Extraction of Copper from Sulfuric Acid Solutions Based on Pseudo-Liquid Membrane Technology

Abstract

1. Introduction

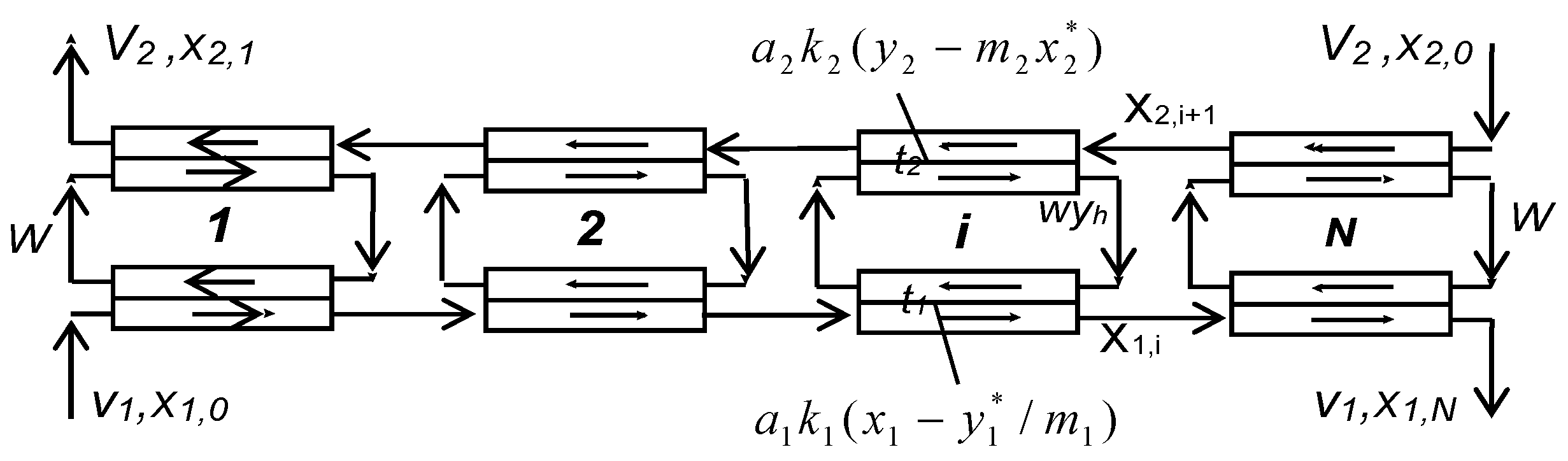

- is the extraction factor; .

2. Materials and Methods

2.1. Reagents

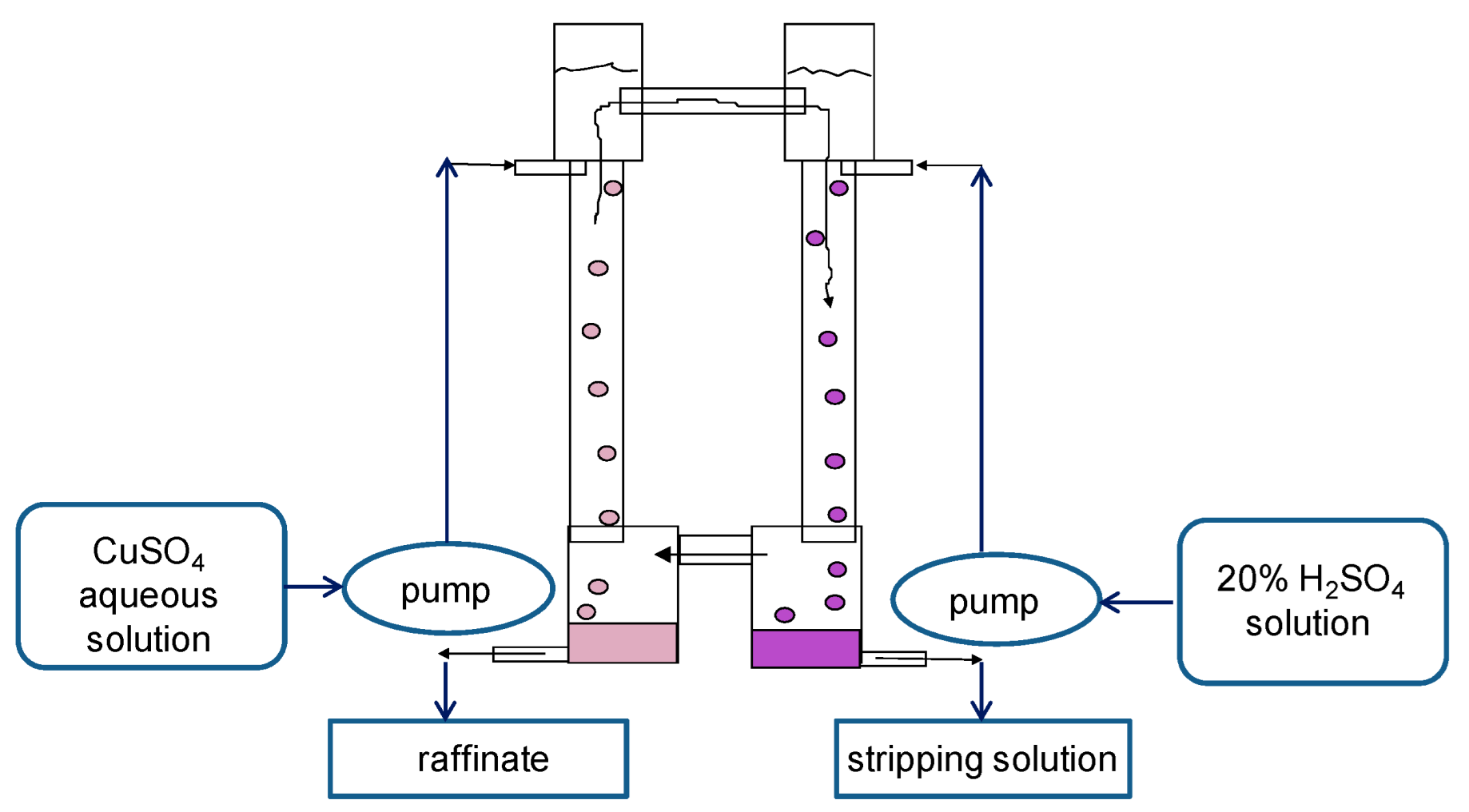

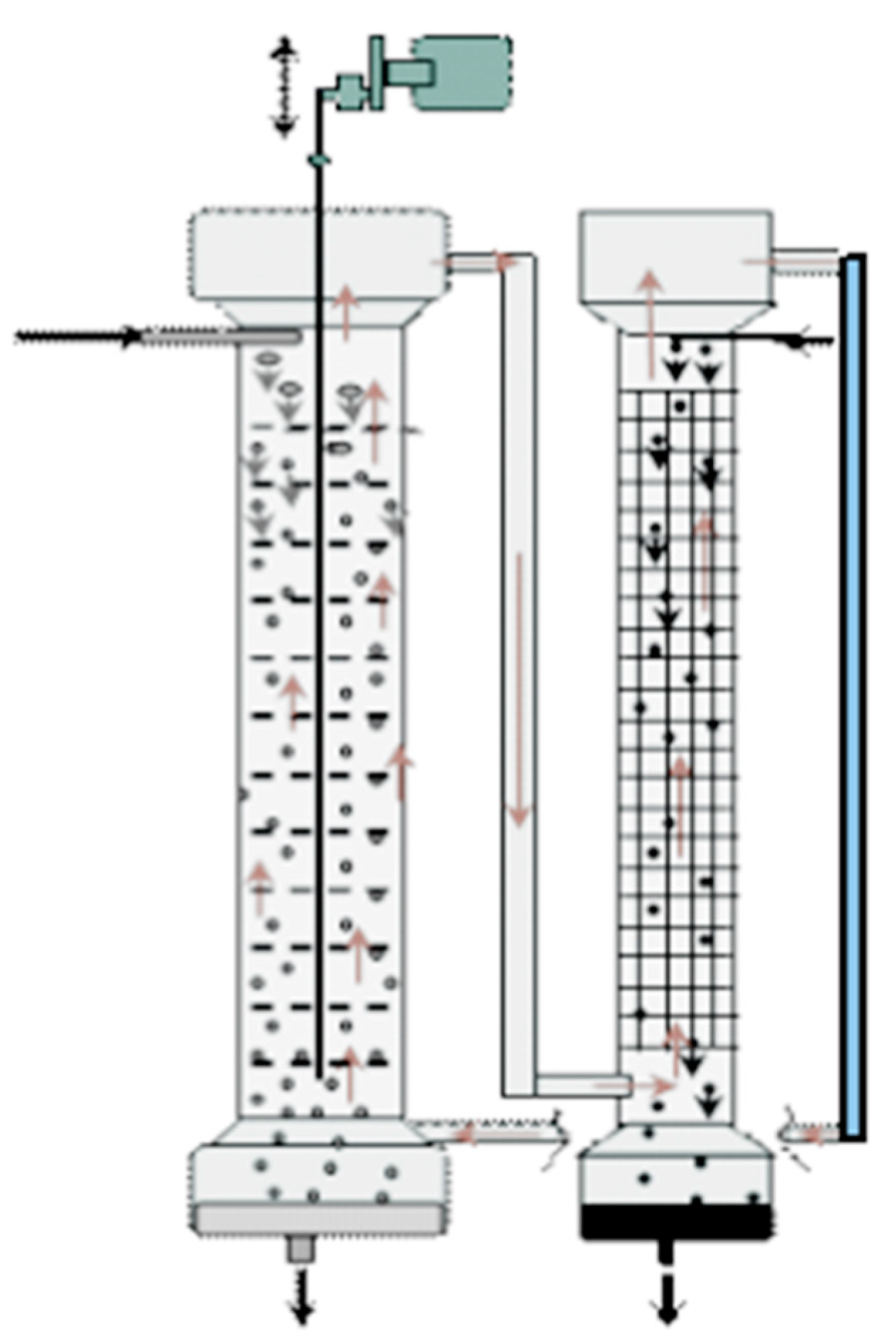

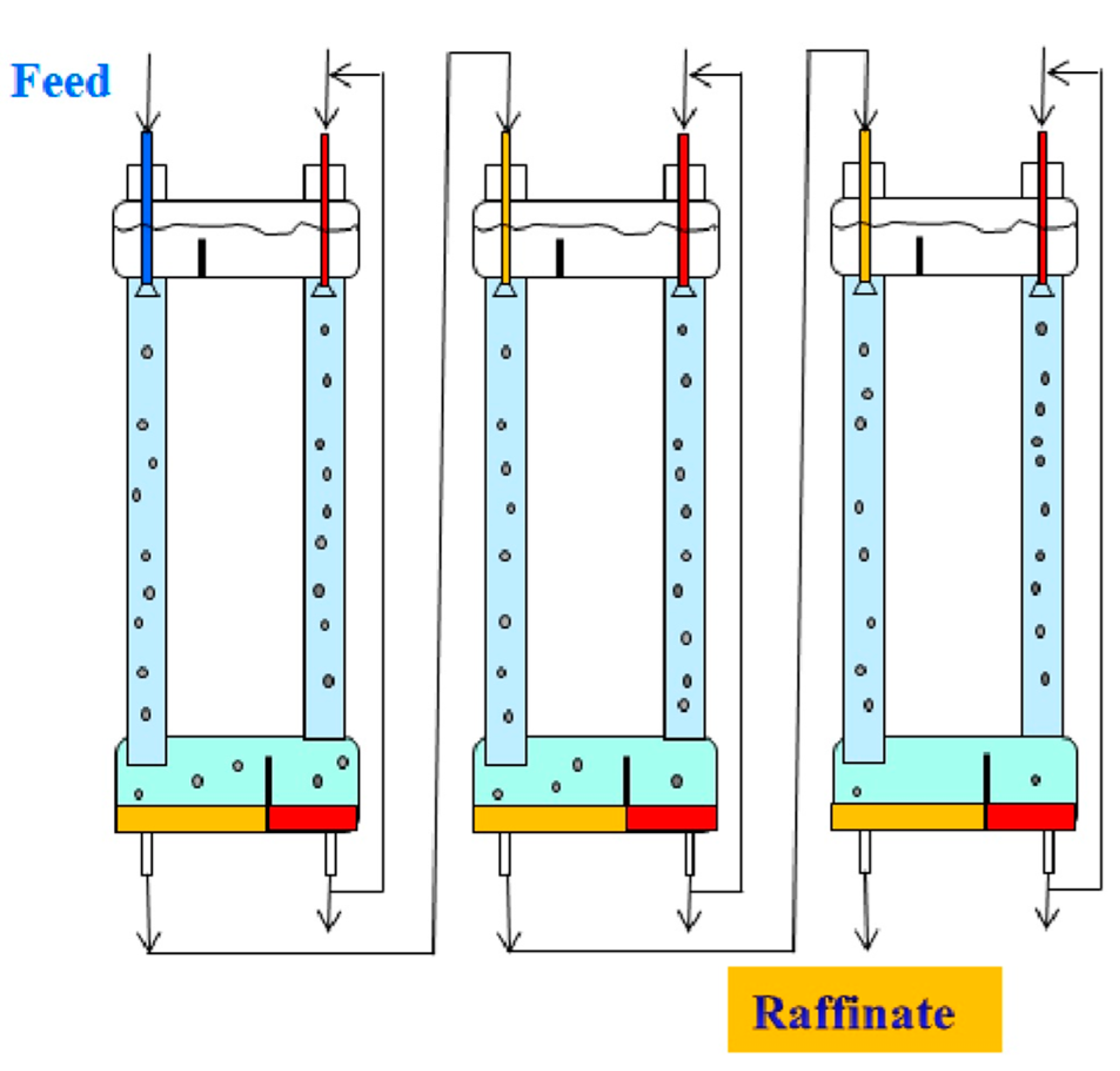

2.2. Apparatuses

2.3. Feed Solutions and Extraction Systems

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

References

- Albu, P.C.; Tanczos, S.-K.; Ferencz (Dinu), A.; Pîrtac, A.; Grosu, A.R.; Pascu, D.; Grosu, V.-A.; Bungău, C.; Nechifor, A.C. pH and design on n–alkyl alcohol bulk liquid membranes for improving phenol derivative transport and separation. Membranes 2022, 12, 365. [Google Scholar] [CrossRef] [PubMed]

- Ferencz (Dinu), A.; Grosu, A.R.; Al-Ani, H.N.A.; Nechifor, A.C.; Tanczos, S.-K.; Albu, P.C.; Crăciun, M.E.; Ioan, M.-R.; Grosu, V.-A.; Nechifor, G. Operational limits of the bulk hybrid liquid membranes based on dispersion systems. Membranes 2022, 12, 190. [Google Scholar] [CrossRef] [PubMed]

- Aldwaish, M.; Kouki, N.; Algreiby, A.; Tar, H.; Tayeb, R.; Hafiane, A. An Ionic supported liquid membrane for the recovery of bisphenol A from aqueous solution. Membranes 2022, 12, 869. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.H. Types of bulk liquid membrane and its membrane resistance in heavy metal removal and recovery from wastewater. Desalination Water Treat. 2016, 57, 19785–19793. [Google Scholar] [CrossRef]

- Wang, B.-Y.; Zhang, N.; Li, Z.-Y.; Lang, Q.-L.; Yan, B.-H.; Liu, Y.; Zhang, Y. Selective separation of acetic and hexanoic acids across polymer inclusion membrane with ionic liquids as carrier. Int. J. Mol. Sci. 2019, 20, 3915. [Google Scholar] [CrossRef] [PubMed]

- Nezhadali, A.; Es’haghi, Z.; Bahar, S.; Banaei, A.; Shiran, J.A. Selective separation of silver(I) ion through a bulk liquid membrane containing 1,1’-(1,3-phenylene)bis(3-allylthiourea) as carrier. J. Braz. Chem. Soc. 2016, 27, 99–108. [Google Scholar] [CrossRef]

- Khalaf, Z.A.; Hassan, A.A. Studying of the effect of many parameters on a bulk liquid membrane and its opposition in Cd(II) removal from wastewater. J. Phys. Conf. Ser. 2021, 1973, 012097. [Google Scholar] [CrossRef]

- Ramkumar, J.; Chandramouleeswaran, S. A perceptive on bulk liquid membrane: A brief review. Indian J. Adv. Chem. Sci. 2015, 3, 293–298. [Google Scholar]

- Singh, R.; Mehta, R.; Kumar, V. Simultaneous removal of copper, nickel and zinc metal ions using bulk liquid membrane system. Desalination 2011, 272, 170–173. [Google Scholar] [CrossRef]

- Alemrajabi, M.; Ricknell, J.; Samak, S.; Varela, R.R.; Martinez, J.; Hedman, F.; Forsberg, K.; Rasmuson, A.C. Separation of rare-earth elements using supported liquid membrane extraction in pilot scale. Ind. Eng. Chem. Res. 2022, 61, 18475–18491. [Google Scholar] [CrossRef]

- Li, L.; Yu, B.; Davis, K.; King, A.; Dal-Cin, M.; Nicalek, A.; Du, N. Separation of neodymium (III) and lanthanum (III) via a flat sheet-supported liquid membrane with different extractant-acid systems. Membranes 2022, 12, 1197. [Google Scholar] [CrossRef] [PubMed]

- Jean, E.; Villemin, D.; Hlaibi, M.; Lebrun, L. Heavy metal ions extraction using new supported liquid membranes containing ionic liquid as carrier. Sep. Purif. Technol. 2018, 201, 1–9. [Google Scholar] [CrossRef]

- Zante, G.; Boltoeva, M.; Masmoudi, A.; Barillon, R.; Trébouet, D. Supported ionic liquid and polymer inclusion membranes for metal separation. Sep. Purif. Rev. 2022, 51, 100–116. [Google Scholar] [CrossRef]

- Naim, M.M.; Moneer, A.A.; Elewa, M.M.; El-Shafei, A.A. Desalination using modified configuration of supported liquid membrane with enhancement of mass transfer of NaCl. Water Sci. Technol. 2019, 79, 175–187. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Sun, Y.; Tang, N.; Miao, C.; Wang, Y.; Tang, L.; Wang, S.; Yang, X. Simultaneous extraction and recovery of gold(I) from alkaline solutions using an environmentally benign polymer inclusion membrane with ionic liquid as the carrier. Sep. Purif. Technol. 2019, 222, 136–144. [Google Scholar] [CrossRef]

- Rzelewska-Piekut, M.; Regel-Rosocka, M. Liquid membranes for separation of metal ions from wastewaters. Phys. Sci. Rev. 2021, 20210049. [Google Scholar] [CrossRef]

- Amini, M.; Rahbar-Kelishami, A.; Alipour, M.; Vahidi, O. Supported liquid membrane in metal ion separation: An overview. J. Membr. Sci. Res. 2018, 4, 121–135. [Google Scholar]

- León, G.; Hidalgo, A.M.; Miguel, B.; Guzmán, M.A. Pertraction of Co(II) through novel ultrasound prepared supported liquid membranes containing D2EHPA. Optimization and transport parameters. Membranes 2020, 10, 436. [Google Scholar] [CrossRef]

- Yang, B.; Bai, L.; Li, T.; Deng, L.; Liu, L.; Zeng, S.; Han, J.; Zhang, X. Super selective ammonia separation through multiple-site interaction with ionic liquid-based hybrid membranes. J. Membr. Sci. 2021, 628, 119264. [Google Scholar] [CrossRef]

- Khan, H.W.; Elgharbawy, A.A.M.; Bustam, M.A.; Goto, M.; Moniruzzaman, M. Ionic liquid-based green emulsion liquid membrane for the extraction of the poorly soluble drug ibuprofen. Molecules 2023, 28, 2345. [Google Scholar] [CrossRef]

- Zamouche, M.; Tahraoui, H.; Laggoun, Z.; Mechati, S.; Chemchmi, R.; Kanjal, M.I.; Amrane, A.; Hadadi, A.; Mouni, L. Optimization and prediction of stability of emulsified liquid membrane (ELM): Artificial neural network. Processes 2023, 11, 364. [Google Scholar] [CrossRef]

- León, G.; Otón, J.; Hidalgo, A.M.; Saavedra, M.I.; Miguel, B. Comparative study of 4-aminophenol removal from aqueous solutions by emulsion liquid membranes using acid and basic type 1 facilitations: Optimisation and kinetics. Membranes 2022, 12, 1213. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Wang, Q.; Zhang, X.; Liu, T.; Zhang, H. Conversion of waste oil from oil refinery into emulsion liquid membrane for removal of phenol: Stability evaluation, modeling and optimization. Membranes 2022, 12, 1202. [Google Scholar] [CrossRef]

- El Batouti, M.; Al-Harby, N.F.; Elewa, M.M. A Review on promising membrane technology approaches for heavy metal removal from water and wastewater to solve water crisis. Water 2021, 13, 3241. [Google Scholar] [CrossRef]

- Naim, M.M.; Moneer, A.A.; El-Shafei, A.A.; Elewa, M.M. Automated prototype for desalination by emulsion liquid membrane technique. Desalin. Water Treat. 2017, 73, 164–174. [Google Scholar] [CrossRef]

- León, G.; Gómez, E.; Miguel, B.; Hidalgo, A.M.; Gómez, M.; Murcia, M.D.; Guzmá, M.A. Feasibility of adsorption kinetic models to study carrier-mediated transport of heavy metal ions in emulsion liquid membranes. Membranes 2022, 12, 66. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Kusumastutib, A.; Derek, C.J.C.; Ooi, B.S. Emulsion liquid membrane for heavy metal removal: An overview on emulsion stabilization and destabilization. Chem. Eng. J. 2011, 171, 870–882. [Google Scholar] [CrossRef]

- León, L.; León, G.; Senent, J.; Pérez-Sirvent, C. Optimization of copper removal from aqueous solutions using emulsion liquid membranes with benzoylacetone as a carrier. Metals 2017, 7, 19. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Shafie, Z.M.; Zaulkiflee, N.D.; Pang, W.Y. Preliminary Study of emulsion liquid membrane formulation on acetaminophen removal from the aqueous phase. Membranes 2019, 9, 133. [Google Scholar] [CrossRef]

- Kohli, H.P.; Gupta, S.; Chakraborty, M. Extraction of Ethylparaben by emulsion liquid membrane: Statistical analysis of operating parameters. Colloids Surf. A Physicochem. Eng. Asp. 2018, 539, 371–381. [Google Scholar] [CrossRef]

- Seifollahi, Z.; Rahbar-Kelishami, A. Diclofenac extraction from aqueous solution by an emulsion liquid membrane: Parameter study and optimization using the response surface methodology. J. Mol. Liq. 2017, 231, 1–10. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Atiya, M.A.; Hussein, M.A. Removal of antibiotic tetracycline using nano-fluid emulsion liquid membrane: Breakage, extraction and studies. Colloids Surf. A Physicochem. Eng. Asp. 2020, 595, 124680. [Google Scholar] [CrossRef]

- Al-Ani, F.H.; Alsalhy, Q.F.; Al-Dahhan, M. Enhancing emulsion liquid membrane system (ELM) stability and performance for the extraction of phenol from wastewater using various nanoparticles. Desalination Water Treat. 2021, 210, 180–191. [Google Scholar] [CrossRef]

- Björkegren, S.; Karimi, R.F.; Martinelli, A.; Jayakumar, N.S.; Hashim, M.A. A New emulsion liquid membrane based on a palm oil for the extraction of heavy metals. Membranes 2015, 5, 168–179. [Google Scholar] [CrossRef]

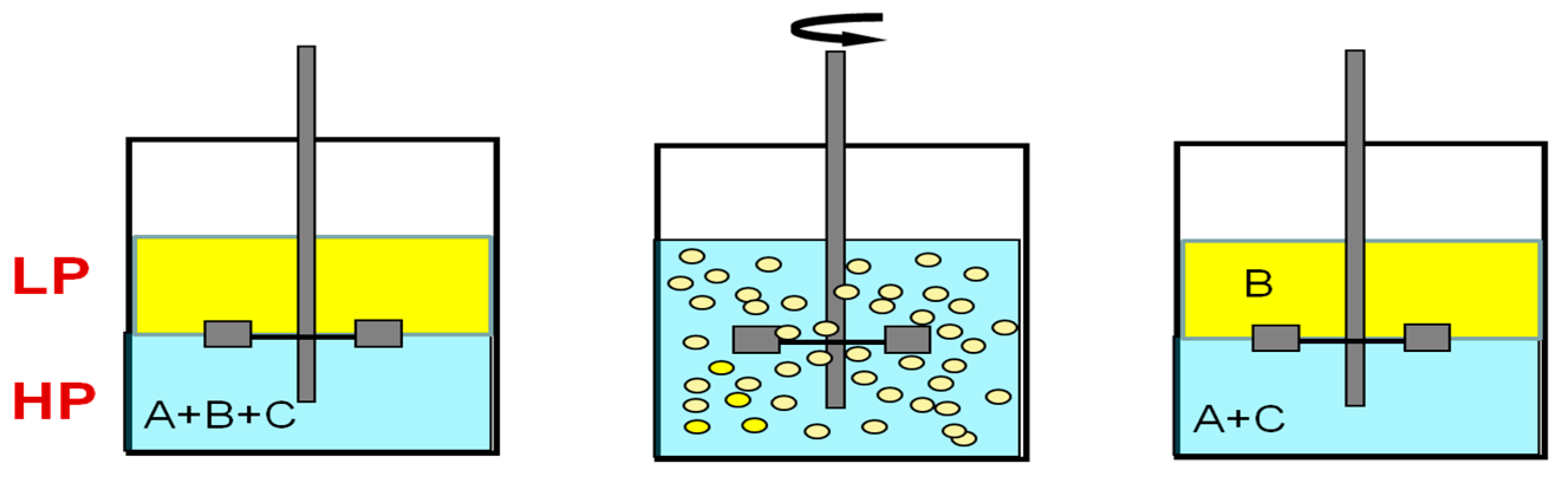

- Gu, Z.M. A new liquid membrane technology—Electrostatic pseudo liquid membrane. J. Membr. Sci. 1990, 52, 77–88. [Google Scholar] [CrossRef]

- Yang, X.J.; Gu, Z.M.; Fane, A.G. Multicomponent separations by a combined extraction/electrostatic pseudo-liquid membrane: (I): Separation of Al, La, Sm, and Y. Hydrometallurgy 1998, 49, 275–288. [Google Scholar] [CrossRef]

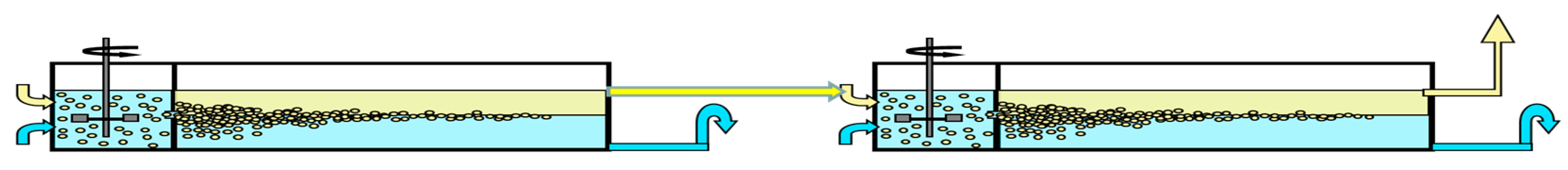

- Kostanyan, A.E.; Belova, V.V.; Voshkin, A.A. Three- and multi-phase extraction as a tool for the implementation of liquid membrane separation methods in practice. Membranes 2022, 12, 926. [Google Scholar] [CrossRef]

- Kostanyan, A.E.; Egorova, N.S.; Voshkin, A.A.; Zonov, S.S. Extraction of uranyl, ytterbium, and lanthanum nitrates in a three-compartment multiphase extractor. Theor. Found. Chem. Eng. 2008, 42, 718–723. [Google Scholar] [CrossRef]

- Kostanyan, A.E. On the application of liquid-membrane principle in a system of mixing-settling extractors. Theor. Found. Chem. Eng. 2013, 47, 495–498. [Google Scholar] [CrossRef]

- Kostanian, A.E. Staged versions of liquid membrane extraction processes. Solvent Extr. Ion Exch. 2013, 31, 297–305. [Google Scholar] [CrossRef]

- Kostanian, A.E. Multi-Stage Extraction Process. U.S. Patent No. 6,143,178, 7 November 2000. [Google Scholar]

- Kostanian, A.E. Multistage Three-Phase Extractor. U.S. Patent No. 6,090,352, 18 July 2000. [Google Scholar]

- Kostanian, A.E. Multiphase Extractor. U.S. Patent No. 6,129,842, 10 October 2000. [Google Scholar]

- Kostanian, A.E. Multiple Phase Extractor. U.S. Patent No. 6,446,815, 10 September 2002. [Google Scholar]

- Kostanian, A.E. Multi-Phase Extraction Apparatus. U.S. Patent No. 6,521,195, 18 February 2003. [Google Scholar]

- Kostanyan, A.E.; Safiulina, A.M.; Tananaev, I.T.; Myasoedov, B.F. Multiphase extraction: Design of single-and multistage separation using liquid pseudomembranes. Dokl. Chem. 2005, 404, 203–205. [Google Scholar] [CrossRef]

- Heckley, P.S.; Ibana, D. Extraction and separation of nickel and cobalt by electrostatic pseudo liquid membrane. Membr. Technol. 2003, 2003, 8–11. [Google Scholar] [CrossRef]

- Yang, X.J.; Gu, Z.M.; Bai, S.Y.; Wang, D.X. Extraction and preconcentration of scandium from aqueous solution by electrostatic pseudo liquid membrane. Chin Chem Lett. 1994, 5, 681–684. [Google Scholar]

- Eow, J.S.; Ghadiri, M. Motion, deformation and break-up of aqueous drops in oils under high electric field strengths. Chem. Eng. Process. 2003, 42, 259–272. [Google Scholar] [CrossRef]

- Moradi, R.; Monfared, S.M.; Amini, Y.; Dastbaz, A. Vacuum enhanced membrane distillation for trace contaminant removal of heavy metals from water by electrospun PVDF/TiO2 hybrid membranes. Korean J. Chem. Eng. 2016, 33, 2160–2168. [Google Scholar] [CrossRef]

- Pei, L.; Wang, L.; Fu, X. Separation of Eu3+ using a novel dispersion combined liquid membrane with P507 in kerosene as the carrier. Chin. J. Chem. Eng. 2011, 19, 33–39. [Google Scholar] [CrossRef]

- Kostanyan, A.E.; Safiulina, A.M.; Tananaev, I.G. Linear models of three-phase extraction processes. Theor. Found. Chem. Eng. 2007, 41, 755–759. [Google Scholar] [CrossRef]

- Belova, V.V.; Kostanyan, A.E.; Zakhodyaeva, Y.A.; Kholkin, A.I.; Logutenko, O.A. On the application of bulk-supported liquid membrane techniques in hydrometallurgy. Hydrometallurgy 2014, 150, 144–152. [Google Scholar] [CrossRef]

| № | pH(feed) | pH(equilibrium) | CCu(aqueous), ppm | CCu(organic), ppm | Distribution Coefficient |

|---|---|---|---|---|---|

| Extraction | |||||

| 1 | 3.10 | 2.11 | 16.0 | 2420 | 151 |

| 2 | 2.96 | 1.89 | 21.5 | 2360 | 110 |

| 3 | 2.96 | 1.64 | 42.5 | 2580 | 61 |

| 4 | 2.96 | 1.55 | 60 | 2530 | 42 |

| Stripping by 20% H2SO4 | |||||

| 1 | 10,500 | 320 | 33 | ||

| 2 | 10,750 | 210 | 51 | ||

| 3 | 11,880 | 200 | 59 | ||

| 4 | 12,250 | 80 | 153 | ||

| № | Feed Flow Rate, L/h | Distributor Hole Diameters, mm (Extraction) | Stripping Phase Flow Rate, L/h | Distributor Hole Diameters, mm (Stripping) | CCu (Feed), ppm | CCu (Raffinate), ppm |

|---|---|---|---|---|---|---|

| 1 | 3.3 | 2 | 5.2 | 2 | 490 | 410 |

| 2 | 3.3 | 2 | 5.2 | 2 | 410 | 385 |

| 3 | 3.3 | 0.7 | 5.2 | 2 | 490 | 355 |

| 4 | 5.2 | 0.7 | 8.4 | 1 | 490 | 350 |

| 5 | 3.3 | 0.7 | 5.2 | 1 | 340 | 275 |

| 6 | 3.3 | 0.7 | 5.2 | 1 | 275 | 222 |

| 7 | 3.3 | 0.7 | 5.2 | 1 | 2320 | 2010 |

| 8 | 4.3 | 0.7 | 9.6 | 1 | 2320 | 2000 |

| 9 | 5.2 | 0.7 | 8.4 | 1 | 2320 | 1960 |

| 10 | 7.1 | 0.7 | 10 | 1 | 2320 | 1900 |

| № | Feed Flow Rate, L/h | Distributor Hole Diameters, mm (Extraction) | Stripping Phase Flow Rate, L/h | Distributor Hole Diameters, mm (Stripping) | CCu (Feed), ppm | CCu (Raffinate), ppm |

|---|---|---|---|---|---|---|

| 1 | 3.3 | 0.7 | 5.2 | 1 | 460 | 330 |

| 2 | 5.2 | 0.7 | 8.4 | 1 | 460 | 328 |

| 3 | 7.1 | 0.7 | 10 | 1 | 460 | 315 |

| № | Feed Flow Rate, L/h | Distributor Hole Diameters, mm (Extraction) | Stripping Phase Flow Rate, L/h | Distributor Hole Diameters, mm (Stripping) | CCu (Feed), ppm | CCu (Raffinate), ppm |

|---|---|---|---|---|---|---|

| 1 | 7.1 | 0.7 | 10 | 1 | 460 | 20 |

| 2 | 5.2 | 0.7 | 5.2 | 1 | 525 | 29 |

| 3 | 5.2 | 0.7 | 8.4 | 1 | 525 | 23 |

| 4 | 5.2 | 0.7 | 8.4 | 1 | 525 | 2.5 |

| 5 | 5.2 | 0.7 | 10 | 1 | 525 | 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kostanyan, A.E.; Belova, V.V.; Zakhodyaeva, Y.A.; Voshkin, A.A. Extraction of Copper from Sulfuric Acid Solutions Based on Pseudo-Liquid Membrane Technology. Membranes 2023, 13, 418. https://doi.org/10.3390/membranes13040418

Kostanyan AE, Belova VV, Zakhodyaeva YA, Voshkin AA. Extraction of Copper from Sulfuric Acid Solutions Based on Pseudo-Liquid Membrane Technology. Membranes. 2023; 13(4):418. https://doi.org/10.3390/membranes13040418

Chicago/Turabian StyleKostanyan, Artak E., Vera V. Belova, Yulia A. Zakhodyaeva, and Andrey A. Voshkin. 2023. "Extraction of Copper from Sulfuric Acid Solutions Based on Pseudo-Liquid Membrane Technology" Membranes 13, no. 4: 418. https://doi.org/10.3390/membranes13040418

APA StyleKostanyan, A. E., Belova, V. V., Zakhodyaeva, Y. A., & Voshkin, A. A. (2023). Extraction of Copper from Sulfuric Acid Solutions Based on Pseudo-Liquid Membrane Technology. Membranes, 13(4), 418. https://doi.org/10.3390/membranes13040418