The Application of Membrane Separation Technology in the Pharmaceutical Industry

Abstract

1. Introduction

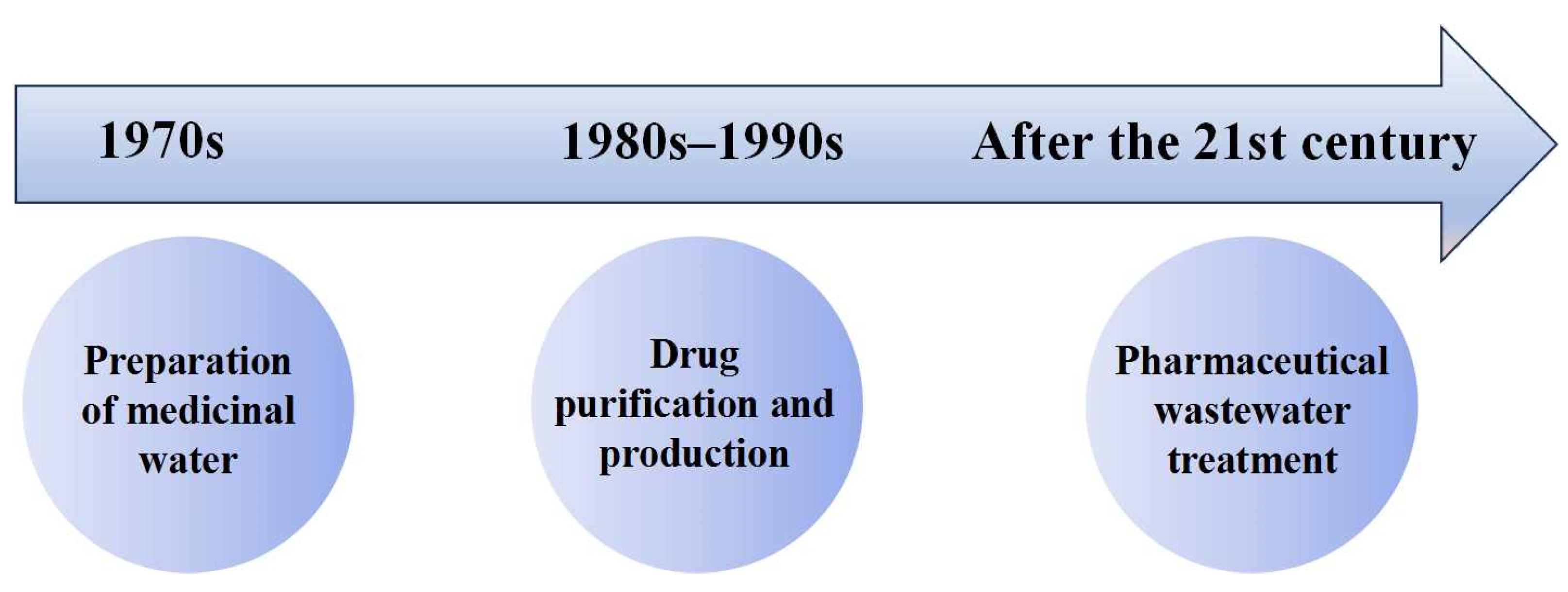

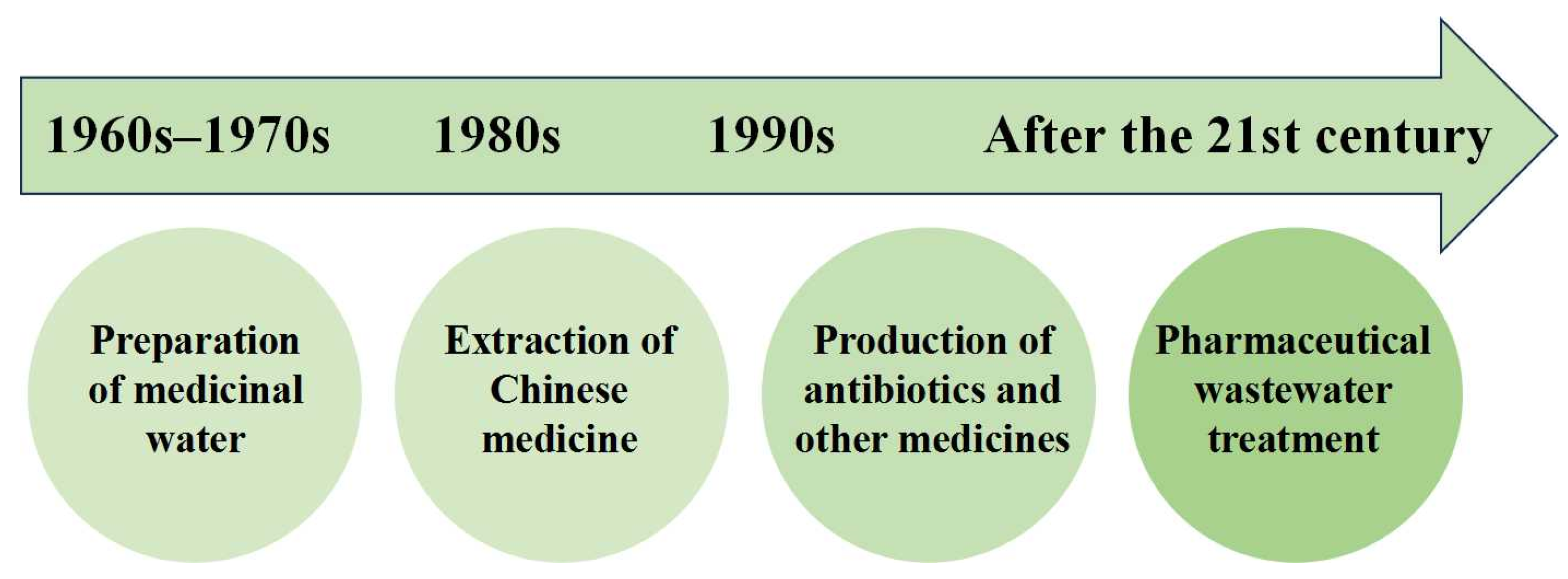

2. History of Membrane Technology Application in the Pharmaceutical Industry

3. Application of Membrane Technology in the Pharmaceutical Industry

| Membrane Technology Types | Application Areas | Earliest Application Time | References |

|---|---|---|---|

| Microfiltration | Pharmaceutical production | 1994 | [56] |

| Wastewater treatment | 2005 | [57] | |

| Wastewater product recovery | 2015 | [58] | |

| Ultrafiltration | Pharmaceutical production | 1983 | [10] |

| Wastewater treatment | 2004 | [59] | |

| Nanofiltration | Pharmaceutical production | 2003 | [60] |

| Wastewater treatment | 1993 | [61] | |

| Wastewater product recovery | 2003 | [62] | |

| Reverse Osmosis | Pharmaceutical production | 1984 | [63] |

| Wastewater treatment | 2003 | [64] | |

| Wastewater product recovery | 2017 | [65] | |

| Membrane Bioreactor | Wastewater treatment | 1995 | [66] |

| Pharmaceutical production | 2008 | [67] | |

| Electrodialysis | Pharmaceutical production | 2020 | [68] |

| Wastewater treatment | 2019 | [69] | |

| Wastewater product recovery | 2013 | [70] | |

| Osmosis | Wastewater treatment | 2011 | [71] |

| Wastewater product recovery | 2015 | [72] | |

| Osmotic Vaporization | Wastewater treatment | 2016 | [73] |

| Wastewater product recovery | 2006 | [74] | |

| Combined Processes | Wastewater treatment | 1987 | [75] |

| Pharmaceutical production | 2004 | [76] | |

| Reuse of reclaimed water | 2011 | [77] |

4. Development of Membrane Technology and Its Application in the Pharmaceutical Industry by International Membrane Technology Enterprises

4.1. Pall Corporation (USA)

4.2. Novasep (France)

4.3. Millipore (USA)

5. Development of Membrane Technology and Its Application in the Pharmaceutical Industry by Chinese Membrane Technology Enterprises

5.1. Santar Membrane

5.2. Jiangsu Jiuwu High-Tech Co., Ltd.

5.3. Hangzhou Qiushi Membrane Technology Co., Ltd.

6. Conclusions and Prospect

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Fane, A.G.; Wang, R.; Jia, Y. Membrane Technology: Past, Present and Future. In Membrane and Desalination Technologies; Wang, L.K., Chen, J.P., Hung, Y.T., Shammas, N.K., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 13, pp. 1–45. [Google Scholar]

- Wang, C.; Wang, Y.; Qin, H.; Lin, H.; Chhuon, K. Application of Microfiltration membrane Technology in Water treatment. IOP Conf. Ser. Earth Environ. Sci. 2020, 571, 012158. [Google Scholar] [CrossRef]

- Wee, S.-L.; Tye, C.-T.; Bhatia, S. Membrane separation process—Pervaporation through zeolite membrane. Sep. Purif. Technol. 2008, 63, 500–516. [Google Scholar] [CrossRef]

- Ankush; Mandal, M.K.; Sharma, M.; Khushboo, S.; Pandey, S.; Dubey, K.K. Membrane Technologies for the Treatment of Pharmaceutical Industry Wastewater. In Water and Wastewater Treatment Technologies. Energy, Environment and Sustainability; Bui, X.T., Chiemchaisri, C., Fujioka, T., Varjani, S., Eds.; Springer: Singapore, 2019; pp. 103–116. [Google Scholar]

- Liu, H.B.; Li, B.; Guo, L.W.; Pan, L.M.; Zhu, H.X.; Tang, Z.S.; Xing, W.H.; Cai, Y.Y.; Duan, J.A.; Wang, M.; et al. Current and Future Use of Membrane Technology in the Traditional Chinese Medicine Industry. Sep. Purif. Rev. 2022, 51, 484–502. [Google Scholar] [CrossRef]

- Production of Solutions. British Patent 1450030, 22 September 1976. Available online: https://technology.matthey.com/article/20/1/33-36/ (accessed on 11 January 2023).

- Juberg, D.L.; Pauli, W.A.; Artiss, D.H. Application of reverse osmosis for the generation of water for injection. Bull. Parenter. Drug Assoc. 1977, 31, 70–77. [Google Scholar] [PubMed]

- United States Pharmacopeial Convention. The United States Pharmacopoeia XIX; United States Pharmacopeial Convention: North Bethesda, MD, USA, 1975. [Google Scholar]

- Hao, C.; Huang, X. Membrane separation technology and its application in pharmaceutical production. Chem. Pharm. Eng. 2004, 25, 1–4. [Google Scholar]

- Warashina, T.; Hashino, Y.; Kobayashi, T. Development of Hollow-Fiber Type Ultrafiltration System. Research and Development in Japan Awarded the Okochi Memorial Prize; Elsevier: Amsterdam, The Netherlands, 1983; pp. 51–54. [Google Scholar]

- Toussaint, G.; Ding, L.H.; Jaffrin, M.Y.; Hassairi, I.; Nonus, M. Recovery of α-Agarase Enzyme from Fermentation Broths by Membrane Crossflow Filtration. Sep. Sci. Technol. 2000, 35, 795–809. [Google Scholar] [CrossRef]

- Manrong, J.; Pingli, L.; Qinghui, S.; Shichang, W. Composite hollow fiber membrane and its application in concentrating vitamine B12. Water Treat. 1995, 10, 215–219. [Google Scholar]

- Chaufer, B.; Rollin, M.; Grangeon, A.; Dulieu-Barton, J.M. Tetracycline Removal or Concentration with an Inorganic Ultrafiltration Membrane Modified by Quaternized Polyvinylimidazole Coating. Key Eng. Mater. 1992, 61–62, 249–254. [Google Scholar] [CrossRef]

- Stremovskii, L.L.; Navashin, S.M. Purification and separation of benzylpenicillin and phenoxymethylpenicillin by ultrafiltration through a semipermeable membrane. Dokl. Chem. Technol. 1984, 274–276, 42–45. [Google Scholar]

- Al-Rifai, J.; Khabbaz, H.; Schäfer, A.I. Removal of pharmaceuticals and endocrine disrupting compounds in a water recycling process using reverse osmosis systems. Sep. Purif. Technol. 2011, 77, 60–67. [Google Scholar] [CrossRef]

- Kimura, K.; Hara, H.; Watanabe, Y. Elimination of selected acidic pharmaceuticals from municipal wastewater by an activated sludge system and membrane bioreactors. Environ. Sci. Technol. 2007, 41, 3708–3714. [Google Scholar] [CrossRef]

- Quintana, J.B.; Weiss, S.; Reemtsma, T. Pathways and metabolites of microbial degradation of selected acidic pharmaceutical and their occurrence in municipal wastewater treated by a membrane bioreactor. Water Res. 2005, 39, 2654–2664. [Google Scholar] [CrossRef]

- Clara, M.; Strenn, B.; Ausserleitner, M.; Kreuzinger, N. Comparison of the behaviour of selected micropollutants in a membrane bioreactor and a conventional wastewater treatment plant. Water Sci. Technol. A J. Int. Assoc. Water Pollut. Res. 2004, 50, 29–36. [Google Scholar] [CrossRef]

- Ren, S.; Boo, C.; Guo, N.; Wang, S.; Elimelech, M.; Wang, Y. Photocatalytic Reactive Ultrafiltration Membrane for Removal of Antibiotic Resistant Bacteria and Antibiotic Resistance Genes from Wastewater Effluent. Environ. Sci. Technol. 2018, 52, 8666–8673. [Google Scholar] [CrossRef] [PubMed]

- Gong, C. Review and prospect of membrane production of medicinal water. Membr. Sci. Technol. 1999, 19, 8–13. [Google Scholar]

- Gong, C.; Li, M.; Dai, F.; Sun, X.; Sun, S.; Chen, W. Water for injection is prepared by reverse osmosis. Mil. Med. Sci. 1982, 17, 383–389. [Google Scholar]

- The Pharmacy Bureau of the PLA Air Force Beijing Hospital. Chinese herbal medicine injection was prepared by ultrafiltration technology. Chin. Tradit. Herb. Drugs 1979, 10, 12–13+49. [Google Scholar]

- The Pharmacy Bureau of the PLA Air Force Beijing Hospital. Experimental study on preparation of compound Chinese medicine injection by ultrafiltration method. Chin. Tradit. Herb. Drugs 1981, 12, 8–12. [Google Scholar]

- Zhang, Z.; Wang, S.; Jiang, Z.; Jing, Y.; Lin, Y.; Chu, Q. Application of plate reverse osmosis device in streptomycin production process. Technol. Water Treat. 1994, 6, 349–351. [Google Scholar]

- Li, C.; Fang, F.; He, X.; Xia, H.; Lan, W. Application of Ultrafiltration for Purification of Cephalosporin C. J. Fujian Med. Univ. 2001, 35, 53–56. [Google Scholar]

- Zhang, L.; Gao, Y.; Li, J. Application of ultrafiltration in improvement of the vitamin C production process. Membr. Sci. Technol. 2000, 5, 60–61. [Google Scholar]

- Wang, X.; Zhang, C.; Zhao, J. Separation mechanism of nanofiltration membranes and its applications in food and pharmaceutical industries. Membr. Sci. Technol. 2000, 1, 29–36. [Google Scholar]

- Li, X.; Luan, B.; Han, G. Application of ultrafiltration in the extraction of antibiotics. Technol. Water Treat. 1996, 4, 33–36. [Google Scholar] [CrossRef]

- Huang, W.; Zhou, R.; Liao, Z. Reconstruction of pharmaceutical fermentation wastewater treatment project. Ind. Water Treat. 2010, 30, 82–84. [Google Scholar]

- Zheng, W.; Chen, L.; Yao, C.; Li, Y.; Li, W. Treatment of Wastewater in Chemical Synthesis of Cephalosporin by Contact Oxidation-Hydrolysis-MBR Process. Environ. Prot. Chem. Ind. 2010, 30, 395–399. [Google Scholar]

- Su, Y.; Lin, F. Treatment of pharmaceutical wastewater by coagulation precipitation—MBR process. Water Wastewater Eng. 2011, 47, 63–64. [Google Scholar]

- Huang, H.; Xu, H.; Zhou, B.; Yang, W.; Huang, J.; Cheng, Z. Hydrolysis Acidification-A/O-MBR Process for Treatment of Biopharmaceutical Wastewater. China Water Wastewater 2013, 29, 117–119+130. [Google Scholar]

- Xu, G.; Liu, W.; Zhong, L.; Tu, K.; Luo, X. Project Case of Intermediate Water Recovery for Membrane Bioreactor Treatment Process of One Pharmaceutical Wastewater. Mod. Chem. Res. 2016, 9, 76–77. [Google Scholar]

- Feng, J. Engineering Example of Pharmaceutical Wastewater Treatment. Guangdong Chem. Ind. 2016, 43, 130–131. [Google Scholar]

- Ma, Y.; Liu, X.; Feng, H.; Zhang, J.; Zhai, Y.; Wang, L. Pharmaceutical wastewater treatment process design and operational example. China Water Wastewater 2016, 32, 94–96. [Google Scholar]

- Zhao, Z. The Application of the Flat Sheet Membrane MBR Process in the Modification of Pharmaceutical Wastewater Treatment Plant. Guangdong Chem. Ind. 2017, 44, 212–213. [Google Scholar]

- Chen, H.; Ren, X.; Zhang, W.; Liu, X. Engineering Project of the Treatment and Reuse of Biological Pharmaceutical Wastewater. Technol. Water Treat. 2017, 43, 130–133. [Google Scholar]

- Xu, J.; Liu, F.; Yang, H. Engineering Example of A Pharmaceutical Wastewater Treatment. Guangdong Chem. Ind. 2018, 45, 160–161+172. [Google Scholar]

- Xu, F. Treatment of biopharmaceutical wastewater by air floating-compound oxygen-MBR process. Ind. Water Wastewater 2019, 50, 74–76+80. [Google Scholar]

- Zhang, H.; Zhang, F. Pharmaceutical wastewater treatment process design example. Energy Conserv. 2019, 38, 109–111. [Google Scholar]

- Fu, J. Pharmaceutical wastewater treatment upgrading project. Plant Maint. Eng. 2019, 3, 189–190. [Google Scholar]

- Han, Z. Case study on advanced treatment of high salt pharmaceutical wastewater and reuse of boiler make-up water in power plant. Electr. Power Technol. Environ. Prot. 2020, 36, 42–44. [Google Scholar]

- Wang, M.; Yu, K.; Liu, G.; Zhang, J. Engineering example of treatment of high salinity and high ammonia wastewater by electrodialysis + MVR combined technology. Coal Chem. Ind. 2020, 43, 158–160. [Google Scholar]

- Han, Z. A project example of advanced treatment and reuse of biopharmaceutical wastewater. Ind. Water Wastewater 2020, 51, 65–67+83. [Google Scholar]

- Zhang, Z. Engineering example of pharmaceutical wastewater reuse and zero discharge. Resour. Econ. Environ. Prot. 2020, 1, 77–79. [Google Scholar]

- Shen, X.-L. An example of project design of biopharmaceutical wastewater advanced treatment. Ind. Water Wastewater 2021, 52, 57–60. [Google Scholar]

- Zeng, G.L.; Li, J. Application case of MBR process in high salinity and high concentration organic wastewater treatment in pharmaceutical industry. Water Purif. Technol. 2023, 42, 153–159+173. [Google Scholar]

- Baker, R.W. Membrane Technology and Applications, 3rd ed.; John Wiley & Sons: Chichester, UK; Hoboken, NJ, USA, 2012. [Google Scholar]

- Hao, C.; Huang, X. Application of membrane technology in pharmaceutical production. J. Filtr. Sep. 2004, 3, 34–37. [Google Scholar]

- Xue, G.; Hu, X.; Chen, X.; Zheng, X. Applications of Membrane Separation Technology in the Production of Medicine and Medical Treatment. Chem. Ind. Eng. 2009, 26, 183–188. [Google Scholar]

- Mallakpour, S.; Azadi, E. Nanofiltration membranes for food and pharmaceutical industries. Emerg. Mater. 2022, 5, 1329–1343. [Google Scholar] [CrossRef]

- Peters, T. Membrane Technology for Water Treatment. Chem. Eng. Technol. 2010, 33, 1233–1240. [Google Scholar] [CrossRef]

- Gu, Y.L.; Huang, J.H.; Zeng, G.M.; Shi, L.X.; Shi, Y.H.; Yi, K.X. Fate of pharmaceuticals during membrane bioreactor treatment: Status and perspectives. Bioresour. Technol. 2018, 268, 733–748. [Google Scholar] [CrossRef]

- Yu, X.; Sun, Y. Application of membrane bioreactor technology in the transformation of biopharmaceutical wastewater treatment system. Chin. J. Biol. 2019, 32, 1169–1171, 1176. [Google Scholar]

- Nasrollahi, N.; Vatanpour, V.; Khataee, A. Removal of antibiotics from wastewaters by membrane technology: Limitations, successes, and future improvements. Sci. Total Environ. 2022, 838, 156010. [Google Scholar] [CrossRef]

- Goldner, H. Pharmaceutical Processes Benefit From New Filtration Systems. RD Mag. 1994, 36, 25. [Google Scholar]

- Doll, T.E.; Frimmel, F.H. Cross-flow microfiltration with periodical back-washing for photocatalytic degradation of pharmaceutical and diagnostic residues-evaluation of the long-term stability of the photocatalytic activity of TiO2. Water Res. 2005, 39, 847–854. [Google Scholar] [CrossRef] [PubMed]

- Samaia, M.; Chikhi, M.; Bouzerara, F. Elimination of Penicillin V by Membrane Process. Chem. Eng. Trans. 2015, 43, 2467–2472. [Google Scholar]

- Li, S.Z.; Li, X.Y.; Wang, D.Z. Crystallization of oxytetracycline from fermentation waste liquor: Influence of biopolymer impurities. J. Colloid Interface Sci. 2004, 279, 100–108. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; He, G.H.; Gao, P.; Chen, G.H. Development and characterization of composite nanofiltration membranes and their application in concentration of antibiotics. Sep. Purif. Technol. 2003, 30, 27–35. [Google Scholar] [CrossRef]

- Treffry-Goatley, K.; Gilron, J. The application of nanofiltration membranes to the treatment of industrial effluent and process streams. Filtr. Sep. 1993, 30, 63–66. [Google Scholar] [CrossRef]

- Zhu, A.; Zhu, W.P.; Wu, Z.; Jing, Y.F. Recovery of clindamycin from fermentation wastewater with nanofiltration membranes. Water Res. 2003, 37, 3718–3732. [Google Scholar] [CrossRef] [PubMed]

- McBain, D. Reverse-Osmosis Offers Many Advantages. Water Serv. 1984, 88, 144–145, 147. [Google Scholar]

- Reinhard, M.; Montgomery-Brown, J.; Louie, J.S.; Gross, B. From effluent to new water: Performance evaluation and quality assurance. Chimia 2003, 57, 561–566. [Google Scholar] [CrossRef]

- Hsieh, D.S.; Lindrud, M.; Lu, X.J.; Zordan, C.; Tang, L.Y.; Davies, M. A Process for Active Pharmaceutical Ingredient Recovery from Tablets Using Green Engineering Technology. Org. Process Res. Dev. 2017, 21, 1272–1285. [Google Scholar] [CrossRef]

- Benitez, J.; Rodriguez, A.; Malaver, R. Stabilization and dewatering of wastewater using hollow fiber membranes. Water Res. 1995, 29, 2281–2286. [Google Scholar] [CrossRef]

- Ong, A.L.; Kamaruddin, A.H.; Bhatia, S.; Aboul-Enein, H.Y. Enantioseparation of (R,S)-ketoprofen using Candida antarctica lipase B in an enzymatic membrane reactor. J. Sep. Sci. 2008, 31, 2476–2485. [Google Scholar] [CrossRef]

- Gao, W.T.; Chen, Q.; Du, M.G.; Zhang, W.M.; Cao, C.Y.; Song, W.G. Enabling an atom-economic production of chiral amino alcohols by electrodialysis with bipolar membranes. Green Chem. 2020, 22, 2213–2224. [Google Scholar] [CrossRef]

- Arola, K.; Ward, A.; Mänttäri, M.; Kallioinen, M.; Batstone, D. Transport of pharmaceuticals during electrodialysis treatment of wastewater. Water Res. 2019, 161, 496–504. [Google Scholar] [CrossRef] [PubMed]

- Ravikumar, Y.V.L.; Sridhar, S.; Satyanarayana, S.V. Development of an electrodialysis-distillation integrated process for separation of hazardous sodium azide to recover valuable DMSO solvent from pharmaceutical effluent. Sep. Purif. Technol. 2013, 110, 20–30. [Google Scholar] [CrossRef]

- Hancock, N.T.; Xu, P.; Heil, D.M.; Bellona, C.; Cath, T.Y. Comprehensive Bench- and Pilot-Scale Investigation of Trace Organic Compounds Rejection by Forward Osmosis. Environ. Sci. Technol. 2011, 45, 8483–8490. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.F.; Zhu, M.P.; Chen, J.P.; Yuan, Z.H.; Zhong, L.B.; Zheng, Y.M. Separation of tetracycline from wastewater using forward osmosis process with thin film composite membrane—Implications for antibiotics recovery. Sep. Purif. Technol. 2015, 153, 76–83. [Google Scholar] [CrossRef]

- Woldemariam, D.; Kullab, A.; Fortkamp, U.; Magner, J.; Royen, H.; Martin, A. Membrane distillation pilot plant trials with pharmaceutical residues and energy demand analysis. Chem. Eng. J. 2016, 306, 471–483. [Google Scholar] [CrossRef]

- Kreis, P.; Górak, A. Process analysis of hybrid separation processes: Combination of distillation and pervaporation. Chem. Eng. Res. Des. 2006, 84, 595–600. [Google Scholar] [CrossRef]

- Cai, B.X.; Lang, K.M.; Liu, Y.R.; Chen, Y.M. The refinement and concentration of agricultural antibiotic A in aqueous solution using membrane processes. Desalination 1987, 62, 341–351. [Google Scholar]

- Li, S.Z.; Li, X.Y.; Wang, D.M. Membrane (RO-UF) filtration for antibiotic wastewater treatment and recovery of antibiotics. Sep. Purif. Technol. 2004, 34, 109–114. [Google Scholar] [CrossRef]

- Joss, A.; Baenninger, C.; Foa, P.; Koepke, S.; Krauss, M.; McArdell, C.S.; Rottermann, K.; Wei, Y.; Zapata, A.; Siegrist, H. Water reuse: >90% water yield in MBR/RO through concentrate recycling and CO2 addition as scaling control. Water Res. 2011, 45, 6141–6151. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.suntar.com/application/cases/5 (accessed on 11 January 2023).

- Available online: http://www.jiuwu.com/gc.html (accessed on 11 January 2023).

- Available online: http://www.creflux.net/?mod=case&classid=1 (accessed on 11 January 2023).

| Year | Treatment Process | Membrane Module | Scale (m3/d) | Wastewater Type | Influent Quality | Effluent Quality | Investment and Operating Cost Analysis | Ref. |

|---|---|---|---|---|---|---|---|---|

| 2010 | Anoxic + aerobic + MBR process | SMM-1520 PVDF membrane | 2000 | Fermented pharmaceutical wastewater | CODCr 18,000 mg/L, BOD5 7200 mg/L | CODCr < 120 mg/L, BOD5 < 40 mg/L | - | [29] |

| 2010 | Contact oxidation + hydrolysis + MBR | PVDF hollow fiber membrane | 385 | Wastewater from chemical synthesis of cephalosporin antibiotics | pH 5.2–10.5, COD 2125–11,561 mg/L, BOD5 421–3356 mg/L, TN 34.98–299.72 mg/L, NH4+-N 0.09–5.46 mg/L, NO3−-N 9.77–81.12 mg/L, TP 3.90–156.96 mg/L, TDS 567–7876 mg/L | COD 79–282 mg/L, BOD5 < 10 mg/L, TN 8.90–148.13 mg/L, NH4+-N 1.88–161.56 mg/L, NO3−-N 2.15–75.11 mg/L | - | [30] |

| 2011 | Coagulation precipitation + MBR | - | 120 | Pharmaceutical wastewater of Chinese patent medicines | pH 5–7, COD 3000–6000 mg/L, BOD5 1500–2000 mg/L, SS 450 mg/L | pH 6–9, COD < 100 mg/L, BOD5 < 20 mg/L, SS < 20 mg/L | Total project investment: USD 294,000. Treatment cost: 0.25 USD/m3. | [31] |

| 2013 | Hydrolytic acidification + A/O + MBR process | Double-layered, large-area flat film | 360 | Integrated biomedical wastewater | pH 6–9, COD 400–600 mg/L, BOD5 100–200 mg/L, SS 150–250 mg/L, NH4+-N 30–70 mg/L, TP 4–9 mg/L | pH 6–9, COD < 50 mg/L, BOD5 < 10 mg/L, SS< 5 mg/L, NH4+-N < 10 mg/L, TP < 0.5 mg/L | Total project investment: USD 187,880. Operating cost: 0.11 USD/m3. | [32] |

| 2016 | Comprehensive regulation + aerobic + MBR | SADF-2590 membrane | 100 | Pharmaceutical factory production equipment cleaning water, purified water preparation wastewater discharge, workshop floor washing water, waste gas treatment equipment cleaning water, and production workshop domestic sewage | pH 6–9, COD ≤ 1600 mg/L, BOD ≤ 480 mg/L, NH4+-N ≤ 30 mg/L, TN ≤ 40 mg/L, SS ≤ 100 mg/L, petroleum products ≤ 10 mg/L | pH 6–9, COD < 30 mg/L, BOD < 7 mg/L, NH4+-N < 5 mg/L, TN < 14 mg/L, SS < 9 mg/L, petroleum products < 1 mg/L | Total project investment: USD 840,000. Cost of wastewater treatment: 0.168 USD/m3. Cost of reclaimed water reuse: 0.21 USD/m3. | [33] |

| 2016 | Pretreatment + hydrolytic acidification + UASB + secondary A/O + MBR | - | 800 | Chemical synthetic pharmaceutical production wastewater | CODCr 35,955 mg/L, BOD5 5000 mg/L, NH4+-N 1141 mg/L | CODCr 84 mg/L, BOD5 16 mg/L, NH4+-N 7 mg/L | Total project investment: USD 3,206,000. Treatment cost: 7.86 USD/m3. | [34] |

| 2016 | Advanced oxidation + hydrolytic acidification + MBR + activated carbon filtration process | - | 600 | High concentration of pharmaceutical wastewater that is difficult to degrade | pH 6–9, COD 920 mg/L, BOD5 360 mg/L, SS 200 mg/L, NH4+-N 15 mg/L, TN 25 mg/L, TP 1.4 mg/L | pH 6–9, COD 30 mg/L, BOD5 6 mg/L, SS10 mg/L, NH4+-N 1.5 (2.5) mg/L, TN 10 mg/L, TP 0.3 mg/L | Operational cost is 0.532 USD/m3. | [35] |

| 2017 | Flat film MBR process | Flat membrane | 500 | Biological pharmaceutical wastewater | COD 400 mg/L, BOD5 200 mg/L, SS 50 mg/L, TN 62 mg/L, NH4+-N 32 mg/L, TP 1.2 mg/L | COD ≤ 80 mg/L, BOD5 ≤ 10 mg/L, SS ≤ 1 mg/L, TN ≤ 30 mg/L, NH4+-N ≤ 10 mg/L, TP ≤ 0.5 mg/L | Electricity cost for operation: 0.14 USD/m3. Membrane cleaning chemical cost: 0.002 USD/m3. Operation and maintenance cost: 0.15 USD/m3. | [36] |

| 2017 | Anaerobic + A/O + sand filter + carbon filter + ultrafiltration + reverse osmosis + triple-effect evaporation | - | 150 | Biological pharmaceutical wastewater | pH 5–6, COD 7632 mg/L, NH4+-N 106 mg/L, TP 17 mg/L, SS 157 mg/L | pH 6–9, COD 34 mg/L, NH4+-N 1.3 mg/L, TP 0.12 mg/L, SS 2.6 mg/L | The operating cost is 5.51–6.48 USD/m3. | [37] |

| 2018 | Hydrolytic acidification + efficient anaerobic reactor + biochemistry + MBR | - | 4000 | Chemical synthesis of raw material production wastewater | COD 6000 mg/L | COD 300 mg/L | Operational cost is 22.68 USD/m3. | [38] |

| 2019 | Air floating + compound oxygen + MBR process | Hollow fiber membrane | 100 | Biological pharmaceutical wastewater | pH 4–9, CODCr 500–8000 mg/L, BOD5 200–3000 mg/L, NH4+-N 10–500 mg/L, TP 1–60 mg/L, SS 300–2000 mg/L | pH 6–9, CODCr 86 mg/L, BOD5 3.9 mg/L, NH4+-N 9.8 mg/L, TP 0.46 mg/L, SS ≤ 70 mg/L | Total project investment: USD 157,920. Operational cost: 1.52 USD/m3. | [39] |

| 2019 | Pretreatment + ABR + A/O + MBR | - | 240 | High concentration, biochemical pharmaceutical wastewater | pH 5–6, COD 3000 mg/L, BOD5 300 mg/L, NH4+-N 180 mg/L, SS 1000 mg/L | pH 6–9, COD ≤ 200 mg/L, BOD5 ≤ 150 mg/L, NH4+-N ≤ 20 mg/L, SS ≤ 100 mg/L | - | [40] |

| 2019 | AA/O + MBR | - | 100 | Pharmaceutical wastewater | pH 6–9, COD 2820–5910 mg/L, SS 210–620 mg/L, petroleum products 52–80 mg/L | pH 6–9, COD 2820–5910 mg/L, SS 210–620 mg/L, petroleum products 52–80 mg/L | Total investment: USD 107,800. Operational costs: 0.37 USD/m3. | [41] |

| 2020 | Biochemical treatment + ultrafiltration + reverse osmosis + ion exchange resin | - | 9600 | High-salt pharmaceutical wastewater | pH 6–9, COD 294–816 mg/L, BOD 120–300 mg/L, NH4+-N 71–150 mg/L, TP 10–20 mg/L, SS 120–1100 mg/L | - | Total investment: USD 7 million. Treated effluent meets cooling water standards (operating costs: 0.63 USD/m3) and secondary desalination water standards (operating costs: 1.26 USD/m3). | [42] |

| 2020 | Electrodialysis + steam recompression technology | - | 96 | High salt and high ammonia nitrogen pharmaceutical wastewater | pH 5–6, COD 15,000–25,000 mg/L, 3%–5% NH4Cl | - | The total investment: USD 1.4 million. Annual operating cost: USD 0.28 million. | [43] |

| 2020 | Biochemical treatment + membrane treatment (ultrafiltration + reverse osmosis) + ion exchange resin | SMT600-P50 ultrafiltration membrane; W30XFR-400/34i and SW30XLE-400iB reverse osmosis membrane | 400 | Biological pharmaceutical wastewater | pH 7.0–9.0, COD 60–80 mg/L, BOD5 10–20 mg/L, NH4+-N 15–20 mg/L, TP 1–2 mg/L, Cl− 200–350 mg/L, TDS 4500–6000 mg/L | pH 6.5–9.0, COD ≤ 60 mg/L, BOD5 ≤ 10 mg/L, NH4+-N ≤ 5 mg/L, TP ≤ 1 mg/L, CL-X ≤ 250 mg/L, TDS ≤ 1000 mg/L, EC ≤ 0.15 μS/cm, SiO2 ≤ 10 μg/L | The total project investment: USD 5.32 million. Treated effluent meets cooling water standards (operating costs: 0.63 USD/m3) and secondary desalination water standards (operating costs: 1.26 USD/m3). | [44] |

| 2020 | Multi-effect clarifier + ultrafiltration + recovery system | - | 7500 | Biochemical secondary sedimentation tank effluent | pH 6.5–8, CODCr 200–500 mg/L, BOD5 20–200 mg/L, SS350 mg/L, TDS 3000–6000 mg/L, hardness 500 mg/L, TN 50–70 mg/L | - | The treatment cost is 0.55 USD/m3. | [45] |

| 2021 | A combined process of coagulation sedimentation + AAO + MBR + ozone contact oxidation + high-efficiency air floatation + activated carbon adsorption + contact disinfection | PVDF hollow fiber membrane | 2000 | Biopharmaceutical wastewater | COD 150 mg/L, BOD5 60 mg/L, TN 20 mg/L, NH3-N 15 mg/L, TP 6.0 mg/L, SS 250 mg/L | COD 20 mg/L, BOD5 8 mg/L, TN 1.0 mg/L, NH3-N 0.5 mg/L, TP 0.1 mg/L, SS 5 mg/L | Operational cost is 1.39 USD/m3. | [46] |

| 2023 | Biotreatment + MBR | - | 8000 | High salinity and high concentration organic wastewater in pharmaceutical industry | CODCr 8700–9300 mg/L, SS 3600–4250 mg/L | CODCr 270–290 mg/L, SS 170–190 mg/L | The treatment cost is 3.45 RMB/m3. | [47] |

| Project Name | Membrane Technology | Scale (m3/d) | Application Type | Source |

|---|---|---|---|---|

| Erythromycin nanofiltration concentration project of a pharmaceutical company | Nanofiltration | 3840 | Desalination, dewatering, and concentration process of erythromycin filtrate | [78] |

| Amino acid treatment project of a Xinjiang company | Ceramic membrane filtration + nanofiltration concentration | 100 | Amino acid production | |

| Erythromycin nanofiltration concentration project of a biotechnology company | Nanofiltration | 5700 | Erythromycin concentration production | |

| Membrane treatment technology of erythromycin of a Ningxia pharmaceutical company | Ceramic membrane and nanofiltration membrane technology | - | Ceramic membrane technology is applied to clarify impurities in red mold antibiotic fermentation broth, and nanofiltration membrane technology is applied to desalination and concentration of red mold antibiotic filtrate. |

| Project Name | Scale (m3/d) | Application Type | Source |

|---|---|---|---|

| Jiaozuo Jiankangyuan Bioproducts Co., Ltd. | 320 | Fermentation broth separation | [79] |

| Huabei Pharmaceutical Hebei Huamin Pharmaceutical Co., Ltd. | 300 | Fermentation broth separation | |

| Lunan New Era Biotechnology Co., Ltd. | 520 | Fermentation broth separation | |

| Lizhu Group Ningxia Fuxing Pharmaceutical Co., Ltd. | 400 | Fermentation broth separation | |

| Yili Chuanning Biotechnology Co., Ltd. | 400 | Fermentation broth separation | |

| Huabei Pharmaceutical Hebei Huamin Pharmaceutical Co., Ltd. | 300 | Continuous filtration of fermentation broth by ceramic membrane |

| Project Name | Membrane Technology | Scale (m3/d) | Application Type | Source |

|---|---|---|---|---|

| Shandong Pulodebang Pharmaceutical Co., Ltd. | MBR | 1500 | Pharmaceutical wastewater treatment | [80] |

| Hebei Jianmin MBR System | MBR | 12,000 | Pharmaceutical wastewater treatment | |

| Hebei Jianmin Starch MBR Project | MBR | 6000 | Pharmaceutical wastewater treatment | |

| Shanghai Pharmaceutical Co., Ltd. | Ultrafiltration + reverse osmosis | 760 | Separation of sugar fermentation broth |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, R.; Li, J.; Zeng, P.; Duan, L.; Dong, J.; Ma, Y.; Yang, L. The Application of Membrane Separation Technology in the Pharmaceutical Industry. Membranes 2024, 14, 24. https://doi.org/10.3390/membranes14010024

Ma R, Li J, Zeng P, Duan L, Dong J, Ma Y, Yang L. The Application of Membrane Separation Technology in the Pharmaceutical Industry. Membranes. 2024; 14(1):24. https://doi.org/10.3390/membranes14010024

Chicago/Turabian StyleMa, Ruirui, Juan Li, Ping Zeng, Liang Duan, Jimin Dong, Yunxia Ma, and Lingkong Yang. 2024. "The Application of Membrane Separation Technology in the Pharmaceutical Industry" Membranes 14, no. 1: 24. https://doi.org/10.3390/membranes14010024

APA StyleMa, R., Li, J., Zeng, P., Duan, L., Dong, J., Ma, Y., & Yang, L. (2024). The Application of Membrane Separation Technology in the Pharmaceutical Industry. Membranes, 14(1), 24. https://doi.org/10.3390/membranes14010024