Nanocarbon-Based Mixed Matrix Pebax-1657 Flat Sheet Membranes for CO2/CH4 Separation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instrumentation-Characterization

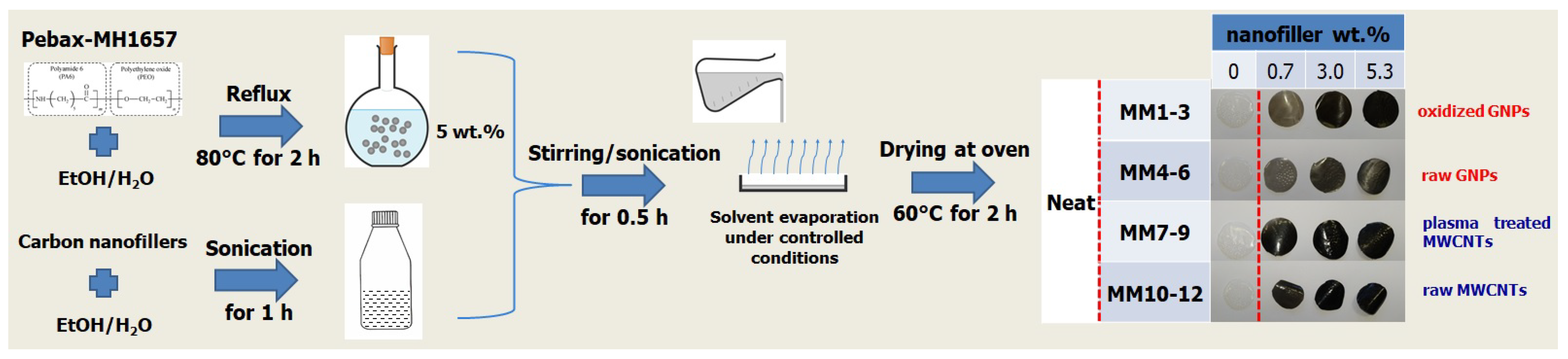

2.3. Membrane Preparation

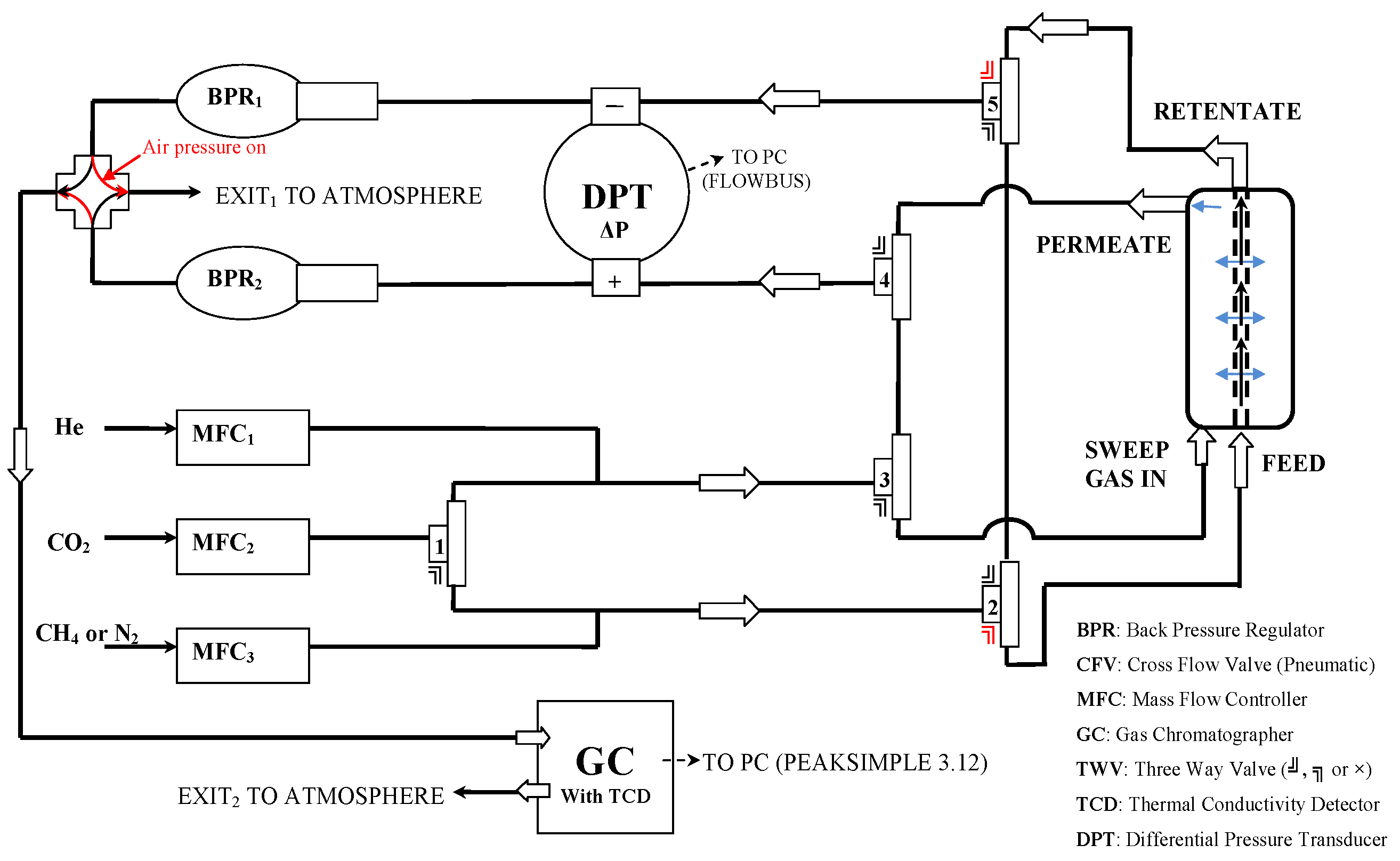

2.4. Gas Permeability/Separation Measurements under Continuous Flow Conditions

3. Results and Discussion

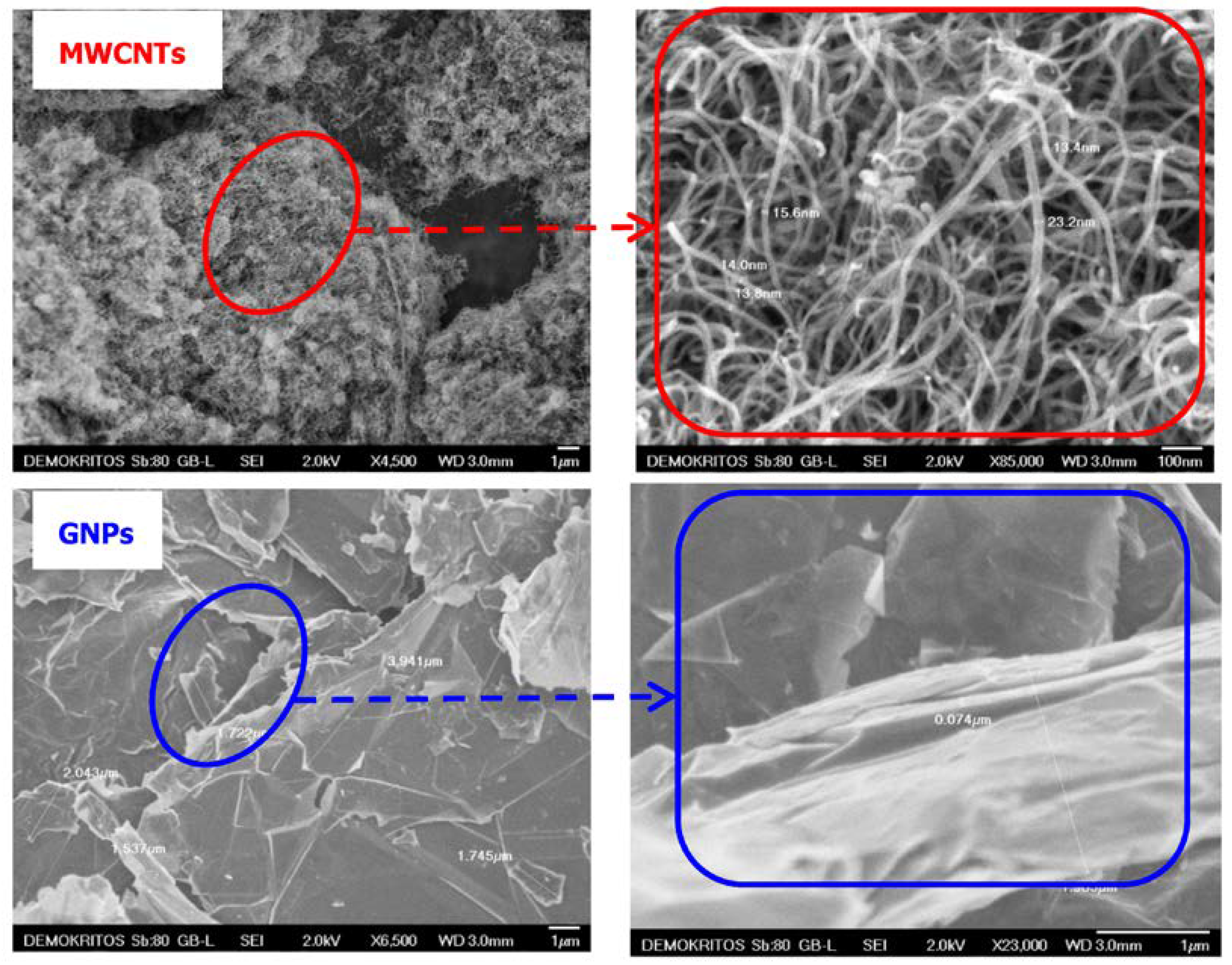

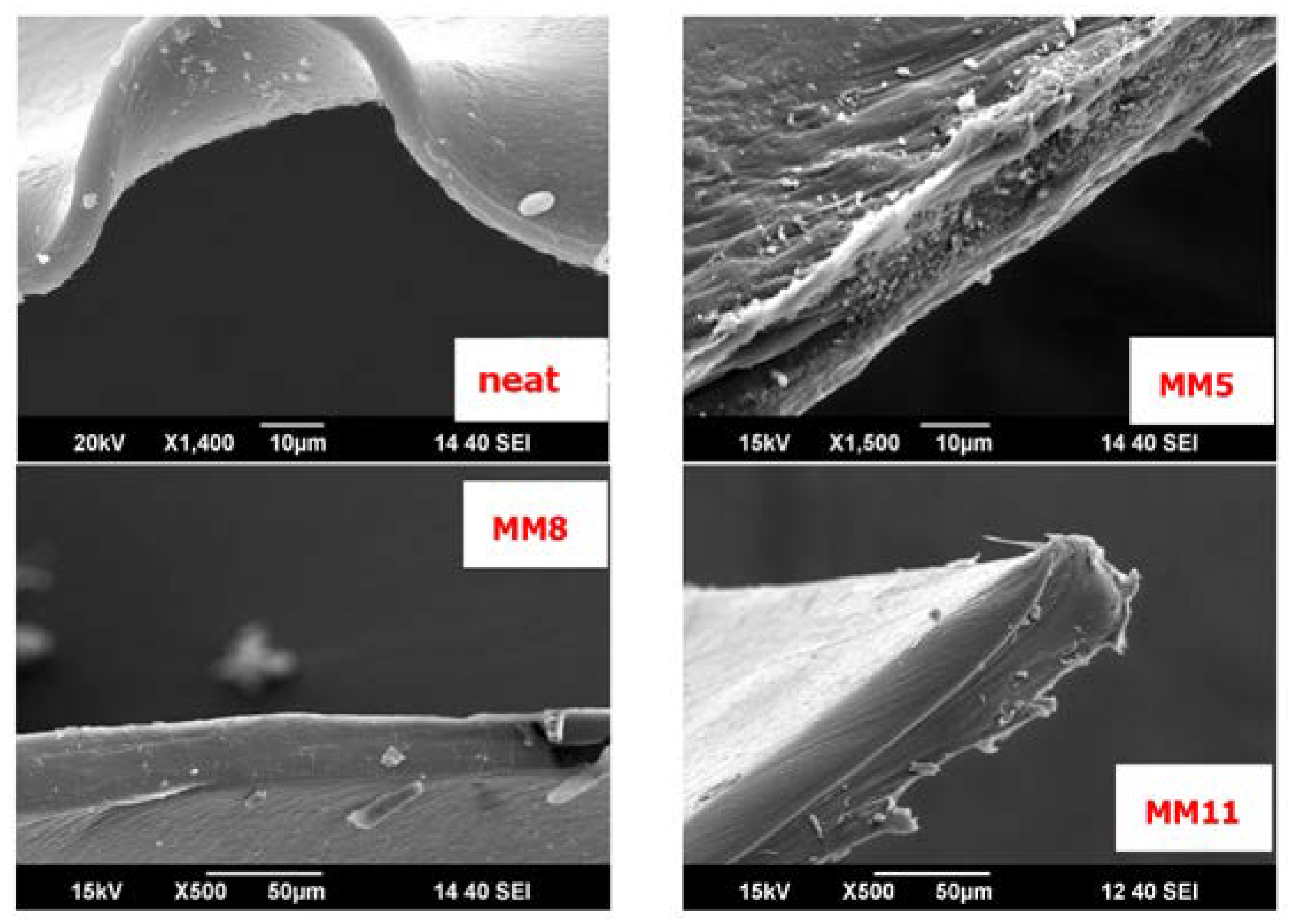

3.1. Morphology of Nanofillers/Prepared MMMs

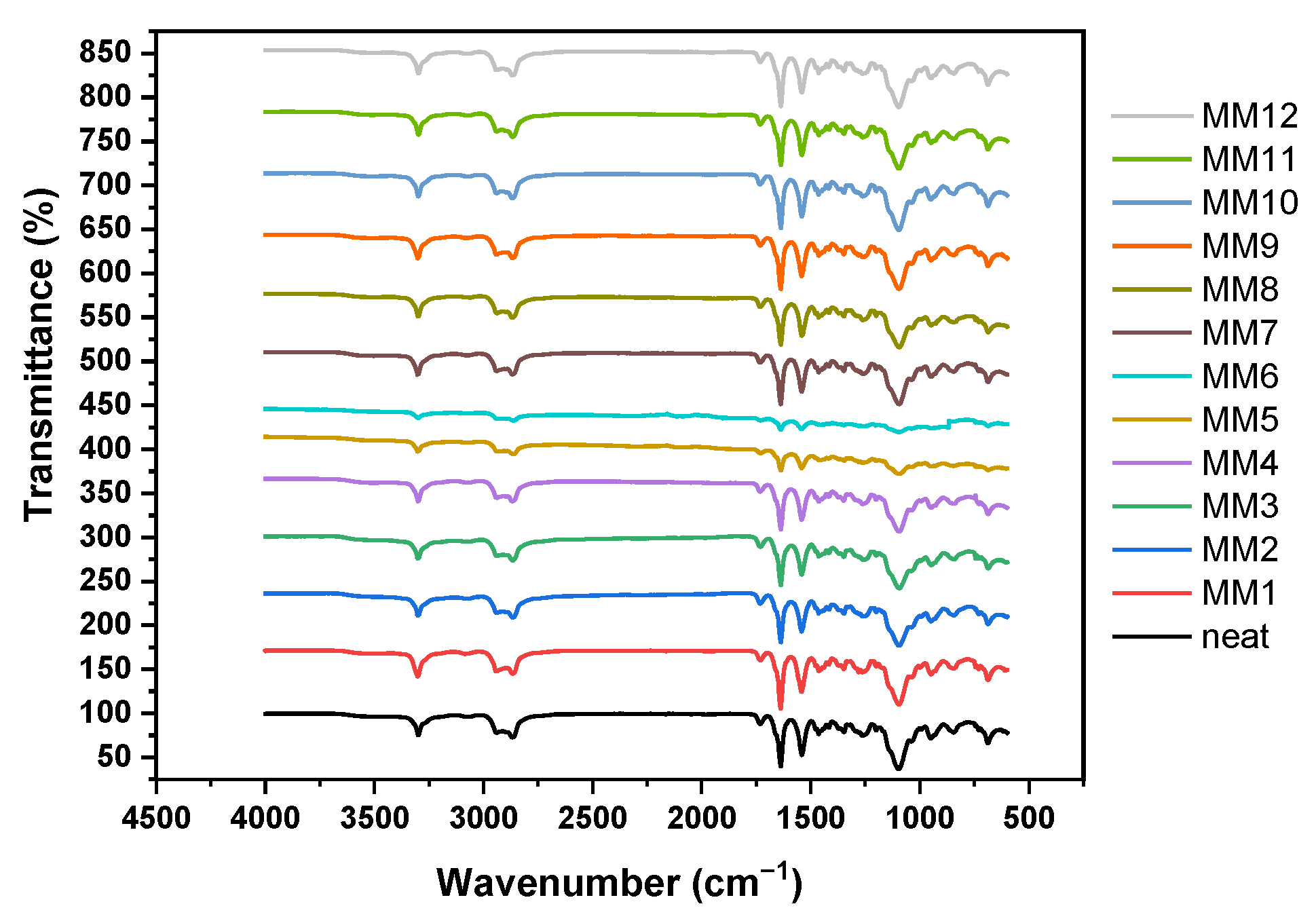

3.2. FTIR Analysis

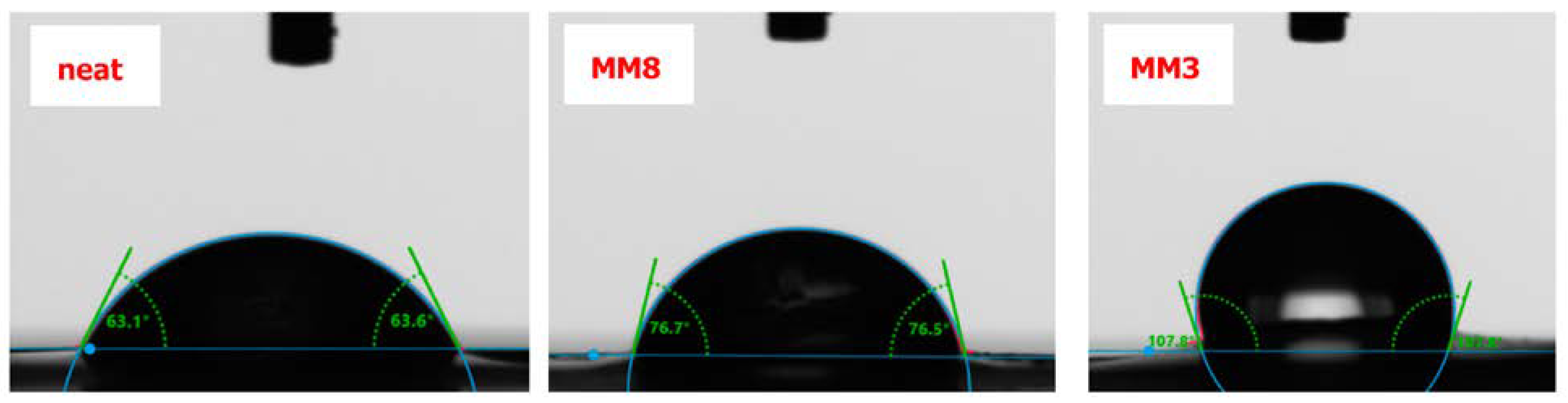

3.3. Water Contact Angle Measurements

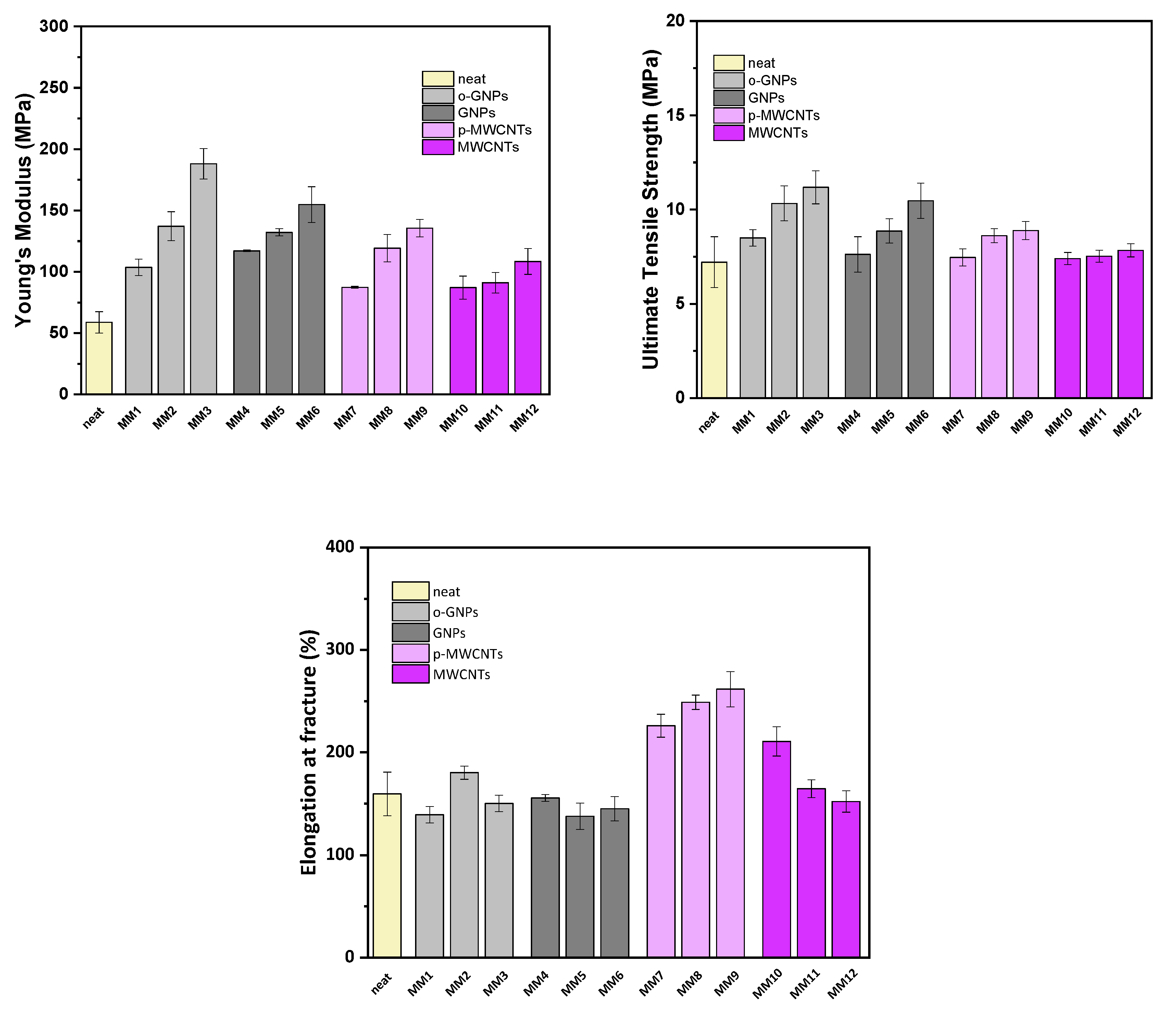

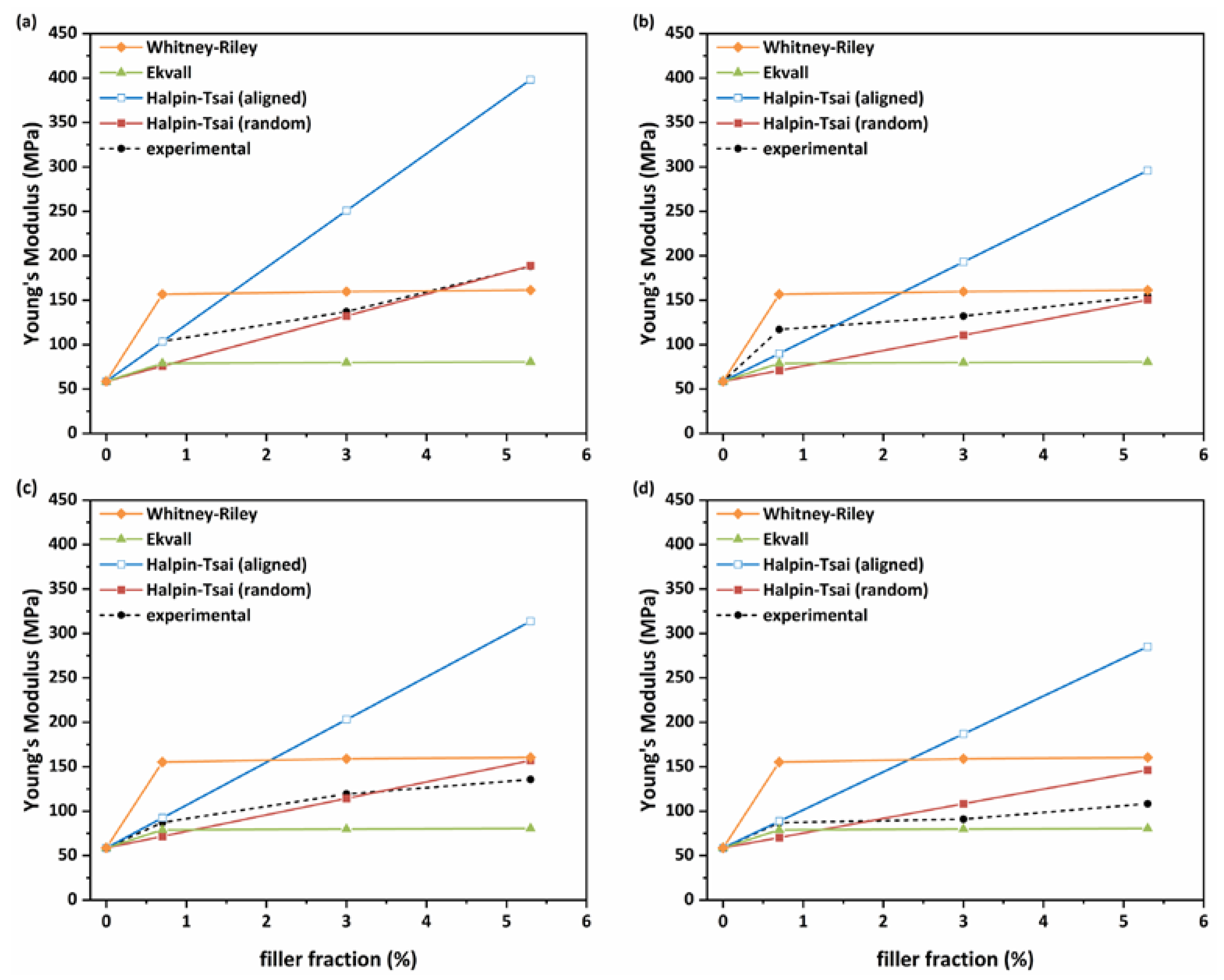

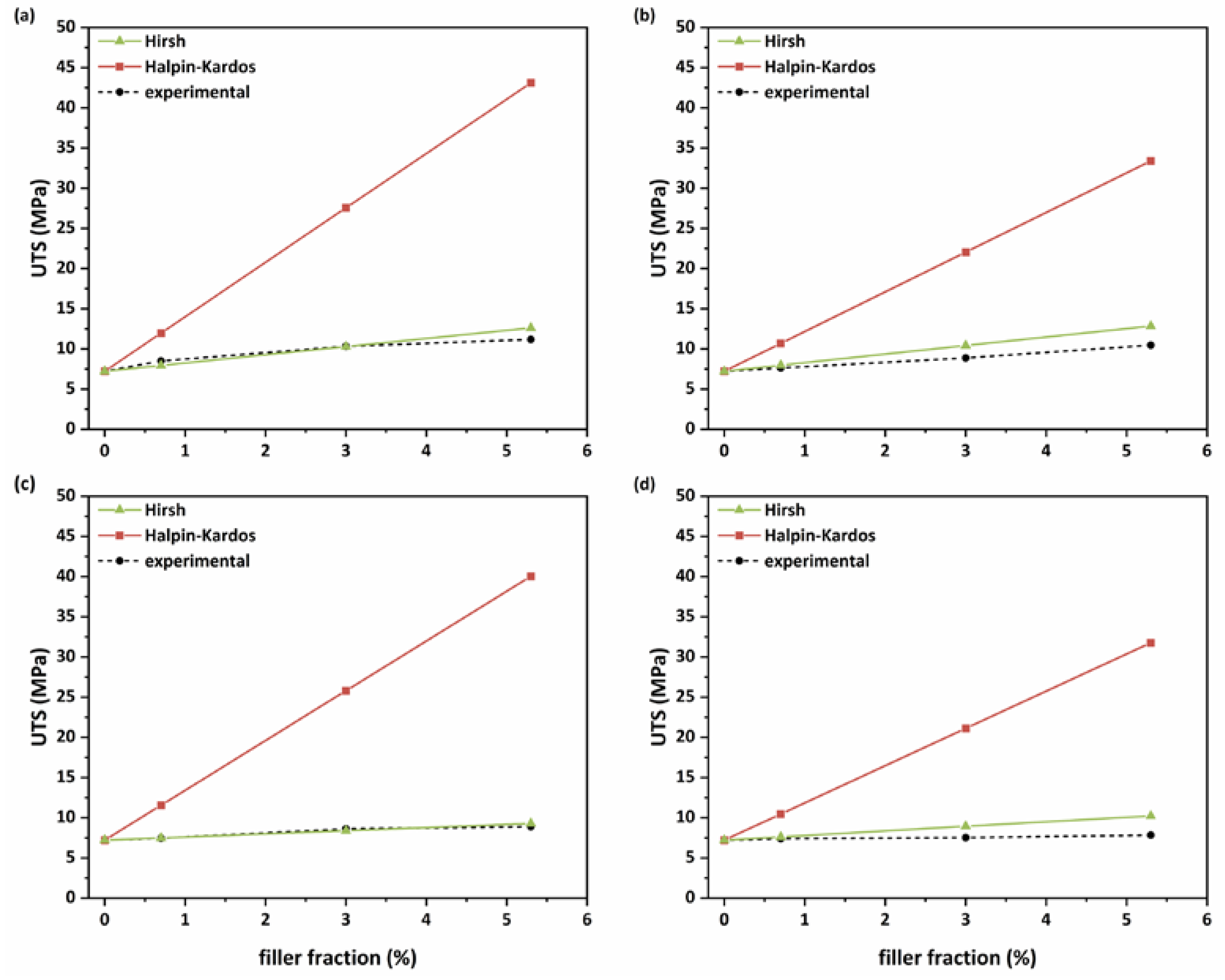

3.4. Mechanical Properties

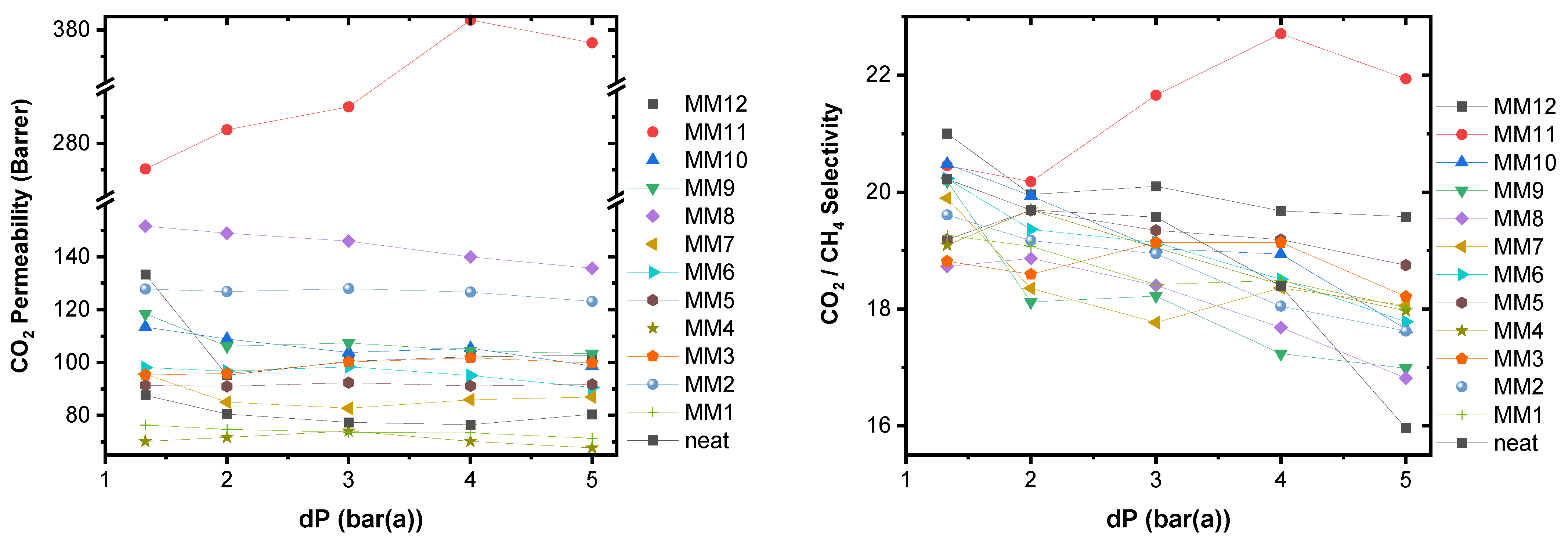

3.5. CO2/CH4 Permeability and Selectivity Results

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Favvas, E.P.; Katsaros, F.K.; Papageorgiou, S.K.; Sapalidis, A.A.; Mitropoulos, A.C. A Review of the Latest Development of Polyimide based Membranes for CO2 Separations. React. Funct. Polym. 2017, 120, 104–130. [Google Scholar] [CrossRef]

- Azizi, N.; Mohammadi, T.; Behbahani, R.M. Synthesis of a new nanocomposite membrane (PEBAX-1074/PEG-400/TiO2) in order to separate CO2 from CH4. J. Nat. Gas Sci. Eng. 2017, 37, 39–51. [Google Scholar] [CrossRef]

- Robeson, L.M. The upper bound revisited. J. Membr. Sci. 2007, 320, 390–400. [Google Scholar] [CrossRef]

- Yeo, Z.Y.; Chew, T.L.; Zhu, P.W.; Mohamed, A.R.; Chai, S.P. Conventional Processes and Membrane Technology for Carbon Dioxide Removal from Natural Gas: A Review. J. Nat. Gas Chem. 2012, 32, 282–298. [Google Scholar] [CrossRef]

- Salehi, E.; Heidary, F.; Daraei, P.; Keyhani, M.; Behjomanesh, M. Carbon nanostructures for advanced nanocomposite mixed matrix membranes: A comprehensive overview. Rev. Chem. Eng. 2020, 36, 723–748. [Google Scholar] [CrossRef]

- Mannan, H.A.; Mukhtar, H.; Murugesan, T.; Nasir, R.; Mohshim, D.F.; Mushtaq, A. Recent Applications of Polymer Blends in Gas Separation Membranes. Chem. Eng. Technol. 2013, 36, 1838–1846. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, Y.; Yuan, Z.; Li, X.; Zhang, H.; Vankelecom, I.F.J. Highly Stable Anion Exchange Membranes with Internal Cross-Linking Networks. Adv. Funct. Mater. 2015, 25, 2583–2589. [Google Scholar] [CrossRef]

- Amirilargani, M.; Sadrzadeh, M.; Sudhölter, E.J.R.; de Smet, L.C.P.M. Surface modification methods of organic solvent nanofiltration membranes. Chem. Eng. J. 2016, 289, 562–582. [Google Scholar] [CrossRef]

- Ang, M.B.M.Y.; Tang, C.-L.; De Guzman, M.R.; Maganto, H.L.C.; Caparanga, A.R.; Huang, S.-H.; Tsai, H.-A.; Hu, C.-C.; Lee, K.-R.; Lai, J.-Y. Improved performance of thin-film nanofiltration membranes fabricated with the intervention of surfactants having different structures for water treatment. Desalination 2020, 481, 114352. [Google Scholar] [CrossRef]

- Xiang, J.; Xie, Z.; Hoang, M.; Zhang, K. Effect of amine salt surfactants on the performance of thin film composite poly(piperazine-amide) nanofiltration membranes. Desalination 2013, 315, 156–163. [Google Scholar] [CrossRef]

- Agboola, O.; Sadiku, E.R.; Mokrani, T. Nanomembrane materials based on polymer blends. In Design and Applications of Nanostructured Polymer Blends and Nanocomposite Systems; Thomas, S., Shanks, R., Chandrasekharakurup, S., Eds.; Elsevier: Oxford, UK, 2016; pp. 101–123. [Google Scholar]

- Yao, M.; Woo, Y.C.; Tijing, L.D.; Cesarini, C.; Shon, H.K. Improving Nanofiber Membrane Characteristics and Membrane Distillation Performance of Heat-Pressed Membranes via Annealing Post-Treatment. Appl. Sci. 2017, 7, 78. [Google Scholar] [CrossRef]

- Salehi, E.; Madaeni, S.S.; Heidary, F. Dynamic adsorption of Ni(II) and Cd(II) ions from water using 8-hydroxyquinoline ligand immobilized PVDF membrane: Isotherms, thermodynamics and kinetics. Sep. Purif. Technol. 2012, 94, 1–8. [Google Scholar] [CrossRef]

- Dechnik, J.; Gascon, J.; Doonan, C.J.; Janiak, C.; Sumby, C.J. Mixed-Matrix Membranes. Angew. Chem. Int. 2017, 56, 9292–9310. [Google Scholar] [CrossRef] [PubMed]

- Favvas, E.P.; Stefanopoulos, K.L.; Nolan, J.W.; Papageorgiou, S.K.; Mitropoulos, A.C.; Lairez, D. Mixed matrix hollow fiber membranes with enhanced gas permeation properties. Sep. Purif. Technol. 2014, 132, 336–345. [Google Scholar] [CrossRef]

- Favvas, E.P.; Nitodas, S.F.; Stefopoulos, A.; Stefanopoulos, K.L.; Papageorgiou, S.K.; Mitropoulos, A.C. High Purity Multi-Walled Carbon Nanotubes: Preparation, Characterization and Performance as Filler Materials in co-polyimide Hollow Fiber Membranes. Sep. Purif. Technol. 2014, 122, 262–269. [Google Scholar] [CrossRef]

- Moore, T.T.; Mahajan, R.; Vu, D.Q.; Koros, W.J. Hybrid membrane materials comprising organic polymers with rigid dispersed phases. AIChE J. 2004, 50, 311–321. [Google Scholar] [CrossRef]

- Kamble, A.R.; Patel, C.M.; Murthy, Z.V.P. A review on the recent advances in mixed matrix membranes for gas separation processes. Renew. Sustain. Energy Rev. 2021, 145, 111062. [Google Scholar] [CrossRef]

- Najari, S.; Saeidi, S.; Gallucci, F.; Drioli, E. Mixed matrix membranes for hydrocarbons separation and recovery: A critical review. Rev. Chem. Eng. 2021, 37, 363–406. [Google Scholar] [CrossRef]

- Krokidas, P.; Spera, M.B.M.; Boutsika, L.G.; Bratsos, I.; Charalambopoulou, G.; Economou, I.G.; Steriotis, T. Nanoengineered ZIF fillers for mixed matrix membranes with enhanced CO2/CH4 selectivity. Separ. Purif. Technol. 2023, 307, 122737. [Google Scholar] [CrossRef]

- Farashi, Z.; Azizi, S.; Arzhandi, M.R.-D.; Noroozi, Z.; Azizi, N. Improving CO2/CH4 separation efficiency of Pebax-1657 membrane by adding Al2O3 nanoparticles in its matrix. J. Nat. Gas Sci. Eng. 2019, 72, 103019. [Google Scholar] [CrossRef]

- Embaye, A.S.; Martínez-Izquierdo, L.; Malankowska, M.; Téllez, C.; Coronas, J. Poly(ether-block-amide) Copolymer Membranes in CO2 Separation Applications. Energy Fuels 2021, 35, 17085–17102. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, S.; Wu, H.; Li, Y.; Wang, S.; Tian, Z.; Jiang, Z. High permeability hydrogel membranes of chitosan/poly ether-block-amide blends for CO2 separation. J. Membr. Sci. 2014, 469, 198–208. [Google Scholar] [CrossRef]

- Estahbanati, E.G.; Omidkhah, M.; Amooghin, A.E. Preparation and characterization of novel Ionic liquid/Pebax membranes for efficient CO2/light gases separation. J. Ind. Eng. Chem. 2017, 51, 77–89. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Y.; Hou, J.; Zhang, Y.; Fam, W.; Liu, J.; Bennett, T.D.; Chen, V. Ultraselective Pebax Membranes Enabled by Templated Microphase Separation. ACS Appl. Mater. Interfaces 2018, 10, 20006–20013. [Google Scholar] [CrossRef] [PubMed]

- Dong, G.; Hou, J.; Wang, J.; Zhang, Y.; Chen, V.; Liu, J. Enhanced CO2/N2 separation by porous reduced graphene oxide/Pebax mixed matrix membranes. J. Membr. Sci. 2016, 520, 860–868. [Google Scholar] [CrossRef]

- Huang, T.-C.; Liu, Y.-C.; Lin, G.-S.; Lin, C.-H.; Liu, W.-R.; Tung, K.-L. Fabrication of pebax-1657-based mixed-matrix membranes incorporating N-doped few-layer graphene for carbon dioxide capture enhancement. J. Membr. Sci. 2020, 602, 117946. [Google Scholar] [CrossRef]

- Iqbal, A.K.M.A.; Sakib, N.; Iqbal, A.K.M.P.; Nuruzzaman, D.M. Graphene-based nanocomposites and their fabrication, mechanical properties and applications. Materialia 2020, 12, 100815. [Google Scholar] [CrossRef]

- Sapalidis, A.A.; Katsaros, F.K.; Steriotis, T.A.; Kanellopoulos, N.K. Properties of Poly(vinyl alcohol)—Bentonite Clay Nanocomposite Films in Relation to Polymer–Clay Interactions. J. Appl. Polym. Sci. 2012, 123, 1812–1821. [Google Scholar] [CrossRef]

- Stoitsas, K.A.; Gotzias, A.; Kikkinides, E.S.; Steriotis, T.A.; Kanellopoulos, N.K.; Stoukides, M.; Zaspalis, V.T. Porous ceramic membranes for propane–propylene separation via the p-complexation mechanism: Unsupported systems. Microporous Mesoporous Mater. 2005, 78, 235–243. [Google Scholar] [CrossRef]

- Favvas, E.P.; Heliopoulos, N.S.; Papageorgiou, S.K.; Mitropoulos, A.C.; Kapantaidakis, G.C.; Kanellopoulos, N.K. Helium and hydrogen selective carbon hollow fiber membranes: The effect of pyrolysis isothermal time. Sep. Purif. Technol. 2015, 142, 176–181. [Google Scholar] [CrossRef]

- Esser, T.; Wolf, T.; Schubert, T.; Benra, J.; Forero, S.; Maistros, G.; Barbe, S.; Theodorakopoulos, G.V.; Karousos, D.S.; Sapalidis, A.A.; et al. CO2/CH4 and He/N2 separation properties and water permeability valuation of mixed matrix MWCNTs–based cellulose acetate flat sheet membranes: A study of the optimization of the filler material dispersion method. Nanomaterials 2021, 11, 280. [Google Scholar] [CrossRef] [PubMed]

- Favvas, E.P.; Papageorgiou, S.K.; Stefanopoulos, K.L.; Nolan, J.W.; Mitropoulos, A.C. Effect of air gap on gas permeance/selectivity performance of BTDA-TDI/MDI co-polyimide hollow fiber membranes. J. Appl. Polym. Sci. 2013, 130, 4490–4499. [Google Scholar]

- Pereira, C.M.C.; Nóvoa, P.; Martins, M.; Forero, S.; Hepp, F. Characterization of carbon nanotube 3D-structures infused with low viscosity epoxy resin system. Compos. Struct. 2010, 92, 2252–2257. [Google Scholar] [CrossRef]

- Hammerstein, R.; Schubert, T.; Braun, G.; Wolf, T.; Barbe, S.; Quade, A.; Foest, R.; Karousos, D.S.; Favvas, E.P. The optimization of dispersion and application techniques for nanocarbon-doped mixed matrix gas separation membranes. Membranes 2022, 12, 87. [Google Scholar] [CrossRef]

- Murali, R.S.; Sridhar, S.; Sankarshana, T.; Ravikumar, Y.V.L. Gas Permeation behavior of Pebax-1657 nanocomposite membrane incorporated with multiwalled carbon nanotubes. Ind. Eng. Chem. Res. 2010, 49, 6530–6538. [Google Scholar] [CrossRef]

- Habib, N.; Durak, O.; Zeeshan, M.; Uzun, A.; Keskin, S. A novel IL/MOF/polymer mixed matrix membrane having superior CO2/N2 selectivity. J. Membr. Sci. 2022, 658, 120712. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Y.; Huang, S.; Wu, H.; Li, Y.; Tian, Z.; Jiang, Z. Pebax–PEG–MWCNT hybrid membranes with enhanced CO2 capture properties. J. Membr. Sci. 2014, 460, 62–70. [Google Scholar] [CrossRef]

- Arkas, M.; Favvas, E.P.; Giannakopoulos, K.; Mouti, N.; Karakasiliotis, I.; Vardavoulias, M.; Arvanitopoulou, M.; Athanasiou, A.; Kythreoti, G.; Soto, S.M. Hydrophilic antimicrobial coatings for medical leathers from silica-dendritic polymer-silver nanoparticle composite xerogels. Textiles 2022, 2, 464–485. [Google Scholar] [CrossRef]

- Aburabie, J.; Peinemann, K.-V. Crosslinked poly(ether block amide) composite membranes for organic solvent nanofiltration applications. J. Membr. Sci. 2017, 523, 264–272. [Google Scholar] [CrossRef]

- Ge, C.; Wang, G.; Zhao, J.; Zhao, G. Poly(ether-block-amide) membrane with deformability and adjustable surface hydrophilicity for water purification. Polym. Eng. Sci. 2021, 61, 2137–2146. [Google Scholar] [CrossRef]

- Mitropoulos, A.C.; Stefanopoulos, K.L.; Favvas, E.P.; Vansant, E.F.; Hankins, N. On the Formation of Nanobubbles in Vycor Porous Glass During Desorption of Halogenated Hydrocarbons. Sci. Rep. 2015, 5, 10943. [Google Scholar] [CrossRef] [PubMed]

- Theodorakopoulos, G.V.; Karousos, D.S.; Mansouris, K.G.; Sapalidis, A.A.; Kouvelos, E.P.; Favvas, E.P. Graphene nanoplatelets based polyimide/Pebax dual-layer mixed matrix hollow fiber membranes for CO2/CH4 and He/N2 separations. Int. J. Greenh. Gas Control. 2022, 114, 103588. [Google Scholar] [CrossRef]

- Duan, K.; Wang, J.; Zhang, Y.; Liu, J. Covalent organic frameworks (COFs) functionalized mixed matrix membrane for effective CO2/N2 separation. J. Membr. Sci. 2019, 572, 588–595. [Google Scholar] [CrossRef]

- Zhang, J.; Xin, Q.; Li, X.; Yun, M.; Xu, R.; Wang, S.; Li, Y.; Lin, L.; Ding, X.; Ye, H.; et al. Mixed matrix membranes comprising aminosilane-functionalized graphene oxide for enhanced CO2 separation. J. Membr. Sci. 2019, 570, 343–354. [Google Scholar] [CrossRef]

- Fam, W.; Mansouri, J.; Li, H.; Chen, V. Improving CO2 separation performance of thin film composite hollow fiber with Pebax®1657/ionic liquid gel membranes. J. Membr. Sci. 2017, 537, 54–68. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Moriche, R.; Jiménez-Suárez, A.; Sánchez, M.; Ureña, A. Advantages and disadvantages of the addition of graphene nanoplatelets to epoxy resins. Eur. Polym. J. 2014, 61, 206–214. [Google Scholar] [CrossRef]

- Al-Saleh, M.A.; Yussuf, A.A.; Al-Enezi, S.; Kazemi, R.; Wahit, M.U.; Al-Shammari, T.; Al-Banna, A. Polypropylene/graphene nanocomposites: Effects of GNP loading and compatibilizers on the mechanical and thermal properties. Materials 2019, 12, 3924. [Google Scholar] [CrossRef]

- Chatterjee, S.; Nüesch, F.A.; Chu, B.T.T. Comparing carbon nanotubes and graphene nanoplatelets as reinforcements in polyamide 12 composites. Nanotechnology 2011, 22, 275714. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Favvas, E.P.; Vairis, A.; Mitropoulos, A.C. MWCNTs/resin nanocomposites: Structural, themal, mechanical and dielectric investigation. J. Eng. Sci. Technol. Rev. 2015, 8, 7–14. [Google Scholar] [CrossRef]

- Wang, R.; Aakyiir, M.; Qiu, A.; Oh, J.-A.; Adu, P.; Meng, Q.; Ma, J. Surface-tunable, electrically conductive and inexpensive graphene platelets and their hydrophilic polymer nanocomposites. Polymer 2020, 205, 122851. [Google Scholar] [CrossRef]

- Ekvall, J.C. Structural behaviour of monofilament composites. In Proceedings of the AIAA 6th Structures and Materials Conference, Atlanta, GA, USA, 1–3 February 1965; AIAA: New York, NY, USA, 1965. [Google Scholar]

- Whitney, J.M.; Riley, M.B. Elastic properties of fiber reinforced composite materials. AIAA J. 1966, 4, 1537–1542. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar]

- Venkateshwaran, N.; ElayaPerumal, A. Modeling and evaluation of tensile properties of randomly oriented banana/epoxy composite. J. Reinf. Plast. Compos. 2011, 30, 1957–1967. [Google Scholar] [CrossRef]

- Melicchio, A.; Favvas, E.P. Preparation and characterization of graphene oxide as a candidate filler material for the preparation of mixed matrix polyimide membranes. Surf. Coat. Technol. 2018, 349, 1058–1068. [Google Scholar] [CrossRef]

- Zhao, D.; Ren, J.; Li, H.; Li, X.; Deng, M. Gas separation properties of poly(amide-6-b-ethylene oxide)/amino modified multi-walled carbon nanotubes mixed matrix membranes. J. Membr. Sci. 2014, 467, 41–47. [Google Scholar] [CrossRef]

- Pishva, S.; Hassanajili, S. Investigation on effect of ionic liquid on CO2 separation performance and properties of novel co-casted dual-layer PEBAX-ionic liquid/PES composite membrane. J. Ind. Eng. Chem. 2022, 107, 180–196. [Google Scholar] [CrossRef]

- Sapalidis, A.A.; Karantzis, P.I.; Vairis, A.; Barbe, S.; Nitodas, S.; Favvas, E.P. A study of reinforcement effect by MWCNTs into BTDA–TDI/MDI (Ρ84) polyimide flat sheet membranes. Polymers 2020, 12, 1381. [Google Scholar] [CrossRef]

- Bernardo, P.; Clarizia, G. Enhancing Gas Permeation Properties of Pebax® 1657 Membranes via polysorbate nonionic surfactants doping. Polymers 2020, 12, 253. [Google Scholar] [CrossRef]

| Case | Polymer in Solution A | Filler in Solution B | Concentration in Final Solutions (A + B) | Filler Concentrations in MMMs | |

|---|---|---|---|---|---|

| Polymer | Filler | ||||

| “I” | 5 | 0.052 | 3.0 | 0.021 | 0.7 |

| “II” | 5 | 0.225 | 3.0 | 0.090 | 3.0 |

| “III” | 5 | 0.398 | 3.0 | 0.159 | 5.3 |

| Sample | Neat | MM1 | MM2 | MM3 | MM4 | MM5 | MM6 | MM7 | MM8 | MM9 | MM10 | MM11 | MM12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average WCA (ο) | 63.4 | 83.0 | 85.0 | 107.8 | 76.0 | 78.0 | 86.0 | 69.0 | 76.6 | 87.0 | 68.9 | 70.5 | 71.0 |

| Sample | Filler Material | Filler Fraction (%) | Young’s Modulus (MPa) | Ultimate Tensile Strength (MPa) | Elongation at Fracture (%) |

|---|---|---|---|---|---|

| neat | --- | --- | 58.7 ± 8.8 | 7.20 ± 1.35 | 159.5 ± 21.3 |

| MM1 | Oxid. GNPs | 0.7 | 103.6 ± 6.6 | 8.50 ± 0.44 | 139.2 ± 8.0 |

| MM2 | 3.0 | 137.2 ± 11.9 | 10.33 ± 0.93 | 180.2 ± 6.4 | |

| MM3 | 5.3 | 188.0 ± 8.8 | 11.18 ± 0.87 | 150.1 ± 8.0 | |

| MM4 | Raw GNPs | 0.7 | 117.0 ± 0.7 | 7.62 ± 0.94 | 155.5 ± 3.3 |

| MM5 | 3.0 | 132.0 ± 2.9 | 8.86 ± 0.64 | 137.7 ± 12.9 | |

| MM6 | 5.3 | 154.8 ± 14.6 | 10.47 ± 0.93 | 145.0 ± 11.9 | |

| MM7 | Plasma MWCNTs | 0.7 | 87.3 ± 0.8 | 7.46 ± 0.45 | 226.0 ± 11.2 |

| MM8 | 3.0 | 119.3 ± 11.1 | 8.61 ± 0.37 | 249.0 ± 7.0 | |

| MM9 | 5.3 | 135.6 ± 7.1 | 8.89 ± 0.48 | 261.7 ± 17.2 | |

| MM10 | Raw MWCNTs | 0.7 | 87.0 ± 9.5 | 7.40 ± 0.32 | 210.8 ± 14.2 |

| MM11 | 3.0 | 91.0 ± 8.2 | 7.53 ± 0.32 | 164.5 ± 8.7 | |

| MM12 | 5.3 | 108.4 ± 10.6 | 7.84 ± 0.35 | 152.0 ± 10.4 |

| Sample | Filler Material | % Concentr. | CO2 Permeability (Barrer) at | CO2/CH4 Selectivity at | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.3 | 2 | 3 | 4 | 5 (bar) | 1.3 | 2 | 3 | 4 | 5 (bar) | |||

| neat | --- | --- | 87.6 | 80.5 | 77.4 | 76.5 | 80.4 | 20.2 | 19.7 | 19.6 | 18.4 | 16.0 |

| MM1 | Oxid. GNPs | 0.7 | 76.5 | 74.8 | 73.6 | 73.4 | 71.4 | 19.3 | 19.0 | 18.4 | 18.5 | 18.0 |

| MM2 | 3.0 | 127.8 | 126.8 | 128.0 | 126.6 | 123.1 | 19.6 | 19.2 | 18.9 | 18.0 | 17.6 | |

| MM3 | 5.3 | 95.3 | 95.6 | 100.2 | 101.8 | 99.9 | 18.8 | 18.6 | 19.1 | 19.1 | 18.2 | |

| MM4 | Raw GNPs | 0.7 | 70.1 | 71.7 | 74.0 | 70.2 | 67.7 | 19.0 | 19.7 | 19.0 | 18.4 | 18.0 |

| MM5 | 3.0 | 91.4 | 91.0 | 92.4 | 91.2 | 91.8 | 19.2 | 19.7 | 19.3 | 19.2 | 18.7 | |

| MM6 | 5.3 | 98.1 | 96.7 | 98.4 | 95.1 | 90.6 | 20.2 | 19.4 | 19.1 | 18.5 | 17.8 | |

| MM7 | Plasma MWCNTs | 0.7 | 95.6 | 85.0 | 82.7 | 85.9 | 86.9 | 19.9 | 18.4 | 17.8 | 18.4 | 18.0 |

| MM8 | 3.0 | 151.6 | 148.9 | 145.9 | 140.0 | 135.6 | 18.7 | 18.9 | 18.4 | 17.7 | 16.8 | |

| MM9 | 5.3 | 118.4 | 106.2 | 107.4 | 104.5 | 103.3 | 20.2 | 18.1 | 18.2 | 17.2 | 17.0 | |

| MM10 | Raw MWCNTs | 0.7 | 113.4 | 108.9 | 103.8 | 105.4 | 98.7 | 20.5 | 19.9 | 19.0 | 18.9 | 17.7 |

| MM11 | 3.0 | 270.3 | 285.1 | 293.8 | 383.7 | 375.1 | 20.5 | 20.2 | 21.7 | 22.7 | 21.9 | |

| MM12 | 5.3 | 133.3 | 95.2 | 100.5 | 102.2 | 102.7 | 21.0 | 20.0 | 20.1 | 19.7 | 19.6 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasileiou, A.N.; Theodorakopoulos, G.V.; Karousos, D.S.; Bouroushian, M.; Sapalidis, A.A.; Favvas, E.P. Nanocarbon-Based Mixed Matrix Pebax-1657 Flat Sheet Membranes for CO2/CH4 Separation. Membranes 2023, 13, 470. https://doi.org/10.3390/membranes13050470

Vasileiou AN, Theodorakopoulos GV, Karousos DS, Bouroushian M, Sapalidis AA, Favvas EP. Nanocarbon-Based Mixed Matrix Pebax-1657 Flat Sheet Membranes for CO2/CH4 Separation. Membranes. 2023; 13(5):470. https://doi.org/10.3390/membranes13050470

Chicago/Turabian StyleVasileiou, Athanasios N., George V. Theodorakopoulos, Dionysios S. Karousos, Mirtat Bouroushian, Andreas A. Sapalidis, and Evangelos P. Favvas. 2023. "Nanocarbon-Based Mixed Matrix Pebax-1657 Flat Sheet Membranes for CO2/CH4 Separation" Membranes 13, no. 5: 470. https://doi.org/10.3390/membranes13050470

APA StyleVasileiou, A. N., Theodorakopoulos, G. V., Karousos, D. S., Bouroushian, M., Sapalidis, A. A., & Favvas, E. P. (2023). Nanocarbon-Based Mixed Matrix Pebax-1657 Flat Sheet Membranes for CO2/CH4 Separation. Membranes, 13(5), 470. https://doi.org/10.3390/membranes13050470