Recyclability Definition of Recycled Nanofiltration Membranes through a Life Cycle Perspective and Carbon Footprint Indicator

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overal Methodology

- Strategy A: Pressure increments with an equal number of elements. This strategy maintains the number of modules and compensates for the lower permeability with increments of Prin. Therefore, the expected SEC of r-NF membranes is higher. This strategy would represent the substitution of commercial elements with r-NF modules in existing systems.

- Strategy B: Incrementing the number of elements. Within this strategy, low permeability is compensated for via increments of the active areas within the PV, that is, an increment of the number of elements that are consecutively installed in each stage. This increment of elements (and thus membrane active area) compensates totally or partially for Prin. This strategy cannot be easily adapted to existing systems where PVs are constrained to a particular module capacity. However, it is relevant to explore whether new designs for r-NF systems could minimise and mitigate their energy impact.

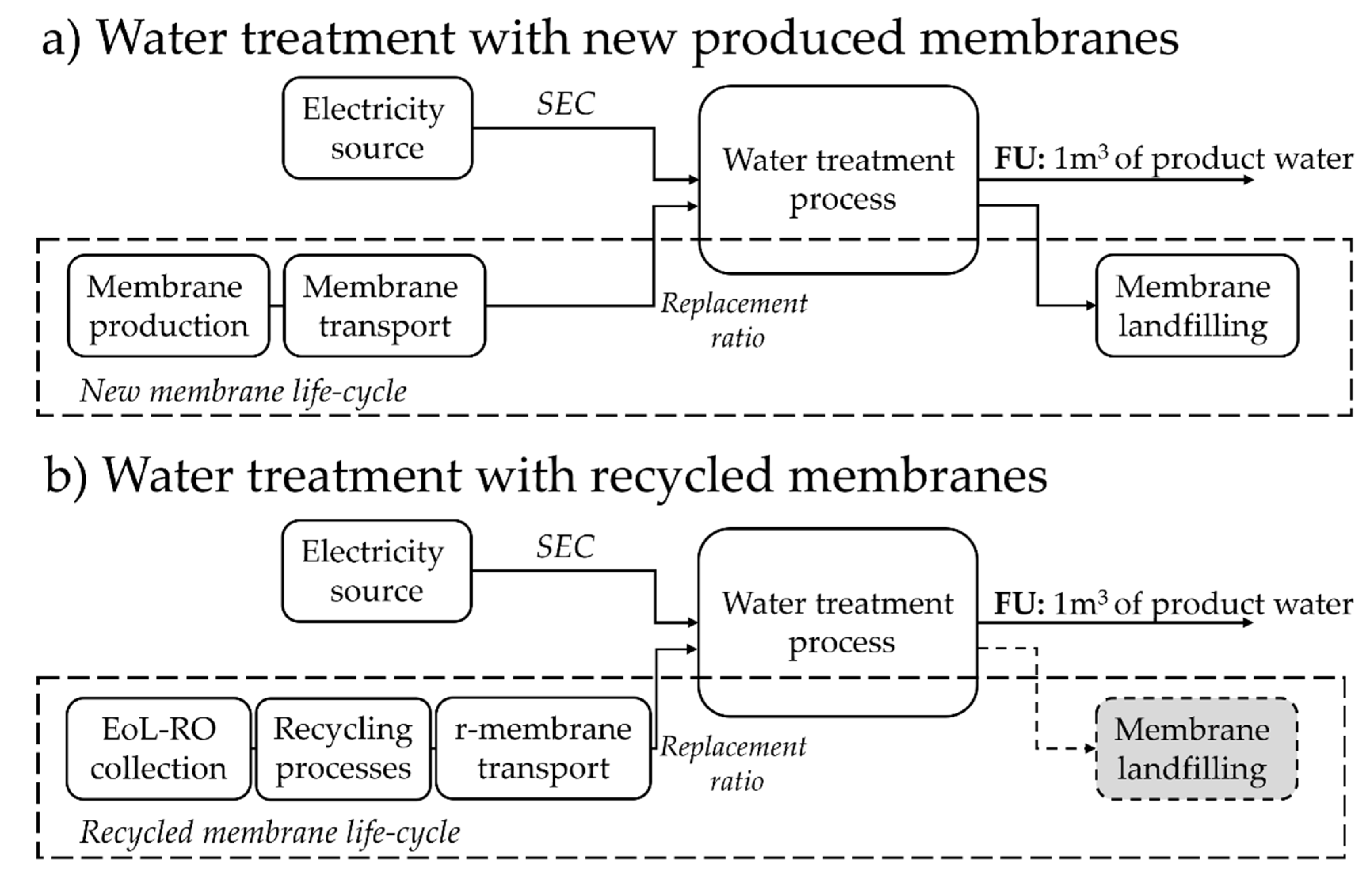

2.2. Life Cycle Assessment

2.2.1. Goal and Scope

2.2.2. System Boundaries

2.2.3. Life-Cycle Inventory Data Collection

2.2.4. Life-Cycle Impact Assessment Category

2.3. Specific Energy Consumption (SEC) Modelling

2.4. Case Study Description

2.5. Technological Niche Exploration via Analytical–Numerical Method and LCA-Based Indicators

2.5.1. Life Cycle Assessment-Based Indicators

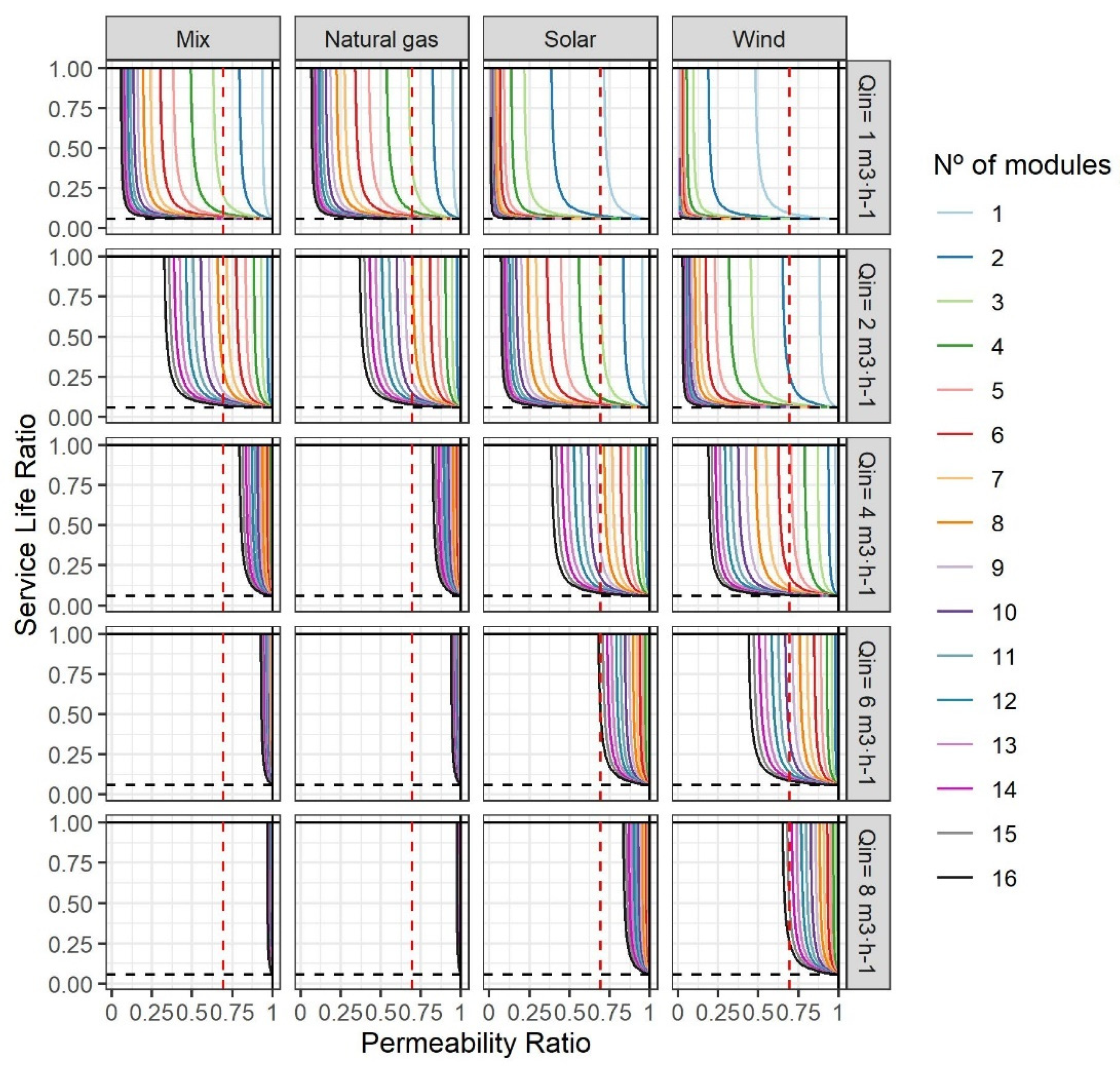

2.5.2. Numerical Simulation: Framework Conditions

- Water flow (Qin in m3·h−1): {1..16}

- Number of elements per pressure vessel (n): {1..16}

- Recovery rate (WR): [0.1, 0.95]

- Energy sources: Mix, Natural gas, Solar and Wind

2.6. Software, Hardware, and Databases

3. Results and Discussion

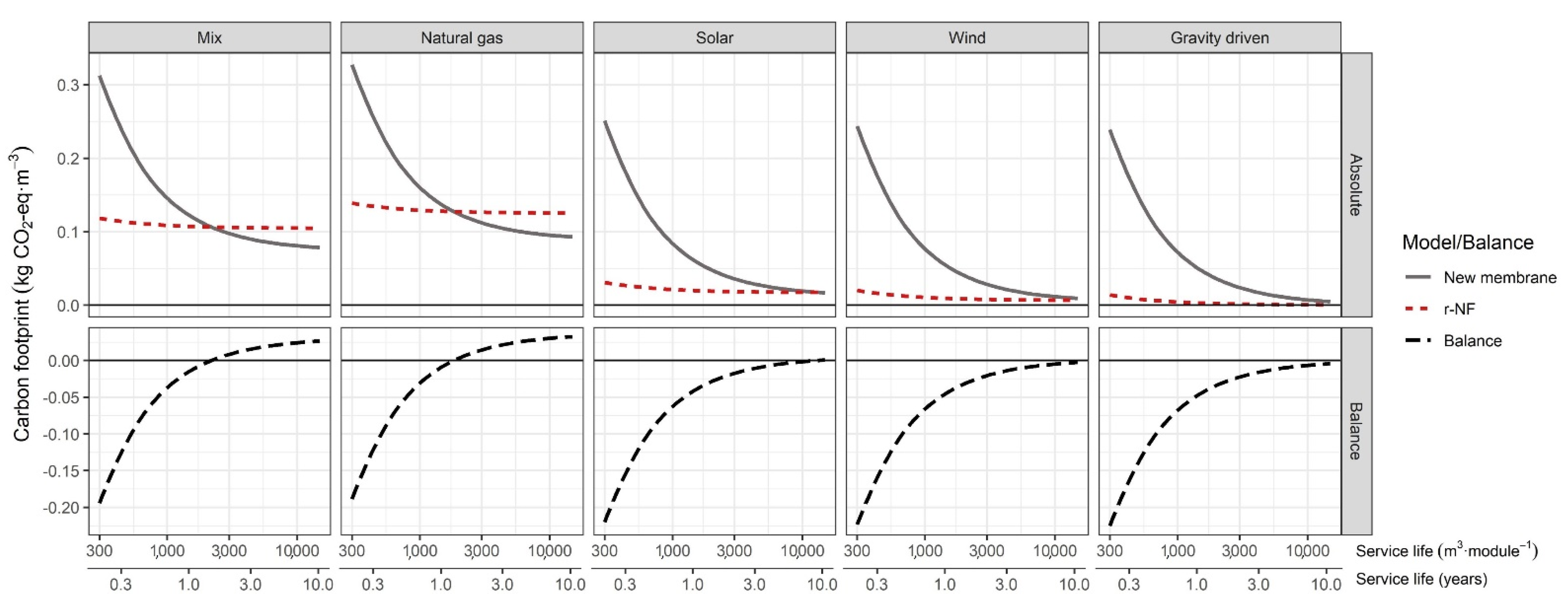

3.1. Case Study: Concept Illustration of Strategy A and Strategy B

3.2. Hybrid Analytical–Numerical Modelling

3.2.1. Application of the Hybrid Analytical–Numerical Method in Strategy A

3.2.2. Application of the Hybrid Analytical–Numerical Method in Strategy B

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol/Abbr. | Description |

| µ | Viscosity (in m2·pa·s−1) |

| a | Area (in m2) |

| BW | Brackish water |

| CE | Circular Economy |

| CF | Carbon footprint (in kg CO2-eq) |

| CFC | Chlorofluorocarbon |

| Cl- | Chloride |

| dH | Hydraulic diameter (in mm) |

| Ef | Efficiency factor |

| EoL | End-of-life |

| ERD | Energy Recovery Device |

| EU | European Union |

| g | Gravity force |

| GD | Gravity-driven |

| h | Hours |

| i | Van ’t Hoff index |

| ILCD | International Life Cycle Data system |

| Imp | Environmental impact (in kg CO2-eq) |

| Inf. | Infinite |

| IPCC | Intergovernmental Panel on Climate Change |

| ISO | International Standard Organization |

| L | Permeability (in L·m−2·h−1·bar−1) |

| L (unit) | Litre |

| LCA | Life Cycle Assessment |

| LR | Permeability ratio |

| m | Metre |

| M | Molarity |

| n | Number of modules |

| Na+ | Sodium ion |

| NaClO | Sodium hypochlorite |

| NF | Nanofiltration |

| NPD | Net Pressure Driven (in bar) |

| ppm | Parts per million |

| Pr | Pressure (in bar) |

| Prl | Pressure loss (in bar) |

| PV | Pressure vessel |

| Q | Flow (in m3·h−1) |

| R | Ideal gas constant |

| Re | Reynolds number |

| r-NF | Recycled nanofiltration |

| RO | Reverse osmosis |

| SEC | Specific energy consumption (in kwh·m−3) |

| SL | Service Life (in years) |

| SLR | Service life ratio |

| SW | Seawater |

| T | Temperature (in K) |

| TRL | Technology Readiness Level |

| UF | Ultrafiltration |

| v | Velocity (in m·s−1) |

| ν | Kinematic viscosity |

| vs. | Versus |

| WR | Water recovery rate |

| П | Osmotic pressure (in bar) |

| Subscript | |

| Subscript | Description |

| c | Relative to new commercial produced membranes |

| conc | Relative to concentrated water flow |

| e | Relative to energy |

| in | Relative to inlet water flow |

| pr | Relative to product water flow |

| r | Relative to recycled membranes |

| rep | Relative to replacement activity |

| total | Relative to the total of the system |

References

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy-a new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy, Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- European Environmental Agency (EEA). Circular Economy in Europe Developing the Knowledge Base; Publications Office of the European Union: Luxembourg, 2016; ISBN 978-9-29-213719-9. [Google Scholar]

- European Comission. Directive 2008/98/EC of the European parliament and of the council of 19 November 2008 on waste and repealing certain directives. Off. J. Eur. Union 2008, L312, 3–30. [Google Scholar]

- Müller, L.J.; Kätelhön, A.; Bachmann, M.; Zimmermann, A.; Sternberg, A.; Bardow, A. A guideline for life cycle assessment of carbon capture and utilization. Front. Energy Res. 2020, 8, 1–20. [Google Scholar] [CrossRef]

- Lacirignola, M.; Blanc, P.; Girard, R.; Pérez-lópez, P.; Blanc, I. LCA of emerging technologies: Addressing high uncertainty on inputs’ variability when performing global sensitivity analysis. Sci. Total Environ. 2017, 578, 268–280. [Google Scholar] [CrossRef]

- Bergerson, J.A.; Brandt, A.; Cresko, J.; Carbajales-Dale, M.; MacLean, H.L.; Matthews, H.S.; McCoy, S.; McManus, M.; Miller, S.A.; Morrow, W.R.; et al. Life cycle assessment of emerging technologies: Evaluation techniques at different stages of market and technical maturity. J. Ind. Ecol. 2020, 24, 11–25. [Google Scholar] [CrossRef]

- Tufa, R.A. Perspectives on environmental ethics in sustainability of membrane based technologies for water and energy production. Environ. Technol. Innov. 2015, 4, 182–193. [Google Scholar] [CrossRef]

- Landaburu-Aguirre, J.; García-Pacheco, R.; Molina, S.; Rodríguez-Sáez, L.; Rabadan, J.; García-Calvo, E.; Rodríguez-Sáez, L.; Rabadán, J.; García-Calvo, E. Fouling prevention, preparing for re-use and membrane recycling. Towards Circular economy in RO desalination. Desalination 2016, 393, 16–30. [Google Scholar] [CrossRef]

- Rodríguez-Sáez, L.; Patsios, S.I.; Senán-Salinas, J.; Landaburu-Aguirre, J.; Molina, S.; García-Calvo, E. A novel application of recycled ultrafiltration membranes in an aerobic membrane bioreactor (AMBR): A proof-of-concept study. Membranes 2022, 12, 218. [Google Scholar] [CrossRef]

- Lejarazu-Larrañaga, A.; Molina, S.; Ortiz, J.M.; Navarro, R.; García-Calvo, E. Circular economy in membrane technology: Using end-of-life reverse osmosis modules for preparation of recycled anion exchange membranes and validation in electrodialysis. J. Memb. Sci. 2020, 593, 117423. [Google Scholar] [CrossRef]

- Contreras, J.; García-Payo, C.; Arribas, P.; Rodriguez-Saez, L.; Lejarazu-larrañaga, A.; García-Calvo, E.; Khayet, M. Recycled reverse osmosis membranes for forward osmosis technology. Desalination 2021, 519, 115312. [Google Scholar] [CrossRef]

- Rogalla, F.; Simon, F.X. LIFE + REMEMBRANE: Recuperación de Las Membranas de Ósmosis Inversa Al Final de Su Vida Útil. Desalin.-Reuse 2014, 25–29. [Google Scholar]

- García-Pacheco, R.; Landaburu-Aguirre, J.; Terrero-Rodríguez, P.; Campos, E.; Molina-Serrano, F.; Rabadán, J.; Zarzo, D.; García-Calvo, E. Validation of recycled membranes for treating brackish water at pilot scale. Desalination 2018, 433, 199–208. [Google Scholar] [CrossRef]

- García-Pacheco, R.; Landaburu-Aguirre, J.; Molina, S.; Rodríguez-Sáez, L.; Teli, S.B.S.B.; García-Calvo, E. Transformation of end-of-life RO membranes into NF and UF membranes: Evaluation of membrane performance. J. Memb. Sci. 2015, 495, 305–315. [Google Scholar] [CrossRef]

- Mohammad, A.W.; Teow, Y.H.; Ang, W.L.; Chung, Y.T.; Oatley-Radcliffe, D.L.; Hilal, N. Nanofiltration membranes review: Recent advances and future prospects. Desalination 2015, 356, 226–254. [Google Scholar] [CrossRef]

- Senán-Salinas, J.; Blanco, A.; García-Pacheco, R.; Landaburu-Aguirre, J.; García-Calvo, E. Prospective life cycle assessment and economic analysis of direct recycling of end-of-life reverse osmosis membranes based on geographic information systems. J. Clean. Prod. 2021, 282, 124400. [Google Scholar] [CrossRef]

- Senán-Salinas, J.; García-Pacheco, R.; Landaburu-Aguirre, J.; García-Calvo, E. Recycling of end-of-life reverse osmosis membranes: Comparative LCA and cost-effectiveness analysis at pilot scale. Resour. Conserv. Recycl. 2019, 150, 104423. [Google Scholar] [CrossRef]

- Lawler, W. Assessment of End-of-Life Opportunities for Reverse Osmosis Membranes. Ph.D. Thesis, UNSW Sydney, Sydney, NSW, Australia, 2015. [Google Scholar]

- European Commission-Joint Research Centre-Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook-Recommendations for Life Cycle Impact Assessment in the European Context, 1st ed.; Publications Office of the European Union: Luxemburg, 2011; ISBN 978-9-27-917451-3. [Google Scholar]

- Muñoz, I.; Flury, K.; Jungbluth, N.; Rigarlsford, G.; Milà, L.; King, H. Life cycle assessment of bio-based ethanol produced from different agricultural feedstocks. Int. J. Life Cycle Assess. 2013, 19, 109–119. [Google Scholar] [CrossRef]

- Kim, J.E.; Phuntsho, S.; Chekli, L.; Choi, J.Y.; Shon, H.K. Environmental and economic assessment of hybrid FO-RO/NF system with selected inorganic draw solutes for the treatment of mine impaired water. Desalination 2018, 429, 96–104. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M. Application of life cycle assessment for desalination: Progress, challenges and future directions. Environ. Pollut. 2021, 268, 115948. [Google Scholar] [CrossRef]

- Krzeminski, P.; Leverette, L.; Malamis, S.; Katsou, E. Membrane bioreactors–A review on recent developments in energy reduction, fouling control, novel configurations, LCA and market prospects. J. Memb. Sci. 2017, 527, 207–227. [Google Scholar] [CrossRef]

- Zarzo, D.; Prats, D. Desalination and energy consumption. what can we expect in the near future? Desalination 2018, 427, 1–9. [Google Scholar] [CrossRef]

- Ali, A.; Tufa, R.A.; Macedonio, F.; Curcio, E.; Drioli, E. Membrane technology in renewable-energy-driven desalination. Renew. Sustain. Energy Rev. 2018, 81, 1–21. [Google Scholar] [CrossRef]

- Okamoto, Y.; Lienhard, J.H. How RO membrane permeability and other performance factors affect process cost and energy use: A review. Desalination 2019, 470, 114064. [Google Scholar] [CrossRef]

- Shemer, H.; Semiat, R. Sustainable RO desalination–Energy demand and environmental impact. Desalination 2017, 424, 10–16. [Google Scholar] [CrossRef]

- Singh, R. Design, energy and cost analyses of membrane processes. In Membrane Technology and Engineering for Water Purification, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2015; pp. 339–368. [Google Scholar] [CrossRef]

- Auer, J.; Meincke, A. Comparative life cycle assessment of electric motors with different efficiency classes: A deep dive into the trade-offs between the life cycle stages in ecodesign context. Int. J. Life Cycle Assess. 2017, 23, 1590–1608. [Google Scholar] [CrossRef]

- Cherif, H.; Champenois, G.; Belhadj, J. Environmental life cycle analysis of a water pumping and desalination process powered by intermittent renewable energy sources. Renew. Sustain. Energy Rev. 2016, 59, 1504–1513. [Google Scholar] [CrossRef]

- European Commission-Joint Research Centre-Institute for Environment and Sustainability. General Guide for Life Cycle Assessment-Detailed Guidance; European Commission: Ispra, Italy, 2010; ISBN 978-92-79-19092-6. [Google Scholar]

- García-Pacheco, R.; Li, Q.; Comas, J.; Taylor, R.A.; Le-Clech, P. Novel housing designs for nanofiltration and ultrafiltration gravity-driven recycled membrane-based systems. Sci. Total Environ. 2021, 767, 144181. [Google Scholar] [CrossRef]

- Ding, A.; Liang, H.; Li, G.; Szivak, I.; Traber, J.; Pronk, W. A low energy gravity-driven membrane bioreactor system for grey water treatment: Permeability and removal performance of organics. J. Memb. Sci. 2017, 542, 408–417. [Google Scholar] [CrossRef]

- Dow Company FILMTECTM Membranes: FILMTECTM NF270-400 Nanofiltration Element. 2020, Form No. 6, 1–2. Available online: https://www.lenntech.com/Data-sheets/Dow-Filmtec-NF270-400.pdf (accessed on 1 July 2022).

- Giagnorio, M.; Steffenino, S.; Meucci, L.; Zanetti, M.C.; Tiraferri, A. Design and performance of a nanofiltration plant for the removal of chromium aimed at the production of safe potable water. J. Environ. Chem. Eng. 2018, 6, 4467–4475. [Google Scholar] [CrossRef]

- Dupon System Design Membrane System Design Guidelines for Midsize FilmTec Elements. 2020, 1, 2–4. Available online: https://www.dupont.cn/content/dam/dupont/amer/us/en/water-solutions/public/documents/en/RO-NF-FilmTec-Membrane-Sys-Design-Guidelines-Midsize-Manual-Exc-45-D01588-en.pdf (accessed on 22 June 2022).

- Mutel, C. Brightway: An open source framework for life cycle assessment. J. Open Source Softw. 2017, 2, 236. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Van Rossum, G.; Drake, F.L., Jr. Python Reference Manual; Centrum voor Wiskunde en Informatica Amsterdam: Amsterdam, The Netherland, 1995. [Google Scholar]

- Myhre, G.; Bréon, S.; Collins, W.; Fuglestvedt, J.; Huang, J.; Koch, D.; Lamarque, J.-F.; Lee, D.; Mendoza, B.; Nakajima, T. Climate Change 2013: The Physical Science Basis; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2018. [Google Scholar]

- Wickham, H. Ggplot2: Elegant Graphics for Data Analysis; Springer: New York, NY, USA, 2016. [Google Scholar]

- Wickham, H. Tidyverse: Easily Install and Load the “Tidyverse”. CRAN-R; R-Studio: Boston, MA, USA, 2019. [Google Scholar]

- Cornejo, P.K.; Santana, M.V.E.; Hokanson, D.R.; Mihelcic, J.R.; Zhang, Q. Carbon footprint of water reuse and desalination: A Review of greenhouse gas emissions and estimation tools. J. Water Reuse Desalin. 2014, 4, 238–252. [Google Scholar] [CrossRef]

- Shen, J.; Jeihanipour, A.; Richards, B.S.; Schäfer, A.I. Renewable energy powered membrane technology: Experimental investigation of system performance with variable module size and fluctuating energy. Sep. Purif. Technol. 2019, 221, 64–73. [Google Scholar] [CrossRef]

- Dolar, D.; Košutić, K.; Strmecky, T. Hybrid processes for treatment of landfill leachate: Coagulation/UF/NF-RO and adsorption/UF/NF-RO. Sep. Purif. Technol. 2016, 168, 39–46. [Google Scholar] [CrossRef]

- Renou, S.; Givaudan, J.G.; Poulain, S.; Dirassouyan, F.; Moulin, P. Landfill leachate treatment: Review and opportunity. J. Hazard. Mater. 2008, 150, 468–493. [Google Scholar] [CrossRef] [PubMed]

- Heijman, S.G.J.; Guo, H.; Li, S.; van Dijk, J.C.; Wessels, L.P. Zero liquid discharge: Heading for 99% recovery in nanofiltration and reverse osmosis. Desalination 2009, 236, 357–362. [Google Scholar] [CrossRef]

- Macura, B.; Johannesdottir, S.L.; Piniewski, M.; Haddaway, N.R.; Kvarnström, E. Effectiveness of ecotechnologies for recovery of nitrogen and phosphorus from anaerobic digestate and effectiveness of the recovery products as fertilisers: A systematic review protocol. Environ. Evid. 2019, 8, 1–9. [Google Scholar] [CrossRef]

- Pedizzi, C.; Noya, I.; Sarli, J.; González-García, S.; Lema, J.M.; Moreira, M.T.; Carballa, M. Environmental assessment of alternative treatment schemes for energy and nutrient recovery from livestock manure. Waste Manag. 2018, 77, 276–286. [Google Scholar] [CrossRef]

- Bonton, A.; Bouchard, C.; Barbeau, B.; Jedrzejak, S. Comparative life cycle assessment of water treatment plants. Desalination 2012, 284, 42–54. [Google Scholar] [CrossRef]

- Terrero, P.; García-Pacheco, R.; Campos, E.; Rabadan, J.; Mollina, S.; Ortiz, A.; Calzada, M.; Zarzo, D.; García-Calvo, E. Transformation of end-of-life RO membranes into recycled NF and UF membranes: Results f transformation process. In Proceedings of the IDA World Congress 2017, São Paulo, Brazil, 15–17 October 2017; Volume 495, pp. 305–315. [Google Scholar]

- Liu, J.; Yuan, J.; Xie, L.; Ji, Z. Exergy analysis of dual-stage nanofiltration seawater desalination. Energy 2013, 62, 248–254. [Google Scholar] [CrossRef]

- García-Pacheco, R. Nanofiltration and Ultrafiltration Membranes from End-of-Life Reverse Osmosis Membranes A Study of Recycling. Ph.D. Thesis, University of Alcalá, Madrid, Spain, 2017. [Google Scholar]

- Hospido, A.; Sanchez, I.; Rodriguez-garcia, G.; Iglesias, A.; Buntner, D.; Reif, R.; Moreira, M.T.; Feijoo, G. Are all membrane reactors equal from an environmental point of view? Desalination 2012, 285, 263–270. [Google Scholar] [CrossRef]

- Rahimi, Z.; Zinatizadeh, A.A.; Zinadini, S. Milk processing wastewater treatment in an MBR: A comparative study on the use of two synthetic anti-fouling PES-UF membranes. J. Environ. Chem. Eng. 2019, 7, 103369. [Google Scholar] [CrossRef]

- Senán-Salinas, J.; Landaburu-Aguirre, J.; Blanco, A.; García-Pacheco, R.; García-Calvo, E. Data of the life cycle impact assessment and cost analysis of prospective direct recycling of end-of-life reverse osmosis membrane at full scale. Data Br. 2020, 33, 106487. [Google Scholar] [CrossRef] [PubMed]

| System | N° of Elements | Prin (in bar) | SEC (in kwh·m−3) | Crossing Service Life (SL, in Years) | ||||

|---|---|---|---|---|---|---|---|---|

| EU-27 Mix | Natural Gas | Solar | Wind | GD | ||||

| NF-270 | 8 | 0.678 | 0.188 | - | - | - | - | - |

| r-NF | 8 | 0.962 | 0.267 | 1.46 | 1.22 | 8.98 | 24.3 | -Inf. |

| 9 | 0.863 | 0.240 | 2.22 | 1.85 | 13.6 | 36.8 | -Inf. | |

| 10 | 0.785 | 0.218 | 3.79 | 3.16 | 23.3 | 62.9 | -Inf. | |

| 11 | 0.722 | 0.200 | 9.02 | 7.53 | 55.5 | 150 | -Inf. | |

| 12 | 0.670 | 0.186 | <0 | <0 | <0 | <0 | -Inf. | |

| 14 | 0.591 | 0.164 | <0 | <0 | <0 | <0 | -Inf. | |

| 16 | 0.533 | 0.148 | <0 | <0 | <0 | <0 | -Inf. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senán-Salinas, J.; Landaburu-Aguirre, J.; García-Pacheco, R.; García-Calvo, E. Recyclability Definition of Recycled Nanofiltration Membranes through a Life Cycle Perspective and Carbon Footprint Indicator. Membranes 2022, 12, 854. https://doi.org/10.3390/membranes12090854

Senán-Salinas J, Landaburu-Aguirre J, García-Pacheco R, García-Calvo E. Recyclability Definition of Recycled Nanofiltration Membranes through a Life Cycle Perspective and Carbon Footprint Indicator. Membranes. 2022; 12(9):854. https://doi.org/10.3390/membranes12090854

Chicago/Turabian StyleSenán-Salinas, Jorge, Junkal Landaburu-Aguirre, Raquel García-Pacheco, and Eloy García-Calvo. 2022. "Recyclability Definition of Recycled Nanofiltration Membranes through a Life Cycle Perspective and Carbon Footprint Indicator" Membranes 12, no. 9: 854. https://doi.org/10.3390/membranes12090854

APA StyleSenán-Salinas, J., Landaburu-Aguirre, J., García-Pacheco, R., & García-Calvo, E. (2022). Recyclability Definition of Recycled Nanofiltration Membranes through a Life Cycle Perspective and Carbon Footprint Indicator. Membranes, 12(9), 854. https://doi.org/10.3390/membranes12090854