Evaluation of Different Reverse Osmosis Membranes for Textile Dyeing and Finishing Wastewater Reuse

Abstract

1. Introduction

2. Materials and Methods

2.1. Lab-Scale RO Setup and RO Membranes

2.2. Wastewater Sample and Analytical Methods

2.3. Batch RO Tests and Analytical Methods

3. Results and Discussion

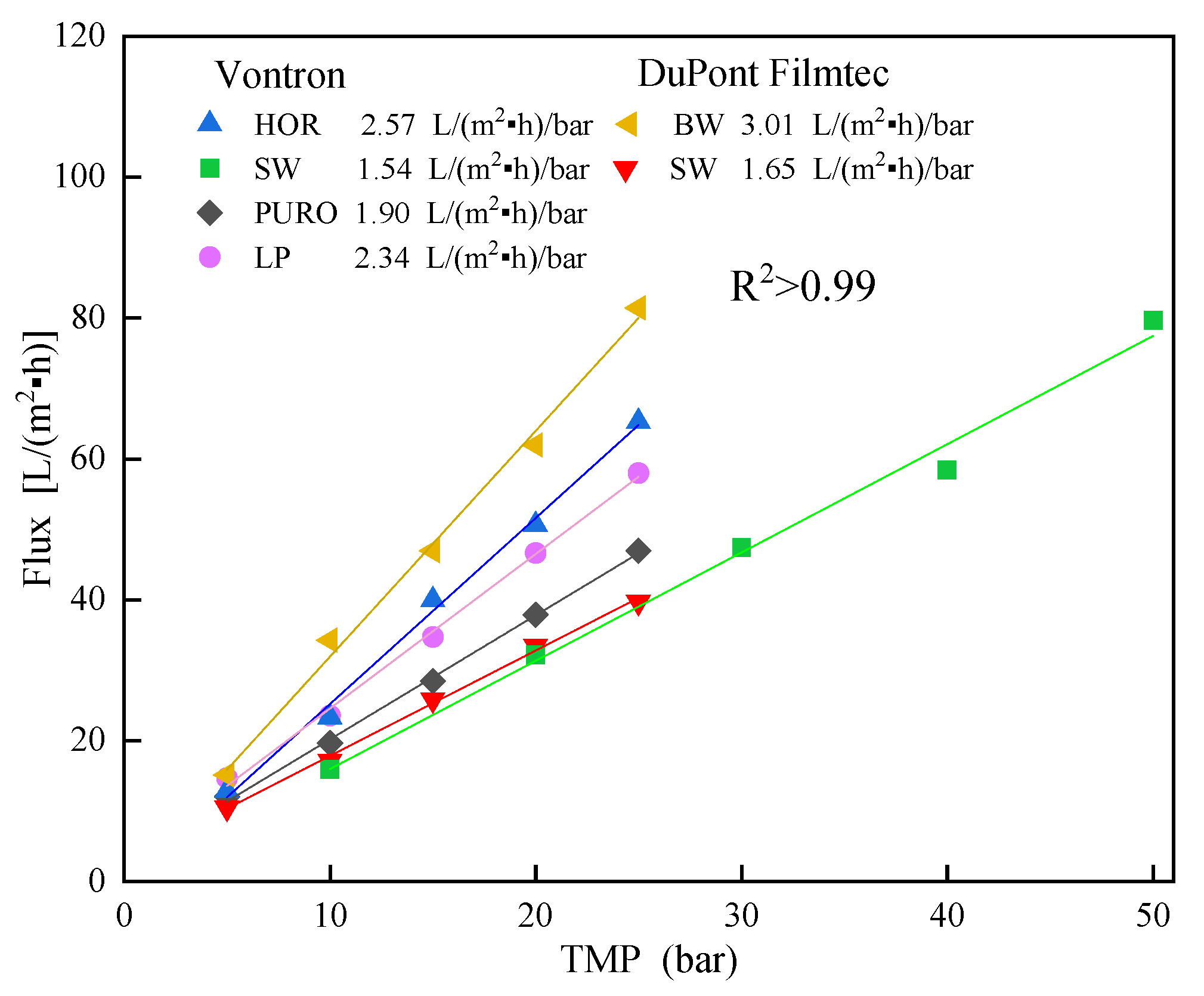

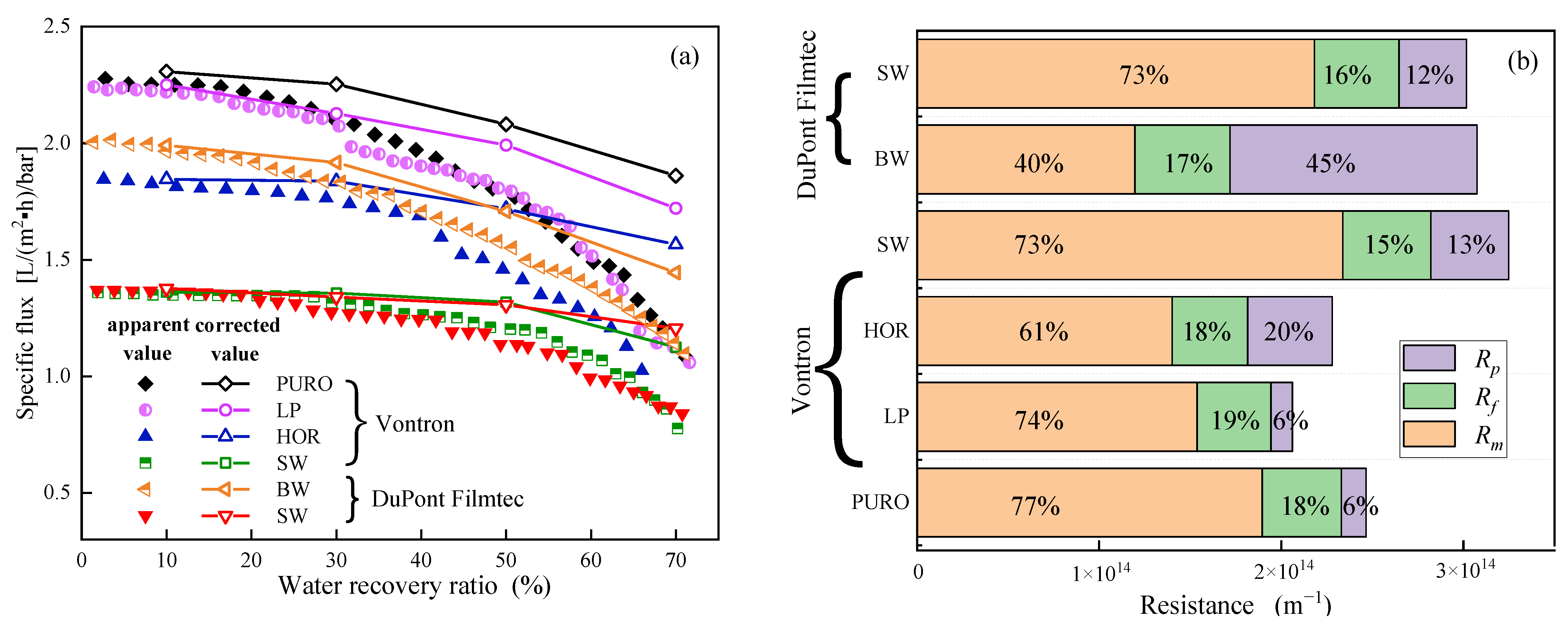

3.1. Candidate RO Membranes Selection via Single Batch Test for TDFW reuse in Phase 1

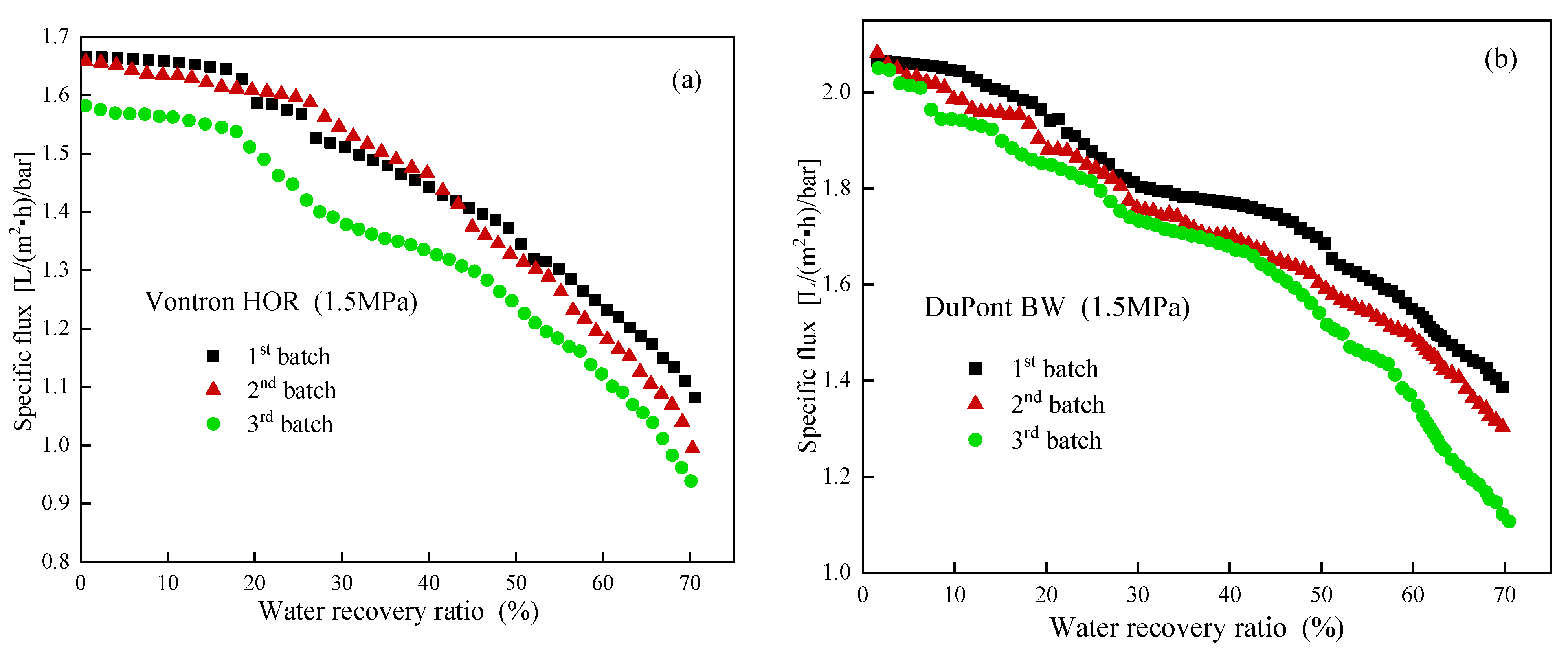

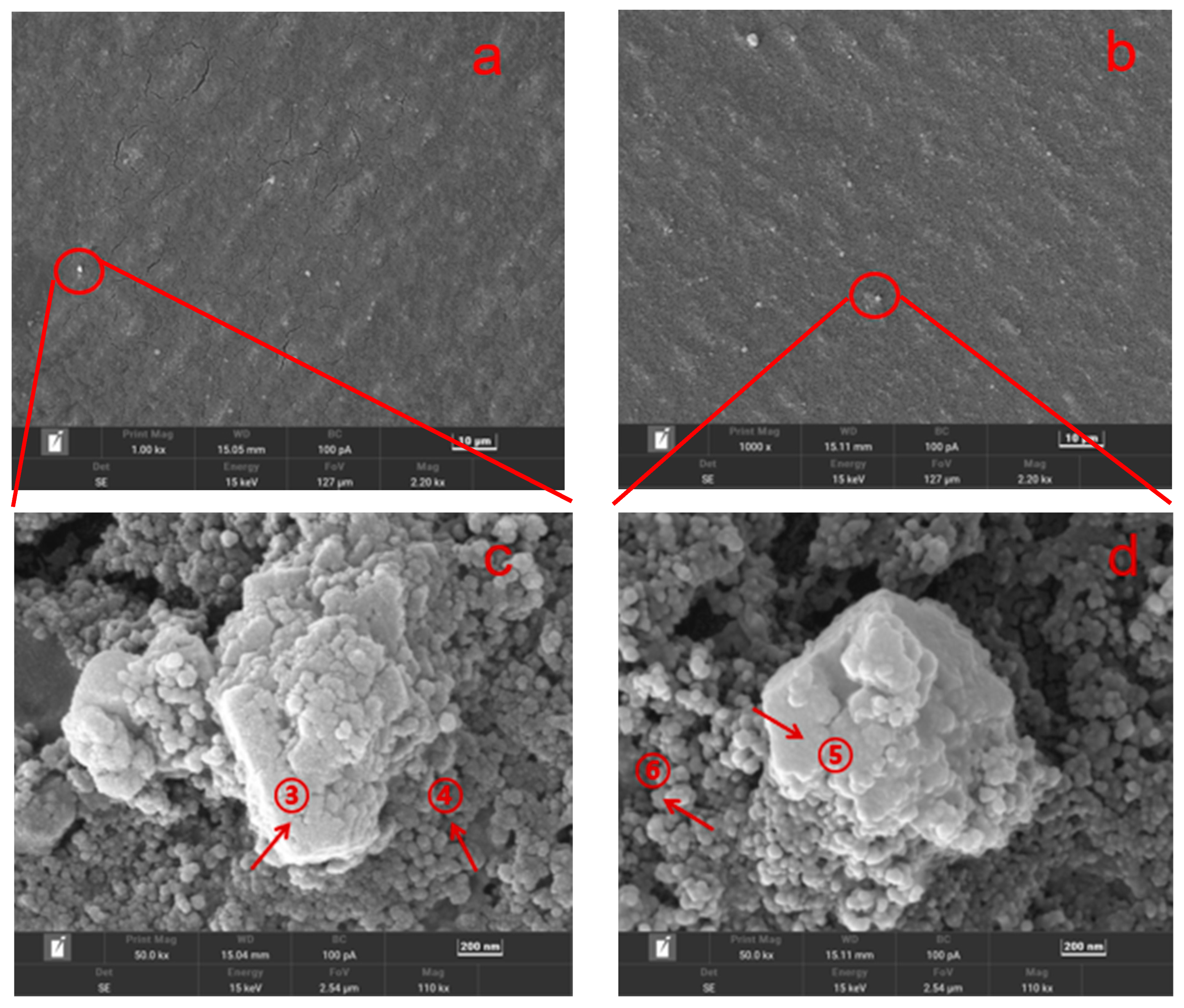

3.2. Reproducibility and Fouling Development of Candidate RO Membranes in Phase 2

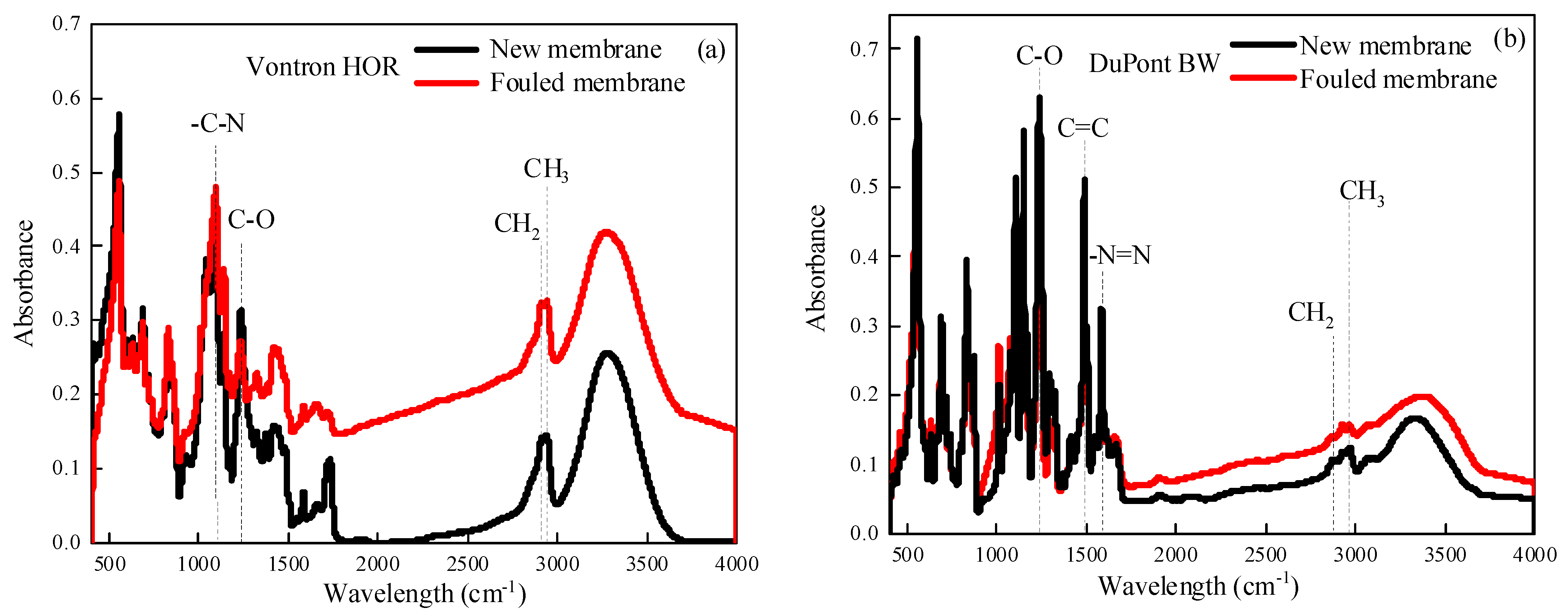

3.3. Parameters Optimization for Candidate RO Membranes via Orthogonal Tests in Phase 3

3.4. Performance of Candidate RO Membranes with the Optimal Parameters in Phase 4

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Biesheuvel, P.M.; Porada, S.; Elimelech, M.; Dykstra, J.E. Tutorial review of reverse osmosis and electrodialysis. J. Membr. Sci. 2022, 647, 120221. [Google Scholar] [CrossRef]

- Moossa, B.; Trivedi, P.; Saleem, H.; Zaidi, S.J. Desalination in the GCC countries—A review. J. Clean. Prod. 2022, 357, 131717. [Google Scholar] [CrossRef]

- Honarparvar, S.; Zhang, X.; Chen, T.Y.; Alborzi, A.; Afroz, K.; Reible, D. Frontiers of Membrane Desalination Processes for Brackish Water Treatment: A Review. Membranes 2021, 11, 246. [Google Scholar] [CrossRef]

- Zheng, X.; Wen, J.; Shi, L.; Cheng, R.; Zhang, Z. A top-down approach to estimate global RO desalination water production considering uncertainty. Desalination 2020, 488, 114523. [Google Scholar] [CrossRef]

- Yang, J.Q.; Monnot, M.; Ercolei, L.; Moulin, P. Membrane-Based Processes Used in Municipal Wastewater Treatment for Water Reuse: State-of-the-Art and Performance Analysis. Membranes 2020, 10, 131. [Google Scholar] [CrossRef]

- Jeffrey, P.; Yang, Z.; Judd, S.J. The status of potable water reuse implementation. Water Res. 2022, 214, 118198. [Google Scholar] [CrossRef]

- Date, M.; Patyal, V.; Jaspal, D.; Malviya, A.; Khare, K. Zero liquid discharge technology for recovery, reuse, and reclamation of wastewater: A critical review. J. Water Process Eng. 2022, 49, 103129. [Google Scholar] [CrossRef]

- Lim, Y.J.; Goh, K.; Kurihara, M.; Wang, R. Seawater desalination by reverse osmosis: Current development and future challenges in membrane fabrication ? A review. J. Membr. Sci. 2021, 629, 119292. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Z.; Liu, L.; Cheng, R.; Shi, L.; Zheng, X. RO applications in China: History, current status, and driving forces. Desalination 2016, 397, 185–193. [Google Scholar] [CrossRef]

- Liu, L.; Cheng, R.; Chen, X.; Zheng, X.; Shi, L.; Cao, D.; Zhang, Z. Applications of membrane technology in treating wastewater from the dyeing industry in China: Current status and prospect. Desalin. Water Treat. 2017, 77, 366–376. [Google Scholar] [CrossRef]

- Shi, J.X.; Huang, W.P.; Han, H.J.; Xu, C.Y. Review on treatment technology of salt wastewater in coal chemical industry of China. Desalination 2020, 493, 114640. [Google Scholar] [CrossRef]

- Lin, S.S.; Zhao, H.Y.; Zhu, L.P.; He, T.; Chen, S.F.; Gao, C.J.; Zhang, L. Seawater desalination technology and engineering in China: A review. Desalination 2021, 498, 114728. [Google Scholar] [CrossRef]

- Ruan, G.L.; Wang, M.; An, Z.H.; Xu, G.R.; Ge, Y.H.; Zhao, H.L. Progress and Perspectives of Desalination in China. Membranes 2021, 11, 206. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.W.; Wu, Y.H.; Luo, L.W.; Li, G.L.; Li, Y.B.; Hu, H.Y. Application of disk tube reverse osmosis in wastewater treatment: A review. Sci. Total Environ. 2021, 792, 148291. [Google Scholar] [CrossRef] [PubMed]

- Ray, H.; Perreault, F.; Boyer, T.H. Ammonia recovery and fouling mitigation of hydrolyzed human urine treated by nanofiltration and reverse osmosis. Environ. Sci.-Water Res. 2022, 8, 429–442. [Google Scholar] [CrossRef]

- Gunes, E.; Gonder, Z.B. Evaluation of the hybrid system combining electrocoagulation, nanofiltration and reverse osmosis for biologically treated textile effluent: Treatment efficiency and membrane fouling. J. Environ. Manag. 2021, 294, 113042. [Google Scholar] [CrossRef]

- Qrenawi, L.I.; Abuhabib, A.A. A review on sources, types, mechanisms, characteristics, impacts and control strategies of fouling in RO membrane systems. Desalin. Water Treat. 2020, 208, 43–69. [Google Scholar] [CrossRef]

- Zhou, C.Q.; Gu, H.K.; Wei, C.H.; Rong, H.W.; Ng, H.Y. Dyeing and finishing wastewater treatment via a low-cost hybrid process of hydrolysis-acidification and alternately anoxic/oxic sequencing batch reactor with synchronous coagulation. J. Water Process Eng. 2022, 49, 12. [Google Scholar] [CrossRef]

- Ouyang, R.L.; Huang, B.; Wei, C.H.; Rong, H.W.; Yu, H.R.; Qu, F.S.; Xiao, K.; Huang, X. Cake Layer Fouling Potential Characterization for Wastewater Reverse Osmosis via Gradient Filtration. Membranes 2022, 12, 810. [Google Scholar] [CrossRef]

- Rice, E.W.; Baird, R.B.; Eaton, A.D. (Eds.) Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association, American Water Works Association, Water Environment Federation: Washington, DC, USA, 2017. [Google Scholar]

- Chen, R.F.; Liu, T.; Rong, H.W.; Zhong, H.T.; Wei, C.H. Effect of Organic Substances on Nutrients Recovery by Struvite Electrochemical Precipitation from Synthetic Anaerobically Treated Swine Wastewater. Membranes 2021, 11, 594. [Google Scholar] [CrossRef]

- Yu, H.R.; Shangguan, S.Y.; Xie, C.Y.; Yang, H.Y.; Wei, C.H.; Rong, H.W.; Qu, F.S. Chemical Cleaning and Membrane Aging in MBR for Textile Wastewater Treatment. Membranes 2022, 12, 704. [Google Scholar] [CrossRef] [PubMed]

- Thirugnanasambandham, K.; Sivakumar, V.; Shine, K. Optimization of reverse osmosis treatment process to reuse the distillery wastewater using Taguchi design. Desalin. Water Treat. 2016, 57, 24222–24230. [Google Scholar] [CrossRef]

- Li, M. A spatiotemporal model for dynamic RO simulations. Desalination 2021, 516, 115229. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Z.; Yan, B.; Yin, S.; Mao, Y.; Liu, Y.; Feng, L.; Zhang, L. Utilization of reverse osmosis concentrated brine to produce novel excellent deicers: Critical assessment of deicing performance and environmental impact. Sep. Purif. Technol. 2023, 312, 123362. [Google Scholar] [CrossRef]

- AlSawaftah, N.; Abuwatfa, W.; Darwish, N.; Husseini, G. A Comprehensive Review on Membrane Fouling: Mathematical Modelling, Prediction, Diagnosis, and Mitigation. Water 2021, 13, 1327. [Google Scholar] [CrossRef]

- Alshami, A.; Taylor, T.; Ismail, N.; Buelke, C.; Schultz, L. RO system scaling with focus on the concentrate line: Current challenges and potential solutions. Desalination 2021, 520, 115370. [Google Scholar] [CrossRef]

- Karabelas, A.J.; Mitrouli, S.T.; Kostoglou, M. Scaling in reverse osmosis desalination plants: A perspective focusing on development of comprehensive simulation tools. Desalination 2020, 474, 114193. [Google Scholar] [CrossRef]

- Vatanpour, V.; Sanadgol, A. Surface modification of reverse osmosis membranes by grafting of polyamidoamine dendrimer containing graphene oxide nanosheets for desalination improvement. Desalination 2020, 491, 114442. [Google Scholar] [CrossRef]

| Manufacturer | Model Name | Specific Pure Water Flux at 20 °C [L/(m2·h)/bar] | Pure Membrane Resistance (×1014 m−1) | Na+ Rejection Ratio (%) | Mg2+ Rejection Ratio (%) |

|---|---|---|---|---|---|

| Vontron | PURO | 1.90 | 1.90 | 99.18 | 99.81 |

| LP | 2.34 | 1.54 | 98.51 | 99.71 | |

| HOR | 2.57 | 1.40 | 98.98 | 99.76 | |

| SW | 1.54 | 2.34 | 98.89 | 99.76 | |

| DuPont Filmtec | BW | 3.01 | 1.20 | 96.30 | 98.46 |

| SW | 1.65 | 2.18 | 98.75 | 99.34 |

| Water Type | pH | COD (mg/L) | TOC (mg/L) | SS (mg/L) | Chroma (Dilution Times) | Fe (mg/L) | Mn (mg/L) | Total Hardness as CaCO3 (mg/L) | Conductivity (ms/cm) |

|---|---|---|---|---|---|---|---|---|---|

| MBR effluent | 8.84 | 71.6 | 14.3 | 0 | 90 | 6 | 0.4 | 310.8 | 5.22 |

| Reuse water | 6.5–8.5 | ≤50 | - | ≤30 | ≤25 | ≤0.3 | ≤0.2 | ≤450 | ≤2.5 |

| Manufacturer | Model Name | pH | COD (mg/L) | TOC (mg/L) | SS (mg/L) | Chroma (Dilution Times) | Fe (mg/L) | Mn (mg/L) | Total Hardness as CaCO3 (mg/L) | Conductivity (mS/cm) |

|---|---|---|---|---|---|---|---|---|---|---|

| Vontron | PURO | 7.20 | 2.5 | 0.37 | 0 | 1 | 0.019 | 0.003 | 2.45 | 0.173 |

| LP | 7.88 | 4.6 | 0.60 | 0 | 1 | 0.020 | 0.002 | 4.27 | 0.388 | |

| HOR | 7.98 | 1.9 | 0.26 | 0 | 1 | 0.029 | 0.003 | 2.96 | 0.185 | |

| SW | 7.95 | 1.5 | 0.19 | 0 | 1 | 0.018 | 0.005 | 3.35 | 0.202 | |

| DuPont Filmtec | BW | 8.04 | 3.3 | 0.50 | 0 | 1 | 0.082 | 0.006 | 5.55 | 0.344 |

| SW | 7.99 | 3.1 | 0.47 | 0 | 1 | 0.088 | 0.006 | 3.17 | 0.319 |

| Vontron HOR RO Membrane | DuPont Filmtec BW RO Membrane | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Point Scanning ③ | Point Scanning ④ | Aera Scanning | Point Scanning ⑤ | Point Scanning ⑥ | Aera Scanning | ||||||

| Element | wt% | Element | wt% | Element | wt% | Element | wt% | Element | wt% | Element | wt% |

| O | 43.14 | C | 43.60 | C | 49.40 | O | 41.43 | C | 65.72 | C | 58.32 |

| C | 26.95 | O | 24.54 | O | 24.8 | C | 26.91 | O | 20.41 | O | 21.78 |

| Ca | 16.80 | Fe | 12.73 | Fe | 6.99 | Ca | 22.86 | Fe | 3.97 | Ca | 4.44 |

| Fe | 3.80 | Al | 5.74 | Ca | 5.30 | Fe | 2.03 | Na | 2.51 | Fe | 3.75 |

| Al | 3.02 | Si | 5.52 | Al | 4.30 | Na | 1.96 | Cl | 1.84 | Na | 2.61 |

| Si | 2.64 | Na | 3.68 | Si | 3.93 | N | 1.16 | Al | 1.75 | Cl | 2.29 |

| Na | 2.17 | Ca | 1.80 | Na | 2.64 | Al | 1.20 | Si | 1.53 | Al | 2.04 |

| Cl | 0.41 | Cl | 0.98 | Cl | 0.81 | Si | 0.95 | Mn | 0.76 | N | 1.87 |

| Mg | 0.33 | N | 0.55 | N | 0.67 | Cl | 0.84 | Ca | 0.64 | Si | 1.74 |

| Mn | 0.30 | K | 0.36 | S | 0.63 | Mg | 0.34 | K | 0.48 | Mn | 0.37 |

| Zn | 0.27 | Cu | 0.25 | K | 0.22 | Mn | 0.28 | Mg | 0.39 | S | 0.35 |

| K | 0.19 | Mg | 0.21 | Mg | 0.21 | K | 0.04 | K | 0.22 | ||

| Zn | 0.04 | Mn | 0.05 | Mg | 0.12 | ||||||

| Zn | 0.05 | Cu | 0.08 | ||||||||

| Test No. | Operational Parameters | Operational Performance of Vontron HOR RO Membrane | Operational Performance of DuPont Filmtec BW RO Membrane | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TMP (MPa) | CFV (m/s) | T (°C) | WRR (%) | TOCr (%) | Condr (%) | Jf/Ji (%) | TOCr (%) | Condr (%) | Jf/Ji (%) | |

| 1 | 2 | 0.5 | 20 | 60 | 81.95 | 82.93 | 78.86 | 97.69 | 97.37 | 70.88 |

| 2 | 2 | 1 | 25 | 70 | 99.85 | 99.32 | 71.93 | 79.27 | 80.56 | 62.61 |

| 3 | 2 | 1.5 | 30 | 80 | 99.23 | 98.86 | 45.29 | 77.49 | 77.69 | 49.56 |

| 4 | 3 | 0.5 | 25 | 80 | 79.94 | 79.86 | 53.37 | 74.95 | 76.78 | 55.71 |

| 5 | 3 | 1 | 30 | 60 | 86.15 | 87.20 | 82.17 | 78.48 | 80.14 | 77.50 |

| 6 | 3 | 1.5 | 20 | 70 | 99.83 | 99.54 | 70.17 | 94.22 | 93.60 | 66.84 |

| 7 | 4 | 0.5 | 30 | 70 | 89.14 | 87.79 | 67.13 | 85.04 | 82.78 | 71.90 |

| 8 | 4 | 1 | 20 | 80 | 87.11 | 85.93 | 59.70 | 89.34 | 80.98 | 70.66 |

| 9 | 4 | 1.5 | 25 | 60 | 85.79 | 86.82 | 81.46 | 88.07 | 87.56 | 71.71 |

| Performance Index | Operational Parameters | Summary | ||||

|---|---|---|---|---|---|---|

| TMP | CFV | T | WRR | |||

| TOCr (%) | A1 | 93.68 | 83.68 | 89.63 | 84.63 | Quantitative impact order: WRR ≥ CFV > TMP > T Optimal parameters: WRR 70%, CFV 1.5 m/s, TMP 2 MPa, T 30 °C |

| A2 | 88.64 | 91.03 | 88.53 | 96.27 | ||

| A3 | 87.34 | 94.95 | 91.51 | 88.76 | ||

| R | 6.33 | 11.28 | 2.98 | 11.64 | ||

| Condr (%) | A1 | 93.70 | 83.52 | 89.47 | 85.65 | Quantitative impact order: CFV > WRR > TMP > T Optimal parameters: CFV 1.5 m/s, WRR 70%, TMP 2 MPa, T 30 °C |

| A2 | 88.87 | 90.82 | 88.67 | 95.55 | ||

| A3 | 86.84 | 95.07 | 91.28 | 88.22 | ||

| R | 6.86 | 11.55 | 2.62 | 9.90 | ||

| Jf/Ji (%) | A1 | 65.36 | 66.46 | 69.58 | 80.83 | Quantitative impact order: WRR >> CFV > T > TMP Optimal parameters: WRR 60%, CFV 1.0 m/s, T 20 °C, TMP 4 MPa |

| A2 | 68.57 | 71.27 | 68.92 | 69.74 | ||

| A3 | 69.43 | 65.64 | 64.86 | 52.79 | ||

| R | 4.07 | 5.62 | 4.71 | 28.04 | ||

| P (%) | A1 | 79.52 | 75.03 | 79.56 | 82.99 | Quantitative impact order: WRR > CFV > T ≥ TMP Optimal parameters: WRR 60%, CFV 1.0 m/s, T 20 °C, TMP 2 MPa |

| A2 | 78.66 | 81.10 | 78.76 | 82.83 | ||

| A3 | 78.26 | 80.33 | 78.13 | 70.64 | ||

| R | 1.26 | 6.07 | 1.43 | 12.35 | ||

| Performance Index | Operational Parameters | Summary | ||||

|---|---|---|---|---|---|---|

| TMP | CFV | T | WRR | |||

| TOCr (%) | A1 | 84.82 | 85.89 | 93.75 | 88.08 | Quantitative impact order: T > WRR > TMP > CFV Optimal parameters: T 20 °C, WRR 60%, TMP 4 MPa, CFV 1.5 m/s |

| A2 | 82.55 | 82.37 | 80.76 | 86.17 | ||

| A3 | 87.49 | 86.59 | 80.34 | 80.60 | ||

| R | 4.94 | 4.23 | 13.41 | 7.49 | ||

| Condr (%) | A1 | 85.21 | 85.64 | 90.65 | 88.36 | Quantitative impact order: T ≥ WRR > CFV > TMP Optimal parameters: T 20 °C, WRR 60%, CFV 1.5 m/s, TMP 2 MPa |

| A2 | 83.50 | 80.56 | 81.63 | 85.64 | ||

| A3 | 83.77 | 86.28 | 80.20 | 78.48 | ||

| R | 1.70 | 5.73 | 10.45 | 9.88 | ||

| Jf/Ji (%) | A1 | 62.07 | 66.16 | 69.46 | 73.36 | Quantitative impact order: WRR > TMP > CFV > T Optimal parameters: WRR 60%, TMP 4 MPa, CFV 1.0 m/s, T 20 °C |

| A2 | 66.68 | 71.31 | 64.40 | 68.17 | ||

| A3 | 71.42 | 62.70 | 66.32 | 58.64 | ||

| R | 9.35 | 8.61 | 5.06 | 14.72 | ||

| P (%) | A1 | 73.54 | 75.97 | 80.83 | 80.79 | Quantitative impact order: WRR > T > TMP > CFV Optimal parameters: WRR 60%, T 20 °C, TMP 4 MPa, CFV 1.0 m/s |

| A2 | 74.85 | 76.39 | 72.80 | 77.04 | ||

| A3 | 78.53 | 74.57 | 73.29 | 69.09 | ||

| R | 4.98 | 1.82 | 8.03 | 11.70 | ||

| Test No. | pH | COD (mg/L) | TOC (mg/L) | Fe (mg/L) | Mn (mg/L) | Total Hardness as CaCO3 (mg/L) | Conductivity (mS/cm) | Jf/Ji (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 8.46 | 25.6 | 3.65 | 0.089 | 0.029 | 2.37 | 2.510 | 78.9 |

| 2 | 7.93 | 0.2 | 0.03 | 0.017 | 0.005 | 1.86 | 0.085 | 71.9 |

| 3 | 7.79 | 0.8 | 0.12 | 0.007 | 0.003 | 1.93 | 0.125 | 45.3 |

| 4 | 8.33 | 21.3 | 3.04 | 0.058 | 0.015 | 2.38 | 2.220 | 53.4 |

| 5 | 8.25 | 19.6 | 2.80 | 0.028 | 0.011 | 2.17 | 1.881 | 82.2 |

| 6 | 7.65 | 0.2 | 0.03 | 0.009 | 0.003 | 1.94 | 0.058 | 70.2 |

| 7 | 8.14 | 13.2 | 1.88 | 0.021 | 0.012 | 2.04 | 1.539 | 67.1 |

| 8 | 8.2 | 13.7 | 1.96 | 0.032 | 0.013 | 2.25 | 1.551 | 59.7 |

| 9 | 8.21 | 20.1 | 2.87 | 0.036 | 0.004 | 2.42 | 1.938 | 81.5 |

| 10 | 7.64 | 0.7 | 0.05 | 0.012 | 0.005 | 1.94 | 0.079 | 82.7 |

| Test No. | pH | COD (mg/L) | TOC (mg/L) | Fe (mg/L) | Mn (mg/L) | Total Hardness as CaCO3 (mg/L) | Conductivity (mS/cm) | Jf/Ji (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 7.73 | 3.3 | 0.47 | 0.042 | 0.007 | 1.69 | 0.386 | 80.3 |

| 2 | 8.41 | 25.2 | 3.59 | 0.05 | 0.017 | 2.60 | 2.450 | 65.8 |

| 3 | 8.56 | 23.9 | 3.42 | 0.05 | 0.016 | 2.73 | 2.460 | 49.6 |

| 4 | 8.41 | 26.6 | 3.80 | 0.055 | 0.022 | 2.91 | 2.560 | 55.7 |

| 5 | 8.34 | 30.5 | 4.35 | 0.057 | 0.016 | 2.47 | 2.920 | 77.5 |

| 6 | 8.08 | 7.0 | 1.05 | 0.023 | 0.006 | 2.16 | 0.807 | 66.8 |

| 7 | 8.35 | 18.2 | 2.59 | 0.037 | 0.012 | 2.36 | 2.170 | 67.0 |

| 8 | 8.34 | 11.3 | 1.62 | 0.047 | 0.014 | 2.04 | 2.097 | 64.9 |

| 9 | 8.05 | 16.9 | 2.41 | 0.046 | 0.007 | 2.13 | 1.828 | 71.7 |

| 10 | 8.10 | 6.9 | 0.84 | 0.055 | 0.006 | 1.94 | 0.704 | 82.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, C.; Lao, Y.; Ouyang, R.; Zhang, G.; Huang, G.; Deng, F.; Tan, Q.; Lin, G.; Zhou, H. Evaluation of Different Reverse Osmosis Membranes for Textile Dyeing and Finishing Wastewater Reuse. Membranes 2023, 13, 420. https://doi.org/10.3390/membranes13040420

Wei C, Lao Y, Ouyang R, Zhang G, Huang G, Deng F, Tan Q, Lin G, Zhou H. Evaluation of Different Reverse Osmosis Membranes for Textile Dyeing and Finishing Wastewater Reuse. Membranes. 2023; 13(4):420. https://doi.org/10.3390/membranes13040420

Chicago/Turabian StyleWei, Chunhai, Yequan Lao, Rulu Ouyang, Guorui Zhang, Guijing Huang, Feilong Deng, Qicheng Tan, Genghao Lin, and Hong Zhou. 2023. "Evaluation of Different Reverse Osmosis Membranes for Textile Dyeing and Finishing Wastewater Reuse" Membranes 13, no. 4: 420. https://doi.org/10.3390/membranes13040420

APA StyleWei, C., Lao, Y., Ouyang, R., Zhang, G., Huang, G., Deng, F., Tan, Q., Lin, G., & Zhou, H. (2023). Evaluation of Different Reverse Osmosis Membranes for Textile Dyeing and Finishing Wastewater Reuse. Membranes, 13(4), 420. https://doi.org/10.3390/membranes13040420