Review. Membranes 2016, 6, 57. [Google Scholar] [CrossRef] [PubMed]

- Nady, N. PES surface modification using green chemistry: New generation of antifouling membranes. Membranes 2016, 6, 23. [Google Scholar] [CrossRef] [PubMed]

- Taheri, A.; Sim, L.; Chong, T.; Krantz, W.; Fane, A. Prediction of reverse osmosis fouling using the feed fouling monitor and salt tracer response technique. J. Membr. Sci. 2015, 475, 433–444. [Google Scholar] [CrossRef]

- Taheri, A.; Sim, S.; Sim, L.; Chong, T.; Krantz, W.; Fane, A. Development of a new technique to predict reverse osmosis fouling. J. Membr. Sci. 2013, 448, 12–22. [Google Scholar] [CrossRef]

- Ho, J.S.; Sim, L.N.; Webster, R.D.; Viswanath, B.; Coster, H.G.; Fane, A.G. Monitoring fouling behavior of reverse osmosis membranes using electrical impedance spectroscopy: A field trial study. Desalination 2017, 407, 75–84. [Google Scholar] [CrossRef]

- Esfahani, I.J.; Kim, M.; Yun, C.; Yoo, C. Proposed new fouling monitoring indices for seawater reverse osmosis to determine the membrane cleaning interval. J. Membr. Sci. 2013, 442, 83–96. [Google Scholar] [CrossRef]

- Koo, C.; Mohammad, A. Experimental Investigation on Performance of Fouling Prediction Devices for NF/RO System. Int. J. Chem. Eng. Appl. 2015, 6, 179. [Google Scholar] [CrossRef]

- Rabie, H.R.; Côté, P.; Adams, N. A method for assessing membrane fouling in pilot- and full-scale systems. Desalination 2001, 141, 237–243. [Google Scholar] [CrossRef]

- Jin, Y.; Lee, H.; Jin, Y.O.; Hong, S. Application of multiple modified fouling index (MFI) measurements at full-scale SWRO plant. Desalination 2017, 407, 24–32. [Google Scholar] [CrossRef]

- Wei, C.H.; Laborie, S.; Aim, R.B.; Amy, G. Full utilization of silt density index (SDI) measurements for seawater pre-treatment. J. Membr. Sci. 2012, 405–406, 212–218. [Google Scholar] [CrossRef]

- Jin, Y.; Ju, Y.; Lee, H.; Hong, S. Fouling potential evaluation by cake fouling index: Theoretical development, measurements, and its implications for fouling mechanisms. J. Membr. Sci. 2015, 490, 57–64. [Google Scholar] [CrossRef]

- Ju, Y.; Hong, S. Nano-colloidal fouling mechanisms in seawater reverse osmosis process evaluated by cake resistance simulator-modified fouling index nanofiltration. Desalination 2014, 343, 88–96. [Google Scholar] [CrossRef]

- Wilf, M.; Klinko, K. Performance of commercial seawater membranes. Desalination 1994, 96, 465–478. [Google Scholar] [CrossRef]

- Zhu, M.; El-Halwagi, M.M.; Al-Ahmad, M. Optimal design and scheduling of flexible reverse osmosis networks. J. Membr. Sci. 1997, 129, 161–174. [Google Scholar] [CrossRef]

- Abbas, A.; Al-Bastaki, N. Performance decline in brackish water Film Tec spiral wound RO membranes. Desalination 2001, 136, 281–286. [Google Scholar] [CrossRef]

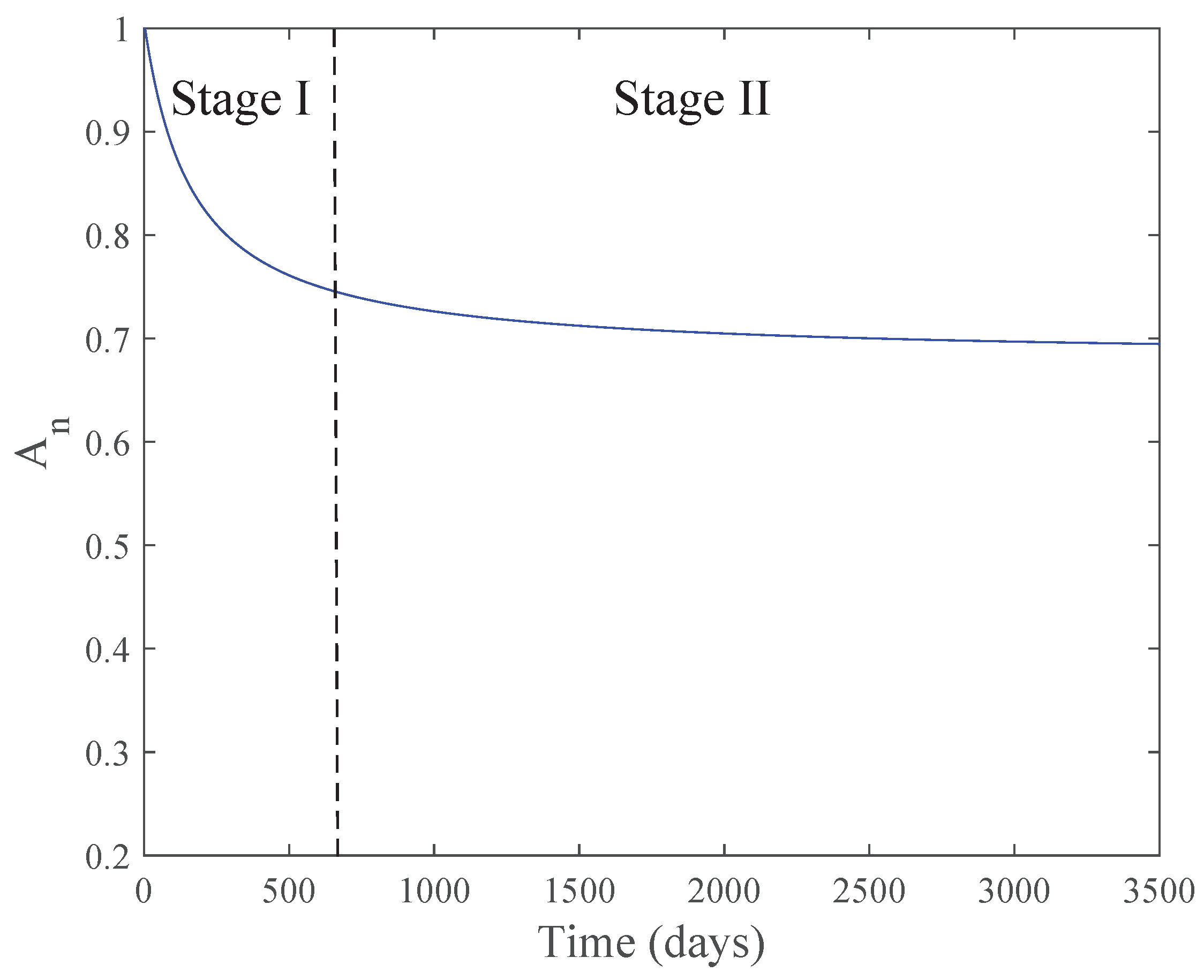

- Ruiz-García, A.; Nuez, I. Long-term performance decline in a brackish water reverse osmosis desalination plant. Predictive model for the water permeability coefficient. Desalination 2016, 397, 101–107. [Google Scholar] [CrossRef]

- ASTM. The Annual Book of ASTM Standard, Designation: D 4189-95. Standard Test Method for Silt Density Index (SDI) of Water; American Society for Testing and Materials: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Schippers, J.; Verdouw, J. The modified fouling index, a method of determining the fouling characteristics of water. Desalination 1980, 32, 137–148. [Google Scholar] [CrossRef]

- Boerlage, S.F.; Kennedy, M.; Aniye, M.P.; Schippers, J.C. Applications of the MFI-UF to measure and predict particulate fouling in RO systems. J. Membr. Sci. 2003, 220, 97–116. [Google Scholar] [CrossRef]

- Yiantsios, S.G.; Karabelas, A.J. An assessment of the Silt Density Index based on RO membrane colloidal fouling experiments with iron oxide particles. Desalination 2003, 151, 229–238. [Google Scholar] [CrossRef]

- Boerlage, S. Understanding the SDI and Modified Fouling Indices (MFI0. 45 and MFI-UF). In Proceedings of the IDA World Congress On Desalination and Water Reuse 2007-Desalination: Quenching a Thirst, Maspalomas, Gran Canaria, Canary Islands, Spain, 21–26 October 2007. [Google Scholar]

- Boerlage, S.F.; Kennedy, M.D.; Dickson, M.R.; El-Hodali, D.E.; Schippers, J.C. The modified fouling index using ultrafiltration membranes (MFI-UF): Characterisation, filtration mechanisms and proposed reference membrane. J. Membr. Sci. 2002, 197, 1–21. [Google Scholar] [CrossRef]

- ASTM. D 8002-15, Standard Test Method for Modified Fouling Index (MFI-0.45) of Water. In Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Sanz Ataz, J.; Guerrero Gallego, L.; Taberna Camprubí, E.; Peña García, N.; Carulla Contreras, C.; Blavia Bergós, J. Prevención del ensuciamiento coloidal en sistemas de ósmosis inversa y nanofiltración. Aplicación del ánalisis de superficies con haces de electrones. Tecnol. Agua 2003, 239, 58–63. [Google Scholar]

- Koo, C.H.; Mohammad, A.W.; Suja, F.; Talib, M.Z.M. Review of the effect of selected physicochemical factors on membrane fouling propensity based on fouling indices. Desalination 2012, 287, 167–177. [Google Scholar] [CrossRef]

- Sioutopoulos, D.C.; Karabelas, A.J. Correlation of organic fouling resistances in RO and UF membrane filtration under constant flux and constant pressure. J. Membr. Sci. 2012, 407, 34–46. [Google Scholar] [CrossRef]

- Sioutopoulos, D.C.; Karabelas, A.J. Evolution of organic gel fouling resistance in constant pressure and constant flux dead-end ultrafiltration: Differences and similarities. J. Membr. Sci. 2016, 511, 265–277. [Google Scholar] [CrossRef]

- Sioutopoulos, D.; Karabelas, A.; Yiantsios, S. Organic fouling of RO membranes: Investigating the correlation of RO and UF fouling resistances for predictive purposes. Desalination 2010, 261, 272–283. [Google Scholar] [CrossRef]

- Khirani, S.; Aim, R.B.; Manero, M.H. Improving the measurement of the Modified Fouling Index using nanofiltration membranes (NF-MFI). Desalination 2006, 191, 1–7. [Google Scholar] [CrossRef]

- Sioutopoulos, D.; Yiantsios, S.; Karabelas, A. Relation between fouling characteristics of RO and UF membranes in experiments with colloidal organic and inorganic species. J. Membr. Sci. 2010, 350, 62–82. [Google Scholar] [CrossRef]

- Alhadidi, A.; Kemperman, A.; Schippers, J.; Blankert, B.; Wessling, M.; van der Meer, W. SDI normalization and alternatives. Desalination 2011, 279, 390–403. [Google Scholar] [CrossRef]

- Koo, C.H.; Mohammad, A.W.; Suja, F.; Talib, M.Z.M. Use and Development of Fouling Index in Predicting Membrane Fouling. Sep. Purif. Rev. 2013, 42, 296–339. [Google Scholar] [CrossRef]

- Boerlage, S.F.; Kennedy, M.; Tarawneh, Z.; Faber, R.D.; Schippers, J.C. Development of the MFI-UF in constant flux filtration. Desalination 2004, 161, 103–113. [Google Scholar] [CrossRef]

- Chellam, S.; Wiesner, M.R. Evaluation of crossflow filtration models based on shear-induced diffusion and particle adhesion: Complications induced by feed suspension polydispersivity. J. Membr. Sci. 1998, 138, 83–97. [Google Scholar] [CrossRef]

- Adham, S.; Fane, A. Crossflow Sampler Fouling Index; National Water Research Institute: Fountain Valley, CA, USA, 2008. [Google Scholar]

- Javeed, M.; Chinu, K.; Shon, H.; Vigneswaran, S. Effect of pre-treatment on fouling propensity of feed as depicted by the modified fouling index (MFI) and cross-flow sampler-modified fouling index (CFS-MFI). Desalination 2009, 238, 98–108. [Google Scholar] [CrossRef]

- Sim, L.N.; Ye, Y.; Chen, V.; Fane, A.G. Crossflow Sampler Modified Fouling Index Ultrafiltration (CFS-MFIUF)-An alternative Fouling Index. J. Membr. Sci. 2010, 360, 174–184. [Google Scholar] [CrossRef]

- Sim, L.N.; Ye, Y.; Chen, V.; Fane, A.G. Investigations of the coupled effect of cake-enhanced osmotic pressure and colloidal fouling in RO using crossflow sampler-modified fouling index ultrafiltration. Desalination 2011, 273, 184–196. [Google Scholar] [CrossRef]

- Hoek, E.M.V.; Elimelech, M. Cake-Enhanced Concentration Polarization: A New Fouling Mechanism for Salt-Rejecting Membranes. Environ. Sci. Technol. 2003, 37, 5581–5588. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.S.; Hwang, T.M.; Lee, S.; Hong, S. A systematic approach to determine the fouling index for a RO/NF membrane process. Desalination 2009, 238, 117–127. [Google Scholar] [CrossRef]

- Yu, Y.; Lee, S.; Hong, K.; Hong, S. Evaluation of membrane fouling potential by multiple membrane array system (MMAS): Measurements and applications. J. Membr. Sci. 2010, 362, 279–288. [Google Scholar] [CrossRef]

- Naceur, M. The Modified Fouling Index Revisited: Proposal of A Novel Dimensionless Fouling Index for Membranes. Int. J. Eng. 2014, 3. [Google Scholar]

- Hong, K.; Lee, S.; Choi, S.; Yu, Y.; Hong, S.; Moon, J.; Sohn, J.; Yang, J. Assessment of various membrane fouling indexes under seawater conditions. Desalination 2009, 247, 247–259. [Google Scholar] [CrossRef]

- Boerlag, S.F.; Kennedy, M.D.; Bonne, P.A.; Galjaard, G.; Schippers, J.C. Prediction of flux decline in membrane systems due to particulate fouling. Desalination 1997, 113, 231–233. [Google Scholar] [CrossRef]

- Sim, L.N.; Ye, Y.; Chen, V.; Fane, A.G. Comparison of MFI-UF constant pressure, MFI-UF constant flux and Crossflow Sampler-Modified Fouling Index Ultrafiltration (CFS-MFIUF). Water Res. 2011, 45, 1639–1650. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Chen, K.L.; Ong, S.L.; Ng, W.J. A new normalization method for determination of colloidal fouling potential in membrane processes. J. Colloid Interface Sci. 2004, 271, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Vrouwenvelder, J.; van Paassen, J.; Wessels, L.; van Dam, A.; Bakker, S. The Membrane Fouling Simulator: A practical tool for fouling prediction and control. J. Membr. Sci. 2006, 281, 316–324. [Google Scholar] [CrossRef]

- Vrouwenvelder, J.; Bakker, S.; Wessels, L.; van Paassen, J. The Membrane Fouling Simulator as a new tool for biofouling control of spiral-wound membranes. Desalination 2007, 204, 170–174. [Google Scholar] [CrossRef]

- Tay, K.G.; Song, L. A more effective method for fouling characterization in a full-scale reverse osmosis process. Desalination 2005, 177, 95–107. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, L.; Ong, S.L. Fouling behavior and foulant characteristics of reverse osmosis membranes for treated secondary effluent reclamation. J. Membr. Sci. 2010, 349, 65–74. [Google Scholar] [CrossRef]

- Chen, K.L.; Song, L.; Ong, S.L.; Ng, W.J. The development of membrane fouling in full-scale RO processes. J. Membr. Sci. 2004, 232, 63–72. [Google Scholar] [CrossRef]

- Belkacem, M.; Bekhti, S.; Bensadok, K. Groundwater treatment by reverse osmosis. Desalination 2007, 206, 100–106. [Google Scholar] [CrossRef]

| Methods, Indices and Parameters | Characteristics | Equation | Comments |

|---|---|---|---|

| (1995, [30]) |

| Disadvantages: is a standardized method (ASTM D4189), but empirical, and it is not based on fouling mechanisms. It is not related to foulant concentration in feedwater. It does not take into account the temperature or variation in membrane resistance. | |

| (J.C. Schippers and J. Verdouw, 1980 [31]) |

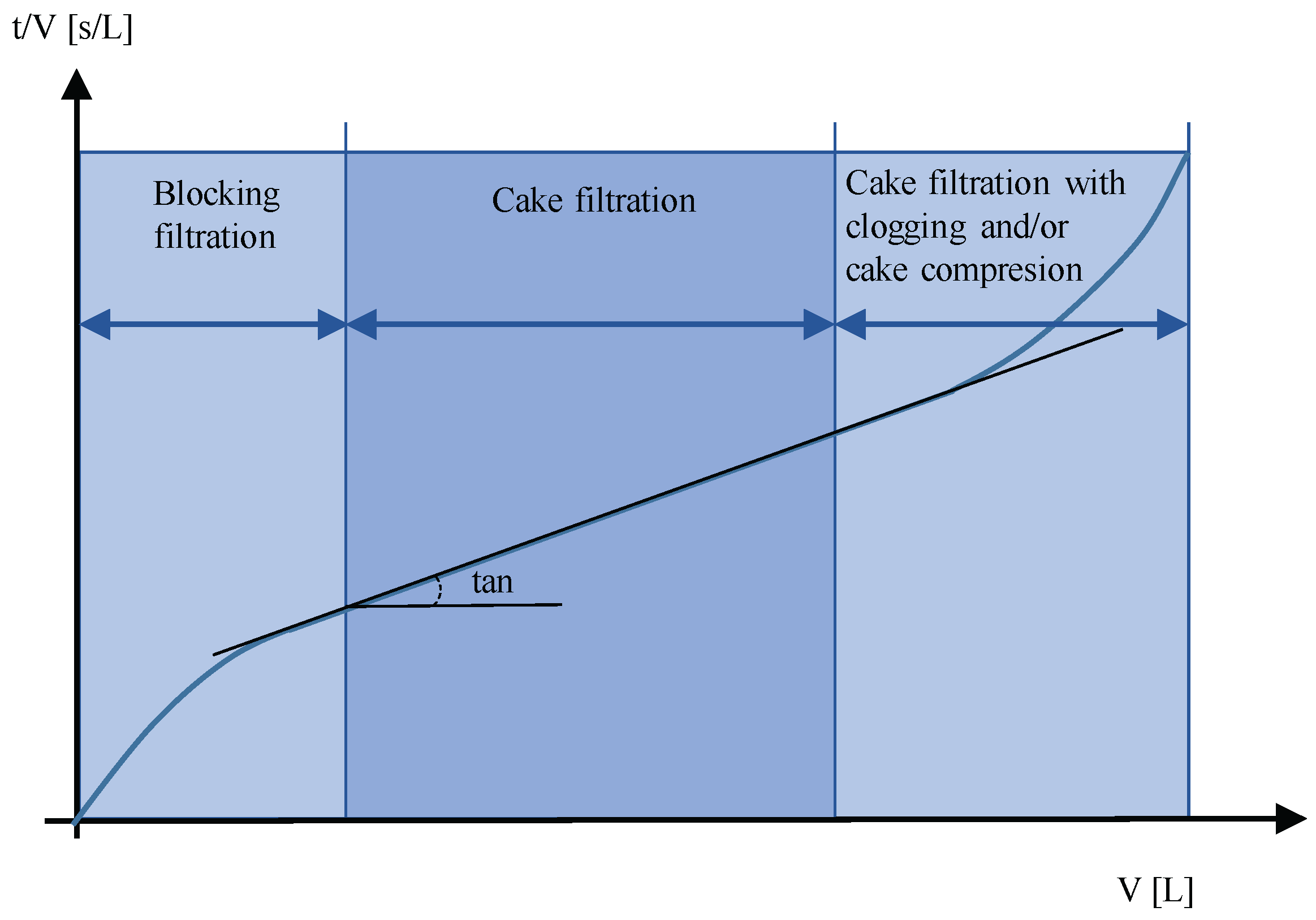

| Characteristics:

is an improved version of and is related to cake filtration theory. The fouling index I is obtained from the slope of the lineal region of the graph vs. V (filtrated volume). Disadvantages: It is not very accurate as foulant agents with a diameter less than 0.45 m pass across the membrane. | |

| (A. Alhadini et al., 2011 [44]) |

| — | Characteristics:

is a normalization of taking into consideration the variation of temperature, pressure and membrane resistance. Different fouling mechanisms could be assumed based on line charts and parameters’ calculation. Disadvantages: It is not very accurate as foulant agents with a diameter less than 0.45 m pass across the membrane. |

| (A. Alhadini et al., 2011 [44]) |

| Characteristics:

showed a more linear relationship with foulant concentration in feedwater than standard . Besides, it is independent of testing parameters, such as temperature and pressure, and less sensitive to membrane resistance. Disadvantages: It is not very accurate as foulant agents with a diameter less than 0.45 m pass across the membrane. | |

| (S.F.E. Booerlage et al., 1997 [57]) |

| Characteristics: UF membrane is used instead of MF, so colloidal fouling can be detected.

is a constant, the compressibility factor of the cake and the concentration of particles in the feedwater. Disadvantages: is not able to show fouling behavior in constant flow precesses. Twenty hours are required to obtain a measurement, and the method to obtain the deposition factor is tedious. Although the UF membrane used in the tests is capable of retaining particles and colloidal matter, it is not efficient enough to retain organic matter. | |

| (S.F.E. Boerlage et al., 2004 [46]) |

| Characteristics: The operating mode is constant flow as happens in the majority of actual RO processes. The fouling index

I is obtained from the slope of the graph (Net Driven Pressure) vs. filtration time. is the standard pressure (2 bar). Disadvantages: The test is performed under conditions of accelerated flow that do not allow representation of the behavior of fouling to flows of 20–30 L/mh. As with , the deposition of particles is considered through a deposition factor, and although through the UF, it is possible to retain particulate matter and colloids, it is not enough to retain the organic matter present in the feed. Despite the improvements of , the measurement cannot be simulated in cross-flow. | |

| (S. Khirani et al., 2006 [42]) |

| Characteristics: The test tries to take into consideration the organic matter in the feedwater. Disadvantages: The test is carried out under constant pressure, and the deposition factor of particles in cross-flow is not considered. The total retention of organic matter is not achieved in this procedure. | |

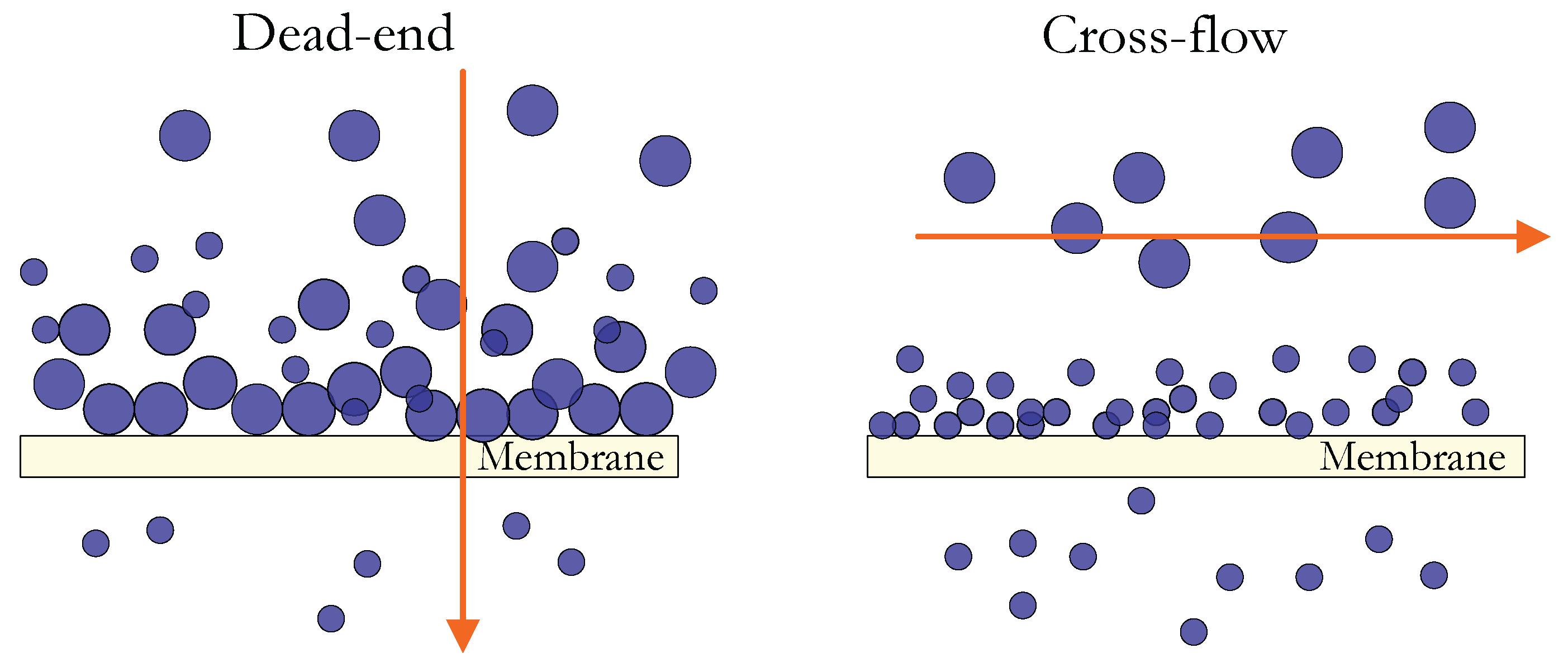

| (S.S. Adham and A.G. Fane, 2008 [48]) |

| Characteristics: This index incorporates the hydrodynamic behavior of the cross-flow in the measurement of the fouling index. CFS allow small particle to pass across the MF membrane to be deposited on the MF membrane located in

in dead-end flow. Disadvantages: Discontinued operating mode. | |

| (M.A. Javeed et al., 2009 [49]) |

| Characteristics:

is measured in continuous mode. Disadvantages: It uses the same MF membrane as in , and the operating mode is at constant pressure. | |

| (L.N. Sim et al., 2011 [58]) |

| Characteristics: This index takes into account the hydrodynamic effect of cross-flow and the deposition factor. is the modified resistivity of the cake. can be a more precise method to determine the effect of fouling agents on the RO process. The method is easy due to its short time of filtration. | |

| (J. Choi et al., 2009 [53]) |

| Characteristics: It is a combination of various indices, denoted as

(using a Hydrophilic MF membrane), (using a MF Hydrophobic membrane) and (using a hydrophilic UF membrane). This test tries to take into consideration all types of foulant agents using different membranes. is the value of ; is the value of ; and is the value of . The weighting factors , , and depend on the characteristics of the membrane. Disadvantages: The method is difficult since it requires different types of membranes, and the procedure to obtain is very tedious. In addition, the fouling index is still measured under constant pressure conditions. | |

| (Y. Yu et al., 2010 [54]) |

| — | Characteristics: MF, UF and NF membranes are connected in series for simultaneous separation of target foulants. This index was shown to be precise and selective in the prediction of the fouling potential of different feedwaters. Disadvantages: The method is not simple since it requires different types of membranes to determine the particle- , colloid- and organic-. Furthermore, the fouling indices are still measured under constant pressure conditions. |

| (M. W. Naceur, 2014 [55]) |

| Characteristics: The experimental procedure is similar to

. By introducing the equation of Ruth in the model, the authors obtained a dimensionless fouling index, which is a simple linear equation. Disadvantages: Experimental work to validate was not carried out, so the accuracy of this index has not been validated. | |

| “Normalized Fouling Rate” () (H.R. Rabie et al. 2001 [21]) |

| — | Characteristics: This method is used to analyze data from a pilot plant in a large-scale facility.

is the curve of the graph vs. , where is the specific volume (the volume collected per unit area and per in time t). Disadvantages: It cannot be used as a fouling potential indicator of feedwater. |

| (L. Song et al. 2004 [59]) |

| Characteristics: This normalization method has the objective of eliminating the effects of different operating parameters in the determination of the fouling rate. In this way, the fouling potential of feed water can be compared on a fair basis. Disadvantages: One of its results indicates that the fouling potential of large colloidal particles increases as the operating pressure increases. This is mainly due to the compressibility effect of the cake, which is strongly related to the nature of the colloid. | |

| Membrane Fouling Simulator (MFS) (J.S.Vrowenvelder et al. 2006 [60]) | — | MFS uses the same membrane materials as spiral-wound RO/NF membrane, with the same dimensions and hydrodynamic behavior, and is equipped with a visor. Suitable for in situ observations in real time, non-destructive observations and parameters such as pressure drop can be monitored. It is mainly used as a biofouling monitor [61]. Disadvantages: There is no instant response of the fouling potential. | |

| Feed Fouling Monitor (FFM) (A.H. Taheri et al., 2013 [17]) | — | This technique uses a UF membrane to predict the increase of transmembrane pressure at constant fluxes in the presence of colloidal fouling. This prediction includes the developing hydraulic resistance and the CEOP components. Disadvantages: Lack of extension of this monitoring and modeling approach to real-world foulants and a full-scale RO desalination plant. | |

| Feed Fouling Monitor-Salt Tracer Response (FFM-STRT) (A.H. Taheri et al., 2015 [16]) | — | This method uses the FFM including an STRT to measure the development of concentration polarization in estimating (CEOP) the contribution. Foulants studied were humic acid and colloidal silica Disadvantages: There is no instant response of the fouling potential. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-García, A.; Melián-Martel, N.; Nuez, I. Short Review on Predicting Fouling in RO Desalination. Membranes 2017, 7, 62. https://doi.org/10.3390/membranes7040062

Ruiz-García A, Melián-Martel N, Nuez I. Short Review on Predicting Fouling in RO Desalination. Membranes. 2017; 7(4):62. https://doi.org/10.3390/membranes7040062

Chicago/Turabian StyleRuiz-García, Alejandro, Noemi Melián-Martel, and Ignacio Nuez. 2017. "Short Review on Predicting Fouling in RO Desalination" Membranes 7, no. 4: 62. https://doi.org/10.3390/membranes7040062

APA StyleRuiz-García, A., Melián-Martel, N., & Nuez, I. (2017). Short Review on Predicting Fouling in RO Desalination. Membranes, 7(4), 62. https://doi.org/10.3390/membranes7040062