Preparation of Thin Film Composite (TFC) Membrane with DESPs Interlayer and Its Forward Osmosis (FO) Performance for Organic Solvent Recovery

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

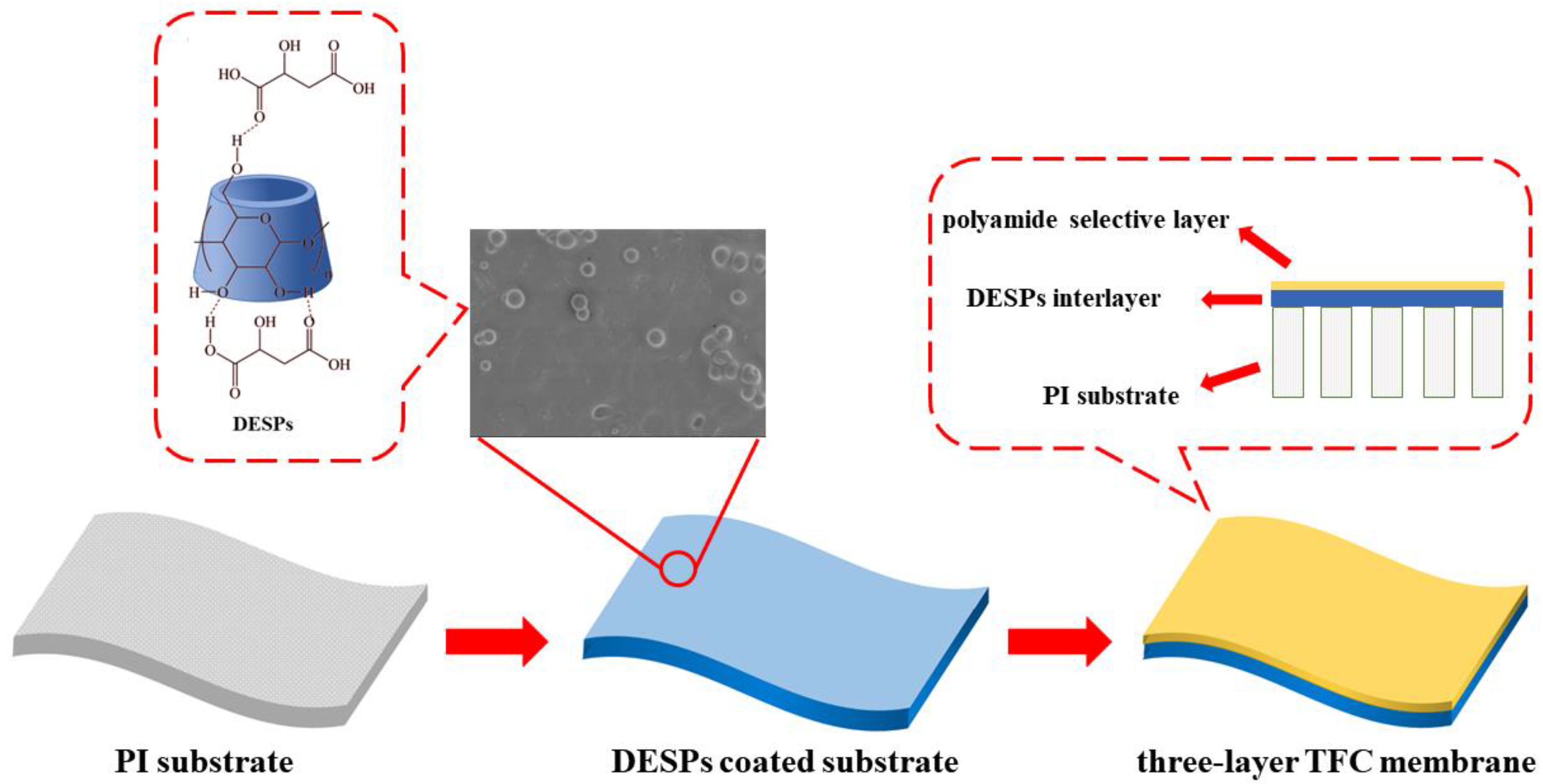

2.2. Thin-Film Composite Membrane Fabrication

2.2.1. Preparation of PI Substrate

2.2.2. Preparation of Triple-Layer TFC Membranes

2.3. Membrane Characterization

2.4. OSFO Membrane Performance Evaluation

3. Results and Discussion

3.1. Membrane Characterization

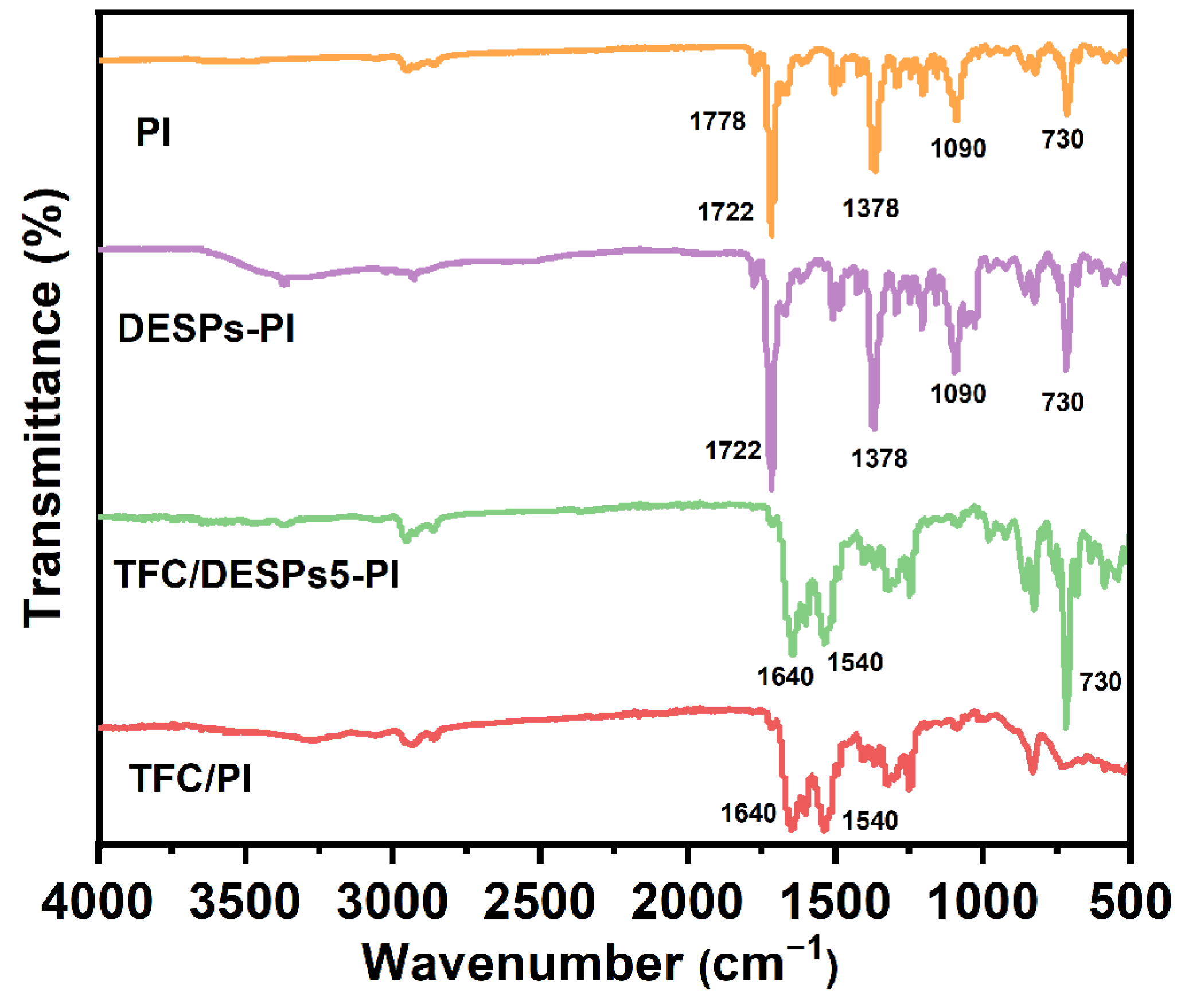

3.1.1. FTIR Spectra

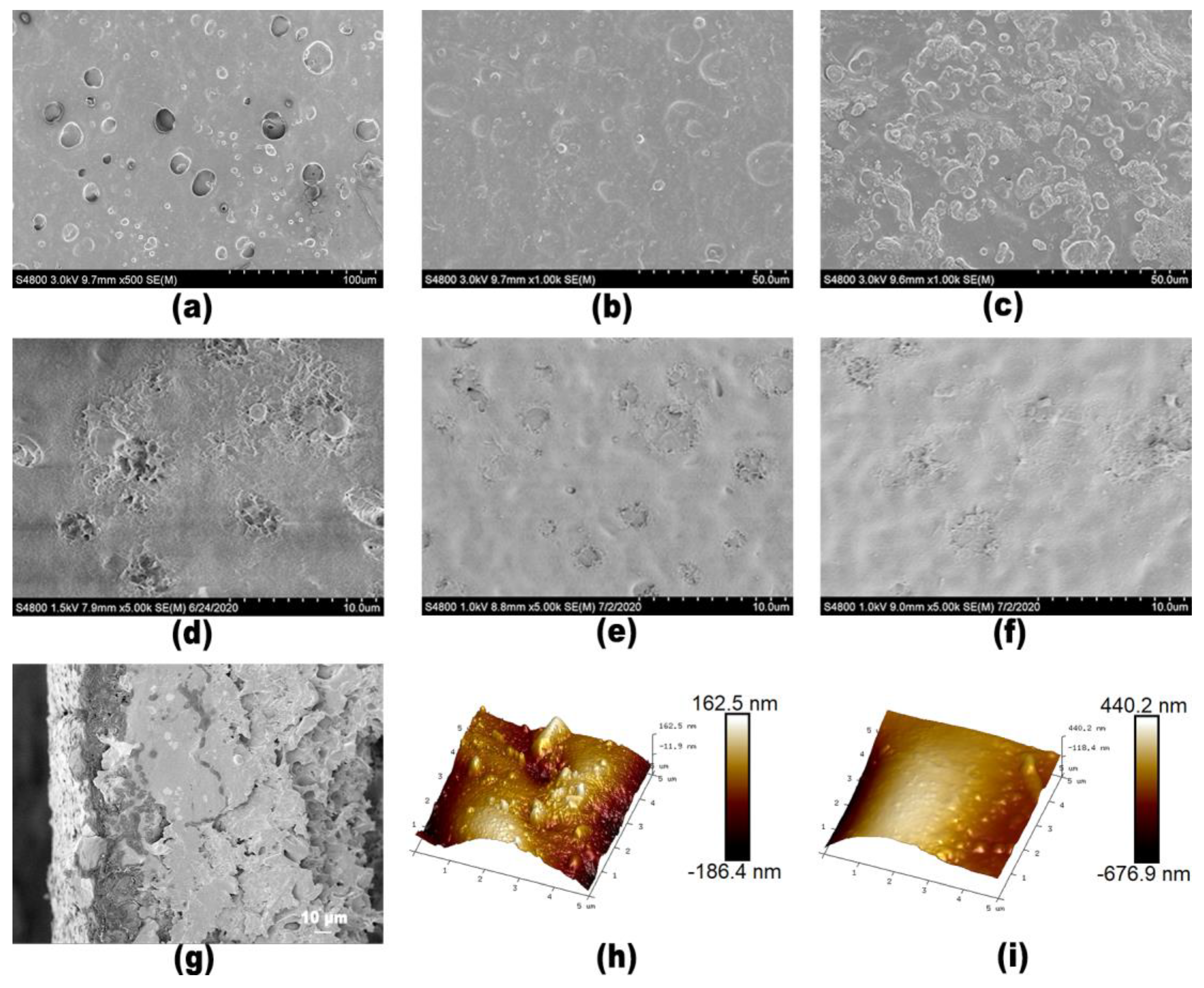

3.1.2. Morphology Characterizations

3.1.3. Solvent Philicity Characterizations

3.1.4. The Swelling Degree and Porosity of Membranes

3.2. OSFO Membrane Performance Evaluation

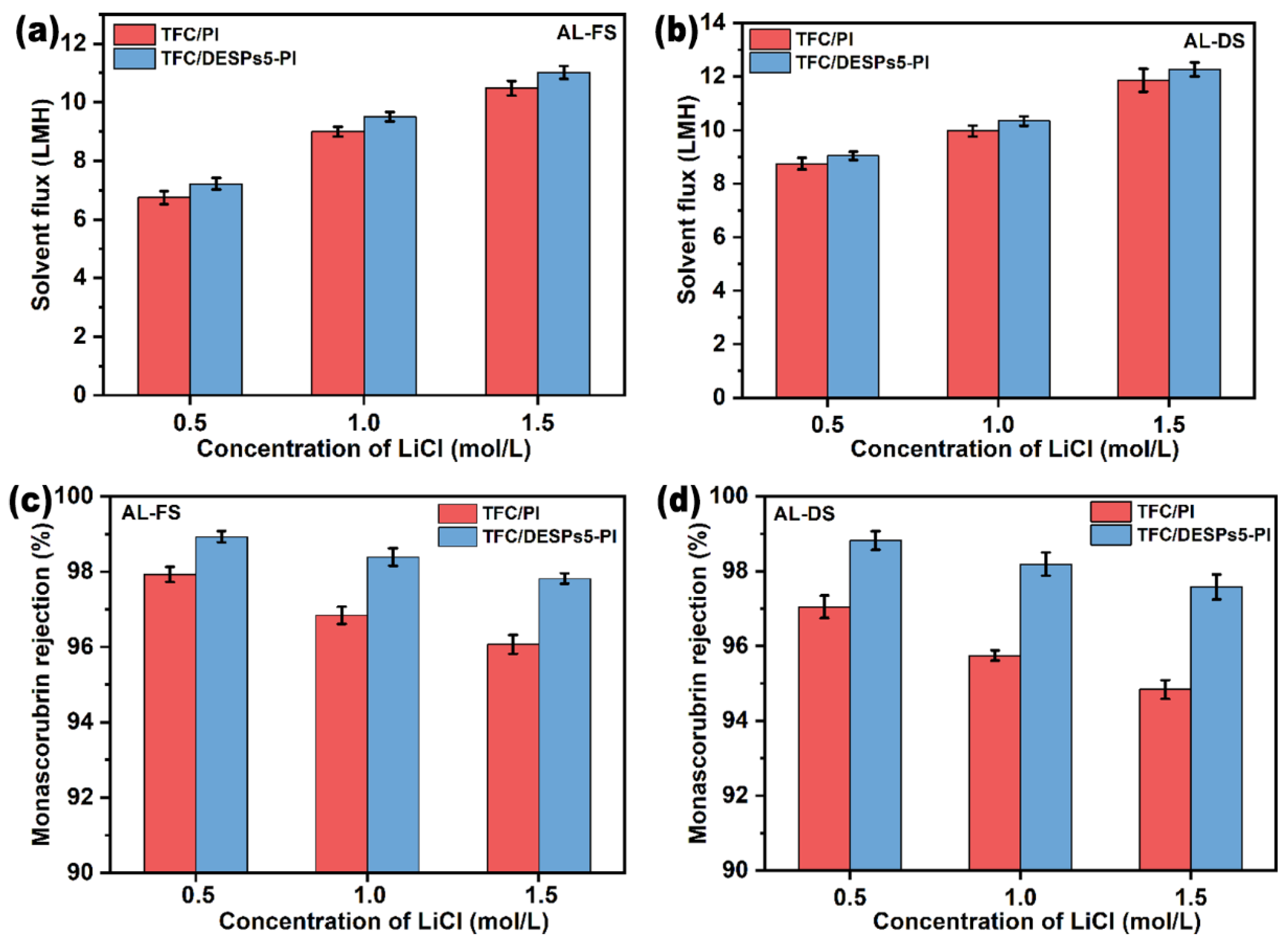

3.2.1. Effect of DESPs Interlayer on the Performance

3.2.2. Effect of Draw Solution Concentration on the Performance

3.3. OSFO Membrane Stability Evaluation

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Benvenutti, L.; Zielinski, A.A.F.; Ferreira, S.R.S. Which is the best food emerging solvent: IL, DES Or NADES? Trends Food Sci. Technol. 2019, 90, 133–146. [Google Scholar] [CrossRef]

- Farrán, A.; Cai, C.; Sandoval, M.; Xu, Y.M.; Liu, J.; Hernáiz, M.J.; Linhardt, R.J. Green solvents in carbohydrate chemistry: From raw materials to fine chemicals. Chem. Rev. 2015, 115, 6811–6853. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-González, C.; Poechlauer, P.; Broxterman, Q.B.; Yang, B.S.; Ende, D.A.; Baird, J.; Bertsch, C.; Hannah, R.E.; Dell Orco, P.; Noorman, H.; et al. Key green engineering research areas for sustainable manufacturing: A perspective from pharmaceutical and fine chemicals manufacturers. Org. Process Res. Dev. 2011, 15, 900–911. [Google Scholar] [CrossRef]

- Aboagye, E.A.; Chea, J.D.; Yenkie, K.M. Systems level roadmap for solvent recovery and reuse in industries. iScience 2021, 10, 103114. [Google Scholar] [CrossRef] [PubMed]

- Furukawa, H.; Cordova, K.E.; Keeffe, M.; Yaghi, O.M. The Chemistry and applications of metal-organic frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef] [PubMed]

- Muralikrishna, I.V.; Manickam, V. Hazardous waste management. Environ. Manag. 2017, 17, 463–496. [Google Scholar]

- Shirsat, S.P. Separation of isobutyl alcohol and isobutyl acetate by extractive distillation and pressure-swing distillation: Simulation and optimization. Sep. Purif. Technol. 2013, 118, 652. [Google Scholar] [CrossRef]

- Ruthusree, S.; Sundarrajan, S.; Ramakrishna, S. Progress and perspectives on ceramic membranes for solvent recovery. Membranes 2019, 9, 128. [Google Scholar] [CrossRef]

- Lively, R.P.; Sholl, D.S. From water to organics in membrane separations. Nat. Mater. 2017, 16, 276–279. [Google Scholar] [CrossRef]

- Cui, Y.; Chung, T.S. Pharmaceutical concentration using organic solvent forward osmosis for solvent recovery. Nat. Commun. 2018, 9, 1426. [Google Scholar] [CrossRef]

- Cui, Y.; Chung, T.S. Solvent recovery via organic solvent pressure assisted osmosis. Ind. Eng. Chem. Res. 2019, 58, 4970–4978. [Google Scholar] [CrossRef]

- Marchetti, P.; Jimenez Solomon, M.F.; Szekely, G.; Livingston, A.G. Molecular separation with organic solvent nanofiltration: A critical review. Chem. Rev. 2014, 114, 10735–10806. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.F.; Zou, L.; Tang, C.Y.Y.; Mulcahy, D. Recent developments in forward osmosis: Opportunities and challenges. J. Membr. Sci. 2012, 396, 1–21. [Google Scholar] [CrossRef]

- Chung, T.S.; Li, X.; Ong, R.C.; Ge, Q.C.; Wang, H.L.; Han, G. Emerging forward osmosis (FO) technologies and challenges ahead for clean water and clean energy applications. Curr. Opin. Chem. Eng. 2012, 1, 246–257. [Google Scholar] [CrossRef]

- Cath, T.Y.; Childress, A.E.; Elimelech, M. Forward osmosis: Principles, applications, and recent developments. J. Membr. Sci. 2006, 281, 70–87. [Google Scholar] [CrossRef]

- Yasukawa, M.; Mishima, S.; Tanaka, Y.; Takahashi, T.; Matsuyama, H. Thin-film composite forward osmosis membrane with high water flux and high pressure resistance using a thicker void-free polyketone porous support. Desalination 2017, 402, 1–9. [Google Scholar] [CrossRef]

- Peyravi, M.; Rahimpour, A.; Mohsen Jahanshahi, M. Thin film composite membranes with modifified polysulfone supports for organic solvent nanofiltration. J. Membr. Sci. 2012, 423–424, 225–237. [Google Scholar] [CrossRef]

- Liaw, D.J.; Wang, K.L.; Huang, Y.C.; Lee, K.R.; Lai, J.Y.; Ha, C.S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2011, 37, 907–974. [Google Scholar] [CrossRef]

- See-Toh, Y.H.; Silva, M.; Livingston, A. Controlling molecular weight cut-off curves for highly solvent stable organic solvent nanofiltration (OSN) membranes. J. Membr. Sci. 2008, 324, 220–232. [Google Scholar] [CrossRef]

- Soroko, I.; Livingston, A. Impact of TiO2 nanoparticles on morphology and performance of crosslinked polyimide organic solvent nanofiltration (OSN) membranes. J. Memb. Sci. 2009, 343, 189–198. [Google Scholar] [CrossRef]

- Guiver, M.D.; Robertson, G.P.; Dai, Y.; Bilodeau, F.; Kang, Y.S.; Lee, K.J.; Jho, J.Y.; Won, J. Structural characterization and gas-transport properties of brominated matrimid polyimide. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 4193–4204. [Google Scholar] [CrossRef]

- Liu, S.L.; Chng, M.L.; Chung, T.S.; Goto, K.; Tamai, S.; Pramoda, K.P.; Tong, Y.J. Gas-transport properties of indan-containing polyimides. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 2769–2779. [Google Scholar] [CrossRef]

- Kurdi, J.; Tremblay, A.Y. The influence of casting solution structure on the microporosity of polyetherimide gas separation membranes prepared by the coagulation post-leaching method. J. Membr. Sci. 2001, 184, 175–186. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, P.F.; Li, X.H.; Gan, B.W.; Wang, L.; Song, X.X.; Park, H.D.; Tang, C.Y. A critical review on thin-film nanocomposite membranes with interlayered structure: Mechanisms, recent developments, and environmental applications. Environ. Sci. Technol. 2020, 54, 15563–15583. [Google Scholar] [CrossRef] [PubMed]

- Dai, R.; Li, J.; Wang, Z. Constructing interlayer to tailor structure and performance of thin-film composite polyamide membranes: A review. Adv. Colloid Interfac. 2020, 282, 102204. [Google Scholar] [CrossRef] [PubMed]

- Liao, M.; Zhu, Y.; Gong, G.; Qiao, L. Thin-Film Composite Membranes with a Carbon Nanotube Interlayer for Organic Solvent Nanofifiltration. Membranes 2022, 12, 817. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; Li, S.; Su, B.; Han, L.; Mandal, B. Graphene oxide (GO)-interlayered thin-film nanocomposite (TFN) membranes with high solvent resistance for organic solvent nanofiltration (OSN). J. Mater. Chem. A 2019, 7, 13315–13330. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, Y.; Yang, H.; Du, Y.; Xu, Z. Polyphenol coating as an interlayer for thin-film composite membranes with enhanced nanofiltration performance, ACS Appl. Mater. Interfaces 2016, 8, 32512–32519. [Google Scholar] [CrossRef]

- Engeldinger, E.; Armspach, D.; Matt, D. Capped cyclodextrins. Chem. Rev. 2003, 103, 4147–4174. [Google Scholar] [CrossRef]

- Del Valle, E.M. Cyclodextrins and their Uses: A Review. Process Biochem. 2004, 39, 1033–1046. [Google Scholar] [CrossRef]

- Larsen, K.L. Large cyclodextrins. J. Incl. Phenom. Macro Chem. 2002, 43, 1–13. [Google Scholar] [CrossRef]

- Harada, A.; Takashima, Y.; Yamaguchi, H. Cyclodextrin-based supramolecular polymers. Chem. Soc. Rev. 2009, 38, 875. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.G.; Cai, C.Y.; Li, F.F.; Tan, Z.J.; Dong, S.Y. Deep eutectic supramolecular polymers: Bulk supramolecular materials. Angew. Chem. Int. Ed. 2020, 59, 11871–11875. [Google Scholar] [CrossRef] [PubMed]

- Abbott, A.P.; Harris, R.C.; Ryder, K.S. Application of Hole Theory to define ionic liquids by their transport properties. J. Phys. Chem. B 2007, 111, 4910–4913. [Google Scholar] [CrossRef]

- Vendruscolo, F.; Bühler, R.M.M.; de Carvalho, J.C.; de Oliveira, D.; Moritz, D.E.; Schmidell, W.; Ninow, J.L. Monascus: A reality on the production and application of microbial pigments. Appl. Biochem. Biotech. 2016, 178, 211–223. [Google Scholar] [CrossRef]

- Akihisa, T.; Tokuda, H.; Ukiya, M.; Kiyota, A.; Yasukawa, K.; Sakamoto, N.; Kimura, Y.; Suzuki, T.; Takayasu, J.; Nishino, H. Anti-tumor-initiating effects of monascin, an azaphilonoid pigment from the extract of monascus pilosus fermented rice (Red-mold rice). Chem. Biodivers. 2005, 2, 1305–1309. [Google Scholar] [CrossRef]

- Agboyibor, C.; Kong, W.B.; Zhang, A.M.; Niu, S.Q. Nutrition regulation for the production of monascus red and yellow pigment with submerged fermentation by monascus purpureus. Biocatal. Agric. Biotechnol. 2019, 21, 101276. [Google Scholar] [CrossRef]

- Gray, G.T.; McCutcheon, J.R.; Elimelech, M. Internal concentration polarization in forward osmosis: Role of membrane orientation. Desalination 2006, 197, 1–8. [Google Scholar] [CrossRef]

| Substrates/ Membranes | PI | DESPs5-PI | DESPs10-PI | TFC/PI | TFC/ DESPs5-PI | TFC/ DESPs10-PI |

|---|---|---|---|---|---|---|

| Porosity (%) | 76.1 | 79.0 | 77.3 | 45.4 | 48.6 | 47.0 |

| Membrane | Solvent Flux (Jw, LMH) | Reverse Solute Flux (Js, gMH) | Js/Jw (g/L) |

|---|---|---|---|

| TFC/PI | 8.99 | 3.16 | 0.352 |

| TFC/DESPs5-PI | 9.51 | 2.28 | 0.240 |

| TFC/DESPs10-PI | 9.37 | 2.74 | 0.292 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, J.; Huang, H.; Zhang, H.; Wu, Y.; Zhuang, Y. Preparation of Thin Film Composite (TFC) Membrane with DESPs Interlayer and Its Forward Osmosis (FO) Performance for Organic Solvent Recovery. Membranes 2023, 13, 688. https://doi.org/10.3390/membranes13070688

Liang J, Huang H, Zhang H, Wu Y, Zhuang Y. Preparation of Thin Film Composite (TFC) Membrane with DESPs Interlayer and Its Forward Osmosis (FO) Performance for Organic Solvent Recovery. Membranes. 2023; 13(7):688. https://doi.org/10.3390/membranes13070688

Chicago/Turabian StyleLiang, Jingyi, Hansheng Huang, Hao Zhang, Yanhui Wu, and Yongbing Zhuang. 2023. "Preparation of Thin Film Composite (TFC) Membrane with DESPs Interlayer and Its Forward Osmosis (FO) Performance for Organic Solvent Recovery" Membranes 13, no. 7: 688. https://doi.org/10.3390/membranes13070688

APA StyleLiang, J., Huang, H., Zhang, H., Wu, Y., & Zhuang, Y. (2023). Preparation of Thin Film Composite (TFC) Membrane with DESPs Interlayer and Its Forward Osmosis (FO) Performance for Organic Solvent Recovery. Membranes, 13(7), 688. https://doi.org/10.3390/membranes13070688