Abstract

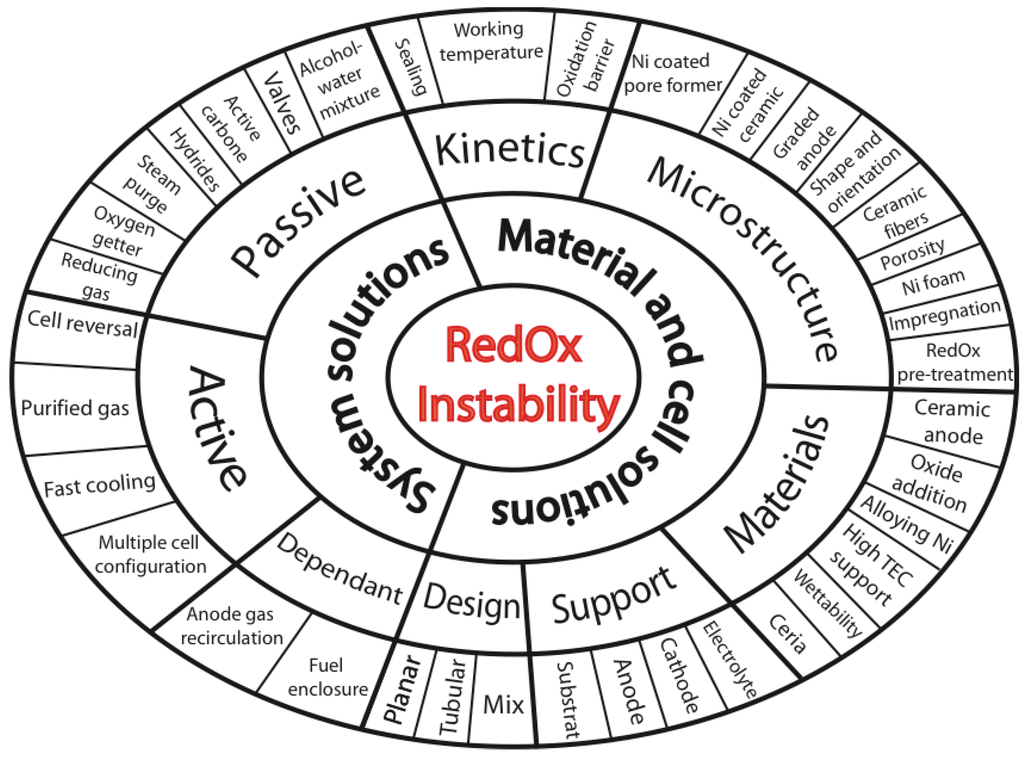

Solid oxide fuel cells are able to convert fuels, including hydrocarbons, to electricity with an unbeatable efficiency even for small systems. One of the main limitations for long-term utilization is the reduction-oxidation cycling (RedOx cycles) of the nickel-based anodes. This paper will review the effects and parameters influencing RedOx cycles of the Ni-ceramic anode. Second, solutions for RedOx instability are reviewed in the patent and open scientific literature. The solutions are described from the point of view of the system, stack design, cell design, new materials and microstructure optimization. Finally, a brief synthesis on RedOx cycling of Ni-based anode supports for standard and optimized microstructures is depicted.

Content

- Introduction

- RedOx instability

- 2.1.

- Problematic

- 2.2.

- High Temperature Nickel Oxide Reduction and Nickel Oxidation

- 2.2.1.

- Reduction of NiO

- 2.2.2.

- High Temperature Oxidation of Ni

- 2.3.

- Reduction of NiO-YSZ Cermet

- 2.4.

- Oxidation of Ni-Ceramics Composite

- 2.4.1.

- Kinetics of Oxidation

- 2.4.2.

- Homogeneous Versus Inhomogeneous Oxidation

- 2.4.3.

- Expansion during Reoxidation

- 2.4.4.

- Bending and Stresses in Half-Cell Samples (Anode Support)

- 2.4.5.

- Young’s Modulus and Strength Variation with Reoxidation

- 2.4.6.

- RedOx Expansion Limits: Mathematical Approaches

- 2.4.7.

- Electrical Conductivity versus RedOx Cycles

- 2.4.8.

- Temperature Variation during Oxidation

- 2.4.9.

- Reoxidation by Ionic Current

- 2.4.10.

- Micro and Nano-Structural Changes upon Redox Cycling

- 2.4.11.

- Electrochemical Performance and Electrochemical Impedance Spectroscopy

- 2.4.12.

- Single Chamber SOFC

- 2.5.

- Summary of the RedOx Instability

- RedOx Solutions

- 3.1.

- System Solutions

- 3.1.1.

- Dependent System Solutions

- 3.1.2.

- Passive System Solutions

- 3.1.3.

- Active System Solutions

- 3.2.

- Stack Design

- 3.2.1.

- Planar Design

- 3.2.2.

- Tubular Design

- 3.3.

- Cell Design

- 3.3.1.

- Cathode Supported Cell (CSC)

- 3.3.2.

- Electrolyte Supported Cell (ESC)

- 3.3.3.

- Metal Supported Cell (MSC)

- 3.3.4.

- Inert Substrate Supported Cells (ISSC)

- 3.3.5.

- Anode Supported Cell (ASC)

- 3.4.

- Modification of the Microstructure

- 3.4.1.

- Anode Functional Layer, Anode Support and Anode Current Collecting Layer

- 3.4.2.

- Particles Size

- 3.4.3.

- Sintering Temperature

- 3.4.4.

- Porosity

- 3.4.5.

- Composition

- 3.4.6.

- Orientation and Particle Shape of Nickel Phase

- 3.4.7.

- Ni coated Pore-Former

- 3.4.8.

- Ni Foam

- 3.4.9.

- Wet Impregnation (WI)

- 3.4.10.

- Ni Coated Ceramic

- 3.4.11.

- Graded Composition and Porosity

- 3.4.12.

- Controlled RedOx Cycle

- 3.5.

- Alternative Anode Materials

- 3.5.1.

- Alloys and Additives for Metal-Ceramic Anode

- 3.5.2.

- Full Ceramic Anode

- 3.5.3.

- Mechanically Stronger Materials

- 3.5.4.

- Use Support with Higher Thermal Expansion Coefficient (TEC)

- 3.6.

- Kinetics

- 3.6.1.

- Oxidation Barrier

- 3.6.2.

- Improved Sealing

- 3.6.3.

- Lower Operating Temperature

- Synthesis for Ni-Based Anode-Supported Cells

- Conclusions

- Acknowledgments

- Appendix

- References

1. Introduction

Fuel cells will play a key role in the future as (1) they convert fuel to electricity with high efficiency (>60%) even for small systems; (2) in electrolyzer mode, they can produce hydrogen from electricity and water to store energy; (3) they are clean (negligible NOx and SOx emissions) and (4) they are silent.

Solid oxide fuel cells (SOFCs) are based on a ceramic electrolyte and work at elevated temperature between 600 and 1000 °C. Their advantages are (1) design flexibility thanks to the solid electrolyte; (2) fuel flexibility including hydrogen, hydrocarbons and bio-fuels and (3) co-generation of heat and electricity (reaching total efficiencies up to 95%) [1].

Patented in the 1970s, the state-of-the art anode is based on a nickel-ceramic composite material due to its high activity, electrical conductivity and relatively low cost [2]. The goals of the ionically conducting ceramic are, first, to limit nickel agglomeration at high temperature, second to increase the active electrode thickness and finally to match the anode thermal expansion coefficient (TEC) to that of the ceramic electrolyte. The most used ceramics are yttria stabilized zirconia (YSZ) and gadolinia doped ceria (GDC). During its fabrication, the anode is sintered at elevated temperature (1300–1450 °C), producing a NiO-ceramic composite. The first anode utilization reduces the nickel oxide and creates a porous structure due to the volume reduction from NiO to Ni.

Majors limitations of the Ni-ceramic anodes are (1) the nickel microstructural changes to lower the interfacial energy, which decreases the electrochemical activity [3,4,5]; (2) the volatilization of the nickel under high steam concentration [6,7]; (3) promotion of the competitive catalytic cracking of hydrocarbons that produces a rapid deposition of carbon in the anode [8]; (4) impurities in the fuel stream, particularly sulfur and phosphorus, that inhibit anode functionality [9] and (5) anode expansion during re-oxidation of the Ni if a fuel supply cut occurs, under high fuel utilization operation or with seal leakage occurrence [10,11,12,13].

Nickel is not stable, at high temperature, against oxidation in air. The volume changes during successive reduction and reoxidation cycles (“RedOx cycle”) may be detrimental for the anode unity. The problem is even worse if the cell design is anode supported because the volume change puts the electrolyte under tension and, once cracked, produces leakage between fuel and oxidant gases [10].

During the last 15 years, a large amount of work has been carried out on the RedOx problematics of SOFC anodes, including three review papers (two considering Ni-YSZ anodes [12,14] and one focused on ceramic anodes [15]), about 10 PhD theses [16,17,18,19,20,21,22,23,24], tens of patents and hundreds of scientific papers. This review will try to be as exhaustive as possible. It describes first the reduction and oxidation of nickel at high temperature, then continues with the reduction and oxidation of Ni-based composites. The effects of RedOx cycles on ceramic-metal (cermet) anode properties, like conductivity, electrochemical performance, dimension, etc., are reported. Finally, it reviews the solutions at system, design and materials levels. A brief synthesis precedes the conclusion.

2. RedOx Instability

2.1. Problematic

RedOx instability refers to the chemo-mechanical instability of the solid oxide fuel cell anode and support under oxygen partial pressure variation of more than 20 orders of magnitude during reduction and oxidation (pO2,air = 0.21 atm and pH2,3%H2O,800°C = 4 × 10−22 atm) at high temperature (600–1000 °C).

This was first reported in 1996 by Cassidy et al. for Ni-YSZ anode supported thin electrolyte cells [10]. The volume increase upon reduction and reoxidation (“RedOx cycle”) of the anode support was measured as well as the loss of the open circuit voltage (OCV) due to cracking of the thin electrolyte.

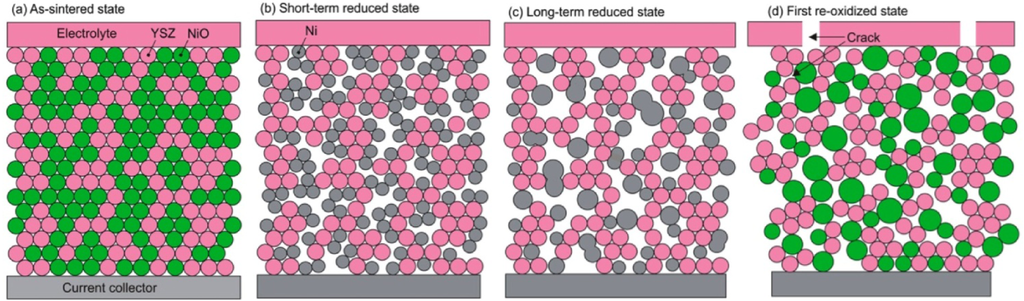

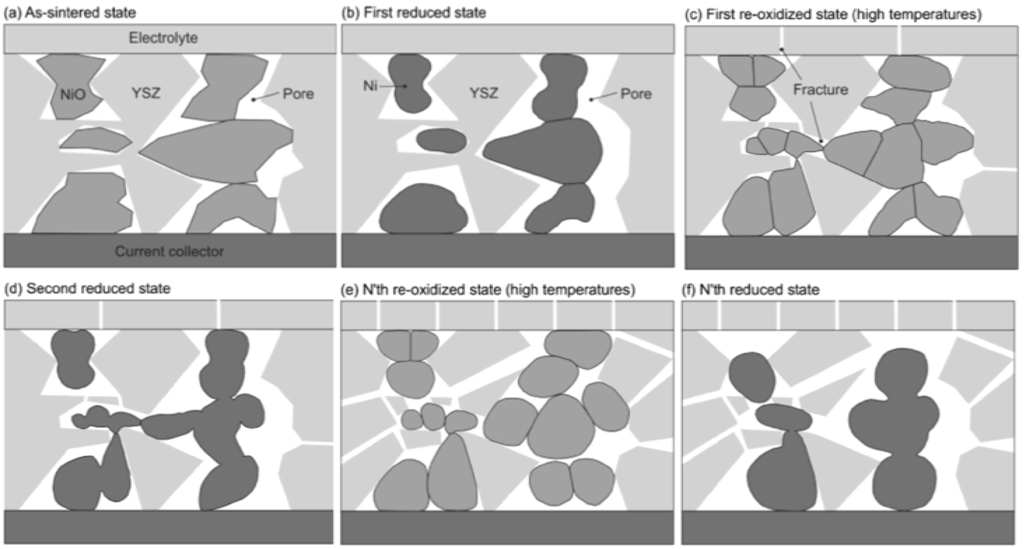

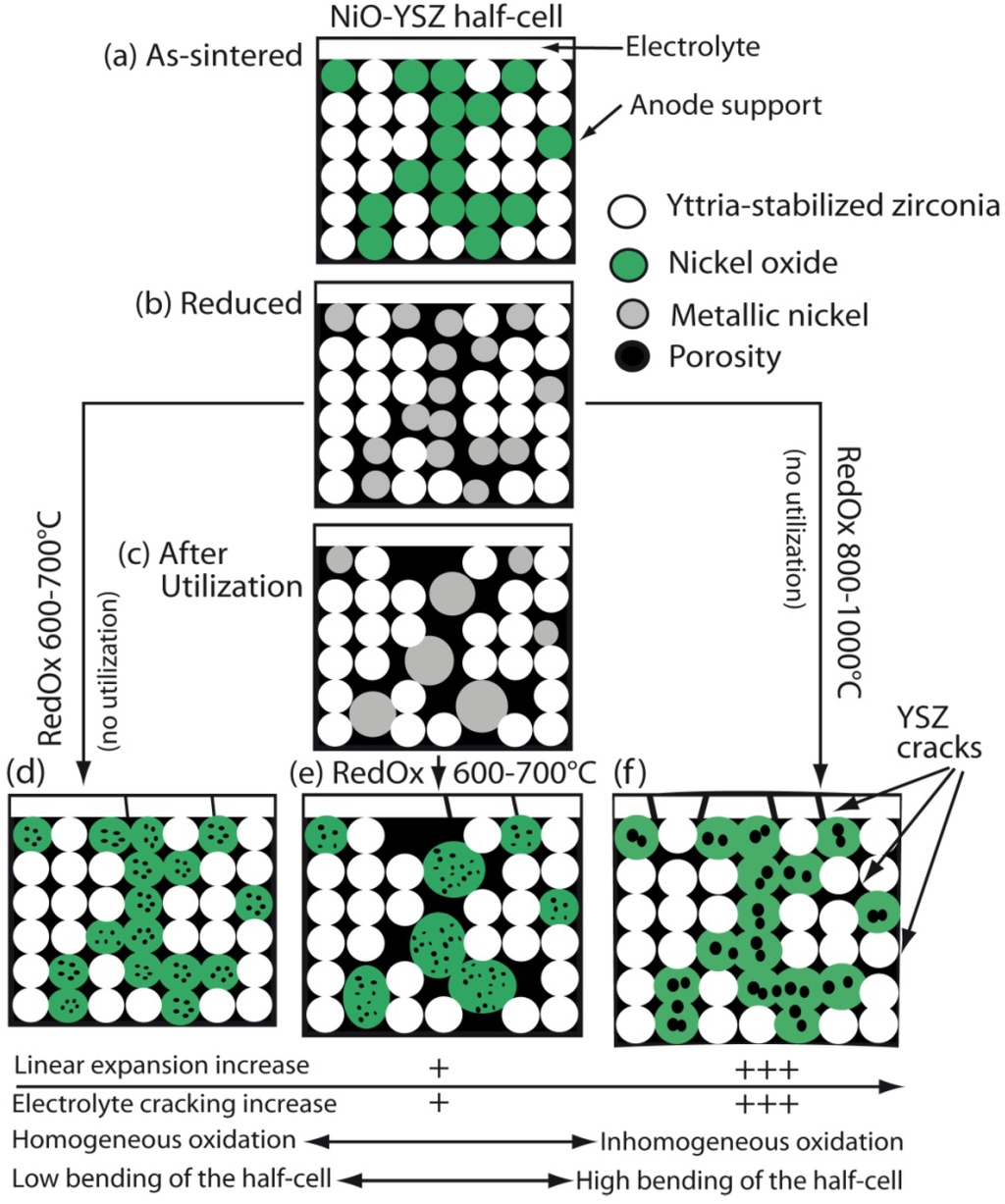

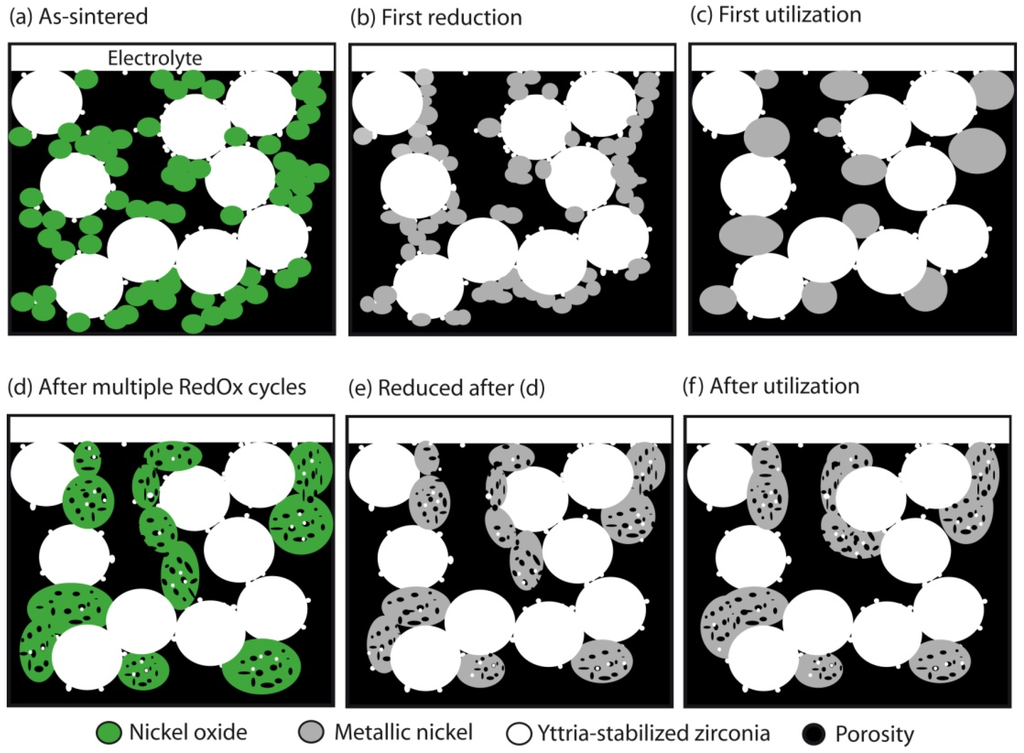

This pointed out one of the main limitations of the nickel-ceramic based anode. These anodes show a large bulk volume change upon Ni reoxidation. The shrinkage of nickel oxide particles during reduction is around 40 vol %, and during reoxidation nickel expansion is around 66 vol %. The molar volumes of NiO and Ni are given in Table 1. The ratio of molar volume of the oxide and the metal is known as the Pilling–Bedworth ratio and is about 1.66 for nickel [25]. Based on Cassidy’s and following works, Klemensø drew a schematic of the mechanisms underlying the anode RedOx, as shown in Figure 1 [26,27,28].

Table 1.

Nickel and nickel oxide molar mass, specific mass and molar volume [29,30].

| NiO | Ni | |

|---|---|---|

| M [g/mol] | 74.71 | 58.71 |

| ρ [g/cm3] | 6.67 | 8.9 |

| V [cm3/mol] | 10.97 | 6.58 |

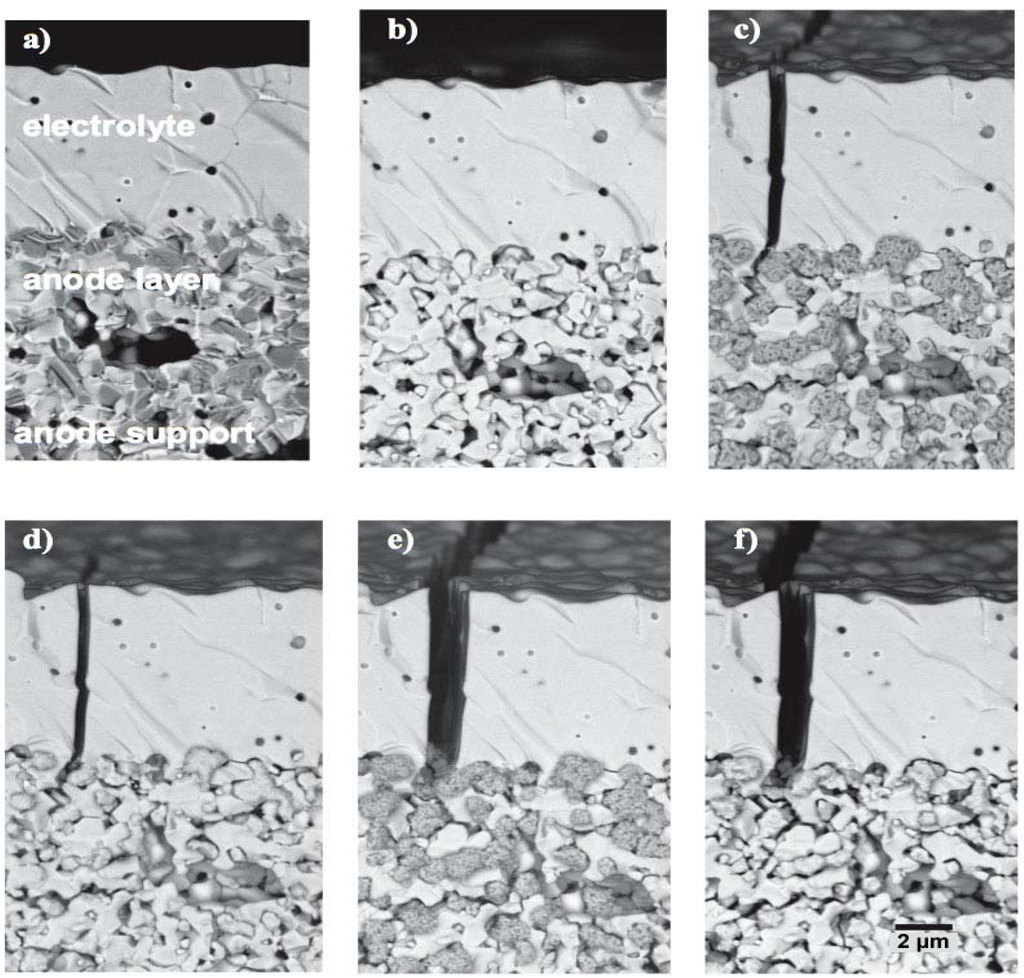

Figure 1.

Microstructural changes during a RedOx process in Ni-YSZ (yttria stabilized zirconia) based anodes [27].

Anode reduction increases porosity because of the NiO to Ni volume change. During utilization, the metallic nickel phase re-organizes due to high temperature, water vapor content and surface tension equilibrium [3,31,32]. If the oxygen partial pressure increases, nickel can rapidly oxidize at high temperature (above 600 °C). The ensuing volume increase can then destroy the electrolyte and the anode support.

Reoxidation of Ni can occur for a variety of reasons at the operating temperature:

- Under high load or high fuel utilization conditions, the oxygen partial pressure can locally increase up to a critical value [33];

- The oxygen partial pressure increases in the vicinity of compressive seals, which causes small air leakage to the anode [34];

- Accidental fuel supply interruption;

- To reduce cost and system complexity, shut down and start up is done without protective gas.

This limitation of the state-of-the-art Ni-YSZ anode induced a large research effort from the scientific community as it is considered as one of the bottlenecks of SOFC technology [35]. Before considering the composite, the reduction and oxidation of pure nickel is discussed.

2.2. High Temperature Nickel Oxide Reduction and Nickel Oxidation

2.2.1. Reduction of NiO

The reduction of NiO occurs by H2 supply and H2O removal according to Equation (1). The kinetics of NiO reduction in H2 are commonly approximated by a linear equation with time at constant temperature (Equation (2)), implying a surface controlled process [36]. Usually the slope is taken at a certain conversion degree (x between 20% and 80%) and its logarithm reported against T−1 to obtain an activation energy (Ea), as the reaction is thermally activated and follows an Arrhenius law (Equation (3)). Deviation of linear kinetics at low conversion degree is due to an initial induction period for nucleation of Ni clusters, which then grow at a linear rate. At the end of the reaction, it slows down as the diffusion path for H2 reactant and H2O product gets longer through the porous Ni metallic layer. This will thus give an “s”-shape curve at low temperature; at high temperature, the induction period is short and the densification of Ni at the surface decreases the gas diffusion process further. This is a reason for lower activation energy reported at higher temperature (see Table 2). Richardson et al. presented a good description of NiO reduction by hydrogen [37]. More generally, there are multiple reaction rate equations describing the reduction of metals like a power law, Avrami kinetics or first order kinetics [37,38].

with x the degree of conversion, k the reaction rate, t the time, k0 the reaction rate constant, Ea the activation energy, R the gas constant (8.314 J mol−1 K−1) and T the temperature.

with x the degree of conversion, k the reaction rate, t the time, k0 the reaction rate constant, Ea the activation energy, R the gas constant (8.314 J mol−1 K−1) and T the temperature.

Table 2.

Reduction kinetics for NiO with H2 from Richardson et al. [37] and other authors.

| Source reference | Sample and measurement technique | Temperature range (°C) | Ea (kJ mol−1) |

|---|---|---|---|

| Pure nickel oxide | |||

| Szekely and Evans [37] | Large porous single pellet, TGA | 372–753 | 17 |

| Deb Roy and Abraham [37] | Non-porous spherical pellets, TGA | 400–800 | 22 |

| Bandrowski et al. [37] | Large porous NiO pellet in a packed bed, H2O detection | 261–298 | 52 |

| Szekely and Evans [37] | Large porous NiO pellet, TGA | 226–308 | 65 |

| Nakajima et al. [37] | Powdered NiO sample | 277–377 | 69 |

| Rao and Rashed [39] | Thin NiO slab, TGA | 300–400 | 73 |

| Richardson et al. [37] | Porous NiO powder, TGA | 220–355 | 84 |

| Richardson et al. [37] | Porous NiO powder thin slab, XRD | 175–300 | 85 |

| Szekely et al. [37] | Pressed thin discs, TGA | 224–259 | 133 |

| NiO and ceramic composite | |||

| Modena et al. [40] | Tape-cast NiO-YSZ, TGA | 700–800 | 25–29 |

| Modena et al. [40] | Tape-cast NiO-YSZ 2nd reduction, TGA | 700–800 | 51–87 |

| Waldbillig et al. [41] | Tape-cast NiO-YSZ, TGA | 500–950 | 54–78 |

| Tikekar et al. [36] | Pressed NiO-YSZ rectangular bar, thickness of reduced layer | 600–800 | 94 |

| Pihlatie et al. [38] | Tape-cast NiO-YSZ, TGA | 500–750 | 84 |

Both nickel and its oxide have a face-centered cubic (FCC) structure with the respective lattice parameters equal to 0.368 and 0.418 nm. Nickel growth is epitaxial on NiO even if the difference in lattice parameter is 13.6% [42,43]. The reduction rate is fairly high: at 600 °C a 0.5 mm NiO particle is reduced in 30 min (32% H2 in N2). At higher temperature, the kinetics become distorted by sintering of the porous Ni, which limits the access of gas to the oxide [44]. Addition of water vapor to hydrogen reduces the reduction rate and increases the activation energy at low temperature 175–300 °C for relatively coarse particles (10–20 µm) (for 20% H2 in N2) [37]. Contradictorily, Müller relates that if the water vapor is increased from 3% to 10%, the reduction temperature decreases and the rate increases for fine NiO particles of 0.5 µm (for 6% H2 in N2) [16].

2.2.2. High Temperature Oxidation of Ni

This section is based on three different books [25,45,46] and a review paper from Atkinson [47] describing high temperature oxidation of metals.

The oxidation forms on top of the metal an oxide layer that separates the gas containing the oxidant species and the metal. In case of nickel, the reaction occurring in air is Ni + ½O2 = NiO. For a thin oxide layer (< about 0.1 µm), transport is governed by the electric field built within the layer by the cathodic reaction (½O2 + 2e− = O2−) and the anodic one (Ni = Ni2+ + 2e−). This oxidation rate is described by the Mott–Cabrera theory and follows logarithmic laws.

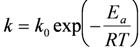

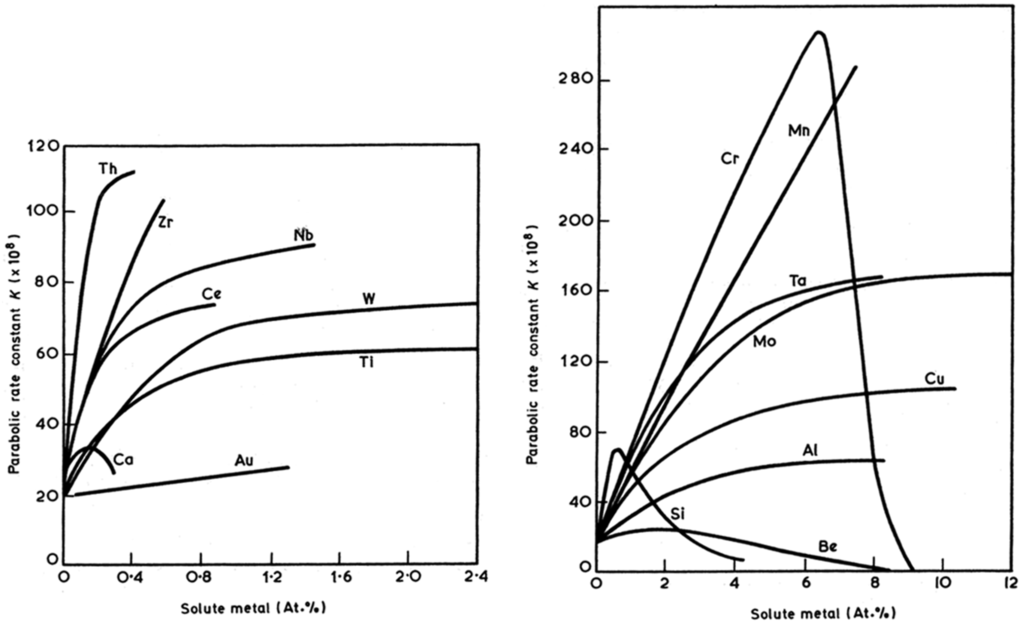

For thicker oxide layers (>0.1 µm), oxidation is governed by ion diffusion through the oxide scale, which follows a parabolic behavior (Wagner theory), with y2 = kp·t, where y is the oxide layer thickness, t the time and kp the parabolic rate constant. The Ni2+ cation diffusion in its oxide is about 6 orders of magnitude faster than the oxygen anion diffusion at 1400 °C. This can cause internal voids during the growth of the oxide layer. For large surfaces, the inward diffusion of oxygen occurs through microcracking or microchannel formation. The microstructure of the oxide surface and cross-section varies depending on the oxide thickness and the oxidation temperature as shown by Peraldi et al. (see Figure 2) [48,49].

Figure 2.

Arrhenius plot of parabolic rate constant kp as a function of oxidation temperature and scale thickness indicating NiO scale morphologies and microstructures [48,49].

In the case of small metal particles, it was observed by focused ion beam cross-sectioning that internal porosity is formed due to different diffusion coefficients between Ni2+ and O2− in the nickelous oxide like a pseudo Kirkendall effect (a pure Kirkendall effect is for a metal solid solution; in the case of NiO, Ni2+ and O2− are on different crystallographic positions). Up to 1000 °C, outward diffusion of nickel cations is faster than the inward diffusion of oxygen anions, leaving NiO internal porosity [50]. For metal nanoparticles, the number of voids and the void’s growth depend on the relative rate of self-diffusion in the core material (i.e., Ni or vacancy diffusion in Ni crystal) versus cation diffusion through the shell (i.e., Ni2+ diffusion in NiO crystal) [51]. If self-diffusion is fast, a single void may form inside the particle and grow until conversion is completed (e.g., NiO). Alternatively, if self-diffusion is significantly slower than cation diffusion through the oxide shell, then several voids remain (e.g., CoO and CoxSy) [52]. For the Ni case, the particle size plays a role: smaller nanoparticles show single voids compared to larger nanoparticles presenting multiple voids. For the larger nanoparticles, the Ni self-diffusion is not fast enough to condense all the vacancies into a single void [53]. The key factor in microstructural modification during oxidation is the difference in diffusion coefficients defining the mass transport.

By decreasing the oxygen partial pressure, the oxidation rate should decrease proportionally to kp = C × (pO2)1/6 (with C a constant).

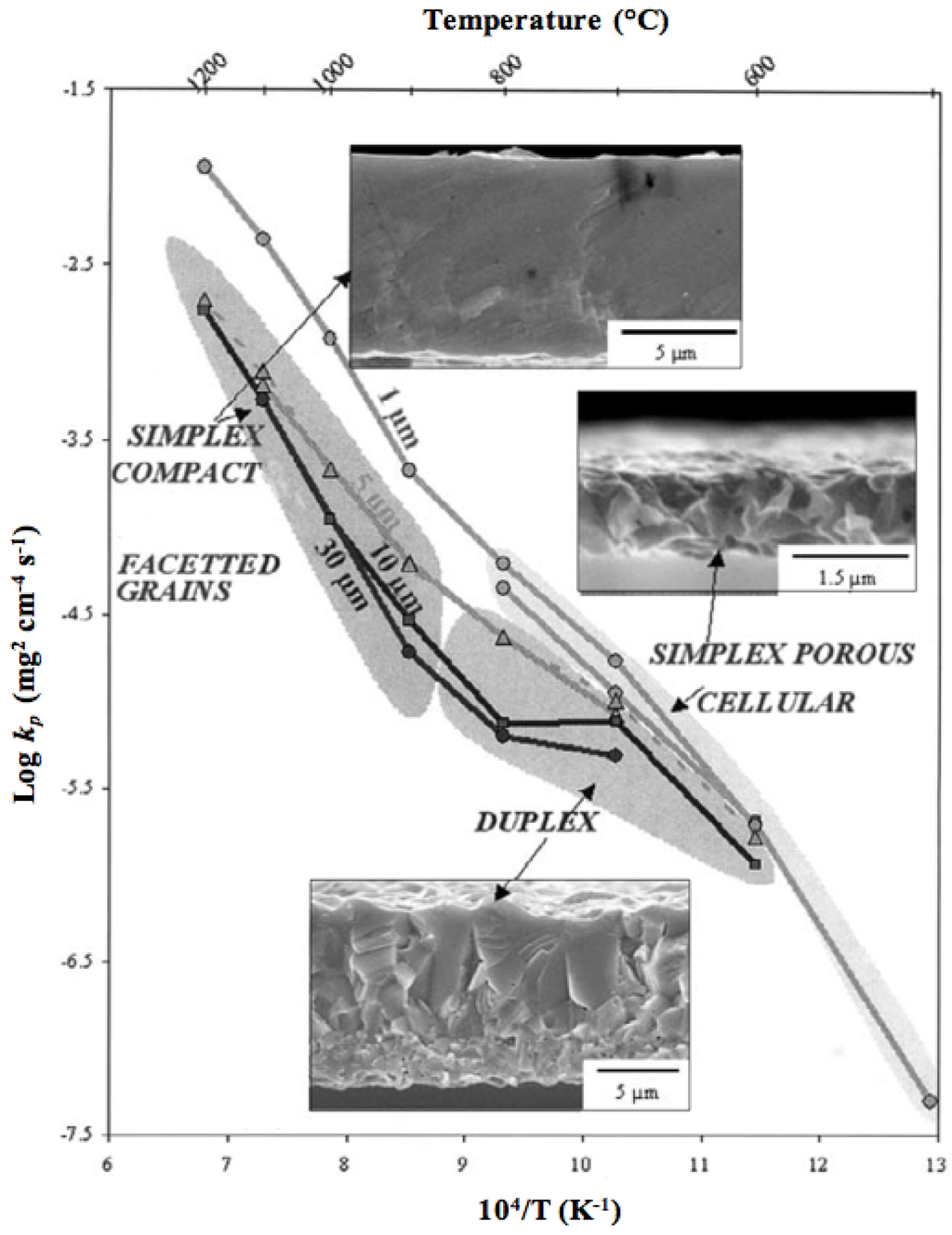

The equilibrium partial pressure of oxygen can be calculated using the Gibbs free energy of the nickel oxidation reaction (Ni + ½ O2 ↔ NiO). From this a Nernst potential can be calculated against an electrode in air depending on the temperature:

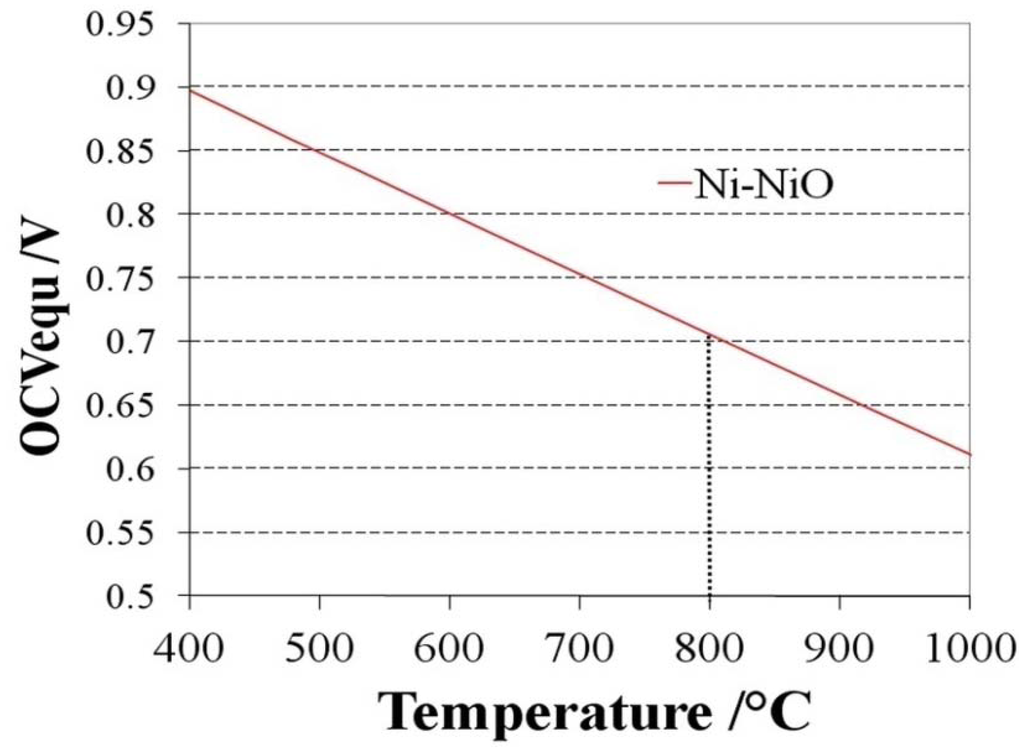

where T is the temperature in Kelvin, R the gas constant, F the Faraday constant and pO2cathode the partial pressure of oxygen at the cathode side. The value of the Nernst potential (or open circuit potential, OCV) versus temperature during Ni oxidation is given in Figure 3: at 800 °C, the OCV is between 0.68 and 0.71 V depending on the chosen database for the Gibbs free energy [54,55].

where T is the temperature in Kelvin, R the gas constant, F the Faraday constant and pO2cathode the partial pressure of oxygen at the cathode side. The value of the Nernst potential (or open circuit potential, OCV) versus temperature during Ni oxidation is given in Figure 3: at 800 °C, the OCV is between 0.68 and 0.71 V depending on the chosen database for the Gibbs free energy [54,55].

Figure 3.

Open circuit voltage (OCV) or Nernst potential versus temperature for the Ni/NiO equilibrium [54,55].

Solid state diffusion is activated by temperature as expressed by the Arrhenius Equation (3). Values of the activation energy are given in Table 3. It is observed that the rate at low temperature is higher than predicted by the exponential approach. At low temperature, the metal ions diffuse through the NiO grain boundaries and linear defects (dislocation and twins). Thus the oxidation rate will depend on the grain size in the oxide layer [47]:

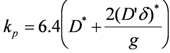

where g is the grain size, D* the diffusion coefficient of Ni2+ in the NiO lattice, D' the diffusion coefficient of Ni2+ at the NiO grain boundaries and δ the thickness of the NiO grain boundaries (about 1 nm).

where g is the grain size, D* the diffusion coefficient of Ni2+ in the NiO lattice, D' the diffusion coefficient of Ni2+ at the NiO grain boundaries and δ the thickness of the NiO grain boundaries (about 1 nm).

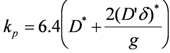

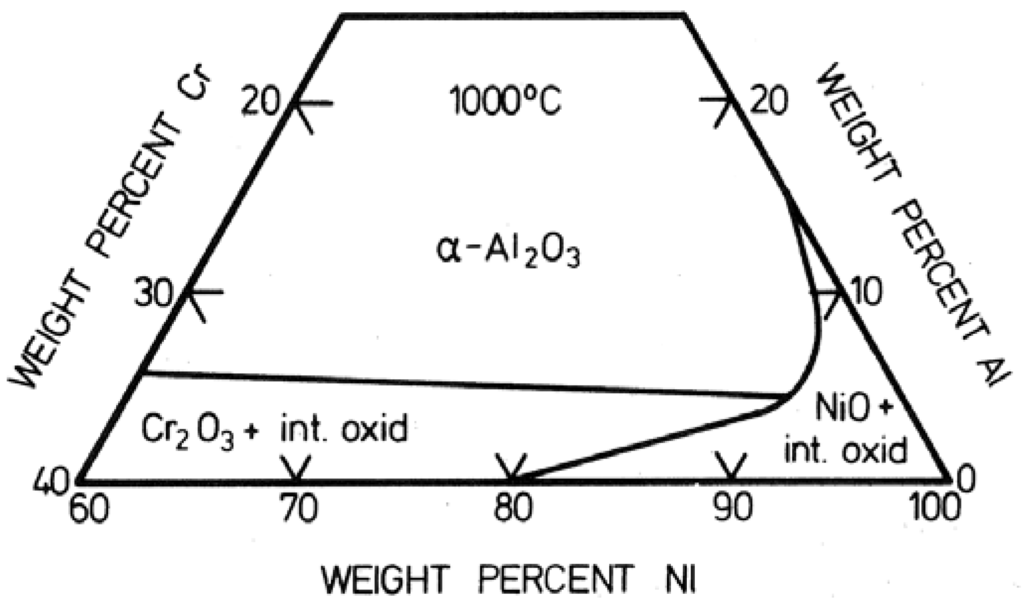

Alloying the nickel increases the oxidation rate constant (see Figure 4). If the alloying element concentration is high enough to form a dense protective layer, the rate constant decreases (see Si and Cr in Figure 4). The simultaneous addition of two alloying elements can form a stable oxide layer at lower overall weight concentration than a single element (see Figure 5).

Table 3.

Oxidation kinetics of nickel and nickel cermet in air (with Ø for particle diameter).

| Source Reference | Sample | Temperature range (°C) | Ea (kJ mol−1) | Kinetics |

|---|---|---|---|---|

| Pure nickel | ||||

| Suwanwatana et al. [56] | Ni particles, Ø = 79 nm | 250–350 | 150 | Deviation from parabolic |

| Suwanwatana et al. [56] | Ni particles, Ø = 0.7 µm | 250–350 | 127 | Deviation from parabolic |

| Suwanwatana et al. [56] | Ni particles, Ø = 3 µm | 250–350 | 108 | Deviation from parabolic |

| Karmhag et al. [57] | Ni particles, Ø = 15 nm | 135–235 | 129 | Deviation from parabolic |

| Karmhag et al. [58] | Ni particles, Ø = 5 µm | 300–700 | 145 | Deviation from parabolic |

| Karmhag et al. [59] | Ni particles, Ø = 158 µm | 500–700 | 183 | Deviation from parabolic |

| Haugsrud [60] | Polycrystalline Ni-mechanically polished | 500–800 | 150 | Deviation from parabolic |

| Karmhag et al. [59] | Ni particles, Ø = 158 µm | 800–1200 | 116 | Deviation from parabolic |

| Haugsrud [60] | Polycrystalline Ni-mechanically polished | 1100–1300 | 200 | Parabolic |

| Peraldi et al. [61] | Polycrystalline bulk Ni-mechanically polished | 1000–1200 | 200 | Parabolic |

| Nickel–ceramic composite | ||||

| Waldbillig et al. [41] | Tape-cast NiO-YSZ | 500–850 | 87–92 | Deviation from parabolic |

| Tikekar et al. [36] | Pressed NiO-YSZ rectangular bar | 600–800 | – | Parabolic |

| Stathis et al. [62] | Warm pressed NiO-YSZ | 550–650 | Logarithmic | |

| Modena et al. [40] | Tape-cast NiO-YSZ | 700–800 | 37–44 | Logarithmic |

| Pihlatie et al. [38] | Tape-cast NiO-YSZ | 500–1000 | Linear–parabolic–logarithmic part | |

| Roche et al. [41] | Tape-cast NiO-YSZ | 600–1000 | 118 | Deviation from parabolic |

| Czerwinski et al. [63] | Polycristalline Ni with CeO2-mechanically polished | 600–800 | 88 | – |

| Czerwinski et al. [63] | Polycristalline Ni with CeO2-chemically polished | 600–800 | 100 | – |

| Galinski et al. [64] | Thin sprayed NiO-40CGO | 500–575 | 164 | Parabolic–cubic |

| Galinski et al. [65] | Thin sprayed NiO-CGO | 500–575 | 270 | Mott–Cabrera equation for spherical geometries |

Figure 4.

Effect of alloying on the rate constant for oxidation of nickel in air at 900 °C [46].

Figure 5.

Oxide map for alloys in the Ni-Cr-Al system delineating the composition ranges for formation of different types of oxide scales [25].

2.3. Reduction of NiO-YSZ Cermet

The composite structure of the as-sintered NiO-YSZ anode changes the behavior during reduction and re-oxidation, compared to pure Ni/NiO.

Comparison of the reduction behavior of original NiO powder and NiO-YSZ anode during heating under reducing atmosphere in a thermogravimetric analyzer (TGA) shows a higher starting temperature and a slower rate for the composite structure [66]. By contrast, in situ transmission electron microscopy (TEM) shows a NiO-reduction starting at the NiO-YSZ interface. This contradictory result may come from the lower hydrogen pressure in the TEM and the different surface defects between TEM and bulk samples [67].

Tikekar et al. performed reduction on dense NiO-YSZ fabricated by compaction and measured the reduction rate by measuring the reduced layer thickness versus time. They found linear kinetics with an activation energy of 94 kJ/mol [36]. Waldbillig et al. performed reduction of tape-cast samples in a TGA and measured the activation energy (Ea) by constant heating rate and constant temperature reduction and found a similar activation energy as for NiO powder, showing that the gas diffusion in NiO-YSZ dense samples is not limiting the kinetics (see Table 1) [41]. Pihlatie et al. observed also linear kinetics up to 80% NiO conversion with similar Ea (between 500 and 750 °C) [38]. At high temperature (between 750 and 1000 °C), they reported a small decrease in the reduction rate by adding 3% water vapor to 9% H2 in N2 and attributed it to coarsening of the Ni phase under water vapor.

Grahl-Madsen et al. observed an increase in electrical conductivity by increasing the temperature of reduction [68]. The high conductivity could not be obtained by increasing the temperature after an initial reduction at lower temperature. This shows that the Ni phase is highly mobile during reduction of NiO.

Li et al. measured the performance of anode-supported cells against temperature of reduction (between 550 and 750 °C) and found for their case an optimal reduction temperature for 650 °C [69]. Jung et al. proposed to carry out the reduction via the ionic current (applying external potential to drive the O2− from the NiO based electrode through the electrolyte) to enhance cell performance [70].

Pihlatie et al. observed a transient shrinkage (0.08%) of the composite sample during reduction at lower temperature (600 °C), which is due to the contraction of NiO to Ni [38,71]. At higher temperature the stress in the Ni phase is released by creep. The shrinkage of the Ni-YSZ composite depends on the temperature, with 0.04%, 0%, 0.01%, 0.05% and 0.3% of shrinkage after 15 h of reduction at 600, 750, 850, 1000 and 1100 °C, respectively [72]. It also depends on the as-sintered porosity of the sample: no shrinkage was noted up to 14% porosity, but 24% and 33% porosity led to 0.01% and 0.03% of shrinkage after 10 h of reduction at 850 °C, respectively [73]. The sample composition plays a big role: coarse NiO and YSZ powders could show up to 2.1% shrinkage after 25 h at 850 °C, while the addition of 20% of fine YSZ reduced the shrinkage to 0.5% for the same conditions [68].

Multiple RedOx cycles lead to a faster reduction rate after the first reoxidation [27,74,75]. This is due to the opening of the microstructure by breaking the thin electrolyte and the YSZ backbone and the change in the nickel oxide nano- and micro-structure. This will be described in more detail in the next section. Temperature programmed reduction showed that reoxidized NiO re-reduced at lower temperature than before the reoxidation, confirming the change in NiO nanostructure [76].

2.4. Oxidation of Ni-Ceramics Composite

This section reports observations during oxidation of the Ni-YSZ composite as described in the literature. The nomenclature introduced by Ettler et al. includes “external parameters”, like temperature, incident oxidant flow, duration of oxidation and gas flow rate, versus “internal parameters”, which are linked to the Ni-YSZ design, microstructure and composition [77]. This section will discuss the external parameters.

2.4.1. Kinetics of Oxidation

In comparison to pure Ni (reduced in similar conditions), the composite starts to oxidize at lower temperature and with a faster rate [66].

An early study on in situ reduction of NiO-YSZ in a X-ray diffractometer showed that isothermal reoxidation at 600 °C is faster than the reduction at the same temperature [78].

The study of the oxidized layer thickness vs. time showed a parabolic behavior during re-oxidation of Ni-YSZ, indicating a diffusion-controlled process. As this process is not thermally activated, the conclusion is that the limiting rate is the diffusion of oxygen gas through the oxidized layer with an effective diffusion coefficient of 10−7 cm2/s [36]. A TGA study observed a parabolic behavior at low temperature (400–650 °C) and a divergence from parabolic behavior between 700 and 850 °C, the activation energy being lower than the usual values observed for pure Ni (see Table 2) [41]. Other studies show logarithmic behavior of the oxidation of Ni-YSZ cermet activated by temperature at 550–650 °C [62] and 700–800 °C [40]. The difference in these results could come from the fact that the limiting process changes from solid state diffusion at lower temperature to gas phase diffusion at higher temperature, due to pore closing when Ni changes to NiO at the composite surface. The ideal-gas law gives a diffusion coefficient proportional to T3/2 [79] (high temperature cermet oxidation), compared to solid-state diffusion following the Arrhenius law (proportional to exp(−Ea/RT), for low temperature cermet oxidation). Pihlatie et al. show a change in activation energy around 750 °C [38], whereas Roche et al. observe this transition around 800 °C in 20% O2. At lower pO2, the transition occurs at a lower temperature: with 1% O2, the gas diffusion is limiting the oxidation down to 600 °C [80]. The porosity of the support plays a role in the oxidation kinetics and makes the direct comparison of the different studies problematic, due to their different microstructures.

Kinetics of oxidation of a Ni-Gd0.4Ce0.6O2 (40CGO) anode was studied by in situ X-ray diffraction between 500 and 575 °C, where a transition between parabolic to cubic behavior was observed. The time for full oxidation of nickel in the anode is 4 min at 650 °C and only 0.5 s at 850 °C [64] (the anode thickness was not given but it can be estimated to around 25 µm from a parallel study [81]). A following study fitted the oxidation kinetics between 500 and 575 °C of Ni-CGO composite with a Mott–Cabrera equation for spherical geometries. The higher activation energy compared to other studies (see Table 3) should be related to the compressive stress built up in the composite [65].

Multiple RedOx cycles showed a faster rate for the second reduction and second oxidation [27,74,75]. This is closely related to the faster reduction process: higher gas diffusion in the more open microstructure due to cracks in the YSZ electrolyte and skeleton, and finer Ni grains after the first cycle, as the oxidation is inversely related to the grain size (see Equation (5)). A temperature programmed oxidation study also revealed a finer Ni microstructure after a RedOx cycle [82].

2.4.2. Homogeneous Versus Inhomogeneous Oxidation

The change in cermet oxidation kinetics with temperature can be linked to the transition from “homogeneous” to “inhomogeneous” oxidation. The first observation of homogeneous oxidation appears at low temperature (550–650 °C) under dry air where the full anode layer starts to oxidize homogeneously. By comparison, between 900 and 950 °C under Ar with 40% to 80% water vapor, oxidation starts at the surface and then moves inward with time. In inhomogeneous oxidation, a sharp border between oxidized and reduced side of the sample can be observed. This inhomogeneous oxidation leads to a warping or bending of the composite sample [62]. Further studies showed that oxidation under air between 700 and 800 °C also presented “inhomogeneity” and bending of the samples, compared to lower temperature oxidation (600 °C) [14,77,83]. At low temperature, oxidation kinetics is limited by the diffusion in solid state. At higher temperature, the limitation comes from gas diffusion through the re-oxidized layer, which has high tortuosity and low porosity. These observations can be compared to the results from Tikekar et al. [36], where they measured the thickness of the oxidized layer in air versus time, down to a temperature of 650 °C. Intrinsically, the sample oxidation has to be inhomogeneous in order to perform the measurement of oxidized layer thickness versus time. Only the gas limitation kinetics can be observed using this technique. Therefore Tikekar et al. did not observe thermally activated oxidation [36]. As mentioned before, the ideal gas law gives a diffusion coefficient proportional to T3/2 [79] compared to solid-state diffusion following the Arrhenius law (proportional to exp(−Ea/RT)). This can be related to the kinetics of the reaction: inhomogeneous oxidation corresponds to O2 gas diffusion limited oxidation (high temperature and low pO2) and homogeneous oxidation is related to solid state diffusion limitation (low temperature and high pO2).

Some authors observed oxidation inhomogeneity at 650 °C [36] and others only from 750 °C [14]. This is probably related to the cermet microstructure: Lower porosity samples show inhomogeneous oxidation and bending at lower temperature.

By lowering the partial pressure of oxygen of the oxidizing flow (from 50% to 20% and to 0.1% in He), the inhomogeneity of oxidation (and the sample bending) increased [83,84].

2.4.3. Expansion during Reoxidation

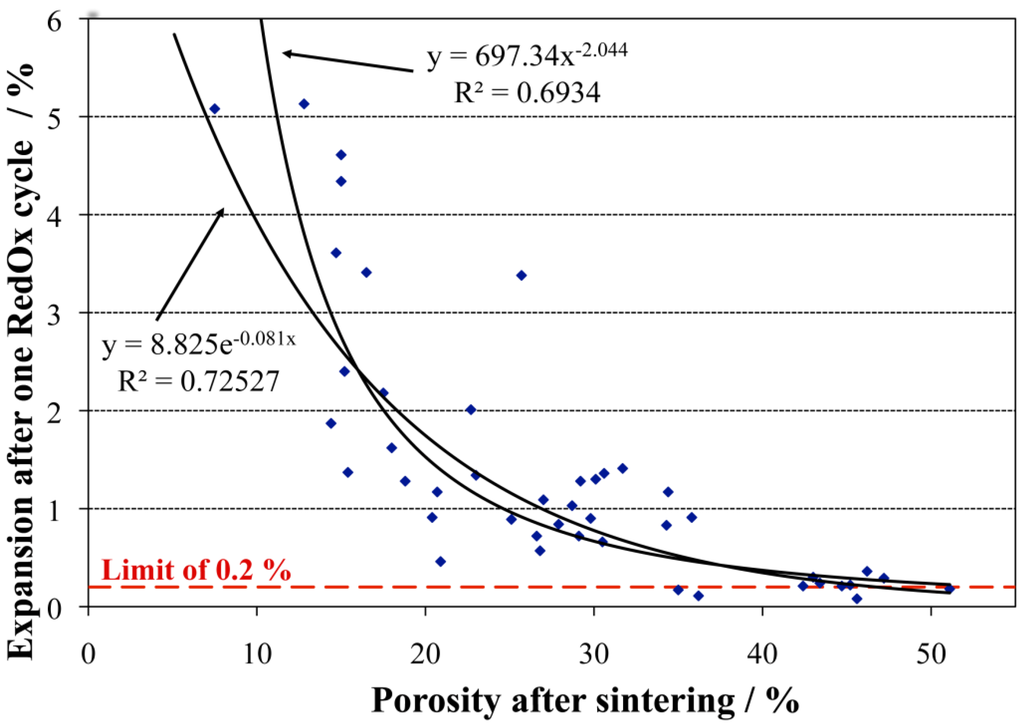

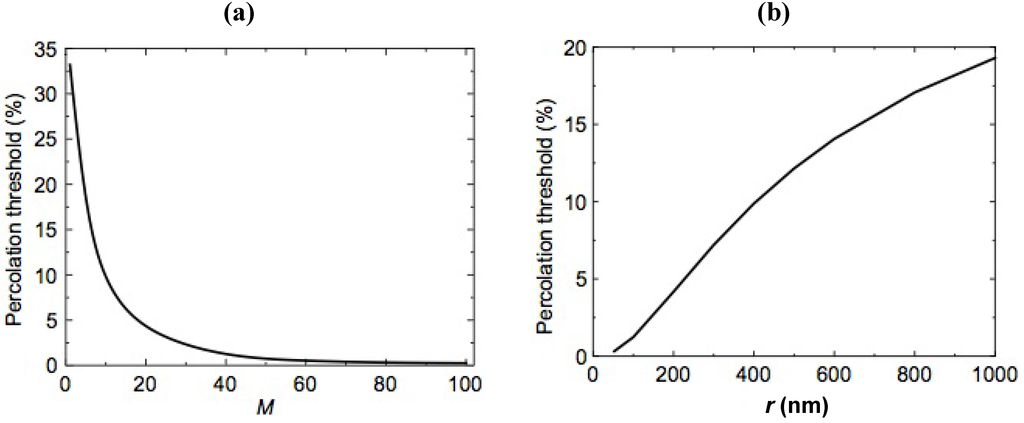

The volume expansion of the anode due to nickel oxidation creates stresses in the different layers (compression in the anode and tension in the electrolyte). The stresses are proportional to the expansion: an essential measurement for the anode RedOx stability is dilatometry during re-oxidation. Theoretically, an expansion higher than 0.2% will fracture the thin electrolyte in case of an anode supported cell (see Section 2.4.6 for more details) [12,85]. Expansion was also measured at room temperature after re-oxidation [76,86] but the TEC variation between NiO-YSZ and Ni-YSZ composite should be taken into account [87]; the maximal strain can occur during oxidation and not after completion [88]. Dilatometry was performed in situ during oxidation at the initial stage of Ni-YSZ studies [62,89,90]. In 1998, Mori et al. reported an important expansion during TEC measurement of a 35 vol % Ni-YSZ sample in air [87]: At around 900 °C the expansion strongly increased, by about 1.2% to 1.5%. They observed cracks at the 8YSZ grain boundaries.

Stathis et al. observed an increase in expansion with oxidation temperature in air, from 0.27% to 0.54% at 650 and 800 °C, respectively [62]. This is confirmed by other authors: Pihlatie et al. observed an expansion from 0.19% to 0.28% and to 0.93% at 600, 800 and 1000 °C, respectively [72]. Klemensø et al. saw even much higher expansion, from 0.99% to 4.95% at 700 and 1000 °C, respectively [26]. The difference in expansion for similar conditions could be related to a difference in microstructure, as shown by Fouquet et al. [66] and Waldbillig et al. [41]. This will be discussed in more detail in the next section.

The effect of nickel sintering in reducing atmosphere on the expansion during a RedOx cycle was confirmed by Pihlatie et al., who found a doubling of the expansion for a sample reduced for 4.5 h at 1100 °C, compared to a sample reduced for 5.5 h at 800 °C [72]. This confirms the suggestion proposed by Cassidy et al. in 1996 [10] and presented in the small model (Figure 1) shown by Klemensø et al. about ten years later [26].

The water vapor plays an important role also during reoxidation as shown by the increase of expansion from 0.68% to 0.96% at 850 °C under dry air resp. air with 6% H2O, though at 600 °C no difference was observed. The effect of humidity at 850 °C is similar to the effect of increasing temperature up to 1000 °C [72]. This is an important result as at high fuel utilization, the water vapor on the anode side can reach high values depending on the fuel (up to 80%–90% under pure hydrogen). Then reoxidation will occur under high water vapor concentration.

A small expansion at 850 °C was observed at an oxygen partial pressure of 5 × 10−12 atm, which is about 50 times the equilibrium partial pressure of oxygen for the Ni/NiO couple at this temperature [72].

Usually, subsequent RedOx cycles present an irreversible behavior as the contraction is smaller than the expansion; the second oxidation therefore reaches a higher maximal cumulative RedOx strain (CRSmax) than during the first oxidation [72]. This behavior is observed by other authors [26,66,76]. At lower temperature the behavior can be reversible [76].

Sarantaridis et al. presented a nearly linear behavior between the oxidation strain and the degree of oxidation (DoO) with a small shrinkage of 0.05% at 5% DoO and a maximum strain of 0.55% reached at a DoO between 90% and 95%. The second oxidation presents the same behavior with a shift to a higher strain of about 0.1%. They also observed a difference in strain after the first oxidation at 800 °C when the sample was measured at room temperature (i) with interruption during oxidation; (ii) without interruption and (iii) for in situ dilatometry measurement (high temperature). Results were 0.55%, 0.65% and 0.80%, respectively [50].

Another study used crack widths in the thin electrolyte and the porosity increase in the anode for the expansion calculation after multiple RedOx cycles. From temperature variation, a “RedOx safe” temperature could be extrapolated downwards to 550 °C for this microstructure at which the thin electrolyte will not crack upon RedOx cycling. This was confirmed experimentally, also for real stacks experiencing fuel supply interruption. Repeated RedOx cycles at 800 °C showed a stabilization of the RedOx strain after multiple cycles [85].

Based on dilatometry measurements, Pihlatie et al. proposed a model based on continuum mechanics to fit all experimental expansion data versus temperature. The simulation shows that during reduction at low temperature (600 °C), the contraction of the sample is due to the limited creep in the nickel at these temperatures. During reoxidation at low temperature, the model shows that pseudo-plasticity or micro-cracking occurs in NiO, that at 850 °C the 3 mol % Y2O3-tetragonal zirconia polycrystal (3Y-TZP) backbone fractures and that at 1000 °C the 3Y-TZP creeps and undergoes micro-cracking. The main limitations of the model are that (1) the strength of 3Y-TZP is back-calculated and (2) the critical stress for pseudo-plasticity in NiO is directly dependent on the value used for NiO fracture toughness and critical flaws in NiO. These unknown parameters basically allow the fit of any RedOx strain [71].

2.4.4. Bending and Stresses in Half-Cell Samples (Anode Support)

Stresses in the layers are present due to the difference in thermal expansion coefficient (TEC) between the anode and the electrolyte. The TECs for pure 8YSZ, NiO and Ni are 10.3, 14.1 and 16.9 × 10−6 K−1, respectively [87]. For a standard composition containing 58 wt % NiO, which corresponds to 56 vol % NiO and 43 vol % Ni, the corresponding TEC is 12.3 and 11.5 × 10−6 K−1, for the oxidized and reduced states, respectively [87]. This means that the electrolyte, which shrinks less during cooling, will be under compression and the anode under tension with a maximal value at the interface with the electrolyte [91]. The stress and bending calculations were done for CGO-YSZ, by Atkinson and Selçuk, and gave good results with a “stress free” state around 1200 °C [92].

Stress measurements were done on NiO-YSZ half-cells with a thin 8YSZ electrolyte using X-ray diffraction (XRD) at room temperature: The thin electrolyte stress is about −560 MPa and does not vary when the cell is flattened for stacking. The reduction of the half-cell for 10 h at 900 °C reduces the stress by about 10% [91]. These results are comparable to those reported by Sumi et al. on NiO-3YSZ anode-supports (300 µm) with 10ScSZ electrolyte (20 µm). At room temperature, the as-sintered electrolyte stress is −400 MPa, in the reduced state −250 MPa, and −170 MPa in the reoxidized state. The thin electrolyte showed cracks after reoxidation. The compressive stresses after reoxidation are due to the cooling from the RedOx temperature to room temperature. The anode is under tension of 50–100 MPa at the interface with the electrolyte. In situ measurements in a high energy (70 keV) X-ray synchrotron beam showed that the stresses are released at 1000 K [91]. Reasons for the electrolyte internal stress change between reduced and oxidized states are: (1) At high temperature, the porosity increase in the reduced anode lowers its Young modulus [93] and (2) at room temperature, the TEC changes between the oxidized and reduced Ni-YSZ composite [87]. Another study reported higher compressive stresses measured on NiO-YSZ anode-supports and YSZ electrolyte using a similar XRD technique and microscopic strain in 5 µm electrolyte grains (with an advanced method and synchrotron radiation [94]): The values were −690 MPa, −600 MPa and about 0 MPa, for room temperature as-sintered, reduced and re-oxidized samples, respectively. The electrolyte residual stress at 800 °C was measured as −60 MPa [95].

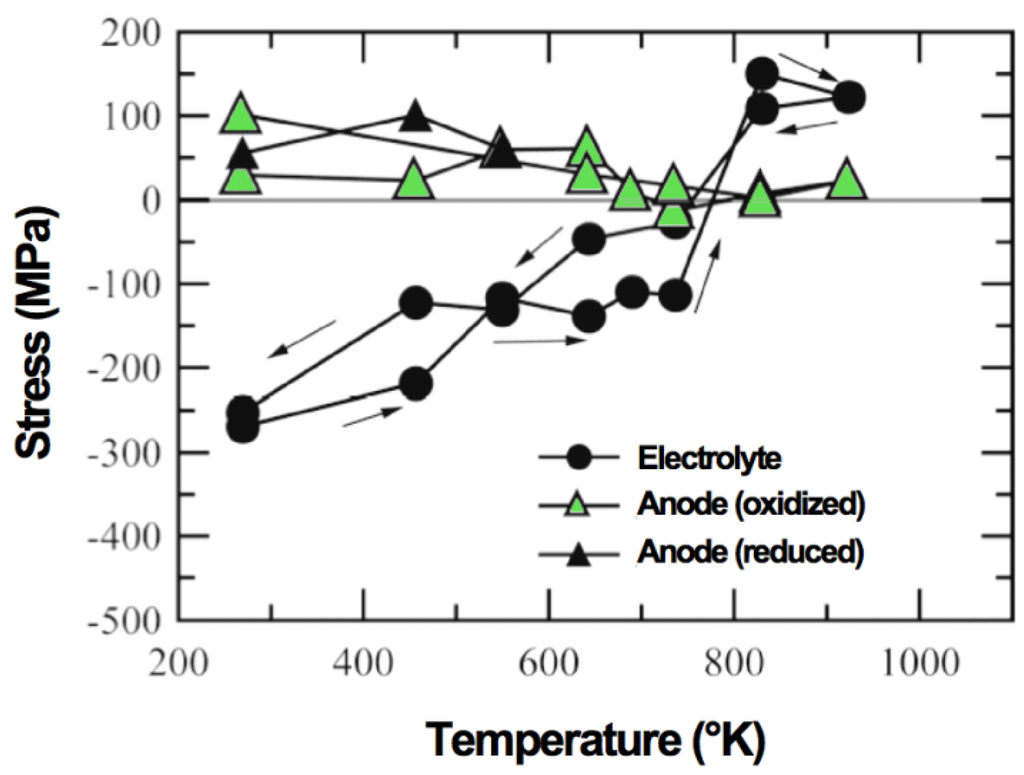

Tanaka et al. presented the following work of Sumi et al. on similar samples. The in situ oxidation of Ni-3YSZ anode-supports during measurement showed a tensile stress in the electrolyte of 150 MPa at 800 K (see Figure 6). The Ni peaks disappear between 550 and 650 K when the nickel oxidizes. A difference of more than 100 K exists between the Ni peak disappearance and the tensile stress occurance [96]. The final stress in the electrolyte is similar to the one before the RedOx cycle; the thermal stresses are built up again, in contradiction to the stress release observed by Villanova et al. at room temperature [95].

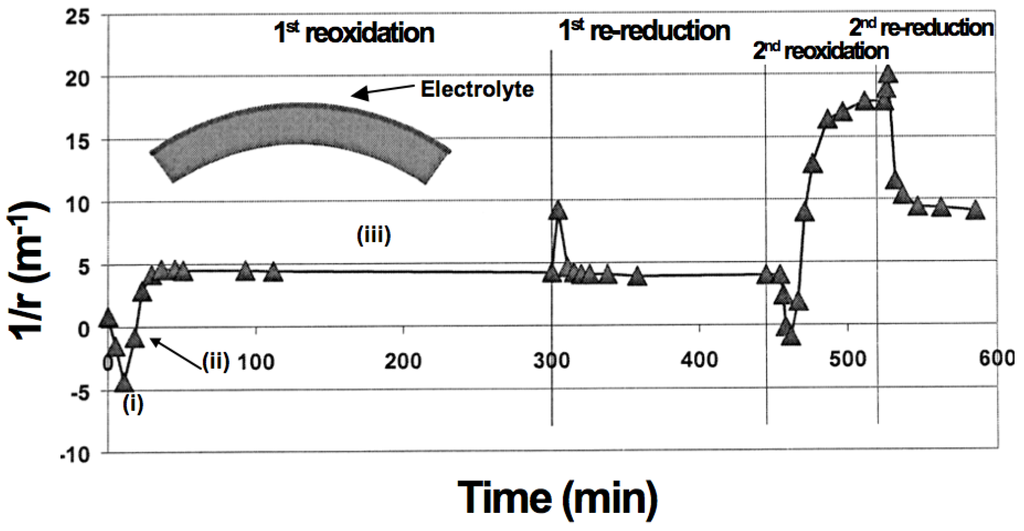

When oxidation occurs on one side, the half-cell bends due to chemo-mechanical expansion. This was observed in situ during oxidation at 800 °C of a half-cell composed of an anode-support, an active layer and a thin electrolyte of a total thickness of 0.27 mm [97]. As the oxidation starts at the anode, the cell bends towards the electrolyte (electrolyte on the concave side), then the curvature comes back to its initial value and bends further towards the anode (Figure 7). The authors explain the bending towards the electrolyte with an elastic deformation model but such a model cannot explain the bending towards the anode. Other authors propose plastic deformation of the anode during reoxidation to describe the anode being on the concave side after RedOx cycles [85,98].

Figure 6.

Changes in stresses in 10ScSZ (scandium-stabilized zirconia) electrolyte and anode during heating Ni-3YSZ under air [96].

Figure 7.

Curvature change during reoxidation and re-reduction cycles (0.27 mm half-cell, 800 °C) [97]. During re-oxidation, the half-cell shows (i) an initial curvature towards the electrolyte (on the concave side); then (ii) it reverts to “zero”-curvature and finally (iii) it stabilizes with a curvature towards the anode (on the concave side).

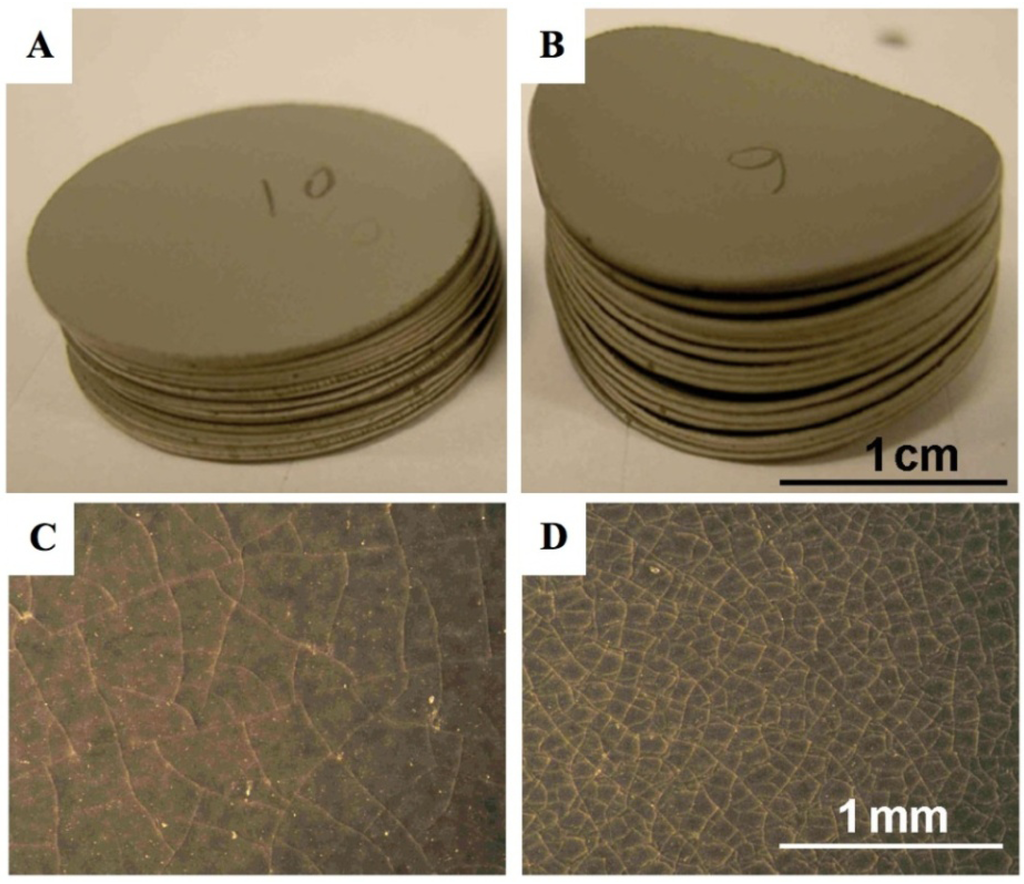

Other studies with NiO anode-supports with a 10CGO (10 mol % gadolinia-doped ceria) thin electrolyte showed bending with the anode on the concave side after reoxidation at 750 °C [99]. Ettler et al. showed that their NiO-YSZ (half-cell and full cell) bending towards the anode occurs at oxidation temperature higher than 700 °C, but that at lower temperature the bending is towards the electrolyte. They conclude that inhomogeneous oxidation bends the half-cell towards the anode (on the concave side, as shown in Figure 7) and homogeneous oxidation does the opposite [14]. Another in situ study revealed a curvature towards the electrolyte after re-oxidation at 800 °C [100]. By lowering the partial pressure of oxygen during reoxidation of a half-cell (at a constant temperature), the bending towards the anode is increased [83,84]. Half-cell samples with low porosity bent towards the anode (on the concave side) after 5 RedOx cycles at 750 °C, compared to higher porosity samples that stayed flat. The crack density in the thin electrolyte was higher in the case of the lower porosity samples as shown in Figure 8 [98].

Figure 8.

Picture of Ni-YSZ anode supported half-cell discs after 5 reduction-oxidation cycling (RedOx cycles) at 750 °C. (A) and (C): samples with 17.5% as-sintered porosity and (B) and (D): samples with 12% as-sintered porosity. The electrolyte is face-down for (A) and (B). A clear difference in curvature is observed between the two groups of samples comparing (A) and (B), (B) is bent towards the anode (anode face-up on the concave side). A clear difference in crack density is observed between the two groups of samples comparing (C) and (D) [98].

Laurencin et al. studied the creep of the Ni-YSZ anode under reducing atmosphere. In the case of anode-supported cells (ASC), the compressive stresses decrease during the first 500 h of utilization from −220 to −120 MPa (based on creep measurement). This means that the RedOx tolerance of the thin electrolyte becomes lower with time as the compressive stresses in the electrolyte “work” against the RedOx anode strain. In the case of electrolyte-supported cells (ESC), the creep behavior will be beneficial by preventing the build-up of a high stress level after several RedOx cycles [101].

2.4.5. Young’s Modulus and Strength Variation with Reoxidation

Young's modulus, strength and fracture toughness of NiO-YSZ and Ni-YSZ composites are well described by Atkinson and Selçuk [102] and Radoviç and Lara-Curzio [93]. The general trend is a decrease of the mechanical properties with increasing porosity (models are presented).

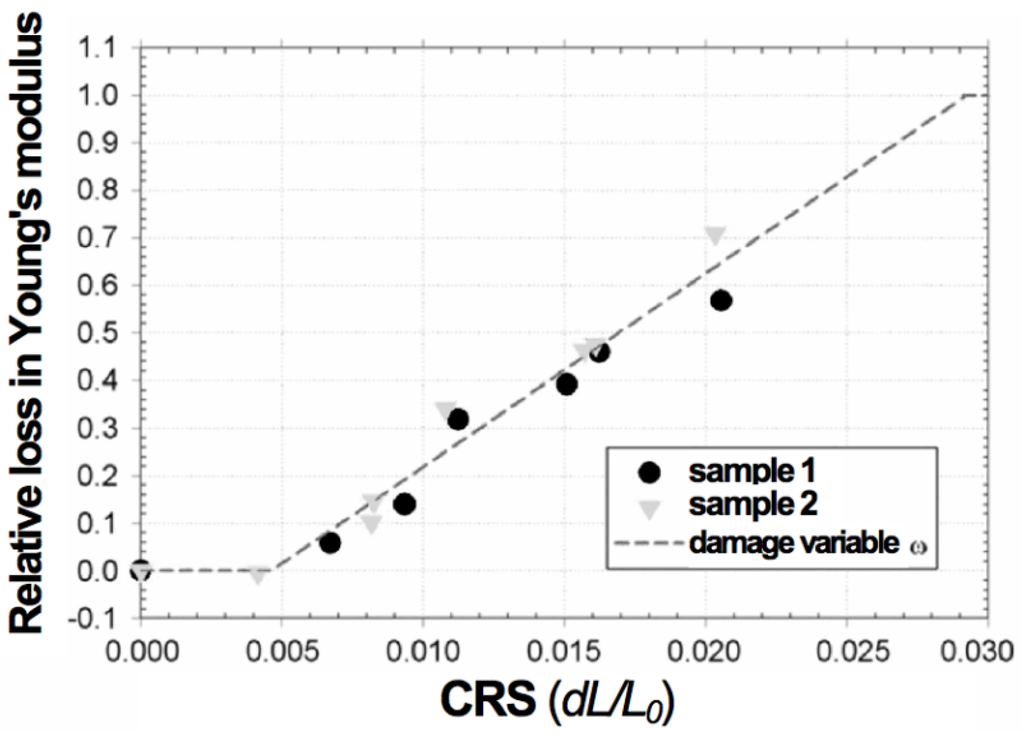

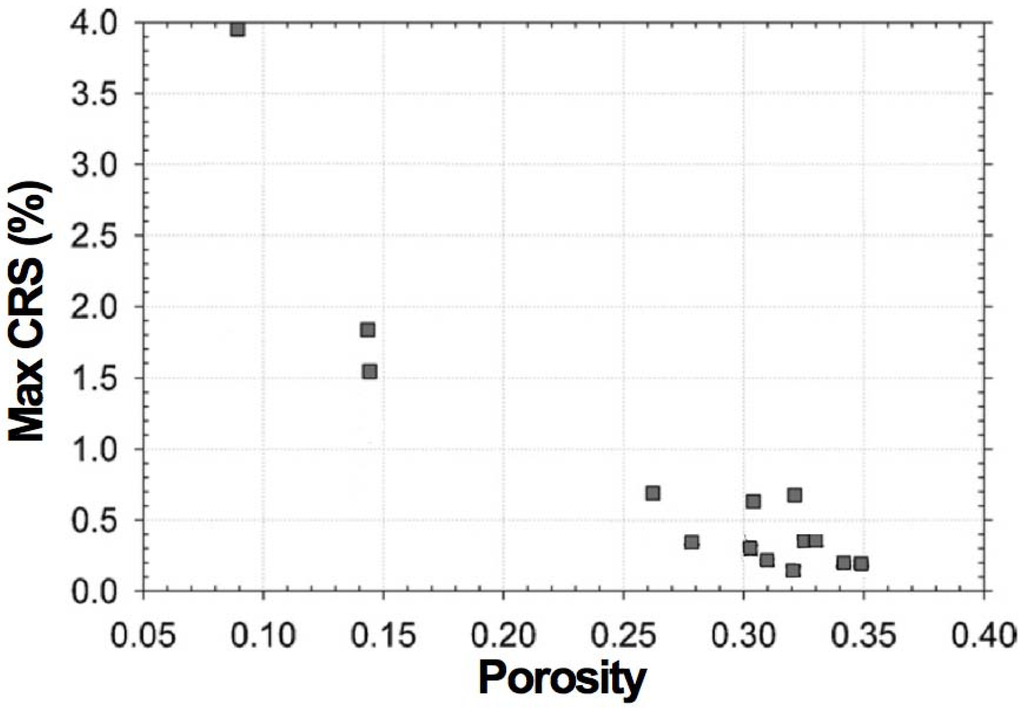

Pihlatie et al. used the impulse excitation technique (EIT) to study the evolution of Young’s modulus of NiO-YSZ with temperature in the as-sintered, reduced and reoxidized states [103]. They obtained a relation between the RedOx strain and the decrease in Young’s modulus. The damages caused by the RedOx cycles degrade the elastic properties. It starts linearly from 0.5% to 0.6% redox strain to macroscopic sample failure at 2.5%. An isotropic continuum damage model is given to fit the degradation: E = (1 − w) × E0 , with w the damage variable as a function of the oxidation strain (see Figure 9).

Sarantaridis et al. showed a linear increase of the Young modulus (E) with the degree of oxidation (DoO), starting at 32 GPa and ending at 74 GPa [50]. The as-sintered E with 79 GPa is higher than for the reoxidized sample. The Young modulus is directly linked to the sample porosity [102], therefore the 5 GPa decrease can be related to a total porosity increase from 26.4% before to 27.6% after the RedOx cycle.

Figure 9.

Mechanical degradation in terms of relative loss of elastic modulus of NiO-YSZ composite in its oxidized state during RedOx cycle as a function of the oxidation strain (CRS: cumulative redox strain). The measurement is reproducible (i.e., samples 1 and 2) [103].

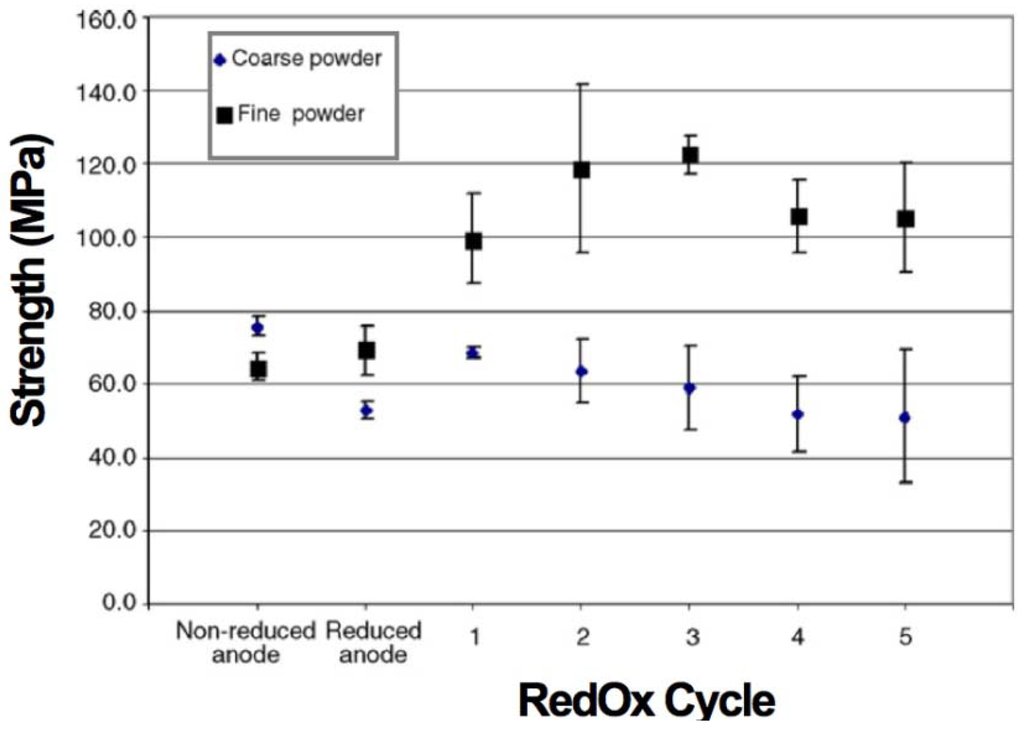

Pusz et al. presented NiO-YSZ anode-supported tubular cells with an external diameter of 7.31 mm and a wall thickness of 1.7 mm. This study compared the strength evolution with RedOx cycles using ten samples each time of two compositions: (1) A fine structure containing black nickel oxide and (2) a coarse structure based on green NiO (dv,50 = 0.95 µm) with 40:40:20 vol % of NiO:8YSZ:Carbon pore former. Strength was measured at room temperature after 1 h RedOx cycling at 800 °C (see Figure 10). The strength of the fine microstructure sample doubled after 3 RedOx cycles. After the third RedOx cycle, the strength starts to decrease. The coarse microstructure showed a decrease in strength after reduction, a small increase for the first RedOx cycle and then a linear decrease with the RedOx cycle number [104].

Similar results were shown for planar anode supported cells after 10 RedOx cycles at 800 °C using 10 disc samples per measurement (25 mm of diameter). The mechanical strength of these supports increased slightly from 145 to 155 MPa after 10 RedOx cycles (the Weibull modulus also increased from 6 to 9) [105]. Another study on planar Ni-3YSZ half-cells showed no variation on strength after one RedOx cycle at 750 °C [98].

The authors were not very clear about the increase in strength during RedOx cycles. As maximal stress is located at the tube surface and the strength depends on the flaw distribution, this evolution can be linked to the surface change during RedOx cycles: densification of the surface lowers the flaw size at the surface.

Figure 10.

Strength of the C-shaped uniaxial compressed anode rings versus number of RedOx cycles. The samples were fabricated using two different powders, coarse green NiO and fine black nickel oxide [104].

2.4.6. RedOx Expansion Limits: Mathematical Approaches

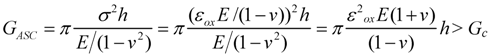

Sarantaridis and Atkinson presented an analytical approach based on the release of stored elastic energy under plane strain conditions for modeling the maximal strain of the anode during RedOx cycles in case of anode-supported cells (ASC), electrolyte-supported cells (ESC) and inert substrate or metal-supported cells (MSC) [106].

The maximal strain of planar ASC before cracking the thin electrolyte can be deduced from Equation (6):

with E the Young modulus of the electrolyte, v the Poisson ratio, h the electrolyte thickness, εox the oxidation strain, GASC and Gc the stored and the critical energy release rate, respectively.

with E the Young modulus of the electrolyte, v the Poisson ratio, h the electrolyte thickness, εox the oxidation strain, GASC and Gc the stored and the critical energy release rate, respectively.

Substituting the typical values given in [106], the product ε2ox hc = 7.4 × 10−12 m is a constant, with hc the critical thickness when GASC = Gc. The interesting point is that a decrease in electrolyte thickness increases the RedOx stability (more RedOx strain possible). Thus, for a given oxidation strain of 1%, the critical thickness is as small as 0.074 µm. An electrolyte thickness of about 2 µm gives a RedOx strain limit of 0.2%. In case of elastic relaxation, the crack spacing, l, is given by 8h/ln(h/hc), which means no extensive damage will occur until hc < 2h. Hence an electrolyte of 4 µm thickness could be tolerated.

For the electrolyte-supported configuration, the failure mode will be delamination of the anode. Based on 8YSZ with a certain porosity, delamination occurs if the anode exceeds 2.6 µm; for a 10 µm anode, an oxidation strain of 0.5% can be tolerated. Buckling of the anode requires an initial delamination of 170 µm in size. Decreasing the thickness increases the strain linearly; hence a thin anode layer is more RedOx stable.

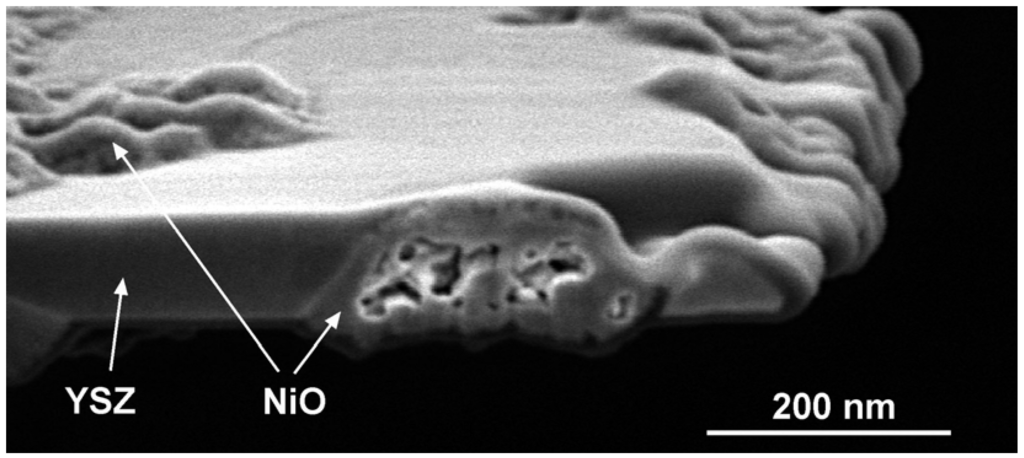

Cracks in the thin electrolyte for ASC configuration (Figure 11) and delamination of the anode for ESC (Figure 12) are shown by other authors confirming the degradation mechanisms proposed by Sarantaridis and Atkinson.

Figure 11.

Thin electrolyte crack formation during two RedOx cycles in the anode supported cell design. (a) co-firing; (b) reduced (c) re-oxidized; (d) second reduction; (e) second oxidation and (f) third reduction with an additional 100 h under reducing atmosphere [14,107,108].

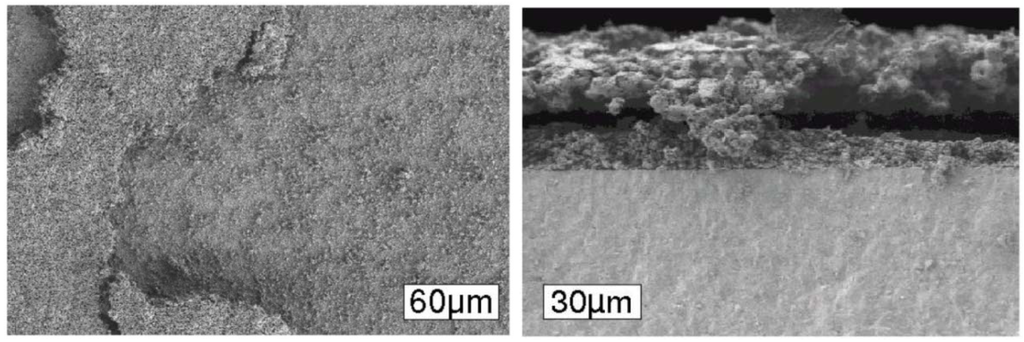

Figure 12.

Delamination of anode and anode current collection layer in case of 8YSZ electrolyte supported cells after five RedOx cycles at 950 °C and 40 min. Right: Only Ni-8YSZ active anode; left: active anode plus Ni-8YSZ current collecting layer [16].

For a metal support, in case of edge initiation delamination with a thickness of 10 µm each for the cathode, the electrolyte and the anode layers, a limit of 1% strain can be obtained.

In summary, the maximum RedOx strain before degradation is: 0.2% for ASC, 0.5% for ESC and 1% for MSC. ASC is the most sensitive geometry in terms of RedOx stability, not only because it is breaking the gas tight electrolyte, but also due to the layer configuration.

Klemensø [27] and Klemensø and Sørensen [109] proposed an approach including anode support (AS), active functional layer (AFL) and electrolyte for the ASC case. Usually, the AFL has a finer microstructure to enhance electrochemical performance whereas the AS serves proper mechanical stability, sufficient electrical conductivity and gas transport properties. Lowering the temperature and decreasing the anode support thickness will increase the RedOx stability. For AS thickness of 300 µm, AFL and electrolyte thickness of 10 µm, the maximal strains before electrolyte cracking are:

- at 650 °C, 0.2% for AS and 0.7% for AFL;

- at 800 °C, 0.2% for AS and 0.25% for AFL.

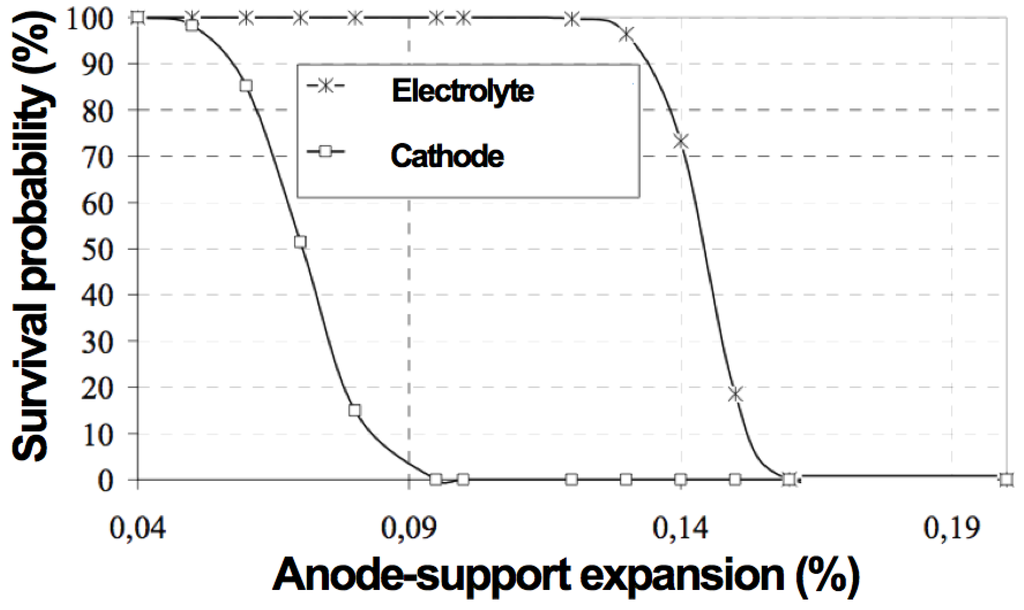

Based on finite element modeling (FEM) calculations and failure probabilities of a Ni-YSZ anode-supported cell with 1 mm thick support, 10 µm thick 8YSZ electrolyte and 60 µm thick LSM cathode with a cell diameter of 116 mm, it has been shown that the cathode will crack when the support expands by more than 0.05%–0.09% and when the electrolyte expands by more than 0.12%–0.15% (see Figure 13) [110].

Figure 13.

Survival probability of LaSrMn-oxide (LSM) cathode (60 µm) and YSZ electrolyte (10 µm) against the strain of the Ni-YSZ anode support (1 mm) [110].

Some singularities are considered in the modeling and give hints for the fabrication, e.g., that the cathode/electrolyte contact angle at the cathode side in an ASC should be higher than 90° to increase stability [111]. The ESC configuration with a 10 µm thick anode will delaminate after 0.3% to 0.35% expansion. Experimental results based on the ASC from the Forschungszentrum Jülich (FZJ) showed that the electrolyte cracked after a degree of oxidation between 56% and 70.7% at 800 °C (similar to the value obtained by Sarantaridis et al. [112]), which corresponds to an expansion between 0.26% and 0.34%. Modeling underestimated the maximal value of expansion, which could be due to the inhomogeneity of oxidation at 800 °C in that only the anode side opposite to the electrolyte was oxidized. Cracks in the electrolyte were quantified by SEM and permeability of the electrolyte and expansion were measured using micro-Vickers marks distance before and after expansion [113]. Based on Weibull statistics and FEM, it can be seen that sample size influences the maximal anode strain before ACS thin electrolyte cracking, from 0.18% for small samples (0.1 cm2) to 0.12% for total stack surface (2000 cm2) [85].

Sarantaridis et al. compared the oxidation in air with oxidation by ionic current at 800 °C. They proposed a model that takes into account the non-uniformity of the electrochemical reoxidation on the failure probability of the electrolyte. The critical degree of ionic current reoxidation occurs at 3% (compared to 49% to 75% by oxidation in air), it creates a compressive stress in the central reoxidized anode located under the cathode and a radial tensile stress in the non-reoxidized anode [112].

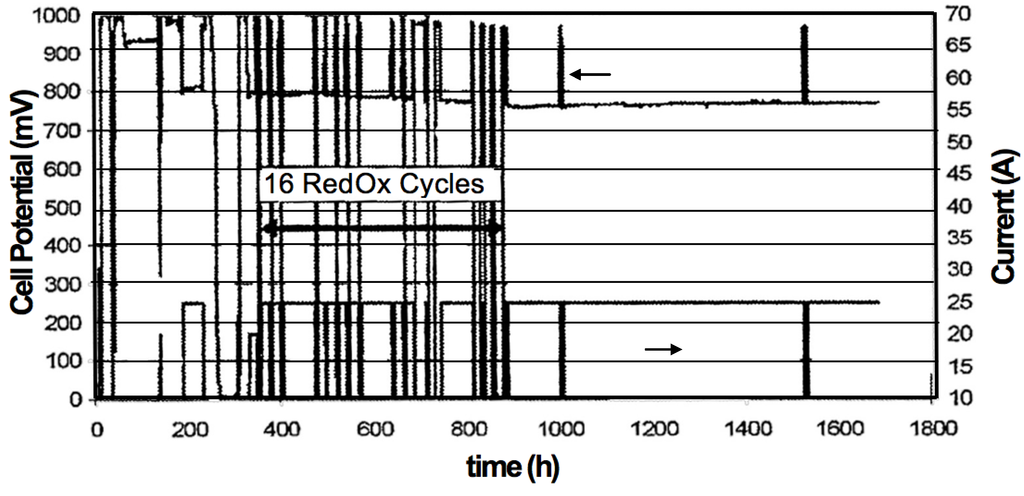

2.4.7. Electrical Conductivity versus RedOx Cycles

Robert et al. tested 800 µm thick anode-supports produced by slip casting with a porosity gradient created by sedimentation during the production process. The conductivity was measured on 120 mm diameter cells at 900 °C: it decreased from 2400 to 1300 S/cm after 7 RedOx cycles [90].

A doubling in electrical conductivity was observed after a RedOx cycle at 850 °C of a Ni-YSZ composite based on coarse YSZ (from 500 to 1000 S/cm). After conductivity decrease due to nickel coarsening, the experiment was repeated on the same sample and the conductivity rose back to the highest level. Grahl-Madsen et al. reported that conductivity degrades faster after RedOx cycling [68].

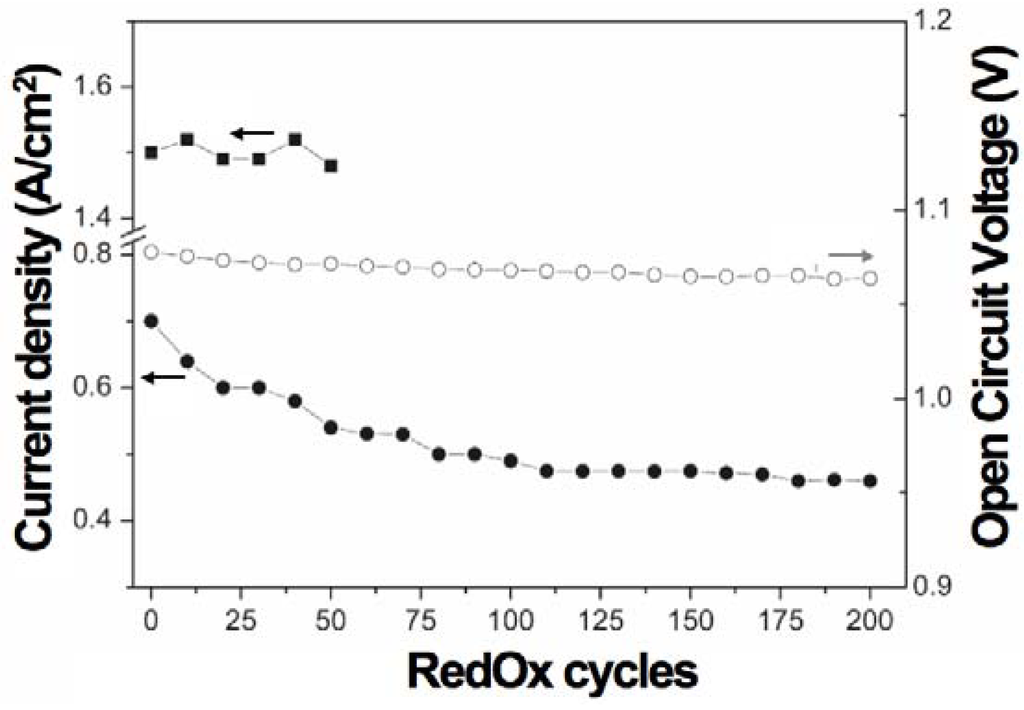

Ni-YSZ samples produced by tape-casting showed a conductivity decrease after the initial reduction [114]. After the first RedOx cycle at 1000 °C, the conductivity increases to a value higher than the original value. After multiple RedOx cycles, the conductivity decreased and the degradation was faster than after the initial reduction. After removing Ni from the cermet with acid leaching, the ionic conductivity of the YSZ cermet was measured and showed a decrease due to cracks produced in the YSZ backbone by the RedOx cycle. A new proposed model included the increase in Ni contact after a RedOx cycle due to breaking of the zirconia skeleton. Further RedOx cycles will create too much porosity to maintain sufficient conductivity (see Figure 14).

The conductivity of Ni-YSZ was measured at different temperatures and atmospheres (dry, wet or diluted hydrogen) [21]. At 600 °C under wet hydrogen, the conductivity starts at 1200 S/cm and is constant over 150 h. RedOx cycles increase the conductivity to 2300 S/cm. At 850 °C under dry 40% H2 (diluted in He), the conductivity degraded by about 35% over 200 h. After a RedOx cycle, initial conductivity was restored at first. After the RedOx cycle, the conductivity degradation with time is lower over the same time period. An interesting point is that the dilution of dry hydrogen has an influence on conductivity losses, with a faster degradation in the case of He-dilution compared to Ar-dilution.

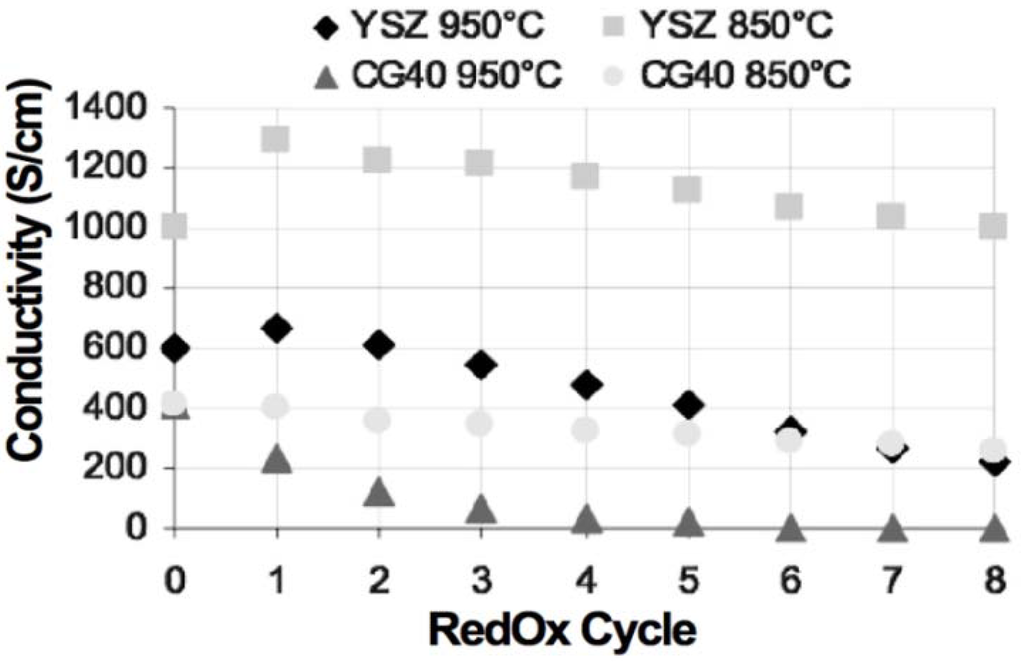

A comparison of electrical conductivity for Ni-8YSZ and Ni-40CGO composites (on electrolyte supports) under RedOx treatments was performed by Iwanschitz et al. The conductivity was measured during 8 RedOx cycles at 850 and 950 °C: at higher temperature, the degradation was fast after 4 RedOx cycles and the Ni-CGO sample was not conductive anymore. In the case of Ni-YSZ, an increase in conductivity was observed during the first cycles (see Figure 15). The conductivity is always higher for Ni-YSZ than for Ni-CGO composites. The degradation after RedOx cycling is related to microstructure coarsening [81].

Figure 14.

Model proposed by Klemensø et al. including the increase of Ni contact after a RedOx cycle due to breaking of the zirconia skeleton. Further RedOx cycles will create too much porosity to maintain sufficient conductivity [114].

Figure 15.

Comparison between Ni-YSZ and Ni-CGO composite electrical conductivity under RedOx treatments [81].

Liu et al. studied the conductivity of a NiO-YSZ anode of 800 µm thickness covered with a 10 µm thin YSZ electrolyte by electrochemical impedance spectroscopy (EIS) during reoxidation and re-reduction. EIS spectra were taken between 9 and 1000 kHz each minute during oxidation in air at 500, 600, 700 and 800 °C. The high frequency impedance spectra give the ohmic resistivity of the cell. The evolution in ohmic resistance during oxidation occurs in three phases: (1) low constant resistance; (2) a strong increase to a maximum value and (3) finally a decrease to reach an intermediate plateau. These stages correspond to the oxidation of the Ni particles until cutting the Ni conduction path followed by the creation of a new conduction path through NiO after volume increase (spongy-like porous NiO after reoxidation). The maximum ohmic resistance was reached after 3, 19 and 73 min at 800, 700 and 600 °C, respectively. No change was observed at 500 °C over 450 min due to slower kinetics. During reduction, the conductivity increases faster, meaning that the Ni network forms much faster [115].

2.4.8. Temperature Variation during Oxidation

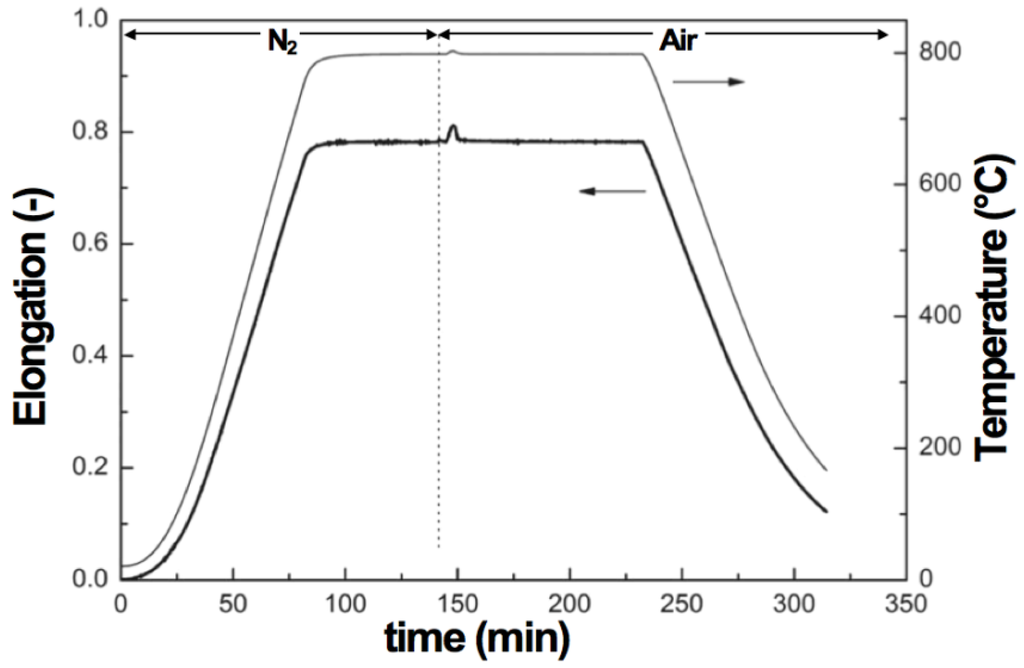

Pomfret et al. observed a 20 K increase of temperature during anode-support reoxidation (at around 725 °C under air) using near infra-red imaging [116].

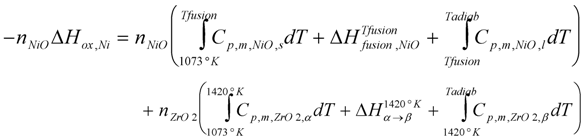

With basic thermodynamic data, a temperature increase of 1678 K is calculated from the adiabatic reaction of an anode-support (final composition of 55 wt % NiO and 45 wt % YSZ) from Equation (7) [85]:

where nNiO and nZrO2 are the number of moles of NiO and zirconia, respectively, Cp,m is the molar heat capacity (at a constant pressure), ∆Hox,Ni is the enthalpy of nickel oxidation, ∆Hfusion,NiO is the fusion enthalpy of nickel oxide (the melting point of NiO is Tfusion = 1990 K), ∆Hα→β is the enthalpy for zirconia phase change (from α to β phase) and Tadiab is the calculated final temperature for the adiabatic reaction (Tadiab = 2478 °C). Cp,m is calculated from equation: Cp,m = a + bT; the heat capacities for pure α and β-zirconia and solid and liquid NiO were used for the calculation [29]. Thermodynamic constants are given in Table 4. For the local anode temperature, the heat exchange with other parts and gases surrounding the anode should also be taken into account. This thermal effect can influence in situ expansion measurements (and even the furnace temperature, see Figure 16 in [117]), but it is nearly never taken into account in the different studies. After cracking the thin electrolyte, the combustion of the fuel at these locations creates hot spots with high water vapor that can induce accelerated nickel coarsening or cathode decomposition [85].

where nNiO and nZrO2 are the number of moles of NiO and zirconia, respectively, Cp,m is the molar heat capacity (at a constant pressure), ∆Hox,Ni is the enthalpy of nickel oxidation, ∆Hfusion,NiO is the fusion enthalpy of nickel oxide (the melting point of NiO is Tfusion = 1990 K), ∆Hα→β is the enthalpy for zirconia phase change (from α to β phase) and Tadiab is the calculated final temperature for the adiabatic reaction (Tadiab = 2478 °C). Cp,m is calculated from equation: Cp,m = a + bT; the heat capacities for pure α and β-zirconia and solid and liquid NiO were used for the calculation [29]. Thermodynamic constants are given in Table 4. For the local anode temperature, the heat exchange with other parts and gases surrounding the anode should also be taken into account. This thermal effect can influence in situ expansion measurements (and even the furnace temperature, see Figure 16 in [117]), but it is nearly never taken into account in the different studies. After cracking the thin electrolyte, the combustion of the fuel at these locations creates hot spots with high water vapor that can induce accelerated nickel coarsening or cathode decomposition [85].

Figure 16.

Dilatometry measurements of oxidation for a YSZ composite bar infiltrated with 16 wt % Ni [117].

Table 4.

Thermodynamic constants for NiO and ZrO2. Cp,m is the molar heat capacity (at constant pressure), ∆Hox is the enthalpy of nickel oxidation (Ni +1/2O2 → NiO at 800 °C), ∆Hfusion the fusion enthalpy of nickel oxide (melting point of NiO is Tf = 1990 °C) and ∆Hα→β the enthalpy for zirconia phase change (from α to β phase). Cp,m is calculated from equation Cp,m = a + bT [29].

| a (J mol−1 K−1) | b (J mol−1 K−2) | ∆ Hox,Ni (kJ mol−1) | ∆ Hfusion (kJ mol−1) | ∆Hα→β (kJ mol−1) | |

|---|---|---|---|---|---|

| NiO solid | 46.81 | 8.46 × 10−3 | 239.8 [29] | 50.66 [34] | – |

| NiO liquid | 59.87 | – | – | – | – |

| α-ZrO2 | 57.80 | 16.67 × 10−3 | – | – | 4.75 [34] |

| β-ZrO2 | 78.63 | – | – | – | – |

2.4.9. Reoxidation by Ionic Current

The ionic current coming from the cathode side can oxidize the Ni if no fuel is available at the anode side, as in the following equation:

The charge (in C) is directly calculated by the multiplication of the current density (A/cm2) by the active surface (cm2) and the time (s).

Hatae et al. observed spongy-like structures of the Ni-NiO phase closer to the anode/electrolyte interface for a sample oxidized under N2 at 800 °C (YSZ electrolyte and 8YSZ-NiO active anode and support). The current conditions were 7.5 mA/cm2 for 30 min, giving 54 C. X-ray stress measurements in the electrolyte showed a lower compressive stress under the cathode (−298 MPa) compared to the side of the cell (−324 MPa) and to a non-reoxidized cell tested in similar conditions (−339 MPa) [118].

Other studies from Hatae et al. reported contradictory results: one showed an activation of the electrochemical performance after oxidizing the anode with 15 C at 800 °C under nitrogen at current densities of 25 and 259 mA/cm2 [119]; another study presented degradation of the cell after a charge transfer of 15 C at a current density of 12.5 mA/cm2 [120]. In both cases, the open circuit voltage (OCV) was constant. In a recent study on anode-supported cells, Hatae et al. showed an increase of electrochemical performance of about 36% after reoxidation via ionic current (250 mA cm−2 and 15 C = oxidation of 0.6% of Ni anode and anode support). In the same time OCV increased by about 2%. After 17 such RedOx cycles, the performance slightly decreased due to delamination between the anode and the electrolyte and cracks in the YSZ anode network. Two longer oxidation periods at the same current density (equal to 31% oxidation of the Ni) showed a decrease in OCV (−2%) but with an increase in performance at 0.25 A cm−2 of +26% [121].

Sarantaridis et al. compared the oxidation in air with the oxidation by ionic current at 800 °C [112]. Due to the non-uniformity of the electrochemical oxidation, the critical degree of such oxidation occurs at 3%, compared to 49%–75% by oxidation in air.

Increase of the ohmic and polarization resistances was observed after electrochemical oxidation of nickel from a cell from the Forschungszentrum Jülich [122]. As the peak frequency in the electrochemical impedance response and the OCV remained constant, the authors proposed a delamination-degradation mechanism occurring at the interface between anode support and active layer.

Takagi et al. studied the influence of humidity in nitrogen during oxidation by ionic current. They analyzed the microstructure of a Ni-YSZ anode on a 500 µm electrolyte (YSZ) by 3D reconstruction with dual beam SEM-FIB and measured the electrochemical performance after 2 electrochemical RedOx cycles under dry N2 and 20% humidified N2. The humidity during oxidation makes the particles more spherical, which lowers their connectivity and decreases the electrochemical performance. The oxidation under dry conditions makes the particle size increase without change in the shape. Degradation is thus much lower in case of dry reoxidation by ionic current [123].

2.4.10. Micro and Nano-Structural Changes upon Redox Cycling

Macrostructural changes and physical property variations gave already some understanding on RedOx cycle effects on Ni-YSZ composite microstructures.

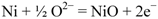

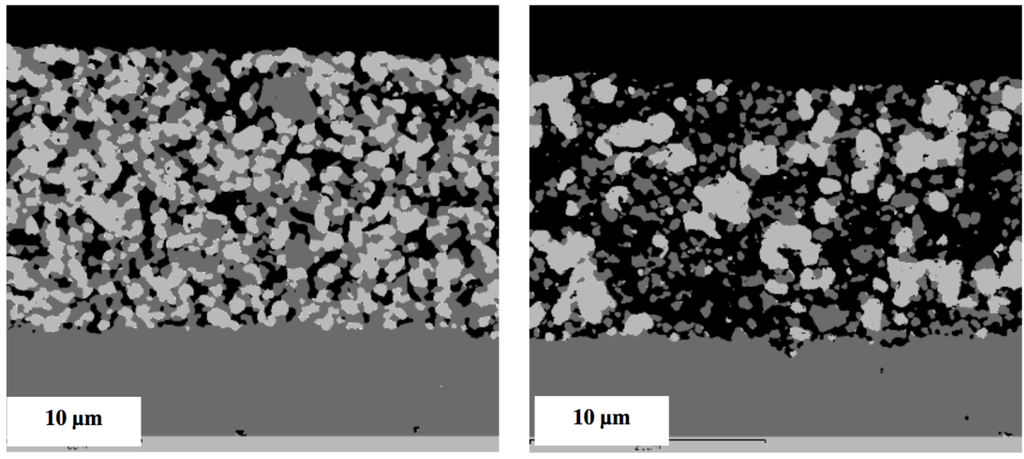

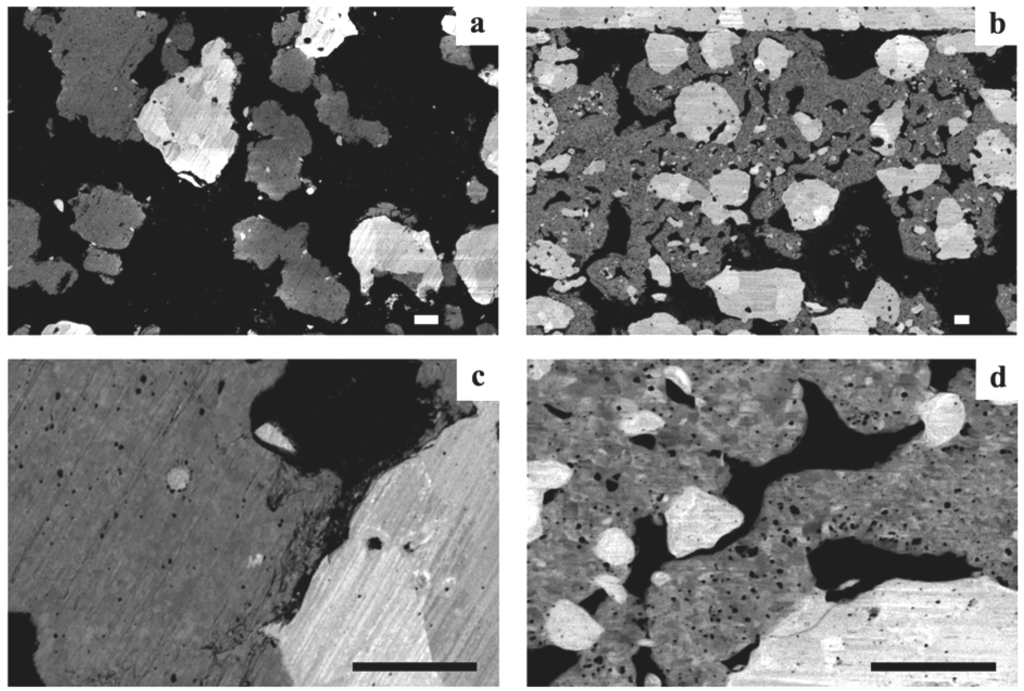

The most used technique to observe post-microstructures is scanning electron microscopy (SEM). First observations showed coarsening of the NiO particles and microcracks in the YSZ skeleton [66]. Zhang et al. observed a sponge-like aggregate of NiO crystallites. The re-reduction of this microstructure led to coarse Ni particles, suggesting a re-dispersion inducing some transport of nickel and nickel oxide during RedOx cycling [76]. In parallel, Waldbillig et al. observed smaller pores in this sponge-like reoxidized NiO microstructure. In the same study, ex situ oxidation of a transmission electron microscope (TEM) lamella at 700 °C during 15 min showed nanometric polycrystalline NiO, even if the original nickel grain was a porous micrometric crystal [124]. An in situ environmental SEM study showed live re-oxidation of nickel-YSZ composite under low pressure of 5–10 mbar of air. Isothermal oxidation at 850 °C showed a rapid oxidation with a separation of original nickel grains in 2–4 smaller particles that grew in the voids and out of the polished plane. In case of a temperature ramp oxidation, the oxidation starts at around 300 °C and progresses slowly until 450–500 °C, at which point the rate increases. This procedure presents the formation of a protective nickel oxide surface layer around the original nickel particle. The microstructure will depend on the oxidation condition of the composite; even the partial pressure of oxygen, which is much lower in the case of in situ SEM observation, can change the microstructure evolution [17].

To understand the increase of the closed porosity by a factor of 3 before and after a RedOx cycle at 800 °C of a NiO-YSZ composite, Sarantaridis et al. used dual beam SEM-focused ion beam (FIB) to study the microstructure evolution of pure nickel particles of 5µm in diameter after oxidation at 800 °C. The surface of the sample using secondary electrons from the electron beam after oxidation is more textured and shows the sponge-like structure (see Figure 17 left). This effect is less pronounced when using the secondary electrons from the ion beam. To study the internal porosity, FIB was used to cut the particles after various oxidation times at 800 °C (see Figure 17 right). The evolution shows an increase of subsurface porosity during oxidation due to the outward diffusion of Ni2+ [50].

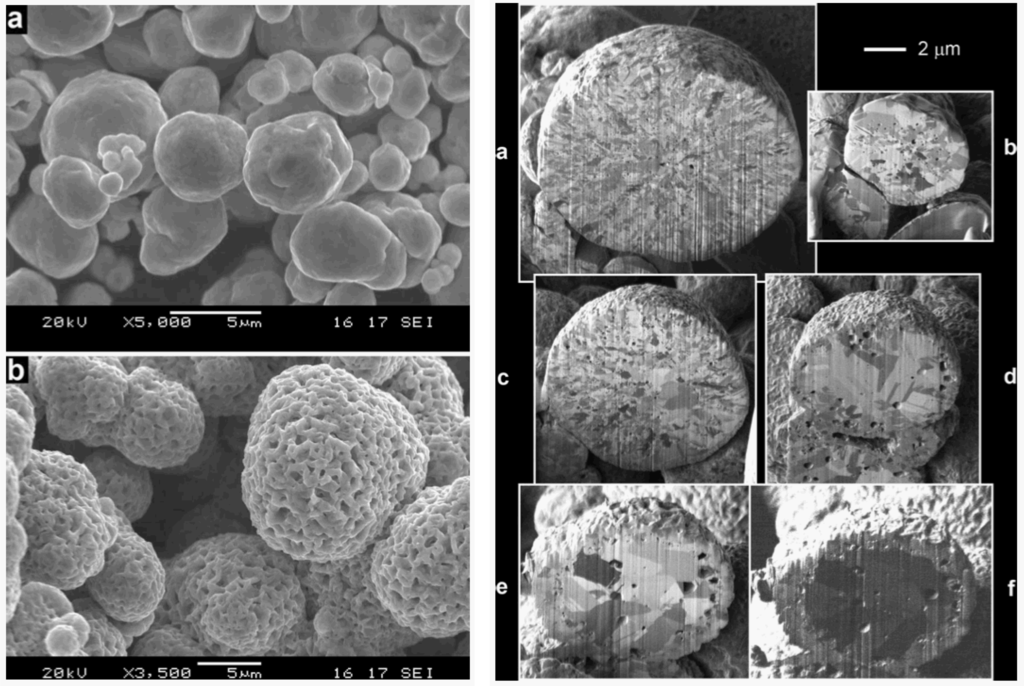

Similar observations were done on Ni-YSZ composite reoxidized at 550, 800 and 1000 °C under air. Cross sections of the sample with SEM/FIB showed bigger NiO closed porosity at elevated temperature and small well dispersed NiO porosity at low temperature (see Figure 18) [85]. This change in NiO closed porosity can be related to the outward Ni diffusion process during oxidation. At relatively low temperature (i.e., 550 °C), the Ni transport occurs via grain boundary of the NiO outer layer, and at elevated temperature (i.e., 1000 °C) the Ni transport occurs through the NiO crystal lattice [47].

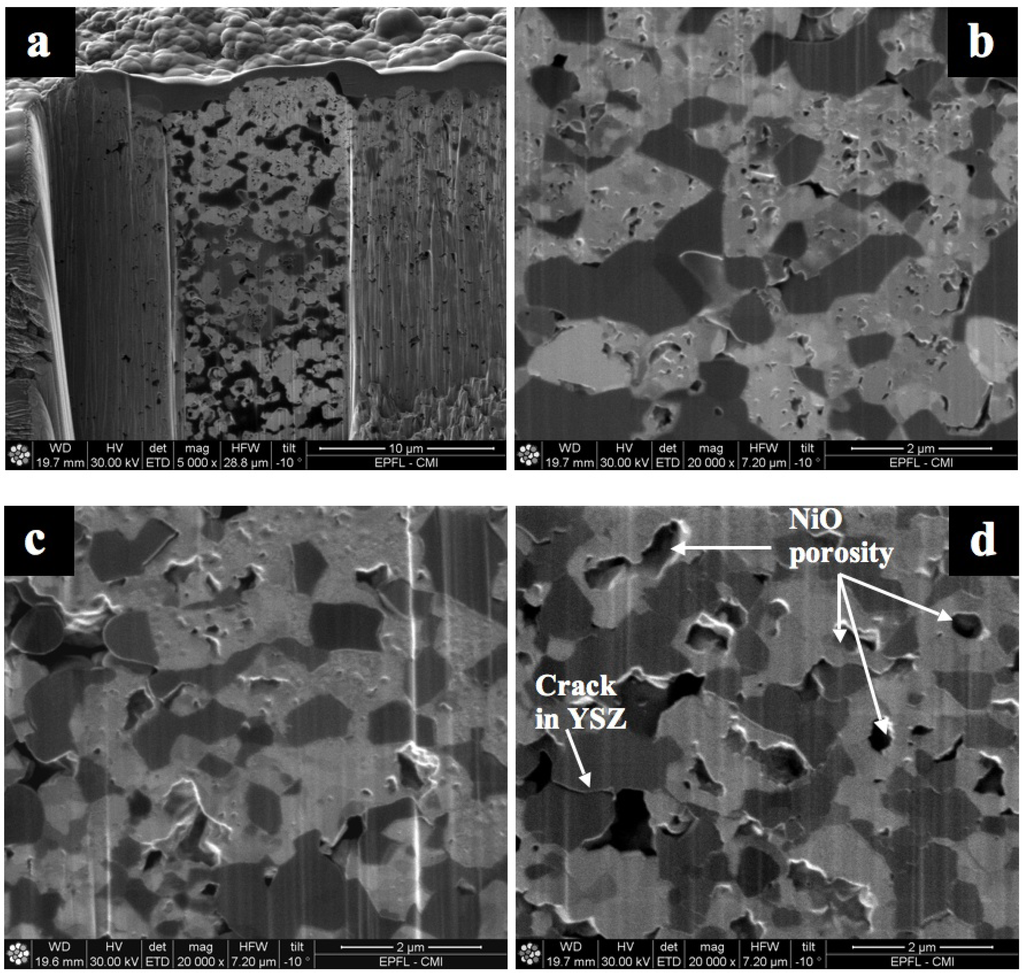

TEM observations showed porous NiO after an in-situ RedOx cycle. After the RedOx cycle, NiO grains grow out of the TEM-lamella plane and inside preexisting pores [125]. Cross-section observation of the tested TEM lamella shows closed porosity inside the NiO (Figure 19). These observations can explain an irreversible strain after a RedOx cycle due to the re-oxidation process that increases the nickel oxide closed porosity. Understanding better the nickel oxidation process shows that the nickel coarsening during anode utilization is not the only cause of Ni-YSZ anode instability.

Multiple RedOx cycles at elevated temperatures destroy the Ni-YSZ microstructure of an electrolyte-supported cell. A strong increase in porosity and in Ni particle size was observed after the process in Figure 20 [126].

After an initial RedOx cycle, temperature programmed reduction (TPR) showed a lower temperature of reduction and a faster reduction rate [76]. X-ray diffraction (XRD) revealed a broadening of the NiO peaks [127,128]. These two observations confirm the decrease of particles and crystallites size during the Ni reoxidation process in a Ni-YSZ composite.

Figure 17.

Left: SEM of (a) as received Ni and (b) fully oxidized Ni (NiO) particles. The secondary electron images were recorded using a beam energy of 20 keV. Right: FIB cross-sectional secondary electron images of Ni particles oxidized at 800 °C for (a) 30 s; (b) 60 s; (c) 90 s; (d) 180 s; and (e) 300 s. Image (f) is the same particle as in (e) but obtained using the secondary ion signal [50].

Figure 18.

Secondary electron image from FIB cross-section from half-cells after one RedOx cycle (a) at 550 °C (lower magnification); (b) at 550 °C (higher magnification); (c) at 800 °C and (d) at 1000 °C. NiO contains small pores after a RedOx cycle at 550 and 800 °C but a single big pore after a RedOx cycle at 1000 °C. Dark grey is YSZ and light grey is NiO. The vertical lines come from the FIB milling process (“curtain effect”) [85].

Figure 19.

Cross-section of a transmission electron microscope (TEM) lamella after an in situ RedOx cycle, showing the hilly surface and closed porosity of the nickel oxide after reoxidation [129].

Figure 20.

Fine Ni-8YSZ anode before (left) and after (right) eight RedOx cycles at 950 °C (SEM, backscattered electron detector, 10 kV) [126].

3-D reconstructions using FIB-SEM microscopy of oxidized Ni-CGO cermet at 510 and 575 °C showed nucleation of temperature-dependent pseudo-Kirkendall voids. Larger pores were observed at the highest oxidation temperature [65].

Microstructural evolution of Ni-YSZ composite was observed by X-ray computed tomography. Limited microstructural change was seen after 10 min oxidation steps at 500 °C but a porous NiO layer of about 700 nm was reported after 10 min at 700 °C [130].

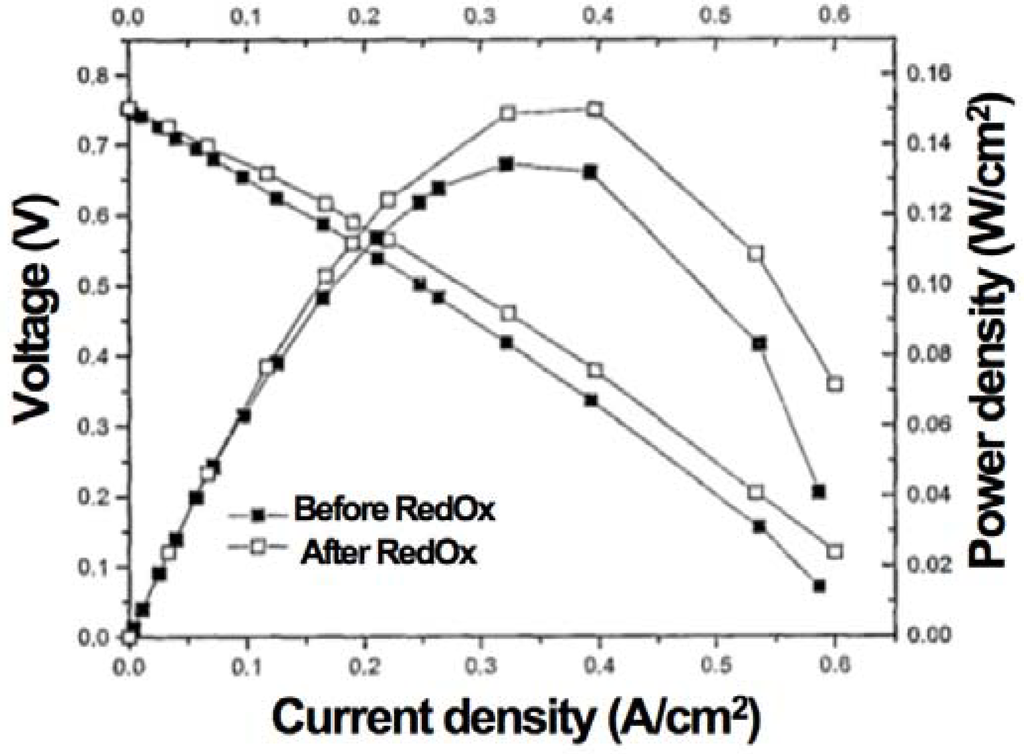

2.4.11. Electrochemical Performance and Electrochemical Impedance Spectroscopy

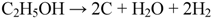

The electrochemical performance after a RedOx cycle can vary a lot. In case of ASC, a decrease in OCV can occur, indicating the thin electrolyte to crack [10,90,113].

The performance can increase due to, first, a better electrical contact between cell and current collecting layer [131] and, second, an activation [73,132] or re-activation after degradation [133] of the active anode.

Pihlatie et al. observed a decrease in Rp after a RedOx cycle at 650 °C and a small decrease in Rs after a RedOx cycle at 850 °C, of symmetrical Ni-ScSZ anodes on a ScSZ electrolyte-supported cell. Microstructural observation revealed a finer microstructure after the 650 °C RedOx cycle and cracks in the electrolyte after the 850 °C RedOx cycle [73].

In many cases, the performances decrease due to an increase in polarization resistance (Rp) [16,66,81,126,127,131] and in some cases an increase in ohmic resistance (especially for Ni-CGO, see Figure 21) [81,126].

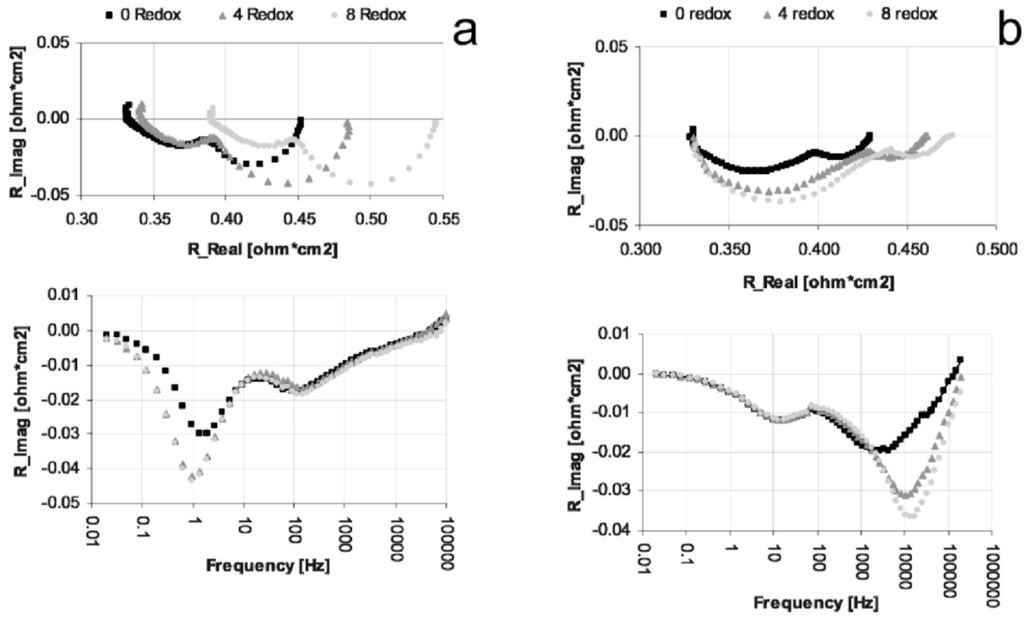

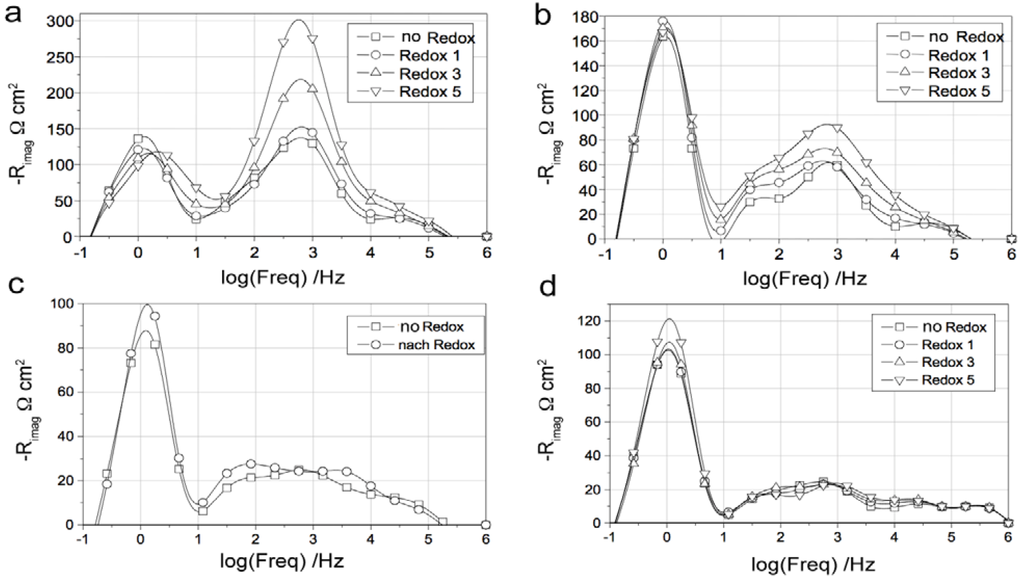

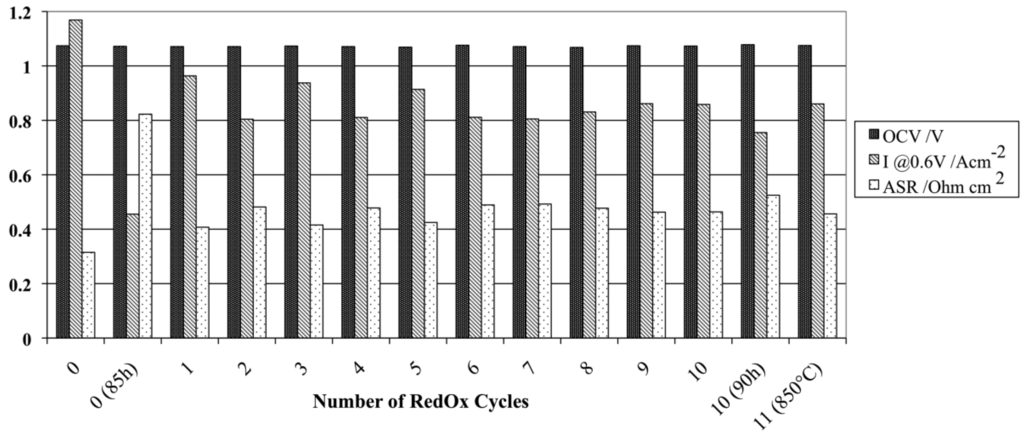

Iwanschitz et al. showed the evolution of the imaginary part of impedance versus frequencies after RedOx cycles for Ni-8YSZ and Ni-40CGO [81,126] (see Figure 21). After a cycle at 950 °C, the Ni-CGO anode showed an increase of the peak at 1 Hz (corresponding to the conversion and diffusion impedances [134,135]) as well as of the ohmic resistance Rs. This increase in peak height means a change in the gas transport process, while the Rs evolution is linked to the electronic conductivity decrease in the Ni-40CGO layer (see Figure 15). The Ni-YSZ anode showed an increase of the high frequency peak (corresponding to the charge transfer impedance [136,137]) from 1 kHz to 10 kHz. The variation in frequency after the RedOx cycles means that the capacity layer between Ni and YSZ is changed. The change in peak height showed a degradation of the anode due to a decrease in active sites.

A correlation study between the electrochemical characteristics and the microstructural evolution was done using 3D microstructure reconstruction with a FIB/SEM microscope. RedOx cycles of a Ni-YSZ thin anode on an electrolyte-supported cell at 1000 °C showed electrochemical performance degradation: Anode polarization losses increased from about 0.06 initially to about 0.09 Ω cm2 after the fourth RedOx cycle. This was correlated to a decrease in triple phase boundary (TPB) length of the anode from initial 2.49 to 2.11 µm−2 after 4 RedOx cycles [138,139].

Figure 21.

Impedance spectra at OCV during RedOx cycling at 950 °C of (a) Ni-40CGO (Ce0.6Gd0.4O2−d) and (b) Ni-8YSZ anodes with a 8YSZ electrolyte support. Top: Nyquist plot; bottom: complex impedance plot [81,126].

Laurencin et al. studied Kerafol 3YSZ supports with a 8YSZ porous interlayer (15 µm) and a NiO-8YSZ anode of 25 µm (with 31% porosity in oxidized state) [127]. RedOx cycles were performed during 30 min under air at 800 °C. The impedance spectra were fitted with an equivalent circuit based on a resistance (Rs, ohmic resistance) in series with three RC processes of a resistance and a constant phase element in parallel. This gives three semi-circles of low (0.4–0.8 Hz), intermediate (6.2–10.9 Hz) and high (330–590 Hz) frequency phenomena. Ohmic resistance is constant while the polarization resistances at high and low frequency increase with RedOx cycling. The high frequency response is related to charge transfer and the low frequency response to gas diffusion and conversion. The authors explained the peak increase by the densification and the deterioration of the anode microstructure.

Müller presented the evolution of the imaginary part of impedance versus frequencies after RedOx cycles at 950 °C [16] (Figure 26). In general, he observed an increase in the peak around 1 kHz and in some cases a slight increase in the low frequency peak around 1 Hz.

All studies on ESC Ni-YSZ revealed an increase of the complex impedance around 1 kHz during RedOx cycling. This is linked to the charge transfer at the Ni-YSZ anode active sites; an increase in complex impedance means a deterioration of the microstructure at the anode/electrolyte interface.

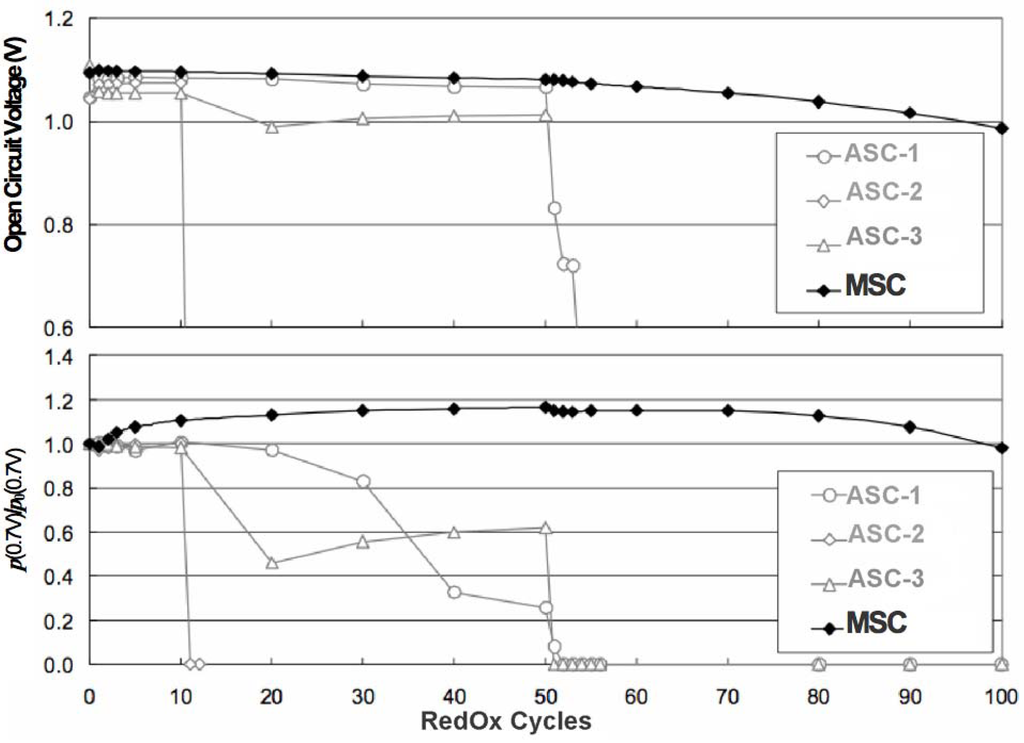

2.4.12. Single Chamber SOFC

In the case of a single chamber SOFC, the problem is different as both reducing and oxidizing gases are introduced together in the fuel cell. The specific activities of the two electrodes will produce a potential difference and generate current. Jaques-Bedard et al. observed an oscillation of the potential of a Ni-YSZ anode supported cell under a methane-to-oxygen ratio (M/O) lower than 2. This oscillation with a period of 20 s is related to the reduction and oxidation ongoing at the nickel surface. The degradation is more elevated for M/O < 2 and is explained by higher Ni evaporation at the fuel entrance and damages due to RedOx cycles [140]. Similar tests were done adding anode resistivity measurements. A voltage decrease was correlated to the anode resistivity increase; it was concluded that reduction-oxidation of Ni in the anode induced the voltage oscillation [141].

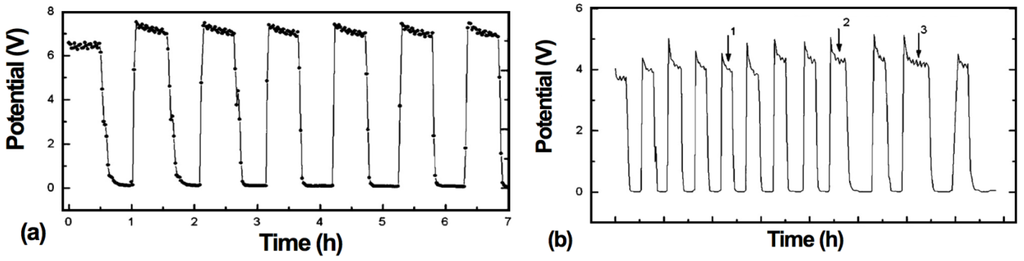

To clarify the effect of flowing both reducing and oxidizing gases over the anode, Kellogg et al. studied the Ni-YSZ anode in a double chamber, electrolyte-supported cell configuration. They flew 2/3 H2 and 1/3 O2 diluted in 95% of Ar over the anode, and pure oxidizer gas over the cathode. Oscillations of the open circuit voltage were observed around the equilibrium voltage of NiO/Ni at 600 °C. The explanation is an oxidation of the nickel and a re-reduction due to accumulation of H2 (the period is about 70 s in this case). Electrical conductivity measurements under these conditions showed a similar oscillation. When the H2/O2 mixture was flown over the cathode (with reducing gas over the anode) no variation was observed [142].

2.5. Summary of the RedOx Instability

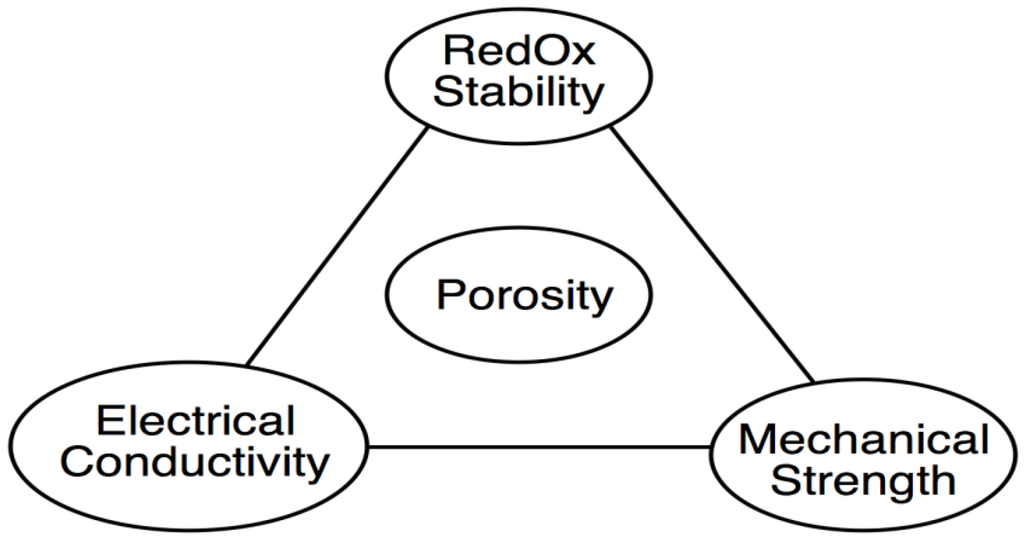

One of the main limitations of nickel-based SOFC anodes is its RedOx cycling instability. The RedOx instability is coming from the volume change of nickel between its reduced and oxidized states. The volume increase during nickel oxidation induces an expansion of the composite. This expansion has three origins: (1) The reorganization of the metallic nickel during utilization; (2) the fast oxidation kinetics of the nickel at the operating temperature (between 600 and 800 °C) and (3) the closed porosity formation during the oxidation process. At low temperature or high oxygen partial pressure, the oxidation-limiting factor is the solid-state diffusion (which is thermally activated) giving a homogeneous oxidation of the full anode layer. In opposition, at elevated temperature and low oxygen partial pressure, the oxidation-limiting factor is the O2 gas diffusion through the oxidized anode layer leading to an inhomogeneous oxidation and higher layer internal stresses. Increasing reoxidation temperature will increase the expansion of the anode and the damages to the ceramic network.

The anode-supported cell (ASC) configuration is the most sensitive cell design: an anode expansion of 0.2% already induces cracks in the thin electrolyte. For the electrolyte-supported cells (ESC), the expansion limit before delamination of the anode is increased to 0.5%. In the case of cells on inert supports (RedOx stable metal or ceramic support), the expansion limit is even higher (around 1%).

Various causes might induce anode oxidation during operation: air leakage (lack of fuel, shutdown and start-up without reducing gas, compressive sealing), high current demand, and fuel starvation. In the last two cases, the anode will oxidize due to ionic current (O2−) coming via the electrolyte. With these kinds of RedOx cycles, only a low amount of oxidized nickel (small degree of oxidation) will cause damages to the cell.