Bi-Objective Optimization of Techno-Economic and Environmental Performance of CO2 Capture Strategy Involving Two-Stage Membrane-Based Separation with Recycling

Abstract

1. Introduction

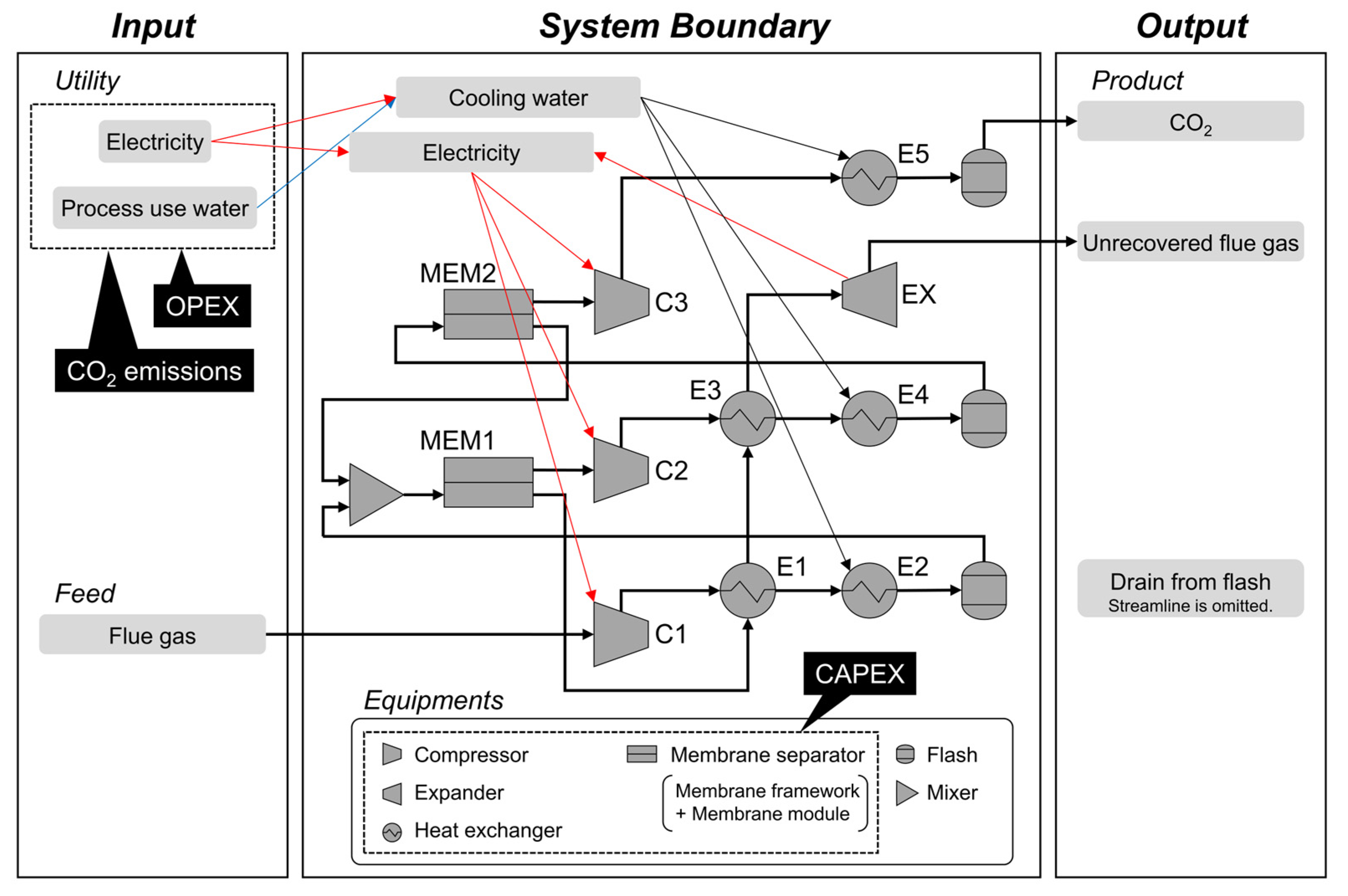

2. Materials and Methods

2.1. Boundary and Process Simulation Settings

2.2. Analyses of the Selected Evaluation Indices

2.3. Algorithm of MLB-MOGABO

2.4. Settings for the Case Studies

3. Results

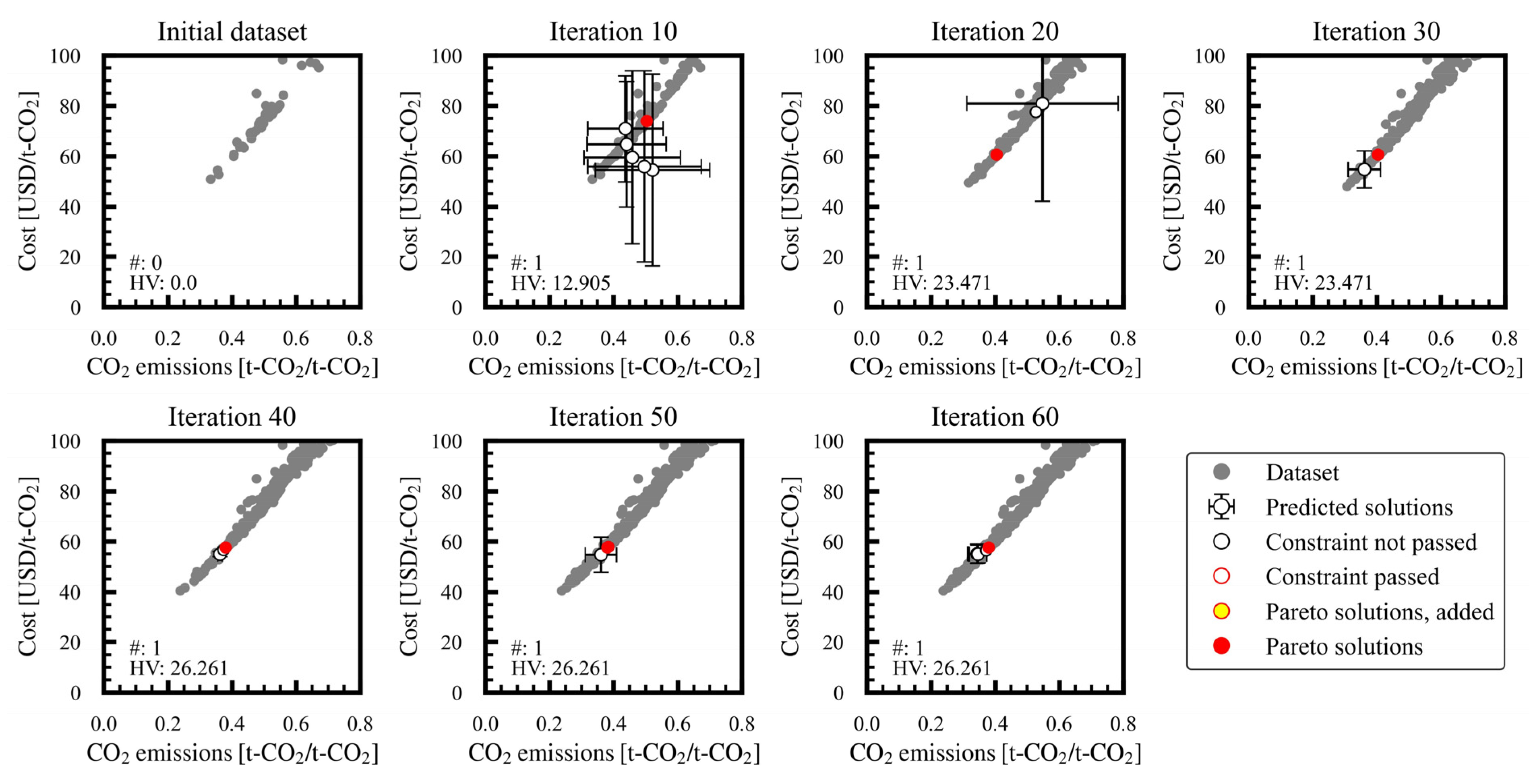

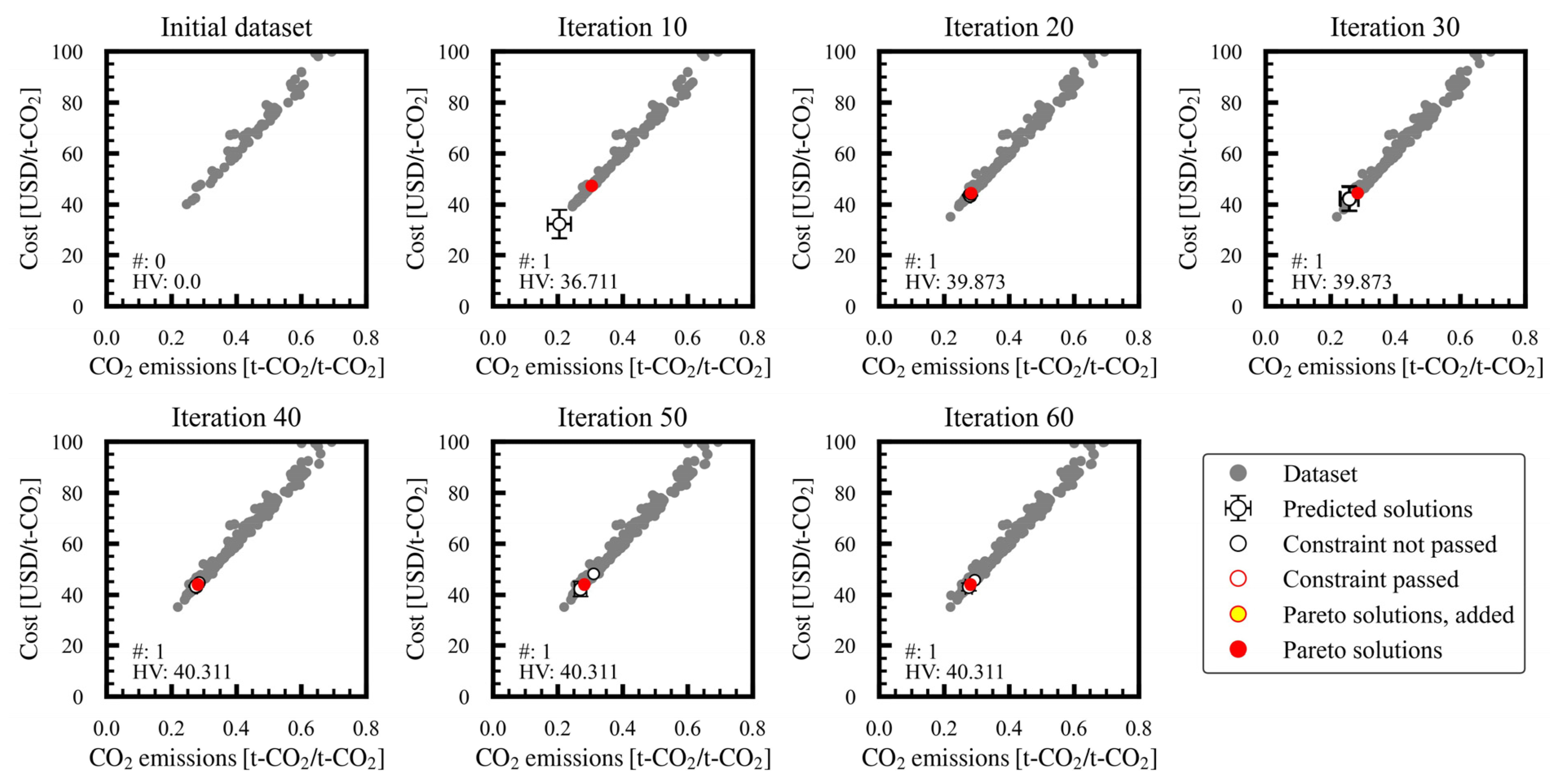

3.1. Progress in Bi-Objective Optimization

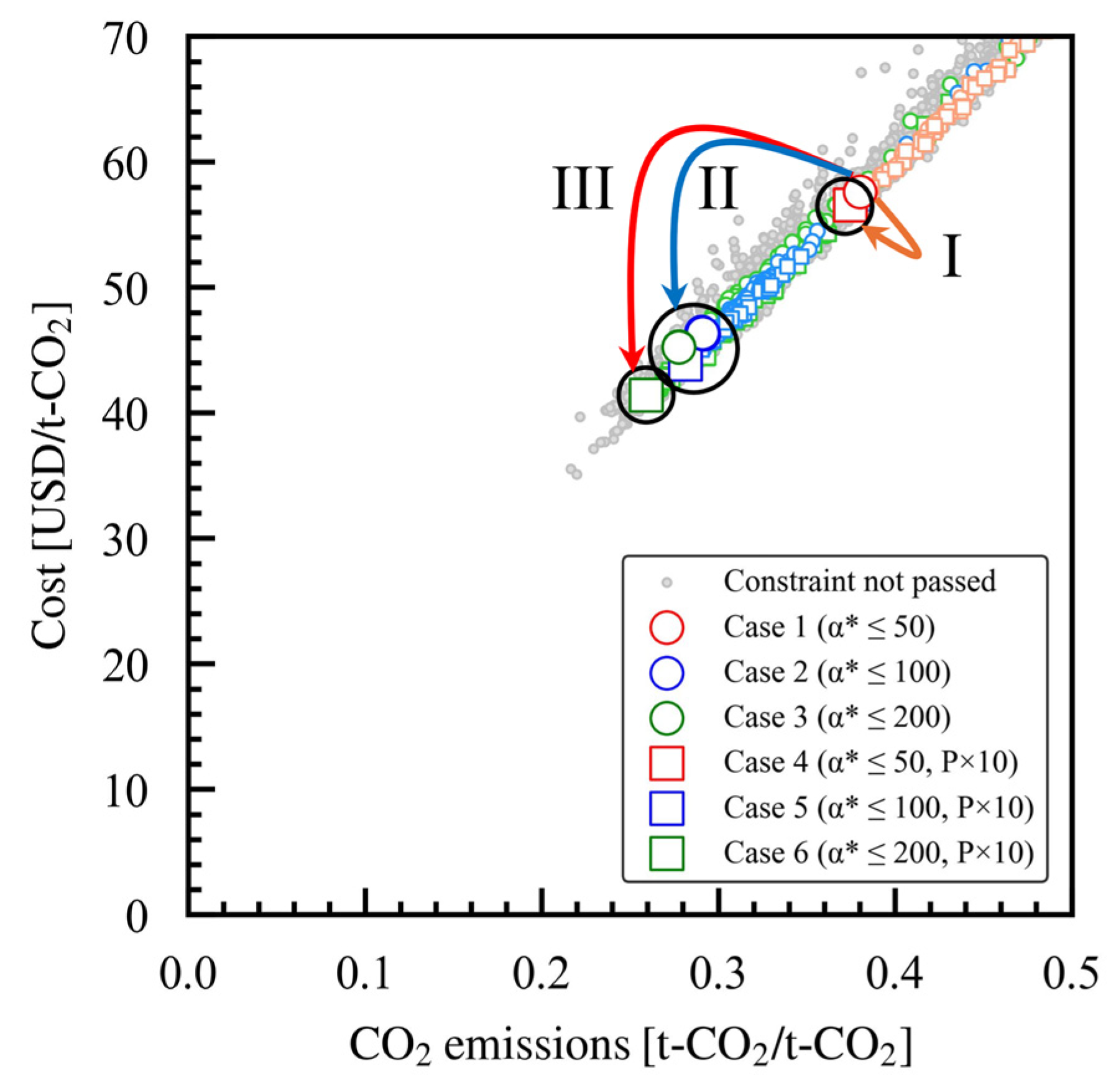

3.2. Trends in the Pareto Solutions

3.3. Membrane Area and Its Relationship to α*(CO2/N2), Ph, and Pl

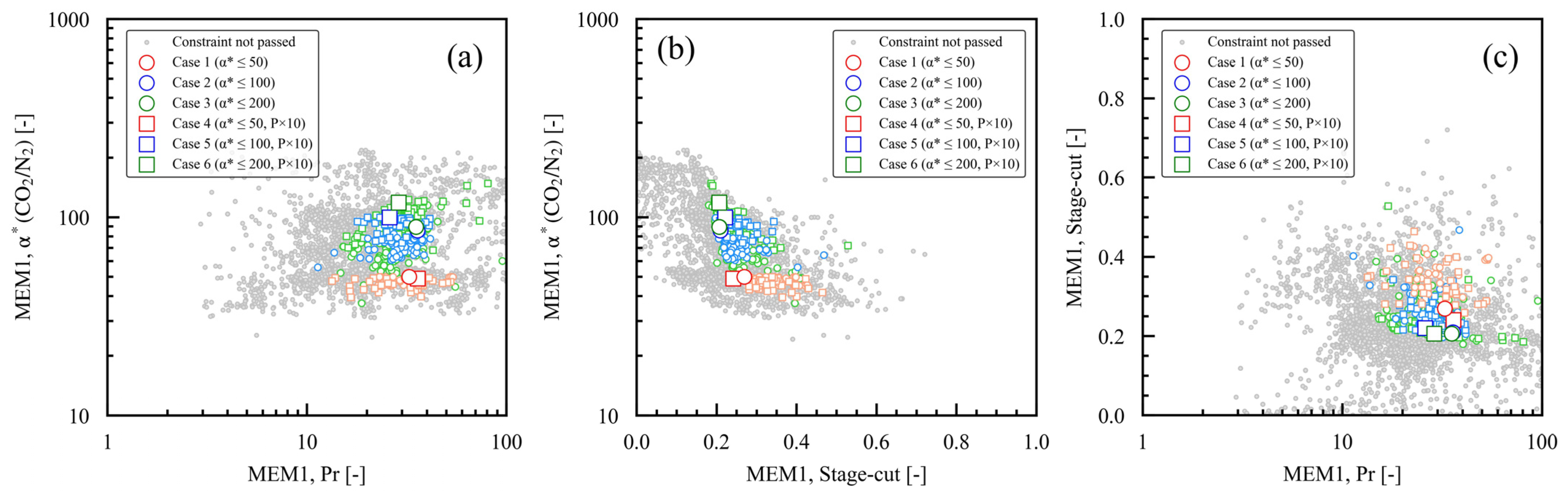

3.4. Relationships Between Dimensionless Numbers α*(CO2/N2) and Pr and the Stage Cut

3.5. Relationships Between Membrane Performances and Membrane Area and Power Consumption

3.6. Optimal Membrane Performance and Directions for Membrane Development

4. Implications and Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | |

| CAPEX | capital expenditure, USD/t-CO2 |

| CEPCI | chemical engineering plant cost index |

| CRF | capital recovery factor |

| CTM | total module cost, USD |

| FBM | bare module factor |

| OPEX | operation expenditure, USD/t-CO2 |

| Ph | feed-side pressure (absolute pressure), kPa |

| Pl | permeate-side pressure (absolute pressure), kPa |

| Pr | pressure ratio (Ph/Pl) |

| Equipment | |

| C | compressor |

| E | heat exchanger |

| Ex | expander |

| MEM | membrane module |

| Acronyms | |

| ADoE | adoptive design of experiment |

| CAPCOST | capital equipment-costing program |

| CCUS | carbon dioxide capture, utilization, storage |

| GPR | Gaussian process regression |

| LCA | life cycle assessment |

| ML | machine learning |

| MLB-MOGABO | machine learning-based multi-objective genetic algorithm Bayesian optimization |

| NSGA-II | elitist nondominated sorting genetic algorithm-II |

| RFC | random forest classification |

Appendix A. Progress of Bi-Objective Optimization Using MLB-MOGABO

References

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Review of technological progress in carbon dioxide capture, storage, and utilization. Gas Sci. Eng. 2023, 117, 205070. [Google Scholar] [CrossRef]

- Zhang, S.H.; Shen, Y.; Zheng, C.H.; Xu, Q.Q.; Sun, Y.F.; Huang, M.; Li, L.; Yang, X.W.; Zhou, H.; Ma, H.L.; et al. Recent advances, challenges, and perspectives on carbon capture. Front. Environ. Sci. Eng. 2024, 18, 75. [Google Scholar] [CrossRef]

- Lin, Z.H.; Yuan, Z.Y.; Dai, Z.D.; Shao, L.; Eisen, M.S.; He, X.Z. A review from material functionalization to process feasibility on advanced mixed matrix membranes for gas separations. Chem. Eng. J. 2023, 475, 146075. [Google Scholar] [CrossRef]

- Gkotsis, P.; Peleka, E.; Zouboulis, A. Membrane-Based Technologies for Post-Combustion CO2 Capture from Flue Gases: Recent Progress in Commonly Employed Membrane Materials. Membranes 2023, 13, 898. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Ho, W.S.W. Moving beyond 90% Carbon Capture by Highly Selective Membrane Processes. Membranes 2022, 12, 399. [Google Scholar] [CrossRef]

- Favre, E. Membrane Separation Processes and Post-Combustion Carbon Capture: State of the Art and Prospects. Membranes 2022, 12, 884. [Google Scholar] [CrossRef]

- Kancherla, R.; Nazia, S.; Kalyani, S.; Sridhar, S. Modeling and simulation for design and analysis of membrane-based separation processes. Comput. Chem. Eng. 2021, 148, 107258. [Google Scholar] [CrossRef]

- Chatziasteriou, C.C.; Kikkinides, E.S.; Georgiadis, M.C. Recent advances on the modeling and optimization of CO2 capture processes. Comput. Chem. Eng. 2022, 165, 107938. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Elsaid, K.; Sayed, E.T.; Maghrabie, H.M.; Abdelkareem, M.A. Large scale application of carbon capture to process industries—A review. J. Clean. Prod. 2022, 362, 132300. [Google Scholar] [CrossRef]

- Tapia, J.F.D.; Lee, J.Y.; Ooi, R.E.H.; Foo, D.C.Y.; Tan, R.R. A review of optimization and decision-making models for the planning of CO2 capture, utilization and storage (CCUS) systems. Sustain. Prod. Consum. 2018, 13, 1–15. [Google Scholar] [CrossRef]

- Hara, N.; Taniguchi, S.; Yamaki, T.; Nguyen, T.T.H.; Kataoka, S. Bi-objective optimization of post-combustion CO2 capture using methyldiethanolamine. Int. J. Greenh. Gas Control 2023, 122, 103815. [Google Scholar] [CrossRef]

- Hara, N.; Taniguchi, S.; Yamaki, T.; Nguyen, T.T.H.; Kataoka, S. Impacts of hydrogen price and carbon dioxide emission factor on bi-objective optimizations of absorption and subsequent methanation processes of carbon dioxide capture, utilization, and storage. J. Clean. Prod. 2024, 456, 142358. [Google Scholar] [CrossRef]

- Hara, N.; Taniguchi, S.; Yamaki, T.; Nguyen, T.T.H.; Kataoka, S. Bi-Objective Optimization of Techno-Economic and Environmental Performance for Membrane-Based CO2 Capture via Single-Stage Membrane Separation. Membranes 2025, 15, 57. [Google Scholar] [CrossRef] [PubMed]

- Merkel, T.C.; Lin, H.Q.; Wei, X.T.; Baker, R. Power plant post-combustion carbon dioxide capture: An opportunity for membranes. J. Membr. Sci. 2010, 359, 126–139. [Google Scholar] [CrossRef]

- Huang, Y.; Merkel, T.C.; Baker, R.W. Pressure ratio and its impact on membrane gas separation processes. J. Membr. Sci. 2014, 463, 33–40. [Google Scholar] [CrossRef]

- Li, Q.H.; Wu, H.Y.; Wang, Z.; Wang, J.X. Analysis and optimal design of membrane processes for flue gas CO2 capture. Sep. Purif. Technol. 2022, 298, 121584. [Google Scholar] [CrossRef]

- Ramasubramanian, K.; Verweij, H.; Ho, W.S.W. Membrane processes for carbon capture from coal-fired power plant flue gas: A modeling and cost study. J. Membr. Sci. 2012, 421, 299–310. [Google Scholar] [CrossRef]

- Xu, J.Y.; Wang, Z.; Qiao, Z.H.; Wu, H.Y.; Dong, S.L.; Zhao, S.; Wang, J.X. Post-combustion CO2 capture with membrane process: Practical membrane performance and appropriate pressure. J. Membr. Sci. 2019, 581, 195–213. [Google Scholar] [CrossRef]

- Micari, M.; Dakhchoune, M.; Agrawal, K.V. Techno-economic assessment of postcombustion carbon capture using high-performance nanoporous single-layer graphene membranes. J. Membr. Sci. 2021, 624, 119103. [Google Scholar] [CrossRef]

- Van Der Sluijs, J.P.; Hendriks, C.A.; Blok, K. Feasibility of Polymer Membranes for Carbon-Dioxide Recovery from Flue-Gases. Energy Convers. Manag. 1992, 33, 429–436. [Google Scholar] [CrossRef]

- Mat, N.C.; Lipscomb, G.G. Membrane process optimization for carbon capture. Int. J. Greenh. Gas Control 2017, 62, 1–12. [Google Scholar] [CrossRef]

- Roussanaly, S.; Anantharaman, R.; Lindqvist, K.; Zhai, H.B.; Rubin, E. Membrane properties required for post-combustion CO2 capture at coal-fired power plants. J. Membr. Sci. 2016, 511, 250–264. [Google Scholar] [CrossRef]

- Arias, A.M.; Mussati, M.C.; Mores, P.L.; Scenna, N.J.; Caballero, J.A.; Mussati, S.F. Optimization of multi-stage membrane systems for CO2 capture from flue gas. Int. J. Greenh. Gas Control 2016, 53, 371–390. [Google Scholar] [CrossRef]

- Asadi, J.; Kazempoor, P. Sustainability Enhancement of Fossil-Fueled Power Plants by Optimal Design and Operation of Membrane-Based CO2 Capture Process. Atmosphere 2022, 13, 1620. [Google Scholar] [CrossRef]

- Chiwaye, N.; Majozi, T.; Daramola, M.O. On optimisation of N2 and CO2-selective hybrid membrane process systems for post-combustion CO2 capture from coal-fired power plants. J. Membr. Sci. 2021, 638, 119691. [Google Scholar] [CrossRef]

- Ramezani, R.; Randon, A.; Di Felice, L.; Gallucci, F. Using a superstructure approach for techno-economic analysis of membrane processes. Chem. Eng. Res. Des. 2023, 199, 296–311. [Google Scholar] [CrossRef]

- AVEVA PRO/II Simulation v2022. Available online: https://www.aveva.com/en/products/pro-ii-simulation/ (accessed on 23 January 2023).

- Turton, R.; Shaeiwitz, J.A.; Bhattacharyya, D.; Whiting, W.B. Analysis, Synthesis, and Design of Chemical Processes, 5th ed.; Pearson Education, Inc.: London, UK, 2018. [Google Scholar]

- Shindo, Y.; Hakuta, T.; Yoshitome, H.; Inoue, H. Calculation Methods for Multicomponent Gas Separation by Permeation. Sep. Sci. Technol. 1985, 20, 445–459. [Google Scholar] [CrossRef]

- Robeson, L.M. The upper bound revisited. J. Membr. Sci. 2008, 320, 390–400. [Google Scholar] [CrossRef]

- CEPCI. Economic Indicators. Chem. Eng. 2022, August, 72. Available online: http://www.chemengonline.com (accessed on 23 January 2023).

- U.S. Energy Information Administration, Electric Power Annual 2021. 2022. Available online: https://www.eia.gov/electricity/annual/ (accessed on 23 January 2023).

- U.S. Energy Information Administration, How much carbon dioxide is produced per kilowatthour of U.S. electricity generation? 2021. Available online: https://www.eia.gov/tools/faqs/faq.php?id=74&t=11 (accessed on 10 November 2023).

- SimaPro PRe Sustainability, SimaPro v9.4.0. Available online: https://support.simapro.com (accessed on 20 January 2023).

- Kaneko, H. Adaptive design of experiments based on Gaussian mixture regression. Chemometr. Intell. Lab. 2021, 208, 104226. [Google Scholar] [CrossRef]

- Misra, S.; Nikolaou, M. Adaptive design of experiments for model order estimation in subspace identification. Comput. Chem. Eng. 2017, 100, 119–138. [Google Scholar] [CrossRef]

- Kennard, R.W.; Stone, L.A. Computer Aided Design of Experiments. Technometrics 1969, 11, 137. [Google Scholar] [CrossRef]

- Scikit-Learn Random Forest Classifier. Available online: https://scikit-learn.org/stable/modules/generated/sklearn.ensemble.RandomForestClassifier.html (accessed on 21 June 2023).

- Kaneko, H. Python_Doe_Kspub. Available online: https://github.com/hkaneko1985/python_doe_kspub (accessed on 14 February 2022).

- Kaneko, H. Examining variable selection methods for the predictive performance of regression models and the proportion of selected variables and selected random variables. Heliyon 2021, 7, e07356. [Google Scholar] [CrossRef] [PubMed]

- Verma, S.; Pant, M.; Snasel, V. A comprehensive review on NSGA-II for multi-objective combinatorial optimization problems. IEEE Access 2021, 9, 57757–57791. [Google Scholar] [CrossRef]

- Srinivas, N.; Krause, A.; Kakade, S.M.; Seeger, M.W. Information-Theoretic Regret Bounds for Gaussian Process Optimization in the Bandit Setting. IEEE Trans. Inform. Theory 2012, 58, 3250–3265. [Google Scholar] [CrossRef]

- Wang, X.L.; Jin, Y.C.; Schmitt, S.; Olhofer, M. An adaptive Bayesian approach to surrogate-assisted evolutionary multi-objective optimization. Inform. Sci. 2020, 519, 317–331. [Google Scholar] [CrossRef]

- Hadka, D. Platypus-Opt 1.1.0. Available online: https://pypi.org/project/Platypus-Opt/ (accessed on 14 February 2022).

- Deb, K. Multi-Objective Optimization Using Evolutionary Algorithms; John Wiley & Sons, Ltd.: Chichester, UK, 2001. [Google Scholar]

- Shang, K.; Ishibuchi, H.; He, L.J.; Pang, L.M. A survey on the hypervolume indicator in evolutionary multiobjective optimization. IEEE Trans. Evolut. Comput. 2021, 25, 1–20. [Google Scholar] [CrossRef]

- Baker, R.W. Membrane Technology and Applications, 3rd ed.; John Wiley and Sons Ltd.: Chichester, UK, 2012. [Google Scholar]

- Ding, Y. Perspective on Gas Separation Membrane Materials from Process Economics Point of View. Ind. Eng. Chem. Res. 2020, 59, 556–568. [Google Scholar] [CrossRef]

| Equipment Code | Equipment Type | Setting for Process Simulation | Setting for CAPEX Evaluation | ||||

|---|---|---|---|---|---|---|---|

| Method | Capacity | ||||||

| Unit | Min. | Max. | |||||

| C1, C2, C3 | Compressor | Adiabatic efficiency: 75%. | CAPCOST [28], centrifugal, axial, and reciprocating | Fluid power, kW | 450 | 3000 | |

| EX | Expander | Adiabatic efficiency: 75%. | CAPCOST [28], radial gas–liquid expanders | Fluid power, kW | 100 | 1500 | |

| E1, E3 | Heat exchanger | Hot side: gas; cold side: gas; solved with minimum internal temperature approach (ΔT: 10 °C); U-value determined by pressure [12]. | CAPCOST [28], floating head | Area, m2 | 10 | 1000 | |

| E2, E4, E5 | Heat exchanger | Hot side: gas (product temperature: 40 °C); cold side: cooling water (inlet temperature: 30 °C; outlet temperature: 40 °C); U-value determined by pressure [12]. | CAPCOST [28], floating head | Area, m2 | 10 | 1000 | |

| MEM1, MEM2 | Membrane separator | Membrane framework | Calculated based on the cross-flow model; pressure on both feed and permeate sides, membrane area, and permeance for all gas components involved in calculation. | Estimated based on previously published equation [22]; reference cost converted from EUR to USD at USD/EUR = 0.75 | Area, m2 | 0 | 25,000 |

| Membrane module | Estimated by multiplying capacity and membrane module price | Area, m2 | 0 | - | |||

| Parameter | Value | Unit | Remark |

|---|---|---|---|

| CAPEX | |||

| Annual operation hour | 8000 | h/year | The annual production rate was calculated by multiplying the hourly production rate obtained from the process simulation by the annual operation hours |

| CEPCI2001 | 397.0 | - | CEPCI for the year 2001 [28] was used as the base year |

| CEPCI2014 | 576.1 | - | CEPCI for 2014 [31] was used as the base year for the evaluation of the membrane framework |

| CEPCI2021 | 708.0 | - | CEPCI for year 2021 [31] |

| CRFst | 0.098 | - | Capital recovery factor calculated from service life: 25 years and interest rate: 0.08 used as standard values |

| CRFMemModule | 0.250 | - | Capital recovery factor calculated from service life: 5 years and interest rate: 0.08 used for membrane module |

| Membrane module price | 50 | USD/m2 | - |

| OPEX | |||

| Electricity | 0.0718 | USD/kWh | Average price in U.S. industrial sector in year 2021 [32] |

| Water | 0.177 | USD/1000 kg | [28] |

| CO2 emissions factor | |||

| Electricity | 0.656 | kg-CO2/kWh | Determined by dividing the total CO2 emissions by the total amount of electricity generated from coal, natural gas, and petroleum, in the U.S. in 2021 [33] |

| Water | - | kg-CO2/1000 kg | Assessed using SimaPro for completely softened water [34]; value concealed in accordance with SimaPro’s terms and conditions |

| Code | Design Variable | Unit | Setting for Bi-Objective Optimization | |||

|---|---|---|---|---|---|---|

| Range for Generating Sample Dataset in Iteration 1 | Limit of Optimization Range | |||||

| Min. | Max. | Min. | Max. | |||

| X1 | MEM1 permeate side pressure | kPa | 1 | 101 | 1 | 101 |

| X2 | MEM1 area | m2 | 1000 | 200,000 | 1 | 10,000,000 |

| X3 | MEM1 ideal separation factor, α*(CO2/N2) | - | 10 | 200 | 10 | 1000 |

| X4 | MEM2 permeate side pressure | kPa | 1 | 101 | 1 | 101 |

| X5 | MEM2 area | m2 | 1000 | 200,000 | 1 | 10,000,000 |

| X6 | MEM2 ideal separation factor, α*(CO2/N2) | - | 10 | 200 | 10 | 1000 |

| X7 | C1 outlet pressure | kPa | 200 | 2000 | 101 | 2000 |

| X8 | E1 area | m2 | 100 | 1000 | 1 | 100,000 |

| X9 | E3 area | m2 | 100 | 1000 | 1 | 100,000 |

| Code | Objective Variable | Unit | Remark | Set Used for ML Model Building | Set Used for Bi-Objective Optimization | ||

|---|---|---|---|---|---|---|---|

| Dataset | Method | Objective | Constraint | ||||

| Y0 | Convergence | - | Convergence of process simulation (1/0) | All data were used | RFC | - | =1 |

| Y1 | Product CO2 purity | - | Molar concentration of CO2 in the product | Only the converged data were used | GPR | - | ≥0.95 |

| Y2 | Product CO2 recovery | - | Recovery of CO2 in the product | - | ≥0.9 | ||

| Y3 | Cost | USD/t-CO2 | Cost per t-CO2 in product | Minimize | - | ||

| Y4 | CO2 emissions | t-CO2/t-CO2 | CO2 emissions per t-CO2 in product | Minimize | - | ||

| Case Study Number | Setting | Result | |

|---|---|---|---|

| Ideal Separation Factor, α*(CO2/N2) | Membrane Permeability | Number of Pareto Solutions | |

| 1 | ≤50 | Robeson Upper Bound | 1 |

| 2 | ≤100 | Robeson Upper Bound | 3 |

| 3 | ≤200 | Robeson Upper Bound | 4 |

| 4 | ≤50 | Robeson Upper Bound × 10 (P × 10) | 1 |

| 5 | ≤100 | Robeson Upper Bound × 10 (P × 10) | 1 |

| 6 | ≤200 | Robeson Upper Bound × 10 (P × 10) | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hara, N.; Taniguchi, S.; Yamaki, T.; Nguyen, T.T.H.; Kataoka, S. Bi-Objective Optimization of Techno-Economic and Environmental Performance of CO2 Capture Strategy Involving Two-Stage Membrane-Based Separation with Recycling. Membranes 2025, 15, 190. https://doi.org/10.3390/membranes15070190

Hara N, Taniguchi S, Yamaki T, Nguyen TTH, Kataoka S. Bi-Objective Optimization of Techno-Economic and Environmental Performance of CO2 Capture Strategy Involving Two-Stage Membrane-Based Separation with Recycling. Membranes. 2025; 15(7):190. https://doi.org/10.3390/membranes15070190

Chicago/Turabian StyleHara, Nobuo, Satoshi Taniguchi, Takehiro Yamaki, Thuy T.H. Nguyen, and Sho Kataoka. 2025. "Bi-Objective Optimization of Techno-Economic and Environmental Performance of CO2 Capture Strategy Involving Two-Stage Membrane-Based Separation with Recycling" Membranes 15, no. 7: 190. https://doi.org/10.3390/membranes15070190

APA StyleHara, N., Taniguchi, S., Yamaki, T., Nguyen, T. T. H., & Kataoka, S. (2025). Bi-Objective Optimization of Techno-Economic and Environmental Performance of CO2 Capture Strategy Involving Two-Stage Membrane-Based Separation with Recycling. Membranes, 15(7), 190. https://doi.org/10.3390/membranes15070190