A Novel Empirical Fractional Approach for Modeling the Clogging of Membrane Filtration During Protein Microfiltration

Abstract

1. Introduction

2. Materials and Methods

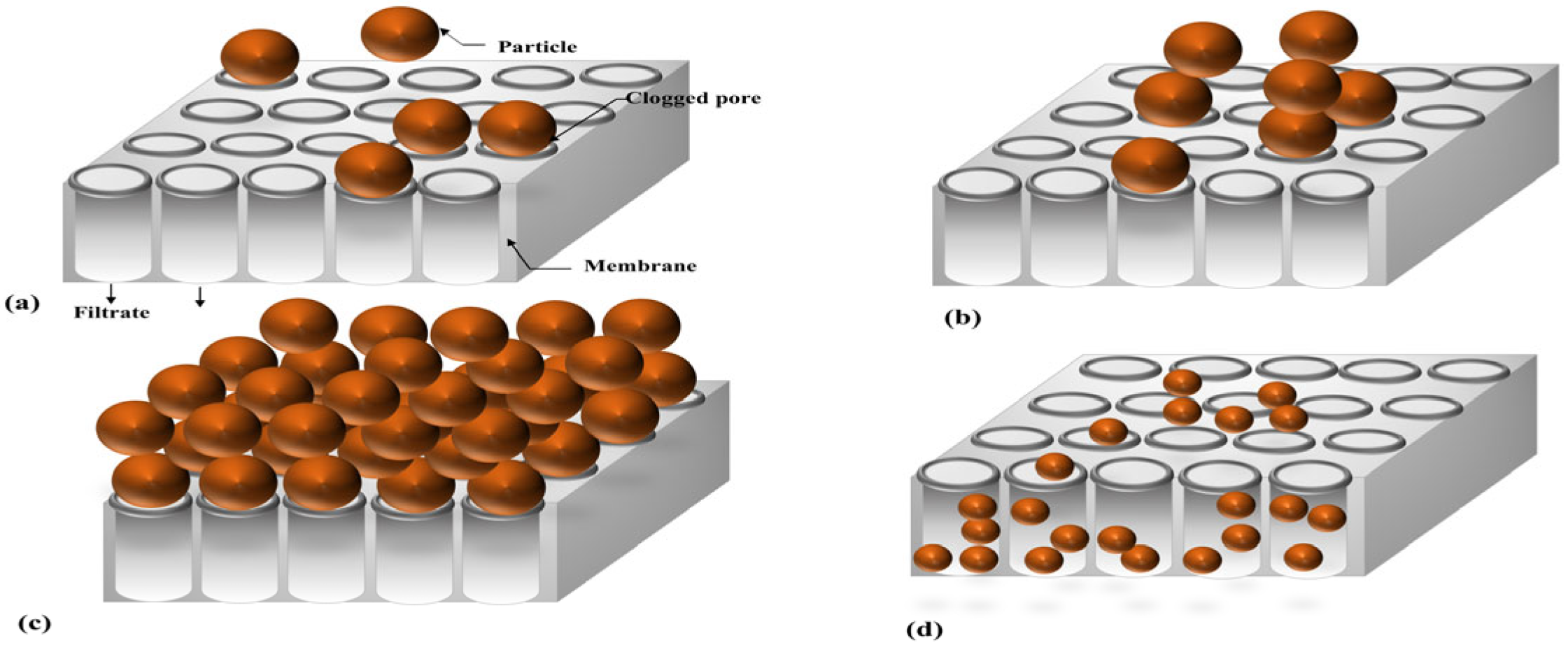

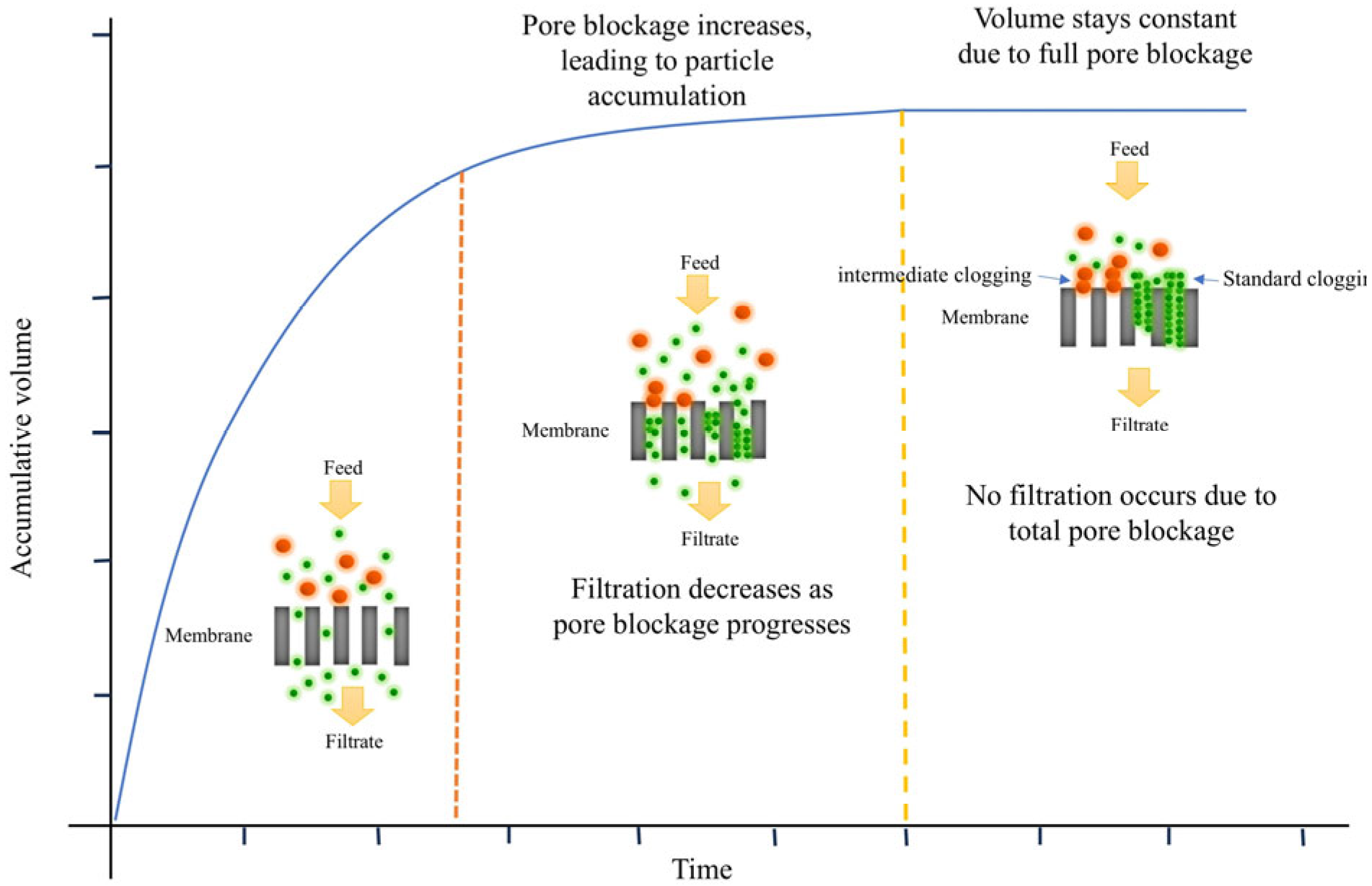

2.1. Clogging of Membrane Filtration

2.2. The Proposed Empirical Fractional Estimation Models

2.3. Building a Database

2.4. Dragonfly Algorithm Nonlinear Regression (DA_Nlinfit)

2.5. Performance Study of Proposed Models

2.6. Identifiability of Model Parameters

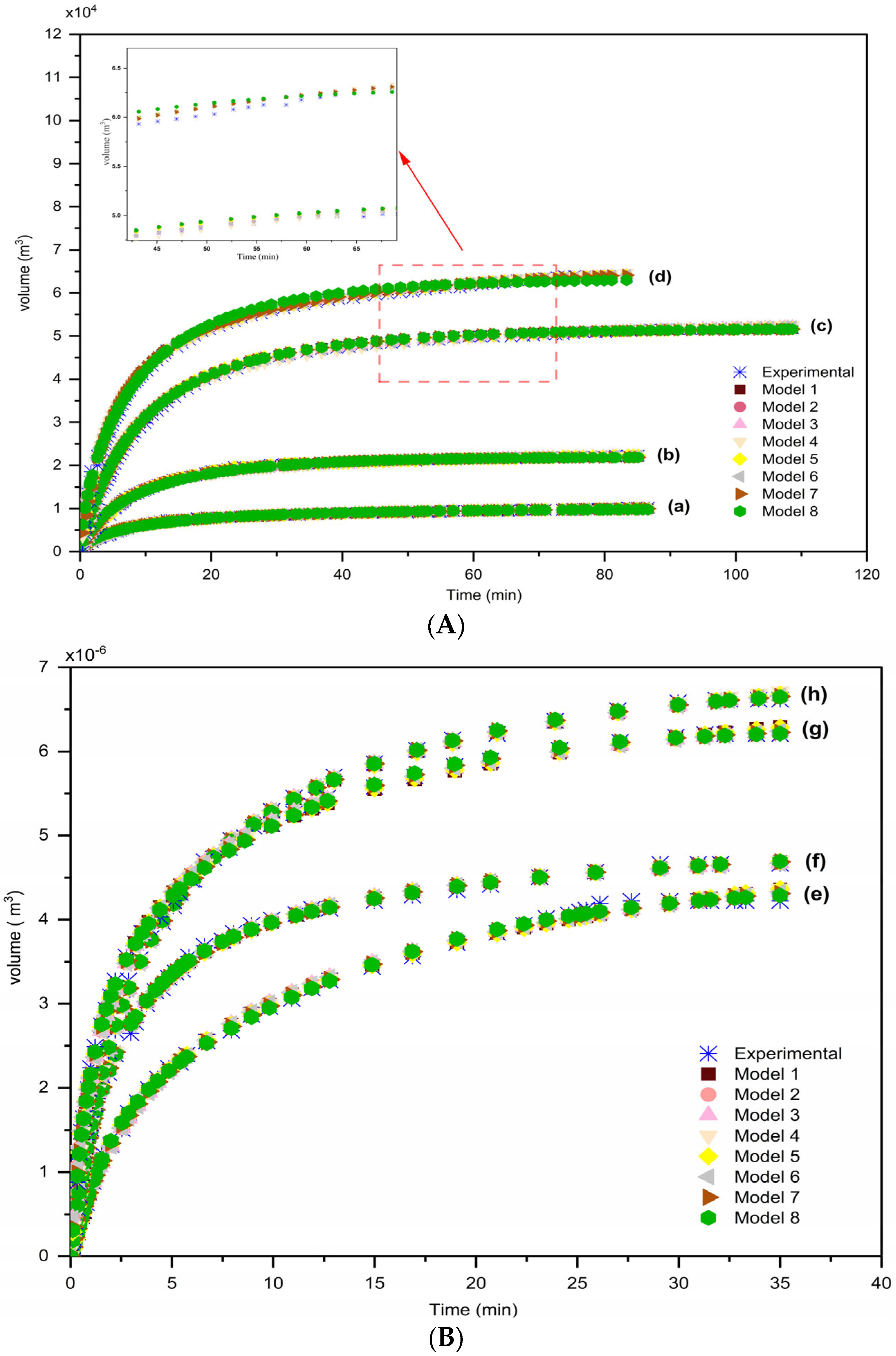

3. Results and Discussion

An Analysis of the Clogging of Membrane Filtration Mechanism Based on the Equation of Hermia

4. Conclusions and Perspectives

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Glossary

- Clogging Index (N): A value derived from the Hermia equation used to characterize the degree of clogging of membrane filtration.

- Empirical Fractional Estimation Model: A model created using experimental data based on volume changes during membrane clogging.

- Dragonfly Algorithm (DA-nlinfit): An optimization algorithm coupled with nonlinear regression used to predict membrane filtration performance.

Abbreviations

| BSA | Bovine serum albumin |

| BD | Database |

| Da | Dragonfly algorithm |

| N | Clogging index |

| nMAE | Relative mean absolute error |

| nRMSE | Relative root mean squared error |

| pGEc47 | Tetracycline resistance 56 kb |

| pQR150 | Kanamycin resistance 20 kb |

| P | Pressure (psi) |

| R | Coefficient of correlation |

| R2 | Coefficient of determination |

| Time of filtration maximal optimal (min) | |

| Time of filtration infinite optimal (min) | |

| V | Volume accumulation (m3) |

| Volume accumulation infinite optimal (m3) | |

| Volume accumulation maximal optimal (m3) | |

| VAF | Variance accounted for metric |

| Var | Variance |

References

- Hentabli, M.; Belhadj, A.E.; Benimam, H.; Dahmoune, F.; Keskes, S. Vacuum drying of the Terbinafine HCl powder: A kinetics study and mathematical modeling. Powder Technol. 2021, 383, 220–232. [Google Scholar] [CrossRef]

- Iritani, E. A Review on Modeling of Pore-Blocking Behaviors of Membranes During Pressurized Membrane Filtration. Dry. Technol. 2013, 31, 146–162. [Google Scholar] [CrossRef]

- Bolton, G.R.; Boesch, A.W.; Lazzara, M.J. The effects of flow rate on membrane capacity: Development and application of adsorptive membrane fouling models. J. Memb. Sci. 2006, 279, 625–634. [Google Scholar] [CrossRef]

- Tien, C.; Ramarao, B.V.; Yasarla, R. A blocking model of membrane filtration. Chem. Eng. Sci. 2014, 111, 421–431. [Google Scholar] [CrossRef]

- McLoughlin, C.M.; McMinn, W.A.M.; Magee, T.R.A. Microwave-vacuum drying of pharmaceutical powders. Dry. Technol. 2003, 21, 1719–1733. [Google Scholar] [CrossRef]

- Rico-Martínez, S.; Álvarez, C.; Hernández, A.; Miguel, J.A.; Lozano, Á.E. Mixed Matrix Membranes Loaded with a Porous Organic Polymer Having Bipyridine Moieties. Membranes 2022, 12, 547. [Google Scholar] [CrossRef]

- Sorrentino, G.; Gajjar, P.; Withers, P.J.; Chellappah, K.; Biscontin, G. Experimental investigation of filter cake deposition under cross-flow and static filtration conditions. Chem. Eng. Sci. 2024, 283, 119417. [Google Scholar] [CrossRef]

- Mannina, G.; Alliet, M.; Brepols, C.; Comas, J.; Heran, M.; Robles, A.; Rodriguez-Roda, I.; Ruano, M.V.; Garcia, V.S.; Smets, I.; et al. Optimization of MBRs through integrated modelling: A state of the art. J. Environ. Manag. 2024, 370, 122720. [Google Scholar] [CrossRef]

- Luján-Facundo, M.J.; Mendoza-Roca, J.A.; Cuartas-Uribe, B.; Álvarez-Blanco, S. Evaluation of cleaning efficiency of ultrafiltration membranes fouled by BSA using FTIR–ATR as a tool. J. Food Eng. 2015, 163, 1–8. [Google Scholar] [CrossRef]

- Jelemenský, M.; Sharma, A.; Paulen, R.; Fikar, M. Time-optimal control of diafiltration processes in the presence of membrane fouling. Comput. Chem. Eng. 2016, 91, 343–351. [Google Scholar] [CrossRef]

- Ciobanu, G.; Carja, G.; Istrati, L.; Harja, M. Etude du colmatage des membranes. Sci. Stud. Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2006, 7, 397–404. [Google Scholar]

- Hermia, J. Constant pressure blocking filtration laws—Application to power-law non-Newtonian fluids. Inst. Chem. Eng. Trans. 1982, 60, 183–187. [Google Scholar]

- Charfi, A.; Ben Amar, N.; Harmand, J. Analysis of fouling mechanisms in anaerobic membrane bioreactors. Water Res. 2012, 46, 2637–2650. [Google Scholar] [CrossRef] [PubMed]

- de Souza Matias, G.; Bissaro, C.A.; de Matos Jorge, L.M.; Rossoni, D.F. The fractional calculus in studies on drying: A new kinetic semi-empirical model for drying. J. Food Process Eng. 2019, 42, 12955. [Google Scholar] [CrossRef]

- Iritani, E.; Mukai, Y.; Tanaka, Y.; Murase, T. Flux decline behavior in dead-end microfiltration of protein solutions. J. Memb. Sci. 1995, 103, 181–191. [Google Scholar] [CrossRef]

- Ho, C. Measurement of membrane pore interconnectivity. J. Memb. Sci. 2000, 170, 101–112. [Google Scholar] [CrossRef]

- Zydney, A.L. Development of a new blocking model for membrane fouling based on a composite media model. J. Membr. Sci. Lett. 2022, 2, 100018. [Google Scholar] [CrossRef]

- Bowen, W.R.; Calvo, J.I.; Hernández, A. Steps of membrane blocking in flux decline during protein microfiltration. J. Memb. Sci. 1995, 101, 153–165. [Google Scholar] [CrossRef]

- Ho, C.-C.; Zydney, A.L. A Combined Pore Blockage and Cake Filtration Model for Protein Fouling During Microfiltration. J. Colloid. Interface Sci. 2000, 232, 389–399. [Google Scholar] [CrossRef]

- Hou, B.; Chen, J.; Li, Y.; Liu, P.; Liu, Y.; Lu, J. Development of a novel model by combining the intermediate blocking and cake filtration models for assessment of the prevailing fouling mechanism in a microbial fuel cell-facilitated membrane bioreactor. AIP Adv. 2021, 11, 065224. [Google Scholar] [CrossRef]

- Hou, L.; Wang, Z.; Song, P. A precise combined complete blocking and cake filtration model for describing the flux variation in membrane filtration process with BSA solution. J. Memb. Sci. 2017, 542, 186–194. [Google Scholar] [CrossRef]

- Iritani, E.; Katagiri, N. Developments of Blocking Filtration Model in Membrane Filtration. KONA Powder Part. J. 2016, 33, 179–202. [Google Scholar] [CrossRef]

- Kim, M.J.; Yoo, G.Y.; Yoo, C.K. Development of combined fouling model in a membrane bioreactor. Asia-Pacific J. Chem. Eng. 2011, 6, 423–432. [Google Scholar] [CrossRef]

- Bolton, G.; Lacasse, D.; Kuriyel, R. Combined models of membrane fouling: Development and application to microfiltration and ultrafiltration of biological fluids. J. Memb. Sci. 2006, 277, 75–84. [Google Scholar] [CrossRef]

- Hlavacek, M.; Bouchet, F. Constant flowrate blocking laws and an example of their application to dead-end microfiltration of protein solutions. J. Memb. Sci. 1993, 82, 285–295. [Google Scholar] [CrossRef]

- Tracey, E.M.; Davis, R.H. Protein Fouling of Track-Etched Polycarbonate Microfiltration Membranes. J. Colloid Interface Sci. 1994, 167, 104–116. [Google Scholar] [CrossRef]

- Affandy, A.; Keshavarz-Moore, E.; Versteeg, H.K. Application of filtration blocking models to describe fouling and transmission of large plasmids DNA in sterile filtration. J. Memb. Sci. 2013, 437, 150–159. [Google Scholar] [CrossRef]

- Emambocus, B.A.S.; Jasser, M.B.; Mustapha, A.; Amphawan, A. Dragonfly Algorithm and Its Hybrids: A Survey on Performance, Objectives and Applications. Sensors 2021, 21, 7542. [Google Scholar] [CrossRef]

- Ammi, Y.; Khaouane, L.; Hanini, S. Stacked neural networks for predicting the membranes performance by treating the pharmaceutical active compounds. Neural Comput. Appl. 2021, 33, 12429–12444. [Google Scholar] [CrossRef]

- Dahmani, A.; Ammi, Y.; Hanini, S. A Novel Non-Linear Model Based on Bootstrapped Aggregated Support Vector Machine for the Prediction of Hourly Global Solar Radiation. Smart Grids Sustain. Energy 2023, 9, 3. [Google Scholar] [CrossRef]

- Golbraikh, A.; Tropsha, A. Predictive QSAR modeling based on diversity sampling of experimental datasets for the training and test set selection. J. Comput.-Aided Mol. Des. 2002, 16, 357–369. [Google Scholar] [CrossRef] [PubMed]

- Janzén, D.; Jirstrand, M.; Evans, N.D.; Chappell, M. Structural Identifiability in Mixed-Effects Models: Two Different Approaches. IFAC PapersOnLine 2015, 48, 563–568. [Google Scholar] [CrossRef]

- Villaverde, A.F.; Barreiro, A.; Papachristodoulou, A. Structural Identifiability of Dynamic Systems Biology Models. PLOS Comput. Biol. 2016, 12, e1005153. [Google Scholar] [CrossRef]

- Janzén, D.L.I.; Jirstrand, M.; Chappell, M.J.; Evans, N.D. Three novel approaches to structural identifiability analysis in mixed-effects models. Comput. Methods Programs Biomed. 2019, 171, 141–152. [Google Scholar] [CrossRef]

- Zydney, A.L.; Ho, C.C. Scale-up of microfiltration systems: Fouling phenomena and Vmax analysis. Desalination 2002, 146, 75–81. [Google Scholar] [CrossRef]

- Lu, W.-M.; Lai, C.-C.; Hwang, K.-J. Constant pressure filtration of submicron particles. Sep. Technol. 1995, 5, 45–53. [Google Scholar] [CrossRef]

- Liu, H.; Yang, C.; Pu, W.; Zhang, J. Formation mechanism and structure of dynamic membrane in the dynamic membrane bioreactor. Chem. Eng. J. 2009, 148, 290–295. [Google Scholar] [CrossRef]

- Laska, M.E.; Brooks, R.P.; Gayton, M.; Pujar, N.S. Robust scale-up of dead end filtration: Impact of filter fouling mechanisms and flow distribution. Biotechnol. Bioeng. 2005, 92, 308–320. [Google Scholar] [CrossRef]

| N° Models Proposed | Equation | Boundary Conditions |

|---|---|---|

| Model 1 | ||

| Model 2 | , | |

| Model 3 | , | |

| Model 4 | , | |

| Model 5 | , | |

| Model 6 | , | |

| Model 7 | , | |

| Model 8 | , |

| Model 6 | Model 6 | First Derivate | Second Derivate | Equation of Hermia |

|---|---|---|---|---|

| Solution | Pressure (psi) | Relative Model Fitting Error | Reference Model | Proposed Model | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Model | Combined Model | Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | Model 7 | Model 8 | |||

| SBA | 2 | R2 | 0.9927 | 0.9934 | 0.9945 | 0.9936 | 0.9936 | 0.9935 | 0.9937 | 0.9936 | 0.9631 | 0.9897 |

| SSR | 4.23 × 106 | 3.80 × 106 | 0.0318 | 0.0372 | 0.0372 | 0.0372 | 0.0361 | 0.0372 | 0.1846 | 0.0600 | ||

| 5 | R2 | 0.9964 | 0.9964 | 0.9981 | 0.9975 | 0.9975 | 0.9944 | 0.9986 | 0.9975 | 0.9920 | 0.9978 | |

| SSR | 1.55 × 107 | 1.55 × 107 | 0.0845 | 0.1096 | 0.1096 | 0.2221 | 0.0611 | 0.1096 | 0.2440 | 0.0892 | ||

| 10 | R2 | 0.9977 | 0.9977 | 0.9993 | 0.9989 | 0.9989 | 0.9962 | 0.9996 | 0.9989 | 0.9942 | 0.9989 | |

| SSR | 5.29 × 107 | 5.29 × 107 | 0.1571 | 0.2624 | 0.2624 | 0.8774 | 0.1000 | 0.2624 | 0.1000 | 0.2624 | ||

| 20 | R2 | 0.9971 | 0.9978 | 0.9978 | 0.9978 | 0.9978 | 0.9972 | 0.9978 | 0.9977 | 0.9978 | 0.9964 | |

| SSR | 8.47 × 107 | 6.60 × 107 | 0.6542 | 0.6546 | 0.6546 | 0.8255 | 0.6538 | 0.7152 | 0.7152 | 1.0685 | ||

| pGEc45 (56 kb) | 5 | R2 | 0.9963 | 0.9989 | 0.9988 | 0.9985 | 0.9985 | 0.9988 | 0.9988 | 0.9985 | 0.9991 | 0.9994 |

| SSR | 0.3914 | 0.1211 | 0.0605 | 0.0652 | 0.0565 | 0.0518 | 0.0924 | 0.0652 | 0.0719 | 0.0887 | ||

| 8 | R2 | 0.9960 | 0.9968 | 0.9987 | 0.9986 | 0.9986 | 0.9987 | 0.9987 | 0.9986 | 0.9986 | 0.9985 | |

| SSR | 0.3270 | 0.2606 | 0.1275 | 0.1745 | 0.1052 | 0.1190 | 0.1745 | 0.0654 | 0.0757 | 0.0677 | ||

| pGEc45 (56 kb) | 5 | R2 | 0.9989 | 0.9993 | 0.9997 | 0.9997 | 0.9997 | 0.9995 | 0.9997 | 0.9997 | 0.9997 | 0.9997 |

| SSR | 0.2119 | 0.1402 | 0.1313 | 0.1415 | 0.1258 | 0.1323 | 0.1571 | 0.0748 | 0.0914 | 0.0685 | ||

| 8 | R2 | 0.9920 | 0.9981 | 0.999 | 0.9987 | 0.9987 | 0.9991 | 0.9992 | 0.9987 | 0.9994 | 0.9995 | |

| SSR | 1.0634 | 0.2575 | 0.1070 | 0.1115 | 0.1041 | 0.1204 | 0.1115 | 0.1211 | 0.1109 | 0.1064 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cherifi, L.; Ammi, Y.; Hanini, S.; Hentabli, M.; Belkacem, O.; Harmand, J. A Novel Empirical Fractional Approach for Modeling the Clogging of Membrane Filtration During Protein Microfiltration. Membranes 2025, 15, 99. https://doi.org/10.3390/membranes15040099

Cherifi L, Ammi Y, Hanini S, Hentabli M, Belkacem O, Harmand J. A Novel Empirical Fractional Approach for Modeling the Clogging of Membrane Filtration During Protein Microfiltration. Membranes. 2025; 15(4):99. https://doi.org/10.3390/membranes15040099

Chicago/Turabian StyleCherifi, Leila, Yamina Ammi, Salah Hanini, Mohamed Hentabli, Ouafa Belkacem, and Jérôme Harmand. 2025. "A Novel Empirical Fractional Approach for Modeling the Clogging of Membrane Filtration During Protein Microfiltration" Membranes 15, no. 4: 99. https://doi.org/10.3390/membranes15040099

APA StyleCherifi, L., Ammi, Y., Hanini, S., Hentabli, M., Belkacem, O., & Harmand, J. (2025). A Novel Empirical Fractional Approach for Modeling the Clogging of Membrane Filtration During Protein Microfiltration. Membranes, 15(4), 99. https://doi.org/10.3390/membranes15040099