Synthesis of Dimpled Particles by Seeded Emulsion Polymerization and Their Application in Superhydrophobic Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

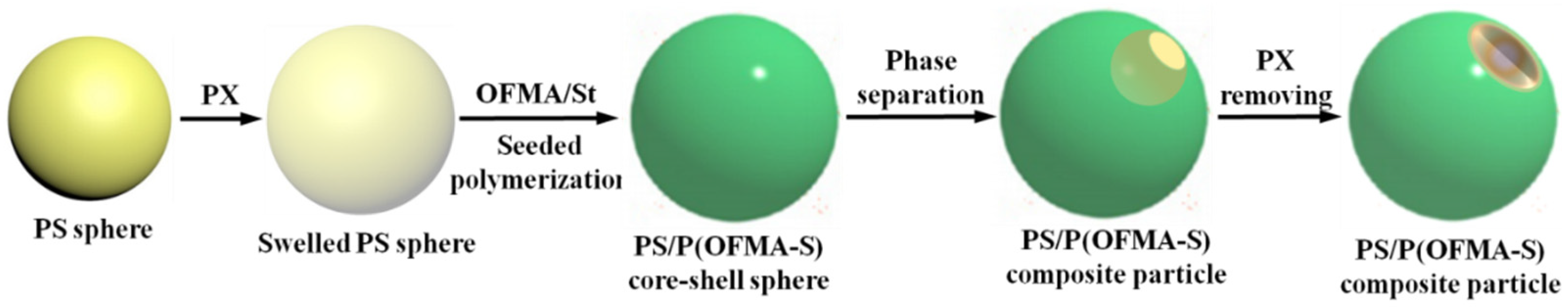

2.2. Synthesis of PS/P(OFMA-S) Composite Particles

2.3. Characterizations

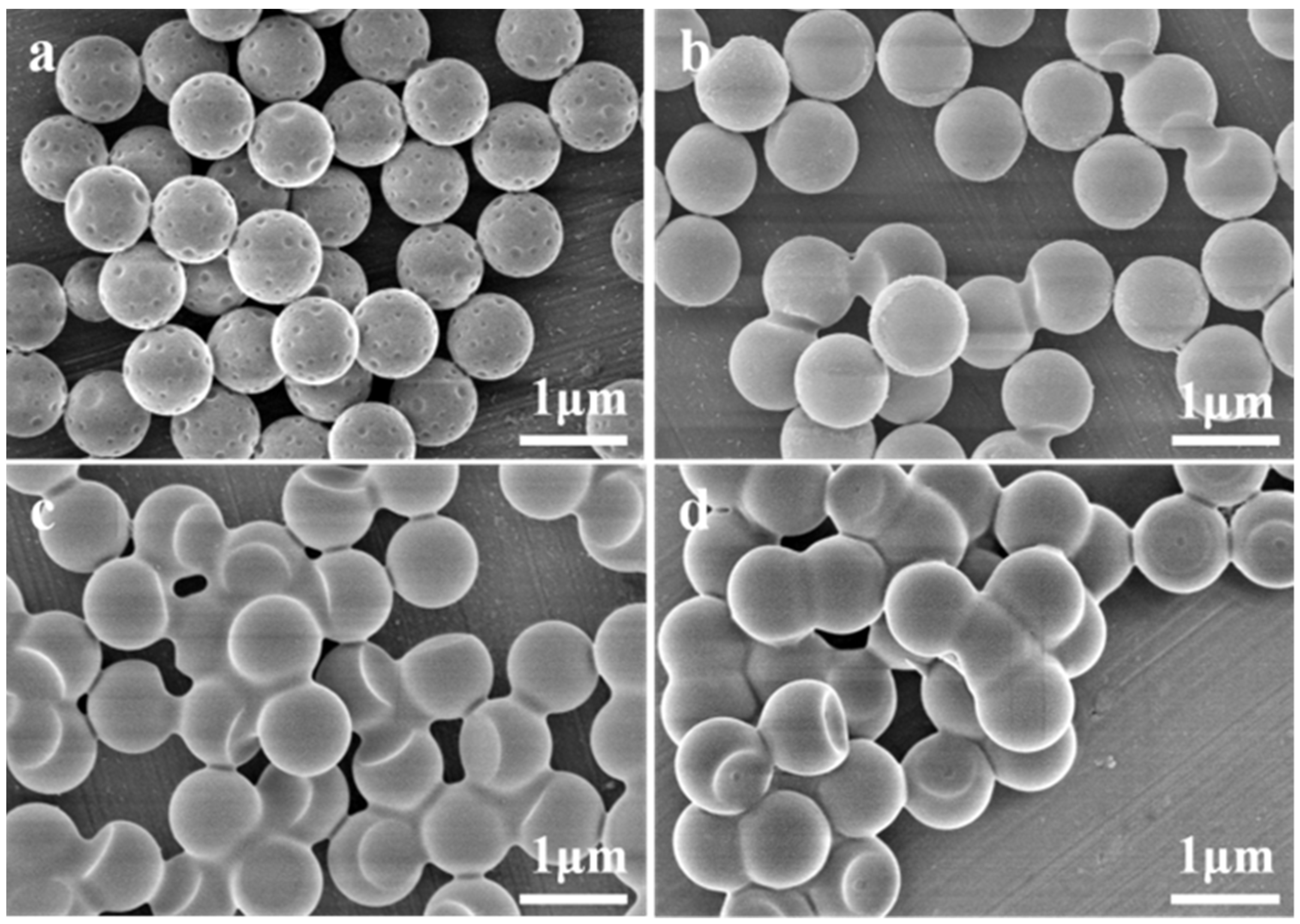

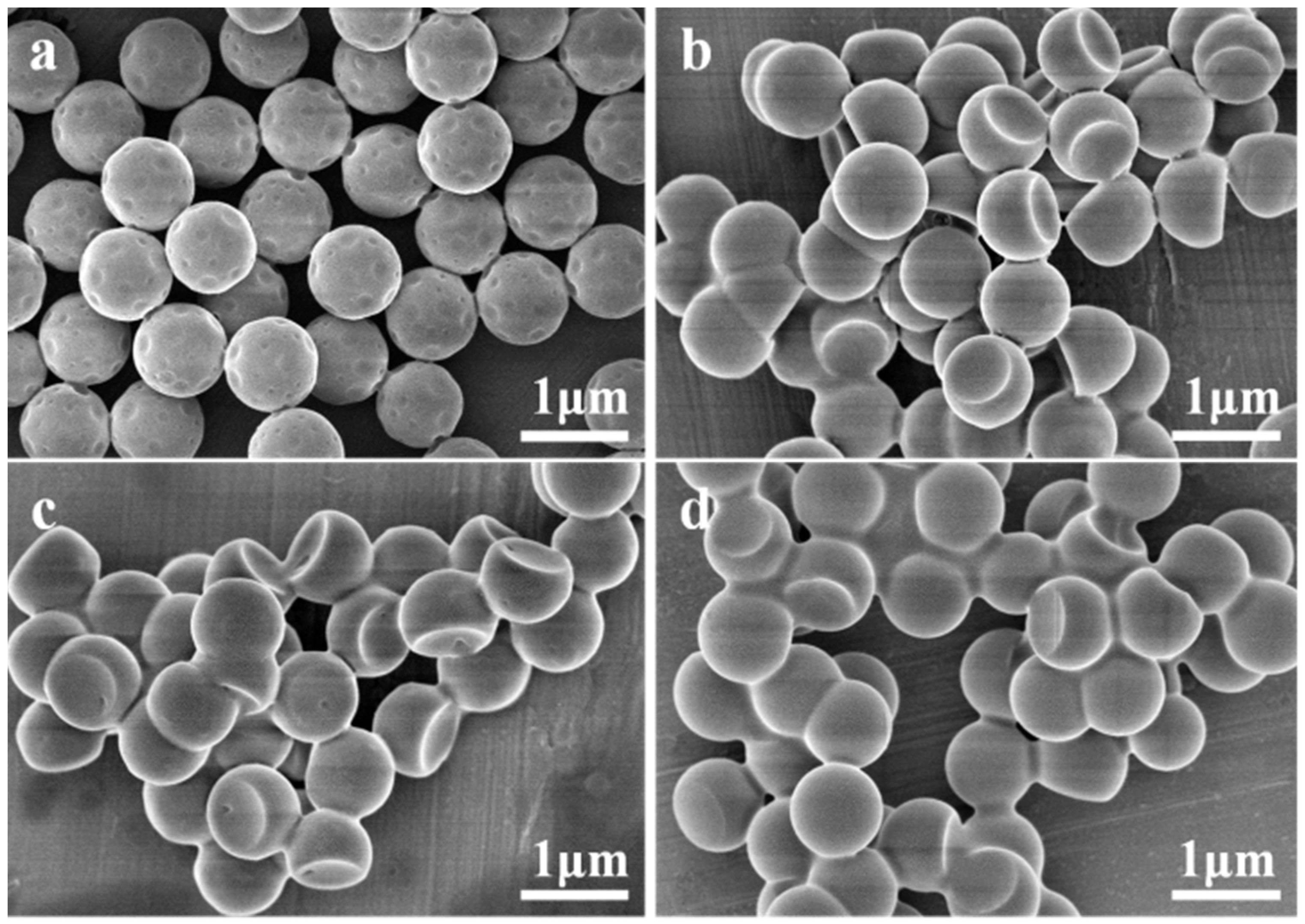

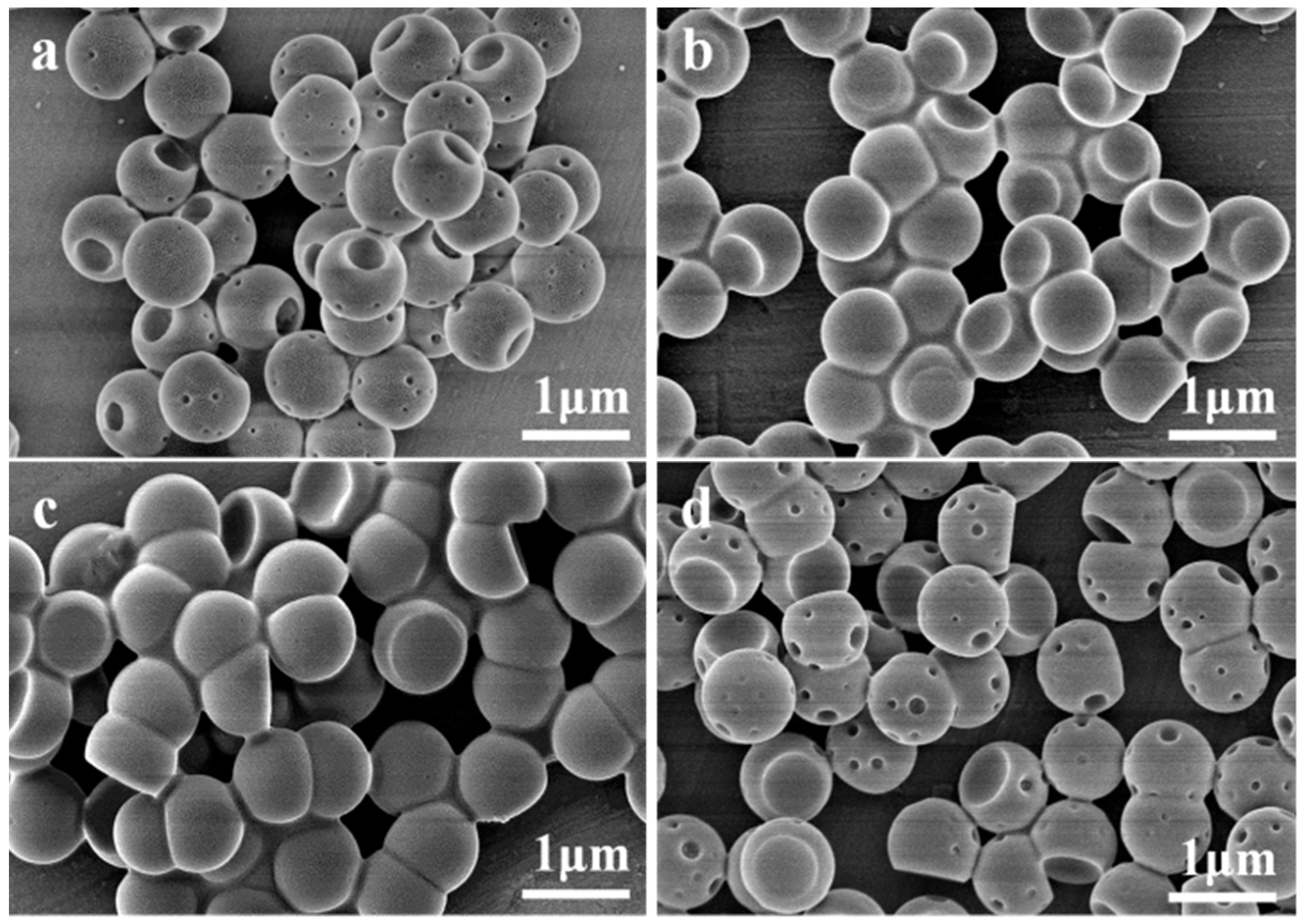

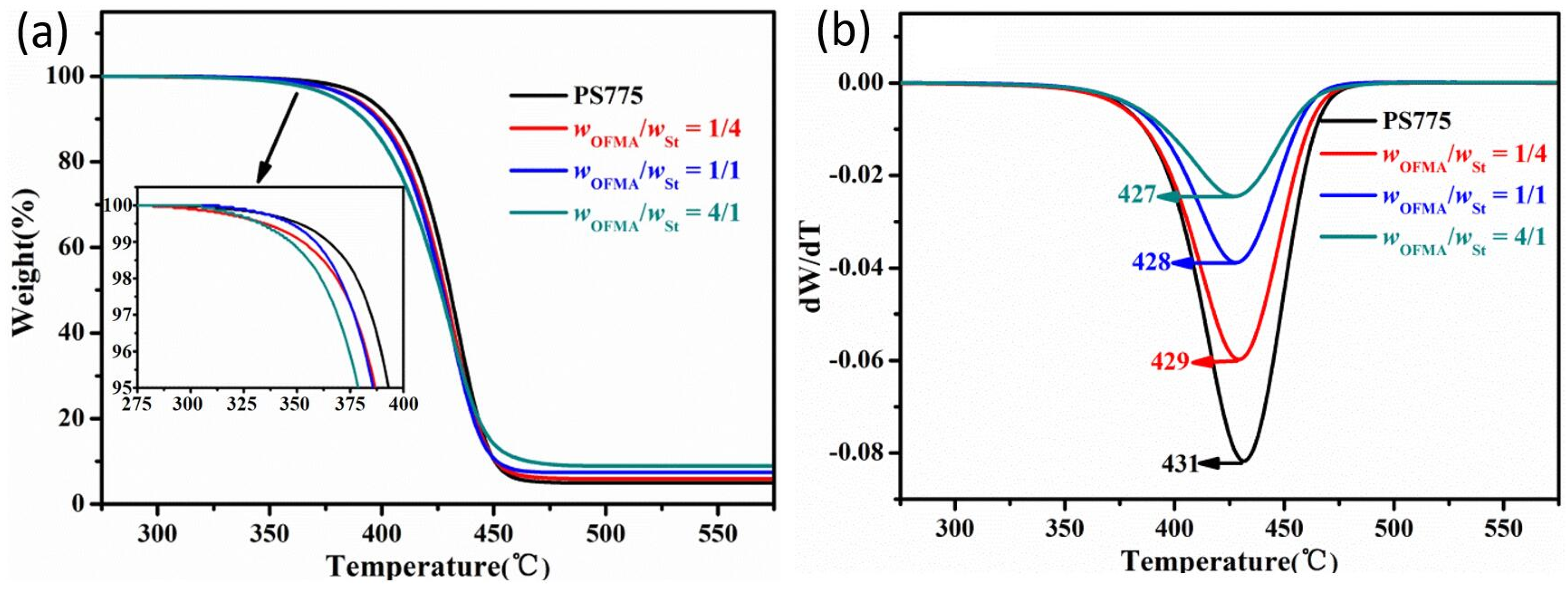

3. Results and Discussions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Walther, A.; Müller, A.H.E. Janus particles: Synthesis, self-assembly, physical properties, and applications. Chem. Rev. 2013, 113, 5194–5261. [Google Scholar] [CrossRef] [PubMed]

- Mao, Z.W.; Xu, H.L.; Wang, D.Y. Molecular mimetic self-assembly of colloidal particles. Adv. Funct. Mater. 2010, 20, 1053–1074. [Google Scholar] [CrossRef]

- Peng, B.; Smallenburg, F.; Imhof, A.; Dijkstra, M.; van Blaaderen, A. Colloidal clusters by using emulsions and dumbbell-shaped particles: Experiments and simulations. Angew. Chem. Int. Ed. 2013, 52, 6709–6712. [Google Scholar] [CrossRef]

- Li, W.Y.; Palis, H.; Merindol, R.; Majimel, J.; Ravaine, S.; Duguet, E. Colloidal molecules and patchy particles: Complementary concepts, synthesis and self-assembly. Chem. Soc. Rev. 2020, 49, 1955–1976. [Google Scholar] [CrossRef] [PubMed]

- Sacanna, S.; Irvine, W.T.M.; Chaikin, P.M.; Pine, D.J. Lock and key colloids. Nature 2010, 464, 575–578. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, M. Beyond drug delivery. Nat. Nanotechnol. 2008, 3, 131–132. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, G.; Agrawal, R. Janus nanoparticles: Recent advances in their interfacial and biomedical applications. ACS Appl. Nano Mater. 2019, 2, 1738–1757. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, S.; Hua, Y.; Zhang, H.; Chen, J. Synthesis of latex particles with a complex structure as an emulsifier of pickering high internal phase emulsions. Ind. Eng. Chem. Res. 2014, 53, 4642–4649. [Google Scholar] [CrossRef]

- Kim, J.-W.; Lee, D.; Shum, H.C.; Weitz, D.A. Colloid surfactants for emulsion stabilization. Adv. Mater. 2008, 20, 3239–3243. [Google Scholar] [CrossRef]

- Bellanger, H.; Darmanin, T.; Taffin de Givenchy, E.; Guittard, F. Chemical and physical pathways for the preparation of superoleophobic surfaces and related wetting theories. Chem. Rev. 2014, 114, 2694–2716. [Google Scholar] [CrossRef]

- Kim, S.-H.; Lee, S.Y.; Yang, S.-M. Janus microspheres for a highly flexible and impregnable water-repelling interface. Angew. Chem. Int. Ed. 2010, 49, 2535–2538. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Su, B.; Jiang, L. Interfacial material system exhibiting superwettability. Adv. Mater. 2014, 26, 6872–6897. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Josephson, D.P.; Stein, A. Colloidal assembly: The road from particles to colloidal molecules and crystals. Angew. Chem. Int. Ed. 2011, 50, 360–388. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Li, Z.; Ravaine, S.; He, M.; Song, Y.; Yin, Y.; Zheng, H.; Teng, J.; Zhang, A. From colloidal particles to photonic crystals: Advances in self-assembly and their emerging applications. Chem. Soc. Rev. 2021, 50, 5898–5951. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wan, Y.; Li, Y.; Cai, Z.; Li, H.-L.; Zhao, X.S.; Li, Q. Binary colloidal crystals fabricated with a horizontal deposition method. Langmuir 2009, 25, 6753–6759. [Google Scholar] [CrossRef]

- Loget, G.; Kuhn, A. Bulk synthesis of janus objects and asymmetric patchy particles. J. Mater. Chem. 2012, 22, 15457–15474. [Google Scholar] [CrossRef]

- Motoyoshi, K.; Tajima, A.; Higuchi, T.; Yabu, H.; Shimomura, M. Static and dynamic control of phase separation structures in nanoparticles of polymer blends. Soft Matter 2010, 6, 1253–1257. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Saadat, Y.; Abdolbaghi, S. Preparation of novel and unique nonspherical particles with almond-shell-like shape via dual-seeded dispersion polymerization in the presence of saturated hydrocarbon droplets. Colloid. Polym. Sci. 2012, 290, 847–853. [Google Scholar] [CrossRef]

- Zhang, J.; Grzybowski, B.A.; Granick, S. Janus particle synthesis, assembly, and application. Langmuir 2017, 33, 6964–6977. [Google Scholar] [CrossRef]

- Sheu, H.R.; El-Aasser, M.S.; Vanderhoff, J.W. Phase separation in polystyrene latex interpenetrating polymer networks. J. Polym. Sci. Part A Polym. Chem. 1990, 28, 629–651. [Google Scholar] [CrossRef]

- Liu, X.; Pan, M.W.; Yuan, J.F.; Niu, Q.; Wang, X.M.; Zhang, K.C. Popcorn-like morphology of asymmetric nanoparticles co-adjusted by hydrophilicity and crosslinking degree of the seeds. RSC Adv. 2014, 4, 4163–4169. [Google Scholar] [CrossRef]

- Hu, J.; Zhou, S.X.; Sun, Y.Y.; Fang, X.S.; Wu, L.M. Fabrication, properties and applications of janus particles. Chem. Soc. Rev. 2012, 41, 4356–4378. [Google Scholar] [CrossRef]

- Park, J.-G.; Forster, J.D.; Dufresne, E.R. High-yield synthesis of monodisperse dumbbell-shaped polymer nanoparticles. J. Am. Chem. Soc. 2010, 132, 5960–5961. [Google Scholar] [CrossRef]

- Wang, L.; Li, H.; Shi, G.; Hong, J.; Chen, Z.; Jin, C.; Sun, C.; Yao, B. Synthesis of sioh-functionalized composite particles with buckled surface by seeded emulsion polymerization. Colloid. Polym. Sci. 2017, 295, 471–478. [Google Scholar] [CrossRef]

- Wang, L.; Xia, L.; Li, G.; Ravaine, S.; Zhao, X.S. Patterning the surface of colloidal microspheres and fabrication of nonspherical particles. Angew. Chem. Int. Ed. 2008, 47, 4725–4728. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Li, Y.; Liu, B. Colloidal particles with complex microstructures via phase separation in swelled polymer microspheres. Chem. Commun. 2017, 53, 8649–8652. [Google Scholar] [CrossRef] [PubMed]

- Okubo, M.; Takekoh, R.; Suzuki, A. Preparation of micron-sized, monodisperse poly(methyl methacrylate)/polystyrene composite particles having a large number of dents on their surfaces by seeded dispersion polymerization in the presence of decalin. Colloid. Polym. Sci. 2002, 280, 1057–1061. [Google Scholar] [CrossRef]

- Okubo, M.; Minami, H.; Morikawa, K. Influence of shell strength on shape transformation of micron-sized, monodisperse, hollow polymer particles. Colloid. Polym. Sci. 2003, 281, 214–219. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhang, D.; Luo, X.; Lai, H.; Liu, Y.; Jiang, L. Superwetting shape memory microstructure: Smart wetting control and practical application. Adv. Mater. 2021, 33, 2001718. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, D.; Sun, Z.; Song, J.; Deng, X. Robust superhydrophobicity: Mechanisms and strategies. Chem. Soc. Rev. 2021, 50, 4031–4061. [Google Scholar] [CrossRef]

- Dalawai, S.P.; Saad Aly, M.A.; Latthe, S.S.; Xing, R.; Sutar, R.S.; Nagappan, S.; Ha, C.-S.; Kumar Sadasivuni, K.; Liu, S. Recent advances in durability of superhydrophobic self-cleaning technology: A critical review. Prog. Org. Coat. 2020, 138, 105381. [Google Scholar] [CrossRef]

- Latthe, S.S.; Sutar, R.S.; Kodag, V.S.; Bhosale, A.K.; Kumar, A.M.; Kumar Sadasivuni, K.; Xing, R.; Liu, S. Self-cleaning superhydrophobic coatings: Potential industrial applications. Prog. Org. Coat. 2019, 128, 52–58. [Google Scholar] [CrossRef]

- Sethi, S.K.; Manik, G. Recent progress in super hydrophobic/hydrophilic self-cleaning surfaces for various industrial applications: A review. Polym. Plast. Technol. Eng. 2018, 57, 1932–1952. [Google Scholar] [CrossRef]

- Sethi, S.K.; Singh, M.; Manik, G. A multi-scale modeling and simulation study to investigate the effect of roughness of a surface on its self-cleaning performance. Mol. Syst. Des. Eng. 2020, 5, 1277–1289. [Google Scholar] [CrossRef]

- Sethi, S.K.; Manik, G. A combined theoretical and experimental investigation on the wettability of mwcnt filled pvac-g-pdms easy-clean coating. Prog. Org. Coat. 2021, 151, 106092. [Google Scholar] [CrossRef]

- Han, S.T.; Gu, Y.; Ma, M.Y.; Chen, M. Light-intensity switch enabled nonsynchronous growth of fluorinated raspberry-like nanoparticles. Chem. Sci. 2020, 11, 10431–10436. [Google Scholar] [CrossRef]

- Shim, S.E.; Cha, Y.J.; Byun, J.M.; Choe, S. Size control of polystyrene beads by multistage seeded emulsion polymerization. J. Appl. Polym. Sci. 1999, 71, 2259–2269. [Google Scholar] [CrossRef]

- Jin, X.; Zhu, Q.; Feng, L.; Li, X.; Zhu, H.; Miao, H.; Zeng, Z.; Wang, Y.; Li, Y.; Wang, L.; et al. Light-trapping SERS substrate with regular bioinspired arrays for detecting trace dyes. ACS Appl. Mater. Interfaces 2021, 13, 11535–11542. [Google Scholar] [CrossRef]

- Li, Y.; Feng, L.; Li, J.; Li, X.; Chen, J.; Wang, L.; Qi, D.; Liu, X.; Shi, G. Fabrication of an insect-like compound-eye SERS substrate with 3D Ag nano-bowls and its application in optical sensor. Sens. Actuators B-Chem. 2021, 330, 129357. [Google Scholar] [CrossRef]

- Brown, D.W.; Wall, L.A. Glass transition temperatures of several fluorine-containing polymers. J. Polym. Sci. Part A-2 Polym. Phys. 1969, 7, 601–608. [Google Scholar] [CrossRef]

- Andruzzi, L.; Hexemer, A.; Li, X.; Ober, C.K.; Kramer, E.J.; Galli, G.; Chiellini, E.; Fischer, D.A. Control of surface properties using fluorinated polymer brushes produced by surface-initiated controlled radical polymerization. Langmuir 2004, 20, 10498–10506. [Google Scholar] [CrossRef] [PubMed]

- Sethi, S.K.; Kadian, S.; Anubhav; Goel; Chauhan, R.P.; Manik, G. Fabrication and analysis of zno quantum dots based easy clean coating: A combined theoretical and experimental investigation. ChemistrySelect 2020, 5, 8942–8950. [Google Scholar] [CrossRef]

| PS Latex (2.5 wt%)/g | OFMA/g | St/g | AIBN/g | PX/g |

|---|---|---|---|---|

| 40 | 0.2 | 0.8 | 0.01 | 2 |

| 40 | 0.333 | 0.667 | 0.01 | 2 |

| 40 | 0.5 | 0.5 | 0.01 | 2 |

| 40 | 0.667 | 0.333 | 0.01 | 2 |

| 40 | 0.8 | 0.2 | 0.01 | 2 |

| 40 | 0.5 | 0.5 | 0.01 | 1 |

| 40 | 0.5 | 0.5 | 0.01 | 3 |

| 40 | 0.5 | 0.5 | 0.01 | 4 |

| 40 | 0.5 | 0.5 | 0.01 | 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Petrescu, F.I.T.; Liu, J.; Li, H.; Shi, G. Synthesis of Dimpled Particles by Seeded Emulsion Polymerization and Their Application in Superhydrophobic Coatings. Membranes 2022, 12, 876. https://doi.org/10.3390/membranes12090876

Wang L, Petrescu FIT, Liu J, Li H, Shi G. Synthesis of Dimpled Particles by Seeded Emulsion Polymerization and Their Application in Superhydrophobic Coatings. Membranes. 2022; 12(9):876. https://doi.org/10.3390/membranes12090876

Chicago/Turabian StyleWang, Likui, Florian Ion Tiberiu Petrescu, Jing Liu, Hongping Li, and Gang Shi. 2022. "Synthesis of Dimpled Particles by Seeded Emulsion Polymerization and Their Application in Superhydrophobic Coatings" Membranes 12, no. 9: 876. https://doi.org/10.3390/membranes12090876

APA StyleWang, L., Petrescu, F. I. T., Liu, J., Li, H., & Shi, G. (2022). Synthesis of Dimpled Particles by Seeded Emulsion Polymerization and Their Application in Superhydrophobic Coatings. Membranes, 12(9), 876. https://doi.org/10.3390/membranes12090876