Targeting Microbial Biofouling by Controlling Biofilm Formation and Dispersal Using Rhamnolipids on RO Membrane

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals, Accessories, and Microbes

2.2. Biofouled RO Membrane Sample and Bacteria Isolation

2.3. Bacterial Growth Assays

2.4. Microtiter Assays for Biofilm Control

2.5. MTT Biofilm Viability Assay

2.6. Biofilm Dispersal in Microtiter Plates by RLs

2.7. Biofilm Dispersal on RO Membrane

2.8. EPS and Biomass Extraction

2.9. Measurement of Cell Biomass Concentration

2.10. Polysaccharide Quantification

2.11. Protein Quantification

2.12. Microscopic Visualization of Biofilm

2.13. Statistical Analysis

3. Results and Discussion

3.1. Effect of Rhamnolipid Concentrations on Bacterial Growth

3.2. Effect of Rhamnolipid Concentrations on the Growth of Bacteria

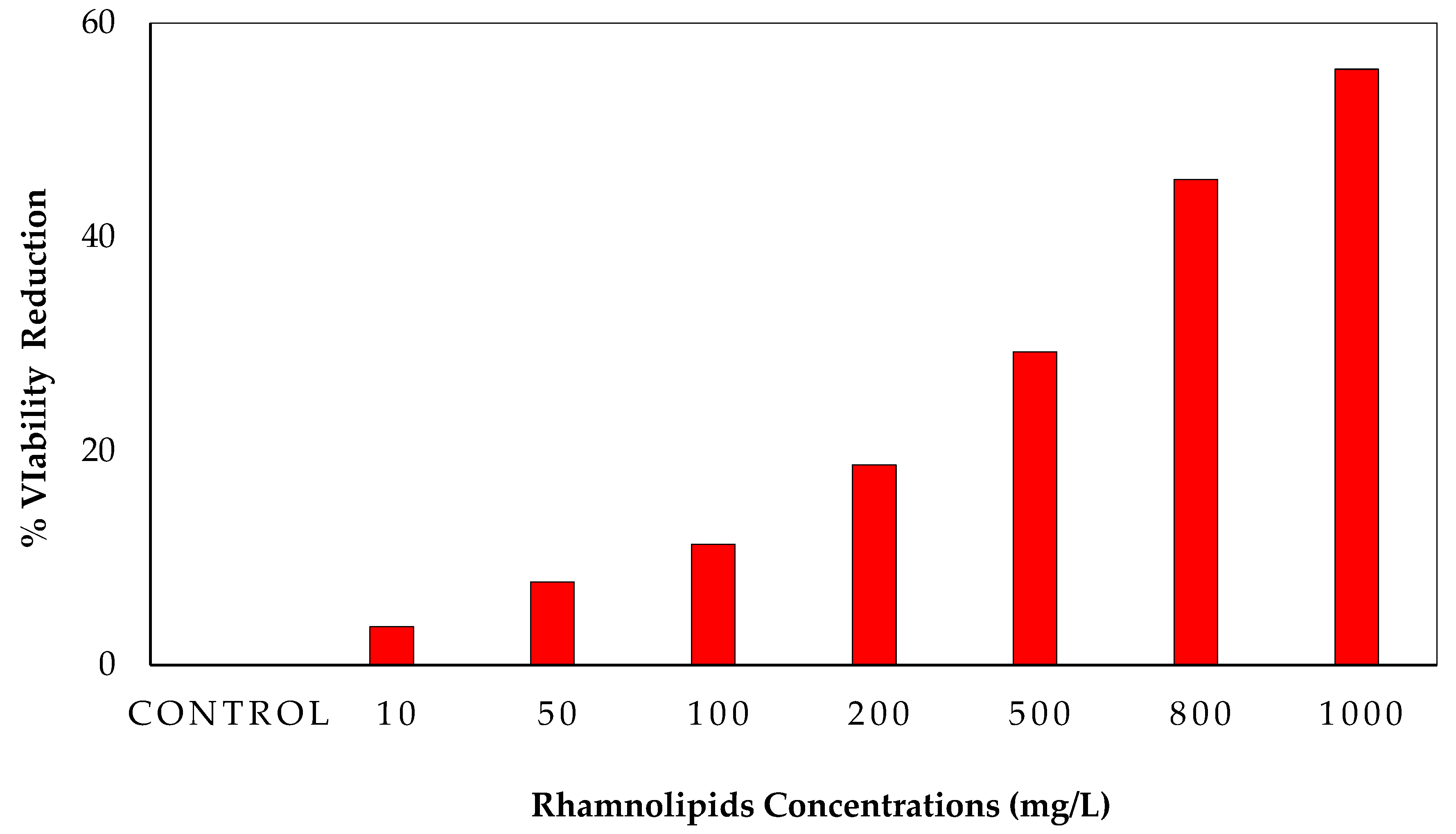

3.3. MTT Assay for Cell Viability in Biofilms upon Using RLs

3.4. Effect of Rhamnolipids on Biofilm Dispersal

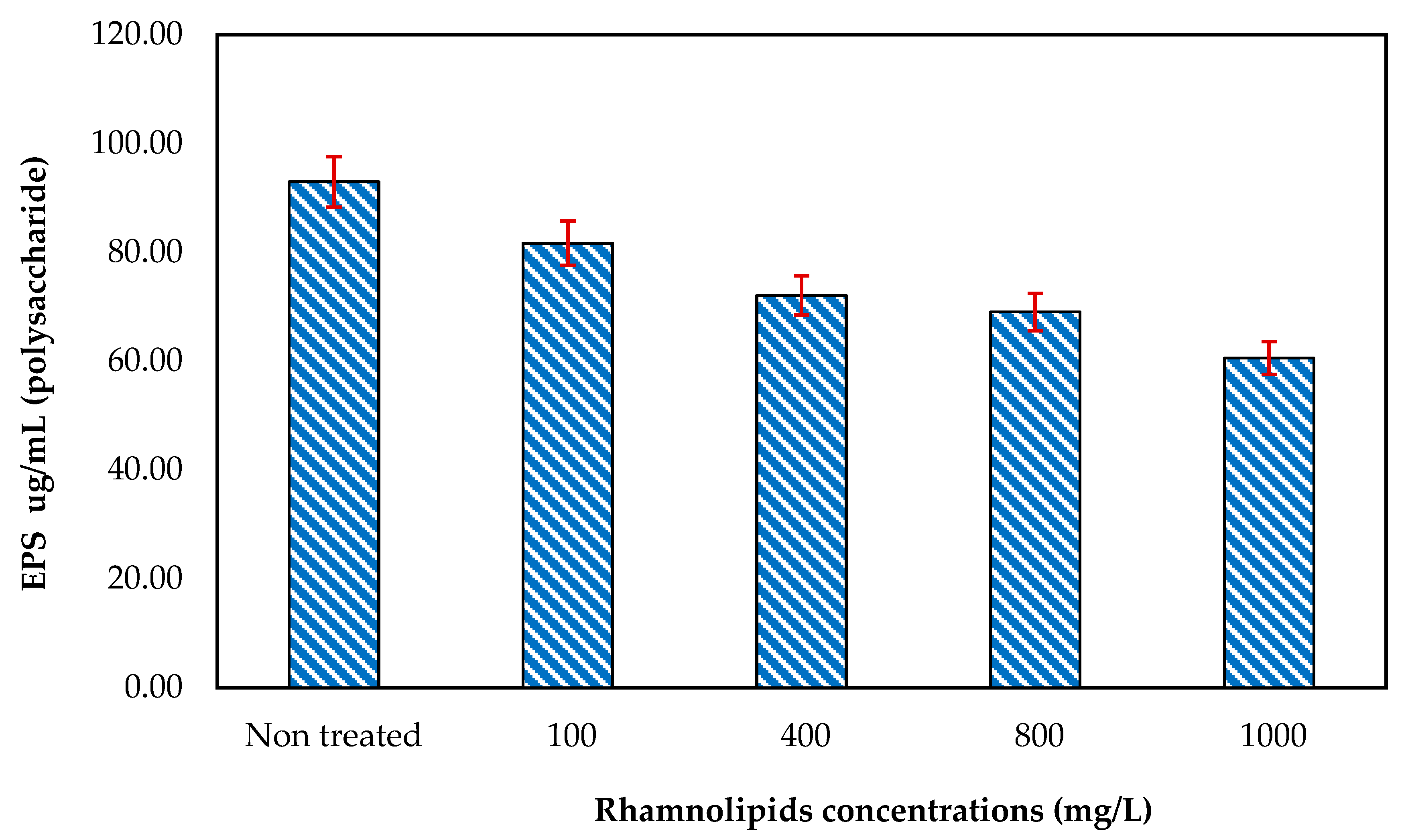

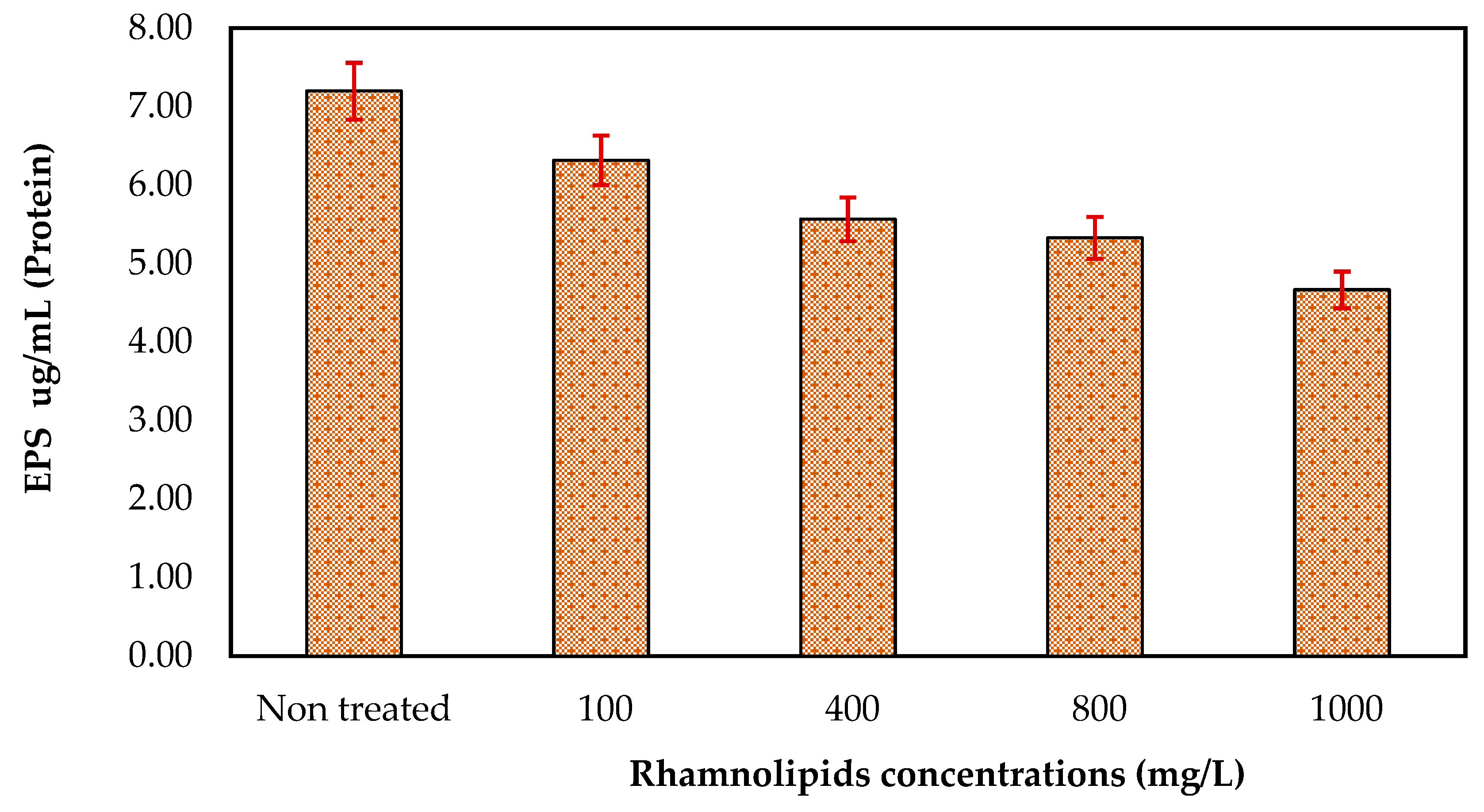

3.5. Effect of Rhamnolipids on EPS Production

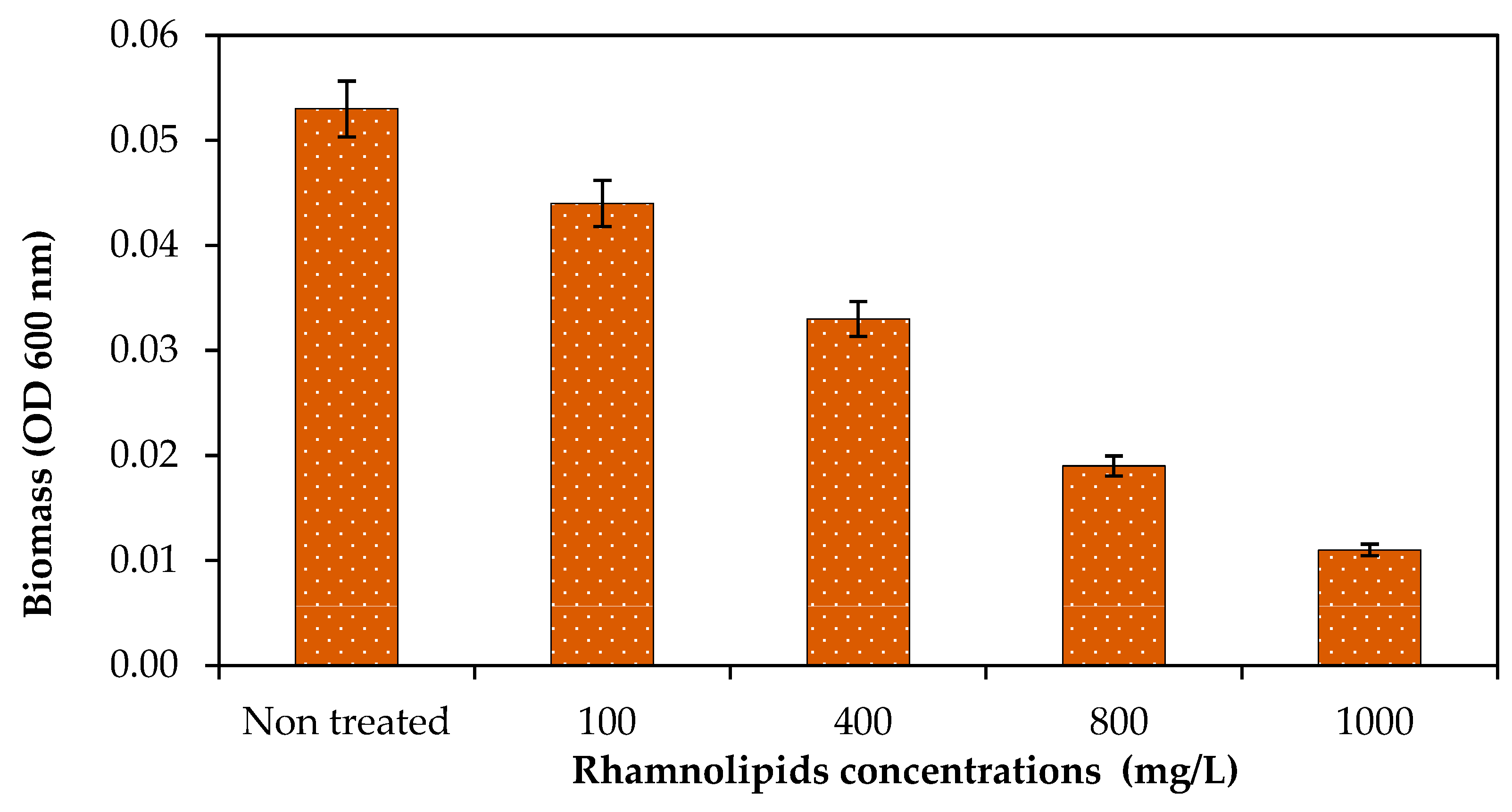

3.6. Effect of Rhamnolipids on Biomass

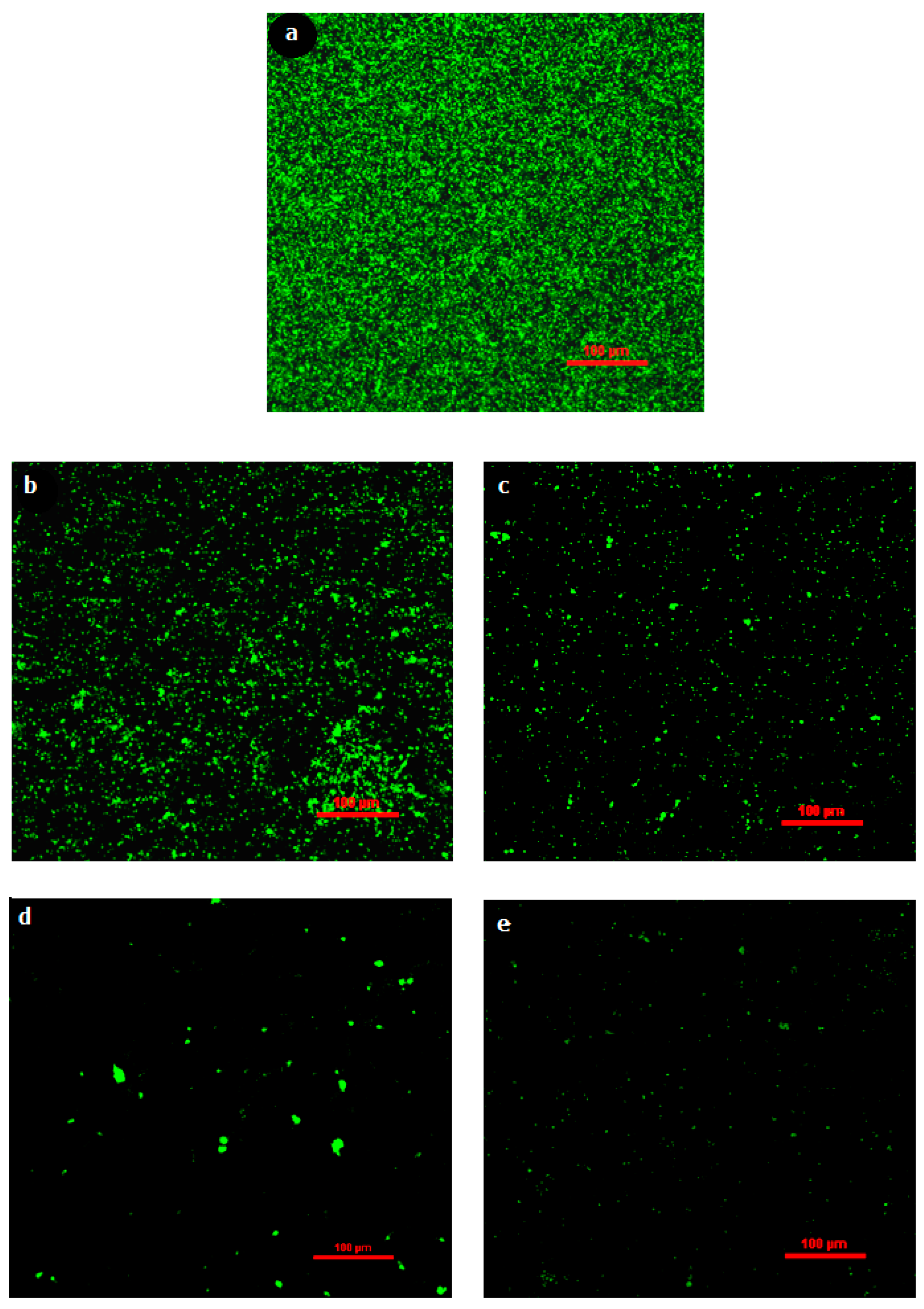

3.7. Microscopic Visualization of Biofilms

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Abushaban, A.; Salinas-Rodriguez, S.G.; Philibert, M.; Le Bouille, L.; Necibi, M.C.; Chehbouni, A. Biofouling potential indicators to assess pretreatment and mitigate biofouling in SWRO membranes: A short review. Desalination 2022, 527, 115543. [Google Scholar] [CrossRef]

- Miura, Y.; Watanabe, Y.; Okabe, S. Membrane biofouling in pilot-scale membrane bioreactors (MBRs) treating municipal wastewater: Impact of biofilm formation. Environ. Sci. Technol. 2007, 41, 632–638. [Google Scholar] [CrossRef] [PubMed]

- Flemming, H.-C.; Schaule, G.; Griebe, T.; Schmitt, J.; Tamachkiarowa, A. Biofouling—The Achilles heel of membrane processes. Desalination 1997, 113, 215–225. [Google Scholar] [CrossRef]

- Aljumaily, M.M.; Alsaadi, M.A.; Binti Hashim, N.A.; Mjalli, F.S.; Alsalhy, Q.F.; Khan, A.L.; Al-Harrasi, A. Superhydrophobic nanocarbon-based membrane with antibacterial characteristics. Biotechnol. Prog. 2020, 36, e2963. [Google Scholar] [CrossRef]

- Abdel-Mawgoud, A.M.; Hausmann, R.; Lépine, F.; Müller, M.M.; Déziel, E. Rhamnolipids: Detection, analysis, biosynthesis, genetic regulation, and bioengineering of production. In Biosurfactants; Springer: Berlin/Heidelberg, Germany, 2011; pp. 13–55. [Google Scholar]

- Nguyen, T.; Roddick, F.A.; Fan, L. Biofouling of water treatment membranes: A review of the underlying causes, monitoring techniques and control measures. Membranes 2012, 2, 804–840. [Google Scholar] [CrossRef]

- Siddiqui, M.F.; Oh, H.-S.; Rzechowicz, M.; Winters, H.; Chong, T.H.; Fane, A.G. Biofouling control potential of tannic acid, ellagic acid, and epigallocatechin against Pseudomonas aeruginosa and reverse osmosis membrane multispecies community. J. Ind. Eng. Chem. 2015, 30, 204–211. [Google Scholar] [CrossRef]

- Siddiqui, M.F.; Rzechowicz, M.; Oh, H.-S.; Saeidi, N.; Hui, L.J.; Winters, H.; Fane, A.G.; Chong, T.H. The efficacy of tannic acid in controlling biofouling by Pseudomonas aeruginosa is dependent on nutrient conditions and bacterial density. Int. Biodeterior. Biodegrad. 2015, 104, 74–82. [Google Scholar] [CrossRef]

- Burton, E.; Yakandawala, N.; LoVetri, K.; Madhyastha, M. A microplate spectrofluorometric assay for bacterial biofilms. J. Ind. Microbiol. Biotechnol. 2007, 34, 1–4. [Google Scholar] [CrossRef]

- Chusri, S.; Sompetch, K.; Mukdee, S.; Jansrisewangwong, S.; Srichai, T.; Maneenoon, K.; Limsuwan, S.; Voravuthikunchai, S. Inhibition of Staphylococcus epidermidis biofilm formation by traditional Thai herbal recipes used for wound treatment. Evid. Based Complement. Alternat. Med. 2012, 2012, 159797. [Google Scholar] [CrossRef]

- Barnes, R.J.; Bandi, R.R.; Wong, W.S.; Barraud, N.; McDougald, D.; Fane, A.; Kjelleberg, S.; Rice, S.A. Optimal dosing regimen of nitric oxide donor compounds for the reduction of Pseudomonas aeruginosa biofilm and isolates from wastewater membranes. Biofouling 2013, 29, 203–212. [Google Scholar] [CrossRef]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.; Smith, F. Colorimetric method for determination of sugars and related substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- He, F. Bradford protein assay. Bio-Protocol 2011, 1, e45. [Google Scholar] [CrossRef]

- Bazargani, M.M.; Rohloff, J. Antibiofilm activity of essential oils and plant extracts against Staphylococcus aureus and Escherichia coli biofilms. Food Control 2016, 61, 156–164. [Google Scholar] [CrossRef]

- do Valle Gomes, M.Z.; Nitschke, M. Evaluation of rhamnolipid and surfactin to reduce the adhesion and remove biofilms of individual and mixed cultures of food pathogenic bacteria. Food Control 2012, 25, 441–447. [Google Scholar] [CrossRef]

- Magalhães, L.; Nitschke, M. Antimicrobial activity of rhamnolipids against Listeria monocytogenes and their synergistic interaction with nisin. Food Control 2013, 29, 138–142. [Google Scholar] [CrossRef]

- Cady, N.C.; McKean, K.A.; Behnke, J.; Kubec, R.; Mosier, A.P.; Kasper, S.H.; Burz, D.S.; Musah, R.A. Inhibition of biofilm formation, quorum sensing and infection in Pseudomonas aeruginosa by natural products-inspired organosulfur compounds. PLoS ONE 2012, 7, e38492. [Google Scholar]

- Raut, U.; Rantai, S.; Narang, P.; Chauhan, D.; Chahar, M.; Narang, R.; Mendiratta, D. Comparison of the 3-(4,5-dimethylthiazole-2-yl)-2,5-diphenyltetrazolium bromide tube method with the conventional method and real-time polymerase chain reaction for the detection of rifampicin resistance in Mycobacterium tuberculosis. Indian J. Med. Microbiol. 2012, 30, 81–84. [Google Scholar] [CrossRef]

- Wood, T.L.; Gong, T.; Zhu, L.; Miller, J.; Miller, D.S.; Yin, B.; Wood, T.K. Rhamnolipids from Pseudomonas aeruginosa disperse the biofilms of sulfate-reducing bacteria. NPJ Biofilms Microbiomes 2018, 4, 22. [Google Scholar] [CrossRef]

- Xiong, Y.; Liu, Y. Biological control of microbial attachment: A promising alternative for mitigating membrane biofouling. Appl. Microbiol. Biotechnol. 2010, 86, 825–837. [Google Scholar] [CrossRef]

- Herzberg, M.; Kang, S.; Elimelech, M. Role of extracellular polymeric substances (EPS) in biofouling of reverse osmosis membranes. Environ. Sci. Technol. 2009, 43, 4393–4398. [Google Scholar] [CrossRef]

- Al-Juboori, R.A.; Yusaf, T. Biofouling in RO system: Mechanisms, monitoring and controlling. Desalination 2012, 302, 1–23. [Google Scholar] [CrossRef]

- Wisniewski, N.; Moussy, F.; Reichert, W. Characterization of implantable biosensor membrane biofouling. Fresenius J. Anal. Chem. 2000, 366, 611–621. [Google Scholar] [CrossRef] [PubMed]

- Wolf, G.; Crespo, J.G.; Reis, M.A. Optical and spectroscopic methods for biofilm examination and monitoring. Rev. Environ. Sci. Biotechnol. 2002, 1, 227–251. [Google Scholar] [CrossRef]

| Conc. mg/L | Absorbance | % Reduction |

|---|---|---|

| Control | 1.750 | 0.000 |

| 1 | 1.343 | 23.253 |

| 5 | 1.163 | 33.536 |

| 10 | 1.063 | 39.250 |

| 20 | 1.030 | 41.154 |

| 40 | 0.973 | 44.392 |

| 50 | 0.890 | 49.153 |

| 100 | 0.843 | 51.819 |

| 200 | 0.337 | 80.766 |

| 400 | 0.253 | 85.527 |

| 800 | 0.127 | 92.763 |

| Sample (mg/L) | Surface Coverage (%) | Biomass (µm2) | % Biomass Reduction |

|---|---|---|---|

| Control | 96.0% | 43,245 | 00.00 |

| 100 | 21.7% | 9766 | 77.41 |

| 400 | 4.8% | 2159 | 95.00 |

| 800 | 1.3% | 567 | 98.68 |

| 1000 | 1.1% | 493 | 98.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahidullah; Siddiqui, M.F.; Tabraiz, S.; Maqbool, F.; Adnan, F.; Ullah, I.; Shah, M.A.; Jadoon, W.A.; Mehmood, T.; Qayyum, S.; et al. Targeting Microbial Biofouling by Controlling Biofilm Formation and Dispersal Using Rhamnolipids on RO Membrane. Membranes 2022, 12, 928. https://doi.org/10.3390/membranes12100928

Zahidullah, Siddiqui MF, Tabraiz S, Maqbool F, Adnan F, Ullah I, Shah MA, Jadoon WA, Mehmood T, Qayyum S, et al. Targeting Microbial Biofouling by Controlling Biofilm Formation and Dispersal Using Rhamnolipids on RO Membrane. Membranes. 2022; 12(10):928. https://doi.org/10.3390/membranes12100928

Chicago/Turabian StyleZahidullah, Muhammad Faisal Siddiqui, Shamas Tabraiz, Farhana Maqbool, Fazal Adnan, Ihsan Ullah, Muhammad Ajmal Shah, Waqar Azeem Jadoon, Tariq Mehmood, Sadia Qayyum, and et al. 2022. "Targeting Microbial Biofouling by Controlling Biofilm Formation and Dispersal Using Rhamnolipids on RO Membrane" Membranes 12, no. 10: 928. https://doi.org/10.3390/membranes12100928

APA StyleZahidullah, Siddiqui, M. F., Tabraiz, S., Maqbool, F., Adnan, F., Ullah, I., Shah, M. A., Jadoon, W. A., Mehmood, T., Qayyum, S., & Rahman, Z. (2022). Targeting Microbial Biofouling by Controlling Biofilm Formation and Dispersal Using Rhamnolipids on RO Membrane. Membranes, 12(10), 928. https://doi.org/10.3390/membranes12100928